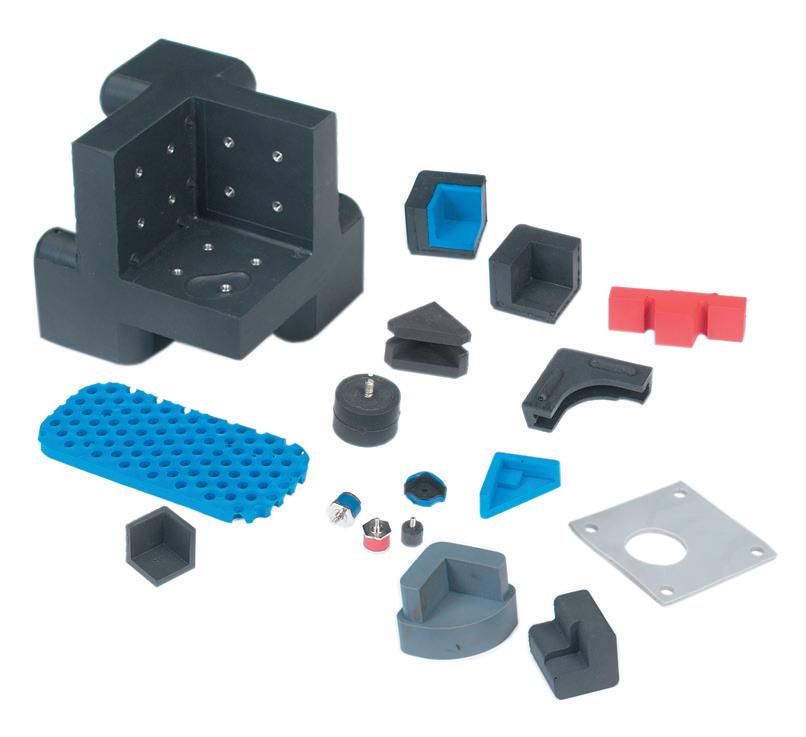

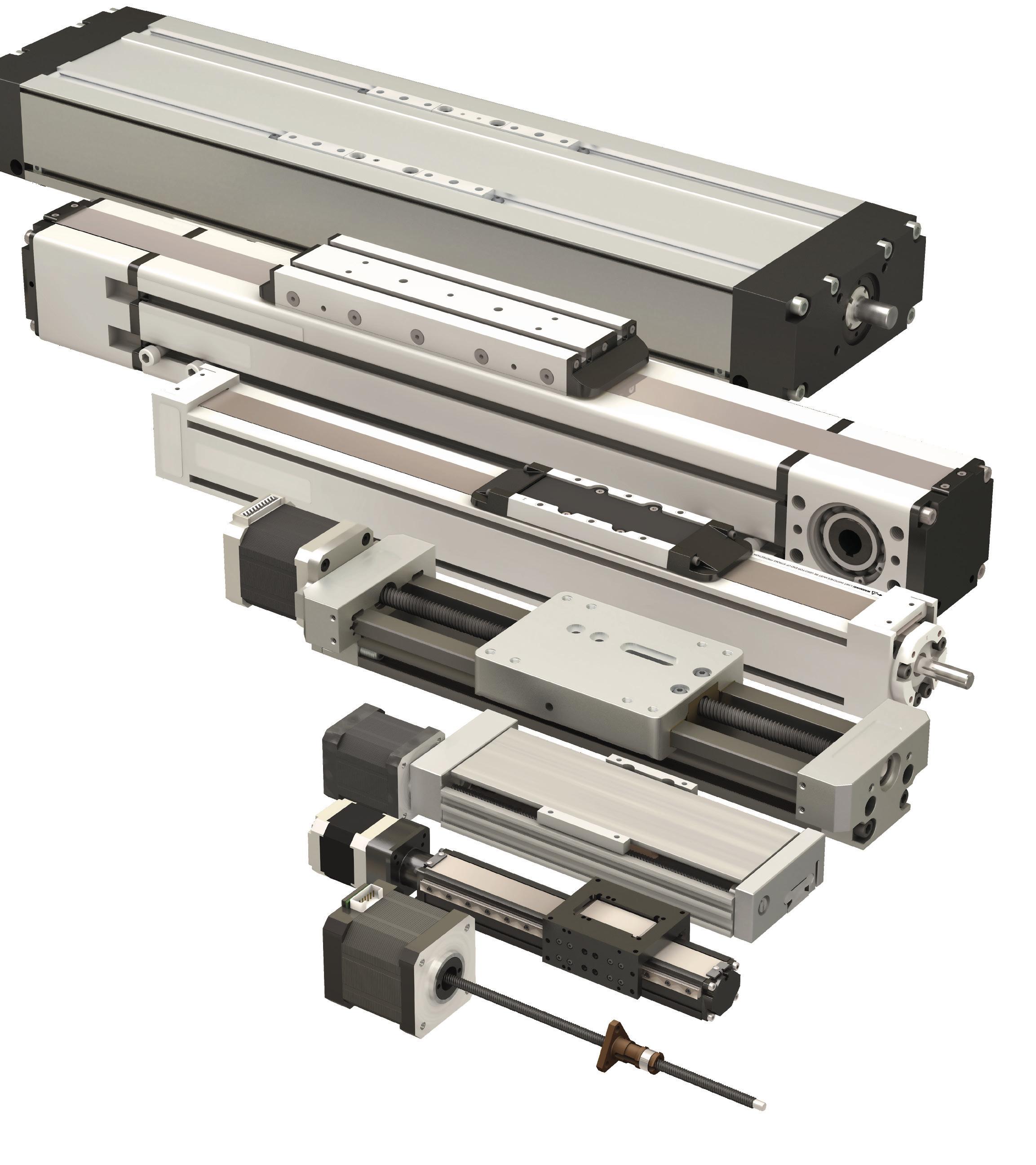

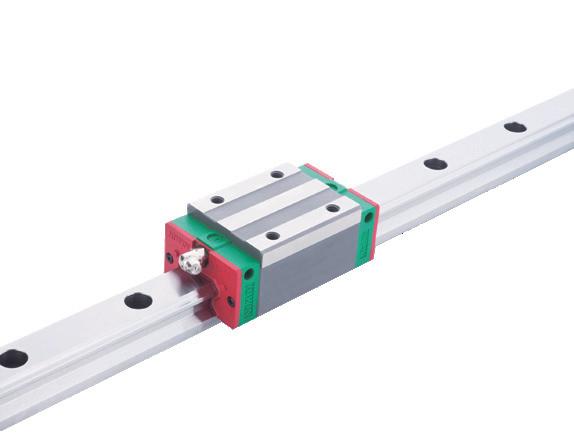

Ball & Crossed Roller Linear Slides

Del-Tron’s

Ball & Crossed Roller Linear Slides

• Accuracy ranging from 0.0005”/” to 0.0000040”/” of travel.

• Low friction straight-line design reduces the coefficient of friction to 0.003.

• Factory preload adjustment prevents side-play and backlash.

• Lightweight aluminum carriage and base with high load capacity.

• Inch or Metric built-in holes simplify installation and component mounting.

• Available with ball slide or crossed roller slide technology, varying precision grades and corrosion resistant materials.

• Solid Models Available for all Del-Tron Models.

LS Electric XMC Motion Controller

Starting at: $779.00 (XMC-E08A)

XMC for Xact motion control - XMC controllers utilize the EtherCAT high-performance protocol which is specifically designed for real-time communication and deterministic data exchange, making it ideal for precise motion control applications.

XMC for EtherCAT Xpansion -XMC controllers feature full EtherCAT Master capabilities, meaning they can communicate with and/or control any EtherCAT device including EtherCAT I/O, encoders, AC drives, etc.

The LS Electric XMC motion controller has numerous tate-of-the-art features built into its compact brick-style design. These controllers are optimized for advanced motion control, are available in 8- or 16-axis models, and offer a variety of high-tech capabilities for a price that can’t be beat! Research, price, buy at: www.automationdirect.com/motion-control

XMC for Xtensive automation -Not only can XMC controllers handle numerous EtherCAT devices, they also support G-code, M-code, and programming specific to robot control including Delta3, Delta3R, Linear Delta, and more.

XMC for blazing fast Xecution -The XMC controllers offer extremely fast processing capabilities, with a scan time of 6.25 ns for basic commands, 5ns for motion commands, and 30ns for arithmetic commands. EtherCAT-based high-speed communication cycle times are 0.5/1/2/4ms.

XMC for Xtreme value - The XMC controller provides both highly advanced motion control with EtherCAT communication and built-in PLC functionality for a price well below the competition. By using the powerful XMC controller for your next motion control application, you could save thousands on hardware costs alone, not to mention the FREE software and support!

