‘At Sellafield’s

‘At Sellafield’s

Centre of Excellence we are challenging people to think what is the art of the possible.’

Welcome to the first edition of our new publication O -Site Insight keeping you up to date with the game-changing solutions, door-opening innovations, collaborations and community outreach happening here in Cleator Moor at the Sellafield Ltd Engineering Centre of Excellence.

In our facility in West Cumbria we are at the forefront of solving nuclear industry challenges. The future really is here today.

We are challenging people to think about what is the art of the possible with a core focus on engineering problem solving.

We want to make West Cumbria the centrepiece for these nuclear industry solutions.

Like any organisation, the Engineering Centre of Excellence is built on its people and its culture - and here at our base in Cleator Moor we are extremely lucky to have some incredible people, achieving world-first innovations, all with a can-do attitude backed by a willingness to collaborate and a determination to succeed.

Our people thrive on solving complex nuclear industry challenges, and they show true resilience and dedication every day to achieve outcomes which are then successfully deployed on the Sellafield site.

What we are implementing at this centre is a UK nuclear industry first. We have adopted a new way of working where we act as the customer and work with the supply chain to develop products which meet Sellafield Ltd’s needs.

Our team works directly with the supply chain to test and trial potential solutions, in our safe o -site environment.

This approach means we are able to introduce innovations aimed at developing bespoke products which achieve Sellafield’s mission safer, faster and more cost e ciently.

Once proven we are then able to share those solutions with the wider Nuclear Decommissioning Authority estate.

These technologies include the use of Unmanned Aerial Vehicles (UAVs) and Remotely Operated Vehicles (ROVs) and the deployment of solutions such as Spot the dog.

With the help of the supply chain, we are also building a strong Virtual Reality (VR) capability at the centre.

Our focus with VR is on electrical safety to start with, but, by utilising these new and emerging technologies, we are looking to increase the capability of our wider Sellafield team and introduce our craft community to a new way of working, along with new ways of thinking.

We are confident that it’s going to be the start of a change in mindset and culture regarding the use of VR solutions in the nuclear industry which also brings added skills enhancement for our people.

The di erent types of projects we are working on are growing all the time. We are liaising very closely with our colleagues on Sellafield site to help get even more problem statements o site, and we look forward to solving these with the supply chain’s help in the very near future.

Located not far from the Sellafield site, but not on it, has also enabled us to truly open the door to West Cumbria and the wider Cumbria community.

