FIND OUT HOW INSIDE

Follow along @Windpower_Eng

Looking for more ways to connect?

Connect with Industry Experts covering everything in wind energy from turbine design to installation to maintenance.

PUBLISHER

Courtney Nagle cseel@wtwhmedia.com 440.523.1685

EDITORIAL

Editorial Director, Renewables Kelly Pickerel kpickerel@wtwhmedia.com

Senior Editor Billy Ludt bludt@wtwhmedia.com

CREATIVE SERVICES & PRINT PRODUCTION

VP of Creative Services Mark Rook mrook@wtwhmedia.com

Senior Art Director Matthew Claney mclaney@wtwhmedia.com

Senior Graphic Designer Allison Washko awashko@wtwhmedia.com

Graphic Designer Mariel Evans mevans@wtwhmedia.com

Director, Audience Development

Bruce Sprague bsprague@wtwhmedia.com

WTWH Media, LLC

1111 Superior Avenue, Suite 2600, Cleveland, OH 44114

Ph: 888.543.2447

Fax: 888.543.2447

VIDEO SERVICES

Videographer Manager Bradley Voyten bvoyten@wtwhmedia.com

Videographer Garrett McCafferty gmcca erty@wtwhmedia.com

Videographer Kara Singleton ksingleton@wtwhmedia.com

MARKETING

VP of Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Digital Marketing Coordinator Emily Gillespie egillespie@wtwhmedia.com

Digital Production/ Marketing Designer Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Webinar Coordinator Halle Sibly hkirsh@wtwhmedia.com

Webinar Coordinator Kim Dorsey kdorsey@wtwhmedia.com

ONLINE DEVELOPMENT & PRODUCTION

Web Development Manager

B. David Miyares dmiyares@wtwhmedia.com

Digital Media Manager Patrick Curran pcurran@wtwhmedia.com

Digital Production Manager

Reggie Hall rhall@wtwhmedia.com

Front End Developer Melissa Annand mannand@wtwhmedia.com

Digital Production Specialist Nicole Lender nlender@wtwhmedia.com

Digital Production Specialist

Elise Ondak eondak@wtwhmedia.com

IN-PERSON EVENTS

Events Manager

Jennifer Kolasky jkolasky@wtwhmedia.com

Events Manager

Brittany Belko bbelko@wtwhmedia.com

Event Marketing Specialist Olivia Zemanek ozemanek@wtwhmedia.com

CUSTOMER SERVICE

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service

Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service

Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

WINDPOWER ENGINEERING & DEVELOPMENT does not pass judgment on subjects of controversy nor enter into disputes with or between any individuals or organizations.

WINDPOWER ENGINEERING & DEVELOPMENT is also an independent forum for the expression of opinions relevant to industry issues. Letters to the editor and by-lined articles express the views of the author and not necessarily of the publisher or publication. Every e ort is made to provide accurate information. However, the publisher assumes no responsibility for accuracy of submitted advertising and editorial information. Non-commissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care.

WINDPOWER ENGINEERING & DEVELOPMENT does not endorse any products, programs, or services of advertisers or editorial contributors. Copyright© 2023 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval systems, without written permission from the publisher.

SUBSCRIPTION RATES: Free and controlled circulation to qualified subscribers. Non-qualified persons may subscribe at the following rates: U.S. and possessions, 1 year: $125; 2 years: $200; 3 years $275; Canadian and foreign, 1 year: $195; only U.S. funds are accepted. Single copies $15. Subscriptions are prepaid by check or money orders only.

SUBSCRIBER SERVICES: To order a subscription or change your address, please email: please visit our web site at www.windpowerengineering.com

WINDPOWER ENGINEERING & DEVELOPMENT (ISSN 2163-0593) is published four times per year in February, May, September and a special issue in December by WTWH Media, LLC, 1111 Superior Avenue, Suite 2600, Cleveland, OH 44114. Periodicals postage paid at Cleveland, OH and additional mailing o ces.

POSTMASTER: Send address changes to: Windpower Engineering & Development, 1111 Superior Avenue, Suite 2600, Cleveland, OH 44114

WINDPOWER ENGINEERING & DEVELOPMENT 2 FEBRUARY 2023 www.windpowerengineering.com 2011 - 2021 2014 Winner 2014 - 2016 2013 - 2017 asbpe.org BRONZE REGIONAL AWARD 2022

INSIDE

CONTRIBUTORS

WINDWATCH

A selection of product and policy news from our website.

WIND WORK AROUND THE UNITED STATES

On- and offshore wind project announcements from across the country.

FIND US ONLINE

COVER STORY

Wind energy operators must address these 5 key areas to exploit the full value of monitoring

Wind asset operation is a fast-moving space encompassing a variety of complex data-analytical needs. To ensure that condition monitoring continues to deliver optimal value, operators must act now to scrutinize their monitoring strategies. Cover image: GE

Three reasons why digitalization of wind farms is reshaping green

energy

Reliable, broadband wireless networks with data, video and voice capabilities enable new applications and capabilities for far-slung wind project portfolios.

Competency is just as important when building the offshore wind workforce

Competence comes from on-thejob experience and the skills and knowledge gained as result. It is not something that can be gained through training alone.

LEADERSHIP PAGE 26 WINDPOWERENGINEERING.COM

Can we power offshore support vessels with renewable energy?

Demand for OSVs is growing. Vessels need to be fully digitized and highly automated to tie into their supporting tech-enabled ecosystems. Hybrid setups can help.

IN WIND POWER 2023

Celebrating the companies and individuals leading the wind power industry. Vote online through October.

WINDPOWER ENGINEERING & DEVELOPMENT 3 FEBRUARY 2023 www.windpowerengineering.com

See the latest wind power developments and U.S. project news as well as expert webinars and more on our website today.

12 04 12 16 20 05 07 20 08 16

CONTRIBUTORS

WINDPOWER ENGINEERING & DEVELOPMENT

EVGENIA GOLYSHEVA is VP of strategy and operations for ONYX Insight. She has been supporting wind farm owners for over 10 years, focusing on using data to increase the efficiency of wind farm operation, improve asset reliability, and de-risk major maintenance activities. As VP of Strategy and Operations at ONYX Insight, Evgenia looks at changes in the renewables sector driven by global energy transformation, analyzes challenges faced by industry players, and supports ONYX in defining future-proof technology solutions for renewables owner-operators worldwide.

WEI HUANG is director and global offshore market sector lead of offshore support vessels at ABS. In 1998, Dr. Huang joined ABS in the engineering department providing engineering plan review and approval. She has participated in research and Rule development for marine and offshore structures with the ABS Europe Division in London, and the ABS Americas Division, ABS Corporate Technology and ABS Global Offshore in Houston. In her current role as Offshore Support Vessel Market Sector Lead, Wei provides strategic insight and direction on changing market conditions that drive client initiatives and programs within the global offshore support vessel sector with a focus on wind farm installation and service vessels, especially in the United States.

WAYNE MULHALL is managing director of James Fisher Renewables. Wayne has significant experience in the offshore wind industry, having held a senior role at MHI Vestas Offshore Wind and prior to this, senior positions at Siemens Gamesa and Rolls Royce. He led the successful delivery of the UK’s first 8-MW turbines at Burbo Bank, and has experience of subsea, topside and onshore balance of plant. Moreover, he worked for two of the largest turbine OEM’s in the world, and managed operations in UK, Benelux, Japan, Taiwan and the United States, offering an international perspective that spans the supply chain.

DOMINIQUE VERHULST currently heads up the global energy practice at Nokia. Leveraging Nokia’s full portfolio of fixed, mobile, IP and optical, applications and analytics and professional services products including Bell-Labs consultancy, Dominique and his team provide complete end to end solutions to utilities, oil & gas and mining companies. He is the author of the “Teleprotection over Packet Networks” e-book available on the iTunes bookstore, and co-author of several publications from the University of Strathclyde. He has over 30 years of experience in the telecommunications networking industry, holding senior sales and marketing positions at Nokia, Alcatel-Lucent, Newbridge Networks, Ungermann-Bass and Motorola.

WINDPOWER ENGINEERING & DEVELOPMENT 4 FEBRUARY 2023 www.windpowerengineering.com

FEBRUARY 2023

EVGENIA GOLYSHEVA WAYNE MULHALL

WEI HUANG

DOMINIQUE VERHULST

WIND WATCH

Burns & McDonnell and Bay Ltd. will build substations for offshore wind projects

Burns & McDonnell and Bay Ltd. are partnering to provide American engineering, procurement, fabrication and construction of offshore substations. The engineering will be led from Burns & McDonnell offices in the Northeast, and the fabrication and construction will take place in existing Bay Ltd. facilities in Corpus Christi, Texas. Bringing U.S. designed and fabricated offshore

substations to market will strengthen the U.S. offshore wind supply chain.

