CIRCLELEDCEILINGLIGHT 12

SQUARELEDCEILINGLIGHT 8 TRACKCEILINGLIGHT 2 COVECEILINGLIGHT 2

4PANELCEILINGFAN 1 3PANELCEILINGFAN 1 AIRVENTILATOR 2 AIRCONDITIONER 1 SWITCH 11 OUTLET 8

CIRCLELEDCEILINGLIGHT 12

SQUARELEDCEILINGLIGHT 8 TRACKCEILINGLIGHT 2 COVECEILINGLIGHT 2

4PANELCEILINGFAN 1 3PANELCEILINGFAN 1 AIRVENTILATOR 2 AIRCONDITIONER 1 SWITCH 11 OUTLET 8

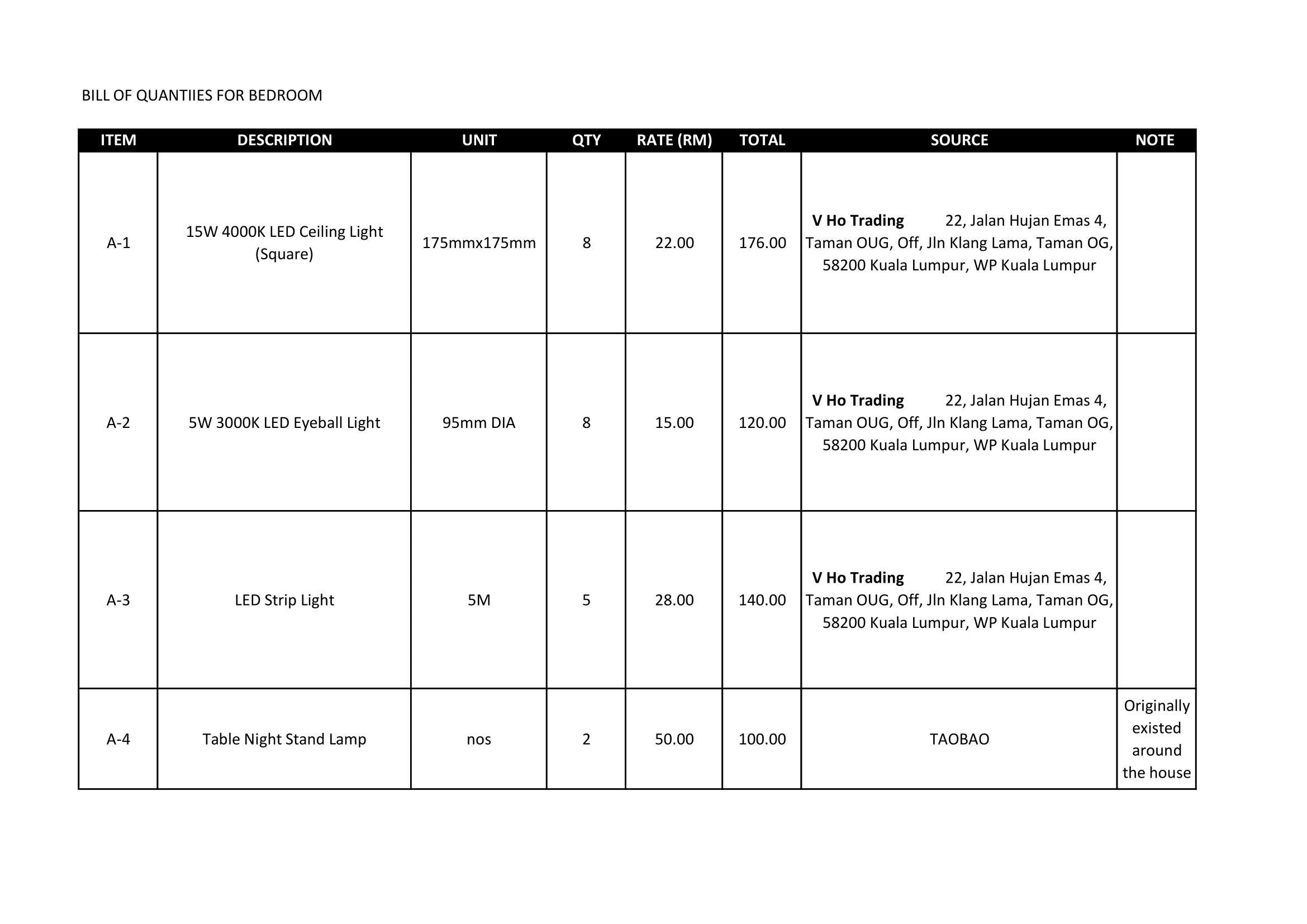

The area that was chosen is my mother's room, master bedroom. She has a private toilet and a walk-in closet. She is particular with temperatures and is sensitive to light due to her pass medical history.

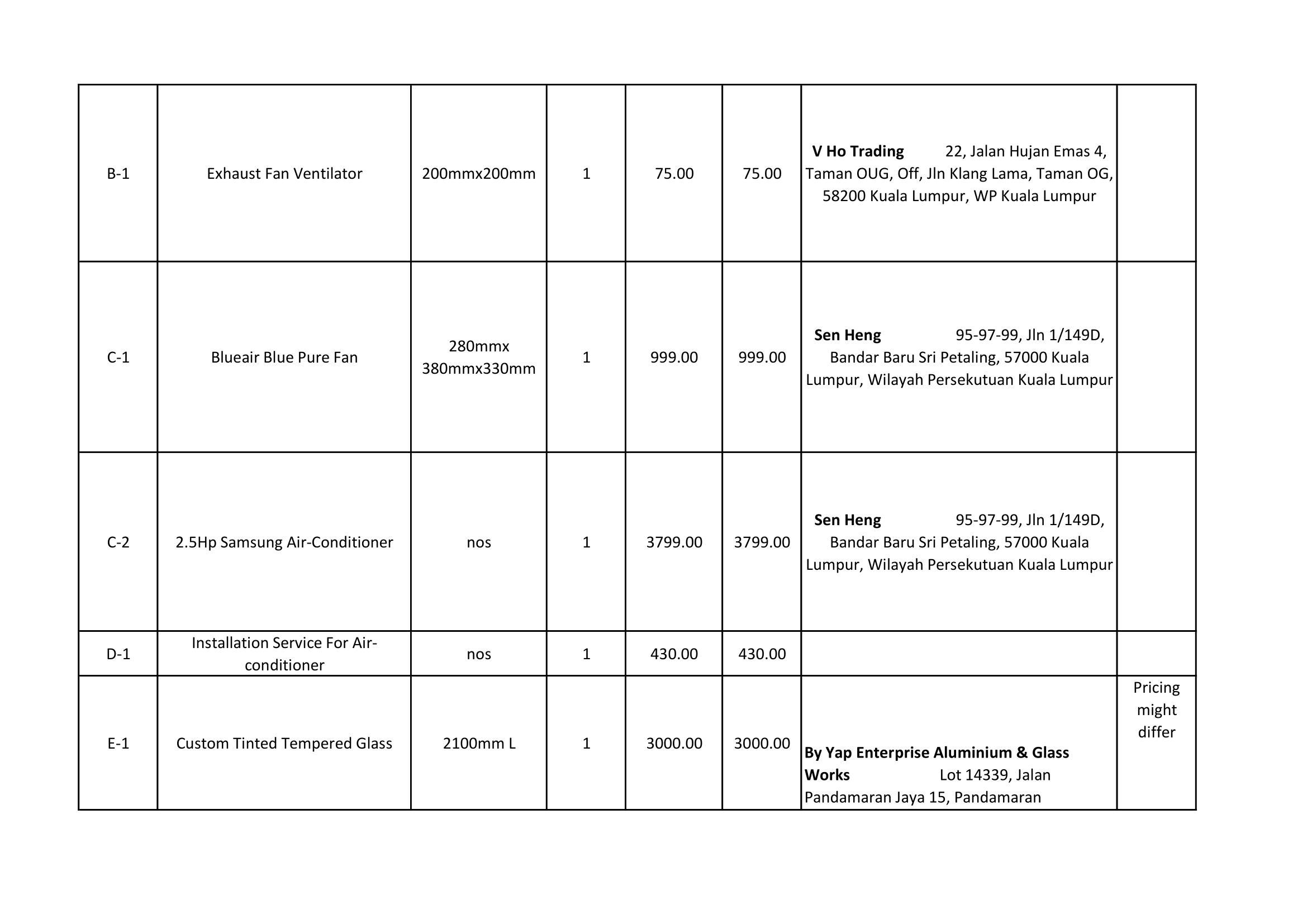

The placement of the air-conditioner is directly facing the bed. My mother tend to get cold easily and the air-conditioner is too cold even when the temperature was set high.

To solve this, by changing the position of the air-conditioner across the room would be much suitable, therefore it can cool the big space easily and the wind will not blow directly to the bed.

The huge window may look aesthetically nice, but during the morning and afternoon, it gets very hot and the sun is direct shining into the room. She complaint that the sofa had change colour due to the heat and sun. Even with the air-conditioner blasting, the temperature is still hot.

To solve this, by changing the size of the window and adding a portable standing fan beside the sofa can decrease the temperature of the room.

The ceiling lights are 6500K which is not soothing for a bedroom setting. The LED light on top of her bed can sometimes become glaring during night hours when client is ready for bed as it hurts her eyes and developing headache after a period of time.

To solve this, by changing the ceiling lights to 4000K for a relaxing environment and remove some of the spotlights, replacing a night stand beside her bed can improve her rest hours.

The walk-in closet is located at the back of the bedroom with a small sliding door. It becomes very humid inside and sometimes it gives out odour due to the humidity. The spotlights can be glaring and it makes the space hotter.

To solve this, by installing a air ventilator in the closet and replace the spotlights with small eyeball LED lights can decrease the humidity and heat.

Even though the space is bright, the lights does not shine every corner of the room. Because there are many compartments and shelfs, it's hard to find the things she needs due to the insufficient light.

To solve this, by installing LED strip lights

underneath can improve sight and does not interrupt with the temperature.