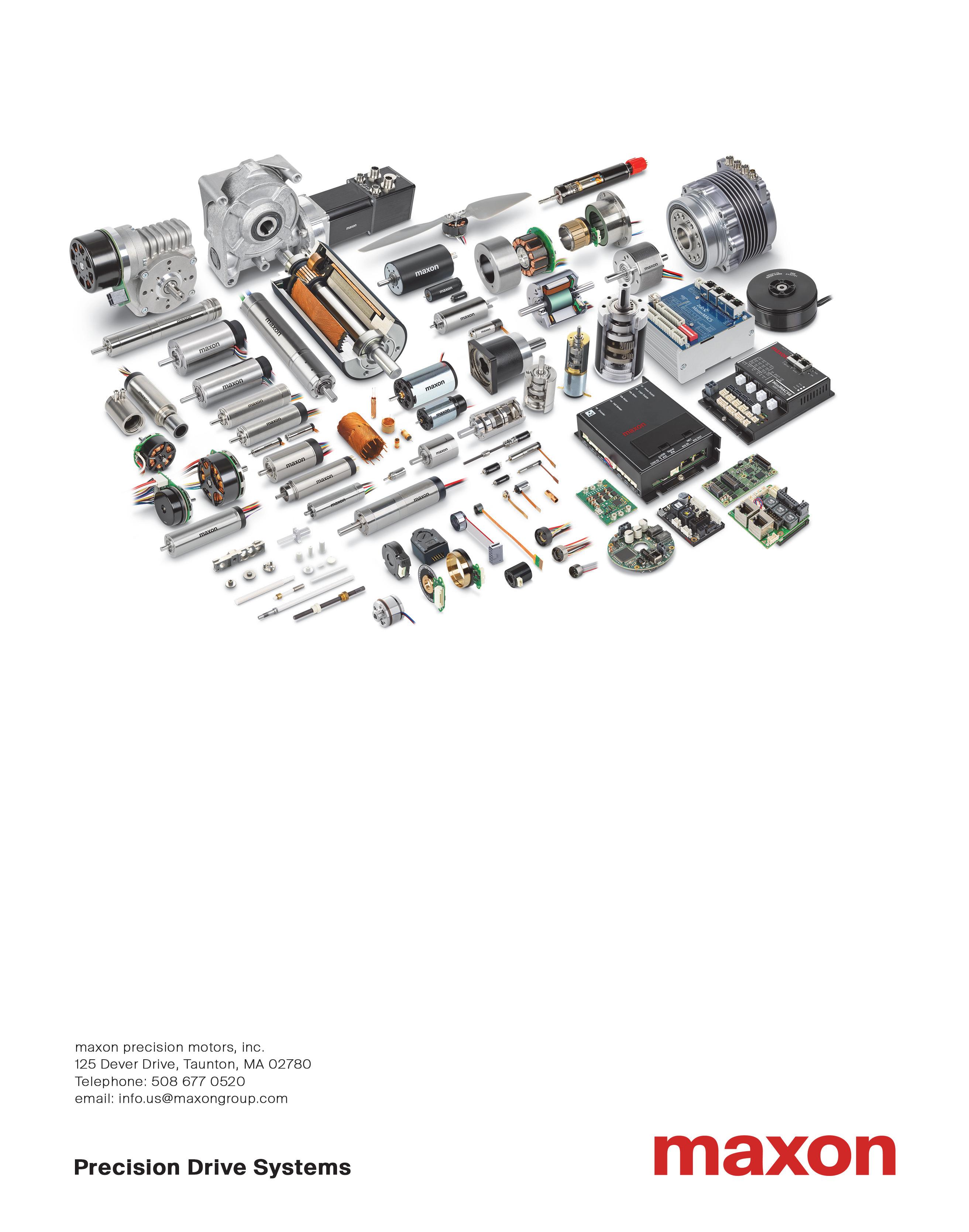

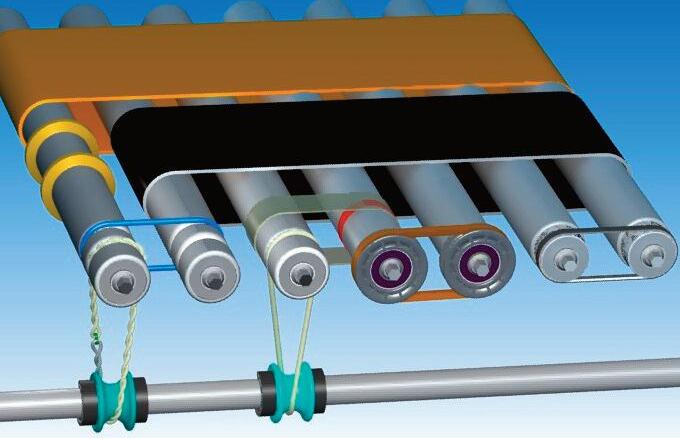

At Regal Rexnord, we are harnessing the power of one to transform innovation in your operations. By bringing together industry-leading engineering and best-in-class brands, we deliver both standard and custom solutions - all from a single source.

Our conveyance systems, predictive maintenance platforms, condition monitoring hardware, servo motors, and precision drives are designed to optimize speed, enhance precision, and ensure unmatched reliability.

One Supplier. One Vision. One step ahead. Learn how our engineering excellence and cutting-edge technology drive innovation forward.

Learn more at rrx.link/one-regalrexnord

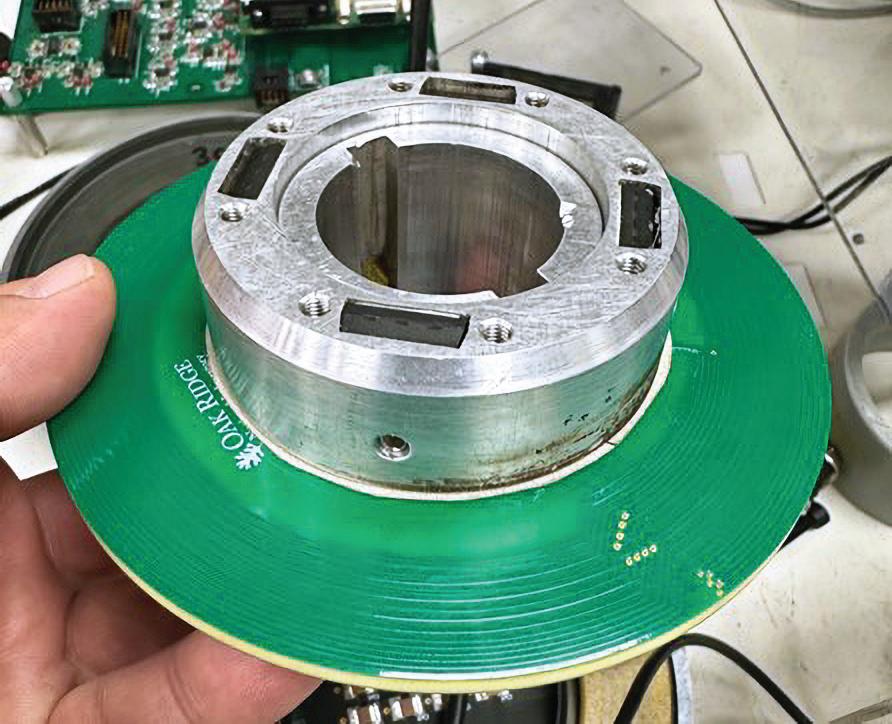

NEW MOTOR COULD SPUR NEW APPLICATIONS

It often happens than new technologies enable new forms of automation — or makes them more practical. One new electric-motor design recognized by this year’s R&D 100 Awards could prove one such technology.

weakening at high speeds to satisfy EV and industrial-machinery applications requiring broad speed ranges. WRSMs can also adjust excitation for optimal efficiency and torque control across varying loads. In contrast, PMSMs suffer from constant magnet flux than can cause inefficiencies at high speeds and limited flexibility in torque control.

Now, researchers at Oak Ridge National Laboratory (ORNL) have designed a rotary-transformer–based wireless excitation system to help WRS

LISA EITEL

LINKEDIN.COM/IN/ELISABETHEITEL

MOST ELECTRIC VEHICLE OR EV MOTORS use permanent-magnet synchronous motors or PMSMs with the magnets on their rotors, and these rareearth materials are imported to the U.S. — 98% from China. That could prove a liability given today’s political upheaval, trade standoffs, supply-chain risks, and commodity-price fluctuations trending upward.

While eliminating permanent magnets, wound-rotor synchronous motors or WRSMs conventionally use brushes or slip-ring systems for an electromagnetic solution to deliver rotor excitation current. The drawback is these electromagnetic elements can be bulky, inefficient at high speeds, and in need of occasional maintenance. That said, all WRSMs have several advantages over PMSMs — particularly in applications for which efficiency, controllability, and sustainability are priorities.

WRSMs enable precise control of the rotor field via external excitation which in turn makes for unbeatable field

A new WRSM design offers the efficiency and reliability of PMSMs sans reliance on rare-earth magnets.

motors better compete against PMSMs. This design leverages 17 years of ORNL expertise in wireless power transfer, 82 years of ORNL electromagnetics expertise, and 40 years of power electronic converter expertise. How does it work? Well, the system has a stationary (primary) side and a spinning (rotor) side. On the stationary side, ORNL’s high-frequency power inverter operates as a high-frequency resonance inverter that powers the primary coil

Brushes and slip rings wear over time, requiring replacement

Commutators incur friction losses

Brushes and slip rings can cause sparking

Brushes and slip rings may destabilize at high rpm

Brush systems generate EMI

Environmental factors (dust, vibration, moisture) degrade brushes

Cost effective

No mechanical wear of electric-transfer elements

High efficiency due to direct permanent-magnet excitation sans contact losses

No risk of electrical arcing

Usually offer superior stability at elevated rpm

Naturally low electrical noise so useful in sensitive systems

Generally reliable but magnet strength can degrade should the motor be exposed to high temperaturesor other extreme conditions

Rare-earth magnets can be costly and are subject to supply-chain interruptions

No mechanical wear of electric-transfer elements (for longer motor life)

No friction losses for efficiency closer to PMSM levels

No risk of electrical arcing (for inherently safe operation in high-voltage environments)

Smooth and stable operation at high rpm

Cleaner transfer to reduce electrical noise

Very robust in harsh settings

Conventional materials are cost effective

through a resonant tuning network. The primary coil generates a magnetic field that is linked to the spinning rotor–side coil inducing voltage. This voltage is rectified on the receiver coil and rectifier integrated assembly while output dc current is applied to the rotor windings.

The design’s advantages abound. The rotor current is accurately estimated sans sensing or communication devices. The rotor side uses an integrated secondary coil with a rectifier on the same printed circuit board. The simple rotor-side architecture eliminates resonant tuning components on the rotor side as well as capacitors. The PCB uses a tracestranding and transpositioning system that can mimic Litz wire with low losses. A dc-measurement method can integrate into the stationary side to read the current on the rotary transformer. A position sensor is semi-integrated into the rotary transformer so there’s no need for an expensive resolver, either.

A polyphase version of the rotary transformer eliminates housing-assembly eddy-current losses that are usually the primary cause of PMSM losses. • R&D WORLD | RDWORLDONLINE.COM

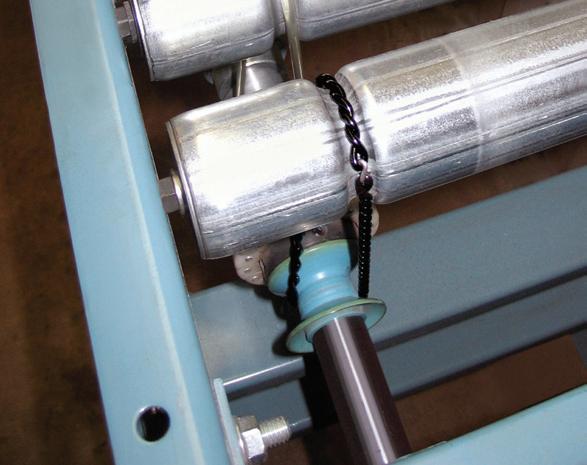

For BKB Cedar, productivity gains and operational reliability creates compelling value. “The operators say the system just runs without a hitch, and that impresses them,” said Zuhlke. “Every day, it starts up and runs the way it should.”

CONTROL MAKES FENCE-POST DRILLING FASTER AND BETTER

On the manufacturing floor of British Columbia-based BKB Cedar Manufacturing, the whine of the drill motor and churning of its bit into tough cedar posts made a reassuringly steady cadence — until, too often, it didn’t.

Workers would manually position posts by moving a heavy carriage back and forth between drilling operations. They would then manually drill into the posts, expecting a smooth down-and-up motion, only to hit a knot that snared the bit and halted production. This labor-intensive process was already slower and more physically straining on operators than BKB Cedar wanted, but jams, dull bits, and other unexpected snags only made it worse. The company struggled to meet production deadlines — often adding a second operator to the drill station just to keep pace. But even with two people, production peaked at 600 posts per eight-hour shift.

“The initial thought was to add some sensors and maybe

Image: BKB Cedar

Drive Forward with EtherCAT from Delta Motion

HYDRAULIC VALVES MOTOR DRIVES

change the hydraulic valves to electric valves, then have it controlled by a PLC to accomplish pretty much the same thing,” said Glenn Zuhlke, owner-operator at MicroWest Design, the automation integrator BKB approached for help. “But when I went to have a look, I realized there could be a major speed advantage if we had better control of the hydraulic axis.”

Upgrading a system like BKB Cedar’s fence drill isn’t just about dropping in a new controller. The original fence drill was built in the 1980s and exemplified that era’s manual control systems. While the basic hydraulic concept remained sound, the manual carriage operation and mechanical stops reflected decades-old thinking about manufacturing efficiency. It was long past time for improvement.

MicroWest ultimately chose a hydraulic motion controller from Delta Motion known as the RMC to achieve major control improvements, but that was only part of the solution. As Robert de Rot of PQ Systems, who collaborated with MicroWest on the hydraulic design, explained, the broader process often involves a more comprehensive overhaul.

