Activity Report ZINKINFO BENELUX 2023

For the sixth time, we offer you Zinkinfo Benelux’s activity report. In the year 2023, we have continued the course based on the new mission and strategic story. It is important that we focus on technical education, clients, end-users and architects to highlight the value of hot-dip galvanised steel. By properly informing these stakeholders, we are convinced that hot-dip galvanised steel will continue to play a significant role in the circular economy.

Among stakeholders of today and tomorrow, we want discontinuous hot-dip galvanizing to be widely recognized as the most effective and sustainable form of corrosion prevention for steel.

Hot-dip galvanizing is a unique process and has been the “world champion in corrosion prevention” for more than 150 years. No other method even comes close to this most complete protection of steel. Moreover, it is also the smartest and most responsible choice. In the fight against global warming, circular construction has a major role to play. Making better use and reusing scarce raw materials is the common thread here. Thanks to hot-dip galvanizing we are going for 100% circular steel. The best protection and the most responsible choice.

2024 will be a remarkable year with the upcoming Intergalva in Bruges, scheduled from 10 to 14 June. The Bruges Meeting and Convention Centre will be the setting for this event, located in the vibrant city centre and easily accessible on foot from the city’s many hotels and restaurants. Make sure to note these important dates in your diary in capital letters! After all, it is crucial for Zinkinfo Benelux to be well represented as the host country during this extraordinary occasion.

Hasco-Thermic Ltd is a wholly owned subsidiary of B.E Wedge Holdings Ltd, the holding company for leading galvanizing businesses in the UK, Continental Europe and the USA.

Celebrating nearly 50 years in industry, Hasco-Thermic has established an enviable reputation for supplying and installing reliable, efficient and durable hot dip galvanizing plants across the globe.

Products include:

- Highly Efficient Furnaces

- Integrated Heat Recovery Systems

- Fume Enclosures to latest standards

- Preheating Ovens

- Consultancy Services

Hasco-Thermic is perfectly placed to offer a flexible approach to meet the needs of its customers.

• Information: www.hascothermic.com

• Contact: Mevr. Angela Curtis | +44 (0)121 552 4911 | angelac@hasco.co.uk

In 2023, Zinkinfo sent the ZEKER ZINK magazine three times to 9,099 Dutch-speaking and 934 French-speaking subscribers. The Dutch magazine was opened by 4,116 people, while the French magazine was opened 497 times. These statistics are closely monitored via Mailchimp and ISSUU. From 2024, we will aim to increase the number of magazines to four a year.

Using the advantages of hot-dip galvanised steel to the full

Vissers & Roelands Architecten & Ingenieurs talking

In this issue of our magazine, an architect immensely enthusiastic about the anti-corrosion properties as well as the aesthetic properties of hot-dip galvanisation. This has led to several consistent and honest designs. The similarity of all the featured buildings in this magazine is that they have all been designed in a circular and flexible way. Which is very impressive: in fact, one of the buildings has now been constructed for the third time, each time in a different location. Had this building not been hot-dip galvanised, it would not have been possible with such a low environmental impact.

This magazine is entirely dedicated to the fourteenth edition of the biennial Benelux Hot Dip Galvanising Trophy. With this magazine, Zinkinfo intends to highlight not only the winners and nominees, but also all the other participating projects that deserve it. All participating projects can also be found on our bilingual website. ZIB would like to thank the submitters of these inspiring projects. Together, they show a range of successful, original and often pioneering applications of hot-dip galvanised steel. Each of them is proof that zinc and steel are a perfect match!

ZEKER ZINK DECEMBER 2023

Hot-dip galvanised steel - a sustainable choice for the agricultural sector

Willem Reijrink (Reijrink Staalconstructie BV) talking

In this most recent issue, we have an exclusive interview with none other than Willem Reijrink, owner of Reijrink Staalconstructie b.v.! Willem is an absolute expert and shares his knowledge and experiences with us. Did you know that hot-dip galvanised steel is an essential component in various applications in the agricultural world? From stable structures to warehouses, this material offers durability and protection against corrosion!

DIPL.-ING. HERWIG provides a full range of Galvanizing Consulting Services aimed to help our customers in achieving the best galvanizing practices and results:

• Environmental-friendly processes and alloys to maximize output and improved galvanized quality

• Custom made solutions to fit each galvanizers’ requirements and demands

• In-plant training and knowledge ‘refreshing’ of galvanizing concepts and best practices

• Seminars in Galvanizing

As one of the world’s leading suppliers of chemicals and zinc alloys for the galvanizing industry, our main principles are: Efficiency, Flexibility and Vision towards the Future. We develop new products for the galvanizing industry and in our portfolio we market and several specialty processes, recycle chemicals and also project and build galvanizing plants. Aside, Herwig is holds numerous patents in Galvanizing. Our personal involvement in this industry ensures state-of-the-art products, as a result of research and development and a comprehensive problem solving know-how, which makes our company the right companion for the Galvanizers.