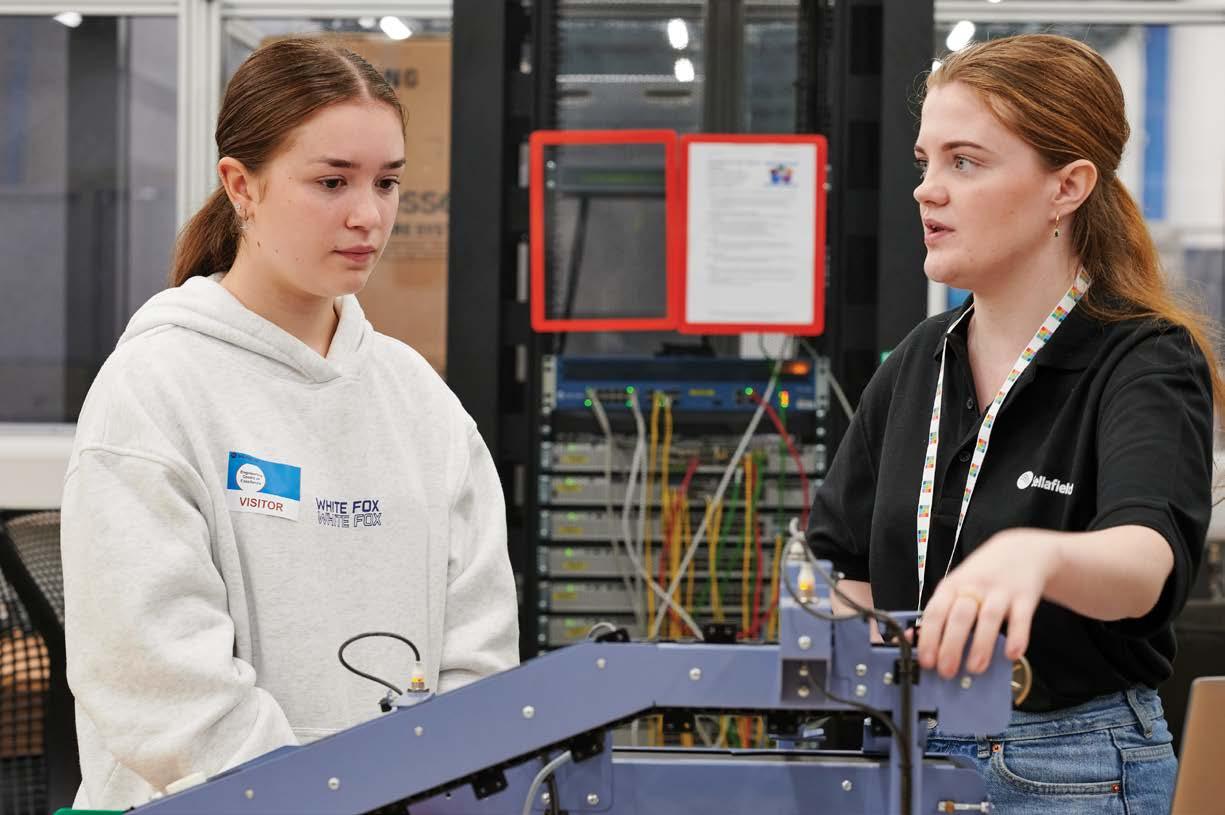

We are very proud to be reaching into many local schools and supporting a range of community projects. We have given work experience opportunities to more than 100 young people, we have multiple school visits, have held open days for cared for children, and hosted Institution of Engineering Technology (IET) events.

We are also opening a second facility on the Leconfield Industrial Estate. We already welcome 150 people through the Centre of Excellence door every day, and that’s not just Sellafield team members, it's also supply chain colleagues, stakeholders, members of the community, and international visitors coming to see what synergies there are with their industry challenges in other parts of the world, to share knowledge, and learn from what we are achieving here.

Soon there will be another 50 coming through the doors every day with Sellafield’s new Operational Technology Engineering Centre just across the road (more of that in our next edition of O -Site Insight).

Every time we open one door another door opens, and another. We want to keep it that way. Keep opening doors.

Change is constant. We are evolving at pace. And we are always looking at how we open the next door.

So if that’s the type of organisation you want to get involved with, or collaborate with, and you want to find out more, please contact us at e&m.centre.of.excellence@sellafieldsites.com

By Craig Branney Head of Engineering Development

Sellafield Ltd Engineering Centre of Excellence, Leconfield Industrial Estate, Cleator Moor,

Name Craig Branney

Title

Head of Engineering Development

What is your area of responsibility at the Centre of Excellence?

Head of facility and organisation

What are you most proud of that has been achieved by the centre so far?

The work experience, school visits and cared for children days. Working with the community uplifts the people within the organisation and seeing my Sellafield colleagues so keen to make a positive di erence, often in their own time, is always a very proud moment.

What positive impact does what you do have on Sellafield and the wider NDA estate, other industry, supply chain companies, and the local and regional community?

We are exposing a new generation to engineering and maintenance and solving complex problems from West Cumbria for the entire nuclear industry. We see the supply chain as an extension to our team.

What future opportunities are you most excited about delivering?

The team here are passionate about making a di erence that will be felt by the community and nuclear industry alike. We are innovators, leaders in change and I want to ensure all of the teams based here have the room they need to grow and succeed. For the community we are constantly evolving and adding to our o ering. Inspiring young people and the next generation is something that's really important to us all. We have a lot planned for 2024 - watch this space!

Name Kevin Rishworth

Title

Engineering Lead

Name Claire O’Connor

Title

Social Impact Lead

What is your area of responsibility at the Centre of Excellence?

Safe and legal operation of the facility; Skills enhancement programme development; Unit 18 occupancy and phase 2 plan; Socio-economic programme; Enabling Condition Based Monitoring deployment; I also work collaboratively with our supply chain partners.

What are you most proud of that has been achieved by the centre so far?

The growth of the work experience programme to include more “hands on” maintenance activities. To see the young people leaving the facility feeling inspired is extremely rewarding.

