together we move forward

Let the numbers speak for us

500+

Successfully completed projects

100+

Highly specialised employees

60 Countries around the world

Countries where our machines are operating

Algeria

Angola

Argentina

Belarus

Belgium

Bolivia

Bosnia and Herzegovina

Brazil

Bulgaria

Cameroon

Canada

Chile

Croatia

Cyprus

Czech Republic

Ecuador

Egypt

France

Gabon

Germany

Ghana

Greece

Italy

Ivory

Kenya

Lebanon

Libya

Madagascar

Mauritius Mexico

Morocco

New

Nigeria

North

Philippines

Poland

Saudi

Senegal

Serbia

Slovakia

Slovenia

South African Republic

Spain

Sri

Sweden

Trinidad and Tobago

Tunisia

Turkey

Ukraine

United

United

Uruguay

Uzbekistan

USA

Venezuela

Emirates

The company “9. Septembar Tissue Converting” was founded on September 9, 1982 in Cacak, Serbia. Four friends joined forces with an idea to improve the way how automated production lines are built. They started in a garage, with plenty of experience, ideas and dreams about revolutionizing the way certain industries produce their products.

More than 42 years of success

“9. Septembar Tissue Converting” is held in high regard and has built a strong reputation among business partners and customers across the globe. Its Paper Handkerchief and Napkin Machines are instantly recognizable brands and have become synonymous for high quality. The company’s production plants are in Cacak, Serbia, and cover a floor area of 1800 square meters. The plants are equipped with state-of-the-art production facilities, guaranteeing the superb quality and reliability of final products.

We have been upgrading our operations to reflect modern developments in the business paradigm, built around high standards, continual improvement and product range expansion. We have kept abreast of new trends and introduced new manufacturing processes to improve our product range. As of 2003, we implemented quality management systems ISO 9001, ISO 14000, ISO 13485 and OHSAS 18001 In 2015 we have renewed management system standards ISO 9001, ISO 14000 and OHSAS 18001. We were one of the first companies to introduce the integrated quality management system in the region which remains fully functional to this day.

Team

Our strong dedication to quality requires the exceptional level of knowledge and experience, to ensure we are perfectly placed to fully meet the market demand. For this reason, our employees are continually honing and fine-tuning their professional skills. Our development and innovation team includes numerous highly experienced mechanical and electrical engineers. Their presence is the best possible guarantee of future progress and success of our company. Since the company’s formation to this day, our business model has been built around a desire to have satisfied customers. We offer the best value for money to our clients.

We deliver tailor made solutions, thanks to our one-stop-shop with integrated functional units:

• Design and development

• Manufacture of a variety of machine parts

• Assembly and installation

• Purchasing & Quality Control

• Programming and software development

• Maintenance

• Round-the-clock technical support

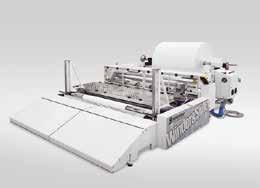

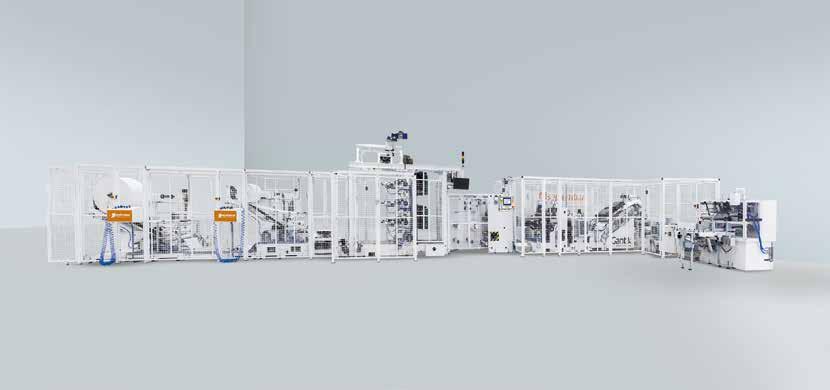

DYNAMIX DUO V Napkin Production Line

• One unwinder, one embossing section, two folding units, four transport channels

• Minimum downtime for changing of the paper roll –turret unwinder with electromechanical and hydraulical replacement system

• M inimum downtime for changing of the embossing roller - cassette system with trolley

• Fast change of folding heads

• Max speed: 750 m/min (for napkin 330x330mm with all over embossing)

• Min and max napkin format: from 200 x200 mm to 400x400 mm

• Min and max pack height: 20 - 200 mm

• Folding options: 1/4 fold, 1/8 fold, 1/6 fold

• Converting material: Tissue Paper 1 x 18 gr/m2, 2 x 17 gr/m2, 3 x 16 gr/m2, Nonwoven textile, Air laid, DRC, Spunlace