We show truly global presence. Being a proven specialist in the galvanizing sector, we are operating worldwide, providing a reliable technical consultation service and offering a broad spectrum of high-quality products. We support our customers through our worldwide network of agents and representatives. Each member of this network operates at once independently and for the general good. We add our support in the form of training courses and joint visits on site. Customers all over the world have their own local contact partner – someone who can support them in their own national language and with an understanding of the local mentality and conditions. The times needed to react to customers’ requirements and needs can thus be kept to a minimum.

• Information: www.herwig-gmbh.com | info@herwig-gmbh.com

• Contact: Mevr. Klaudia Gorajek | +49(0)2331 9 15 5 65 | klaudia.gorajek@herwig-gmbh.com

In order to increase the name recognition of Zinkinfo and especially ZEKER ZINK, we regularly send out press releases to the Belgian and Dutch press. In doing so, we emphasise the collective approach of the sector and the need for proactive communication between galvanisation companies and clients.

Zinkinfo Benelux

Wereldkampioen in corrosiepreventie

Beton & Staalbouw

Construire La

Wallonie/ L’usine nouvelle

Genomineerden Benelux Trofee voor Thermisch Verzinken 2023 bekend

Nederlandse versie van de EN ISO 1461:2022 vanaf nu beschikbaar

Thermisch verzinkt staal heeft de toekomst

Benelux Trofee voor Thermisch Verzinken 2023 Laureaten

InfoZinc Benelux

Championne du monde en prévention de la corrosion

Trophée Benelux de la Galvanisation à chaud 2023

Mise à jour de la “norme de galvanisation”

ArchiComm

België & Nederland

Ding mee naar de trofee voor thermisch verzinken 2023

Genomineerden benelux trofee voor thermisch verzinken 2023 bekend

Oplossingen voor een circulaire economie

Zinkinfo Benelux

Verzinkt staal en duurzaam bouwen

Andere

15 Genomineerden voor 14de Benelux Trofee voor Thermisch Verzinken

Onderscheiden(d) in thermisch verzinken

Infosteel

Architectura

META

Bouwkroniek

Smiemans

In order to spread the ZEKER ZINK philosophy as much as possible, ZIB uses social media such as LinkedIn, Twitter, Instagram and Facebook.

ZIB has a company page followed by nearly 1,800 people. In it, 45 messages were posted by ZIB in 2023:

- New publications

- Events - News about our partners/members

- News about EGGA

- Press releases

- Technical info

- BTTV

In addition, Evi Renard has a professional account with about 4,800 connections on which messages about hot-dip galvanizing are also posted on a regular basis.

Organic impressions

21.333 impressions

Sponsored impressions

Popular posts

30.493 impressions

- Project aanmelden BTTV 2023

- Aanpassing verzinknorm

- Laureaten BTTV 2023

- Intergalva 2024

In our Riepe factory we produce Pilling boilers and other special welding constructions for the galvanising industry.

With our experience of more than one hundred years and continuous improvement of both materials and production technologies, we are able to produce zinc boilers of all sizes and shapes for all types of heating systems.

Our special pilling service for galvanizing plants makes kettle replacement faster and therefore more economical for you. The liquid zinc can be temporarily be stored in our heatable holding furnaces during kettle replacement. These furnaces developed by Pilling make it possible to significantly reduce the startup phase of your new kettle.

In addition, we offer wall thickness measurement of your kettle. At the same time, we check the condition of the kettle in the filled state with an ultrasonic probe at intervals specified by you. This service takes only a few hours and can be carried out in off-peak times without or with little restrictions on your production.

• Information: www.pilling.de | post@pilling.de

• Contact: Mr. Nikolai Prinz | +49 2352 2015 - 30 | n.prinz@pilling.de

FEBRUARY 2023

APRIL 2023

• Activity Report 2022

• Session with Smulders in Arendonk

• Networking Event 2023

• Revision EN ISO 1461

• Nominees BTTV 2023

• EGGA Assembly Salzburg 2023

• Networking Event 2023

• Dutch language trainings

JUNE 2023

OCTOBER 2023

• EGGA Assembly Salzburg 2023

• Website ZIB

DECEMBER 2023

• Evaluation Networking Event

• BTTV 2023

• Intergalva 2024 Bruges

• EGGA meetings Bruges

• Dutch Technical Agreement

• Update Intergalva 2024

Zinkinfo’s annual networking event took place on 14 September at the charming Delta Hotel in Vlaardingen. This event brought together members, associates and suppliers for a day of interaction and connection. Besides ZIB’s associates, three more suppliers enthusiastically registered for the event, namely Stockmeier, Kluthe Benelux and Chemische Fabrik Wocklum. After two extremely interesting presentations by Prof Eric Pirard (Sustainable availability zinc resources) and Prof Jacqueline Cramer (Building Agreement Steel), all attendees were ready to board for a tour of the port of Rotterdam, which is considered the largest seaport in all of Europe. After the short break, some of the group took part in an entertaining pub quiz, while those who had opted for the Schiedam gin tasting were able to enjoy the delicious gins and learn a little more about the history of gin...

We can look back with pleasure on a fantastic day and would like to thank everyone who attended! All photos from the networking event can be found here

Please mark Thursday 12 September 2024 in your diary for the next edition!

