Low Carbon Proposal

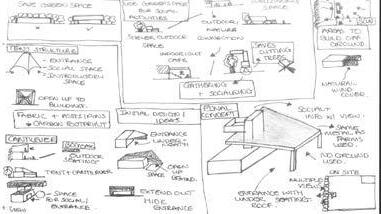

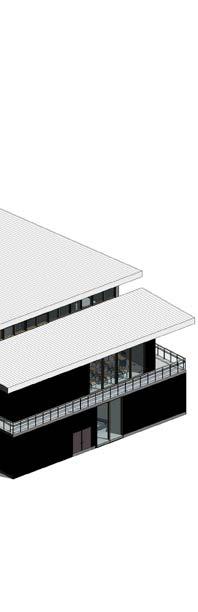

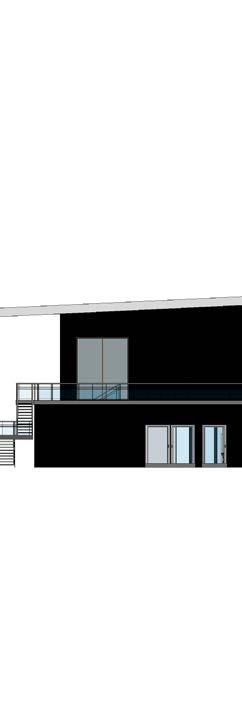

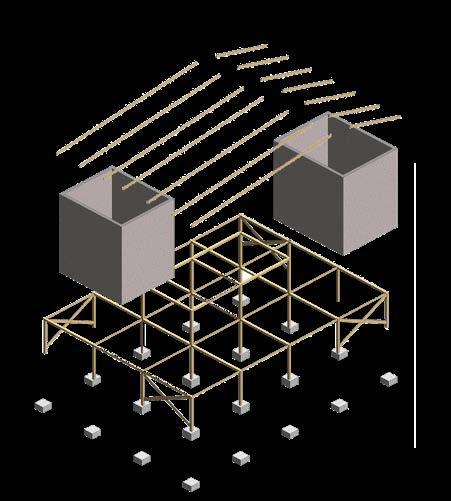

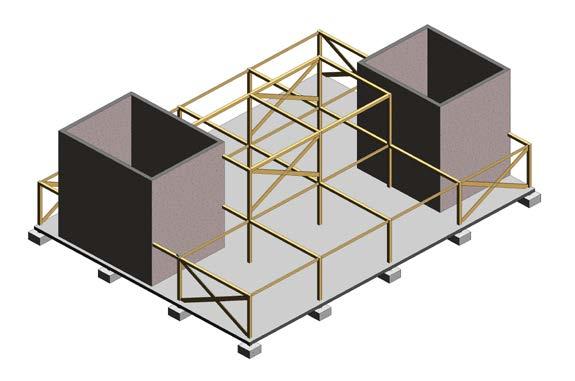

System

Green Roof

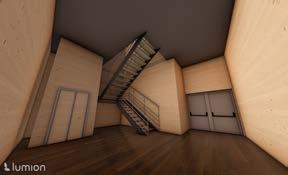

CLT

Also made of timber, hanging onto the frame, CLT will replace the effects and uses of concrete to ensure the structure is strong in compression whilst being largely sustainable.

https://www.naturallywood.com/wp-content/uploads/MGA_ WIDC_In14_emapeter-1600x1050-10ff1ac.jpg

Frame

Constructed of glue laminated timber, the system will help reduce the carbon footprint as apposed to using a concrete frame. Also, timber being a carbon capture material makes it a great alternative to keeping carbon emissions low.

https://zinco-greenroof.co.uk/sites/default/files/styles/flexslid

Extensive

Equiped with a shallow soil and sedum moss with a factor of very low maintenance, a green roof is a great solution to having a low carbon structure. The ability of the roof also ranges into absorbing carbon dioxide and releasing oxygen, being unharmful whilst benefiting the environment. The roof is accompanied by a drainage board with geotextiles with the ability to hold water for the plants which can then be soaked up or drained slowly.