What positive impact does what you do have on Sellafield and the wider NDA estate, other industry, supply chain companies, and the local and regional community?

We can open our doors to the supply chain and local community without the same restrictions the main site has.

What future opportunities are you most excited about delivering?

I am looking forward to developing our expansion plans that will provide suitable space to enable the UAV and ROV programmes to expand and develop to reach their full potential.

What is your area of responsibility at the Centre of Excellence?

Engineering & Maintenance Work; Experience Programme; Centre of Excellence O ce Management; Commercial Support; Engineering Development Solutions; Sprint Support

What are you most proud of that has been achieved by the centre so far?

The growth. Every week we grow, we get better, and we do more.

What positive impact does what you do have on Sellafield and the wider NDA estate, other industry, supply chain companies, and the local and regional community?

We help to make Sellafield accessible, visible; we reach out and we engage with the community and the younger generations.

What future opportunities are you most excited about delivering?

Improving our Engineering & Maintenance Work Experience Programme to include the exposure of, working on, and learning about, our plants, through hands-on use of our new rigs. In general, all those new opportunities that we don’t yet know about, but they will come…

Name Alan Hollinshead

Title

Lead Engineer

What is your area of responsibility the Centre of Excellence?

I manage our additive manufacturing innovative solution team. I am supporting the upgrade and upskilling of our condition-based monitoring capability.

What are you most proud of that has been achieved by the centre so far?

The can-do approach of our team has been amazing.

We have ‘done something di erent’ as was the call from our Site Director, Neil Crewdson.

What a positive impact does what you do have on Sellafield and the wider NDA estate, other industry, supply chain companies, and the local and regional community?

We are benchmarking our innovative solutions for exploration within other NDA estate sites to deliver faster, safer and cheaper.

We also have upwards of 15,000 personnel and visitors through the facility annually and this can only be adding to the local economy

What future opportunities are you most excited about delivering?

Further additive manufacturing, 3D-Printing substantiation for delivery to site.

Name Matthew Dixon

Title

Engineering Development Solutions Lead

What is your area of responsibility at the Centre of Excellence?

Managing Engineering Development Solutions with my main focus being the six-week Sprint projects, through to the site deployment of the project.

What are you most proud of that has been achieved by the centre so far?

For myself it has to be the EDS successes we have had this year from deployed concepts to enhancing the Sprint process. We have branched out and run two supply chain Sprint projects and a community Sprint project.

What positive impact does what you do have on Sellafield and the wider NDA estate, other industry, supply chain companies, and the local and regional community?

The EDS Sprints take the problem away from the plant ensuring we have full focus to come up with a solution that can then be deployed back onto the site. The learning gathered can then be shared with wider NDA estate and other industries. We have close working relationships with the local supply chain and work in collaboration.

What future opportunities are you most excited about delivering?

Taking problems from outside the fence in the wider NDA estate.

Safe/legal/compliance assurance of Unit 6 and Unit 18

Occupancy, usage, and events/ demo support in workshop space

Maintenance support team manager supporting skills enhancement programme and minor facility projects.

What are you most proud of that has been achieved by the Centre so far?

Personally, I am most proud of the work involved and successful completion of the LRQA (Lloyd’s Register Quality Assurance) audit as a facility.

What positive impact does what you do have on Sellafield and the wider NDA estate, other industry, supply chain companies, and the local and regional community?

Enables ease of supply chain collaboration and new technology demonstrations in an o -site location; Support school engagement programmes to help generate an interest in STEM careers and women in engineering/maintenance.

What future opportunities are you most excited about delivering?

Continuing to be involved in the delivery of Unit 18: Operational Technology Engineering Centre and further expansions of o -site developments facilities/workstreams.

Drones are increasingly being used on site as they are safer, faster and more cost e ective than traditional inspection methods.

UAV pilots based at the Centre of Excellence have completed two flight firsts on a UK nuclear site.

The successful deployment of the Elios 3 drone equipped with a LiDAR sensor marks a major milestone for the team, enabling Sellafield Ltd to achieve unparalleled e ciency in mapping and 3D modelling. Hot on the heels of this first flight the team then successfully flew the Elios 3 drone with a RAD (Radiation Activity Detection) dosimeter which they hope will allow them to map radiation hotspots in areas before other colleagues go into unused areas of the site.