Mavom Chemie produces chemical solutions for industrial applications for OEMs, coating companies and industrial service providers.

Increasingly, they are acting as a Total Solution Provider, completely relieving customers of the burden of setting up and controlling a smooth and safe process. In their own R&D lab they develop (customized) products for metal pre-treatment, industrial cleaning and chemical contract blending. They supply these directly from stock in the Netherlands, Belgium and through partners also in other EU countries. In addition, knowledge sharing, preventive advice and safety and laboratory training are an important added value to their product portfolio.

• Information: www.mavom.nl | sales.chemie@mavom.nl

• Contact: Mevr. Daisy de Koning | +31 (0)172 220 460

In 2023, ZIB decided not to attend any fairs as an exhibitor. However, a number of fairs were attended to maintain contacts.

In 2024, ZIB plans to conduct a thorough investigation into which fairs, besides the usual ones, might be suitable to reach other markets. Several examples are being considered such as:

- Timber Construction

- Provada

- Trade fair Energy

- Belgian Offshore Days

Unfortunately, no info sessions took place in the year 2023 around ZEKER ZINK. However, this is something we definitely need to tackle again in 2024.

Rezinal nv from Belgium is the trendsetter in sustainable zinc recycling of zinc ashes, zinc scrap and other zinc-containing materials.

Rezinal nv is among the world leaders in zinc recycling. With our high-performance production process we produce secondary zinc of the highest quality and by-products such as fine zinc ashes and hard zinc. This secondary zinc and the by-products are used in high-grade applications such as hot-dip galvanising, brass production and the production of zinc oxide.

• Information: www.rezinal.be | info@rezinal.be

• Contact:

Mr. Dieter Stulens | +32 (0)13 53 96 35 | dieter.stulens@rezinal.be

Mr. Kristiaan Deckers | +32 (0)13 53 96 34 | kristiaan.deckers@rezinal.be

At the invitation of Iemants/Smulders, we were asked to give an informative session in Arendonk, attended by a diverse group of technical staff, drafters, project managers and other interested parties. The session was also monitored via Teams, due to heavy snowfall that prevented some people from getting to Arendonk in time.

Another interesting session was the invitation from Chemetall/BASF in Bornem. During the monthly Sales Meeting there, we gave a presentation on hot-dip galvanisation. There were as many as 20 people interested in more in-depth information on metallic coatings and specifically hot-dip galvanising. The interest and involvement of the audience were very positive.

FIB Belgium, a family business founded in 1936, offers total solutions for galvanizing small parts (Spinning galvanizing also at high temperature) or larger parts. Services range from the study of the optimal location to the supply of the equipment.

Our teams - consisting of experts with many years of experience in custom galvanizing - are particularly specialized in the thermal field, where heating solutions with low CO2 or NOX emissions are offered. Electric heating technologies are also part of our technology portfolio.

• Information:

https://www.fib-galvatech.com/en/ | info@fib.be

• Contact: Mr. René Branders | +32 475 42 47 97 | r.branders@fib.be

During the networking event on 14 September, ZIB proudly officially announced the laureates of the fourteenth edition of the Benelux Trophy for Hot-dip Galvanisation. In line with the previous edition, three projects were awarded this time, spread over three different categories: Functional Galvanising, Aesthetic Galvanising and Duplex Systems.

Choosing between aesthetic and functional galvanisation stimulates the conversation between executor and galvanisation, thus better matching the client’s expectations with the final result.

In addition, this year the jury once again awarded a prize to the most sustainable or circular project. With this, the industry once again shows its support for the principles of circular construction.

THE PROUD WINNERS ARE:

Category FUNCTIONAL GALVANIZING: Parkeergebouw Zwijsen

Category ESTHETIC GALVANIZING: Dakserre Agrotopia

Category DUPLEX: Brandtoren Kalmthoutse Heide

PRICE CIRCULAR BUILDING: Het Podium

The BTTV book houses all submitted projects and was sent to all ZIB members, submitters and project stakeholders.

In addition, the September edition of the ZEKER ZINK Magazine was entirely dedicated to the BTTV.

On the ZIB website, each submitted project was given a full page to inspire designers and builders.

- Improved paint adhesion, excellent corrosion protection

- Surpasses the market standard in chromium (VI) free chemistry

- Full service chemical supplier

AD Chemicals, part of AD International, has been developing, manufacturing and supplying a wide range of products for the chemical surface treatment of metals for over 40 years. These products can be used in various process applications. Chemical pre-treatment is an essential step in the powder coating, wet painting and anodising process, among others. AD Chemicals has product lines for the substrates aluminium, galvanized steel, steel and multi-metal.

Chemical pre-treatments must meet complex and critical requirements and are often specifically tailored to the end product and associated substrate. For this reason, AD Chemicals has intensive partnerships with its customers. They can rely on high-quality technical advice and extensive testing and development facilities.