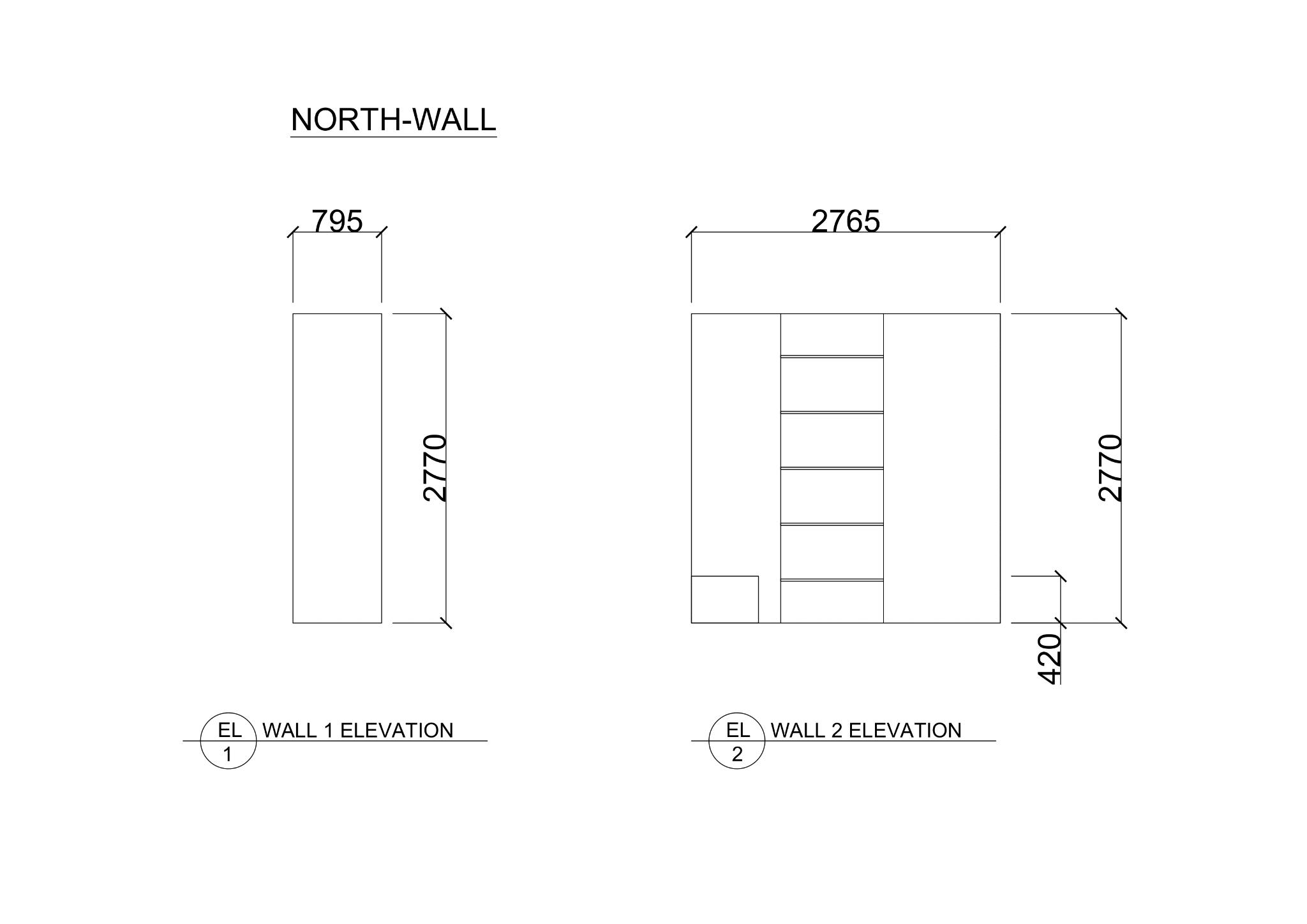

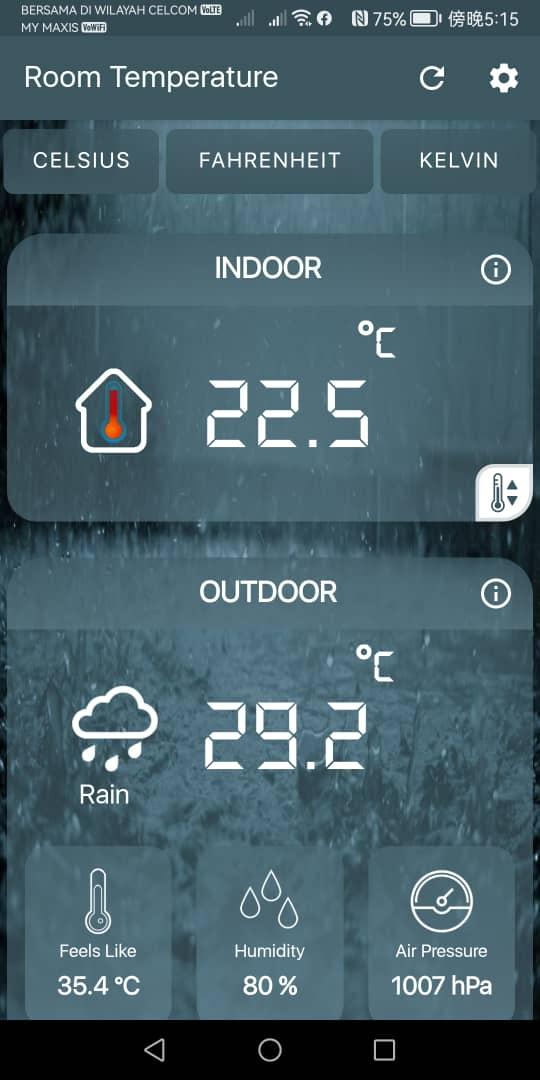

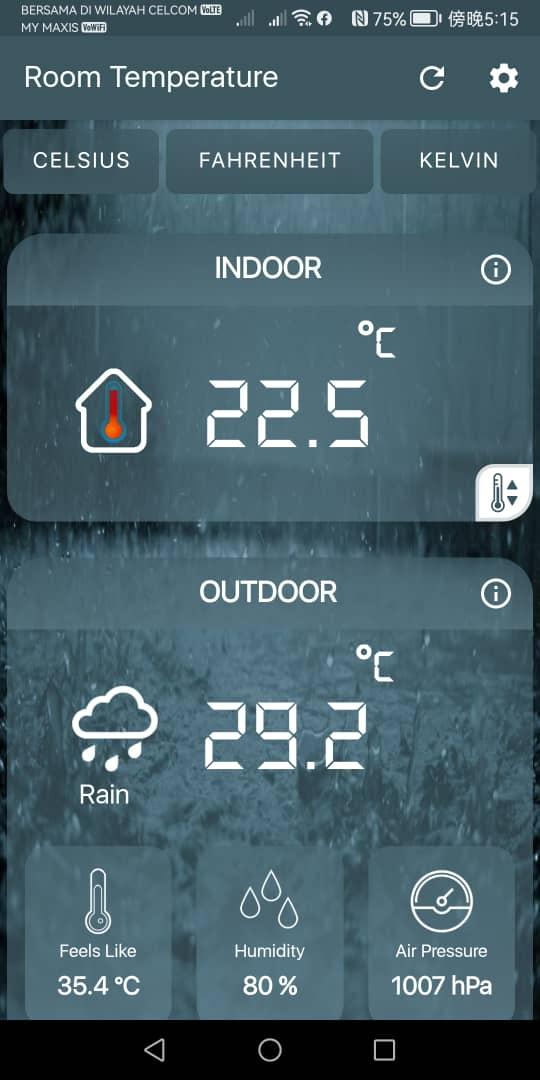

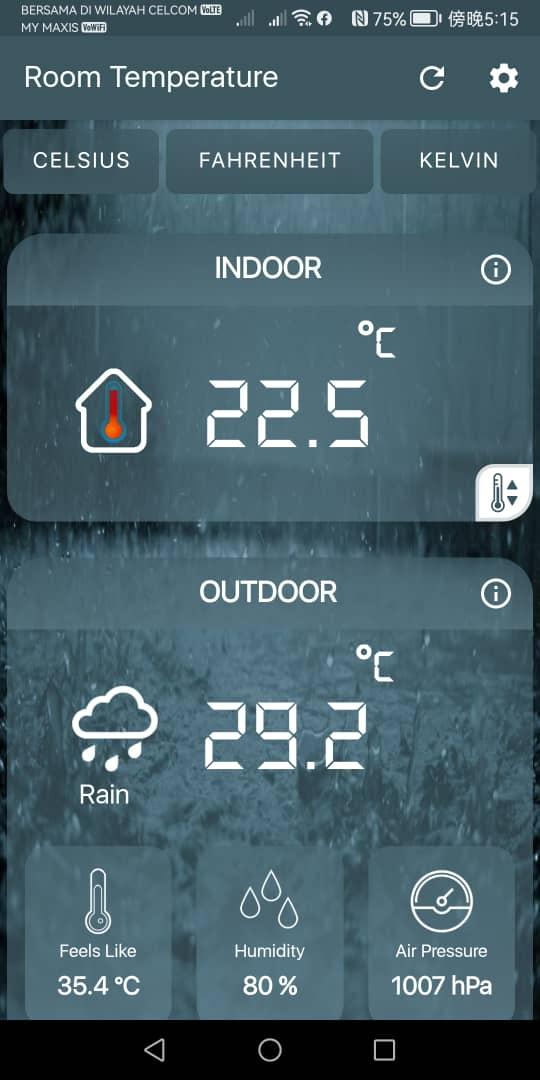

02a: Recording and measurement of 4 facings of external walls of chosen building [10%]

Students are to use their current home or a convenient residential building as their site. Identify the facings (N,E,S,W) of the 4 external walls. Identify their materials and estimate/measure their dimensions. Measure each wall’s internal and external temperature at 3 different times of the day. 7 a.m., 12 p.m. and 5 p.m. Calculate the heat transfer, based on relevant examples. Conclude and briefly reflect on this section by identifying the wall panel that is most critical/highest heat gain/most utilized space for Part 2b.All findings of this section shall be recorded and compiled into one report with Part 2b.Assessment criteria:

5% - Effort, clarity and description of recording process

5% - Understanding and accuracy of heat transfer calculations

My mother’s room is 308.8sqft. There are 3 doors, one for entrance and another for the bathroom.There are 2 windows and a big glass window to allow natural light to penetrate into the room during the day

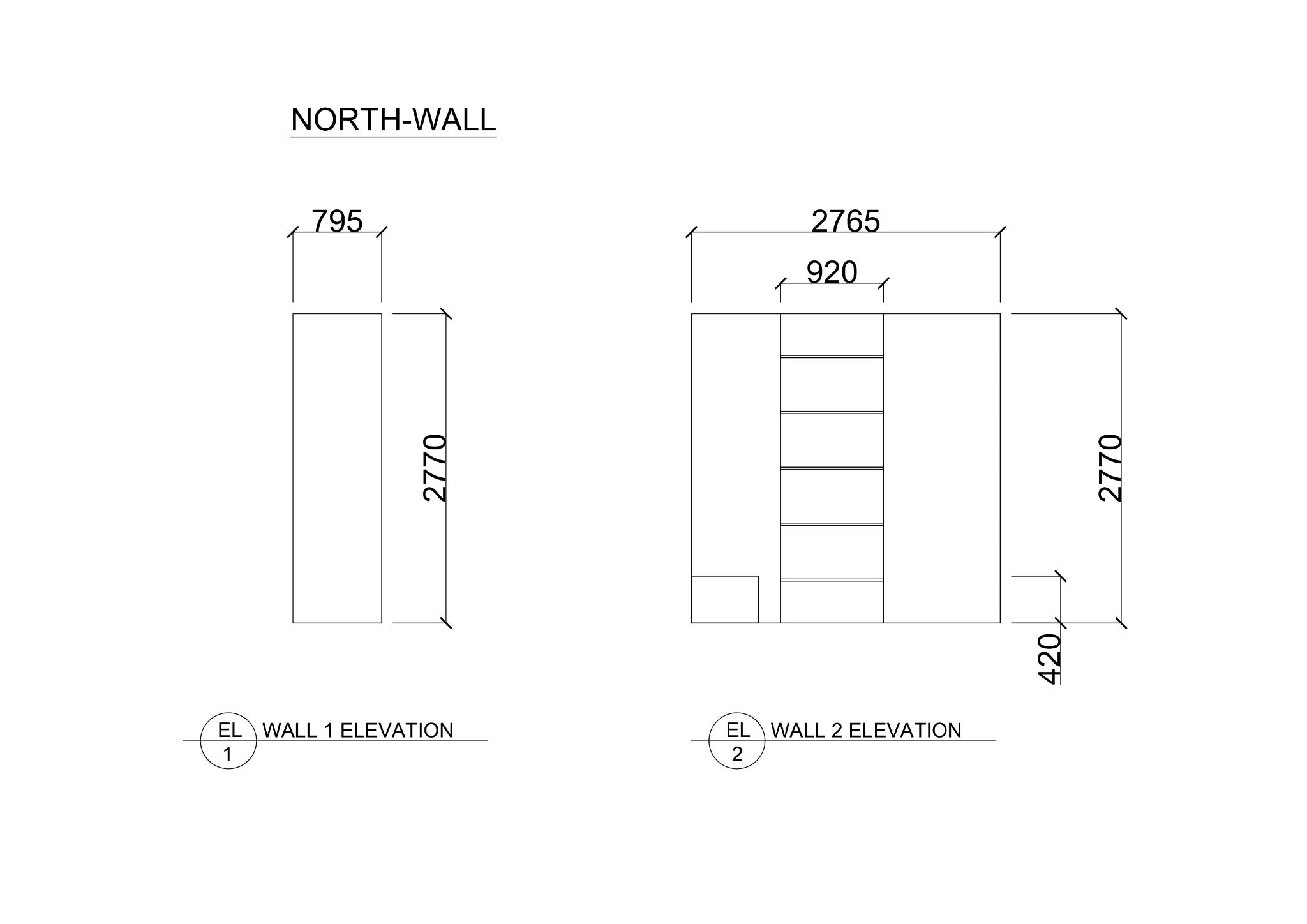

Material Concrete Wall 2 Door 1

Area Including Door 2.765(W) X 2.77(H) = 7.65 82.441 �� 2 ≈ ����2 Excluding door 7 65 - 2 548 = 5 102 54 917 �� 2 �� 2 �� 2 ≈ ����2

(0 92 x 2 77)m = 2.548�� 2 27 426 ≈ ����2

Time 0700 1200 1700

Heat transfer rate of Concrete Wall 2

A= 54.917����2 R= 2 457 = (78 26-68)℉ ∆�� =10 26℉

Q= (54 917 x 10 26℉) / ����2 2 457 = 229.324 btu/hr

A= 54.917����2 R= 2 457 = (86 72-69 62)℉ ∆�� =17 1℉

Q= (54 917 x 17 1℉) ����2 / 2 457 = 382.206 btu/hr

A= 54.917����2 R= 2 457 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (54 917 x 12 06℉) ����2 / 2 457 = 269.556 btu/hr

