The events of this year have given us a very different future. A future where digital technology is central to every interaction we make.

The situation we’ve found ourselves in has revealed the creativity and brilliance of everyone across the industry. We’ve learned that we can adapt quickly and embrace change. And that we can break down barriers to innovation and experimentation. Of course, I don’t know exactly what the future holds, but I do know one thing: the future will not be what it used to be.

In this edition of Digital Insider, we asked the experts what this new future could look like in the face of challenges like COVID-19, the energy transition, the oil price crash and the skills gap.

With the future of many refineries uncertain, we look at what options are available to them in the digital arena and how the survivors can emerge stronger [page 4]. And as the world faces a shortage of data scientists, Head of Digital Platforms and Data Science, Vishal Mehta, explores the concept of whether citizen data scientists are the answer [page 6].

We reimagined a future where non-valuable assets, such as waste heat, become valuable in the realm of renewable energy [page 12]. And how life-saving data can help ensure a future with fewer work-related deaths [page 16]. We also asked Roy Brown, Senior Director of Technology Ventures, how we can harness the momentum that COVID-19 has given clean technology to make sure it is here to stay [page 24].

But as we reimagine the future, one thing remains constant – our commitment to delivering a more sustainable world… whatever it might be.

Stay safe

GEETA THAKORLAL President, Digital and Energy Transition

2 worley.com

Contents 04 OPINION Reimagining the future refinery 06 FUTURE WORKFORCE Wanted! Citizen data scientists 12 TECHNOLOGY SPOTLIGHT Waste heat to energy 16 SAFETY Lifesaving data CONTENTS EDITOR’S LETTER TECHNOLOGY One step forward, no steps back 24 20 REMOTE OPERATIONS Running assets remotely 30 REMOTE WORKING Mobile enablement 34 INTERVIEW 5 minutes with Cameron Druery

I DON’T KNOW EXACTLY WHAT THE FUTURE HOLDS, BUT I DO KNOW ONE THING: THE FUTURE WILL NOT BE WHAT IT USED TO BE.