“It’s critical to build up local offshore wind industry-specific capabilities for both engineering and manufacturing, which currently primarily exist in Europe, and we’re excited to support that knowledge transfer,” said Ray Kowalik, President and CEO of Burns & McDonnell.

WINDPOWER

& DEVELOPMENT 5 FEBRUARY 2023

ENGINEERING

WINDPOWER ENGINEERING & DEVELOPMENT FEBRUARY 2023 WHAT’S

NEW

Burns & McDonnell

WIND WATCH

WHAT’S NEW | CONTINUED

California coastal lease sale could result in 4.6 GW of offshore wind

BOEM recently conducted an auction for five offshore wind project leases off the coast of California. The first offshore lease sale for the Pacific region drew bids from five companies, totaling $757.1 million, accounting for 373,268 acres off central and northern California with the potential to produce 4.6 GW of offshore wind energy. The winning companies were RWE Offshore Wind Holdings, California North Floating, Equinor Wind US, Central Offshore California Wind and Invenergy California Offshore.

BOEM proposes new rules to streamline offshore wind development

BOEM proposed updates to regulations for clean energy development on the U.S. Outer Continental Shelf in January. If enacted, the proposed rules would modernize regulations, streamline complex processes, clarify ambiguous provisions and enhance compliance provisions to decrease costs and uncertainty associated with deploying offshore wind facilities, ultimately saving developers $1 billion over a 20-year period.

DOE awards $3 million for small-scale wind R&D

NREL awarded $2.9 million to 11 manufacturers of small- and medium-scale wind turbines in December. The goal is to mitigate market and regulatory barriers to deploying distributed wind turbines for small-scale customers, like homeowners, farmers, businesses and others under DOE’s Competitiveness Improvement Project.

Biden Administration sets installation goal for floating offshore wind

The Biden-Harris Administration set a new goal of deploying 15 GW of floating offshore wind projects by 2035, in addition to its initial goal of deploying 30 GW of offshore wind by 2030. Two-thirds of the United States’ offshore wind potential resides in deeper waters where conventional offshore platforms could not feasibly be secured to the sea floor. The administration will advance lease areas in deep waters to meet its new floating offshore wind goal.

New Jersey approves country’s first offshore wind transmission project

The New Jersey Board of Public Utilities selected the Larrabee Tri-Collector Solution project proposed by Mid-Atlantic Offshore Development and Jersey Central Power & Light to build the first offshore wind transmission project in the United States. Onshore grid upgrades will be made to accept offshore transmissions from the Larrabee Tri-Collector project and distributed to seven Northeast utilities.

Siemens Gamesa releases

7-MW

turbine platform

Siemens Gamesa has released an offshore wind turbine in its 5.X platform with a rated power of 7 MW. The SG 6.6-170 has upgraded to the SG 7-170 and is built to be deployed in medium- to high-wind sites globally. Additionally, Siemens Gamesa started a blade recycling program for onshore wind projects using its turbines.

WINDPOWER ENGINEERING & DEVELOPMENT 6 FEBRUARY 2023 www.windpowerengineering.com

WANT MORE NEWS? VISIT US AT WWW.WINDPOWERENGINEERING.COM/CATEGORY/NEWS

WIND WORK AROUND THE UNITED STATES

A selection of recently completed wind projects.

Duke Energy completes its first Iowa wind project

Iowa

Duke Energy Sustainable Solutions brought its 207-MW Ledyard Windpower project in Kossuth County, Iowa, to commercial operation in January. Verizon Communications has signed a 15-year virtual PPA for 180 MW of the power from Ledyard. This was Duke’s first wind project in Iowa, generating enough electricity to power 75,000 U.S. homes.

Western Hemisphere’s largest wind project approved for construction

New Mexico

The New Mexico Public Regulatory Commission has approved Pattern Energy Group’s proposed 3.5-GW SunZia Wind project, which is slated to start construction soon in Torrance, Lincoln and San Miguel counties, making it the largest wind project in the Western Hemisphere.

Engie North America starts building

200-MW project

South Dakota

Engie North America’s 200-MW North Bend Wind project is expected to be completed in late 2023. Basin Electric Power Cooperative signed a 25-year PPA on the project, which will support its generation needs for its 131 electric cooperative members located across nine states. North Bend will be composed of 71 turbines built across 47,000 acres of land.

Coastal Virginia Offshore Wind project gets closer to construction

Virginia

BOEM closed a public comment period on the Coastal Virginia Offshore Wind project’s Environmental Impact Study on Feb. 14. The draft contained studies, evaluations and designs meant to reduce environmental impacts and increase environmental benefits for the 2.6-GW offshore project.

Third Headwaters project now under development

Indiana

Indiana

EDP Renewables North America is Headwaters portfolio. The 200-MW

reach commercial operation in 2025. Cleveland-Cliffs, a flat-rolled steel MW.

EDP Renewables North America is developing the third project in its Headwaters portfolio. The 200-MW Headwaters III wind farm in Randolph County, Indiana, is expected to reach commercial operation in 2025. Cleveland-Cliffs, a flat-rolled steel company, signed a 15-year PPA for 180 MW.

Indiana utility signs PPA on 200-MW wind project

Indiana

EDP Renewables North America started construction at the 202-MW Indiana Crossroads II Wind Farm in White County, Indiana. The project is expected to create 250 full-time jobs through construction. Northern Indiana Public Service Company has a PPA on Crossroads II, in addition to two other EDP wind projects in White County.

300-MW Illinois wind farm slated for completion in 2024

Illinois

Apex Clean Energy is developing the 300-MW Goose Creek Wind Farm in Piatt County, Illinois, which is expected to reach commercial operation in 2024. EV manufacturer Rivian signed a 50MW PPA on the project that started the permitting process in December.

Duke Energy

Duke Energy

WINDPOWER ENGINEERING & DEVELOPMENT 7 FEBRUARY 2023

full

value of

Wind energy operators must address these 5 key areas to exploit the full value of monitoring

BY EVGENIA GOLYSHEVA VP OF STRATEGY AND OPERATIONS • ONYX INSIGHT

BY EVGENIA GOLYSHEVA VP OF STRATEGY AND OPERATIONS • ONYX INSIGHT

8 FEBRUARY

& DEVELOPMENT 2023 www.windpowerengineering.com

industry rely on some form of condition monitoring system (CMS) to preserve the operational longevity and high performance of their assets. And it seems to be doing the trick — the implementation of such systems

in wind energy has been transformative.

Where installed, it has virtually eradicated catastrophic failures and made viable the remoteness inherent to offshore wind.

Alongside the adoption of predictive maintenance, this trend has already saved the global wind industry more than $550 million annually in potential lost revenue and lowered the levelized cost of energy (LCoE) by 1.5%, retaining its pull on investors despite rising costs elsewhere along the value chain.

But this is not enough if operators are to maximize the potential of the turbines in their portfolio and drive the energy transition in the most profitable way possible. A surfacelevel, tick-box style of

continued adherence to decisions made deployed adoption of sophisticated digitalization.

condition monitoring, as well as a continued adherence to decisions made years ago about the monitoring strategies and technologies deployed on wind farms today, are slowing the large-scale adoption of sophisticated digitalization. This slowdown risks exposing wind farm owners and operators to greater inflationary pressures.

space encompassing a variety of ever more complex financial, mechanical and data-analytical needs, and static longterm approaches do not gel with rapidly evolving business priorities and market conditions. To ensure that condition monitoring continues to deliver optimal value in such a dynamic environment, operators must act now to scrutinize their monitoring strategies during these five key project lifecycle events:

1. End of warranty

Wind asset operation is a fast-moving rapidly evolving life.