With more than 15 years of experience in chromium (VI) free chemistry, AD Chemicals is a trendsetter in the market. Extensive practical testing and a continuous focus on process improvement have created robust pre-treatment systems that are a formidable competitor to processes containing chromium (VI). The corrosion resistance and adhesion properties of the paint system are comparable on a 1:1 basis with chromate-containing systems.

Quality is a common driver for AD and its customers. AD Chemicals products therefore meet or exceed current market standards such as Qualicoat, Qualisteelcoat, GSB, Qualanod and MIL. AD is a partner who thinks along and adds value to your processes.

• Information: www.adinternationalbv.com | contact@adinternationalbv.com

• Contact: Mr. Roland van Meer | +31 167 526971 | r.vanmeer@adinternationalbv.com

Towards the end of 2023, Jelle Elbers of Coatinc has decided to leave the committee as he has found a new job outside our industry. Nevertheless, we can also welcome numerous new invitees: Annelies Lenssen, Erwin Vogelpoel, Sam Jannes, Roland van Meer and Alfred Stegeman.

The Technical Committee meetings are very popular and we received applications from 2 new committee members, which is great. In 2023, we had three meetings. At the request of the committee, we considered finding another location for our meetings instead of our office in Breda. Fortunately, Roel Sweegers offered his company as a guest location and we were very pleased. After the meeting, we were even offered a tour, which was a nice touch. It was great to see that everyone responded enthusiastically to both this initiative and Roel’s excellent company.

The BAT conclusions have been distributed to members in a simplified version. A presentation with the main points was also circulated, prepared by Murray Cook of EGGA.

Within the Technical Committee, the ‘Workplace Safety’ working group, on the initiative of Edwin Ottens of ZINQ, made significant progress on pro -

tective clothing, especially for use in the zinc bath. During a presentation by Edwin Neef of Hydrowear, all relevant details about this specific clothing were discussed in detail and contact information was exchanged so that every Zinkinfo member can access this high-quality clothing.

In addition, Johan Jongeneel informed us about a very interesting device called the “Mover”, which can be used as an aid for lifting and hanging material. The good news is that one will soon be available in the Netherlands at Rotocoat.

Soon, therefore, we can benefit from both improved protective clothing and handy equipment that makes work easier and safer.

The ARIE 2023 project also emerged under the banner of the committee. Thanks to the alertness of Jelle Elbers, in collaboration with BMD Zuid, the necessary measures to meet the requirements were fleshed out.

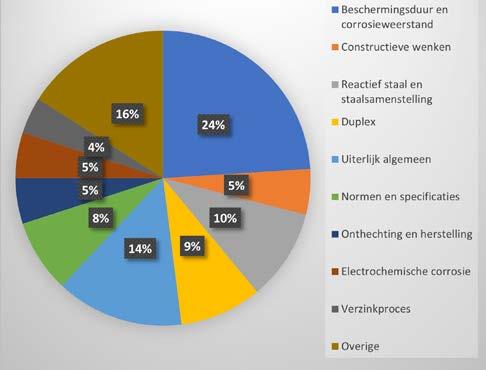

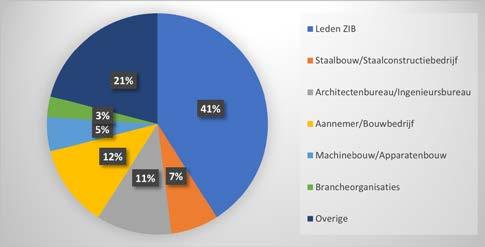

Unlike previous years, there has been an increase (about 16%) rather than a decrease in the number of queries. In particular, the improved Technical Info Sheets and the FAQ page on the website should lead to a reduction in the number of questions. However, this does not seem to be the case as yet.

What is particularly striking this year is the shift in focus. Last year, the focus was mainly on soil placement, while this year the question on lifespan and sustainability is more prominent.

We also see a change among the different target groups. Steel builders asked significantly fewer questions (from 17% to 7%), while the percentage of questions from contractors actually increased (from 5% to 12%). It seems that contractors are more actively looking for problem solutions themselves, while the steel builders may be passing the question by. We will monitor this trend closely in 2024.

THE MAIN QUESTIONS ARE ABOUT:

THE MAIN QUESTIONS ARE:

GIMECO is an Italian family company that has been designing, building, installing and renovating hotdip galvanised installations since 1976. The foundation on which we build the future of our company and that of our successful customers is innovation. We have a habit of listening to our partners in detail and together coming up with the perfect solution that far exceeds initial expectations. In 45 years of experience, we have acquired a global know-how of the entire galvanisation process, having implemented more than 125 complete lines in over 40 countries.

ENGINEERING - CONFIGURATION - INSTALLATION

- Batch galvanising plants (steel constructions, poles, crash barriers, transmission masts, etc.)

- Automatic Tube Galvanising Plant

- Automatic centrifugal galvanizing plants (small parts, fittings, chains, bolts and nuts)

SERVICE

- Boiler management and inspection (boiler inspection device, pumping in and out, boiler replacement, furnace control)

- Rack and pinion station with variable heights and hoists

- Furnace technology (traditional to high speed, dual chamber system)

- Automation, software (Zephir, HerMes) and logistics

- Chemicals

- Renovation

- Energy policy

- Technical Assistance

GIMECO has two Business Units, ZINCO SERVICE (ZS) dedicated to providing exclusive boiler management services and CO.T.IMP.I. (Switzerland) specialising in the galvanisation, finishing and testing of pipes.