WATCH A MESSAGE FROM GEETA 3 worley.com

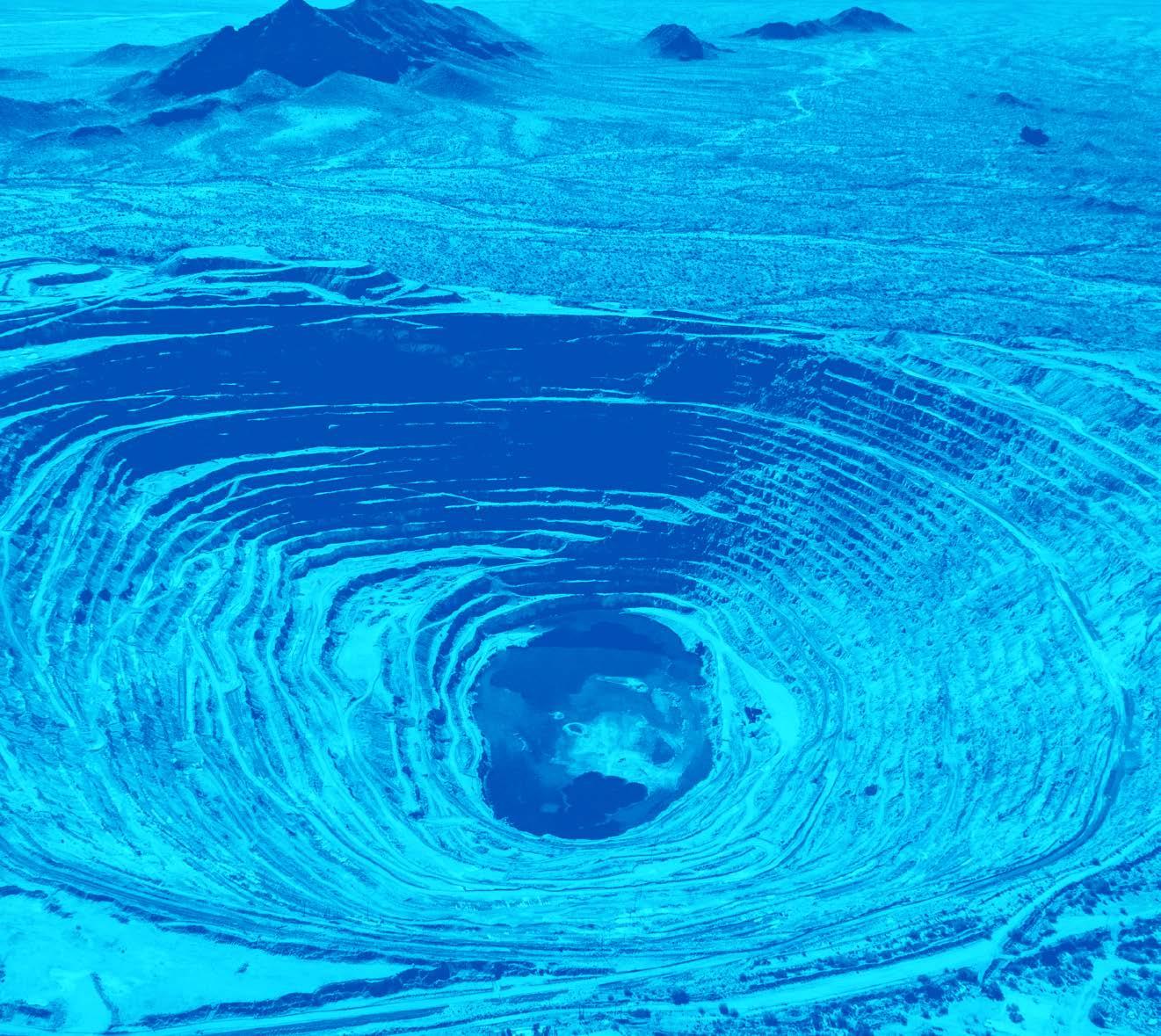

Reimagining the future refinery

The refining landscape is evolving quickly. Lee Dacey, Senior Vice President, Advisian Americas and Global Downstream, Advisian, looks at what this means for the industry

The future of refineries has been under threat from the energy transition for some time. In the past couple of years, we’ve witnessed big companies divesting, closing or transforming assets and accelerating their processes to decarbonize. But the events of 2020, the effects of COVID-19 on oil prices and lack of demand for things like aviation fuel has sped this up. Instead of the expectation of decommissioning in three to five-years, the impact of COVID-19 has meant the decision to shut down refineries has been taken into consideration now.

Those that survive in the long term will be more resilient as they must find ways to become more efficient and capable of taking opportunities when they present themselves.

But, how can they do this?

Digital leaps to build resilience

Digital is a way to be more competitive and more agile as the industry evolves. And the future refinery is data driven.

Refineries will use data to make decisions that keep them operating efficiently and to manage risk. Data will also create opportunities to integrate advanced digital technologies such as machine learning, virtual reality and robotics.

Interest from outside the industry

Like many problems that need solving, the energy transition has meant startups and companies outside of our industry are creating new technologies and looking to apply them in the downstream industry. These players are looking to partner with heritage refining operators. It’s an exciting time. And with that comes opportunities for refineries to partner with those supplying the technology. Non-traditional players have money to invest. They’re obtaining refining assets and will need to operate those assets in a far more flexible and efficient way. And they will be running with more data centric, digital solutions. For example, they might look at digital tools for remote operations and manage a streamlined workforce. These new players will shake up the industry even more.

What’s next for the survivors?

This is a time to try new things. Operators can use digital tools to transform their project development processes to optimize time and resources. They can use the richer data and capability to perform more complex analysis and make better decisions faster than they would normally.

Early decision making will help operators make the best decisions they can. And with more resources they can continue to invest in emerging technologies and other solutions to decarbonize.