“It’s not just a matter of like throwing the RMC at the old valves and the old cylinders because that would not have worked very well at all,” said de Rot. “The existing system featured basic components, like a three-inch bore cylinder chosen to slow down an overly quick system due to rudimentary on-off valves. Their hydraulics needed a complete makeover … to get to the state of even having the opportunity to talk to an RMC.”

This involved careful assessment and multiple iterations. PQ Systems went back and forth a lot with the client to understand the motion, weights, and forces in play. Overhauling the system included sizing a new cylinder, selecting a correctly sized Moog D634 servo proportional valve, and integrating Temposonics position feedback. Through this detailed hydraulic and mechanical refinement, MicroWest and PQ Systems laid the foundation for advanced motion control. As de Rot put it, after the extensive work on the hydraulics, “the magic of the RMC took over from there.”

He added, “We went through several iterations of valves and hydraulic sizing to get the system right, but the Delta was the easy part.”

Zuhlke’s experience with other controllers led him to Delta Motion. MicroWest Design had used other controllers in the past, but each brought its own issues. Zuhlke recounts how one controller would lose its position whenever the power cut out. When MicroWest Design needed support for the bug, the manufacturer promised a fix in a later version, as if the customer could wait a year or more.

In contrast, after successfully implementing a Delta Motion system on a 13-axis project, Zuhlke knew he’d found his preferred solution.

“That project just went so well. There’s no way we’ll go back to what we used before.”

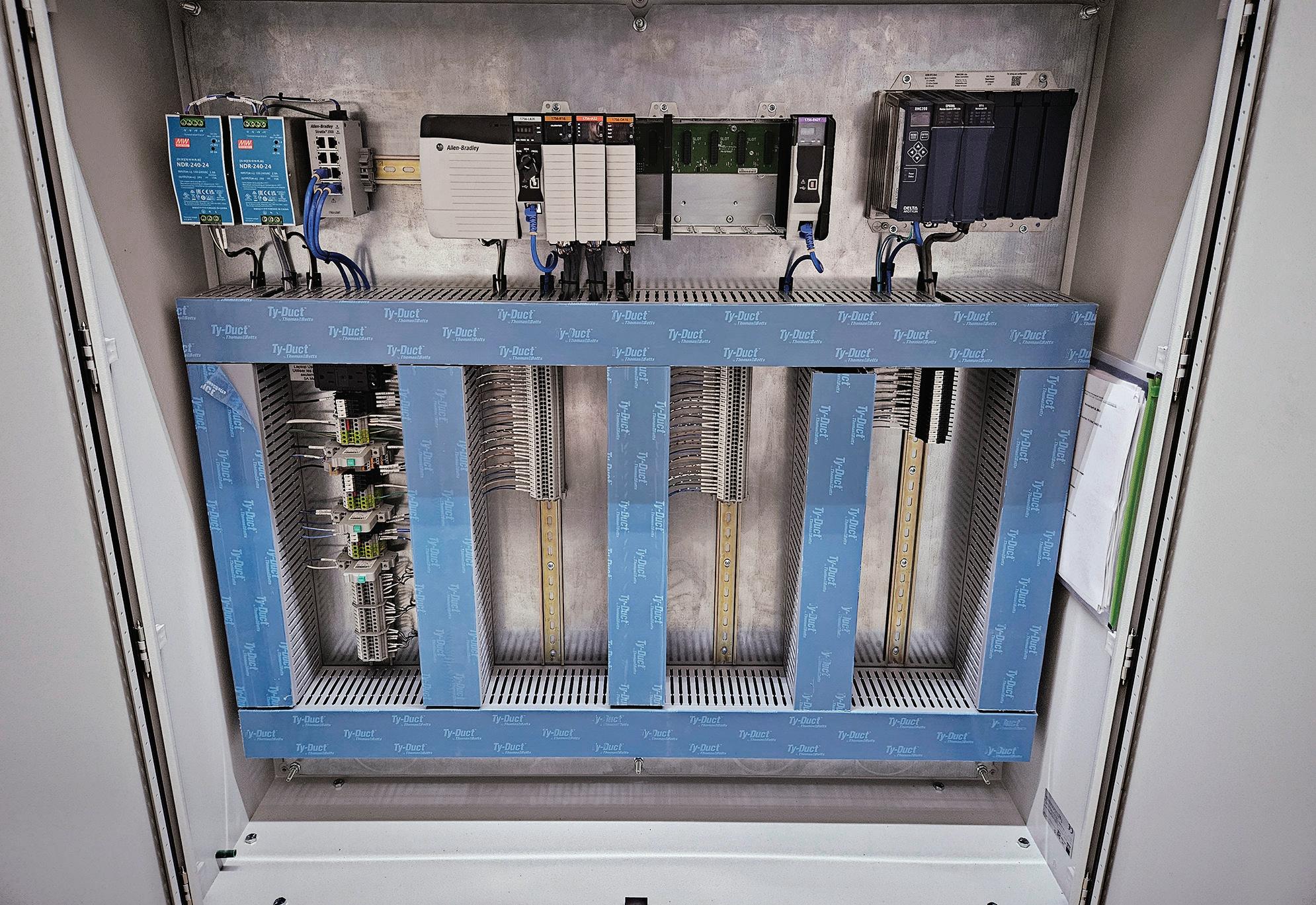

For BKB Cedar, Zuhlke, with guidance from PQ Systems on the motion controller selection, opted for Delta Motion’s RMC200. The controller provided three critical functions

for the fence drill retrofit: vertical drill positioning, horizontal carriage movement, and pressure monitoring to prevent jams. The choice of the RMC200, specifically a seven-slot version, also provided BKB Cedar with room for future expansion.

“The solution uses the vertical position as well as the pressure to control the up-down movement of the drill,” explains Zuhlke. “The Delta controller subtracts the pressure readings from either side of the cylinder and converts that to force. If it’s going down too fast and there’s too much force, the controller sees that pressure feedback and slows the speed, so it doesn’t jam the drills.”

Before automation, BKB’s drill operators drove bits to mechanical stops, wasting motion and time. The Deltapowered system uses lasers to measure post thickness, enabling an exact 1.5inch drilling depth regardless of post variations. This precision enables smarter drilling profiles.

“With Delta’s motion control,” said Zuhlke, “we go full speed down until we get to the wood, then we slow the drilling speed. And when it comes out of the hole, we go full speed, as well. We promised the client fifteen-second cycle times. They’re averaging ten now.”

The ease of use of the Delta Motion platform was a significant factor in the project’s success. Once PQ Systems helped define the hydraulic requirements, the application was handed off to Glenn Zuhlke at MicroWest. His familiarity with Delta controllers ensured a smooth transition. Robert de Rot highlighted this, noting that Glenn “didn’t need to call for assistance with the Delta, nor did he call Delta support — not once” for the Deltaspecific aspects of the project.

Despite a very smooth design and implementation process for the Delta controller, the BKB Cedar job had one or two issues to iron out related to the overall system. Notably, MicroWest Design encountered an unexpected vibration. Delta helped them discover that the problem was actually mechanical in nature and not related to the drilling motion. However, along the way, Delta exposed MicroWest to something they’d never tried

before — using Delta’s bundled RMCTools software to tune motion using a previously captured plot of motion.

This capability helped optimize performance and let MicroWest and BKB continue fine-tuning the system while running. Operators would put the axis through the motions during normal operations as they produced the product. These recorded motion plots were then used to tune the axis on the fly.

Zuhlke emphasizes Delta Motion’s support advantage. “Go to Delta quickly for help. If you’re thinking about implementing a project, call somebody at Delta and tell them what you’re planning.

They’ll help you come up with the best solution right away.”

Results were dramatic. The revamped drill system shattered BKB’s production records while dramatically reducing physical strain on operators. “Their previous record was between five and six hundred posts [per shift] with two people,” Zuhlke noted. “Now they’ve topped over eight hundred with one operator. They’ve almost doubled their previous rate.”

Beyond throughput, the system eliminated the frustrating downtime caused by jammed drills and the safety hazards of manual jam removal.

Previously, operators would

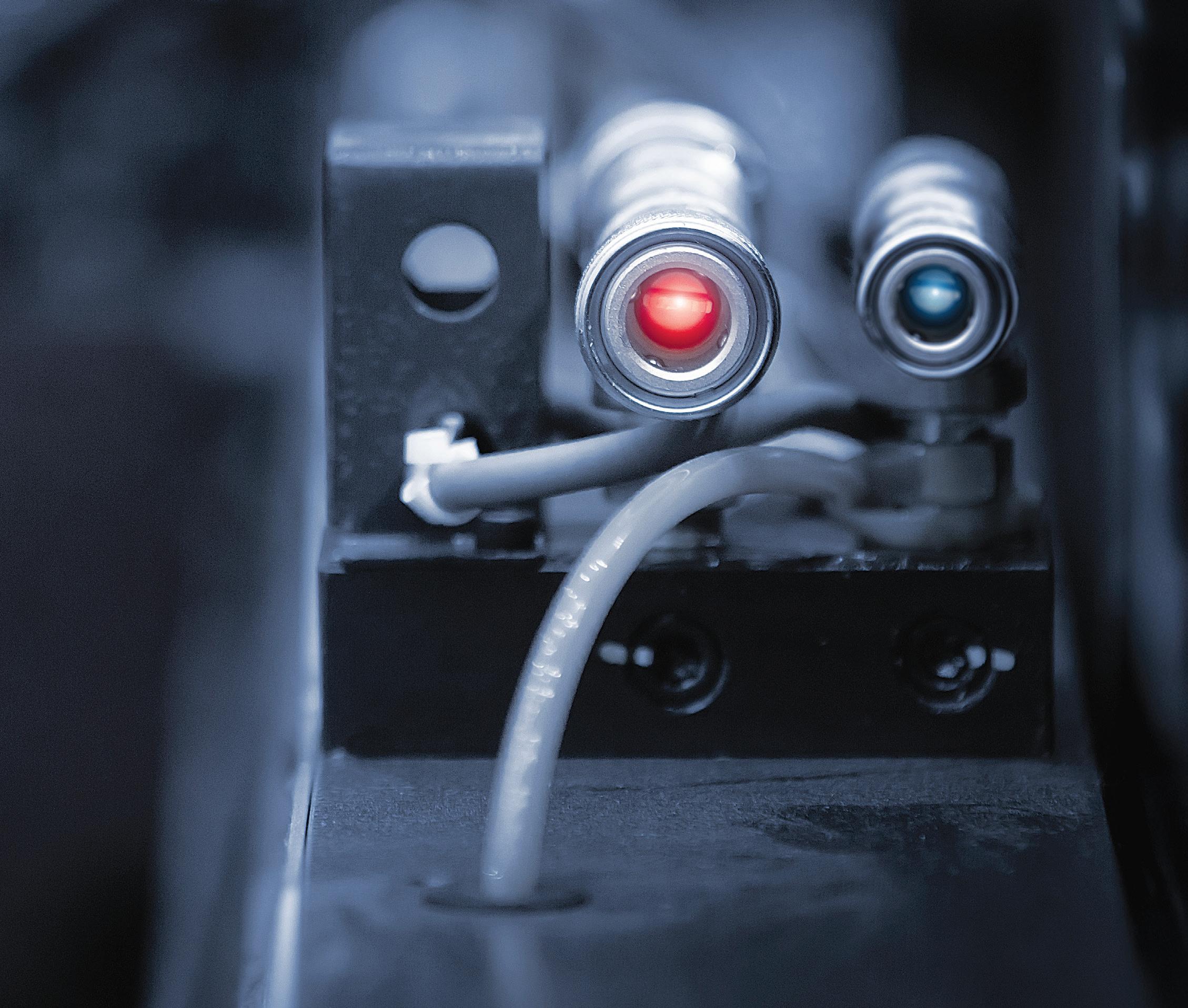

Newfound reliability with Delta’s precision motion-control transformed what was once a manufacturing bottleneck into a competitive advantage, proving that sometimes the smartest investment is to upgrade system controls rather than replacing machines outright. Shown here is the Delta Motion controller in a cabinet with other machine electronics.