The end of warranty (EoW) period typically comes at two to five years into a project’s life. At this point, operators must make

their turbines post-warranty. Full scope service agreements, which are

(OEMs) of the turbines in question, have

understanding of best practices to

critical decisions about how to service their turbines post-warranty. Full scope service agreements, which are comprehensive packages arranged with the original equipment manufacturers (OEMs) of the turbines in question, have traditionally been viewed as a safe option by operators, due to the former’s assumed understanding of best practices to maintain their own technology.

their

However, EoW inspections conducted of coverage of turbine components, an asset’s level of

However, EoW inspections conducted in-house by operators typically do not provide the deep understanding of asset health necessary to negotiate the terms of these servicing packages successfully with OEMs. Inspections have a limited coverage of turbine components, and collecting two years of prior data to prove an asset’s level of

WINDPOWER ENGINEERING

& DEVELOPMENT 9 FEBRUARY 2023

performance — and estimate its remaining useful life — is difficult in the best of cases. OEMs will also tend to dismiss EoW claims as normal wear and tear, further obfuscating negotiations.

However, squeezed project margins and growing confidence in turbine technology have led more asset owners to consider alternatives, such as independent vibration-based CMS technologies, and implement them from Day 1. This enables operators to conduct more targeted EoW inspections, bring the most thorough data possible to the negotiating table and catch any looming maintenance issues along the way.

2. Operational stage

OEM service agreements might seem attractive due to short-term cost savings, but they can prove a false economy. OEMs and operations and maintenance (O&M) service providers may not be adequately incentivized to inform customers about impending failures in a timely manner, leading to much higher maintenance fees at the point of eventual breakdown.

Contrast this with third-party independent service providers (ISPs), who must consistently demonstrate value via digital oversight of faults to enable predictive maintenance. During the main operational stage, independent

condition monitoring is key for managing asset health. While some owners build in-house monitoring teams, others are increasingly looking to third-party providers with extensive track records and broader data pools. In either case, vibration-based condition monitoring is a proven tool for reducing major component failures.

3. Portfolio growth and diversification

The wind sector is growing fast, which means larger, more complex portfolios for most operators. Companies with portfolios over 1.5 GW are set to increase the capacity they own from 45% to 60% by 2030, with 60% of operators set to manage mixed portfolios of wind and solar assets by 2025.

However, larger global portfolios can overwhelm in-house data analysis teams, to the extent that in-house strategies cease to be cost-effective for large multi-brand portfolios. Partnering with established third-party providers can overcome this bottleneck while enabling in-house teams to focus on delivering high-end value instead of routine daily monitoring.

Larger portfolios also mean operators are more likely to have multiple turbine technologies and CMS within a single fleet. Digital platforms that combine analytics from these varied sources and convert them into unified

data sets and actionable maintenance plans unlock untold efficiencies: from the simple IT burden of integrating different technologies, to training staff on different software, to coordinating servicing trips to maximize their effectiveness. The last point is especially true in offshore wind, where turbines are larger and maintenance is more expensive due to marine logistics.

4. Change of O&M contract or mergers and acquisitions

With full scope service agreements beginning to seem less attractive for increasing numbers of asset owners and operators, many are looking to manage costly major component replacements inhouse. Condition monitoring is critical to de-risk this transition — with O&M costs cut by up to 30% in the meantime.

Another consideration is mergers and acquisitions (M&A) activity. From 2020 to 2021, the total value of M&A deals almost doubled, showing the volume of assets changing hands. A wind fleet with an established CMS, and all the data to show for it, is like a car with a full-service history — it enables owners to justify valuations and gives buyers confidence. Crucially, it can shorten lengthy due diligence processes. Retaining flexibility when contracts change is paramount and frees up capital for the seller.

WINDPOWER ENGINEERING & DEVELOPMENT 10 FEBRUARY 2023 www.windpowerengineering.com

GE

5. Late stage and life extension

As assets start to age, reliability issues increase, and the business case for monitoring changes again. Owners and operators must not only have a thorough understanding of the condition of towers, foundations and blades but also the remaining useful life of the drivetrain and other replaceable components.

As the wind industry begins to look inward, evaluating its own carbon contribution, there is a clear need to use data to support the recycling of parts, which can save up to 90% of energy during manufacturing compared to using a new part. Monitoring is key to understanding when to take components out of an asset for refurbishment to enable re-use.

Finally, condition monitoring can inform repowering decisions. For example, partial repowering — adding larger generators and blades without replacing structures and other parts such as yaw gears — is popular with operators in the U.S. market, but this can lead to uneven part lives throughout the turbine. Monitoring shows operators the bigger picture to make informed life extension decisions: which parts of the turbine need replacing, and which can run for longer.

Conclusion

Failures to exploit the advantages monitoring brings in these five areas are leaving many owners and operators on the back foot, unable to leverage advances in sensing and analytics that promise huge strides. Condition monitoring is one of the most powerful technologies operators have for transforming asset profitability, removing uncertainty and improving confidence and control over budgeting decisions from beginning to end of the project lifecycle.

Coupled with multiple data streams and an engineering approach, they will be given overarching visibility to make better servicing decisions, contractual negotiations, and scale with greater confidence. There is also technological innovation happening now that will continue over the next ten years, bringing in additional data sources, including blades, pitch bearings, towers and foundations, enabling a more complete picture of asset health.

The key to a successful monitoring strategy is thinking long-term and continuing to invest in comprehensive, proven solutions which deal not just with the challenges wind operators face today, but also those of tomorrow. Future-proofing assets is key to driving profitability and enabling wind to play its critical role in a low-carbon future. WPE

GETTING THE MOST OUT OF MONITORING WINDPOWER ENGINEERING & DEVELOPMENT 11

FUTURE-PROOFING ASSETS IS KEY TO DRIVING PROFITABILITY AND ENABLING WIND TO PLAY ITS CRITICAL ROLE IN A LOWCARBON FUTURE.

BY DOMINIQUE VERHULST • GLOBAL HEAD OF THE UTILITIES VERTICAL • NOKIA

REASONS WHY OF WIND FARMS IS RESHAPING GREEN ENERGY

digitalization

WINDPOWER ENGINEERING & DEVELOPMENT 12 FEBRUARY 2023 www.windpowerengineering.com

digitalization

ENERGY

WhenHurricane Ian hit Florida in September, it was the 15th climate disaster in the United States in 2022 that individually caused billion-dollar damage. Similar evidence of climate change is everywhere. More than 33 million people were impacted by floods in Pakistan this year, and an ozone hole over the Antarctic formed after the 2020 wildfires in Australia.

These are the kinds of events that have countries worldwide pledging to achieve netzero carbon emissions by 2050. Spurred by this investment in renewable energy capabilities, wind farm operations continue to expand. According to Global Data, the wind power market has grown at a 14% CAGR over the last decade, giving the industry about 10% of the capacity mix in 2021.

Wind farm challenges

Safety and worker welfare are essential on wind farms, as are operational continuity and costefficiency. Yet, offshore wind farms pose unique requirements. Turbine and wind farm sizes are growing, and many are being constructed further from shore. Locations are often remote and conditions harsh, especially given the growing severity of weather events. And hiring is a challenge, as workers must remain offshore for extended periods of time, confined to a vessel for up to two weeks.

This is all driving the demand for digital broadband connectivity and Industry 4.0 technologies available throughout the wind farm. Reliable, broadband wireless networks with data, video and voice capabilities enable new applications and capabilities. Industry 4.0 technologies keep workers, vessels, sensors and operations centers connected, something that satellites cannot deliver in a cost-effective way.

An industry-standard private 4G/LTE wireless network builds on what is already in use at the wind farm. The LTE network connects to onshore communications over the same fiber that is typically used to transmit supervisory control and data acquisition (SCADA) data from

the wind farm to the operations center. The broadband technology complements existing very high frequency (VHF) and Tetra voice communications and replaces an expensive, low bandwidth satellite link as the primary path to shore.

Let’s look at some of the use cases enabled by digital broadband connectivity to address the unique requirements of wind farms, and how this move to private wireless and Industry 4.0 will reshape green energy.

#1: Broadband connectivity is a gamechanger for safety

Many wind farm owners, operators and developers are giving workers the tools to communicate in real-time and transmit large data loads over great distances. Push-to-talk and now push-to-video communication are important between workers at the turbine towers, in helicopters, on-board vessels and onshore.

That’s why wireless connectivity is a gamechanger. Strong, pervasive broadband network connectivity via a private wireless network enables a comprehensive Internet of things (IoT) system that will connect both onshore and offshore personnel – ultimately preserving the safety of wind farm employees. For workers confined to offshore sites, they now have access to a broader range of telemedicine services. Wearables facilitate the monitoring of worker health at all times and locations throughout the wind farm, rather than just on a vessel. Such comprehensive data allows for a more rapid, appropriate response to an emergency.