REFINERIES WILL USE DATA TO MAKE DECISIONS THAT KEEP THEM OPERATING EFFICIENTLY AND TO MANAGE RISK. DATA WILL ALSO CREATE OPPORTUNITIES TO INTEGRATE ADVANCED DIGITAL TECHNOLOGIES SUCH AS MACHINE LEARNING, VIRTUAL REALITY AND ROBOTICS.

READ MORE HOW REFINERS CAN FUTURE-PROOF THEIR BUSINESSES

4 5 worley.com worley.com

OPINION OPINION

Wanted!

Citizen data scientists

There’s no shortage of analytically minded people in the energy, chemicals and resources industries. And it’s these people who have the skills to become citizen data scientists. Here’s how to realize that potential

WORDS BY MEHREEN YUSUF

If you’ve not heard of a citizen data scientist before, you’re not alone. The term, coined by Gartner – a global research and advisory firm – is defined as someone whose primary job is outside the field of statistics and analytics, but who performs the role of a data scientist.

They could work in HR, finance or engineering. And with the right software, they’d be able to use data to unlock business insights and inform decision-making on the challenges their department faces. But why do we need citizen data scientists?

“There’s a worldwide shortage of data scientists, at a time when organizations like ours are striving to be more data driven,” explains Vishal Mehta, Head of Digital Platforms and Data Science. “Many traditional data scientists would rather join consumerfacing companies like Google, because that’s what interests them. Energy, chemicals and resource companies don’t always attract talent when it comes to analytics.”

But Mehta knows that a skills shortage doesn’t need to define an organization’s data journey. “The upside for engineering companies is that they already employ people who have the analytical know-how to navigate data science applications. Best of all, they have the contextual knowledge to gain the best insights. These are the people who will become the citizen data scientists of tomorrow.”

So how do energy, chemicals and resources companies tap into this potential?

Invest in technology and training

Technology has become more intuitive and easier to use. As Mehta explains, you don’t need to know how to code to do exploratory data analysis. “There are several business intelligence and data science tools, which don’t require any coding knowledge, that can help companies navigate through the data world. These tools can process unrelated sources of data and turn them into interactive and visually compelling insights. Users can generate and share useful snapshots of what’s happening in their business. But some organizations are still in the early stages of applying these tools.”

7 worley.com

FUTURE WORKFORCE FUTURE WORKFORCE

6

ENERGY, CHEMICALS AND RESOURCE COMPANIES DON’T ALWAYS ATTRACT TALENT WHEN IT COMES TO ANALYTICS.

Cheryl Ginyard-Jones, Head of Energy Transition and Digital for the Americas, explains that training will be key to unlocking the value of these technologies. “Organizations are beginning to realize they need to invest resources into training programs. Our focus is on building skill sets, so our people can apply digital practices to our processes.”

But for Ginyard-Jones, it isn’t enough to hire data scientists and ask them to pass on their skills. “We need to focus on engaging with external organizations who know how to develop training programs around data analytics. By combining technology with ongoing training, organizations can accelerate the growth of their in-house citizen data scientists and unlock the value of their data.”

Support a data-driven culture

Training and technology are one side of the coin. The other is more complicated.

Mehta is familiar with the difficulties the industry faces when it comes to handling big data. “Collecting data is one thing. But operators need to work out methods of structuring it in a clean and organized way. Only then can it be used to gain insights.”

So how can organizations ensure that their data is accessible and easy to use? For Mehta, the answer is simple. “The most effective way of structuring data is by knowing what it will be used for.

“Take data collection around a compressor for example. Temperature, pressure, lube levels – this is some of the data our customers might collect. The people who run the compressor intuitively know what could go wrong with it.

“But here’s the game changer. Give those same people data-specific training, and they could use the collected information to build a predictive analytics model. Then they can forecast when something will go wrong, and schedule future maintenance in, with minimal disruption. This will also address the skill gaps the industry is facing due to aging workforce.”

