ZINKINFO BENELUX 2024

FOREWORD

We are proud to present the seventh activity report of ZinkInfo Benelux, in which we look back on a year full of important initiatives and educational events. This report not only provides insight into our core activities, but also emphasises how we as an organisation continue to evolve in order to optimally support our members and the industry.

Intergalva 2024

One of the highlights of this year was without doubt Intergalva 2024, which took place in Bruges in June. We are extremely proud of the huge turnout and the extremely positive feedback we received from participants from home and abroad. This international event brought the sector together and provided a platform for sharing expertise and visions.

NEW COMMUNICATIONS STRATEGY

In the autumn, prompted by the need for a revamped website, we started working with a communications agency to develop a new communications strategy. This approach is aimed at increasing our visibility and further improving the services we offer our members.

TEAM ZIB

ZinkInfo Benelux has also undergone internal changes. We have strengthened our team with the arrival of Jelle Elbers, who has been active as Technical Manager since September. His technical expertise will be of great value in addressing the challenges of our sector. We also welcome Bruno Dursin, who is once again contributing to our marketing and communications activities as a consultant. With his experience, network and commitment, he is an important link in our growth.

We would like to thank all our members for their cooperation and trust in ZinkInfo Benelux. Together, we will continue to build a sustainable future for hot-dip galvanising.

Hasco-Thermic Ltd is a wholly owned subsidiary of B.E Wedge Holdings Ltd, the holding company for leading galvanizing businesses in the UK, Continental Europe and the USA.

Celebrating nearly 50 years in industry, Hasco-Thermic has established an enviable reputation for supplying and installing reliable, efficient and durable hot dip galvanizing plants across the globe.

Products include:

- Highly Efficient Furnaces

- Integrated Heat Recovery Systems

- Fume Enclosures to latest standards

- Preheating Ovens

- Consultancy Services

Hasco-Thermic is perfectly placed to offer a flexible approach to meet the needs of its customers.

• Information: www.hascothermic.com

• Contact: Mevr. Angela Curtis | +44 (0)121 552 4911 | angelac@hasco.co.uk PARTNER SINCE 2019

MARKETING & PROMOTIE Marketing Committee ZIB

Kickoff Meeting Marketing Committee ZIB

After a long period of silence, the Zinkinfo Benelux (ZIB) marketing committee met again on 23 February, this time with a completely new composition:

- Quincy Linders - Thielco

- Mike Schong - Rotocoat

- Bobby de Meulder - Verzinkerij Meerveldhoven

- Kris Deferme - ZINQ

- Frank Meyers - WeCoat

- Mark Schouten - Coatinc

- Sandra Heyman - VCD Floridienne

- Roland Schellen - AD Chemicals

- Bruno Dursin - Believe in Steel

The central focus of this kickoff meeting was a full agenda with topics such as:

- Determining the priorities for ZIB 2025-2026

- Overview of current and planned activities

- ZEKER ZINK magazine

- The Trophy for Hot Dip Galvanizing 2025

- Market development and potential new sectors

The meeting was an important first step towards de -

veloping concrete plans and provided inspiring discussions and valuable insights.

Follow-up meetings in 2024

After the kickoff, the workgroup met four more times in 2024 to further explore various topics. The agenda included:

- Intergalva 2024

- The annual ZIB networking event

- Further development of the ZEKER ZINK magazine

- The Zinkinfo Galvanizing Awards

- A brainstorming session about the new communications strategy with TRIMM

The workgroup, in which a large number of our members are represented, has received a significant boost this year. With renewed energy and commitment, the committee is enthusiastically working on developing strategies and initiatives that will shape the future of Zinkinfo.

Publicaties & Communicatie

ZEKER ZINK MAGAZINE

In 2024, Zinkinfo will have sent the ZEKER ZINK magazine twice to 8,898 Dutch-speaking and 886 Frenchspeaking subscribers. The Dutch magazine was opened by 1,703 people, while the French magazine was opened 293 times. These statistics are closely monitored via Mailchimp and ISSUU. From 2025 onwards, we will strive to increase the number of magazines to four per year.

ZEKER ZINK MAY 2024

The sustainable power of hot-dip galvanized steel at the University of Twente

Rick ten Doeschate - CIVIC Public Architecture

In the circular economy, there are a number of models that can help in the development of circularity objectives. One of the most commonly used tools is the R-ladder, which indicates the degree of circularity. The R-ladder has six steps (R1 to R6) that represent different circularity strategies.

Strategies higher up the ladder save more raw materials. The higher a strategy is on the R ladder, the more circular the strategy, with R1 being the highest step. After R1 (refuse), R2 (reduce) and R3 (re-use) come refurbish and repurpose for R4, where extending lifespan is key. Refurbishing or adapting existing buildings to give them a new lease of life, with or without new functions, clearly scores better in terms of circular construction than simply demolishing the building. An excellent example of refurbishment and repurposing is the transformation of the former ‘Langezijds’ laboratory into new premises for the ITC Faculty of the University of Twente (UT).

ZEKER ZINK OCTOBER 2024

Durable infrastructure with hot-dip galvanized steel

The story behind the reused porches of the Agency for Roads & Traffic

Our second issue of 2024 is largely dedicated to an interview with Ben Cannaerts of the Agency for Roads and Traffic (AWV - you could say, the equivalent of Rijkswaterstaat in Flanders). At ZinkInfo Benelux, we have long been firmly convinced of the advantages of hot-dip galvanised steel in terms of reuse. The combination of unrivalled lifespan with an extremely robust preservation system guarantees the carefree reuse of existing steel structures.

It goes without saying that governments play a major role in facilitating and promoting circularity in construction. We are therefore very pleased with the initiative of an important public client in Flanders to give a number of ‘dismantled’ road traffic gantries a second life. This required a significant change in the design method, but to the great satisfaction of the Flemish Road Authority, the process went almost without a hitch. Instead of designing the gantries based on the foundations, they took the opposite approach and placed the foundations based on the dimensions of the existing gantries. A total of five gantries have been given a second life so far. It fits perfectly with the AWV’s objectives to move towards more circular procurement.