er_full/public/2017-02/Kolumbien_Mario_Laserna1.jpg?i -

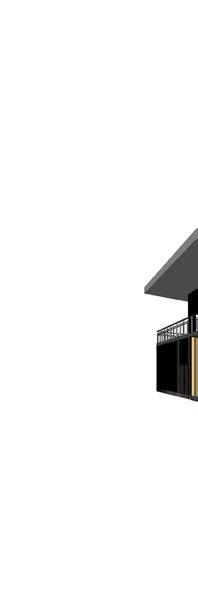

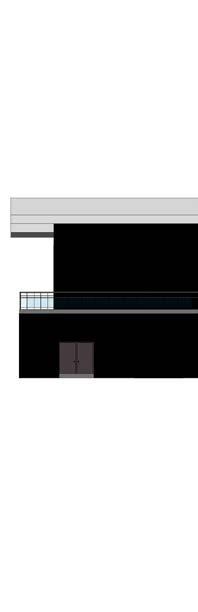

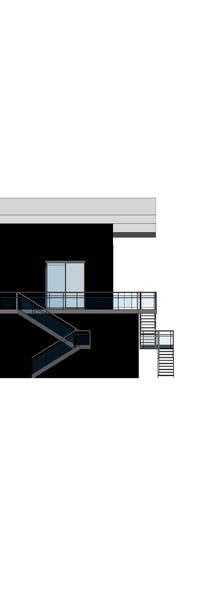

1:20 Strip Details

Strip section and elevation.

03

520mm Parapet extending over green roof for safe access for any maintenance.

Consisting of 25x84mm

Timber rainscreen cladding, 50mm Timber Batten, Support Brackets, 180mm

Fibreglass insulation and 155mm CLT panel.

Norrsken P44A - 400

Series, Low-E Glass Triple

Glazed Window

Accessible glass balcony installation supported by inverted roof below. Consisting of: Aluminum balustrade, 10mm toughened glass, Aluminum panel support fixed with stainless steel bolts.

Balcony - Supported by inverted roof of ground floor below. Consisting of: 155mm

CLT, 100mm

Kooltherm rigid insulation, 50mm screed, 5mm

Geotextiles filter, 85mm Timber decking supported by timber joists.

Flashing above brickwork - to draw out any moisture in cavity behind cladding.

Green RoofConsisting of: 155mm

CLT, 100mm

Kooltherm K112 insulation, Waterproof membrane, 50mm water reservoir and 100mm Growing medium for light vegetation above.

First Floor - Consisting of: 20mm Wood finishing, 5mm acoustic layer, 50mm Gypsum Board, 50mm cavity, 100mm

Kooltherm K112 insulation and 155mm CLT.

340mm Glulam transfer beamSupported by 200mm

Glulam column using Steel slotted plate and a bolted connection

Ground FloorConsisting of: 50mm

polished concrete floor, separation layer, 150mm

Kooltherm K112 Rigid insulation, Damp

Proof Memrane on 50mm sand binding layer and approx. 50mm Compacted Hardcore layer.

Pad foundation to transfer point loads from Glulam column.

1:20 Strip Section

DN 04 DN 01 DN 02 DN 03

Green roof composition consisting of CLT, Insulation, Water Reservoir, and growing medium for vegetation

Timber rainscreen cladding fixed onto Timber batten.

1:20

Strip Elevation

Norrsken P44A - 400 Series, Low-E Glass Triple Glazed Window Inward opening, Timber framed door with triple glazing

Brick on concrete toe brick up to just below cladding

Toughened Glass, Aluminum balustrade balcony

Norrsken P44A - Low-E Glass triple glazed window

Inverted Roof with Timber decking fitted to support accessible balcony, supported by 340mm transfer beam.

Timber framed window sitting 100mm below floor above

Polished concrete floor made from low carbon mixtures 150mm from ground level.

1:5 Sectional Details

Foundation, wall, floor, eave and window details.