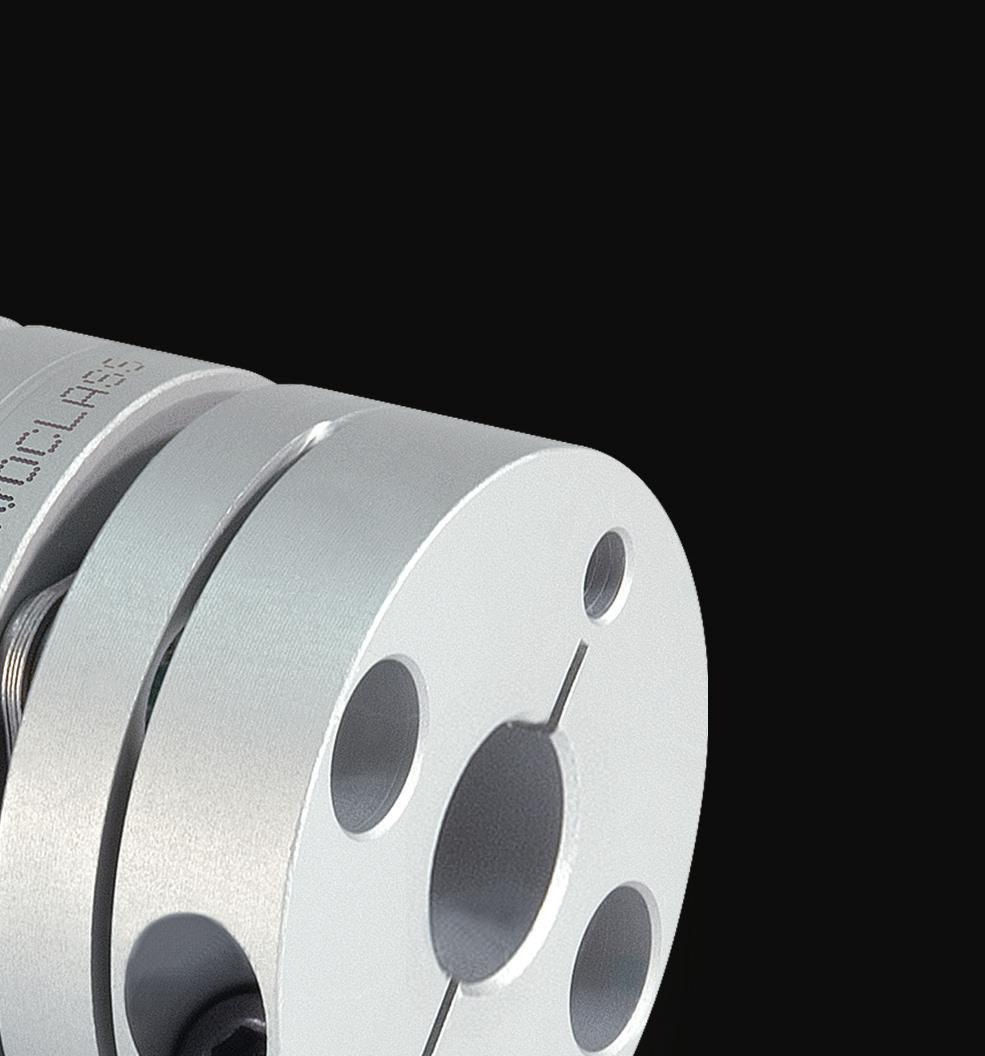

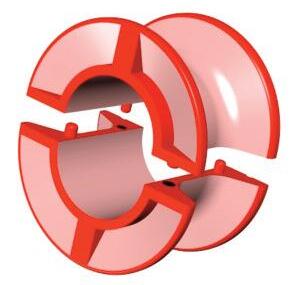

LARGE BORE DISC COUPLINGS

• Bore sizes up to 1-3/4” and 45mm

• Torque up to 1150 in-lbs (130 Nm)

• Reduced vibration due to a balanced design

• Double disc for increased misalignment

LARGE BORE BELLOWS COUPLINGS

• Bore sizes up to 1-3/4” and 45mm

• Torque up to 1300 in-lbs (152 Nm)

• Reduced vibration due to a balanced design

• Highest torsional stiffness

SHAFT COLLARS WITH FACE HOLES

• Maximum mounting flexibility with drilled holes

• Most secure mounting connection with thread- ed holes

• Bore sizes from 3/8”-2” and 10-50mm

• Carefully made by Ruland in aluminum, steel, and stainless steel

INCH-METRIC RIGID COUPLINGS

• Widest selection of standard inch-tometric bores with or without keyways

• Supplied with proprietary Nypatch® anti-vibration hardware

• One-piece style for easy installation

• Two-piece style with a balanced design

encounter knots at typical rotation speeds, and the bit would jam before the operator could detect a problem. Once a bit jammed, getting it out was difficult.

“Whenever something happens out of the norm, that’s when there’s a possibility

of injury,” added Zuhlke. When you need to unstick or fix something, what’s your first instinct? Reach in, right? You shouldn’t get your hands in there, but the temptation is always to try and get production running again.”

Fortunately, the Delta-based solution monitors both pressure and motor current. The system automatically recognizes changes at the microsecond scale and slows the bit accordingly to eliminate jams and their resulting downtime, improving both throughput and safety. The automated system also eliminated the need for operators to lean in close to manually align posts, replacing human positioning with laser guidance that keeps workers at a safe distance from the drilling operation.

This vigilance also improves quality. “Now we’re drilling a one-and-a-halfinch hole,” said Zuhlke. “We’re not just ramming the drill down to a stop that’s strangely high off the work surface. The system actually sees the top of the post and knows precisely how far down we need to go. So, the output is exactly to spec, and customers are happier with the quality.”

So, what of the impact on BKB’s workers? These days, there’s uncertainty about how automation can and will impact human workers. Obviously, BKB’s upgraded drill system is only partially automated, but this Delta upgrade and

BKB Cedar’s new system shows that Delta Motion’s precision hydraulic control can revitalize even decades-old equipment, resulting in dramatic productivity gains without the need for costly capital expenditures. Higher throughput, fewer jams, and reduced labor costs were all made possible with a new controller, valve, and feedback.

BKB Cedar’s new system leverages the full capabilities of Delta Motion’s controller. The success of the BKB project has prompted automation integrator MicroWest to consider Delta Motion for upcoming projects.

Images: BKB Cedar

others brought Zuhlke to an unforeseen insight into the effect of automation — or at least this sort of partial automation — on worker productivity.

“Automate for as much performance as you can,” he advised. “If there’s an operator there, you want to keep him busy. The machine should push the operator.”

With BKB Cedar’s new system, the post platform automatically produces the finished product once drilling is complete. There’s less pause between drill cycles, so it gives operators an incentive to work faster. This approach contrasts with Zuhlke’s previous experiences. “I’ve automated things in the past that would bore the operator, that would slow things down because performance wasn’t prioritized. You want to push the operator, not bore them. Help them rise to the challenge, like how your tennis game improves when you’re up against a slightly better opponent.” •

DELTA MOTION | DELTAMOTION.COM

Superior encoders for position and motion control

With a comprehensive line up of

Powerfully

Shown here is the finished BKB Cedar fence product installed in a field.