Hot-dip galvanised steel is a textbook example of a circular building material. Assemble, disassemble, reuse or recycle? Once galvanised, steel can take more than its fair share of punishment. Together with its sister organisations in Europe, Zinkinfo has published a lengthy document under the auspices of the EGGA (European General Galvanizing Association) entitled: ‘Galvanised Steel and Sustainable Building: solutions for a circular economy’. We recommend that anyone who wants to know more about the benefits of hot-dip galvanised steel in the field of circular construction consult this publication.

PARTNER

SINCE 2011

DIPL.-ING. HERWIG provides a full range of Galvanizing Consulting Services aimed to help our customers in achieving the best galvanizing practices and results:

• Environmental-friendly processes and alloys to maximize output and improved galvanized quality

• Custom made solutions to fit each galvanizers’ requirements and demands

• In-plant training and knowledge ‘refreshing’ of galvanizing concepts and best practices

• Seminars in Galvanizing

Front runner in Galvanizing Market

As one of the world’s leading suppliers of chemicals and zinc alloys for the galvanizing industry, our main principles are: Efficiency, Flexibility and Vision towards the Future. We develop new products for the galvanizing industry and in our portfolio we market and several specialty processes, recycle chemicals and also project and build galvanizing plants. Aside, Herwig is holds numerous patents in Galvanizing. Our personal involvement in this industry ensures state-of-the-art products, as a result of research and development and a comprehensive problem solving know-how, which makes our company the right companion for the Galvanizers.

Herwig Worldwide

We show truly global presence. Being a proven specialist in the galvanizing sector, we are operating worldwide, providing a reliable technical consultation service and offering a broad spectrum of high-quality products. We support our customers through our worldwide network of agents and representatives. Each member of this network operates at once independently and for the general good. We add our support in the form of training courses and joint visits on site. Customers all over the world have their own local contact partner – someone who can support them in their own national language and with an understanding of the local mentality and conditions. The times needed to react to customers’ requirements and needs can thus be kept to a minimum.

• Information: www.herwig-gmbh.com | info@herwig-gmbh.com

• Contact: Mevr. Klaudia Gorajek | +49(0)2331 9 15 5 65 | klaudia.gorajek@herwig-gmbh.com

PRESS

To increase awareness of Zinkinfo and especially ZEKER ZINK, we regularly send press releases to the Belgian and Dutch media. In these messages, we emphasise the joint efforts within the sector and the importance of proactive cooperation and communication between galvanizing plants and clients. Below you will find a selection of these press releases.

Beton & Staalbouw

Construire La Wallonie/ L’usine nouvelle

Intergalva 2024 Brugge

Thermisch verzinkt staal scoort goed voor transformatie TU Twente

Global Galvanizing Awards, winnaar blinkt uit in circulariteit

InfoZinc et EGGA se réjouissent du succès des Global Galvanizing Awards lors de l’Intergalva 2024 à Bruges

ZinkInfo Galvanizing Awards 2025

ArchiComm

België & Nederland

ZinkInfo en EGGA blikken terug op succesvolle Global Galvanizing Awards tijdens Intergalva 2024 in Brugge

Architect kiest voor esthetisch verzinken

Andere

Grond Weg Waterbouw

Bouwen met Staal

Edubuild

GALVANIZED REBAR IN CONCRETE STRUCTURES

Verzinkt wapeningsstaal in betonconstructies

SOCIAL MEDIA

In order to spread the ZEKER ZINK philosophy as much as possible, ZIB uses social media such as LinkedIn, Twitter, Instagram and Facebook.

ZIB’s LinkedIn company page has almost 2,100 followers. In 2024, ZIB posted 42 messages on this page:

- New publications

- Events

- News about our partners/members

- News about EGGA

- Press releases

- Technical info

- ZinkInfo Galvanizing Awards 2025

-

Evi Renard also manages a professional profile with approximately 4,900 connections on which she regularly shares messages about hot-dip galvanization.

PARTNER SINDS 2011

In onze Riepe fabriek maken we Pilling ketels en andere speciale lasconstructies voor de verzinkindustrie.

Met onze ervaring van meer dan honderd jaar en continue verbetering van zowel materialen als productietechnologieën, zijn we in de mogelijkheid om zinkketels te produceren in alle afmetingen en vormen voor alle soorten verwarmingssystemen.

Gesmolten metaal pompen en warm houden

Onze speciale pilling-service voor verzinkingsinstallaties maakt ketelvervanging sneller en dus voordeliger voor u. Het vloeibare zink kan tijdens het vervangen van de ketels tijdelijk worden opgeslagen in onze verwarmbare voorraadovens. Deze door Pilling ontwikkelde ovens maken het mogelijk om de opstartfase van uw nieuwe ketel aanzienlijk te verkorten.

USI meting

Bovendien bieden wij u een wanddiktemeting van uw ketel aan. Tegelijkertijd controleren wij de toestand van de ketel in gevulde toestand met een ultrasone sonde op de door u aangegeven intervallen. Deze dienst neemt slechts enkele uren in beslag en kan buiten de piekuren worden uitgevoerd zonder of met weinig beperkingen voor uw productie.

• Informatie: www.pilling.de | post@pilling.de

• Contactpersoon: Mr. Nikolai Prinz | +49 2352 2015 - 30 | n.prinz@pilling.de

Organic impressions

impressions

Sponsored impressions

impressions

Popular posts - Meeting of the ZIB Technical Committee - National Steel Construction Day 2024 - Zinkinfo Galvanizing Awards 2025 - Jelle Elbers joins the team - Intergalva 2024

MEMBER NEWSLETTER

MARCH 2024

• Update Intergalva 2024

• Marketing Committee Kick-off

• Update Technical Info Sheets

MAY 2024

• Networking Event

• EGGA Meetings Berlin

• Update Intergalva 2024

JULY 2024

SEPTEMBER 2024

• Intergalva 2024

• Correct communication on zinc

• Networking Event 2024

NOVEMBER 2024

• Welcome to Jelle Elbers

• Networking Event 2024

• New communication strategy

• ZinkInfo Galvanizing Awards 2025

• EGGA Meetings Copenhague

• Check on ADR safety advisor for transportations

MAILS TO MEMBERS

Aside from the agendas and reports of the various work groups and the Zinc Info Fortnightly Newsletters, the following emails were sent:

DATE SUBJECT

17/01/2024 Intergalva Plan Visits

29/01/2024 Intergalva International Papers Committee

30/01/2024 Kick-off meeting Marketing Committee

20/02/2024 Intergalva Registration Launch

07/03/2024 Intergalva - planning visits to plants

27/03/2024 EGGA and CEN Partnership

15/05/2024 Intergalva - Day Pass

23/05/2024 Intergalva Plant Visits

04/07/2024 Contribution ZIB 2024

08/07/2024 New website & communication strategy

14/09/2024 Feedback communications strategy

01/10/2024 Permission for Gerlof Koster to join the Board

31/10/2024 EGGA Annual Statistics 2023

05/11/2024 Presentations during General Assembly

02/12/2024 Update EGGA Annual Statistics 2023

03/12/2024 EGGA Staff Tobias Schäfer

SHARED WITH

Board

Board

Marketing Committee

Board & members

Members

Board

Board

Members

Members

Marketing Committee

Marketing Committee

Members

Members

Members

Members

Members

PARTNER

SINDS 2022

Mavom Chemie produceert chemische oplossingen voor industriële toepassingen van OEM’s, coatingbedrijven en industriële dienstverleners.

Steeds vaker treden zij hierbij op als Total Solution Provider, waarbij ze klanten volledig ontzorgen bij het opzetten en controleren van een goedlopend en veilig proces. In hun eigen R&D lab ontwikkelen ze (maat) producten voor de voorbehandeling van metalen, industriële reiniging en chemisch loonmengen. Deze leveren ze direct uit voorraad in Nederland, België en via partners ook in andere EU-landen. Daarnaast vormen kennisdeling, preventieve advisering en veiligheids- en laboratoriumtrainingen een belangrijke toegevoegde waarde bij hun productportfolio.

Mavom Chemie - Master your process

• Informatie: www.mavom.nl | sales.chemie@mavom.nl

• Contactpersoon: Mevr. Daisy de Koning | +31 (0)172 220 460

NETWORKING EVENT 20224

On 12 September, the annual Zinkinfo networking event took place in the beautiful Terhills Hotel in Maasmechelen. This event brought together members, affiliates and suppliers for a day full of interaction and connection.

In addition to ZIB members, three suppliers had also enthusiastically registered for this event: Stockmeier, Bredox and Chemische Fabrik Wocklum.

Due to personal circumstances, the presentation by Michiel Verheij of TRIMM could not take place. This presentation was postponed until the General Members’ Meeting on 20 November 2024. This gave Erendiz Ates, the LinkedeIn specialist, more space to tell his story about the power of LinkedIn & ambassadorship.

After lunch, the guests could enjoy a tour of C-mine

in Genk or a walk in the National Park, accompanied by a real ranger. As a second activity, many guests dared to do the firewalking workshop. Those who did not fancy this could enjoy various beers from Kompel Brewery.

And, as is tradition, this pleasant day was rounded off with a delicious dinner.

We can look back with pleasure on a fantastic day and would like to thank everyone who was present!

All photos of the networking event can be found here

Mark Thursday 18 September 2024 in your diary for the next edition!

PARTNER SINDS 2011

Rezinal nv uit België is dé trendsetter in duurzame zinkrecyclage van zinkassen, zinkschroot en andere zinkhoudende materialen.

Rezinal nv behoort tot de wereldtop in zinkrecyclage. Met onze performant productieproces produceren we secundair zink van de hoogste kwaliteit en nevenproducten zoals fijne zinkassen en hardzink. Dit secundair zink en de nevenproducten worden gebruikt bij hoogwaardige toepassingen, zoals thermisch verzinken, messingproductie en de productie van zinkoxide.

• Informatie: www.rezinal.be | info@rezinal.be

• Contactpersoon: Mr. Dieter Stulens | +32 (0)13 53 96 35 | dieter.stulens@rezinal.be Mr. Kristiaan Deckers | +32 (0)13 53 96 34 | kristiaan.deckers@rezinal.be

TRADE FAIRS

Steel Construction Day

On Tuesday 15 October, Steel Construction Day took place in Leusden, where ZinkInfo was represented with a stand. The theme of the day, circularity, tied in perfectly with our presentation, which attracted a lot of attention. Contractors in particular showed great interest and were visibly enthusiastic.

Sustainability and circularity will become increasingly important in public tenders in the coming years. This offers wonderful opportunities for our industry that we cannot afford to miss. It is an excellent time to emphasise our unique position and added value within these themes.

Concrete day

A trip to a competitor’s event taught us that the concrete industry in the Benelux is among the best in the world when it comes to sustainability. The concrete industry depends on developments in the production of the binding agent to take further steps in improving sustainability. It is precisely in this binder that the most significant part of the environmental impact lies, the rest being sand and gravel. Just as our industry depends on green production of the basic product, the same is true for our biggest competitor. The grass is therefore not always greener on the other side!

Other

In addition to these two trade fairs, a number of others were visited to maintain contacts and to find out which fairs, in addition to the usual ones, could be suitable for reaching other markets. Here are a few examples:

- Sports facilities

- Public space

- Wood Day in Apeldoorn

- Energy trade fair

- Prefab trade fair

- Horticontact

- Wood construction trade fair

- Circularity Day

PARTNER SINDS 2016

FIB Belgium, een familiebedrijf opgericht in 1936, biedt totaaloplossingen voor het verzinken van kleine onderdelen (Spinning verzinken ook bij hoge temperatuur) of grotere onderdelen. De diensten variëren van de studie van de optimale locatie tot de levering van de apparatuur. Onze teams - bestaande uit deskundigen met vele jaren ervaring op het gebied van verzinken op maat - zijn met name gespecialiseerd op thermisch gebied, waar verwarmingsoplossingen met een lage CO2- of NOX-uitstoot worden aangeboden. Elektrische verwarmingstechnologieën maken ook deel uit van onze technologieportfolio.

• Informatie: https://www.fib-galvatech.com/en/ | info@fib.be

• Contactpersoon: Mr. René Branders | +32 475 42 47 97 | r.branders@fib.be

INFOSESSIONS HOT-DIP GALVANIZING

Despite our intention to expand this further, we have only been able to organise three technical information sessions this year. One of these sessions took place during the monthly meeting of the West Welding Group in Uitgeest.