Create an open and collaborative workspace

Citizen data scientists thrive in an open environment, where they can use analytics to unlock insights, and then communicate and action them. This will only be possible if an organization works in a symbiotic and cross-functional way.

“It’s a question of breaking down the operational barriers between departments,” explains Mehta. “In an engineering company, people who work upstream, such as geophysicists and engineers, have different priorities to people working downstream, like operators and marketers.

8 9 worley.com worley.com FUTURE WORKFORCE FUTURE WORKFORCE

GIVE THE RIGHT PEOPLE THE RIGHT DATA AND THEY CAN FORECAST WHEN SOMETHING WILL GO WRONG, AND SCHEDULE FUTURE MAINTENANCE IN, WITH MINIMAL DISRUPTION. THIS WILL ALSO ADDRESS THE SKILL GAPS THE INDUSTRY IS FACING DUE TO AGING WORKFORCE.

“One way to overcome these departmental barriers is by using creative management techniques to get people talking," he adds. This could be through group problem-solving sessions, or by rotating sets of people through different departments. In this way, organizations like ours are working on becoming more open and collaborative. Doing this will help us support our fledgling citizen data scientists.”

Overcome challenges to realize benefits

Our industry is at the beginning of its data science journey, and Mehta knows there are challenges ahead.

“It can be difficult to articulate the value that data science applications provide. There are no guarantees of success –the model may or may not work. But the application of data analytics, combined with on-the-ground contextual information, will totally transform how we do business.

“Let’s take an example in a refinery. We know crude oil chemistry is never the same – even for the oil from the same well. This can make it difficult to predict levels of corrosion accurately. But we have lots of data. Our corrosion engineers know how different fluids react with different pipeline materials, and how much corrosion we can expect from certain oil chemistries.

“If we were to train the corrosion engineers and give them access to analytic tools, they could build models to predict corrosion accurately. The best part is that we’re creating citizen data scientists who have contextual industry information that ordinary data scientists won’t have.”

Recognizing the benefits of data analytics is one of the best ways to overcome these challenges and unlock the value of data analytics. And, having a community of citizen data scientists that come from the industry can help shed light on the business value, from the inside out.

READ MORE WORLEY'S DIGITAL SOLUTIONS

Need proof? Click here

10 worley.com

THE APPLICATION OF DATA ANALYTICS, COMBINED WITH ON-THE-GROUND CONTEXTUAL INFORMATION, WILL TOTALLY TRANSFORM HOW WE DO BUSINESS.

There’s nothing boring in engineering about a career

FUTURE WORKFORCE

WORDS BY TRISTAN CLARK

We often assume that the energy transition is about generating energy from new sources, with novel technologies. While renewables and hydrogen will feature heavily in a low-carbon future, is there more we can do with the energy that’s already being generated by heavy industry?

Heat is integral to industrial processes in the energy, chemicals and resources sectors. Activities such as smelting, steelmaking or refining can’t happen without it, and that’s where the waste heat to energy story begins.

“Imagine you own a house on a suburban street and you take out the trash once a week,” begins Raashi Khanduri, Director of Technology and Ventures at Worley.

“You probably don’t think much about it. Now imagine somebody comes up to you on collection day and says, ‘I will pay you for your trash, because it’s a valuable asset for me.’ You’d say yes, right?

“Now imagine you own a refinery, and somebody wanted to pay you to for waste generated through your industrial processes. Why would your answer be any different?”

Where there is heat, there is opportunity

“Whenever you see an exhaust, heat is being generated,” says Khanduri. “And you see these exhausts across many industrial processes. The scale is enormous, with around half of the energy we generate being wasted when we discharge this heat.

“But we can change that. We have the technology to turn waste heat into a valuable asset; electricity. Current approaches recover some rejected heat from industrial process using standard techniques in the industry, where the economics make sense. However, we can invest in additional technologies to capture the heat that these established technologies lose, and then turn that heat into electricity.”