Amanda Smith, UAV Equipment Programme Lead said:

We are thrilled that this first flight of Elios 3 with the LiDAR payload was a success and the data collected is now being processed in a Computer Aided Design system which will produce a 3D model of the area in question, helping to inform engineering decisions going forwards. Sending a drone into this tight and unused space rather than an employee in the first instance reduces risk, and also saves time and money.

Buoyed by the success of this flight, Sellafield made history again as the first UK nuclear site to employ a drone equipped with a radiation monitor. This innovative addition aims to assess radiation levels and identify potential hotspots in areas where radiation exposure levels are unknown.

The deployment of the drone with a radiation payload demonstrates the organisation's commitment to exploring innovative solutions for radiation assessment, reducing risk to those working on the site.

By leveraging the capabilities of its fleet of drones Sellafield Ltd embraces the future of aerial exploration, improving nuclear site safety and achieving e ciencies.

Your engineering problems stop here

The UAV team was the first to recently complete specialist industry drone training which was developed with key input from Amanda Smith, UAV programme lead.

Through her role as a member of the national Engineering Construction Industry Training Board (ECITB) steering group, Amanda has played a role in developing a quality assured training programme for drone operators in industrial environments to improve flight standards.

Amanda said: The ECITB training is designed to upskill and develop capabilities of teams working with UAVs and increasing the e ciency of workers, while making working environments safer, reducing asset downtime during inspections and saving industry a significant amount of money.

The use of robotics in decommissioning activity is rapidly expanding. Cleaning up legacy nuclear sites like Sellafield is currently taking decades. It often means working in challenging, unknown and hazardous environments.

Remotely Operated Vehicles (ROVs)

The use of robots is increasingly commonplace at Sellafield, helping to make work safer, faster, and cheaper, and delivering valuable lessons for other nuclear sites in the UK.

Robotics can assist in making the clean up job easier by removing workers from harmful radiation environments and often doing jobs more quickly and e ectively.

At the Engineering Centre of Excellence the team are leaders in deploying o -the-shelf Remotely Operated Vehicles (ROVs) and adapting them for on-site needs.

Their knowledge is shared across the NDA estate and wider nuclear sector.

The team became the first in the world to use a LiDAR laser scanning device on an ROV, in this case Spot the dog, in a high radiation environment, allowing the robot to navigate and build a 3D image of the hazardous area and removing the need for humans to enter.

Calvin Smye, ROV equipment engineer, said:

Everything we are using is o -the-shelf but by adding di erent payloads, like a LiDAR sensor and a radiation monitor, we are adapting them to deliver for our business. Since the introduction of this technology we’ve really been at the forefront of testing it and adjusting it to our needs and are now leaders in the nuclear industry for applying it. We’ve seen supply chain colleagues deploying the same technology at other nuclear sites following our success.

Spot’s capabilities were shared with industry colleagues during a live demonstration at one of the site's oldest buildings, Calder Hall.

Like many buildings built in the 1950s, Calder Hall has areas where asbestos is a known hazard, making them inaccessible for humans and di cult to decommission.

AtkinsRéalis, supported with some of the ROV team's equipment and documentation, recently utilised Spot to conduct a livestreamed inspection – via the robot’s on-board camera – to build an accurate understanding of the condition of the area and how best to clean it up.

The same robots are now being used across other NDA sites in the UK, including at Dounreay in Scotland, demonstrating how learning is being shared to deliver better outcomes.

Sellafield is also exploring the use of ROVs to detect potentially dangerous gases in work areas before humans are sent in, much like the canaries used in coal mines over 200 years ago. They’ve recently conducted their first trial using a dosimeter designed by the Radiometrics Systems Group.

Deon Bulman, ROV equipment programme lead, said:

The adoption of new technology is progressing at pace at Sellafield as people start to see the benefits.The technology is here to support people, not replace them, and those that embrace it soon see the advantages. If we can do one task that removes the need for a person to enter a hazardous area, that’s a win.