As soon as the possibilities allow, we will also aim to approach the other welding groups in the Netherlands. For now, a meeting is planned with the Lasgroep Rotterdam in November 2025.

In addition, we were invited to give a presentation at a specialised foundry company about the background and application of hot-dip galvanization.

In Belgium, an information session was given in November at the Ghent University Department of Architecture & Urban Planning (master’s programme) for about thirty students.

PARTNER SINDS 2016

- Verbeterde lakhechting, uitmuntende corrosiebescherming

- Overtreft de marktstandaard in chroom (VI) vrije chemie

- Full service chemie leverancier

AD Chemicals, onderdeel van AD International, ontwikkelt, produceert en levert al meer dan 40 jaar een breed scala aan producten voor de chemische oppervlaktebehandeling van metalen. Deze producten kunnen gebruikt worden in uiteenlopende procestoepassingen. Chemisch voorbehandelen is een essentiële stap in onder andere het poedercoat, natlak en anodisatieproces.

AD Chemicals heeft productlijnen voor de substraten aluminium, verzinkt staal, staal en multimetal.

Chemische voorbehandelingen moeten voldoen aan complexe en kritische eisen en zijn vaak specifiek afgestemd op het eindproduct en bijbehorend substraat. Om die reden heeft AD Chemicals intensieve partnerships met haar klanten. Die kunnen vertrouwen op technisch hoogstaand advies en uitgebreide test en ontwikkelfaciliteiten.

AD Chemicals heeft meer dan 15 jaar ervaring in chroom (VI) vrije chemie en is daarmee trendsetter in de markt. Door uitgebreide praktijktesten en een continue focus op procesverbetering zijn robuuste voorbehandelingssystemen ontstaan die een geduchte concurrent vormen voor chroom (VI) houdende processen. De weerstand tegen corrosie en de hechtingseigenschappen voor het laksysteem zijn 1 op 1 vergelijkbaar met chromaathoudende systemen.

Kwaliteit is een gemeenschappelijke drijfveer voor AD en haar klanten. AD Chemicals producten voldoen dan ook aan of overtreffen huidige marktstandaarden zoals Qualicoat, Qualisteelcoat, GSB, Qualanod en MIL. AD is een partner die meedenkt en waarde toevoegt in uw processen.

• Informatie: www.adinternationalbv.com | contact@adinternationalbv.com

• Contactpersoon: Mr. Roland van Meer | +31 167 526971 | r.vanmeer@adinternationalbv.com

ZINKINFO GALVANIZING AWARDS 2025

We were proud to announce the launch of the ZinkInfo Galvanizing Awards 2025 in October 2024. This renowned architectural competition, formerly known as the Benelux Trophy for Hot-dip Galvanizing, has a revamped name and appearance.

Five categories

The competition once again provides a stage for inspiring projects in which hot-dip galvanized steel plays a central role. This year, there are five categories:

- Buildings

- Infrastructure, Mobility & Public Space

- Characteristic steel elements

- Duplex

- Circular construction (focus on demountable and reusable steel components, designed with circularity in mind)

Visibility for projects

All submitted projects will be bundled in a beautiful book that will be widely distributed to clients, architects, engineering offices, steel builders and contractors. In addition, the projects receive extensive attention via our social media channels and our website.

Independent jury

An expert, independent jury evaluates the entries and selects the nominees and laureates. The winners will receive the eagerly awaited ZinkInfo Galvanizing Awards 2025.

TECHNOLOGY & KNOWLEDGE TRANSFER

TECHNICAL COMMITTEE

Whereas last year we reported the departure of Jelle Elbers, we are now pleased to welcome him back to a new role. From 2025, Jelle will chair the Technical Committee.

This year’s three meetings were well attended and content strong. The first meeting took place at Johan Coolen of WeCoat in Stramproy and was largely dedicated to the members’ course on standards and aesthetic galvanisation. Although a lot of valuable input was gathered, unfortunately it has not yet been possible to work everything out in full. This process will take final shape in 2025. Johan Jongeneel also provided an informative update on hybrid furnace systems and current experiences with them.

In June, we were guests at Rotocoat Dieren, where we discussed current topics such as ARIE 2023, BAT, filter dust processing and the guiderail.

The third meeting took place at ZINQ Pelt and focused on automation and robotisation, a current and important topic. After a short presentation, a lively discussion ensued on the possibilities and preconditions for robotisation in our industry. The conclusion was that robotisation is technically possible, but often a lengthy, complex and costly process. It is especially suitable for work of a repetitive nature. At the same time, it emphasised the importance of nurturing our employees on the production floor, as they are invaluable to our industry.

Would you like to be kept informed about the activities of the Technical Committee, but does your company not yet participate? Let us know so that we can add you to the mailing list for the minutes. You are also welcome to attend a meeting. Please feel free to contact us.

Helpdesk

For the second year in a row, we have seen an increase in the number of questions received by our Helpdesk. Many of these questions concern the corrosion resistance of the galvanised coating, specifically in certain applications or geographical areas. Although the increase last year was around 16%, this year it has decreased slightly to 11%.

What is striking is that the sharp increase in enquiries from contractors and construction companies, which was visible last year, has now returned to its previous level. At the same time, we notice that our members are contacting us more and more often. Could this be due to the fact that more employees know how to find their way to ZIB?

In addition, there is a growing need for information on standards and specifications. These questions come mainly from our members, who contact us more often for these kinds of topics.

PARTNER SINDS 2017

GIMECO is an Italian family company that has been designing, building, installing and renovating hotdip galvanised installations since 1976. The foundation on which we build the future of our company and that of our successful customers is innovation. We have a habit of listening to our partners in detail and together coming up with the perfect solution that far exceeds initial expectations.

In 45 years of experience, we have acquired a global know-how of the entire galvanisation process, having implemented more than 125 complete lines in over 40 countries.

ENGINEERING - CONFIGURATION - INSTALLATION

- Batch galvanising plants (steel constructions, poles, crash barriers, transmission masts, etc.)