In addition to a network of agents, the international group includes:

GIMECO USA (United States) fully operational branch dedicated to the North American market ZINCO TECHNOLOGIES (Canada) special branch dedicated to boiler management RECYCLEAN SYSTEM (Sweden) supplier of special innovative chemicals for the galvanising process

Member of: AGA, EGGA, AIZ, HDGASA, ACSZ, ATEG, ILZDA, GALVAZINC, JGA, INDUSTRIEVERBAND FEUERVERZINKEN, GALVANIZER ASSOCIATION.

• Information: www.gimeco.com | sales@gimeco.it

• Contact: Mr. Johan Jongeneel | +31 6 5433 1796 | johanj@gimeco.it

Zinkinfo maintains a database in Excel of all the contacts it comes into contact with: helpdesk, BTTV, examinations & inspections, trade fairs, meetings, project visits, etc. By the end of 2021, the database will contain over 4,500 unique contacts. It goes without saying that this is a particularly important tool for ZIB in strengthening its network.

Zinkinfo does the daily bookkeeping itself through Asperion - Online bookkeeping: invoicing, booking purchase invoices, checking bank statements, making payment batches. Accountancy firm De Vries & Nell takes care of the payroll administration, VAT declarations and prepares the interim annual statements.

The general administration is also managed by Zinkinfo: genda management, mail traffic, organisation of meetings of ZIB working groups, sending out documentation, archives,

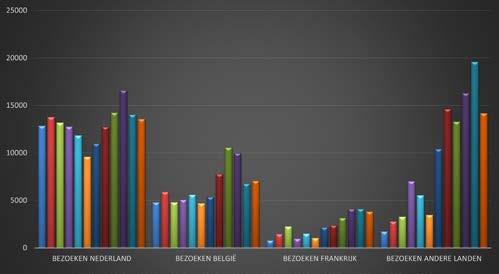

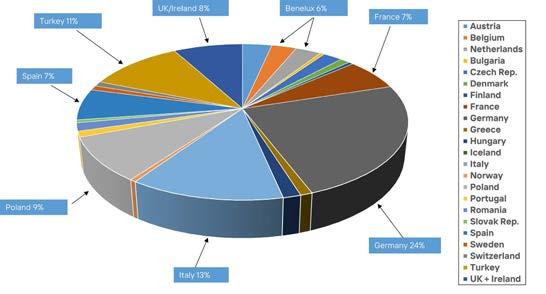

New items are continually added to the Zinkinfo website in Dutch and French, such as all kinds of news items, press releases, BTTV, calendar, ZEKER ZINK magazine, etc. Website statistics are tracked monthly via Google Analytics and Leadinfo. The 2023 visitor figures are down slightly compared to the 2022 figures. Interestingly, visits from countries outside the Benelux increased again.

Thanks to the update to Google Analytics 4, we know the number of sessions with interactions immediately. To speak of a session or visit with engagement, at least one of the following conditions must be met:

- the session must last at least 10 seconds or longer

- 1 conversion event occurred

- 2 or more page views were recorded

The graphs on the next page show the number of visits in 2023, the number of visits per country and the percentage of visits per page.

HaTwee is a provider of a full range of powder coatings, especially tailored to industrial and architectural applications for both indoor and outdoor exposure. Coatings for single and double layer systems on galvanized and non-galvanized steel are the specialty of HaTwee.

In addition to a wide choice of more than 400 standard stock products, they also offer solutions for customer-specific applications. The product quality is attuned to the customer’s needs and HaTwee actively thinks along with the application and process optimization. HaTwee also takes care of smaller customised work for its customers.

• Information: www.hatwee.be | info@hatwee.be

• Contact: Mr. Hans Hooyberg | +32 475 84.90.51 | hhooyberg@hatwee.be

EGGA meetings are held twice a year and bring EGGA’s European members together to discuss current issues and support each other where possible. Within EGGA, there are three committees, namely Environmental & Safety, Technical & Research and Marketing. The Board also meets twice a year.

It is customary for the board member from the host country of Intergalva (in 2024 it will be Belgium) to be appointed president of EGGA. Therefore, Norbert Beljaars is now the new chairman, with a term until June 2026.

Several topics were discussed during the Board meetings:

• Annual report and annual accounts

• Intergalva 2024 in Bruges

• Proposals for Assembly 2025 and 2026

• Confirmation Intergalva 2027 in Spain

• Member-related updates

• EU Critical Raw Materials

• Net Zero Industry

• Emission Trading Scheme “2”

• Construction Products Regulation

The EGGA Marketing meetings included the following items:

• EGGA Statistical Report 2022

• Sustainability: developments for product policy

• Sustainability: communication

• EGGA EPD and PCR update

• SCI Steel ReUse Project & LCA comparison with paint

• National updates and communication

• Competition with other materials:

• ZM Steels

• Weathering steels

• Hot-dip galvanised reinforcing steel

• Global Galvanizing Awards 2024

Reports of these meetings can be requested via ZIB.