It’s the possibility of generating this electricity, then feeding it back into the grid on a large scale, that has the energy startups working late into the evening.

How industrial heat could become a startup’s treasure

If heavy industry relies on heat, and this heat can be converted into electricity, how can an energy startup benefit from it?

“The novel aspect of the waste heat to energy story is the business models behind it,” says Khanduri. “Startups are approaching companies in the energy and chemicals sectors that generate heat, exploring how they can turn this heat into electricity, and then finally, working out how this can be a profitable business.”

13 worley.com

How a revolutionary business model could power the world with energy that’s going to waste

worley.com 12 TECHNOLOGY SPOTLIGHT TECHNOLOGY SPOTLIGHT

THE NOVEL ASPECT OF THE WASTE HEAT TO ENERGY STORY IS THE BUSINESS MODELS BEHIND IT.

Khanduri explains the various business models that are being explored.

“Most startups begin by raising capital to pay for the service provider to install the heat exchangers, take the waste heat, convert it into electricity and find creative ways to feed this electricity back into the grid. Then, as the industrial firm generates electricity from its waste heat, the startup takes a percentage of the revenue.

“The other way some startups can make revenue is by providing a service to industrial firms. They do this by outsourcing the feasibility and engineering to companies like Worley,” continues Khanduri. “This provides a general overview, which they offer to a potential customer to show the economics behind the processes, and the potential benefits.

“There’s a lot of value in this, because in most cases, it’s not a concept industrial firms are doing themselves. They’re focused on optimizing their operations and on their core assets, rather than how much electricity their waste heat could generate.”

New idea. New doubts

The viability of the waste heat to energy concept depends on a couple of factors falling into place. And there’s one that stands out from the rest.

“Power prices,” says Khanduri. “This concept depends on the economics. The power price needs to be high enough to justify the effort of feeding this electricity back into the grid. And while we know we need more clean electricity, it means this concept suits some geographies and jurisdictions better than others.

“As policies mature, we’ll also need to establish which entity gains the carbon credits from generating energy from their waste heat. That’s because most operators and end users will be interested in receiving the carbon credit that deploying this technology could offer.

“Aside from the economics, the other consideration is education,” continues Khanduri. “There is natural skepticism with anything new like this. The challenge is in educating these industries to help them understand the creative business model, how they can participate and the rewards on offer. Many of these companies have never considered waste heat or carbon offset credits as a source of value until very recently.”

Staying lean to chase surplus energy

Faced with the prospect of uncertain economic margins, most energy startups need to remain lean. And that means they can’t hire teams of hundreds to engineer waste heat to energy solutions.

“Rather than scouring the world to hire engineers and contractors to do it themselves, they’re looking for a wellconnected partner who can set up the equipment and infrastructure to harness waste heat in these facilities. As a result, they can stay lean and focus on their core business models,” explains Khanduri.

This means the energy, chemicals and resources industries are becoming more accessible to the startup community than ever before.

“We’re communicating with a growing number of small tech companies who are following a similar ethos,” continues Khanduri.

“They’re looking to Worley as a vendor, as a contractor, and equally importantly, as a pathway to successful relationships in our sectors. When you approach projects in this way, there are almost no barriers to work with well-established industries. It means that in the next 10 years, waste heat to energy solutions should scale significantly, so long as our industry is open to pairing with startups.”

Why waste heat could define the next decade

Khanduri believes waste heat to energy can dramatically change the dynamics of the energy transition.

“This is a compelling value proposition, because there’s so much heat being generated by many thousands of industrial facilities around the world. The second law of thermodynamics means we’ll inevitably lose some of this heat each time we transfer it, but if you can harness even a fraction of it, and turn it into emission-free power, that’s a clean energy resource that has potential to scale into an important contributor to our energy mix.”

But it requires a leap of faith to get there.

“You know, 10 years ago, people were questioning whether it’s worth grabbing data,” says Khanduri. “Yes, is the short answer. But at the time, we didn’t realize the scale of it and how a non-valuable asset would one day become so valuable.”