#2: Quality of life is a competitive differentiator

Pervasive broadband connectivity onshore and offshore helps wind farms attract and retain employees. Consider that, with 4G/5G broadband service, wind farms can now access bandwidth that is anywhere from seven- to 10-times greater than what is typically available with satellite. This has a noticeable impact on quality of life for workers. During downtime,

WINDPOWER ENGINEERING & DEVELOPMENT 13 FEBRUARY

2023

they can now download movies, access social media and engage in video chats with friends and family back home.

And these types of personal activities – though critical for employee quality of life – will not impact essential services. A private LTE network provides priority for mission-critical operations traffic.

Additionally, the private wireless network can provide high-speed data access to onshore company systems so workers can take care of administrative tasks while offshore, rather than make time for it while onshore. This too can improve work/ life balance.

#3: Efficiency drives lower cost of energy

Efficient operations are critical to keeping costs low, and this is another area where pervasive broadband can help. Imagine a technician with access to video at a turbine connected to an onshore or offshore expert. Together, they can more safely and efficiently work through issues and reduce the likelihood that a second dispatch to the turbine will be required.

For field technicians, access to always-on connectivity across the wind farm is ideal when working on top of a nacelle, on a blade, or inside a service vessel. By using a

R-5: Composite Windblade Repair

For those responsible for performing structural repairs to composite windblades, this course covers fundamentals necessary to understanding aerodynamic skin, core, and trailing edge repairs.

R-15: Advanced Windblade Repair

A follow-on to our Composite Windblade Repair course, this course is for those directly involved in providing high performance repairs to large area damage, spars, and tips.

DIGITALIZATION OF WIND FARMS

High Expectations, Higher Level of Skill Aerospace Methods Applied to Windblade Repairs +1.775.827.6568 www.abaris.com training@abaris.com ENROLL TODAY A PRIVATE

NETWORK PROVIDES

TRAFFIC.

LTE

PRIORITY FOR MISSION-CRITICAL OPERATIONS

ruggedized handheld, tablet or laptop when conducting inspections, workers can enter notes and video clips about their learnings as they happen, rather than waiting to input this upon their return to the vessel or shore. This will improve the amount and quality of the details. Plus, by immediately making their inspections available to onshore teams, analysis can be done in real time which will improve work scheduling and reduce the number of maintenance trips.

When using drones, a private 4G/ LTE network ensures low latency during blade inspections, and the broadband to immediately share this information with onshore teams that can then participate in the analysis. Drones equipped with high-definition cameras can be flown remotely by a pilot from any location connected to the network if local regulations permit, or even preprogrammed to follow a set inspection flightpath. The private network then enables these drones to stream the images back to the operator or control center in real-time, transforming visibility across the entire offshore operation, and enhancing safety and security.

Pervasive broadband access also helps with upskilling workers. They can conduct training and gain relevant certification, during downtime while offshore.

A natural outcome of digitalization is massive quantities of data that need to be collected, processed, and stored. This is where Industry 4.0 technologies like artificial intelligence and machine learning come into play. They help to manage asset maintenance programs, upkeep of records, forecasts and weather tracking.

Private wireless networks can also enable performance improvements for the turbines themselves. A whole suite of new sensors and monitoring equipment is currently being developed that will

AS COUNTRIES

INCREASINGLY SET THEIR SIGHTS ON NET-ZERO EMISSION TARGETS, WIND FARMS CAN TURN THE TIDE WITH DIGITALIZATION AND INDUSTRY 4.0 TECHNOLOGIES AND PLAY A PIVOTAL ROLE IN ACCELERATING THE ADOPTION OF CARBON-FREE, RENEWABLE GENERATION.

collect valuable operational data, which can then be used with machine learning and artificial intelligence to optimize asset performance. Sensors connected to the private network quickly transfer data, which can be generated multiple times per second on key operating metrics such as structural changes, temperature, acoustics or even lightning detection.

Reshaping green energy

Wind farm operations are bigger and more complex than ever, and they must provide wireless connectivity at speeds far

beyond what could have been anticipated even 10 years ago. An industry-standard private 4G/LTE wireless network has become a pre-requisite, offering ubiquitous and persistent connectivity to support the highest levels of safety, worker welfare and efficient operations.

As countries increasingly set their sights on net-zero emission targets, wind farms can turn the tide with digitalization and Industry 4.0 technologies and play a pivotal role in accelerating the adoption of carbon-free, renewable generation.

WINDPOWER ENGINEERING & DEVELOPMENT 15 FEBRUARY 2023

WPE

OFFSHORE SUPPORT VESSELS CAN WE POWER

WITH RENEWABLE ENERGY?

BY WEI HUANG • DIRECTOR • ABS

BY WEI HUANG • DIRECTOR • ABS

WINDPOWER ENGINEERING & DEVELOPMENT 16 FEBRUARY 2023 www.windpowerengineering.com

DEMAND for the offshore support vessel (OSV) services is growing. In 2020, the market reached $13.78 billion, despite the economic chaos and disruption caused by the COVID-19 pandemic. By 2028, demand for OSV services is set to expand by almost $10 billion to reach a value of $23.6 billion.

Looking ahead, a key task for the sector is to reimagine OSV designs so they can support demand for services in a way that is sustainable and financially viable.

OSV operations will need to be fully integrated with offshore fields, port infrastructure and supply chains to cater to increasingly complex and multifaceted customer requirements. This means that vessels will need to be fully digitized and highly automated to tie into their supporting tech-enabled ecosystems.

Drawing on its own insight and predictions, ABS recently published a report containing detailed insights on the future of OSV designs and operations. It covers a range of mission critical aspects, from how technology can help to integrate OSV operations to emerging regulations and their impact on design and use by the offshore industry. Crucially, it contextualizes these aspects around a carbon neutral future, detailing numerous ways vessels can be prepared and designed to assist the marine and offshore sectors on the net-zero journey.