The committee worked mainly on standards.

The revision of EN 1090-2 was particularly important, given the increased possibilities for the use of high-strength steels.

A European counterpart to the NTA 8713, called “Reuse of Structural Steel”, is also being worked on. Like the Dutch version, however, this will not be a standard, but a TS (Technical Specification).

Other standards that have received attention are ISO 17607 (International Standard for Steel Fabrication) and the EN-ISO 12944 series (see page 49).

Several topics were discussed during the meetings, including the BAT conclusions and the BREF FPM document.

It was noticeable that various aspects of both the BAT and BREF were addressed, such as the frequency of monitoring.

In addition, there were questions about the national translations, which sometimes turn out not to be accurate. Fortunately, this does not apply to the Dutch version, where Jelle and Hans provided input.

According to the BAT conclusions, every company is required to have a Chemical Management System (CMS), on top of the Environmental Management System (EMS), which aims at continuous improvement. However, it is important to note that this obligation is already stipulated in REACH and also in our national legislation.

Another interesting point concerns the percentage of lead in the zinc bath and the possible limits that may be applied in the future. Currently, further limits are expected to be introduced only after 2029 (information from ECHA).

Finally, we would like to stress that the STM BREF was started for companies with a powder coating department.

The EGGA Annual Statistical Report 2022 contains information on 24 European countries. This information is collected for EGGA by the national associations.

VCD is supplier of all chemical products for surface treatment in the field of hot-dip galvanising, including degreasing and passivation of coatings.

VCD is a promoter of ecological solutions that meet the European REACH and ISO regulations. The processes are modern and designed in accordance with the regulations. They meet the current and future needs of the company’s customers.

VCD’s success depends on the answers to all the following challenges:

- understanding customer needs

- continuous investment in R&D

- developing flexible and available processes

- providing technical expertise through a team of professionals alert to market changes

- ensure continuous process control and optimisation

VCD has a know-how in surface preparation; one of the keys to a successful surface treatment. VCD takes care of the training of its customers through intra- or extra-corporate training courses according to the number of participants. Areas of competence include the practice of analytical methods, surface treatment technology as well as process control and good practices.

VCD assists and advises its customers in the control of the galvanising processes as well as in the continuous improvement of these processes.

• Information: www.vcd-floridienne.com | info@vcd-floridienne.com

• Contact: Mr. Jacques Maubert | +32 (0)476 42 34 30 |jacques.maubert@vcd-floridienne.com

The next Intergalva will take place in beautiful Bruges from 10 to 14 June 2024, as you no doubt already know. The Bruges Meeting and Convention Centre will be the setting for this event, located in the vibrant city centre and easily accessible on foot from the city’s many hotels and restaurants.

The programme promising a diversity of activities:

- On Sunday 9 June, the exhibition floor will be built up, ready to welcome participants.

- Monday 10 June is dominated by conferences and exhibitions, followed by a festive welcome party.

- Tuesday 11 June again offers conferences and exhibitions, culminating in a grandiose gala dinner at a unique venue.

- Wednesday, 12 June again features exciting conferences and trade shows.

- Thursday 13 June features company visits, where you can take a look behind the scenes at various galvanisation plants.

- Friday 14 June will see even more fascinating company visits.

Please mark these dates in your diary in bold letters! After all, the Benelux should be well represented as the host country during this unique event.

The conference sessions will be held on 10, 11 and 12 June in extended plenary sessions. Simultaneous translation to and from French, German, Italian, Spanish, Japanese and Chinese will be provided at these sessions.

Conference topics:

- Decarbonisation and energy efficiency - the industry’s response to the challenges of a climate-neutral economy.

- Circular economy - the contribution of hot-dip galvanising to improving circularity.

- Process technology - including plant design and automation; boiler management; energy efficiency; flux and degreasing technology; post-treatments; bath alloys.

- Market and product development - including durability of coatings; new applications; coating technology; developments in steelmaking and product design.

- Environment and safety - including improvements in environmental performance; operational safety.

- Regulation - including regulatory issues affecting markets/applications; future evolution of environmental controls on processes.

- Galvanisation in architecture - applications in building and construction.

On Thursday and/or Friday, visitors will be invited to visit several galvanisation plants in the Benelux countries. The final programme will be announced shortly, at the start of registrations. We are pleased to announce that the following galvanisers will open their doors:

• Coatinc Ninove

• Coatinc Mook

• Electrocoat Genk

• Rotocoat Dieren

• Rotocoat Heerhugowaard

• Verzinkerij Meerveldhoven

• Wecoat

• ZINQ Gent

• ZINQ Houthalen

More information www.intergalva.com

Flaurea Chemicals has held a patent since 1921 and has developed flux salts for hot-dip galvanising that provide effective protection against corrosion.

Following the closure of Floridienne Chimie in 2014, Flaurea Chemicals has resumed production of flux salts (Florflux), zinc chloride and cadmium salts.