Heat transfer rate of door 1 A= 27.426����2 R= 2.17 = (78 26-68)℉ ∆�� =10 26℉ Q= (27 426 x 10 26℉) / ����2 2 17 = 129 673 btu/hr

Total heat transfer rate 229.324 + 129.673 = 358 997 btu/hr 359 btu/hr ≈

Total heat transfer of Wall 2 = 1379.3 btu/hr

A= 27.426����2 R= 2.17 = (86 72-69 62)℉ ∆�� =17 1℉

Q= (27 426 x 17 1℉) ����2 / 2 17 = 216 122 btu/hr

382.206 + 216.122 =598 328 btu/hr 598 3 btu/hr ≈

A= 27.426����2 R= 2.17 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (27 426 x 12 06℉) ����2 / 2 17 = 152 423 btu/hr

269.556 + 152.423 =421 979 btu/hr 422 btu/hr ≈

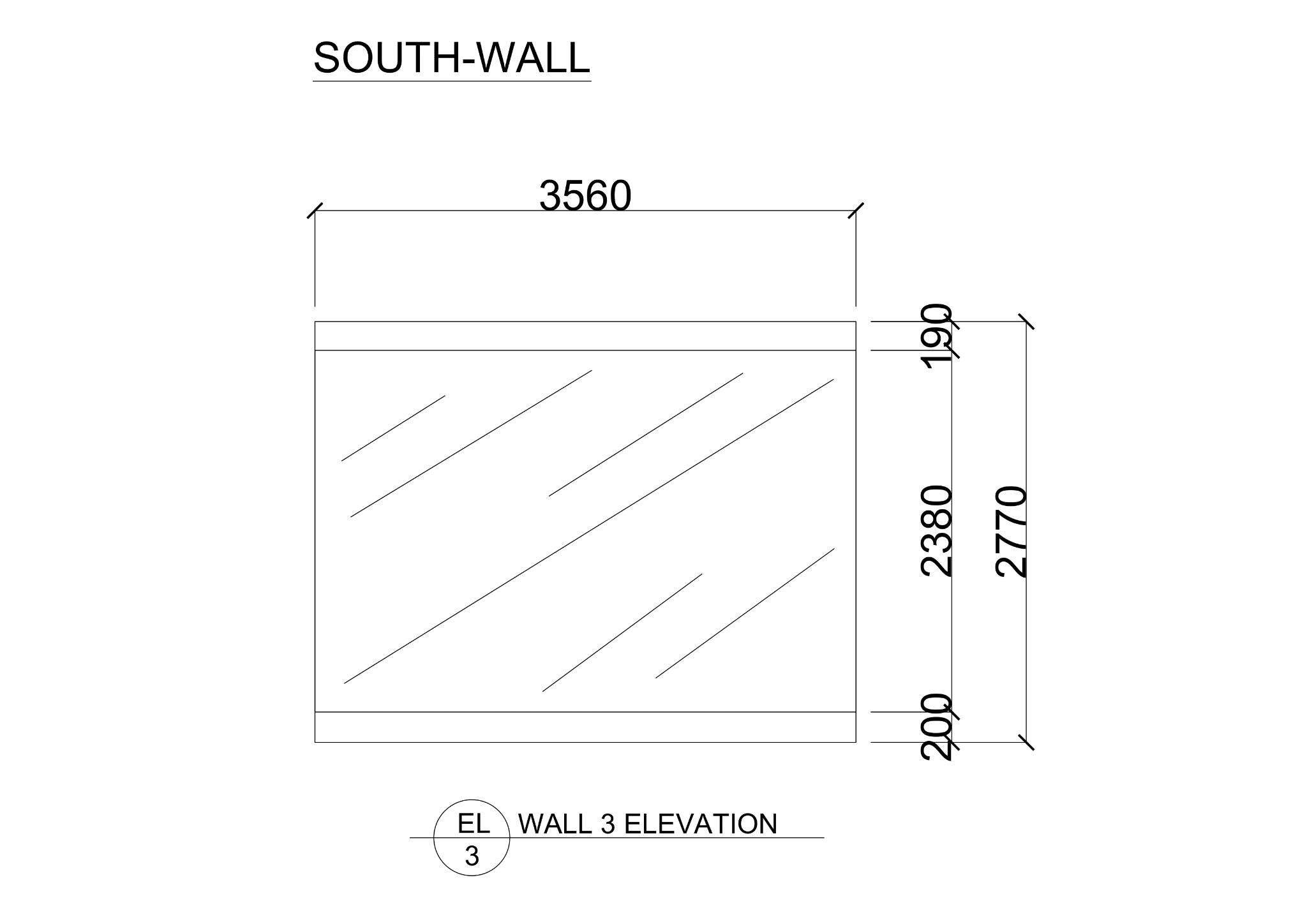

Material Concrete Wall 3 Window 1

Area Including Door 3 56(W) X 2 77(H) = 9 861 106 143 �� 2 ≈ ����2 Excluding door 9 861 - 8 473 = 1 388 14 94 �� 2 �� 2 �� 2 ≈ ����2

(3.56 x 2.38)m = 8 473�� 2 91 203 ≈ ����2

Time 0700 1200 1700

Heat transfer rate of Concrete Wall 3

A= 106 143����2 R= 2.457 = (78.26-68)℉ ∆�� =10.26℉

Q= (106.143 x ����2 10.26℉) / 2.457 = 443 235 btu/hr

Heat transfer rate of Window 1 A= 91 203����2 R= 0 91 = (78.26-68)℉ ∆�� =10 26℉

Q= (91 203 x ����2 10.26℉) / 0.91 = 1028 289 btu/hr

Total heat transfer rate 443 235 + 1028 289 = 1471 524 btu/hr 1471.5 btu/hr ≈

Total heat transfer of Wall 3 = 5653 7 btu/hr

A= 106 143����2 R= 2.457 = (86.72-69.62)℉ ∆�� =17.1℉

Q= (106.143 x ����2 17.1℉) / 2.457 = 738 724 btu/hr

A= 106 143����2 R= 2.457 = (84.56-72.5)℉ ∆�� =12.06℉

Q= (106.143 x ����2 12.06℉) / 2.457 = 520 995 btu/hr

A= 91 203����2 R= 0 91 = (86.72-69.62)℉ ∆�� =17 1℉

Q= (91 203 x 17 1℉) ����2 / 0.91 = 1713 815 btu/hr

A= 91 203����2 R= 0 91 = (84.56-72.5)℉ ∆�� =12 06℉

Q= (91 203 x ����2 12.06℉) / 0.91 = 1208 69 btu/hr

738 724 + 1713 815 =2452 539 btu/hr 2452.5 btu/hr ≈

520 995 + 1208 69 =1729 685 btu/hr 1729.7 btu/hr ≈

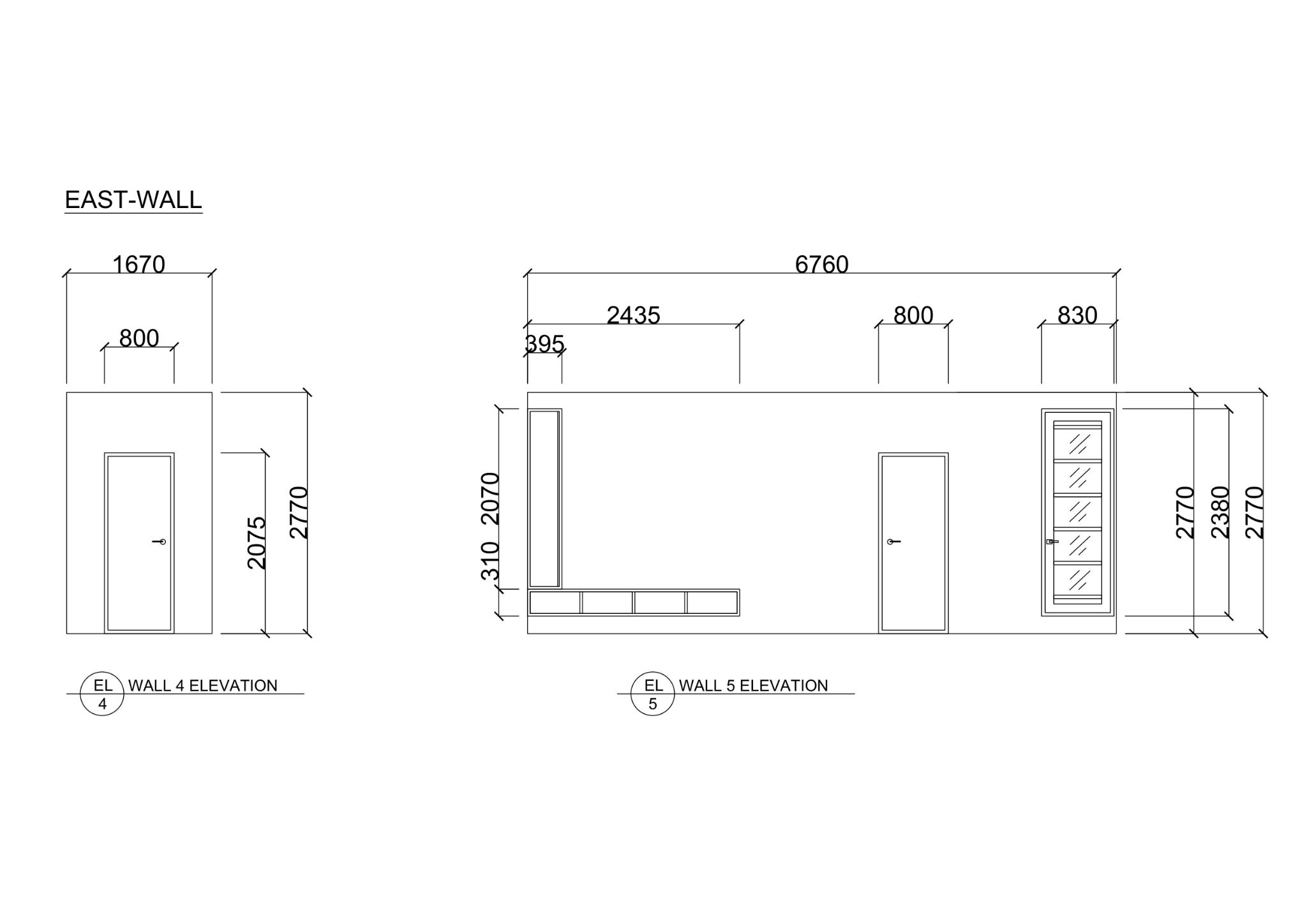

Material Concrete Wall 4 Door 2 Area Including Door 1 67(W) X 2 77(H) = 4 44 47 792 �� 2 ≈ ����2 Excluding door 4 44 - 1 66 = 2 78 29 924 �� 2 �� 2 �� 2 ≈ ����2