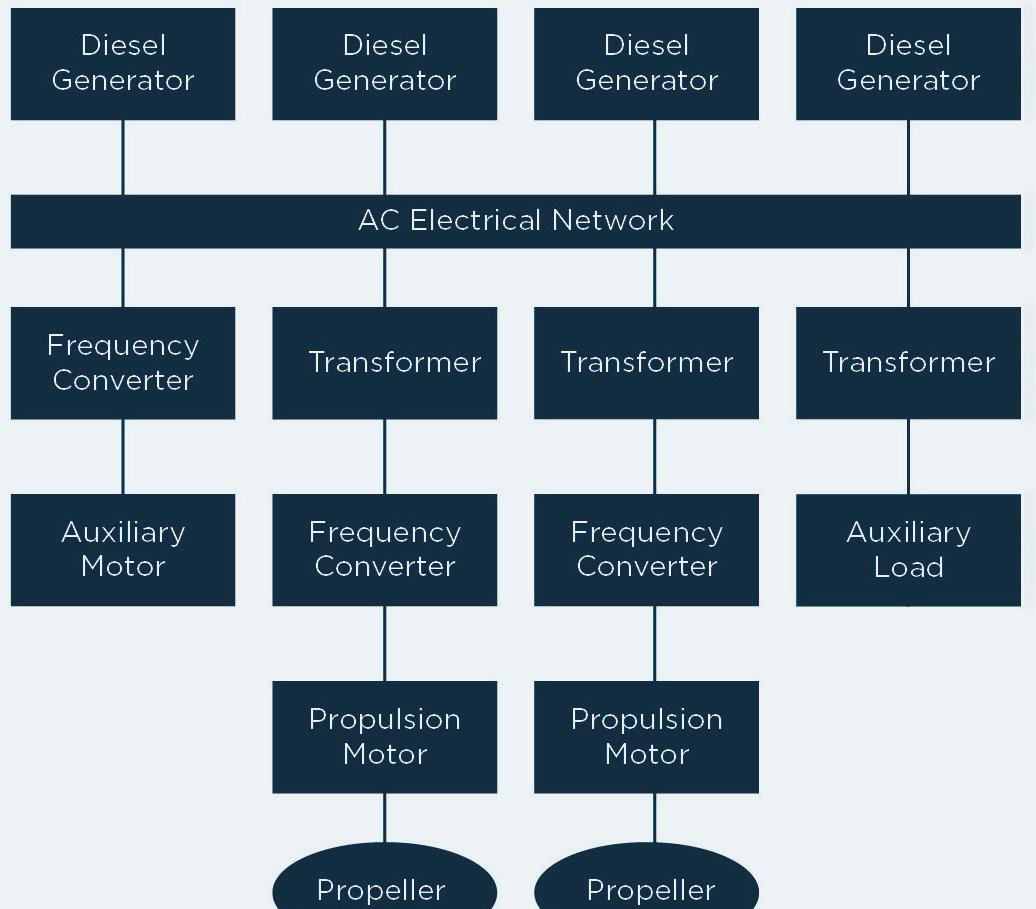

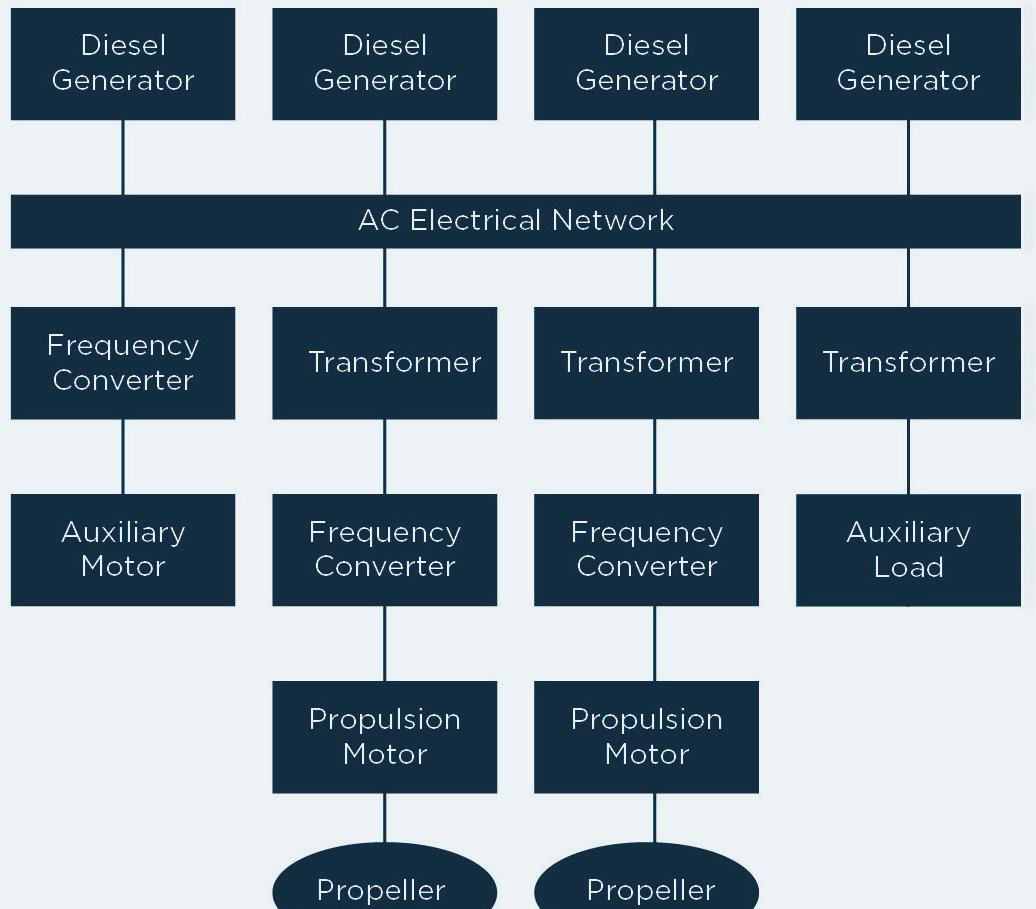

Decarbonizing marine propulsion systems

One of the most obvious ways of achieving carbon neutrality is to decarbonize vessel propulsion systems.

Typically, OSVs rely on diesel-electric propulsion systems – multiple diesel generator sets feed a fixed-frequency electrical bus, which then feeds the electrical propulsion motor drive and the hotel load (most commonly a transformer).

WINDPOWER ENGINEERING & DEVELOPMENT 17 FEBRUARY 2023

By integrating these diesel-electric systems with energy-storage solutions such as lithium-ion batteries, flywheels or supercapacitors, the combination of electrification and hybrid power can increase the flexibility of a vessel’s propulsion system.

Furthermore, this will allow internal combustion engines to run at optimal levels of fuel efficiency and, when running purely on battery power, vessels will be able to operate with zero emissions.

Hybrid power supplies – benefits and challenges await

Indeed, there are several key performance benefits attached to using hybrid power supplies for OSV power and propulsion systems.

When tapping into stored energy, one or more engines can be switched off,

and storage systems themselves can be recharged when engines are running and store regenerated energy when braking on electric motors – this can save fuel, reduce emissions and noise, increase crew comfort and support sailing without emissions, noise and vibrations from the engines.

Batteries also enable load leveling and peak shaving and provide an important source of backup power in the event of combustion power supply failure. However, it should be noted that several challenges need to be overcome or accommodated for if OSV designs are to fully embrace hybrid-electric propulsion systems.

Three challenges:

• Finding the optimum balance in charging and discharging the battery

to enable a maximum reduction in fuel consumption.

• Managing local fluctuation on diesel engines. The control strategy should ideally share dynamic loads between the battery and the diesel engine in ways that minimize fuel consumption, emissions and maintenance loads for all power suppliers.

• Costs relating to battery installations will need to be minimized or offset, perhaps by reducing the installed power from diesel engines.

Another challenge related to electrical propulsion is that an engine’s fuel consumption in partial load is higher when running at fixed as opposed to variable speed.

Here, a DC hybrid power supply and distribution system can help. They allow

POWERING OFFSHORE SUPPORT VESSELS WINDPOWER ENGINEERING & DEVELOPMENT 18 FEBRUARY 2023 www.windpowerengineering.com

operators to run a diesel engine at variable speed, potentially reducing fuel consumption, emissions, operating noise and its mechanical and thermal loading.

However, DC systems are also subject to some challenges. Because they need all power sources to be connected by converters, and this can incur large costs. Meanwhile, fault protection will need to be resolved to enable DC architectures.

Powering ahead

SEACOR currently operates 10 OSVs equipped with hybrid batteries.

Harvey Gulf International Marine also classed two OSVs retrofitted with a battery/converter system. The Harvey Energy is the first ABS-classed dual fuel and battery vessel and the first U.S.-flagged OSV equipped with a battery/converter system. The Harvey America and Harvey Freedom are the second and third vessels in the Harvey Gulf fleet installed battery power system.

The battery capacity will be sufficient to sail in and out of port on electric power with fewer engines running, while also supplementing hotel load electricity, which would reduce noise and pollution levels in the port area. Furthermore, the ability to operate on battery power will assist peak load shaving and increase redundancy during critical dynamic positioning operations at the offshore field.

It is possible that other market-tested infrastructure could be used to provide renewable alternative fuels to the OSV sector. One such strategy would provide the vessels with access to electrical power at ports connected to the grid. Shore power and offshore charging buoys are evolving technologies, but they hold the potential to charge vessels with the renewable energy produced by offshore windfarms. Aside from the environmental benefits, installing electric buoys closer to the offshore assets that the vessels are serving would burn less fuel while the ships are idle and offer the benefit of charging times that are less disruptive to operations.

All hybrid-electric propulsion options explored here and in the ABS report have challenges – crucially, none we believe are insurmountable. WPE

WINDPOWER ENGINEERING & DEVELOPMENT 19 FEBRUARY 2023

ALL HYBRID-ELECTRIC PROPULSION OPTIONS EXPLORED HERE AND IN THE ABS REPORT HAVE CHALLENGES – CRUCIALLY, NONE WE BELIEVE ARE INSURMOUNTABLE.

WINDPOWER ENGINEERING & DEVELOPMENT 20 FEBRUARY 2023 www.windpowerengineering.com Adobe Stock

TRAINING ALONE CANNOT BRIDGE THE

OFFSHORE WIND SKILLS GAP

WE NEED TO BUILD COMPETENCY TOO

BY WAYNE MULHALL • MANAGING DIRECTOR AT JAMES FISHER RENEWABLES

THE news is awash with positive stories about offshore wind; technical surveys have commenced for Finland’s latest 2.1-GW project, Australia’s state of Victoria has released its Offshore Wind Implementation Statement setting out steps to install 9 GW by 2040, while the Chinese city of Chaozhou plans to start work on installing 43.3 GW before 2025.

All around the world, governments, states and private companies are

increasing the pipeline of offshore wind. In fact, 271 GW could be installed or under construction by the end of the decade according to 4COffshore’s latest Market Overview Report. It’s a staggering rate of growth that will necessitate a huge workforce, and it’s widely known that the energy industry will find it increasingly difficult to find sufficiently skilled workers to fill those upcoming vacancies. Worryingly, while the industry hasn’t quite got to grips

with filling the headcount gap, there is yet another workforce gap that looms large: the competency gap.