Flaurea Chemicals offers its customers both its know-how and a wide range of products, ranging from ammoniacal zinc chloride (basic double salt) and a wide range of special fluxes (Florflux®) to zinc chloride adapted to each specific need or process.

Hot-dip galvanising is an industrial process with a bright future ahead of it. In the building sector, it significantly extends the life of metal structures and simplifies their maintenance. For urban and agricultural furniture and certain automotive parts, hot-dip galvanising remains one of the most effective and economical ways of combating corrosion.

- Flaurea Chemicals offers its customers regular flux bath analysis and provides a high level of technical advice.

- Flaurea Chemicals is an important player in the circular economy and has adapted its production processes in such a way that used dezincification baths are not destroyed or thrown away at the end of their life but are instead used as raw materials.

They are one of the few flux and zinc chloride producers in Europe that recycle de-zincing baths.

Packaging

- Flux salts in powder form are available in 25 kg bags.

- Liquid fluxes are available in IBCs or tankers.

- Zinc chloride powder in 25k bags and liquid in several concentrations in bulk or IBC.

Flaurea Chemicals actively participates in international studies on the development of new processes with zinc alloys.

• Information: www.flaureachemicals.com

• Contact: Mr. Christophe Laubignat | +33787143378 | Christophe.Laubignat@flaureachemicals.com

ZIB has been a member of Stichting Duurzaam Bouwmetaal since its beginning, a foundation dedicated to defending the interests of zinc with local, regional and national governments in the Netherlands. Martin van Leeuwen of IZA is the managing director of DBM.

LOBBY

Relevant national government policies are monitored by DBM. This also applies to the Dutch government’s input into the introduction/adjustment of EU regulations. To this end, DBM was also active in relevant networks such as the Dutch shadow committee FDW in 2023. Active lobbying activities are carried out by DBM alone or in coalition. Of course in coordination with the DBM board.

Strukton-ProRail

Strukton plans to use more hot-dip galvanised steel screw foundations for railway portals to replace carbon-intensive concrete foundations. But they are concerned about zinc washing off into the soil and groundwater. A focused letter has been written, with the help of Chris Cooper, stating that hot-dip galvanised

steel poses no environmental risks to soil and groundwater, including a scientific argument.

Falco

Falco is a manufacturer of canopies, cycle racks and street furniture. One of their customers is concerned about zinc running off the hot-dip galvanised steel roof of the canopies. An initial statement of defence has been drafted and sent.

Media have long known how to find DBM when there are developments in zinc. DBM will continue to play that role. Competitors who cast zinc in a bad light can count on a decisive DBM response.

An outline for a new website for DBM is being prepared, to be launched in 2024.

Minutes of DBM meetings can be obtained from ZIB.

Trafigura is one of the world’s leading independent commodity trading groups and one of the largest participants in the global zinc market, with over 1.5 million tonnes of zinc concentrates and 1.4 million tonnes of refined zinc in 2019.

Trafigura’s trading activities are supported by its industrial and financial assets, including a majority stake in global multi-metals company Nyrstar, which has a market-leading position in zinc and lead. Nyrstar has mining, smelting and other operations in Europe, the Americas and Australia.

Nyrstar produces zinc concentrates from its mining operations and a variety of refined zinc products, including special high grade zinc (SHG), zinc alloys and zinc cast alloys resulting from the zinc smelting process.

Combining Nyrstar’s footprint of manufacturing with Trafigura’s global marketing, logistics network and financial expertise provides significant opportunities in today’s zinc market. The two companies combine best market practice and high standards of responsibility in their respective fields, as well as reliability and responsiveness to customers.

The Trafigura Group is a privately held company with 8,000 employees working in 80 offices in 41 countries worldwide. For more than two decades, the Group has connected its customers to the world economy and increased prosperity by promoting trade.

• Information:

www.trafigura.com

• Contact: Mr. Jan Philip Fiedler | +41 22 592 3734 | Janphilip.Fiedler@trafigura.com

The links of the Dutch steel construction chain have joined forces to make steel in construction more sustainable. Their collective vision and ambitions are laid down in the Steel Construction Agreement. ZIB has been a leader within the SCA since its inception and follows up on the necessary meetings and working groups.

All information on the SCA and the roadmap can be found here: https://bouwakkoordstaal.nl

Infosteel has also started work in Belgium to set up a Steel Construction Agreement in which ZIB is also closely involved. All info on this can be found here: https://www.infosteel.be/bouwakkoord-staal

Directive NTA 8713 “Reuse of structural steel” was published on 6 June. Reusing structural steel leads to a much better environmental performance of a structure than recycling structural steel. The reuse of structural steel has already proven itself in projects in the Netherlands. An unambiguous agreement to demonstrate that a building with reused structural steel is safe was not yet available. With the publication of NTA 8713, we now have this standard procedure for reusing structural steel. Rijksvastgoedbedrijf, Bouwen met Staal, ZIB and other market parties have developed a Dutch Technical Agreement (NTA) that supports large-scale reuse of structural steel.