- Automatic Tube Galvanising Plant

- Automatic centrifugal galvanizing plants (small parts, fittings, chains, bolts and nuts)

SERVICE

- Boiler management and inspection (boiler inspection device, pumping in and out, boiler replacement, furnace control)

- Rack and pinion station with variable heights and hoists

- Furnace technology (traditional to high speed, dual chamber system)

- Automation, software (Zephir, HerMes) and logistics

- Chemicals

- Renovation

- Energy policy

- Technical Assistance

GIMECO has two Business Units, ZINCO SERVICE (ZS) dedicated to providing exclusive boiler management services and CO.T.IMP.I. (Switzerland) specialising in the galvanisation, finishing and testing of pipes.

In addition to a network of agents, the international group includes:

GIMECO USA (United States) fully operational branch dedicated to the North American market ZINCO TECHNOLOGIES (Canada) special branch dedicated to boiler management RECYCLEAN SYSTEM (Sweden) supplier of special innovative chemicals for the galvanising process

Member of: AGA, EGGA, AIZ, HDGASA, ACSZ, ATEG, ILZDA, GALVAZINC, JGA, INDUSTRIEVERBAND FEUERVERZINKEN, GALVANIZER ASSOCIATION.

• Information: www.gimeco.com | sales@gimeco.it

• Contact: Mr. Johan Jongeneel | +31 6 5433 1796 | johanj@gimeco.it

MAIN QUESTIONERS

ADMINISTRATION

Database:

Zinkinfo maintains a database in Excel of all the contacts it comes into contact with: helpdesk, BTTV, examinations & inspections, trade fairs, meetings, project visits, etc. By the end of 2021, the database will contain over 4,500 unique contacts. It goes without saying that this is a particularly important tool for ZIB in strengthening its network.

ACCOUNTANCY

Zinkinfo does the daily bookkeeping itself through Asperion - Online bookkeeping: invoicing, booking purchase invoices, checking bank statements, making payment batches. Accountancy firm De Vries & Nell takes care of the payroll administration, VAT declarations and prepares the interim annual statements.

Varia

The general administration is also managed by Zinkinfo: genda management, mail traffic, organisation of meetings of ZIB working groups, sending out documentation, archives,

Website

New items are continually added to the Zinkinfo website in Dutch and French, e.g. all kinds of news items, press releases, ZinkInfo Galvanizing Awards, calendar, ZEKER ZINK magazine, etc. Monthly website statistics are tracked via Google Analytics and Leadinfo.

Visitor numbers have increased slightly in 2024 compared to 2023 figures. Remarkably, visits from countries outside the Benelux increased again.

The graphs on the next page show the number of visits in 2024, the number of visits per country and the percentage of visits per page.

HaTwee is a provider of a full range of powder coatings, especially tailored to industrial and architectural applications for both indoor and outdoor exposure. Coatings for single and double layer systems on galvanized and non-galvanized steel are the specialty of HaTwee. In addition to a wide choice of more than 400 standard stock products, they also offer solutions for customer-specific applications. The product quality is attuned to the customer’s needs and HaTwee actively thinks along with the application and process optimization. HaTwee also takes care of smaller customised work for its customers.

• Information: www.hatwee.be | info@hatwee.be

• Contact: Mr. Hans Hooyberg | +32 475 84.90.51 | hhooyberg@hatwee.be

New website and communication strategy

Zinkinfo engaged TRIMM in 2024 to design a new website and provide support in developing a well thought-out content and communication strategy. This initiative is essential to further strengthen our position as a knowledge partner in the galvanizing industry.

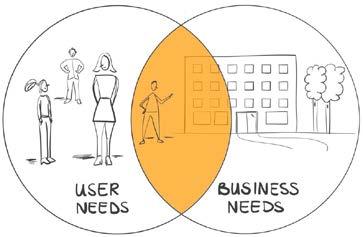

In an industry where professionals are looking for reliable knowledge partners for advice, it is crucial that ZinkInfo profiles itself as the expert and proves this through active online presence.

TRIMM will not only help us ensure that our content regularly reaches the right audiences through various channels, but will also contribute to strengthening our position as a leading thought leader in the industry among other things by publishing opinion pieces on topical issues such as sustainability and circularity.

The development of the new communication strategy is done in close consultation with ZIB’s Marketing Committee.

We look forward to the results of this cooperation and will keep you informed of progress.

VCD is supplier of all chemical products for surface treatment in the field of hot-dip galvanising, including degreasing and passivation of coatings.

VCD is a promoter of ecological solutions that meet the European REACH and ISO regulations. The processes are modern and designed in accordance with the regulations. They meet the current and future needs of the company’s customers.

VCD’s success depends on the answers to all the following challenges:

- understanding customer needs

- continuous investment in R&D

- developing flexible and available processes

- providing technical expertise through a team of professionals alert to market changes

- ensure continuous process control and optimisation

VCD has a know-how in surface preparation; one of the keys to a successful surface treatment.

VCD takes care of the training of its customers through intra- or extra-corporate training courses according to the number of participants. Areas of competence include the practice of analytical methods, surface treatment technology as well as process control and good practices.

VCD assists and advises its customers in the control of the galvanising processes as well as in the continuous improvement of these processes.

• Information: www.vcd-floridienne.com | info@vcd-floridienne.com

• Contact: Mr. Jacques Maubert | +32 (0)476 42 34 30 |jacques.maubert@vcd-floridienne.com

Core ‘why’ message

Members

Key message Goal

Economic

We believe that everyone deserves a product they can trust a reliable, timeless solution that stands the test of time Our mission is to build a secure future through galvanization We aren’t just creating products for today; we’re engineering solutions that will endure for generations to come

Awareness Consideration Commitment Advocacy

“Zinkinfo ensures your voice is heard in the future of galvanization by uniting the industry ”

Enhance member awareness of the role and benefits of Zinkinfo

“Your membership with Zinkinfo is essential in driving industry standards and innovation ”

Foster deeper engagement by showcasing the impact of member contributions

“Together, we ensure that galvanized steel is the backbone of sustainable infrastructure ”

Solidify member commitment to Zinkinfo s initiatives and strategy by ensuring member voices are heard and reflected in Zinkinfo’s actions

“Let's dream about tomorrow by creating a consistent and compelling vision that inspires together ”

Build a network of Zinkinfo ambassadors who actively drive industry awareness within the industry

influencer Awareness Consideration Commitment Advocacy

Key message Goal

Technical

“Galvanizing tomorrow s infrastructure ensure your projects maximize ROI and stand the test of time ”