(0.8 x 2.075)m = 1 66�� 2 17 868 ≈ ����2

Time 0700 1200 1700

Heat transfer rate of Concrete Wall 4

A= 29 924����2 R= 2.457 = (78.26-68)℉ ∆�� =10.26℉

Q= (29.924 x ����2 10.26℉) / 2.457 = 124 957 btu/hr

Heat transfer rate of door 1 A= 17 868����2 R= 2 17 = (78.26-68)℉ ∆�� =10 26℉

Q= (17 868 x ����2 10.26℉) / 2.17 = 84 482 btu/hr

Total heat transfer rate 124 957 + 84 482 = 209 439 btu/hr 209.4 btu/hr ≈

Total heat transfer of Wall 4 = 804 7 btu/hr

A= 29 924����2 R= 2.457 = (86.72-69.62)℉ ∆�� =17.1℉

Q= (29.924 x 17.1℉) ����2 / 2.457 = 208 262 btu/hr

A= 29 924����2 R= 2.457 = (84.56-72.5)℉ ∆�� =12.06℉

Q= (29.924 x ����2 12.06℉) / 2.457 = 146 88 btu/hr

A= 17 868����2 R= 2 17 = (86.72-69.62)℉ ∆�� =17 1℉

Q= (17 868 x 17 1℉) ����2 / 2.17 = 140 803 btu/hr

A= 17 868����2 R= 2 17 = (84.56-72.5)℉ ∆�� =12 06℉

Q= (17 868 x ����2 12.06℉) / 2.17 = 99 303 btu/hr

208 262 + 140 803 =349 065 btu/hr 349.1 btu/hr ≈

146 88 + 99 303 =246 183 btu/hr 246.2 btu/hr ≈

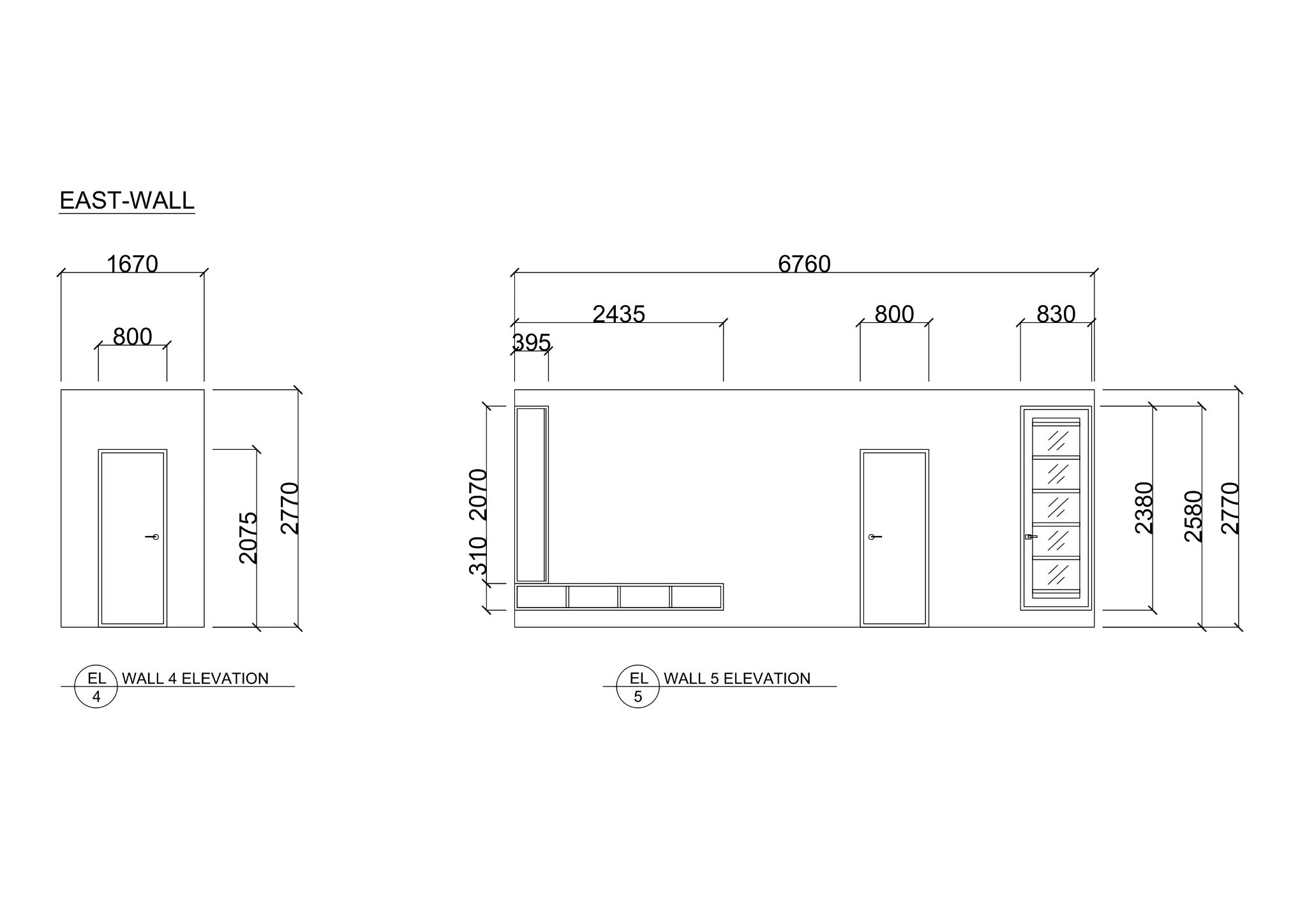

(3.56 x 2 38)m = 8 473�� 2 91.203 ≈ ����2

(0.83 x 2 38)m =1 975�� 2 21 259 ≈ ����2

(0.395 x 2 07)m =0 818�� 2 8 805 ≈ ����2

(2.435 x 0 31)m =0 755�� 2 8 127 ≈ ����2

Material Concrete Wall 5 Door 3 Window 2 Cabinet 1 Cabinet 2 Area Including Door, Window, Cabinet 6 76(W) X 2 77(H) = 18 725�� 2 ≈ 201 554����2 Excluding Door, Window, Cabinet 18 725 - 8 473 - 1 975 - 0 818 �� 2 �� 2 �� 2 - 0.755= 6.704 72.161 �� 2 �� 2 ≈ ����2

Time 0700 1200 1700

Heat transfer rate of Concrete Wall 5 A= 72.161����2 R= 2.457 = (78 26-68)℉ ∆�� =10.26℉

Q= (72.161 x 10.26℉) / ����2 2 457 = 301 332 btu/hr

Heat transfer rate of Door 3 A= 91 203����2 R= 2.17 = (78.26-68)℉ ∆�� =10.26℉

Q= (91.203 x 10.26℉) / ����2 2.17 = 431 218 btu/hr

A= 72.161����2 R= 2.457 = (86 72-69 62)℉ ∆�� =17.1℉

Q= (72.161 x 17.1℉) / ����2 2 457 = 502 219 btu/hr

A= 91 203����2 R= 2.17 = (78.26-68)℉ ∆�� =17.1℉

Q= (91.203 x 17.1℉) / ����2 2.17 = 718 696 btu/hr

A= 72.161����2 R= 2.457 = (84 56-72 5)℉ ∆�� =12.06℉

Q= (72.161 x 12.06℉) / ����2 2 457 = 354 197 btu/hr

A= 91 203����2 R= 2.17 = (84.56-72.5)℉ ∆�� =12.06℉

Q= (91.203 x 12.06℉) / ����2 2.17 = 506 87 btu/hr

Time 0700 1200 1700

Heat transfer rate of Window 2

A= 21.259����2 R= 0.91 = (78 26-68)℉ ∆�� =10 26℉

Q= (21 259 x 10 26℉) / ����2 0 91 = 239 689 btu/hr

A= 21.259����2 R= 0.91 = (78 26-68)℉ ∆�� =10 26℉

Q= (21 259 x 10 26℉) ����2 / 0 91 = 399 482 btu/hr

A= 21.259����2 R= 0.91 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (21 259 x 12 06℉) / ����2 0 91 = 281 74 btu/hr

Heat transfer rate of Cabinet 1

A= 8.805����2 R= 1.25 = (78 26-68)℉ ∆�� =10.26℉

Q= (8.805 x 10.26℉) / ����2 1 25 = 72 271 btu/hr

A= 8.805����2 R= 1.25 = (78 26-68)℉ ∆�� =10.26℉

Q= (8.805 x 10.26℉) / ����2 1 25 = 120 452 btu/hr

A= 8.805����2 R= 1.25 = (84 56-72 5)℉ ∆�� =12.06℉

Q= (8.805 x 12.06℉) / ����2 1 25 = 84 951 btu/hr

Heat transfer rate of Cabinet 2

A= 8.127����2 R= 1.25 = (78 26-68)℉ ∆�� =10.26℉

Q= (8.127 x 10.26℉) / ����2 1 25 = 66 706 btu/hr

Total heat transfer rate 301 332 + 431 218 + 239.689 + 72.271 + 66 706 = 1111.216 btu/hr 1111 2 btu/hr ≈

Total heat transfer of Wall 5 = 4269 4 btu/hr

A= 8.127����2 R= 1.25 = (78 26-68)℉ ∆�� =10.26℉

Q= (8.127 x 10.26℉) / ����2 1 25 = 111 177 btu/hr

A= 8.127����2 R= 1.25 = (84 56-72 5)℉ ∆�� =12.06℉

Q= (8.127 x 12.06℉) / ����2 1 25 = 78 409 btu/hr

502 219 + 718 696 + 399.482 + 120.452 + 111 177 =1852.026 btu/hr 1852 0 btu/hr ≈

354 197 + 506 87 + 281.74 + 84.951 + 78.409 =1306 167 btu/hr 1306 2 btu/hr ≈

Area

Concrete Wall 6 Including Door. Window, Cabinet, Table 8.58(W) X 2.77(H) = 23.767 255.826 �� 2 ≈ ����2 Excluding Door,Window, Cabinet, Table 23 767 - 1 975 - 1 201 - 0 638 - 0 71 - 1 169 = 18 074 194 547 �� 2 �� 2 �� 2 �� 2 �� 2 �� 2 �� 2 ≈ ����2

Window 3 (0 83 x 2 38)m =1 975�� 2 21.259 ≈ ����2 Cabinet 3 (0 52 x 2 31)m =1 201�� 2 12 927 ≈ ����2 Cabinet 4 (1 519 x 0 42)m =0 638�� 2 6.867 ≈ ����2 Cabinet 5 (1 691 x 0 42)m =0 71�� 2 7 642 ≈ ����2

Table 1 (1 25 x 0 935)m =1 169�� 2 12.583≈ ����2

Time 0700 1200 1700

Heat transfer rate of Concrete Wall 6

A= 194 547����2 R= 2 457 = (78.26-68)℉ ∆�� =10 26℉

Q= (194 547 x 10 26℉) ����2 / 2.457 = 812 394 btu/hr

A= 194 547����2 R= 2 457 = (86.72-69.62)℉ ∆�� =17 1℉

Q= (194 547 x 17 1℉) ����2 / 2.457 = 1353 99 btu/hr

A= 194 547����2 R= 2 457 = (84.56-72.5)℉ ∆�� =12 06℉

Q= (194 547 x 12 06℉) ����2 / 2.457 = 954 919 btu/hr

Heat transfer rate of Window 3

A= 21 259����2 R= 0 91 = (78 26-68)℉ ∆�� =10 26℉

Q= (21 259 x 10 26℉) / ����2 0 91 = 239 689 btu/hr

A= 21 259����2 R= 0 91 = (78 26-68)℉ ∆�� =10 26℉

Q= (21 259 x 10 26℉) ����2 / 0 91 = 399 482 btu/hr

A= 21 259����2 R= 0 91 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (21 259 x 12 06℉) / ����2 0 91 = 281 74 btu/hr

Heat transfer rate of Cabinet 3

A= 12 927����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (12 927 x 10 26℉) / ����2 1 25 = 106 105 btu/hr

A= 12 927����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (12 927 x 10 26℉) ����2 / 1 25 = 176 841 btu/hr

A= 12 927����2 R= 1 25 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (12 927 x 12 06℉) / ����2 1 25 = 124 72 btu/hr

Heat transfer rate of Cabinet 4

A= 6 867����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (6 867 x 10 26℉) / ����2 1 25 = 56 364 btu/hr

A= 6 867����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (6 867 x 10 26℉) / ����2 1 25 = 93 941 btu/hr

A= 6 867����2 R= 1 25 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (6 867 x 12 06℉) / ����2 1 25 = 66 253 btu/hr

Heat transfer rate of Cabinet 5

A= 7 642����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (7 642 x 10 26℉) / ����2 1 25 = 62.726 btu/hr

A= 7 642����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (7 642 x 10 26℉) / ����2 1 25 = 104.543 btu/hr

A= 7 642����2 R= 1 25 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (7 642 x 12 06℉) / ����2 1 25 = 73.73 btu/hr

Heat transfer rate of Table 1

A= 12.583����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (12 583 x 10 26℉) / ����2 1 25 = 103.281 btu/hr

Total heat transfer rate 812 394 + 239 689 + 106 105 + 56 364 + 62 726 + 103 281 = 1380 559 btu/hr 1380 6 btu/hr ≈

Total heat transfer of Wall 6 = 5304.3 btu/hr

A= 12.583����2 R= 1 25 = (78 26-68)℉ ∆�� =10 26℉

Q= (12 583 x 10 26℉) ����2 / 1 25 = 172.135 btu/hr

A= 12.583����2 R= 1 25 = (84 56-72 5)℉ ∆�� =12 06℉

Q= (12 583 x 12 06℉) / ����2 1 25 = 121.401 btu/hr

1353 99 + 399 482 + 176 841 + 93 941 + 104 543 + 172 135 =2300 932 btu/hr 2300 9 btu/hr ≈

954 919 + 281 74 + 124 72 + 66 253 + 73 73 + 121 401 =1622 763 btu/hr 1622 8 btu/hr ≈

Total heat transfer rate (btu/hr)

Wall 1 115.9 Wall 2 1379.3 Wall 3 5653.7 Wall 4 804.7 Wall 5 4269.4 Wall 6 5304.3

In conclusion, the South-facing wall (wall 3) has the highest heat transfer rate among the 6 walls. Its heat transfer rate in total is 5653.7 btu/hr, and highest during 12pm at 2452 5 btu/hr This is highly due to having a low transfer rate on the majority of the wall. Moreover, the wall is facing the South where the sun is directly facing the room during noon.Therefore, the heat from the sun can easily penetrate through the wall and windows, hence, higher temperature compared to other walls.