READ MORE TURNING WASTE INTO A SOURCE OF CLEAN ENERGY

14 15 worley.com worley.com

TECHNOLOGY SPOTLIGHT TECHNOLOGY SPOTLIGHT

THERE IS NATURAL SKEPTICISM WITH ANYTHING NEW LIKE THIS. THE CHALLENGE IS IN EDUCATING THESE INDUSTRIES TO HELP THEM UNDERSTAND THE CREATIVE BUSINESS MODEL.

Lifesaving DATA

Our work with energy, chemical and resource companies often identifies significant opportunities to improve the quality and consistency of data collection. This includes a more detailed collection of external variables, such as the ‘phase of work’ or ‘activity being performed’ through to variables related to the people who were injured, such as ‘trade/craft’, ‘time since started shift’, ‘how long in current role on current project’, ‘years of total experience in current role’, and various injury classifications.

If you think your safety data isn’t refined enough, complete enough or clean enough to use predictive analytics, think again. Here's why

WORDS BY HEATHER STEWART

In 2019, 111 people in Great Britain went to work and never came home. The year before that, it was a similar story. In fact, since 2012, the fatality rate across industries in England, Scotland and Wales remained relatively the same. And, despite our best efforts to prevent workplace incidents, the same non-fatal injuries keep occurring year after year. But, what can we do about it?

Start with your safety data

When it comes to workplace injuries, organizations are always looking for new ways to understand what’s causing them –and how to stop them from occurring again. So, they record, report and store information on the incidents that happen, from informal one-on-one conversations to in-depth root cause analyses.

But organizations don’t always make the most of the insights this data can provide. Often fearful that their data is not refined enough, complete enough or clean enough, they don’t take advantage of technologies like predictive analytics or artificial intelligence. Instead, they continue to rely on traditional reporting to deliver onedimensional information about incidents. After people have been hurt – or worse.

Getting your safety data ready

Data quality and consistency are two factors that repeatedly limit the use of an organization’s safety data. To achieve data quality and consistency, organizations must ensure they’re collecting data regularly and that it’s the right data.

If we don’t consider all the variables involved, we often miss the relationships and trends that cause incidents. For example, the length of someone doing certain activities can often influence the propensity for an incident to occur.

But not all data has to come through completing an incident form – data related to a person’s tenure and job role can be taken from a human resources system. Additionally, companies typically fail to collect data in a mutually exclusive, collectively exhaustive (MECE) way. That is, ensuring each variable has a purpose in driving insight, the purpose for each variable doesn’t overlap, and the fields in each variable represent an exhaustive list.

16 17 worley.com worley.com SAFETY SAFETY

IN 2019, 111 PEOPLE IN GREAT BRITAIN WENT TO WORK AND NEVER CAME HOME.

This isn’t saying that there will be hundreds of fields to complete in an incident form. But there is an ideal spot where the fields aren’t too high level that they’re not actionable. Or, too detailed that they limit analysis and are too difficult for the user to manage. To overcome this, standard MECE taxonomies and list boxes and check boxes can help collect data consistently.

The more detailed and consistent your data, the more informed you are to influence safety decision making through specific interventions and safety programs.

Unlocking the power of predictive analytics

There might be tension around asking colleagues in the field to report more detailed data, particularly around near-misses and lower-severity incidents.

But collecting safety data diligently and consistently across employees, contractors, joint venture partners and even customers is critical to unlocking the power of predictive analytics.

Improving enterprise safety data is a process. It isn’t done overnight. But the quickest way of getting it done is to subject your data to predictive analytics. Applying more indepth analytical techniques will mean that opportunities for improvement in data quality and consistency will immediately appear, allowing you to fix them and improve your safety insights.

So, when is the right time to subject your data, warts and all, to predictive analytics? The answer is yesterday. But if you haven’t done it yet, I’d recommend today.