04

180mm Fibreglass Insulation

Insect Mesh

25x84 Timber Rainscreen Cladding

Vertical Timber Batten

Fixed with supports

Flashing over Brickwork to draw out moisture from cavity

Breather Membrane

DPM tucked under VCL

150mm

460mm

155mm 3 Ply CLT Panel with Birch to Internal Face

Vapour Control Layer

Damp proof course attached to Concrete upstand supporting insulation

Blue Engineering Brick in front of Rigid Insulation

Concrete Brick Toe

200x200mm Glulam Column

CLT Connection Bracket

50mm Polished Concrete finish

Separation Layer

150mm Kooltherm K112 Rigid Insulation

Damp Proof Membrane on Sand Binding Layer

50mm Sand Binding Layer

Approximately 50mm Compacted Hardcore Layer

Reinforced Concrete Pad Foundation

1:5 Foundation

DN 01

Vertical Timber Batten

25x84 Timber Rainscreen Cladding

10mm Toughened Glass Timber Decking supported by Timber Joists

Aluminum Support Bolted to Timber

5mm Geotextiles filter Layer

50mm polished Screed to falls Cavity Blocker

100mm Kooltherm K112 Rigid Insulation

Waterproofing Layer under insulation

Breather Membrane

180mm Fibreglass Insulation

155mm 3 Ply CLT with Birch Internal Finish

460mm

200x200mm Glulam Column

20mm Wood Finish

5mm Acoustic Layer

50mm Gypsum Board

50mm Cavity

100mm Kooltherm K112 Insulation

Vapour Control Layer

155mm 3 Ply CLT Panel with Birth Internal Finish

340mm Glulam Beam Fixed to Glulam Column using Steel slotted plate and bolts to support load from inverted roof

200x200mm Glulam Column to Ground Floor

1:5 Intermediate Floor

VCL

VCL

DN 02

100mm Smooth Gravel Edge

Waterproof Membrane tucked under Parapet Flashing

Aluminum Parapet Flashing

28x84mm Timber rainscreen Cladding

Breather Membrane

Vertical Timber Batten with support Brackets

180mm Fibreglass Insulation

Filter Fleece

Light Vegetation

100mm Growing Medium

50mm Drainage Element, Water Reservoir

Waterproof Membrane

100mm Kooltherm K112 Insulation to fall

155mm 3 Ply CLT Panel with Birch Internal Finish

170mm Glulam Beam

Connected to Column with Steel slotted plate and bolts

200x200mm Glulam Column

Vapour Control Layer

1:5 Roof

DN 03

460mm

28x84mm Timber rainscreen Cladding

Breather Membrane

Vertical Timber Batten with support Brackets

180mm Fibreglass Insulation

Window Flashing with ventilation gaps and insect mesh

Insulated Cavity Closer

Insulation to window head

Insulated Packing Strip

Compressible Insulation under sill

Insulated Cavity Closer

Flashing lapped over Cladding

200x200mm Glulam Column

155mm 3 Ply CLT Panel with Birch

Internal Finish

Vapour Control Layer

1:5 Window

DN 04

U - Value Calculations

Wall, floors and roof U-values.

05

Total Thickness of Building Element 460 mm R - Thermal Resistance of the Building element 6.692 m2k/W U - Value of the Building Element 0.149 W/m2K