Raise awareness of the economic benefits of galvanized steel among key decision-makers, and establish it as a financially sound choice

“Galvanized steel offers unmatched ROI through durability and low maintenance ”

Encourage economic influencers to consider galvanized steel in their financial planning by highlighting the costsaving potential

“Secure reliable and financially sound construction solutions by partnering with Zinkinfo ”

Secure decisions from economic influencers to adopt galvanized steel for their upcoming and ongoing projects

“Drive the advancement of sustainable, economically efficient infrastructure by advocating for galvanized steel "

Transform economic influencers into advocates who promote galvanized steel within their networks

influencer Awareness Consideration Commitment Advocacy

Key message Goal

User influencer

Key message Goal

“Maximize durability and ensure safety with galvanized steel in your innovative solutions ”

Build initial awareness of the technical benefits of galvanization among key technical influencers

“Back your designs with the proven durability of galvanized steel ”

Provide technical influencers with the resources they need to consider and advocate for galvanized steel in their projects

“Ensure your projects meet the highest standards with Zinkinfo’s expertise ”

Encourage technical influencers to commit to using galvanized steel by ensuring they have the support and resources needed to do so

“Lead the industry in sustainable design with galvanized solutions ”

Position technical influencers as advocates within their professional communities by spreading the benefits more widely

“Ensuring project success with durable, trustworthy and maintenance-free galvanized steel ”

Increase awareness among end-users by positioning galvanized steel as the preferred, maintenance-free choice

“Galvanized steel is the best choice for your needs - Learn how using galvanized steel delivers value and reliability ”

Persuade end-users of the practical advantages of choosing galvanized steel and overcome any misconceptions

“Commit to quality, reliability and practicality with galvanized steel ”

Secure user commitment to specifying and using galvanized steel in their projects Reinforce the trust and reliability

"Empower the future of construction by showcasing the strengths of galvanized steel ”

Encourage end-users to become advocates for galvanized steel within their networks by building a community of satisfied customers

LOBBYING EGGA

EGGA meetings are held twice a year and bring EGGA’s European members together to discuss topical issues and support each other where possible. Within EGGA, there are three committees, namely Environmental & Safety, Technical & Research and Marketing. The Board also meets twice a year.

BOARD

It is customary for the board member from the host country of Intergalva (in 2024 it was Belgium) to be appointed president of EGGA. Therefore, Norbert Beljaars is now the new president, until June 2026.

The EGGA board gave its agreement in 2024 to recruit a lobbyist who will focus particularly on the European Institutions. As the new EU policy director, Tobias Schäfer brings extensive experience in working with the EU institutions. Also in the field of industrial policy, he will ensure that the voice of the European galvanising industry is even better heard in Brussels.

Tobias Schäfer comes over from WV Metalle, the German trade association for the non-ferrous metal industry. Tobias’ recruitment has led to a reshuffling of tasks within the EGGA organisation.

MARKETING

Items covered during the EGGA Marketing meetings included:

EGGA Statistical Report 2022

- Sustainability: developments for product policy

- Sustainability: communication

- EGGA EPD and PCR update

- SCI Steel ReUse Project & LCA comparisons with paint

- National updates and communication

- Competition with other materials:

- ZM Steels

- Weathering steels

- Hot-dip galvanised reinforcing steel

- Global Galvanizing Awards 2024

In October, EGGA announced a close collaboration with ECCS (The European Association representing the interests of steel builders) around the promotion of hot-dip galvanising in bridge construction, more specifically for bridges with small or medium spans. A working group will identify best practices in design and modular concepts. In addition, topics such as durability, reuse and corrosion specifications will be addressed.

TECHNICAL & RESEARCH

This year, EGGA took an important step by entering into a partnership with CEN. This offers our industry influence on the adaptation of standards related to ecological aspects, such as sustainability, innovation and legislation.

Under the new Construction Products Regulation (CPR), manufacturers will be required to provide environmental data. This will lead to adjustments in existing standards, with some standards possibly disappearing or being renumbered. A key focus of this new regulation is the integration of ‘service life’ as a feature within the standards. This will require a minimum service life of 50 years, with the possibility of extension at product level.

On the standards front, progress has been made. For instance, the new EN 1090-2:2018+A1:2024 has been published, which further tightens technical requirements for steel products. This includes extension of highstrength steels (HSS) to higher grades. These changes have an impact on EN-ISO 14713-2, which will soon be revised. In the process, the word ‘guidelines’ in the title will be replaced by ‘requirements’. This emphasises that full galvanisation according to EN-ISO 1461 is highly dependent on design and construction details.

In addition, EN 1090-201 was recently published, a standard focused on the reuse of structural steel. This standard is similar in content to the Dutch NTA 8713 and will boost the circularity of hot-dip galvanised steel.

There are also developments in the field of fire resistance. In the new Eurocode, the use of hot-dip galvanised steel gives no advantage for main structures, but does for attachments.

Finally, progress has been made within the standards series EN-ISO 12944 (paints and varnishes). Part 9, which covered offshore wind turbines, has been integrated into parts 5 and 6. Offshore-specific guidelines are now housed in a separate series of technical specifications (ISO/NP 25249 series). Within this working group, a collaboration between ISO TC 35 and ISO TC 107, EGGA remains actively involved to represent the interests of our industry.

ENVIRONMENTAL & SAFETY

EGGA heeft haar laatste commissiebijeenkomst van het jaar gehouden in Kopenhagen. Tijdens deze bijeenkomst stonden twee belangrijke thema’s centraal: de invoering van de FMP BREF en de herziening van de *European Industrial Emissions Directive* (EID).

Het traject voor het vaststellen van nieuwe Beste Beschikbare Technieken (BBT) is inmiddels afgerond. De aandacht verschuift nu naar de manier waarop bevoegde autoriteiten de BBT-conclusies gaan toepassen binnen de verzinkerijen. Tot nu toe heeft alleen Wallonië stappen gezet in dit proces, terwijl Vlaanderen en Nederland nog wachten met implementatie. Het waarborgen van een gelijk speelveld binnen de sector blijft daarbij een belangrijk aandachtspunt.