READ MORE PREDICTIVE ANALYTICS FOR SAFETY DATA

18 worley.com

SAFETY SaltGrid

Get your people home safely Reduce the risk to human life by using CAROL®, the world’s first remote-controlled commercial catalyst removal robot. www.worley.com/carol

IS ANYBODY THERE?

If necessity is the mother of invention, we’ve seen years of progress occur within months. In 2020, we’ve stayed apart, changed the way we work and placed our faith in technology. And by doing so, we’ve set a different future in motion.

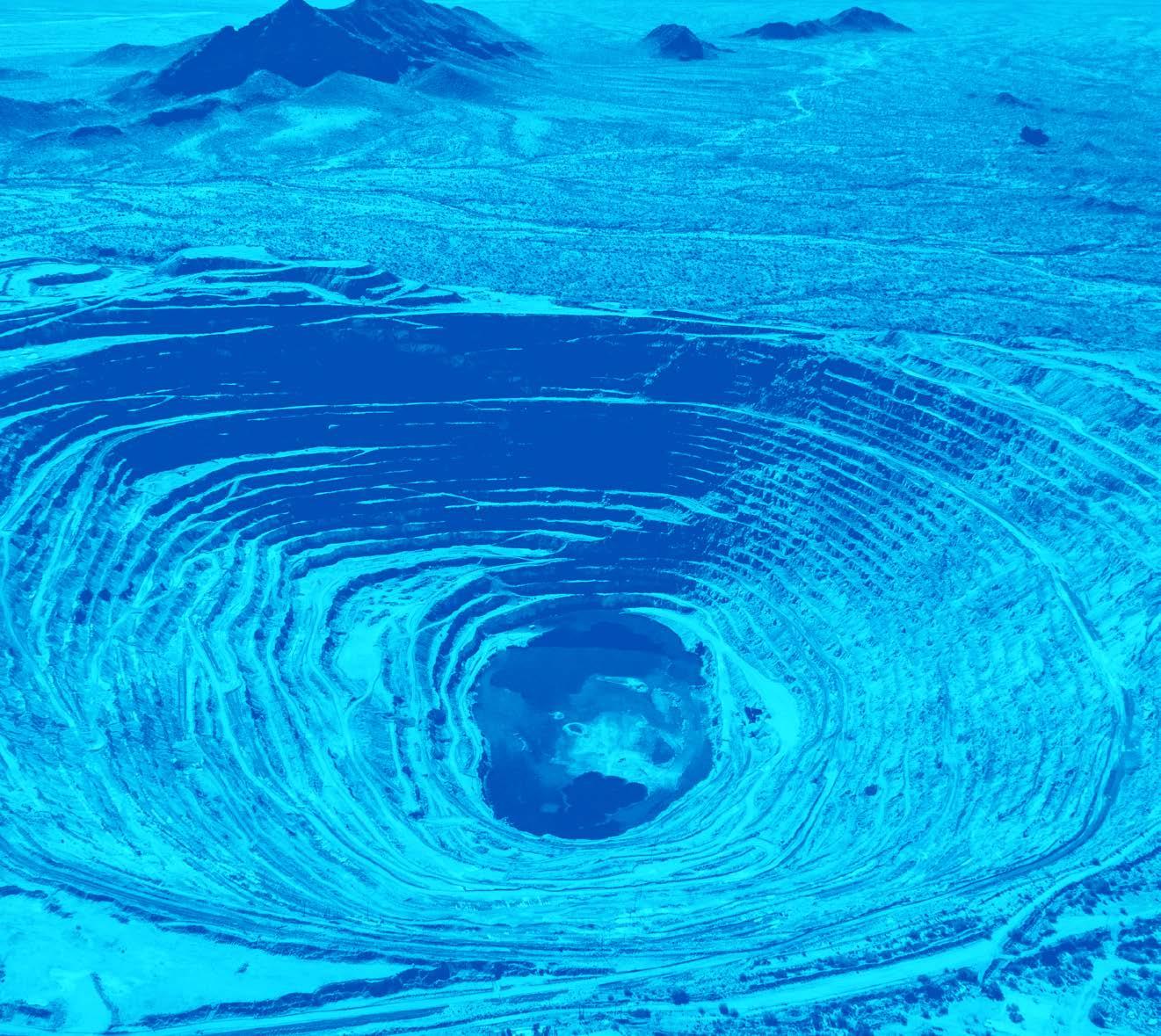

Most oil refineries, offshore platforms, chemicals plants and mines weren’t designed to be operated by small, socially distanced teams on the ground. But technology has helped to fill the gaps, and what was once a pipe dream is becoming more viable each day.

Are we about to see energy, chemicals and resource facilities running with a fraction of their current personnel, or nobody at all?

It depends on the definition

According to Jim Purvis, Senior Director, Digital Solutions Delivery in our Houston office, definitions matter when we talk about remote operations.

“There is an important distinction between the concept of complete autonomous operations versus not normally attended,” he explains. “Not normally attended refers to a facility that could run for a considerable length of time – think years – but at some point, there needs to be some human maintenance intervention on site.

Small steps toward bigger goals

We’re not yet sending complex offshore platforms into the ocean, never to be visited by humans again. However, we shouldn’t mistake that for a lack of progress or ambition. Purvis explains why. “Our industry is reaching the point where relatively complex facilities are capable of running not normally attended.

“However, that’s often a few steps ahead of today’s operating environment,” he says. “Regulations generally require a certain number of people to be present. In those cases, the goal is to operate safely with the minimum number of people regulations permit. And as we reduce this number, we’re also laying the foundation to operate the facility without anybody on site.”

The technologies shouldering the load

While no single technology can displace physical work practices we’ve honed over the years, a combination of them can.

“If we don’t have people on site, it’s important to know what’s happening, as well as what might happen,” says Purvis. “This is where machine learning helps to predict outcomes. Machine learning models can use data collected from sensors to assess how equipment is performing without a human eye, ear or nose.