- Value Calculations Materials Thickness (mm) Thermal Conductivity (W/mk) Resistance (m2k/W ) Polished Concrete 50 2.200 0.02 Fiberglass Insulation 250 0.040 6.25 Reinforced Concrete 150 1.400 0.11 DPM 1 0.039 0.03 Sand Binding 50 0.200 0.25 Internal Surface External Surface 0.00 0.14 FlOOR ON GROUND Total Thickness of Building Element 250 mm R - Thermal Resistance of the Building element 8.320 m2k/W U - Value of the Building Element 0.120 W/m2K Internal Surface Concrete Slab 50 1.400 0.04 Kooltherm K112 150 0.019 7.89 Sand 50 0.200 0.25 External Surface 0.14 0 Materials Thickness (mm) Thermal Conductivity (W/mk) Resistance (m2k/W ) CLT 155 0.130 1.19 Thermafleece cosywool Insulation 180 0.039 4.62 Air 50 0.280 0.18 Gypsum Board 50 0.170 0.29 AcousticWafer Floor 3 0.067 0.04 Hardwood Flooring 15 0.170 0.09 INTERMEDIATE FLOOR Internal Surface External Surface 0.06 0.14 Total Thickness of Building Element 453 mm R - Thermal Resistance of the Building element 6.613 m2k/W U - Value of the Building Element 0.150 W/m2K Materials Thickness (mm) Thermal Conductivity (W/mk) Resistance (m2k/W) CLT 155 0.130 1.19 Kooltherm K112 Insulation 100 0.019 5.26 Drainage Element 50 0.060 0.83 Growing Medium 100 0.290 0.34 ROOF Internal Surface External Surface 0.04 0.10 Total Thickness of Building Element 405 mm R - Thermal Resistance of the Building element 7.774 m2k/W U - Value of the Building Element 0.129 W/m2K

U

Sample Board

1Glue laminated timber is extremely safe for the environment as it is renewable compared to concrete and steel which don’t share these properties. Alongside being environmentally friendly, glulam offers high strength and durability making it great for structural application. Lastly, glulam being of wood makes it a great aesthetic for any environment whilst being highly versatile in it’s use. For the visitor centre, glulam will provide for a strong structural frame and a visually pleasing atmosphere.

2 5 4 3 6 7

Another timber material, CLT provides great low carbon solutions with a versatile application of being applied to walls, floors and roofs. A great attribute of CLT is the use of prefabrication where the panels are created in a factory-controlled environment reducing lead times. For the visitor centre, CLT is the internal finishing providing for good strength, flexibility, with the ability to replicate the qualities of concrete making it’s use in a low carbon project beyond great.

The thermal conductivity of this type of insulation is one of the two reasons for its choice. Having a thermal conductivity of 0.019W/mk makes it exceptional for ensuring the U-values are met to the standards whilst providing for great rigidity in the use of an inverted roof. The second reason for it’s use above others is its environmental credentials where Kooltherm K112 is manufactured with a blowing agent which has zero ozone depletion potential and low risks of global warming as well.

Alongside Kooltherm, the use of fibreglass insulation is implemented as it is one of the most sustainable insulation materials. Alongside being environmentally friendly, fibreglass insulation provides for great fire resistance as it is composed of non-combustible materials whilst being moisture resistant helping to prevent the growth of mould. In the visitor centre, Fibreglass is used in the walls to help protect the internal materials such as CLT and Glulam from being affected by external conditions like the weather and temperature.

The various properties already listed of timber make it a material very much needed in a low carbon educational centre where the awareness on the environment is at the forefront. From being durable, versatile, sustainable to being a great aesthetic, timber is no surprise the biggest talk of any material in the industry today. For the visitor centre its application is varied through being used as a cladding material, to decking for the balcony. To a support system for the structure itself, timber is the best option for this low carbon project.

Despite using timber in various places, the use of concrete is needed especially in the foundations where the use of timber is not applicable. However, the solution for using polished concrete whilst retaining low carbon emissions is using a low carbon mix or alternate fuels to produce concrete. For the visitor centre the use of the low carbon mixture ‘Lc3’ which incorporates the use of limestone and calcined clay to reduce the content of clinker in cement. In doing so, the application of this concrete will have a lower effect on the environment than using regular concrete mixes.

Whilst being widely recyclable, gypsum boards provide great technical qualities which can be extremely beneficial to any structure. Firstly, it has a low embodied energy where the process of production doesn’t greatly affect the environment. Also, there is a great aspect of fire resistance within gypsum boards where water molecules are released as steam when they are exposed to fires helping to contain them. In the visitor centre the use of gypsum board is applied in the floors above ground where its fire containment qualities can definitely come in handy