Talent availability is being squeezed from all sides

The market for high-caliber graduates is increasingly competitive. Where once there was little overlap, as the digitalization of the energy industry continues, the technology sector has become increasingly attractive

WINDPOWER ENGINEERING & DEVELOPMENT 21 FEBRUARY 2023

to candidates, particularly those with specialisms in physics and math. There are also fewer apprentices entering the industry. In the UK, only around 40,000 engineering and manufacturing technology apprentices graduated in 2021 – a 20% decrease since 2019. The situation is worsened by the high proportion of skilled workers that reach pensionable age each year. According to a recent census by the Engineering Construction Industry Training Board, which surveyed 68 energy companies with 16,000+ employees in over 500 locations,

more than a third (35%) of employees are over 50. Altogether, the availability of skilled workers is becoming a major bottleneck to the energy transition and should be on every risk register if it is not already.

The oil and gas workforce won’t save everything

There has been much discussion about retraining and reskilling the oil and gas workforce to meet some of the demand. However, realistically, the oil and gas industry will still exist for decades and

may even see periods of resurgence depending on political will and supply and demand economics. Ex-UK Prime Minister Liz Truss was only in power for 45 days but announced plans to offer nearly 900 locations for oil and gas exploration during her tenure. Further, when fossil fuel prices are high, offshore rates increase comparatively. With higher rates of renumeration, no one can blame the offshore workforce for responding to the siren’s call of oil and gas. Finally, there is also a burgeoning asset life extension and decommissioning industry to consider that

OFFSHORE WIND COMPETENCY

WINDPOWER ENGINEERING & DEVELOPMENT 22 FEBRUARY 2023 www.windpowerengineering.com

James Fisher Renewables

will only grow as the energy transition continues. Altogether, hiring and retraining oil and gas workers won’t deliver the kind of numbers the offshore wind industry will need to meet demand.

Proactive measures may not be enough

More broadly, countries continue to play the skilled workforce numbers game. The European Union is reforming migration policies and has launched a talent partnership program to boost international mobility and match labor market needs and skills. South Korea, meanwhile, has signed several MOUs with international offshore wind partners such as Vestas, Principle Power, RWE and Equinor to collaborate and gain their expertise. And under the Inflation Reduction Act, the United States will provide tax credits to firms offering manufacturing apprenticeships.

Many businesses are also taking a proactive approach, relicensing training materials, working closely with their local communities to increase interest in apprenticeships with school leavers, forming working relationships with universities for high-quality graduates, pooling from skilled workers such as the veteran community and employing flexible working practices to attract women into the workplace (who currently only represent 12% of the workforce). Companies are also doubling down on retention packages as well as ensuring staff members feel valued and have a clear path to grow within the business.

Yet, despite best efforts by governments, states and companies to create a new workforce for the energy industry, a gap will remain — the gap of competence.

The gap of competence

Competence comes from on-thejob experience and the skills and knowledge gained as result. It is not something that can be gained through training alone. Training helps people talk the talk, but they then need to walk the walk.

One of industries’ core pillars – safe operations – requires an exceptional level of competence to ensure operational risk is recognized and the right measures to control and manage those risks are put in place. In high-risk industries, getting it wrong can be catastrophic; something the oil and gas industry knows all too well, although it is now one of safest industries to work in. Offshore wind has been able to implement many of these lessons from the outset, to uphold a high safety record.

Competence is also vital for ensuring quality workmanship. The world is poised to undertake one of the largest infrastructure buildouts of all time; assets will have a life expectancy that exceeds 25 years. The quality of the build and the subsequent operation and maintenance will significantly influence the return on investment, as well as the ability of the asset to meet or exceed its original designed output. In other words, the energy transition partly hangs on the competence of the workforce to execute designs as intended.

Our UL (WTTC)- and CSA (FT4)-approved copper, aluminum and fiber optic cables provide superior performance in climates ranging from -40°C up to +90°C, and can withstand the harsh environmental factors found in both on- and offshore environments. For OEM and MRO customers, pre-assembled cable solutions are available for reliable termination and quicker installation on the factory floor or in the field.

WINDPOWER ENGINEERING & DEVELOPMENT 23 FEBRUARY 2023

HELUKABEL® USA, Inc. | West Dundee, IL www.helukabel.com | sales@helukabel.com

POWERING... WIND TURBINES

HELUKABEL provides cable system expertise throughout the wind turbine — rotor tip to tower base. We focus on control and data cables in the nacelle, torsion-rated cables in the drip loop, and flexible control and power cables in the tower.

COMPETENCE COMES FROM ON-THE-JOB EXPERIENCE AND THE SKILLS AND KNOWLEDGE GAINED AS RESULT.

Further, the competences required will change rapidly as new innovations make it to market. You only have to consider the rate of change in turbine capacity over the last 20 years. The world’s first offshore wind turbines were pocket-sized at 450 kW. Today, the industry is moving 15-MW prototypes into demonstration – an over 3,000% increase in generation capacity. Meanwhile, graduates starting threeyear degrees in 2022 are likely to enter an industry that is increasingly coupling with technologies such as green

hydrogen, creating vast opportunities and generating its own competence requirements.

Tapping into competence by extending the season

One potential route that should boost competence is through the increasing prevalence of offshore wind projects south of the equator. A significant portion of the world’s offshore wind fleet (both current and planned) is located above 0° latitude, with seasonality dictating a high volume of work to be

executed in just a few months. However, with countries including Australia, New Zealand and Uruguay looking at offshore wind, this could begin to change, which would allow international business to work offshore year-round while also upskilling the local workforce. New Zealand is currently undertaking an industry capability mapping study with the first wind farm proposed as 1 GW from 70 wind turbines. Uruguay's state oil and gas firm Ancap is preparing a series of offshore green hydrogen and wind tender rounds starting in 2023.

WINDPOWER ENGINEERING & DEVELOPMENT 24 FEBRUARY 2023 www.windpowerengineering.com

James Fisher Renewables

If the offshore wind industry can build offshore year-round, contractors could then also contribute their competence continuously as well as being available to increase competence in more junior staff members. A greater use of joint ventures and frameworks to allow smaller companies to execute work packages would also help to bridge the competency gap – allowing the industry to tap into small pockets of highly skilled workers.

Finally, service operation vessels built specifically for the wind industry, as well as purpose-built walk-to-work vessels, can increasingly provide access to platforms during bad weather, safely extending the season in Northern Europe. This further increases the opportunity for competence building by extending the potential for cross training from different regions.

We do not have all the answers, but what is apparent is that increasing the headcount of the workforce will not allow the energy industry to achieve its goals in the safest, most efficient and effective way if we do not consider the need for competence. We must begin to prioritize competence before it becomes an unmanageable risk to offshore wind and to the energy transition in general. WPE

Reliable Support With the Model K Bolt-Tension Calibrator

Simple and durable design

of equipment available to rent, lease-to-own and buy. Shop our entire selection of torque wrenches, tensioners, hydraulic pumps and more. With Enerpac tools, you know you’re ready for the job ahead.

OFFSHORE WIND COMPETENCY aztecbolting.com 520 Dallas St. League City, TX 77573 24/7 Service - Call Us 832-271-5120 Wield Absolute Power on the Job Site The

We

Skidmore-Wilhelm

to rent, lease-to-own and buy. Shop our selection of tried and trusted Skidmore Wilhelm calibration and testing units. | Find Your Testing Solution We also provide some of the most sophisticated bolting products from other leading brands in the world including: • Skidmore Bolt Testers • Norbar Electric Torque Wrenches • Norbar Electronic Calibration/Measurement Equipment The Highly Versatile Enerpac HMT1500 Modular Torque Wrench • Lightweight and powerful • Job-site flexibility

long-trusted Skidmore-Wilhelm began over 70 years ago with the invention of the bolt tension calibrator, the first device to measure the tension of a bolt. Since then, they’ve been the go-to brand for calibration and testing units, with the best technology for today’s demands.

carry

tools

• Portable model for job site flexibility • Six sizes are available (1-1/4” to 2-1/2”) to fit wind industry needs • 225,000 lbs preload capacity: 225,000 lbs, and it can be upgraded to 450,000 lbs (2,000 Kn) We are always adding the newest Enerpac tools to our lineup

WINDPOWER ENGINEERING & DEVELOPMENT 25

LEADERSHIP IN WIND ENERGY

Celebrating the companies and individuals leading the wind power industry.