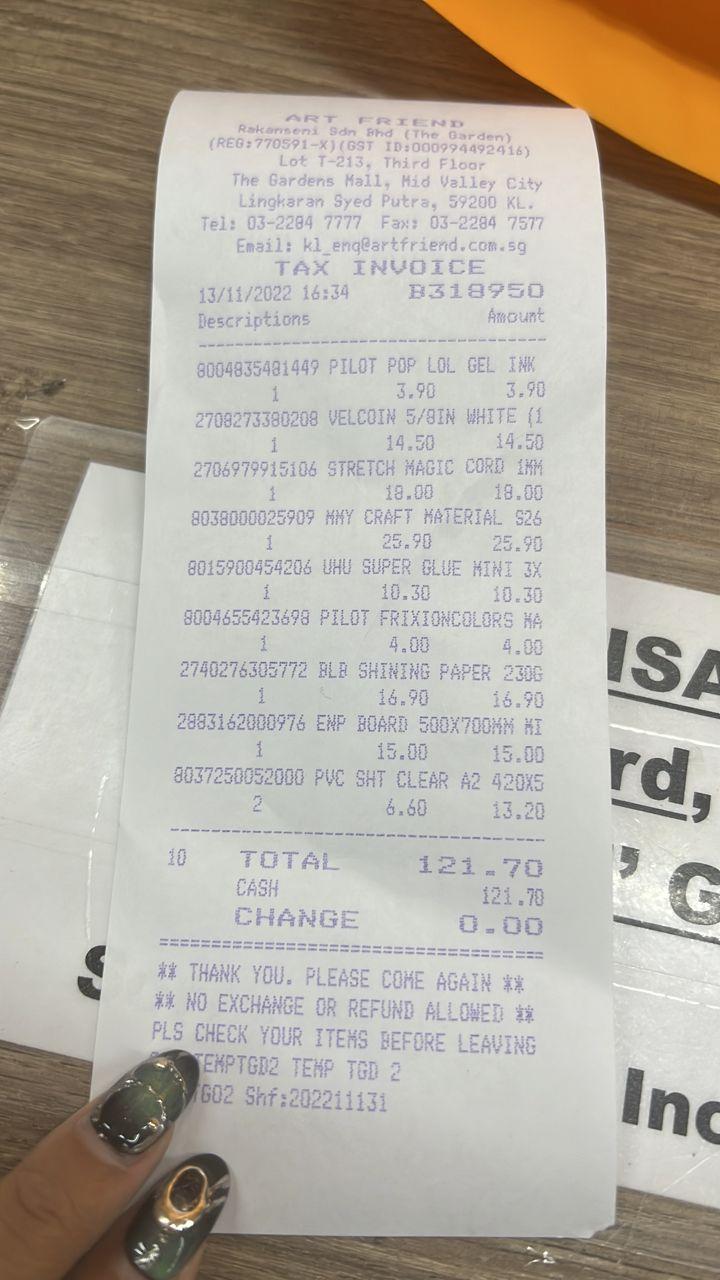

Using the critical wall identified from Part 2a, students are to come up with an original idea design solution to reduce the heat transfer.Your product has no constraints, in terms of material usage, multi-functionality and type of installation (must be mobile/detachable & easy to install securely) as long as the usage is justified. Other than heat transfer, your product may also have enhanced features such as audio comfort/noise control and/or light control/visual comfort The size of the prototype shall be between a total area of 100 square inch to 150 square inch.This can comprise of smaller inter-attached/inter-lockable pieces to make up the panel size or 2 panels (each between 100 sq in – 150 sq in) to show FULLdesign development. Multifunctional examples include (other than minimising heat gain) function of storage, lighting,greenwall etc Note :Air conditioners do not qualify as heat gain reduction panels – please do NOTbuild mini air cond prototypes. Evidence of quantitative benefit (reduced heat transfer etc) should be included in the report and verbally presented during the formal presentation. Record down the costs of the materials, tools you needed to make this product (receipts and evidence, calculations of costs need to be in the report), but keep this private and undisclosed from your classmates and audience during the presentation. File one emptyA4 paper at the end of your report, for handwritten ‘financial value of the design idea’ reflection. Important tip for marks maximization: Hand in your complete report before the presentation! Formal presentation to the class and guests. You may bring a sample or the actual product to help explain your idea during presentation, where practical. Details of the ‘financial value of the design idea’will be briefed in classAssessment criteria:

10% - Understanding, rationale and creativity and originality of idea

10% - Design, effort and workmanship

10% - Product presentation/video and short ‘financial value of idea’ reflection

South-facing wall (wall 3)

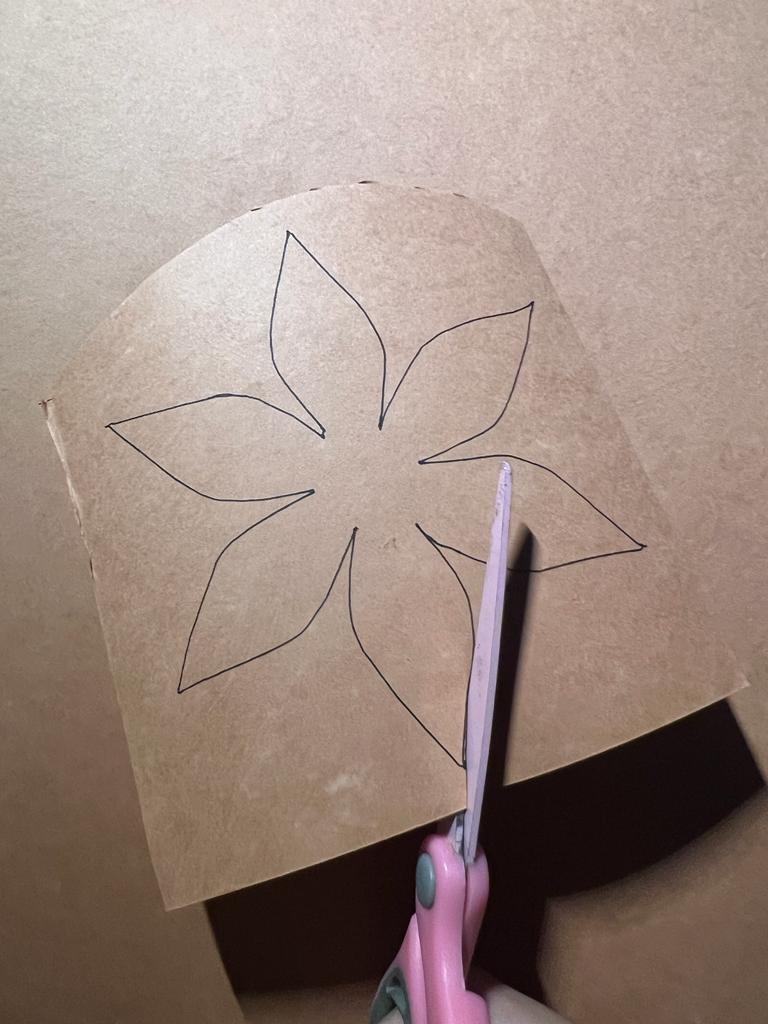

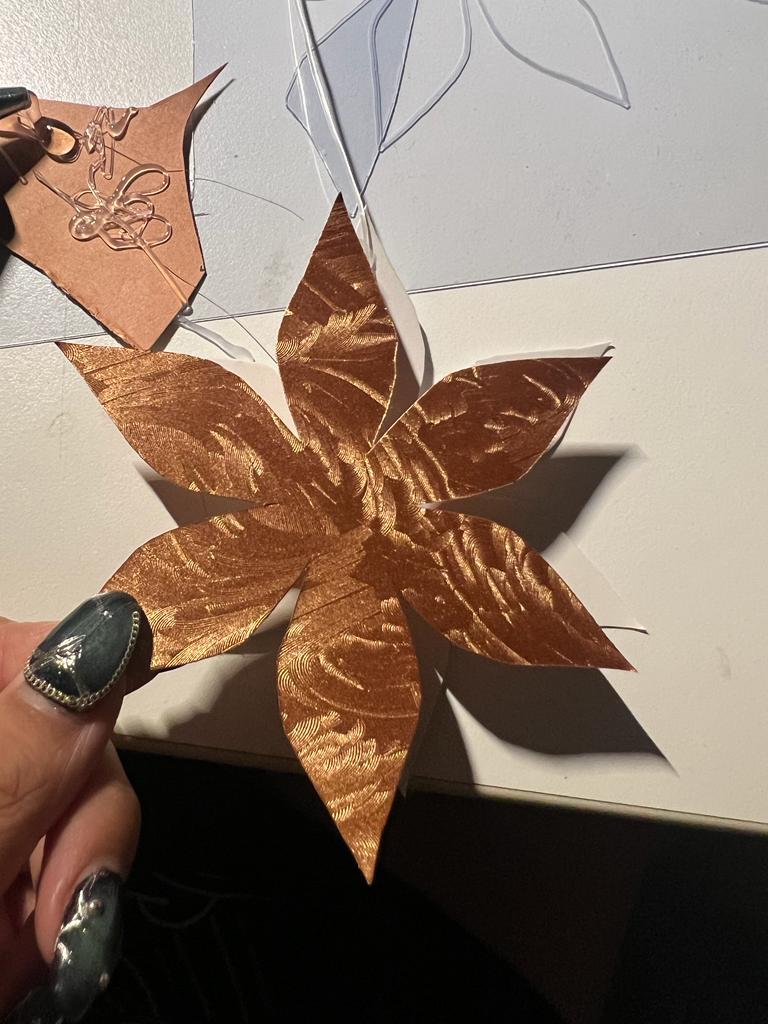

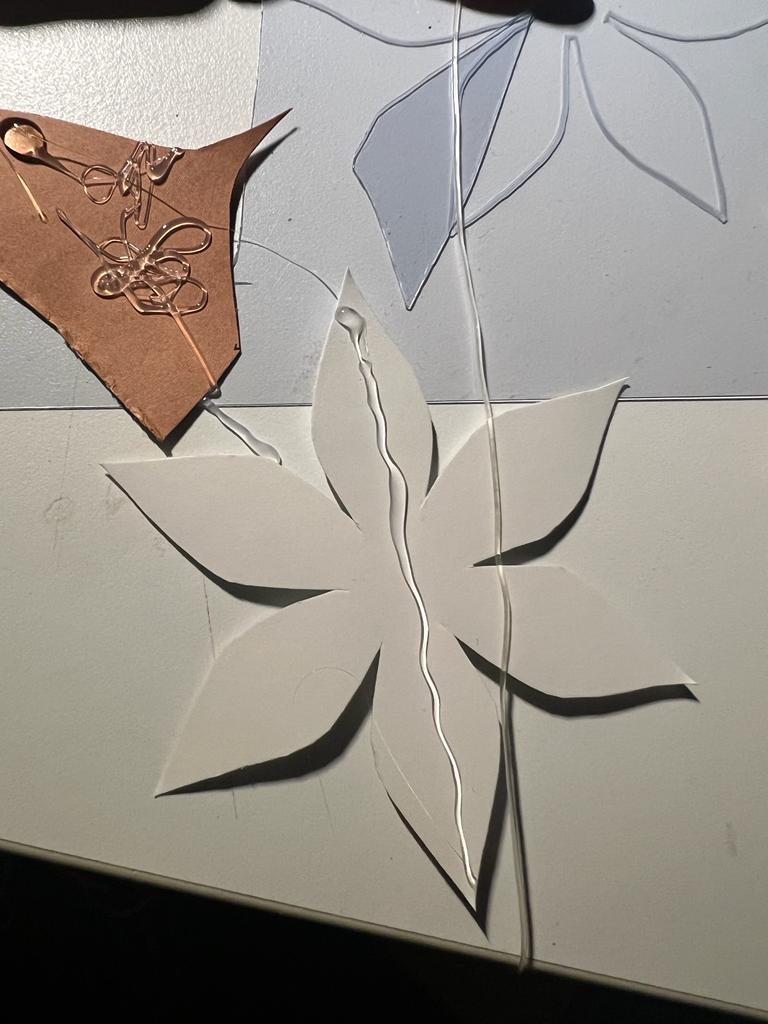

Step 1:Tracing the flower shape

Step 2: Cutting the shape out. onto a transparent PVC sheet.