De herziening van de EID is het volgende grote Europese project. De verwachting is dat de emissie-eisen verder zullen worden aangescherpt. Het goede nieuws is echter dat onze sector voorlopig nog niet direct geraakt wordt, aangezien de BREF voor onze industrie onlangs is herzien. Bij de volgende herziening zullen de effecten merkbaar worden, maar tegen die tijd kunnen we leren van de ervaringen die andere sectoren hebben opgedaan met de vernieuwde EID.

EGGA ANNUAL STATISTICAL REPORT

The EGGA Annual Statistical Report 2023 contains information on 24 European countries. This information is collected for EGGA by the national associations.

Benelux share of European production in 2023

Membership of the branch organisations in 2022-2023

INTERGALVA BRUGES 9-14 JUIN 2024

If you were one of the 691 participants and exhibition staff from 56 countries who attended Intergalva 2024 in Bruges from 10-14 June, EGGA and ZinkInfo Benelux hope you had a great time, learned new things and expanded your personal network in the international galvanising community.

The conference programme demonstrated the value of galvanising steel for the circular economy’s goals of achieving net zero. The industry’s own efforts to decarbonise and improve efficiency also took centre stage.

The inherent sustainability, recyclability and po -

tential for reuse of hot-dip galvanised steel within the circular economy was at the forefront of the conference programme - this was perfectly highlighted by Marjan Poortinga, Senior Advisor Circular Economy, Rijkswaterstaat - Ministry of Infrastructure and Water Management, the Netherlands, who explained the commitment of the Dutch authorities to ensure the reuse and galvanisation of motorway crash barriers.

Keynote speakers including Rene Branders (president of the Belgian trade association VBO-FEB); Michel Vermaerke (president advisory board Impact Finance Belgium) and Olivier Vassart (World Steel) set the tone with excellent perspectives on policy and financial frameworks for decarbonisation strategies for the industry. Leading suppliers of furnaces and other process technologies reported extensively on the progress of the galvanising industry’s decarbonisation challenge. These and other topics were also explored in small master classes alongside the plenary sessions.

The remarkable uses of galvanising in architecture and engineering applications were recognised in the 2024 Global Galvanising Awards, which were presented along with the conference at the Intergalva 2024 Conference Dinner at nearby Lauretum, sponsored by Ani Metal and Atunkimya.

Participants thoroughly enjoyed the welcome party, sponsored by Rezinal, held in a real party atmosphere around the Pilling Bar in the Intergalva 2024 exhibition space, created by Belgian group Domino.

The Intergalva exhibition floor was once again the focal point of the event, where all catering for the event took place and where people could network. 41 exhibiting companies invested in some highly innovative and informative displays of equipment, process technology and materials - combined with the usual conviviality and hospitality on the stands and around the traditional ‘W Pilling Bar’.

A big Intergalva thank you goes to the members of ZinkInfo Benelux who opened the doors of their galvanizing plants at the end of the week to allow more than 300 delegates to visit the facilities. The organisation of the visits and the explanations given were much appreciated. Next appointment: Intergalva 2027 in Spain!

PARTNER SINDS 2019

Flaurea Chemicals has held a patent since 1921 and has developed flux salts for hot-dip galvanising that provide effective protection against corrosion.

Following the closure of Floridienne Chimie in 2014, Flaurea Chemicals has resumed production of flux salts (Florflux), zinc chloride and cadmium salts.

Flaurea Chemicals offers its customers both its know-how and a wide range of products, ranging from ammoniacal zinc chloride (basic double salt) and a wide range of special fluxes (Florflux®) to zinc chloride adapted to each specific need or process.

Hot-dip galvanising is an industrial process with a bright future ahead of it.

In the building sector, it significantly extends the life of metal structures and simplifies their maintenance. For urban and agricultural furniture and certain automotive parts, hot-dip galvanising remains one of the most effective and economical ways of combating corrosion.

- Flaurea Chemicals offers its customers regular flux bath analysis and provides a high level of technical advice.

- Flaurea Chemicals is an important player in the circular economy and has adapted its production processes in such a way that used dezincification baths are not destroyed or thrown away at the end of their life but are instead used as raw materials. They are one of the few flux and zinc chloride producers in Europe that recycle de-zincing baths.

Packaging

- Flux salts in powder form are available in 25 kg bags.

- Liquid fluxes are available in IBCs or tankers.

- Zinc chloride powder in 25k bags and liquid in several concentrations in bulk or IBC.

Flaurea Chemicals actively participates in international studies on the development of new processes with zinc alloys.

• Information: www.flaureachemicals.com

• Contact: Mr. Christophe Laubignat | +33787143378 | Christophe.Laubignat@flaureachemicals.com

DBM

Our participation in Stichting Duurzaam Bouwmetaal (DBM) has paid off this year. Thanks to the commitment of new, active members in the group, much has already been achieved, including the development of new content and a completely revamped website.

With Martin van Leeuwen of the International Zinc Association, we have the right person in the right place. His extensive knowledge of zinc, legislation and lobbying activities makes him a valuable

lynchpin in our cooperation. He is increasingly approached on issues such as refused building permits and also takes action personally.

Therefore, a call to all members: make sure your sales teams are well informed about DBM’s activities. Confidently refer customers to this foundation - they are in good hands!

Circular Construction

Steel construction agreement

The links of the Dutch steel construction chain have joined forces to make steel in construction more sustainable. Their collective vision and ambitions are laid down in the Steel Building Accord. ZIB has been a leader within the BAS since its inception and follows up on the necessary meetings and working groups.

All info on the BAS and the roadmap can be found here: https://bouwakkoordstaal.nl

In Belgium, progress on the Steel Building Accord is at a standstill for the time being. This is mainly due to a lack of resources at Infosteel to ‘pull’ the file. The aim is to make a new start in 2025 by publishing a document (guidance) on all sustainability aspects of steel, in combination with a study day for the sector. Zinkinfo will be closely involved in the further development through its presence in the working group.

STANDARDS & REGULATIONS

The merger of the Dutch NEN Committees 342107 and 342035 has created good and fruitful dynamics in practice. This merger offers the opportunity to develop a strong network of professionals who can influence other surface treatment techniques as well as national authorities.

Meanwhile, Jelle has been signed up as an observer within this committee, alongside Hans, who previously held this role. In addition, Guus is still active as chairman and member of the committee. Guus’ activities and work for ZIB will conclude in 2025.