• Napkin counting: Automatic

• Napkin transport: Automatic

HoReCa

Napkin Production Line

• Bulk Packs of napkins

• Optimal solution for 1 ply napkins with different types of all-over embossing

• Folding options: 1/4 fold, 1/8 head fold

• Optional: high compressed packs

• Max speed: 750 m/min (for napkin 330x330mm with all over embossing)

• Min and max pack length: 220 - 500 mm

• Napkin counting: Automatic

• Napkin transport: Automatic

DYNAMIX NC801

Napkin Production Line

• Improved napkin production line

• Quality, functionality, outstanding productivity and efficiency in a minute

• Designed with modular concept in mind, configured according to requests

• Additional options: Printing (up to 6 colors), Lamination, Perforation, Double line

• Max speed: 750 m/min (for napkin 330x330mm with all over embossing)

• Min and max napkin format: from 200 x200 mm to 400x400 mm

• Min and max pack height (unpacked): 20 - 200 mm

• Folding options:1/4 fold, 1/8 fold, 1/6 fold

• Converting material: Tissue Paper 1 x 18 gr/m2, 2 x 17 gr/m2, 3 x 16 gr/m2, Nonwoven textile, Air laid, DRC, Spunlace

• Napkin counting: Automatic

• Napkin transport: Automatic

ATOMIC NC601

Napkin Production Line

• Exceptionally reliable

• Easy to handle and maintain

• Meeting the highest standards of precision and functionality

• Additional options: Printing (up to 6 colors), Lamination, Perforation, Double line

upto 600m/min

• Max speed : 600 m/min (for napkin 330x330mm with all over embossing)

• Min and max napkin format: from 200 x200 mm to 400x400 mm

• Min and max pack height (unpacked): 20 - 200 mm

• Folding options: 1/4 fold, 1/8 fold (manual transfer)

• Converting material: Tissue Paper 1 x 18 gr/m2, 2 x 17 gr/m2, 3 x 16 gr/m2, Nonwoven textile, Air laid, DRC, Spunlace

• Napkin counting: Automatic

• Napkin transport: Automatic

DYNAMIX NC804

Napkin Production Line

• Semi-automatic production line

• Compact structure requires minimal floor space, but offers consistency of converting process.

• Additional options: Printing (up to 6 colors), Lamination, Automatic napkin transport

• Max speed: 750 m/min (for napkin 330x330mm with all over embossing)

• Min and max napkin format: from 200 x 200 mm to 400 x 400 mm

• Folding options: 1/4 fold, 1/8 fold

• Folding decks: single or double

• Converting material: Tissue Paper 1 x 18 gr/m2, 2 x 17 gr/m2, 3 x 16 gr/m2, Nonwoven textile, Air laid, DRC, Spunlace

• Napkin counting: Automatic

• Napkin transport: Manual

ALPHA NC604

Napkin Production Line

• Manual napkin transfer

• Easy to handle and maintain

• Cost – effective starter solution with optimum performances

• Additional options: Printing (up to 6 colors), Lamination, Perforation, Double line, Automatic napkin transport

• Max speed: 600 m/min (for napkin 330x330mm with all over embossing)

• Min and max napkin format: from 200x200 mm to 400x400 mm

• Folding options: 1/4 fold, 1/8 fold

• Converting material: Tissue Paper 1 x 18 gr/m2, 2 x 17 gr/m2, 3 x 16 gr/m2, Nonwoven textile, Air laid, DRC, Spunlace

• Napkin counting: Automatic

• Napkin transport: Manual

upto 600m/min user friendly modularity widerange of dimensions economy

Kangaroo

Napkin Production Line

• Production capacity (napkins in the package): up to 500 pcs/min

• Napkin dimensions: from 230 mm to 420 mm (upon customers request)

• Folding: 1/8 Book fold; 1/8 Kangaroo fold; 1/4 fold

• Converting material: Tissue Paper, Airlaid, Non woven

• Additional options: Lamination, Printing, Flow pack, Packaging in the boxes, Paper rings;

innovative vacuum foldingheads fastchangeover

Kangaroo single flow-pack

Napkin

Production Line

• Production of single wrapped Kangaroo napkins

• Wrapping in foil, paper, or combination of foil and paper

• Production speed (single napkin flow pack): up to 250 pcs/min

• Napkin dimensions: from 230 mm to 420 mm (upon customers request)

• Fold: 1/8 Book fold; 1/8 Kangaroo fold, 1/6 fold

• Converting material: Tissue Paper, Airlaid, Non woven

• Additional options: Lamination, Printing, Packaging in the boxes, Paper rings

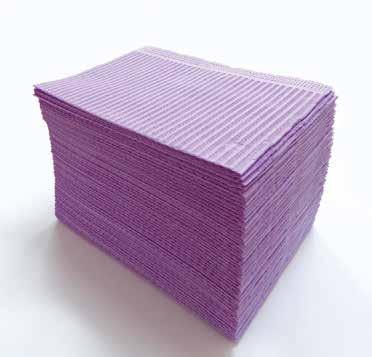

MATS

Placemats Production Line

• Production of disposable placemats popular in HoReCa sector

• As per customer request, placemats can be produced of different materials, in different sizes, becoming multifunctional product which can be used also in medical, beauty and vets sectors.