Bay 4

Engineering Development Solutions (Sprints)

Matt Dixon matthew.dixon@sellafieldsites.com

Bay 5

David Eldon

David.T.Eldon@sellafieldsites.com

Emerging Technology Virtual

Bay 6

Operations Technology Group

Steve Powell steve.d.powell@sellafieldsites.com

Bay 7

Remotely Operated Vehicles team

Deon Bulman deon.c.bulman@sellafieldsites.com

Unmanned Aerial Vehicles team

Amanda Smith amanda.x.smith@sellafieldsites.com

Robotics Team

Idris Hussain idris.hussain@sellafieldsites.com

steven.j.williamson@sellafieldsites.com

3D printing - Jack Williamson jack.n.williamson@sellafieldsites.com

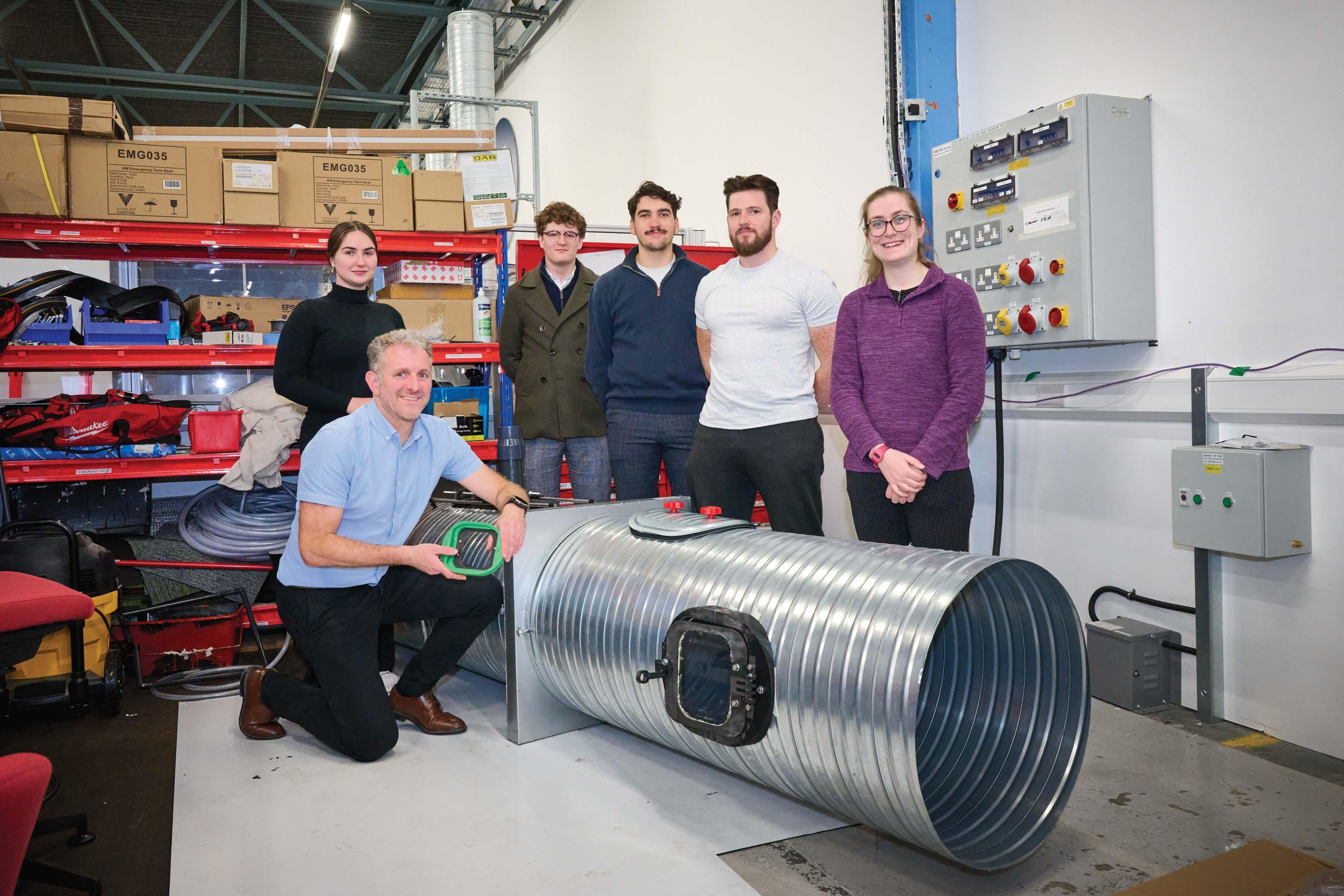

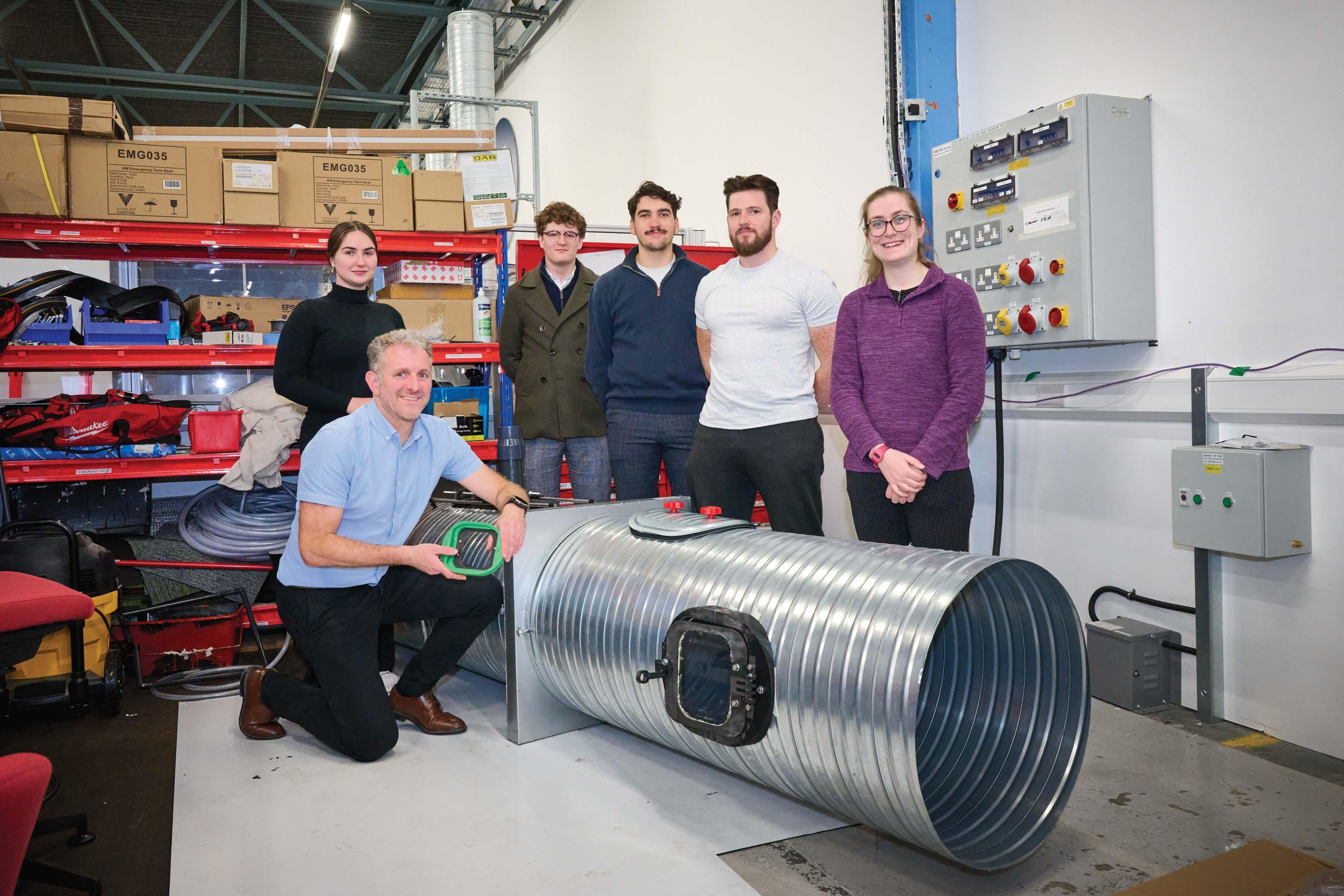

A Sprint project based at the Engineering Centre of Excellence is an opportunity to solve an engineering problem on the Sellafield site.

Working as a small team of up to six people with di erent professional backgrounds, the Sprint project team has six weeks to immerse themselves in a project and come up with a solution(s) for the client.

