DESIGN SERVICES

to be developed). That’s why product development teams should also have access to wet labs, as medical device development can benefit from the advantages offered in both virtual and real-world environments.

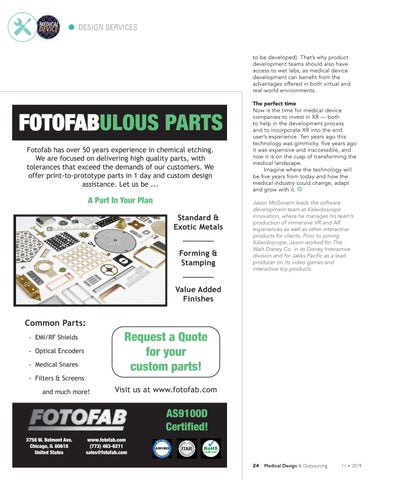

FOTOFABULOUS PARTS Fotofab has over 50 years experience in chemical etching. We are focused on delivering high quality parts, with tolerances that exceed the demands of our customers. We offer print-to-prototype parts in 1 day and custom design assistance. Let us be ...

A Part In Your Plan Standard & Exotic Metals Forming & Stamping

The perfect time Now is the time for medical device companies to invest in XR — both to help in the development process and to incorporate XR into the end user’s experience. Ten years ago this technology was gimmicky, five years ago it was expensive and inaccessible, and now it is on the cusp of transforming the medical landscape. Imagine where the technology will be five years from today and how the medical industry could change, adapt and grow with it. Jason McGovern leads the software development team at Kaleidoscope Innovation, where he manages his team’s production of immersive VR and AR experiences as well as other interactive products for clients. Prior to joining Kaleidoscope, Jason worked for The Walt Disney Co. in its Disney Interactive division and for Jakks Pacific as a lead producer on its video games and interactive toy products.

Value Added Finishes

Common Parts:

Request a Quote for your custom parts!

- EMI/RF Shields - Optical Encoders - Medical Snares - Filters & Screens and much more!

Visit us at www.fotofab.com

AS9100D Certified! 3758 W. Belmont Ave. Chicago, IL 60618 United States

www.fotofab.com (773) 463-6211 sales@fotofab.com 24

DesignServices_11-19_Vs2-NC-FINAL.indd 24

Medical Design & Outsourcing

11 • 2019

11/22/19 8:45 AM