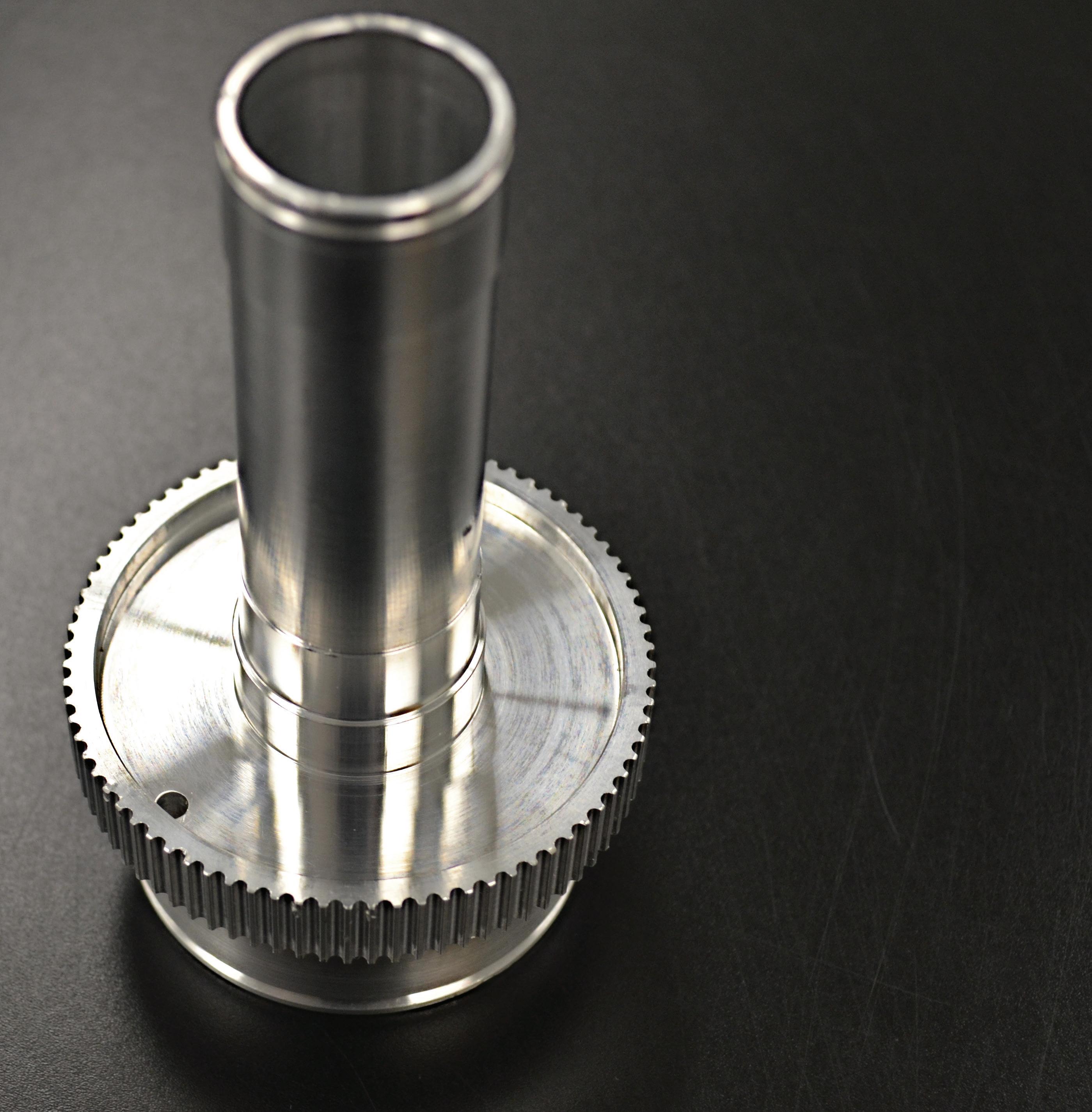

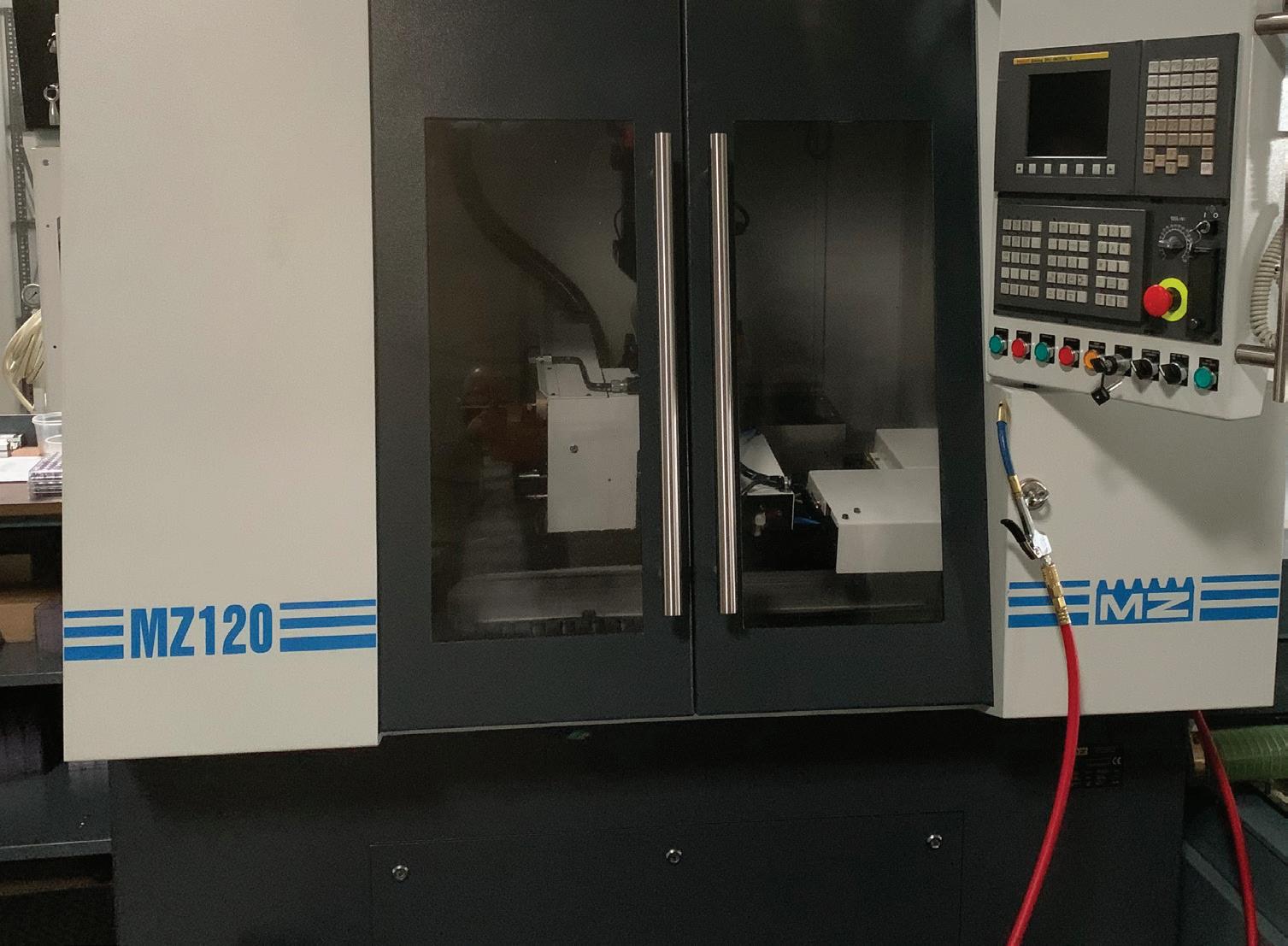

Custom Synchronous Drives

You’ve created a unique design. Now relax. We’ll take it from here.

Custom precision manufacturing.

Manufacturers of Power Transmission and Motion Control Components

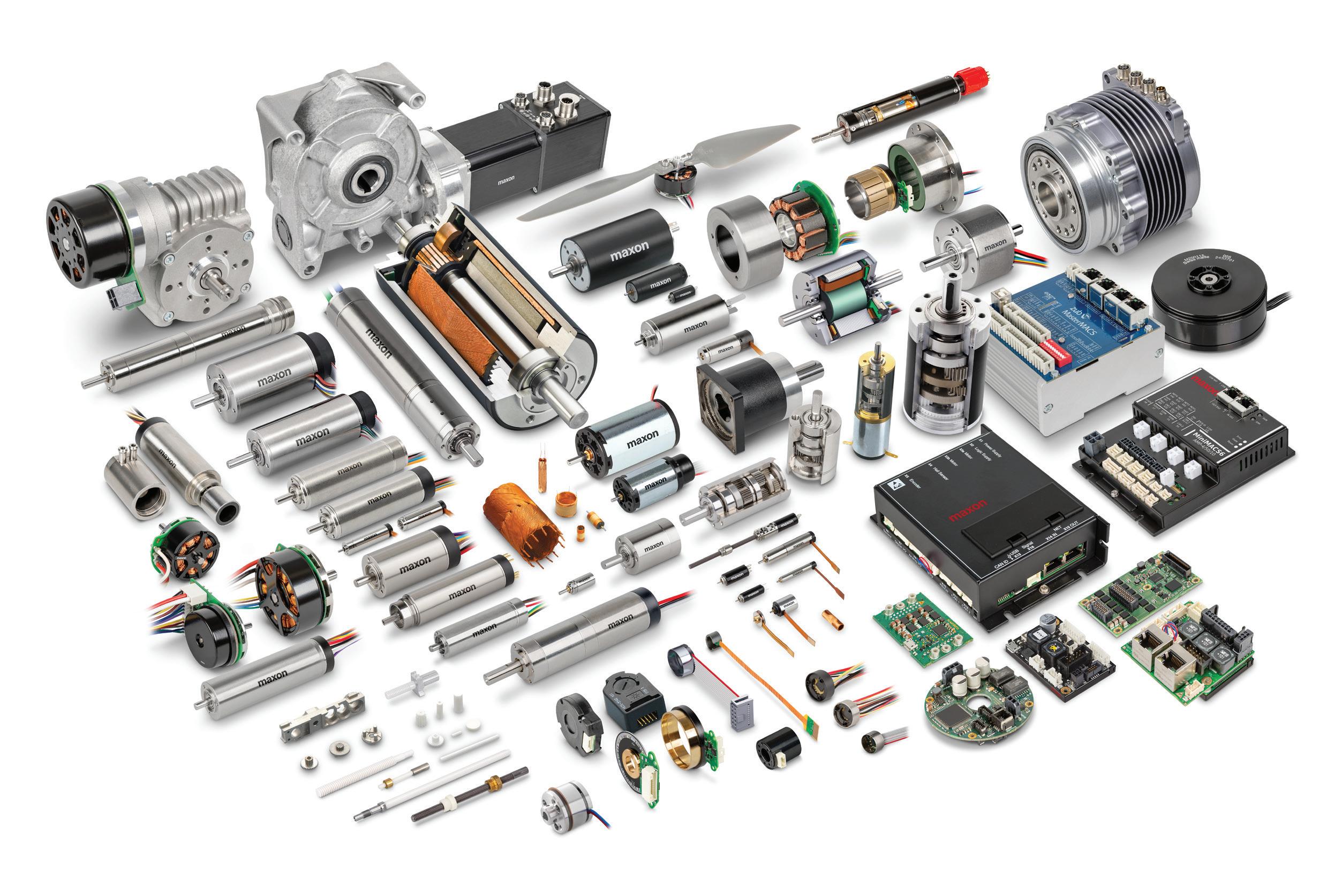

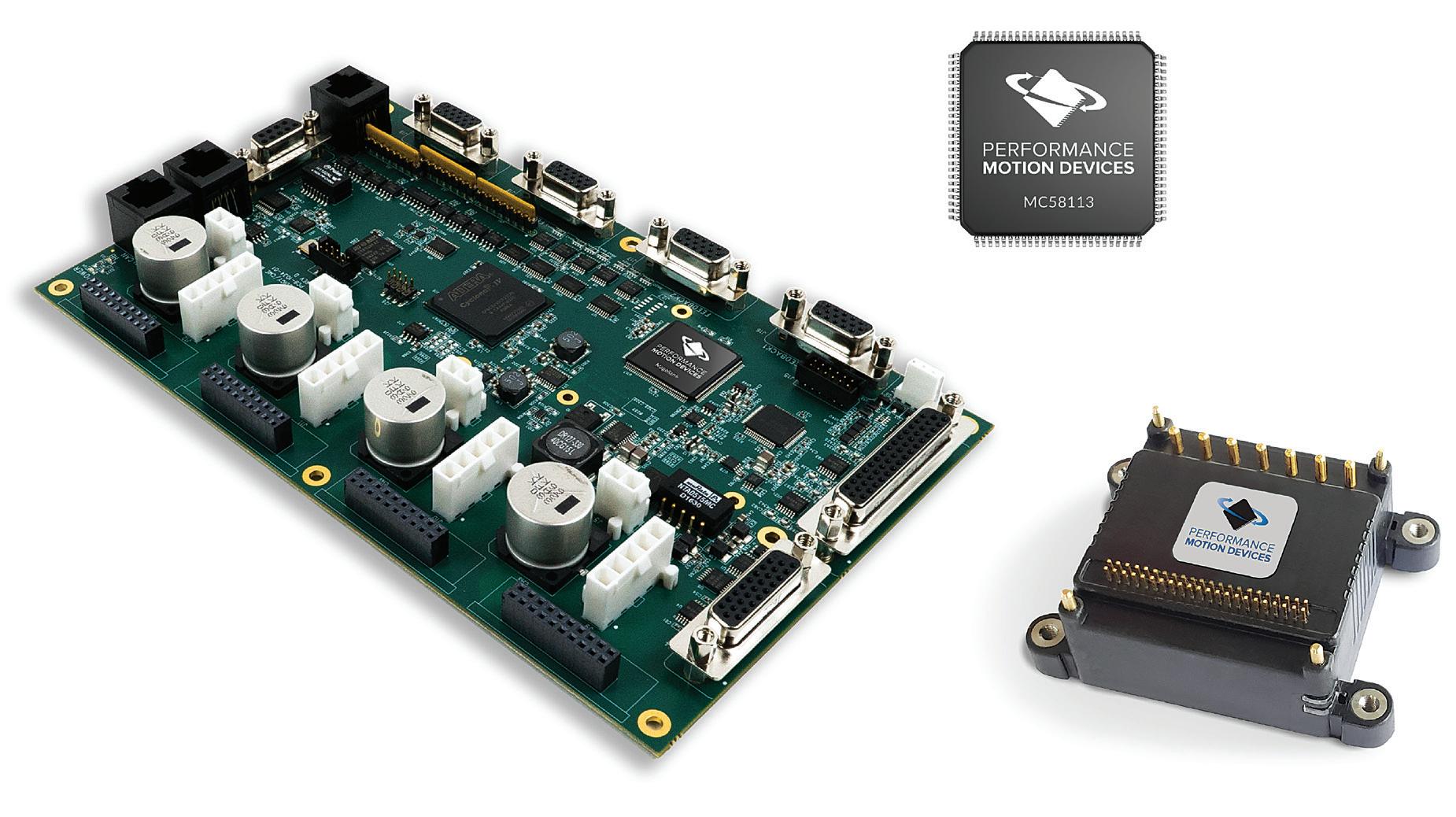

ROBOTICS DESIGN LEVERAGES MOTION DEVELOPMENT

Helping robotics companies bring their projects to completion, OLogic increasingly turns to Performance Motion Devices for motion control technology without limits.

