We Are

Pig Retrieval Tool

PAGE 4-5

PAGE 6-7

PAGE 8-9

PAGE 4-5

PAGE 6-7

PAGE 8-9

Forth is an innovation focused company that prides itself on delivering remotely deployed inspection solutions to meet client needs.

Together we have over 100 years of collective offshore experience, meeting and managing challenges in every aspect of the offshore asset lifecycle.

We are dedicated to producing accurate and repeatable inspection results, forming good working relationships with client teams to deliver tailored solutions. Using capable, experienced management, engineering and inspection technicians for projects involving inspection of subsea items.

Forth’s services include:

● HD Visual Inspection

● HP Water Jet Cleaning

● Ultra Sonic Inspection

● Debris Recovery

● Bespoke Project Solutions

Forth develops and uses specialist technology to provide a range of services and solutions to its clients. This is enhanced by our Caisson Inspection service to the Oil and Gas industry.

Forth can provide the ‘next level’ of technical solutions for accurate, reliable detection of aging caisson defects.

Our aim is to work with our clients in providing the highest quality solution and data, utilising our diverse range of inspection and recovery tooling.

Pigging is a standard process within the Oil and Gas industry involving the deployment of a specialist cleaning device (known as a pig) down a process pipeline using the downstream process pressure to drive it to the end of the line. The pig is then removed to allow the continuation of plant production.

The pig position can differ at the end of the pipeline due to the varying pressure and friction forces encountered in the pipeline during the process.

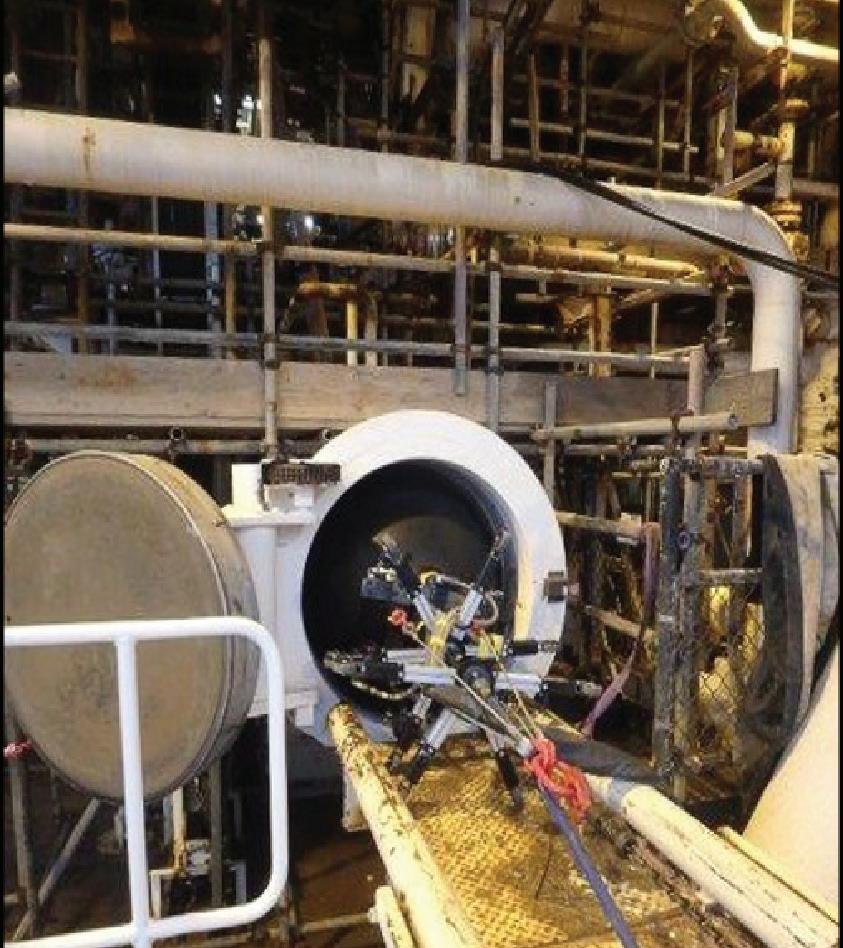

Forth developed a modular tool spread that integrates an ATEX Zone 1 pneumatic winch to a receiving cradle for the pig, which is then coupled to a lightweight, self-supported and centralised long reach grabbing device (adjustable up to 15m), using an auto locking grab at the front of the assembly, which latches to the pig upon contact with the pig’s latching point.