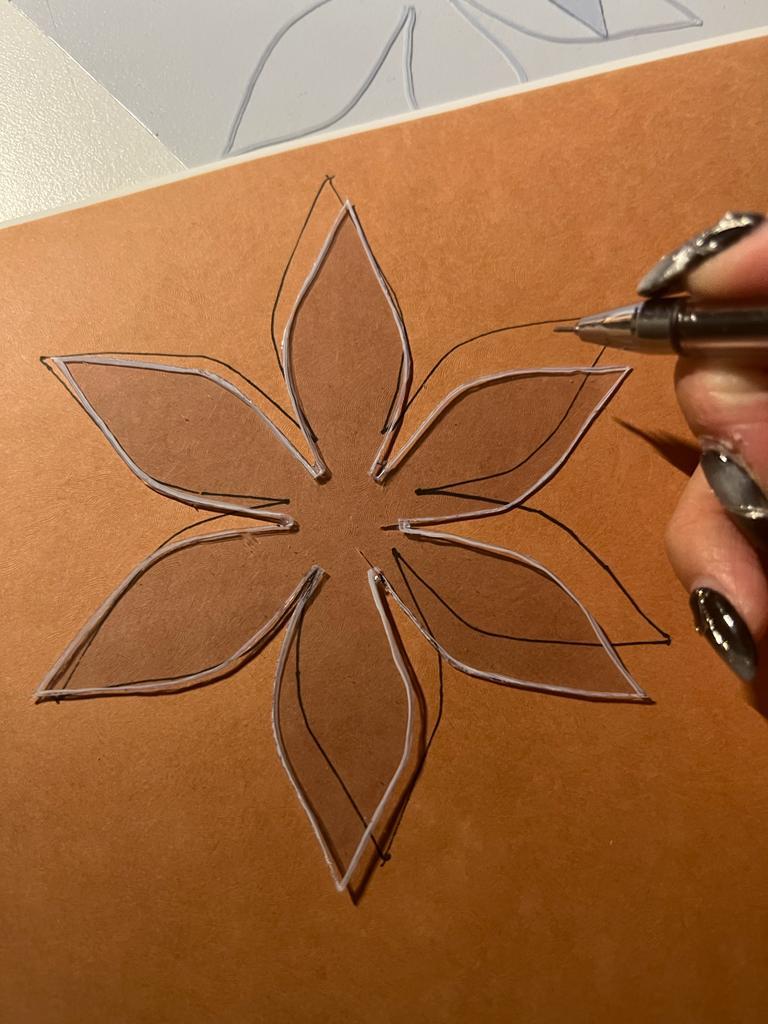

Step 3: Using the cutted

Step 4: Cut out the shape. transparent PVC sheet to trace the shape onto the board and shining paper.

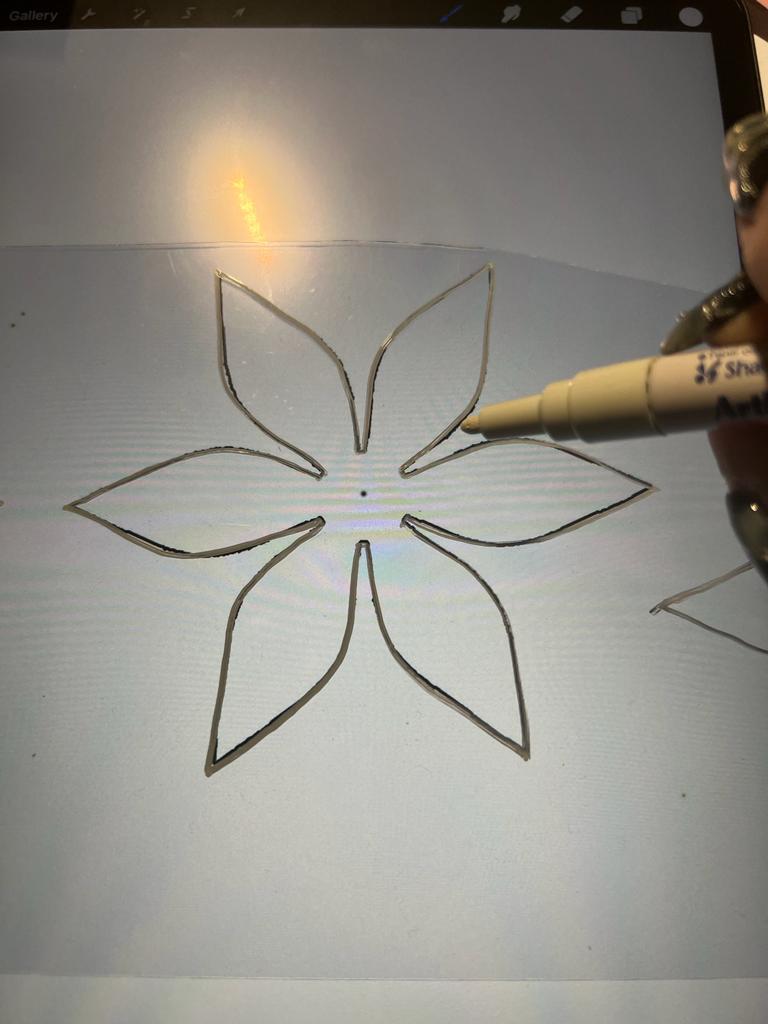

Step 5: Using hot glue, adhere

Step 6: Place the board and the jewelry cord on stick two together. the middle of the shining paper.

Step 7: Sew in the pearls and

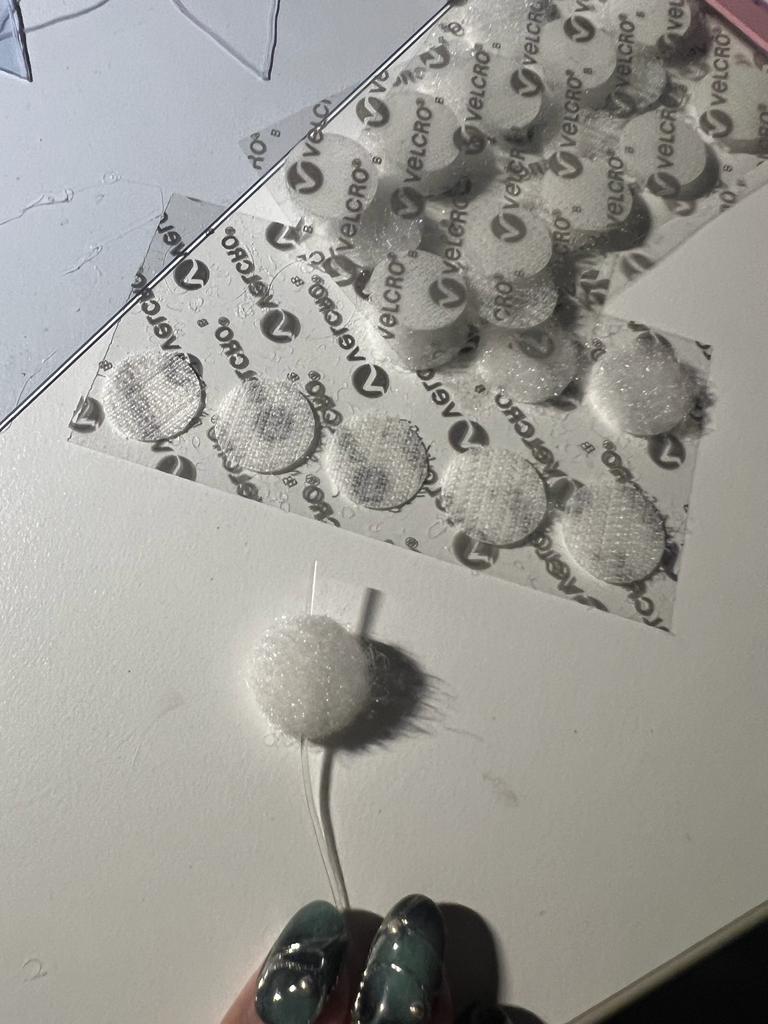

Step 8: Stick on the velcro. crystal beads

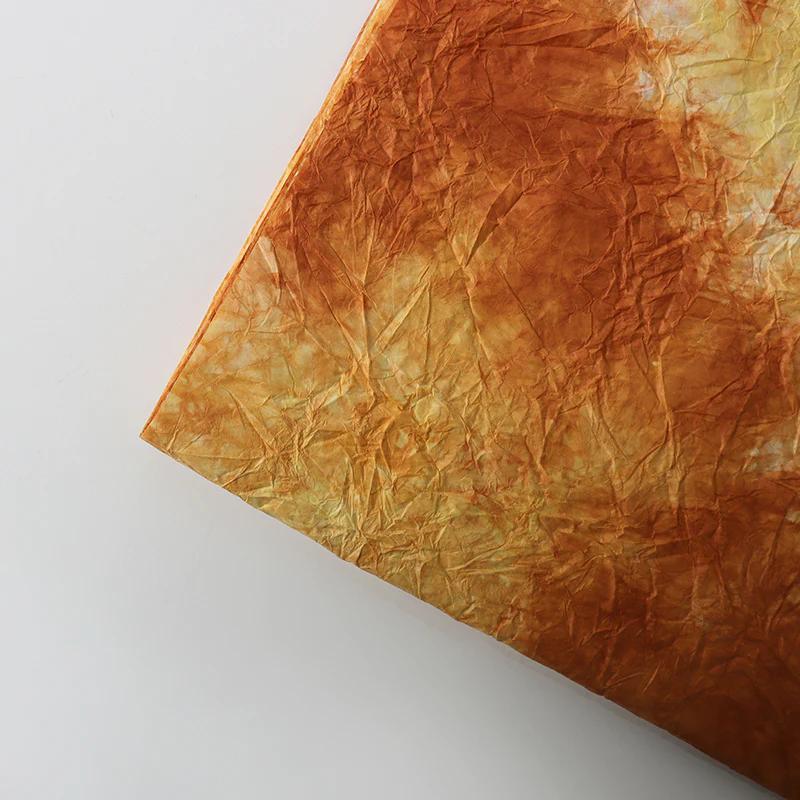

The product can be hung around the window, multiply the product can be like a curtain type on the window.The reflective side (shining paper) can reflect the sunlight and prevent the heat from coming into the room.The texture side (EPV board) can be faced towards the room, making it more aesthetic pleasing. Moreover, the crystal and pearl beads are reflective and are heat insulators too. Jointing