For those taking part, it o ers them the chance to develop their problem solving and reactive thinking skills.

The Sprint team comes together and is handed the mission statement. They now have six weeks to come up with the solution(s) 01 02

The client approaches the Engineering Development Solutions team with their problem

05

hese initial findings are refined. At this stage some concepts will be dropped and the preferred potential solutions taken forward for further testing

03 04

Using the facility, the team has the space to start testing their ideas and potential solutions

The team comes up with a range of initial concepts, starts their in-depth industry research and pulls together a number of potential options to explore further

The benefits of a Sprint project go far beyond delivering a solution(s); they also promote personal growth, teamwork, leadership training and building relationships.

They work in partnership with the Centre for Leadership Performance to ensure that those taking part get as much out of the six weeks as they can; taking new skills with them on completion of the Sprint

The Centre for Leadership Performance provides development support to the Sprint teams. So although they're working on a technical problem, a lot of the learning is about behaviours, the softer skills. We work with them on things like leadership, teamwork, communication and influence. We meet with them on a weekly basis and we go through a personal development plan, find out what they've been working on and try and encourage a little bit more of that development activity.

The Centre of Excellence now o ers support with deployment of the Sprint solutions onto site.

We have grown relationships within the supply chain and with clients on the plant to evolve our process here to enable us to support with deployment of the Sprint solutions onto site. It’s cost e ective and we have proven the credibility of the solution here at the Centre of Excellence. So we don't just come with the concept idea and the rapid prototyping, we actually solve the problem by deploying it.

The Sprints often have members of sta from supply chain partners taking part. Sprints teams also call on local expertise when coming up with and testing their solutions.

Chloe Ferguson, 21, is an apprentice Project Manager at Forth. Chloe is currently part of a Sprint project working with four others from Sellafield. Chloe said: It was a little daunting at first. The process and procedures here and the way of working is di erent in every way. I wanted to take part to experience a new environment and to grow as a person and to take new learnings back to Forth. It has really opened my eyes and I’m really grateful for the opportunity to take part.

Mark Telford, Managing Director at Forth, said: are really proud of the young professional she is becoming. At Forth we work closely with the Sprint teams as they are welcome to come and use our facilities - we are only next door after all. Building relationships and broadening the o er to our employees and our customers is what we do at Forth, we believe strongly in sustainable employment. This is key to that.

The mission statement

The Main Site Command Facility (MSCF) is a newly-built building on the Sellafield site. During an intervention by the O ce of Nuclear Regulation (ONR), the inspector raised a Regulatory Issue regarding the lack of maintenance on fire dampers within the building, identifying key actions needed to improve functionality of the Fire Protection System. The current problem the building has is that there is limited access to the fire dampers in order to carry out the required maintenance checks on them.

The solution(s)

The team of five came up with four options to access the fire dampers to carry out these maintenance checks. This included; using ROVs, Mobile Elevating Work Platforms (MEWPs), and a self-lubrication feeding system.

Shona Tait - The Sprint lead

This Sprint project gave me a chance to develop and really push myself in a safe environment where you are still supported but you really have a chance to grow.It did seem daunting initially and it’s really challenging. It's a lot of work, but it's really, really good to help you personally develop and technically develop, but also you get so much out of it, you become a better all-around engineer. And there are so many skills you can take from the Sprint project that will make a big di erence to whatever team you return to when you go to your normal work.

The client - Chris Bond

The huge benefit of the Sprint is that it o ers the opportunity to step outside of the day-to-day business. You can often get bogged down in the detail of what you need to deliver. And the Sprints are a dedicated resource which spend six weeks to look in great depth to deliver solutions that you may not have already thought about or that you maybe can't test. By bringing together people with di erent experiences they can think outside the box and look at a wide range of potential solutions.

In our pursuit of accessibility and openness, Sellafield extends a warm invitation to all –beyond the site gates and into Cleator Moor. Positioned as the Engineering Centre of Excellence, we not only want to showcase our business but also integrate ourselves seamlessly into the fabric of the community.

We support local community initiatives and enable professional initiatives to reach out to a potential new generation.

At the heart of our commitment lies a desire to engage with the community, be it through opening our doors to local schools or collaborating with the supply chain. We strive to inspire the future talent of Engineering & Maintenance, presenting diverse career options.