Silicon Valley–based OLogic has helped robotics and consumer electronics companies — from startups to industry leaders — bring products to market. Past customers include NVIDIA, Google, Hasbro, Panasonic, Toyota Research Institute, and Carnegie Mellon University.

OLogic brings decades of experience designing DC motor systems for a wide range of applications. But when it comes to delivering advanced motion control for robotics, even OLogic benefits from having a trusted partner.

That’s why the team repeatedly turns to Performance Motion Devices (PMD) — a company with the embedded motion-control technologies, deep motioncontrol expertise, and the engineering support to help bring complex designs across the finish line. As of mid2025, OLogic has used PMD motion control solutions in at least four robotics projects.

For Ted Larson, CEO and co-founder of OLogic, the reason is clear: PMD consistently delivers great technology for commercial products, great solutions and tools for developers, and great support when it matters most.

Larson draws a sharp line between hobbyist

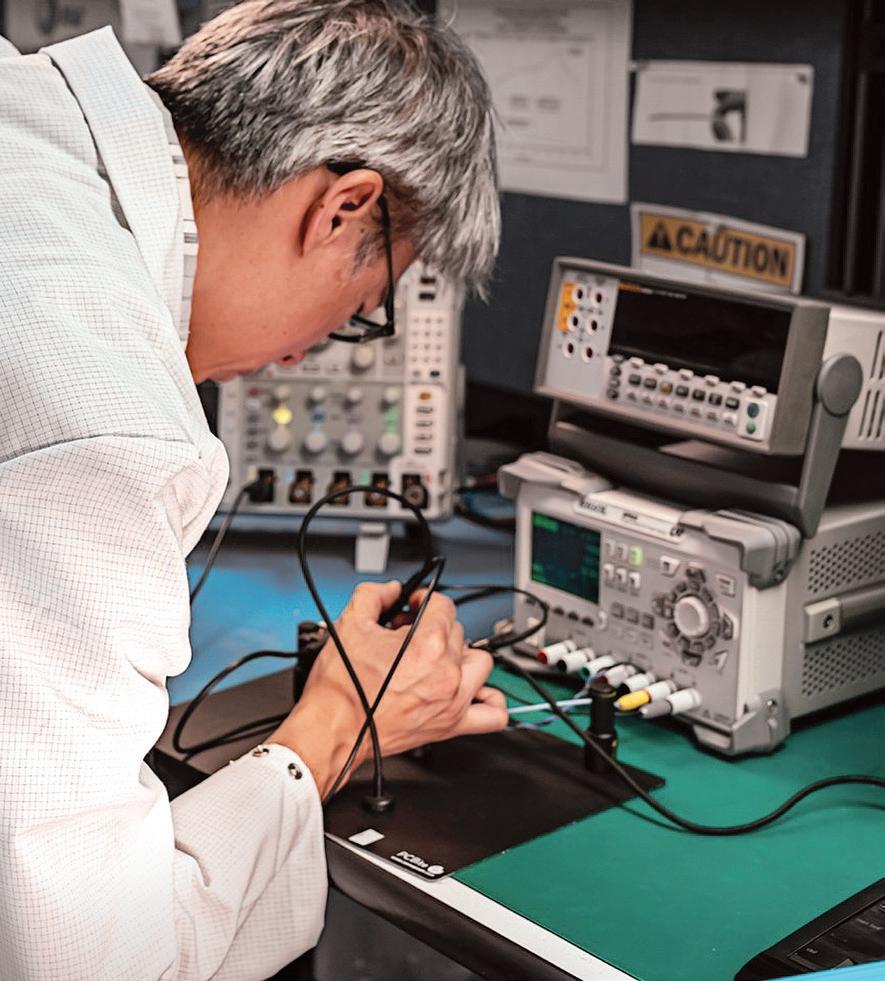

Image: OLOGIC

PMD's ICs and drives are designed for commercial applications.

prototypes and commercial robots. Many developers start with off-the-shelf components, often adapted from industrial or academic settings, but soon find these parts inadequate. Meanwhile, robots also face unique challenges: space and power constraints, variable duty cycles, and the need to switch seamlessly between velocity and position control.

That’s why OLogic relies on PMD, whose ICs and drives are designed from the ground up for commercial applications. They deliver the precision, efficiency, and reliability that OLogic’s customers — from delivery robots to mobile platforms — need in the field. With PMD, OLogic can design motion systems that are robust enough for daily operation, not just one-off demonstrations.

OLogic often works with customers who have run successful trials but lack a path to volume production. The solution, Larson argues, is designing for scale from the start: “We advocate for building a highly bespoke electronic system that’s specifically designed for manufacturing,” he said.

OLogic relies on PMD, whose ICs and drives are designed from the ground up for commercial applications.

That means consolidating electronics onto one or two boards for simpler assembly, troubleshooting, and cost reduction over time. PMD’s product range provides a clear path to this kind of bespoke design. Customers can start with development boards, migrate to motor control modules like the ION/CME N-Series intelligent mini-drives, and eventually embed PMD ICs directly into custom designs. This progression keeps costs manageable while ensuring scalability.

OLogic has found clear advantages in using PMD’s command-based motion chips rather than starting with a raw processor.

“By relying on PMD chips where the control algorithms and command set are already embedded, our engineers avoid the time-consuming process of writing and debugging

Image: Performance Motion Devices

Longer Lasting Belts & Pulleys

« Ultra-Drive belts on standard rollers move 350+ lb boxes

« Super Strong Joints are virtually unbreakable

« Low cost, highly efficient, elastic flat belts.

« High Tension Belts move heavier loads

« HEHT black belts double capacity

l

l

Line-shaft Spools

low-level motor control code,” Larson said. “This speeds development, reduces risk, and allows our team to focus on system-level innovation instead of reinventing the basics of motion control.”

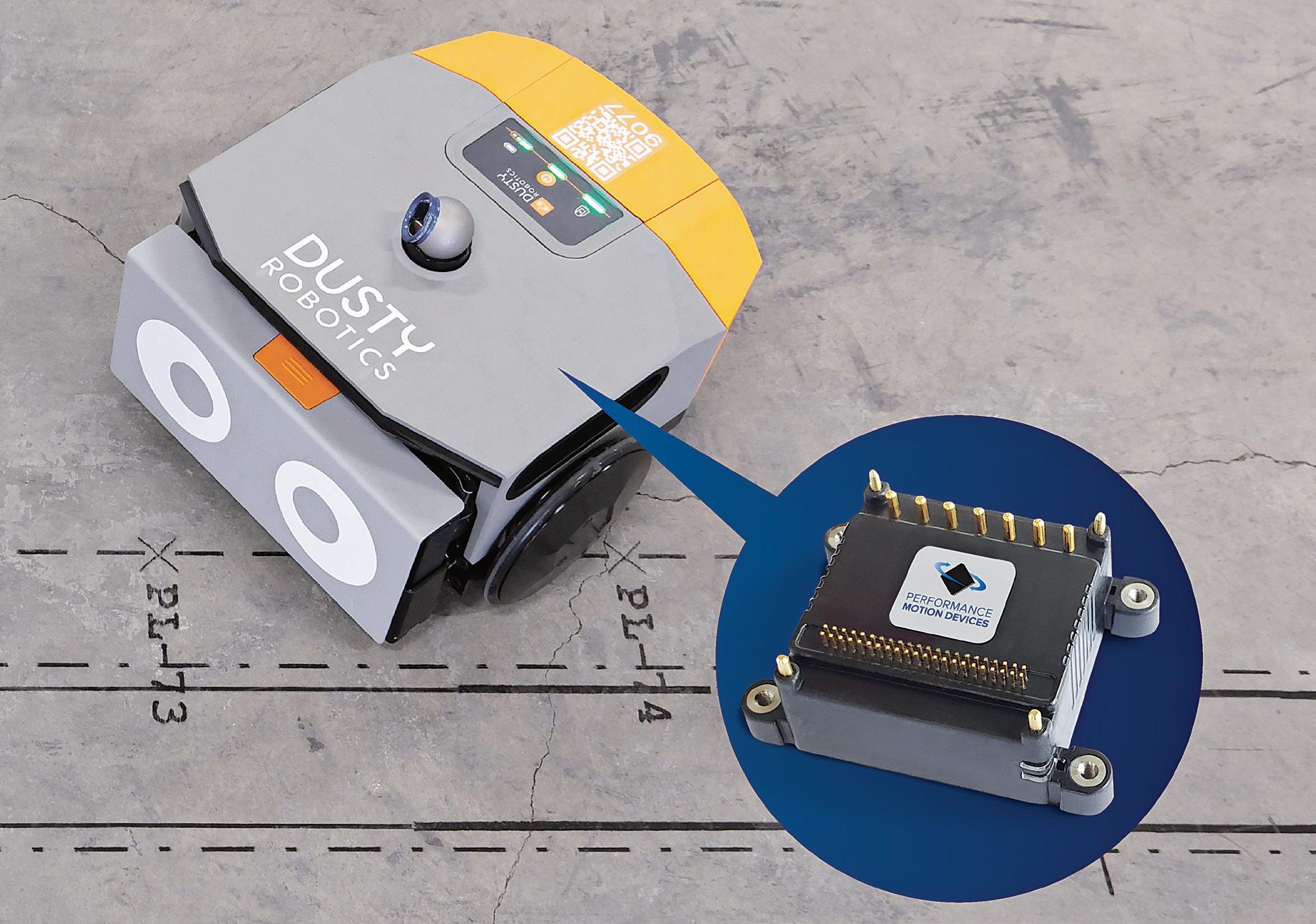

PMD’s ecosystem of motion-control solutions has repeatedly helped OLogic deliver under pressure. One notable example was OLogic’s work with Dusty Robotics on its FieldPrinter autonomous mobile robot (AMR) for construction sites. The robot’s original motion controller became unavailable during the global semiconductor shortage, jeopardizing production.

Dusty needed a replacement controller that fit within the existing footprint and integrated smoothly with the design. PMD’s ION/CME N-series motion control drive proved the perfect solution. Compact and PCB-mountable, it provided both the form factor and the advanced diagnostics Dusty’s engineers needed. By developing a custom carrier board, OLogic ensured seamless integration, allowing Dusty to continue production without missing a beat.

This episode highlighted two critical PMD strengths: reliable supply, even during a global shortage, and products versatile enough to fit demanding robotics applications. For Dusty, PMD technology helped transform a potential crisis into a smooth path forward.

PMD’s N-Series not only fit nicely within the small footprint constraints, but it also provided Dusty’s robotics engineers with essential insight and the access to internal control parameters needed to customize and troubleshoot.