• Additional options: Printing, Lamination

upto500 pcs/min widerange of dimensions

• Max capacity: up to 500 pcs/min

• Placemat format: 400x300mm, 500x350mm

• Pack height: 200mm

• Number of placemats in pack: 100/200/250/500

• Converting material: Tissue Paper, MG , Craft Paper

• Placemats counting: Automatic

• Placemats transport: Automatic

ASTall

Tablec loths Production Line

• Max speed: up to 250 m/min

• Tablecloths dimension: up to 1.5m

• Converting material: Airlaid, Nonwoven, Spunlace, Spunbond

• Folding type: 1/8 M

• Trim removal system

• Optional: movable bandsaw

• Additional sections: printing

• As per customer`s request, tablecloths can be produced of different materials, in different sizes, becoming multifunctional product

UNIVAC

Facial Tissue Production Line

• Tailored by customer`s needs

• Different vacuum based folding types are available according to customer`s request

• Easy and fast change of tissue product dimension

• Production capacity: up to 1000 pcs/min

• Converting material: 1,2 and 3 ply Tissue Paper, Air laid, Nonwoven

• Folding type: vacuum based C fold, 1/4 fold, 1/8 Book fold

• Folding type: vacuum based C fold, 1/4 fold

• Sheet dimensions: 270x280mm, 270x285mm, 270x290mm, 270x300mm

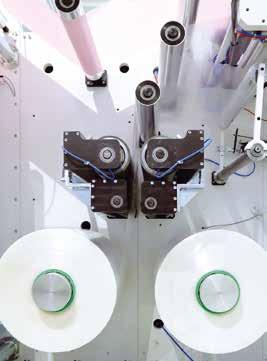

Matrix

Handkerchief Production Line

• Precision, consistency and simplicity of converting process

• Web guiding device ensures precise longitudinal paper folding

• Automatic labeling system

• Double line, Matrix Duo, provides double capacity

• Matrix DUO V line provides capacity up to 100 packs/min.

• Max capacity: 75 packs/min

• Standard handkerchief dimensions: 200x200 mm

• Standard number pcs/pack: 10

• Additional option: perfuming

• ADDITIONAL: Collective packaging unit (for single line)

9.Septembar R&D Team has been implementing and developing new line of products - machines that produce disposable products for medical purposes. First machine developed in this line is machine for production of dental bibs called EOS.

EOS Fold

Folded Dental Bibs Production Line

• Folding section and transport section for production of 1/4 M folded dental bibs

• Dimension of dental bib: 450x330 mm

• Production speed: 400m/min

• Material: Tissue Paper + Polyethylene

• Materials bonding: Lamination or thermo – pressing

• Gantik glue application section

Dental bibs and protective pads are widely used at dentists and hospitals for medical purposes. Composed of one or two ply tissue paper and one polyethylene layer, featuring with embossing to prevent liquid run down, these products are impermeable, disposable and easy to use.

EOS Rolls

Dental Bibs Production Line

• Production speed: up to 200 m/min

• Unwinder with tension control system: paper roll and foil roll

• Printing section

• Lamination

• Hot embossing section

• Gantik glue application section

• Automatic core change and winding system

• Servo driven automatic adjustment of perforation length

• Transfer to wrapper and labeling: Automatic

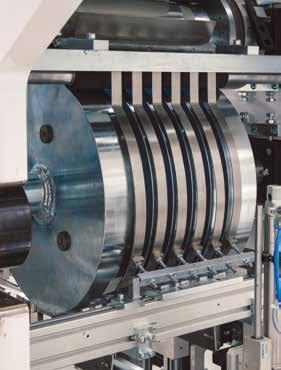

ReSlit

ReWinder & Slitter

• Converting jumbo rolls, up to 2800 mm wide, into manageable and sellable products

• Final products are excellent quality rolls ready for converting or shipping

• Advantage of cost reduction even before converting process starts

ReSlit

• Number of unwinders: 1, 2 or 3

• Max mechanical speed: up to 800 m/min

• Parent roll width: up to 2800 mm

• Parent roll diameter: up to 2500 mm

• Rewind (output) diameter: up to 1600 mm

• Slit width: min 60 mm

• Automatic tension control

• Pneumatic knife holders for easy adjustment of slitting

• Hydraulic roll handling system

• Cut: shear

• Installed power: 100kW

• Compressed air consumption: 1000 l/min (6bar)

ReSlit Compact

• Max mechanical speed: up to 300 m/min

• Roll width: up to 1800 mm

• Parent roll diameter: up to 1600 mm

• Rewind (output) diameter: up to 1400 mm

• Slit width: min 60 mm

• Mechanical knife holders

• Cut: shear

Additional Options

Turret Unwinder

Turret unwinder allows automatic lifting of a new paper roll while converting machine is on and working. This method brings time saving, new position of unwinding arm and perfect paper tension control during high production speed.