The U.S. wind industry is growing into new markets, namely offshore development. Success would not be possible without the ingenuity and determination of our leaders. These individuals and companies are working for the growth of the entire wind industry.

The future of the industry will build on the foundation of today’s efforts. Windpower Engineering & Development would like to acknowledge such achievements on the following pages. These accomplishments in engineering and product advancements are what drive us into new markets and create jobs.

We think they deserve recognition from you, too. Vote online through October for one or more of the companies listed in this special section.

www.windpowerengineering.com/leadership

Select the company you think has provided leadership in the wind industry.

WINDPOWER ENGINEERING & DEVELOPMENT 26 FEBRUARY 2023 www.windpowerengineering.com

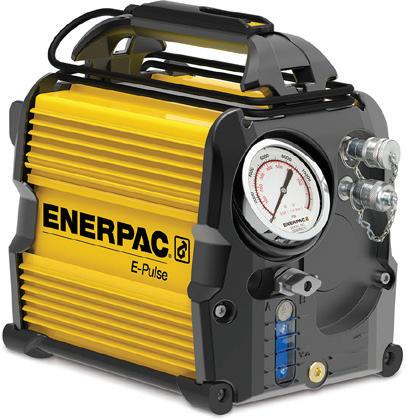

VOTE ONLINE

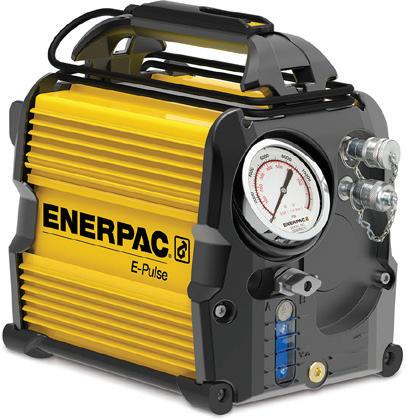

AZTEC BOLTING SERVICES, INC. has been a leading provider of bolting tools to the wind energy industry for over 35 years. Aztec Bolting utilizes the latest products from Enerpac to Skidmore for all your torque and tension requirements. We offer the finest tools available for sale or rent, including hydraulic tools that can yield up to 80,000 ft./lbs. Aztec Bolting also provides calibration services and repairs through our ISO 17025 accredited mobile fleet and calibration facility at the company headquarters in League City, TX.

Working alone, or on site with your labor force, Aztec is committed to delivering the right solution, to meet your timing and budgetary requirements. Aztec Bolting Services, based in League City, TX, continues to provide a state-of-the-art mobile fleet division with office locations in Midland, Corpus Christi, Sweetwater and Nederland, TX, and Oklahoma City, OK.

Since 1987, Aztec Bolting Services has been providing innovative equipment and superior technology. As a distributor of Enerpac Bolting and Tensioning Products, Skidmore-Wilhelm, Stahlwille, and Norbar hand torque wrenches, electronics and torque multipliers, we are prepared to assist our customers in achieving their Wind Power Construction and Maintenance goals.

“Aztec’s mission is to provide quality products and services to meet every torque and tension need with the utmost care, quality and service.”

Our professionals can be on-site anytime, anywhere with our ISO 17025 Accredited Mobile Calibration Fleet. Our Mobile Units can provide more versatile services than ever before from Controlled Bolting Training to onsite calibrations of your products.

Enerpac E-Pulse Pump

The new lightweight, portable solution that is powerful enough to get the job done quickly and safely. The Enerpac E-Pulse Electric pump features a brushless DC motor and speed variable controls to provide typical power from larger pumps in a durable, portable package.

We set the standard in torque wrenches.

Aztec Bolting Services

520 Dallas Street League City, TX 77573

1308 South Midkiff Road, #303

Midland, TX 79701

802 Navigation Boulevard #106

Corpus Christi, TX 78408

1113 Lamar Street

Sweetwater, TX 79556

3620 HWY 69N

Nederland, TX 77627

800.233.8675

www.aztecbolting.com

www.windpowerengineering.com/leadership

Voting for this company will identify it as a leader in the wind power industry.

Enerpac DSX Torque Wrench

The Enerpac DSX Square Drive Aluminum Torque Wrench delivers strength, safety, superior performance and ergonomic design. The DSX makes the ideal choice when you need a simple, lightweight, strong and safe torque wrench. Critical safety features are designed to prevent dropping of on-site components. The DSX also features a compact high-strength unibody design, which provides a small operating radius without sacrificing endurance.

Enerpac HMT

The HMT1500 Modular Torque Wrench is a versatile and durable hydraulic torque wrench. It has a powerful, lightweight design allowing it to perform 25% faster and is twice as durable as other tools in the same class. Interchange cassettes easily for on-site, onthe-fly adjustments across applications, and count on a safety driven performance through standard safety features.

And because Aztec Bolting is an authorized national distributor of Enerpac products, you can count on a lifetime warranty. Aztec Bolting and Enerpac products are guaranteed

The Norbar Evotorque Battery Tool

The Norbar Evotorque Battery Tool boasts high accuracy through features including a built-in torque transducer, a brushless motor, and is fully programmable with safety, smart technology, and comfort at the forefront.

WINDPOWER ENGINEERING & DEVELOPMENT 27 FEBRUARY 2023

Wind Turbine Cable System Solutions

HELUKABEL USA, based near Chicago IL, is a global cable system solutions provider specializing in the production of cables, wires, accessories, and cable assemblies that are found throughout the wind turbine — rotor tip to tower base. Our extensive product line includes bulk or pre-assembled wind turbine torsion cables, flexible control cables, data/network/bus cables, VFD/servo cables, single conductors, fiber optic and multi-norm cables with domestic and international electrical approvals.

HELUKABEL combines excellent cable quality, innovation and technical expertise with a vast product portfolio and smooth logistics operations.

Wind power continues to play a major role in the generation of renewable electricity. From installing new wind farms to retrofitting existing ones, wind turbines are being designed to be more efficient and used in locations that were previously thought to be unsuitable for energy production. The technology found in these power sources allows them to operate safely for long periods of time on every continent and in any climate zone.

HELUKABEL offers you optimum cable solutions for on- and offshore wind turbines from rotor tip to tower base, as well as for the infrastructure cabling at the wind farm to transfer the power to the grid. Our full product range includes low-voltage and medium-voltage cables with copper or aluminum conductors, torsion-resistant cables, data and network technology, pre-assembled fiber optic cables, as well as the necessary connection technology and other accessories for fastening and bundling cables within the turbine.

Our cables are rigorously tested to UL, CSA and many other international standards to ensure their durability to withstand a variety of harsh environmental factors, including humidity, vibration, extreme temperatures, oil exposure, electromagnetic interference and more.

With a 70,000 sq. ft. warehouse near Chicago, IL and backed by a fully automated logistics center in Germany, we can serve the North American market on a just-in-time basis, which truly makes HELUKABEL your one-stop shop for cabling system solutions.

HELUKABEL USA, Inc.

1201 Wesemann Drive West Dundee, IL 60118

T: (847) 930-5118

sales@helukabel.com

www.helukabel.com

www.windpowerengineering.com/leadership

Voting for this company will identify it as a leader in the wind power industry.

WINDPOWER ENGINEERING & DEVELOPMENT 28 FEBRUARY 2023 www.windpowerengineering.com

Norbar Torque Tools introduces EvoTorque2, where we have brought together durability, low cost-of-ownership, Norbar quality and accuracy, and all the features you need, and rolled them into one, price-competitive tool.

EvoTorque2 is easy to program, presents a small and lightweight package, stores thousands of readings, and can be serviced in the field. There are too many features and advantages to list in a few short lines of text, so the best way to measure the advantages and value of EvoTorque2 is to try it yourself. Stack us up against the competition – you’re going to be amazed!

Norbar EBT EvoTorque Battery Tool – Another radical change comes to battery powered torque multipliers!

Norbar Torque Tools has jumped into the battery tool market, and made a big splash!

Meet EBT – EvoTorque Battery Tool, with everything our EvoTorque2 electric brought you, but along the way we lost the power cord, and picked up an 18V battery.

Operating the same EvoLog software as EvoTorque2, EBT is the perfect complimentary tool, because it is set-up, programmed, and operated exactly the same as its corded big brother. With a brushless motor, a durable and accurate Norbar gearbox, and a built-in transducer, Norbar has set the bar high in the world of battery tools.