Designing motion control comes with its fair share of challenges. Not only is PMD there to provide the support necessary to get projects off the ground — including being very able and willing to develop custom features — PMD’s solutions give OLogic the flexibility and tools to address these issues.

• Sensorless motors: PMD chips allow engineers to add encoders and use them as sensors, creating reliable control systems without requiring dedicated motor sensors.

• Current management: Instead of oversizing motors and risking power drain, PMD ICs enable precise matching of motor, FETs, and H-bridges to ensure efficiency and stability.

• Energy handling: Large motors can generate significant energy when slowing down. PMD’s Juno chip supports

We drive your applications forward.

Quickly…Or slowly…Or in reverse.

When you pair Bodine Electric Company 3-phase AC motors and gearmotors with a variable frequency drive you get smooth, consistent power across a wide speed range and maintenance-free AC performance. Our products set the industry standard for demanding applications such as packaging machinery, ventilation equipment, conveyors, material handling equipment, and metering pumps. For adjustable speed and superior AC motor performance, three phases are better than one.

Learn all about how to match 3-phase AC motors with adjustable speed drives. Read the Engineer’s Guide to Driving AC Induction Motors with Inverters.

intelligent shunting, pulsing resistors to dissipate excess energy safely while protecting batteries and circuitry.

Larson recalls projects requiring the control of large, heavy dc motors weighing 40 to 50 pounds. These motors introduced complexities such as managing excess braking energy — a challenge many off-the-shelf controllers aren’t designed to handle. With PMD solutions, OLogic engineers could integrate custom shunting circuits directly into designs, supported by the Juno chip’s intelligent energy management features.

This capability underscores one reason OLogic continues to choose PMD: the products prove themselves in demanding real-world conditions, reducing the likelihood of costly redesigns and enabling customers to scale with confidence.

Technology alone doesn’t solve every challenge. For OLogic, PMD’s engineering support is equally important. Larson recalls a warehouse robot project where the customer required control of four high-powered motors at an update rate of 1,000 times per second — an ambitious benchmark on an aggressive timeline.

OLogic selected PMD’s Juno IC for its advanced velocity and torque control at a cost-effective price. But when early testing revealed that CAN bus message limitations threatened performance, OLogic turned to PMD for help. Within two days,

PMD engineers delivered a firmware update that streamlined message payloads, enabling the robot to achieve its performance target.

Not only was PMD’s Juno chip easy to use and easy to control, Larson said, PMD goes the extra mile to make sure the project is a success.

“If you have a problem, PMD will support you and back it up,” he said. “PMD did exactly what they said they were going to do.” The project also demonstrated the advantage of PMD’s builtin tuning capabilities. Traditionally, fine-tuning motor control requires painstaking adjustments. PMD’s tools made the process straightforward, allowing OLogic to deliver a first revision that performed reliably under demanding conditions.

OLogic’s ongoing collaboration with PMD reflects a relationship that goes beyond supplier and customer. PMD provides the motion control foundation for OLogic’s designs, while also acting as an extension of its engineering team when challenges arise.

By partnering with PMD, OLogic helps its customers cross the gap from prototype to production — faster, more reliably, and with the confidence that their robots are built on commercialgrade motion control. •

OLogic engineers integrated custom circuits to protect a batterypowered system.

Images: OLOGIC

SENSORS ENABLE PRECISE MEASUREMENT FOR A RANGE OF INDUSTRIAL APPLICATIONS

Different criteria are included for the selection of the appropriate sensor for displacement measurements.

Sensors are central to motion control. Whether it's angle, speed, or position sensing, they are a critical element in any motion control application, especially where precision motion is in play. More recently, the rise in robotic applications has put sensors and sensing in the spotlight, as sensors are key in robotic applications as well. Besides their increasing use in robotic applications, sensors for distance or position measurement are central to a range of diverse industrial applications.

Position measurement, or measuring distance, often called displacement, describes measuring the distance between two points. This distance is defined in the measuring technique by the distance of the sensor from the target. Displacement measurements in geometric measuring technology can be found in almost all application areas. Different criteria

EDITED BY MILES BUDIMIR SENIOR EDITOR

Image: ADOBESTOCK / MOLPIX

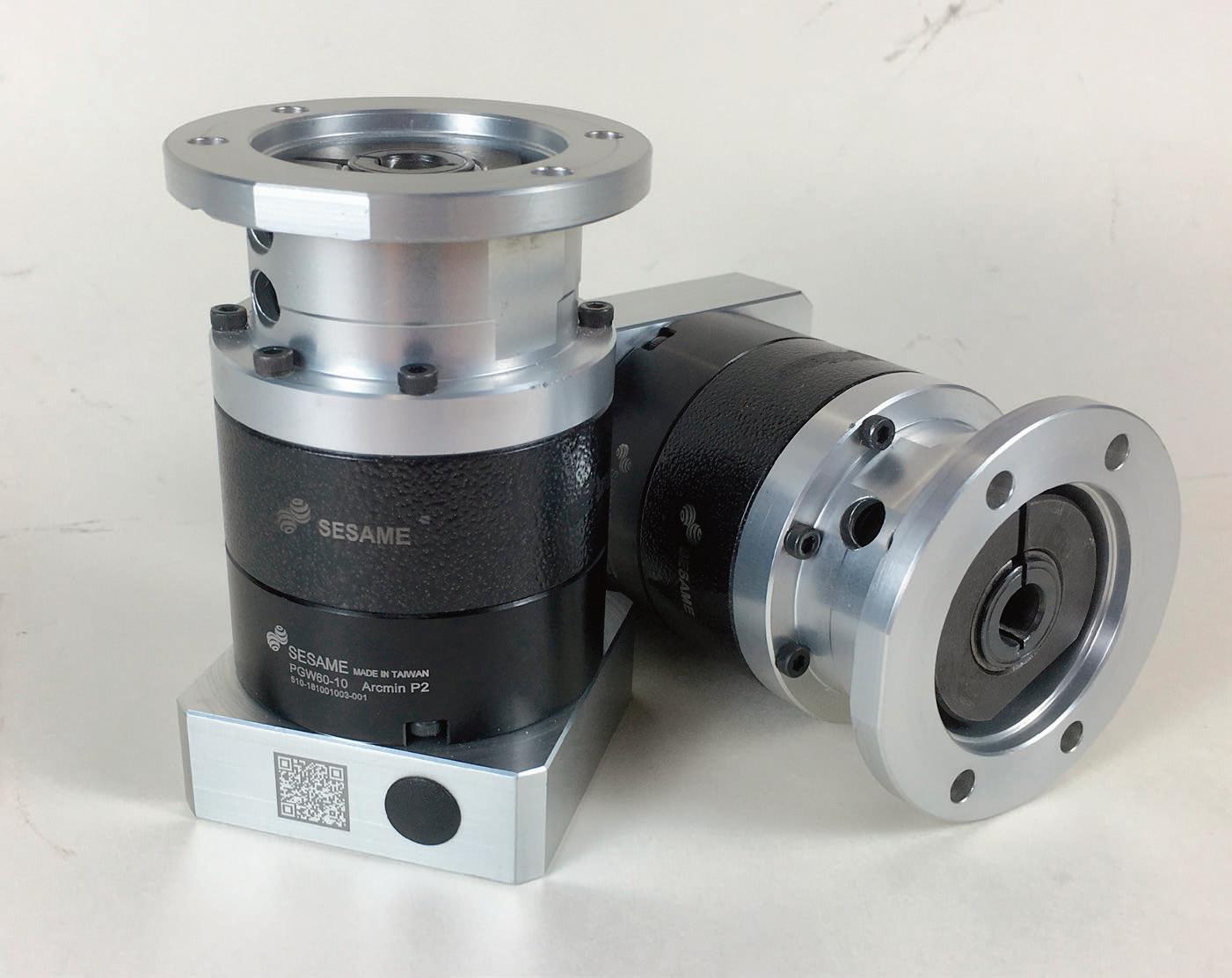

YOUR CUSTOM SOLUTIONS ARE CGI STANDARD PRODUCTS

Advanced Products for Robotics and Automation

CGI Motion standard products are designed with customization in mind. Our team of experts will work with you on selecting the optimal base product and craft a unique solution to help di erentiate your product or application. So when you think customization, think standard CGI assemblies.

Connect with us today to explore what CGI Motion can do for you.

The optoNCDT ILR1040 laser distance sensor from Micro-Epsilon features a compact design and high precision suitbable for a range of applications from automation and logistics to renewable energies and construction machinery.

Micro-Epsilon’s Confocal chromatic sensors measure distances and surface profiles with high accuracy.

are included for the selection of the appropriate sensor for displacement measurements. The frequency of the distance change can be quasi static or high frequency and determines the measuring speed of the sensor.

LASER SENSOR WITH IO-LINK

For instance, sensors from Micro-Epsilon are enabling different measurement applications across a range of industries and uses. The company’s optoNCDT ILR1040 laser distance sensor features a compact design and high precision that can be put to use in a wide range of applications – from automation and logistics to renewable energies and construction machinery. Its high stability even under changing ambient conditions makes it a reliable solution for OEM and series applications.

The laser distance sensor measures large distances up to 10 m, and up to 60 m with a reflector. It’s used in automation,

Image: MICRO-EPSILON

Image: MICRO-EPSILON

construction machinery, logistics and renewable energies, among others. The sensor delivers accurate results with high signal stability on various surfaces. The ILR1040 works with a stray light filter, which always generates clear and reproducible measurement results, even under challenging environmental conditions such as different surface textures, dark surfaces and ambient light.

The compact design and low weight of the sensor as well as the rotatable cable outlet allow flexible mounting in numerous installation situations. What’s more, sensor operation using buttons and LEDs or software is intuitive. The laser distance sensor is also designed for harsh industrial environments and can be used in a temperature range from -30 to +60 °C and is also available with IP67, IP69 and IP69K. The high ambient light resistance up to 50,000 lux allows installation even in

strongly illuminated environments.

The advanced IO-Link interface also offers a host of advantages. These includes the option of manufacturerindependent, digital, bidirectional point-to-point communication as well as continuous communication between sensors, actuators and the control system. With IO-Link, users can call up diagnostic information and dynamically adjust sensor or actuator parameters using an HMI or an external controller.

PRECISE DISTANCE MEASUREMENT

For applications needing high-precision distance measurements, for example in industrial measurement tasks in semiconductor engineering and battery film production, there are Confocal sensors from Micro-Epsilon. With a large

SMOOTH OPERATORS ROTARY MOTION COMPONENTS

DATORKER® STRAIN WAVE GEARS

Available in Standard, Heavy Load, and Lightweight Configurations. Offering High Precision, Efficiency, Torsional Rigidity, and Low Starting Torque.

CROSSED ROLLER BEARINGS

Lightweight And Compact Design. Easy to Install and Maintenance. Varieties of Bearing Types and Sizes for Solution.

measuring range, a high linearity of less than ± 1 µm and exceptionally high light intensity, confocalDT IFS2407-6 sensors detect even difficult surfaces reliably, quickly and with high precision.

The Confocal chromatic sensors measure distances and surface profiles with high accuracy. They’re based on the principle of chromatic aberration, in which white light is broken down into its spectral components. This can be used to precisely determine distance changes and thickness deviations in glass or films.