Safety was the guiding principle for drafting this NTA. Hence, the NTA fits with the Building Decree and NEN-EN 1993 (Eurocode 3: Design and calculation of steel structures). The NTA supplements how an inspection document can be drawn up that includes the geometrical and material properties (including preservation) of steel profiles to be reused. This procedure ensures that the suitability of these profiles in

their new application can be demonstrated with NEN-EN 1993 and can comply with the Building Decree and the future Building Works Decree.

The advantages of hot-dip galvanised steel when reused are that 95% CO2 savings are possible on the production phase (A1 to A3) instead of the 80% that can be achieved by reusing a painted structure. If the construction can be reused without modifications or updating/replacing the preservation, this saving rises to 100%. There are several hot-dip galvanised steel structures in the Netherlands (and Belgium) that have been dismantled in their entirety and reassembled in another location or even another country without any modifications or updating of the preservation.

Another great step towards the circular economy, thanks to hot dip galvanising of steel!

After a series of intense consultations in 2023, it was decided to merge the national NEN committees 342107 and 342035. This merger will bring together paint and metallic coatings, as well as inorganic coatings (such as enamels) and corrosion, into one committee consisting of several working groups. Apart from the fact that this merger brings cost savings, it will also make it easier to influence decisions arising from “paint articles”, especially in the next few years when EN-ISO 12944 is under review. This will allow us to put forward our views in a more focused and clear way.

This particular standard has been under review by the ISO Technical Committee with the aim of completely revising it. Ad hoc working groups have been formed to technically assess the changes. One important modification concerns the reduction of the range for fasteners, with M6 added. This has led to discussions about the zinc coating thickness, as in EN-ISO 1461 we have placed this 6mm in a different category. In addition, washers have now become a more prominent part of this standard. So bolts, nuts and washers now fall within the guidelines of this standard. To make this possible, a research process also had to be started regarding possible zinc coating thicknesses on such washers.

This standard for paints and varnishes consists of 9 parts. However, it is planned to merge Part 9 with Parts 5 and 6 of this series of standards. This is the reason for starting with these parts. The topic of discussion revolves around whether or not the galvanised coating is a part of the coating/conservation system. The question Is whether it is permissible for this committee working group (ISO/TC35/SC14/ WG12) to just make statements about this. The galvanisers object nationally and internationally to such a course of action. There is a risk of suddenly talking about accelerated corrosion tests but also adhesion tests. Methods of measuring layer thicknesses and definitions of words are also being discussed. Meanwhile, there have been several moments of contact between the WG 12 spokesperson (Serviel Smolders) and the SC14 chairman (Philipp Suppan). The latter came to Verzinkerij Weert to talk mainly about the Scribe test. Norbert Beljaars also showed the results of this in their own laboratory.

The latest news is that the approach to the socalled scribe test has been voted on. It seems that hot-dip galvanisation will be taken into account as a substrate or as an additional, and therefore different, form of corrosion protection.

For companies working with large quantities of hazardous substances, the ARIE regulation has been amended such that by 1 January 2024, all Dutch galvanisation plants must comply with legal requirements as stated in this revised ARIE.

ARIE stands for Additional Risk Inventory and Evaluation. From then on, galvanisation plants will be subject to partly the same regulations as companies falling under the BRZO 2015 (Major Accident Hazards Decree).

The rationale behind requiring all companies to comply with this legislation is the threshold value for hazardous substances of these revised ARIE regulations. This includes, for example, alkalis and acids found in degreasing baths, pickling baths, strip baths and possibly other installations within your company, such as a water treatment system. The set threshold with regard to skin corrosion is 15 tonnes. Here, skin corrosion categories 1, subcategories 1a, 1b and 1c (causes severe burns and eye damage).apply

BMD Zuid has been asked to prepare a plan of action for participating members to work on. Meanwhile, these companies have filed a notification with the Netherlands Labour Inspectorate.

Like previous years, the trend is also confirmed this year. There is again a clear decline in the number of tests and inspections. As mentioned earlier, there are several reasons that can be given for this:

1. Accessibility of technical support through help desk function. Many issues can be resolved through e-mails and photographic material without the need for a site visit.

2. The high cost of inspection compared to previous rates (doubling).

3. Members also see complaints as an opportunity to connect with customers and try to solve problems themselves.

4. Inspections required to issue guarantees beyond 10 years have been dropped.

5. Virtually shutting down a project that required regular inspections.

6. Inspections abroad will be honoured only when the request comes from one of the members.

7. Dealing selectively with requests to inspect galvanisation from abroad in Benelux.

8. Rejecting requests from VVEs (Owners’ Associations of an apartment complex or the like) in case of a failing duplex coating after a number of years. Only in the case of a new delivery do we deviate from this.

A total of six inspections were carried out, of which only one took place in Belgium. Two inspections were related to a duplex system. And strangely enough, there were also 2 inspections that had nothing to do with discontinuous hot-dip galvanising. One of the projects concerned ZM strip steel (Magnelis), while the other concerned continuously galvanised tubular material according to EN 10240. For both projects, this only became clear later, during the visit.