Regarding standards, it is crucial to continue paying attention to a selection of current changes and new standards relevant to our industry. Monitoring these developments remains essential to maintaining our position and influence.

ISO 9225

ISO FDIS 16701

ISO 11474

ISO CD 16364

ISO/CD TR 22861.2

ISO DIS 23225

Corrosion of metals and alloys -- Corrosivity of atmospheres -Measurement of environmental parameters affecting corrosivity of atmospheres (ISO/TC 156 WG4)

Corrosion of metals and alloys -- Corrosion in artificial atmosphere -- Accelerated corrosion test involving exposure under controlled conditions of humidity cycling and intermittent spraying of a salt solution - Secure clear warnings on limitations of accelerated testing/ salt spray are kept and improved - New test cycle at constant dew point introduced (modification of ACT1)

Corrosion of metals and alloys — Corrosion tests in artificial atmosphere — Accelerated outdoor test by intermittent spraying of a salt solution (Scab test)

Corrosion of Metals and Alloys - Guidelines for Galvanic Corrosion Control

Corrosion of metals and alloys—Guidelines of marine environment zonation for the corrosion of embedded steel reinforcement in concrete

Corrosion control engineering life cycle in nuclear power plants — General requirements’

ISO DIS 16674

ISO/PWI 25249 -1 to -5

ISO AWI 14713-2

ISO DIS 24251-1

ISO DIS 8501-3

EN 13438:2013

EN 1090

ISO FDIS 8353

ISO 10684:2004

EN 1994-1-2

ISO 59004

ISO 59020

ISO/CD TR 59031

ISO/TR 59032

ISO/FDIS 59040

Corrosion Control Engineering Life Cycle of Power Transmission and Transformation System- General Requirements

Corrosion protection of offshore wind structures Part 1: Design considerations Part 2: Primary steel components – General requirements for thermal spraying and painting Part 3: Primary steel components - Supplementary requirements for foundations Part 4: Primary steel components - Supplementary requirements for towers Part 5: Supplementary requirements for primary structural steel- and cast components for rotor nacelle assembly (ISO/TC107/JWG 6)

Zinc coatings – Guidelines and recommendations for the protection against corrosion of iron and steel in structures – Part 2: Hot dip galvanizing (ISO/TS 107 SC4)

Prevention of hydrogen assisted brittle fracture of high-strength steel components— Part 1: Fundamentals and measure

Preparation of steel substrates before application of paints and related products – Visual assessment of surface cleanliness – Part 3: Preparation grades of welds, edges and other areas with surface imperfections (ISO TC 35 SC 12)

Paints and varnishes – Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes (CEN TC 139 WG8)

series of standards FPC certification and CE Marking of steel products/ fabrications (CEN/TC 135)

Steel sheet, zinc-aluminium- magnesium alloy-coated by the continuous hot-dip process, of commercial, drawing and structural qualities (ISO TC 17 SC 12)

Fasteners – Hot dip galvanized coatings

Eurocode 4 - Design of composite steel and concrete structures - Part 1-2: Structural fire design (ISO/TC 250 SC4)

Circular economy — Vocabulary, principles and guidance for implementation

Circular economy — Measuring and assessing circularity performance

Circular economy – Performance-based approach – Analysis of cases studies

Circular economy — Review of existing value networks

Circular economy — Product circularity data sheet (ISO TC 323)

PARTNER SINDS 2020

Trafigura is one of the world’s leading independent commodity trading groups and one of the largest participants in the global zinc market, with over 1.5 million tonnes of zinc concentrates and 1.4 million tonnes of refined zinc in 2019.

Trafigura’s trading activities are supported by its industrial and financial assets, including a majority stake in global multi-metals company Nyrstar, which has a market-leading position in zinc and lead. Nyrstar has mining, smelting and other operations in Europe, the Americas and Australia.

Nyrstar produces zinc concentrates from its mining operations and a variety of refined zinc products, including special high grade zinc (SHG), zinc alloys and zinc cast alloys resulting from the zinc smelting process.

Combining Nyrstar’s footprint of manufacturing with Trafigura’s global marketing, logistics network and financial expertise provides significant opportunities in today’s zinc market. The two companies combine best market practice and high standards of responsibility in their respective fields, as well as reliability and responsiveness to customers.

The Trafigura Group is a privately held company with 8,000 employees working in 80 offices in 41 countries worldwide. For more than two decades, the Group has connected its customers to the world economy and increased prosperity by promoting trade.

• Information: www.trafigura.com

• Contact: Mr. Jan Philip Fiedler | +41 22 592 3734 | Janphilip.Fiedler@trafigura.com

TESTS & INSPECTIONS

Outcomes inspections 2024 and plans for 2025

This year’s results confirm the trends of previous years. Although the number of inspections is more than half that of last year, it is still limited to occasional cases. This situation can be explained by several factors:

1. Accessibility of technical support: Many questions are handled via the Helpdesk using photo material and e-mails, which often makes a site visit unnecessary.

2. Cost of inspections: Fees for inspections have doubled compared to previous years, deterring customers.

3. Proactive approach to members: Members often see complaints as an opportunity to engage with customers and solve problems themselves.

4. Uniform warranty conditions: Inspections are no longer required to provide warranties of more than 10 years.

5. Inspections abroad: These are only carried out at the request of a member.

6. Selective approach: Requests for inspections of galvanisation from abroad in the Benelux will be honoured with restraint.

7. Owners’ associations (VvEs): Requests from

VvEs about failing duplex coatings over time are usually not honoured, unless it concerns a new delivery.

A total of 10 inspections were carried out this year, of which only 1 was for Belgian members. Interestingly, 6 of the inspections were related to duplex coatings, and one inspection concerned only powder coating of steel.

Plans for 2025

In order to increase the number of inspections in 2025, the following measures have been taken:

1. Price reduction: the cost of inspections will be reduced for customers of our members and other relevant parties, such as major contractors and governments.

2. Less selective policy: We will be less strict in terms of conditions for inspections and more likely to accept requests.

3. More personal approach: More emphasis will be placed on site visits instead of handling discussions by e-mail.

These adjustments aim to further increase the accessibility and added value of our inspections.