Velcro stickers

Velcro stickers

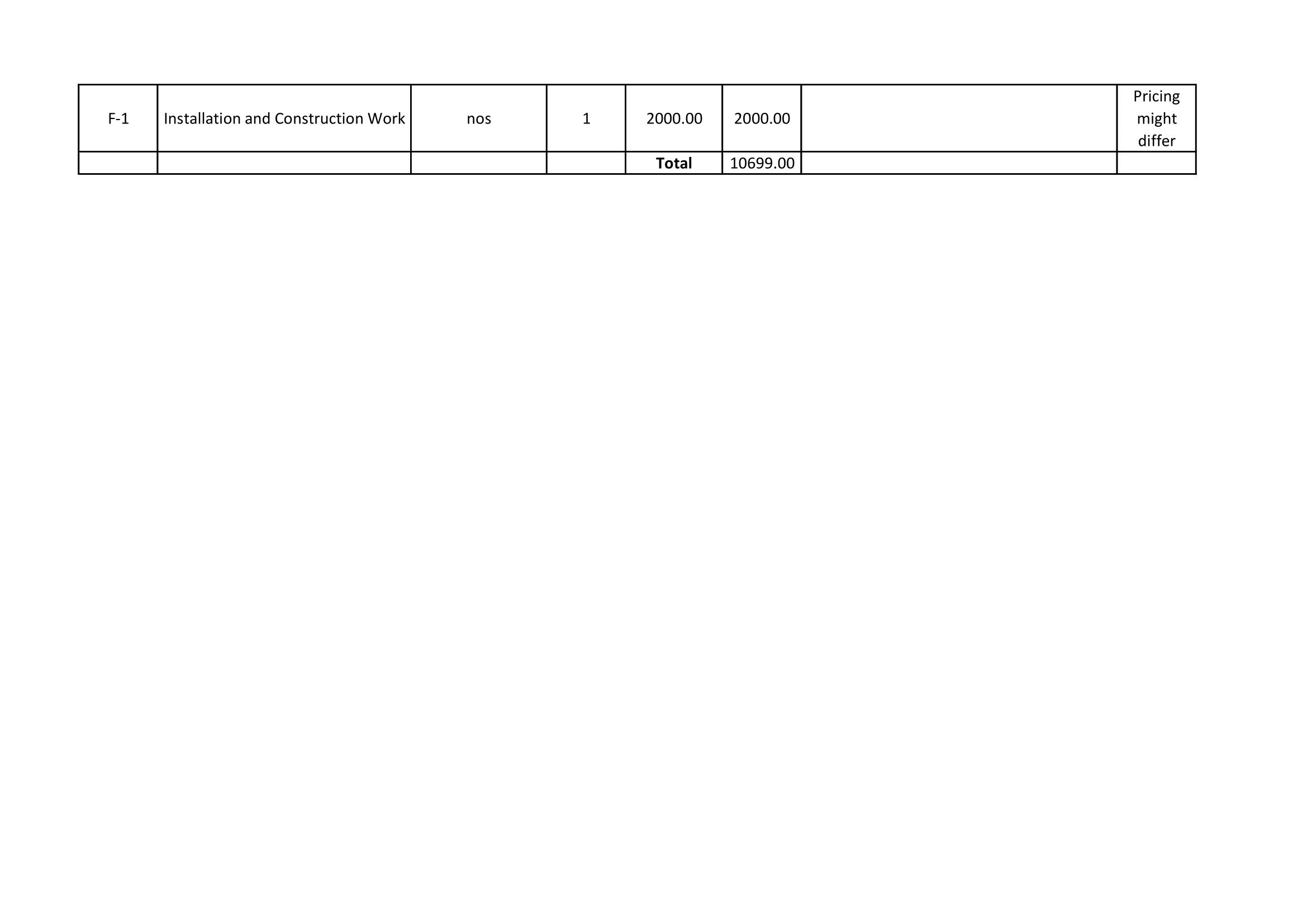

To conclude this project, it has taught me the properties of different materials and how I can cooperate in my daily life. This assignment, I had to design a prototype that not only is a good heat insulator, it is also aesthetically pleasing to the eyes. I spent a total of RM96.90 at the store.After calculating the average score from my presentation, it came up to RM24.60.Therefore, the total I have from this prototype is RM72.30. I had fun compiling all the materials and becoming more aware of the materials’price in the market in order to build a product. Thank you.

1.1 Introduction of Site

1.2 Spaces in the Site

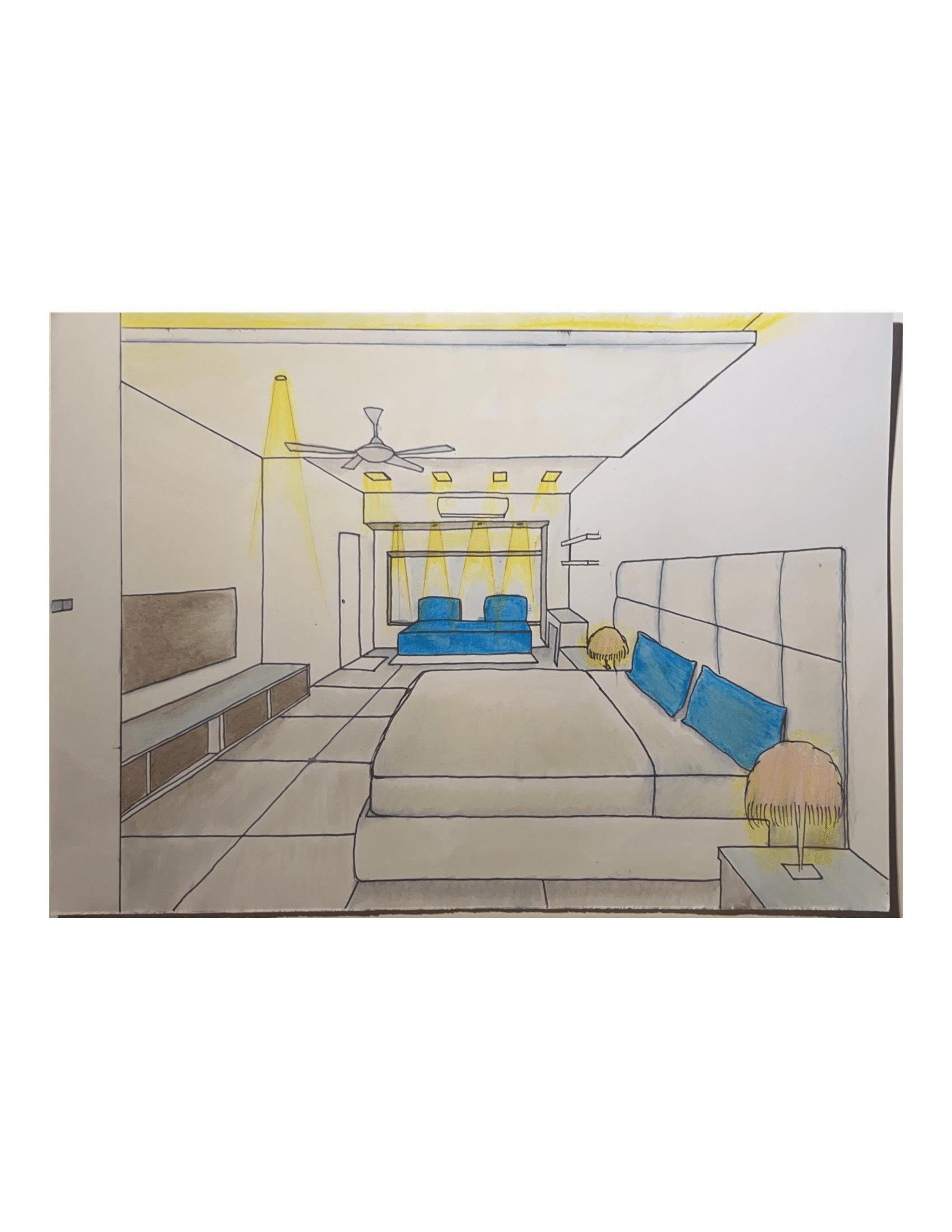

1.3 Perspective view

TASK 1B

2.1 Building Services Design Justification

2.1.1 Lighting Luminous Calculation

2.1.2 Quantity of Light Needed

2.1.3 Air Conditioning Sizing Calculation

2.2 Qualitative and Quantitative Justification

3.1 Water Supply Network & Drainage of Sink

TASK 1D

4.1 Integrated Building Services in Drawing

This site is theTreehouse ofTamarind Square located in Cyberjaya, Selangor. It is also the site I used for IAD 3 project.The treehouse has a 4 storey garden shop-office, with lots of natural lighting and surrounded by greenery. The concept of my design on this site is allowing people to explore themselves through art, such as experimental dance, music and crafts.

In this project, I have chosen the 3rd mezzanine floor which consists of a studio and a workshop space.The studio is filled with different sizes of cubes which allow people to experiment movement with the cubes The workshop space includes activities like costume making, painting, and making art & crafts.

Specification:

- Power: 12W

- Lumens: 1200 lm

- Colour temperature: 3500K

- Light colour: warm white

-Ambience: bright, vibrant

- Material: Brass, Chrome Plating, Mouth-Blown Glass

- Mounting: Pendent

- Dimension: 250mm x 800mm

https://www.pamono.com/vintage-b auhaus-style-cube-ceiling-lamp-bywalter-kostka-for-atrax-gesellschaft

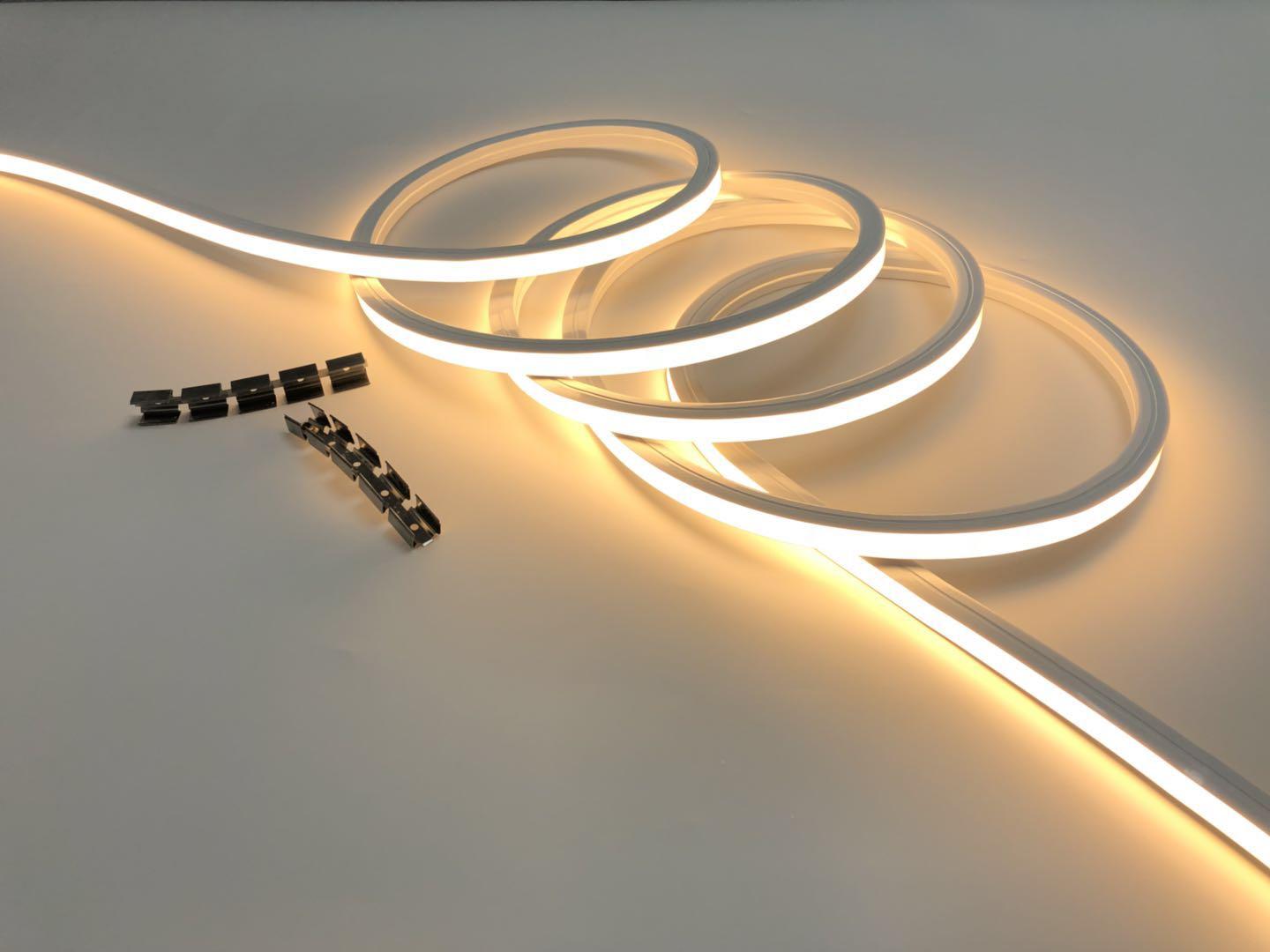

- Power: 10W

- Lumens: 1600 lm

- Input Voltage: 24V

- Colour temperature: 3000K4000K

- Light colour: neutral - warm white

-Ambience: bright, vibrant

- Mounting: wavy wood panel

- Dimension: 2 meters, 5 meters

https://www.architonic.com/en/prod uct/letroh-strip-led/20019137

L

L2- LED Strip Light

L

L2- LED Strip Light

Specification:

- Refrigerant: R32

- Power: 2260 W

- Capacity: 1-3hp

- Voltage: 240V

- Cooling Capacity: 24200 Btu/hr

- Rated running current: 10.5A

- Air flow rate: 699 CFM

- Air flow direction: 1 direction

- Dimension: 298mm x 990mm x 266mm

- Controller: wireless https://www.daikin.com.my/product/ftkm-series-r32/

A/C sizing calculation in studio: Total Heat Calculation (Btu/hr) needed:

Room space area x 700: Area of studio = 5 59m x 6 62m = 37 0 �� 2

Btu/hr = 37.0 x 700 = 25,900 Btu/hr �� 2

Occupant x 500: 6 people x 500 = 3,000 Btu/hr

Heat of electrical equipment x3 5: Lighting: 12W x 17 = 204W 204W x 3.5 = 714 Btu/hr

Total Btu/hr: (25,900 + 3,000 + 714) Btu/hr = 29,614 Btu/hr

Air-conditioner size needed: 29,614 / 9800 = 3.02hp

A/C sizing calculation in workshop:

Total Heat Calculation (Btu/hr) needed:

A) Room space area x 700: Area of workshop = (3 26m x 1 89m) + (6m x 6m) = 6 16 +36 �� 2 �� 2 =42.16 �� 2 Btu/hr = 42 16 x 700 = 29,512 Btu/hr �� 2

B) Occupant x 500: 8 people x 500 = 4,000 Btu/hr

C)Heat of electrical equipment x3.5:

Lighting: 10W x 6 = 60W Laptop: 65 W Sewing machine: 110W Total: 235W 235W x 3.5 = 822.5 Btu/hr

D)Total Btu/hr: (29,512 + 4,000 + 822.5) Btu/hr = 34,334.5 Btu/hr

E) Air-conditioner size needed: 34,334 5 / 9800 = 3 5hp

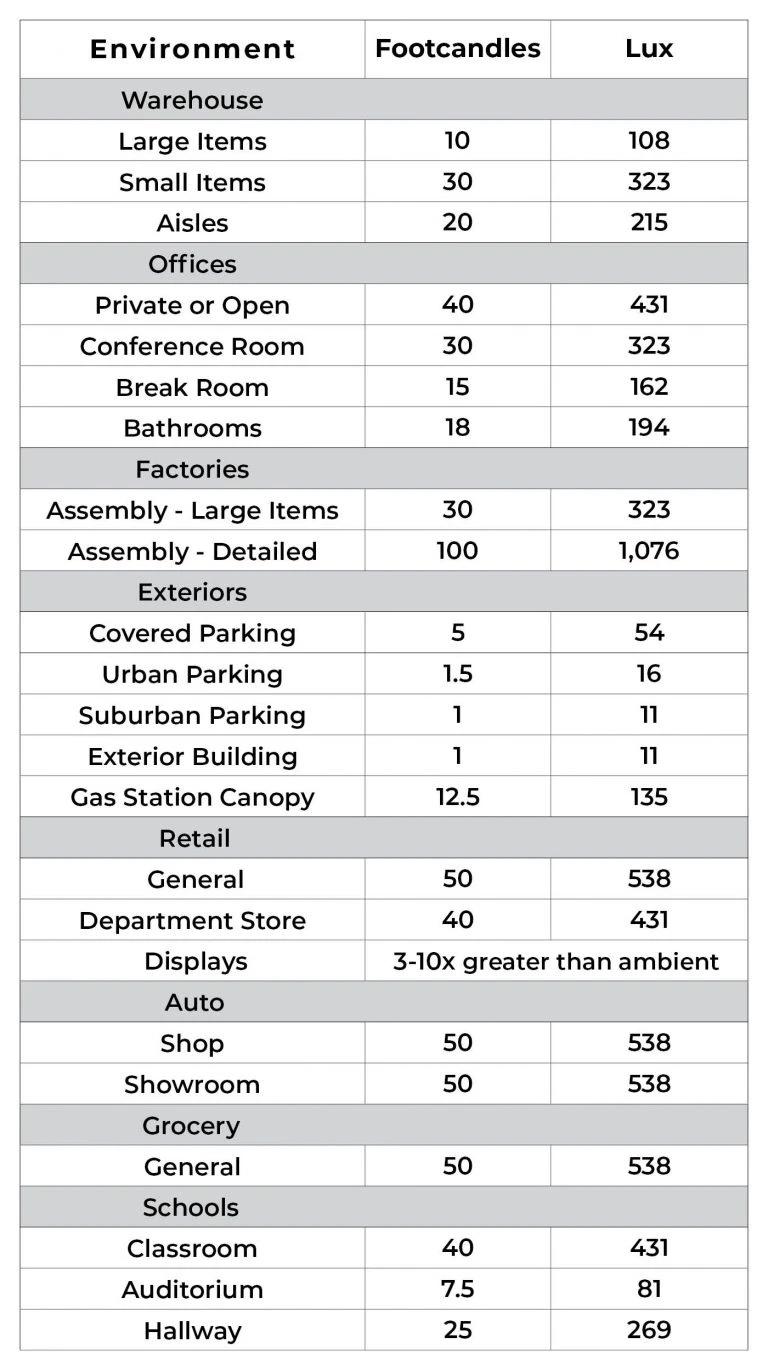

Lighting illuminance levels:

a) Studio area = 5 59m x 6 62m = 37.0 �� 2 = 398.265 ����2

b) Total lumens needed = 398 265 x 40 ����2 = 15,930.6 lm

c) Number of cube ceiling lamp needed = 15,930.6 / 10,000 = 1 59 = 2

d) Workshop area = (3 26m x 1 89m) + (6m x 6m) = 6 16 +36 �� 2 �� 2 = 42.16 �� 2 = 453.8 ����2

e) Total lumens needed = 453 8 x 40 = 18,152 lm

f) Number of LED strip light needed = 18,152 / 10,000 = 1.815 = 2

The studio area and the workshop area will generally require around 40 lumens per square foot.The total lumens needed for the studio is 15,930.6 lumens whereas, the workshop will total 18,152 lumens

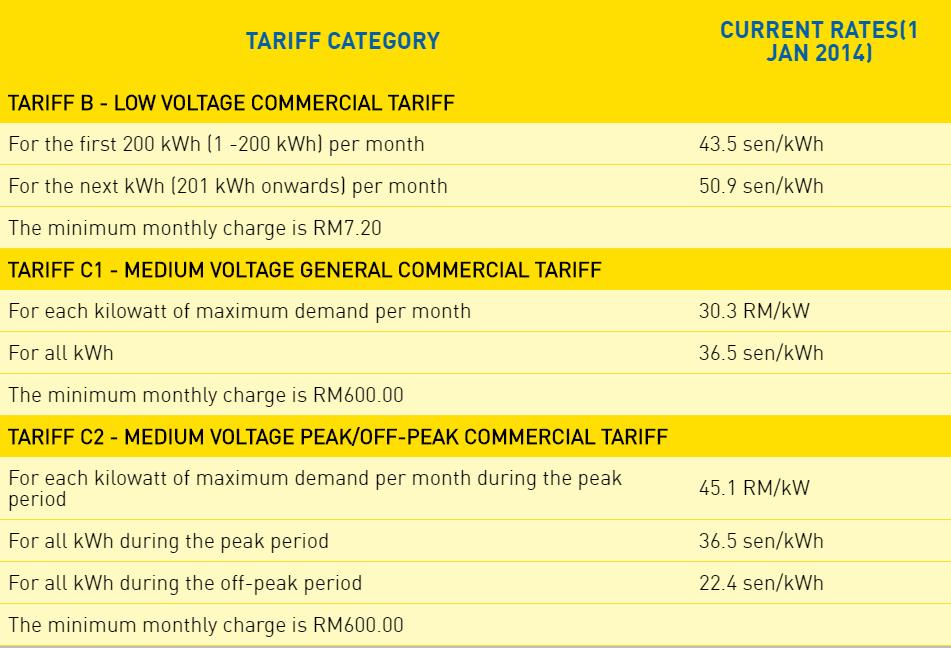

Appliance Quantity Power (W) Total power (W)

Time Units Energy used per day (Wxt) WHr

kWHr

Cube ceiling lamp 17 12 204 11 hrs 2,244 2.24

LED strip light 6 10 60 11 hrs 660 0.66

Wall mounted air-con

2 2,260 4520 11 hrs 49,720 49.72

Laptop 1 65 65 11 hrs 715 0.72

Sewing machine 1 110 110 11 hrs 1,210 1.21

Total Daily Usage (kWHr) 54.55

Total Monthly Usage (kWHr) 1,636.5

Total Bill (RM) 731.18

Total bill = (0.435 x 200) + (0.509 x 1,436.5) =RM731.18

There will be approximately 5-6 occupants in the studio dancing and moving around the space 7-8 occupants are allowed to use the workshop area for art and crafts.The space is an open area but there are other buildings surrounding the treehouse, therefore, all the lighting and ventilation need to be turned on during operating hours (13 hours) to ensure the sufficient lighting and having a comfortable temperature for the people

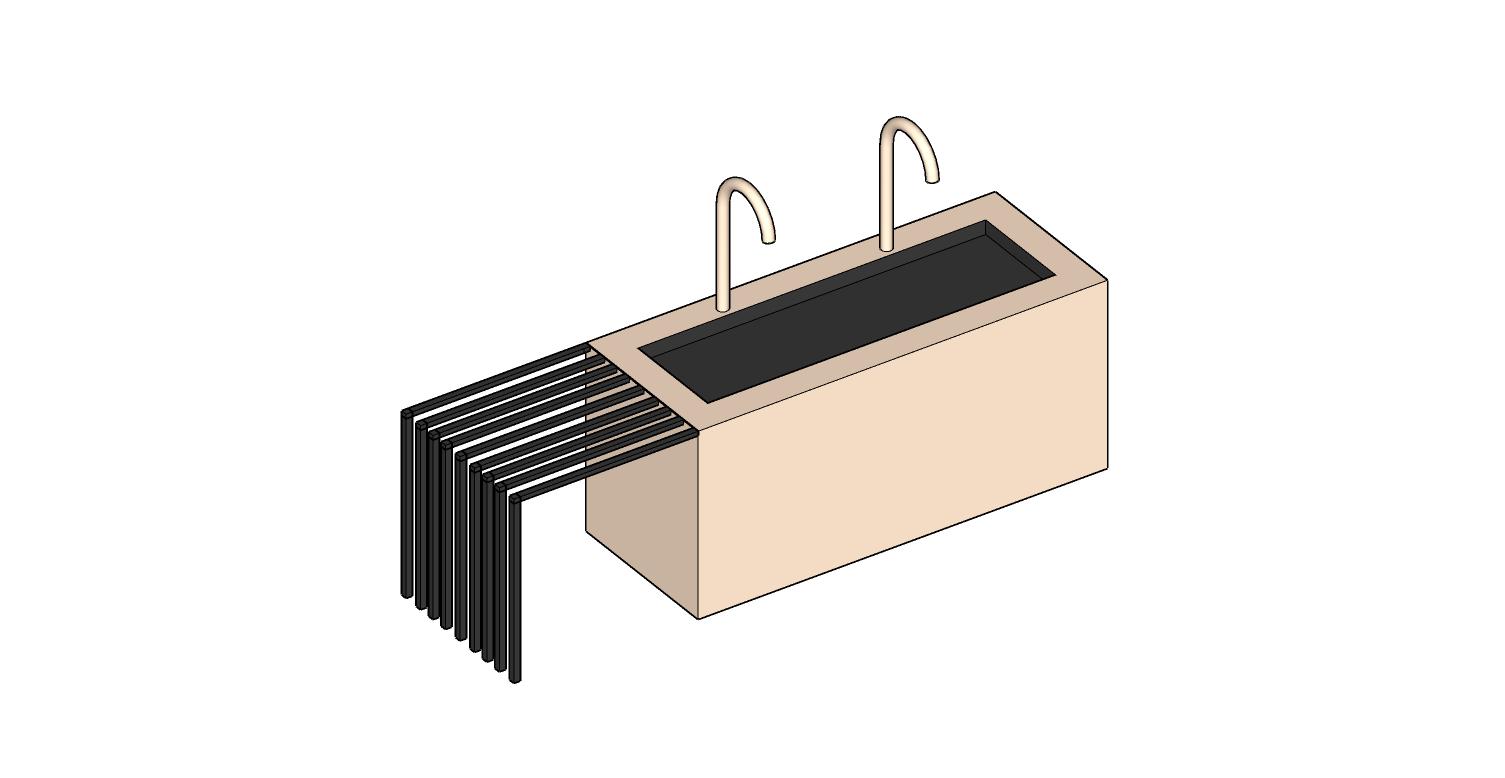

- Function : Rack hanger for art works / Sink to clean up

- Product use location: Interior

- Material: Granite in dark grey colour

- Dimension: 2,900mm x 900mm x 800mm