With an accuracy of +/-3% OF READING, EBT hits the target every time, across the full range of the tool. If accuracy matters to you, if durability matters to you, and if unparalleled service and support matter to you, the only name you need to remember is NORBAR.

Norbar Calibration Fixtures – Accuracy and durability brought to the field!

Norbar Torque Tools knows how critical it is to have and prove the calibration and accuracy of your torque tools. We have been providing calibration equipment to the Wind industry around the world. We can package and configure equipment to suit all your needs, and our modular design allows your equipment to grow and change as your needs grow and change.

Norbar Torque Tools, Inc.

36400 Biltmore Place

Willoughby, OH 44094

Phone: 866.667.2272

Fax: 440.953.9336

Email: info@norbar.us

www.norbar.us

www.windpowerengineering.com/leadership

Voting for this company will identify it as a leader in the wind power industry.

Whether you need fixtures to calibrate hydraulic wrenches, or joint-simulators to calibrate your non-impacting torque tools, or just a way to calibrate or verify torque wrenches, Norbar has the equipment and expertise to cover all your needs!

Norbar HandTorque Multipliers – Big range and a small size, with a Certificate of Calibration!

Norbar Torque Tools Compact Series Torque Multipliers are designed to deliver high torque ranges, in user-friendly gear ratios, packaged in a small and lightweight package. Because size and weight considerations are critical to your business, Norbar has developed a line of torque multipliers that make life in the tower easier by providing a powerful 27:1 gear ratio – an operator input of 100 lb-ft generates 2700 lb-ft of torqueing power!

When it comes to real convenience, Norbar has designed the Compact Series Torque Multipliers to accept the same torque reactions as you will use on your EvoTorque2 tool, saving you even more time and money down the road.

All Compact Series Torque Multipliers include a Certificate of Calibration, and are delivered in a high density plastic carrying case.

WINDPOWER ENGINEERING & DEVELOPMENT 29 FEBRUARY 2023

PPG Engineered Materials (formerly Dexmet Corporation) manufactures precision expanded metal foils and polymers for applications in aerospace, power generation, filtration and automotive industries. Dexmet was founded in 1948 and is based in Wallingford, Connecticut and was acquired in 2019 by PPG. For over 60 years Dexmet has been at the forefront of expanding technology and has redefined the standards for micro mesh materials providing the greatest range of products and capabilities for foil gauge metals and thin polymer films. Dexmet manufactures thin, light-weight precision expanded Copper and Aluminum from .001” thick and widths reaching over 48” that can meet specific weight, conductivity and open area requirements required by aerospace or wind generation applications.

Precision MicroGrid® materials from PPG Engineered Materials are the industry standard for expanded materials used in lightning strike protection, on carbon fiber structures with OEM aircraft manufacturers as well as EMI/RFI, and ESD protection for sensitive internal instrumentation.

The Dexmet Quality System is ISO AS9100:D and ISO 9001:2015 certified.

As the power output requirements increase for wind turbines, wind generator manufacturers are moving towards larger blades to rotate these larger turbines at lower wind speeds. As the wind blades increase to over 45 meters in length, blade construction is moving away from the more traditional all fiberglass construction to utilize more carbon fiber. The carbon fiber provides a substantial weight savings and increased strength to combat the extreme stress loads exerted on the blades during operation. Carbon fiber, however, is conductive and more prone to be struck by lightning. Without proper protection, they are susceptible to severe damage and catastrophic failure.

PPG MicroGrid® Proven Lightning Strike Protection

• Proven Technology for Lightning Strike Protection

• Highly Conductive Patterns Matched to Specific Requirements

• Open Area Design for Easy Dry or Wet Layup without Delaminating

• Easily Repairable for Low Maintenance Costs and Minimal Downtime

MicroGrid® Materials for Hybrid-Carbon Fiber Wind Turbine Blades

Engineered Materials

Wallingford, CT

+1 (203) 294-4440

www.dexmet.com

www.windpowerengineering.com/leadership

Voting for this company will identify it as a leader in the wind power industry.

For two decades Dexmet has been working with aircraft designers developing precision expanded MicroGrid® foils for lightning strike protection on carbon fiber composite aircraft and its components. Benefiting from the development work done in the aircraft industry, Wind Blade Manufacturers are now realizing the importance of having the proper lightning strike protection for larger carbon fiber blades.

As with aerospace applications, weight is always critical so PPG Engineered Materials provides different conductive materials to minimize the weight based on the different strike zones. As with all rotary blades, lighting is more prone to hit the leading edge and the outer blade surfaces towards the tips where the highest amount of static energy is generated. For these locations, the heavier, more conductive materials are utilized. As you move towards the root of the blade, a lighter weight material can be incorporated to reduce weight and cost. The variability with our expanding process provides the capability of producing a custom material based on desired weight, conductivity, or open area to meet exact application requirements.

PPG MicroGrid® materials are thin, open area products applied to a layer on the top of the structural carbon fiber spar/web or other systems that utilize carbon such as de-icing solutions that consume carbon heating mats on the leading edge. PPG MicroGrid® materials can achieve the critical conductivity, sometimes in conjunction with the carbon components, to dissipate 2025 years’ worth of lightning strikes. Expanded copper and aluminum MicroGrid® meshes are essential at extending the life of hybrid carbon fiber composite blades.

PPG engineered materials are used in conjunction with the other parts of the entire lightning strike protection system for a wind turbine blade. Our mesh can provide connections between receptor(s) and anchor blocks/root through which high voltage current pass to ground connections.

To learn more about the benefits of PPG Engineered Materials, witness its lightning protection performance or understand how it can reduce your maintenance costs and down time, contact PPG at sales@dexmet.com or visit our web site and let us show you how to incorporate the innovative MicroGrid® materials into your composite designs and start recognizing the benefits today.

WINDPOWER ENGINEERING & DEVELOPMENT 30 FEBRUARY 2023 www.windpowerengineering.com

Custom content in a live, interactive or on-demand format

WTWH Media's webinars offer:

- Coverage of a wide range of topics

- Help engineers better understand technology or product related issues and challenges

- Present educational material related to specific topics

MEDIA LLC | WEBINAR SERIES

WWW.WINDPOWERENGINEERING.COM/WINDPOWER-ENGINEERING-WEBINARS WTWH

LEADERSHIP TEAM

VP of Sales

Mike Emich 508.446.1823 memich@wtwhmedia.com

Managing Director Scott McCafferty 310.279.3844 smcca erty@wtwhmedia.com

SALES

Jami Brownlee 224.760.1055 jbrownlee@wtwhmedia.com

Ashley Burk 737.615.8452 aburk@wtwhmedia.com

EVP Marshall Matheson 805.895.3609 mmatheson@wtwhmedia.com

Publisher Courtney Nagle cseel@wtwhmedia.com 440.523.1685

Jim Powers 312.925.7793 jpowers@wtwhmedia.com

Abaris .............................................................................. 14 AZTEC Bolting Cover, 25 HELUKABEL USA ............................................................. 23 Norbar Torque Tools, Inc. IFC PPG Engineering .............................................................. 11 Yuken ............................................................................. BC AZTEC Bolting ................................................................. 27 HELUKABEL USA 28 Norbar Torque Tools ........................................................ 29 PPG Engineering 30 WINDPOWER ENGINEERING & DEVELOPMENT 32 FEBRUARY 2023 www.windpowerengineering.com AD INDEX LEADERSHIP WINDPOWER ENGINEERING & DEVELOPMENT

@Windpower_Eng Looking for more ways to connect?

See the latest wind power developments and U.S. project news on our website. Also find expert webinars and more from the leading wind power engineering magazine today.

WWW.WINDPOWERENGINEERING.COM

The most trusted name in the US Wind industry! • Built to weather any storm • 3 Year warranty • Over 4,000 valves installed since 2014 ALA Industries Limited Check Us Out at Booth: S83153 Las Vegas • USA • March 14-18, 2023 ALA Industries Limited • 3410 Delta Drive • Portage, IN 46368 • Tel: (219) 762-2059 • Fax: (219) 762-2066 • www.alaindustrieslimited.com

Duke Energy

Duke Energy

BY EVGENIA GOLYSHEVA VP OF STRATEGY AND OPERATIONS • ONYX INSIGHT

BY EVGENIA GOLYSHEVA VP OF STRATEGY AND OPERATIONS • ONYX INSIGHT

BY WEI HUANG • DIRECTOR • ABS

BY WEI HUANG • DIRECTOR • ABS