The confocalDT IFS2407-6 highperformance confocal sensor features a measuring range of 6 mm and linearity of less than ±1 µm. With a large numerical aperture of 0.45, the sensor offers high light intensity and accurate measurements even on dark or poorly reflective surfaces. The large measuring angle of ±23° provides reliable results even on

Our engineers are available to assist in finding the ideal solution to your application. Contact us for details.

Phone: (877) 804-4946 Fax: (847) 827-2291

structured surfaces. The sensor can be used at temperatures from +5 to +70 °C and can withstand shocks and vibrations. It’s suitable for high-precision areas such as the semiconductor industry, but also for industrial applications such as in battery film thickness measurements. The robust aluminum housing protects the sensor in challenging operating conditions.

PRECISION MEASUREMENTS IN ENVIRONMENTS WITH STRONG VIBRATIONS

Vibrations pose a particular challenge for optical measurements, as they can cause tiny movements of the object during detection. Vibrating targets pose a particular challenge in optical measurement technology: Due to the constant movement, the position of the

target changes during detection, which can cause unclear or incorrect results. The laser can be blurred by the movement or deflected from the target, causing the return signal to be less precise or to fail completely.

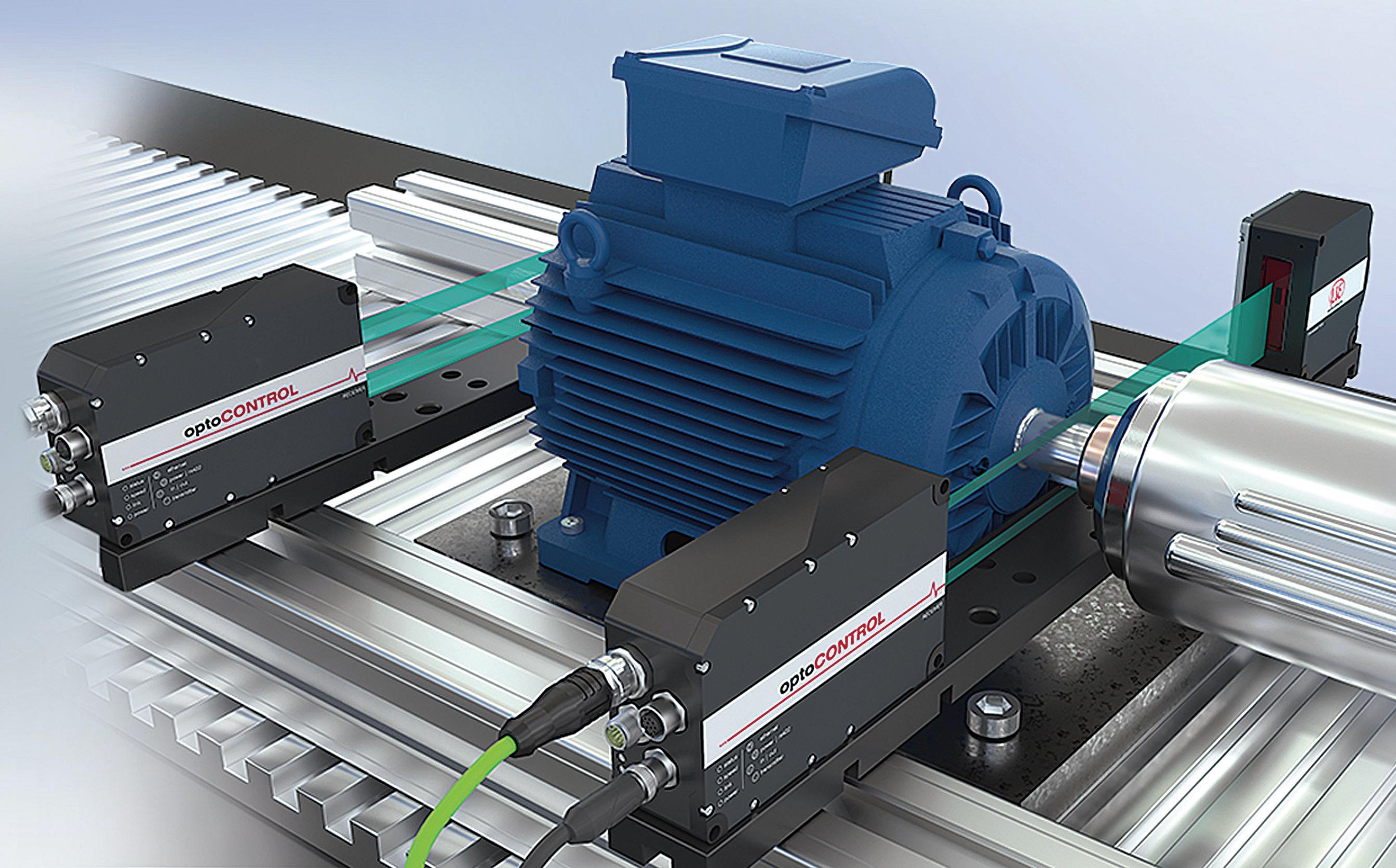

The optical precision micrometers of the optoCONTROL 2700 series from Micro-Epsilon are specially designed for such dynamic measurement tasks. With a sampling rate of 15 kHz and an extremely short exposure time of just 8.5 µsec, they detect even vibrating or fast-moving objects reliably and with high accuracy.

The receiver’s image matrix captures the exact alignment and therefore the angle of the object in the light beam via the primary line and secondary line. The internal controller automatically adjusts the measured value to the inclination of the target. As a result, the exact measured value is output with no measurement

errors. The inclination correction applies over the entire measuring rate and can be used in the measuring programs for outer diameter, web edge, and contour measurement.

With the optoCONTROL 2700, typical measured variables such as diameter, gap width, edge position or segment length can be precisely determined even at high production speeds — for example, in inline quality assurance or machine monitoring. The system is available in measuring ranges of 10 and 40 mm. One highlight is the controller integrated in the receiver, which reduces the cabling and installation effort as no external control unit is required. The precision micrometer outputs the measured values via the integrated web interface and the digital interfaces. •

MICRO-EPSILON

WWW.MICRO-EPSILON.COM

The optoCONTROL 2700 series from Micro-Epsilon detect vibrating or fast-moving objects reliably and with high accuracy.

Image: MICRO-EPSILON

AD INDEX

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com

Chief Editor Rachael Pasini rpasini@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com

Managing Editor Mike Santora msantora@wtwhmedia.com

Senior Editor Miles Budimir mbudimir@wtwhmedia.com

SALES

Ryan Ashdown rashdown@wtwhmedia.com 216.316.6691

Jami Brownlee jbrownlee@wtwhmedia.com 224.760.1055

Mary Ann Cooke mcooke@wtwhmedia.com 781.710.4659

Mike Francesconi mfrancesconi@wtwhmedia.com 630.488.9029

Jim Powers jpowers@wtwhmedia.com 312.925.7793

CREATIVE SERVICES & PRINT PRODUCTION

VP, Creative Director

Matthew Claney mclaney@wtwhmedia.com

Senior Art Director Tory Bartelt tbartelt@wtwhmedia.com

Director, Audience Growth Rick Ellis rellis@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

ONLINE DEVELOPMENT & PRODUCTION

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

LEADERSHIP TEAM

Senior VP, Engineering Courtney Nagle cnagle@wtwhmedia.com 440.523.1685

CEO Matt Logan mlogan@wtwhmedia.com

CFO Ken Gradman kgradman@wtwhmedia.com 773.680.5955

FINANCE

Controller

Nirmit Shukla nshukla@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

MARKETING

VP, Operations Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Digital Design Manager

Samantha Goodrich sgoodrich@wtwhmedia.com

DESIGN

DESIGN

Subscription

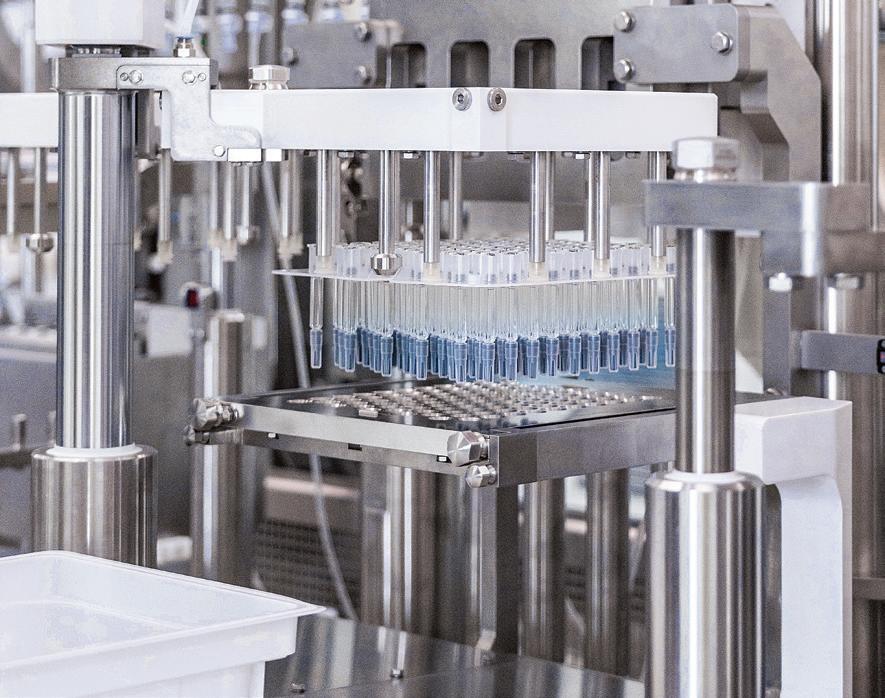

CLEANROOM REQUIREMENTS NEW FOR 2025

Recent changes to cleanroom regulations are affecting the design of automation equipment destined to operate in these environments. After 20 years with no major changes, in August 2025 the International Organization for Standardization (ISO) published a refresh of its 14644-5 standard for cleanrooms. The revision tightens expectations for personnel competency, material flows, documentation, and day-to-day operations yet keeps the familiar particle thresholds of 14644-1 and 14644-2.

For machine builders, the refreshed standard requires explicit installation, startup, maintenance, and change controls for mechatronic equipment going in clean zones. OEMs must now demonstrate that (among other things) motion elements, lubricants, and materials (including those of cables, for example) support contamination-control strategies.

Scan the QR code to join a Design World webinar detailing the changed standards and their effects on robotic and other automated applications.

Of course, some industry-specific regulations build on the ISO foundation by adding more specific and stringent requirements. Consider one industry-specific regulation — the 2023 EU GMP Annex 1 for sterile manufacturing of medicinal products. This sets a Contamination Control Strategy (for controlling microbial, particle, and endotoxin contamination) to a governing framework. In fact, Annex 1 is also forcing equipment-integration re-engineering to ensure cleanability of actuated designs that enter and exit clean areas.

Engineers building or specifying motordriven automated equipment for cleanrooms should ensure it satisfies ISO 14644-5

(and Annex 1’s CCS if applicable). Cleaning regimens and documentation should be made clear for the end user. Equipment for cleanroom settings should feature fanless and brushless motors, gear reducers with the proper sealing and smooth surfaces, mechanical components lubricated with low-outgassing formulas, and cables with FEP/PFA jackets. Validation data for particle emission at design speeds and duty cycles should detail the ISO Class satisfied. Where integrated machine modules and robots are specified, choose products with published cleanroom ratings or third-party certifications (ideally complemented by condition-monitoring capabilities). •