This is used in tandem with a front mounted ATEX Zone 1 camera linked to a topside viewing monitor, to provide a feedback loop to the operator, which reduces manual handling and operating time to allow swift return to production as well as improving the ultimate safety of the process.

• Lightweight, modular and universal design on both the cradle trolley and grabber arrangement. Reducing need for unique, individual parts and extensive spares. Swift assembly and disassembly to minimise production downtime. Ease of adaptation to any operating changes and pig design.

• ATEX Zone 1 Pneumatic Winch for safe use in explosive atmospheres

• Auto locking front grab with manual release

• 1 Tonne WLL pulling capacity.

• 15m grab reach

• Adaptable to any pig and receiver bore size.

• Electrically conductive castors for further explosive atmosphere protection

• Spring loaded castor assemblies for mitigating circumferential imperfections and defects

• Front mounted ATEX Zone 1 Camera and partnering tablet to provide feedback to operator of a successful latch

• Local drain point for residual process liquid extraction, adaptable suction pump for high volumes

Forth was approached by a customer who had a very unusual dilemma; they wished to remove a number of spherical pigs from a launch tube and had concerns about their integrity.

The pigs were operationally ready but the procedure had not gone ahead. Multiple attempts were made to remove the pigs before Forth were called in to help.

Within five weeks the team designed, built and deployed a tool to remove the pigs.

TOOL KEY FEATURES:

• Lightweight, modular and universal design on both the trolley and grab arrangement

• Suction Cup grab system with auto release

• 500Kg WLL pulling capacity

• Adaptable to any pig and receiver bore size

• Electrically conductive castors for further explosive atmosphere protection

• Spring loaded trolley & castor assemblies for mitigating circumferential imperfections and defects

• Optional front mounted ATEX Zone 1 camera and partnering tablet to provide feedback to operator of successful latch

The industry has developed over time to produce oil and gas in a more efficient and sustainable way. This development has created a demand in the market for innovative and efficient ways to support lifetime extension programmes of existing assets and infrastructure. One key area of this is late life asset inspections, often complex due to access issues and risk in gathering information from remote and restricted areas. Forth has developed a Restricted Access Inspection System

• ATEX Zone 1 Rating HD Camera System

• No Scaffolding requirement

• No Specialist Rope Access Teams

• Designed to be mobilised within small transit cases

• Adaptable to a variety of tooling/deployment to suit various inaccessible locations

• Instant Data Feedback

• Allows On/Off Site Integration

• Real Time feedback with live streaming from a remote/restricted site to office locations

• Reduced Permitry

• Allowing access into Remote/Restricted Areas

• Risk Reduction

• Crucial to preventing unplanned downtime and disruption

There is a demand in the market for innovative and efficient ways to support lifetime extension programmes of existing assets and infrastructure. One key area is the asset caisson (seawater inlet, outlet pipes) which suffer from excessive corrosion and fatigue life problems.

Forth can provide the next level of technical solutions for accurate, reliable detection of aging caisson defects.

• Photogrammetry

• Debris Removal/Recovery

• Crash Barrier / Diver Screen Removal

• Caisson Window Access cutting

• Caisson Internal Piping

• Decommissioning

• Intake Hole Cutting

• (Can be modified for a greater range of work scopes with the minimal cost and time contributions)

• Lightweight, completely modular framework, minimising the need for unique individual parts

• 300M Depth Rating, HD Camera System, IP68, trackable positioning, full rotation, pan and tilt

• HP Jetting , Max WP—1000Bar (14500psi)

• Live Feed monitoring of HP Cleaning Operations

• 24ins—42ins Caisson capability with potential scope to increase/decrease diameter working range if required

• Adjustable, skid based, centralising system, allowing for varying ID differentials, quickly deployed, maintaining a failsafe against potential jamming risk of the tool in the caisson

• Designed to be mobilised within small transit cases, for rapid, helicopter mobilisation (if required)