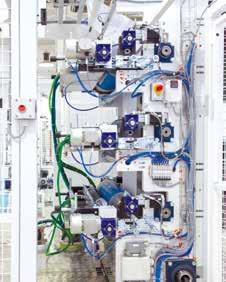

Printing section

Our printing sections can be based on printing system with central drum or stack printing system. Both methods of printing are highly recommended for precise printing with tiny details. Use of anilox rolls for transfer of each color, web guiding system before and after print, closed system “Dr. Blade” and engraved sleeves are the vital parts of printing system. Our printing sections may be equipped with up to 6 colors.

Auto splicer

Change of parent roll has never been so fast and easy. Auto splicer joins two webs together – the end of an expiring roll to the begining of another. Splicing function allows change of roll without stopping machine. Auto splicers can work with paper rolls as well as with foil rolls.

Lamination section

Lamination of tissue paper is a process of sticking two embossed layers using point - to - point technology. This enables special softness to a napkin. Two layers are glued with special water based adhesive, which is applied to one surface. Bonded 2 ply tissue paper is quickly dried in infrared chamber. This process is applied on the whole surface of tissue paper. Production speed of napkin machine with lamination section is up to 450 m/min.

Folding Options

After sales Service

We are in this together, dedicated to help you grow.

Our goal is to develop perfect tailor-made solutions for your business while maintaining the highest level of trust in our products through efficient, professional, and responsive after-sales service.

With over 80 technicians and 20 engineers from R&D and technical services, we ensure top-quality support for our machinery. Our structured technical service offers a wide range of support, including interactive video diagnostics, on-site maintenance, post-sales assistance, preventive services, material supply, emergency interventions, and online support.

This comprehensive system guarantees consistent quality and efficiency across all 9. Septembar –Tissue Converting production lines worldwide.

Service parts & Software support

Along with a 9. Septembar machine, you will obtain the Service Book. This descriptive guide divides the entire machine into sections, each described in detail. Each controllable part of the machine is marked and identified by a number, allowing you to easily locate its information in the Service Book and quickly place orders.

In addition to spare parts, our After-Sales Service team takes great pride in its Software Support. Thanks to the efficient online communication system, we can connect directly to your machine, enabling remote software updates and reprogramming without the need for physical presence. This remote service is one of the most significant cost-saving features available to our customers.

The Aftersales team offers multilingual support, covering English, Spanish, Portuguese, and Italian, ensuring rapid and efficient responses to all customer inquiries. Fast technical support, coupled with tailored training for operational teams, ensures that clients receive maximum value from every installation.

With a structured approach to after-sales service, 9. Septembar guarantees the highest level of support throughout the entire lifecycle of your machine. Whether it's spare parts, software updates, or hands-on training, every effort is made to ensure smooth and efficient operations.

Our commitment to customer satisfaction extends long after installation, providing ongoing value.

24/7 after-sales support is available, with the highestquality components sourced from trusted, global partners. Most service parts are readily available in our facilities, and for any shortages, parts are shipped within 7-15 working days, depending on the item's complexity.

Cutting-edge machinery such as HAAS, DECKEL, and MAHO is utilized in the production of spare parts. Emphasis is placed not only on engineering but also on using the best materials and

Training

Why is this important?

Although training may seem unnecessary to some customers, it often turns out to be the most justified investment, which quickly pays off. With this investment, customers directly magnify machine capacity and reliability. The performance of this modern, high-end equipment depends heavily on the qualifications of the operator. Making it essential for machines to be operated by capable personnel.

If our on-site technical support does not fully meet your needs, you can choose to enhance it with our additional babysitting services, offering continuous monitoring and prompt issue resolution to ensure your machines operate at peak performance.

equipment, ensuring long-term reliability and performance of every machine.

Our continuous drive for improvement aims to satisfy both current and future customers, meeting the demands of a dynamic global market. Ongoing efforts focus on increasing capacity and enhancing reliability, driven by the integration of advanced electronic systems and complex mechanical assemblies. Achieving these objectives requires operators with specialized training in mechanical, electrical engineering, or graphic fields, who are equipped to effectively serve and operate the production lines.