WORDS BY TRISTAN CLARK

“That’s different to an autonomous spaceship that blasts off into the galaxy and runs without having any humans on board at any point,” says Purvis. “That’s called complete autonomous operations, and it’s where the boldest energy, chemicals and resources producers are aiming.”

20 21 worley.com worley.com REMOTE

OPERATIONS

Why we’re ready to operate industrial facilities without anybody on site

REMOTE OPERATIONS

THERE IS AN IMPORTANT DISTINCTION BETWEEN THE CONCEPT OF COMPLETE AUTONOMOUS OPERATIONS VERSUS NOT NORMALLY ATTENDED.

“From these inputs, we create a health index, which shows the status of the equipment. When the data deviates from expected patterns, we can decide if it’s something that needs immediate action, or whether it’s included in the watchlist next time we send a team to site.”

Purvis explains why this leads to more operating time and less physical human intervention.

“Predictive analytics and machine learning give us the confidence to expand the interval between sending people to do maintenance work. It also increases the effectiveness of maintenance activities when people do make a trip, because the decisions are driven by data.”

Visiting sites in a virtual environment

Fewer visits to the actual facility doesn’t mean less time immersed in it. By creating a digital twin of a physical asset, we can modify, maintain and improve it without any risk to the real thing.

“Our customers that have a digital twin of the physical facility are making fewer trips to site, because they can trust in the information they have,” notes Purvis. “They can look at replacing equipment or test a range of scenarios, all through this digital representation. This gives a high degree of confidence that theoretical decisions will work in the actual facility.”

And as Purvis explains, engineers can assess a facility in Arctic conditions from the comfort of their office or home.

“We can explore digital twins through augmented or virtual reality, just like we would a real site. And when we need to see the actual facility, we’ve proven through COVID-19 that sending one person equipped with a specialized set of goggles to a factory acceptance test, or an equipment inspection, is enough. Many people can join as their avatar back in the office, and some of our customers are even deploying robots to perform these inspections.”

Why our industry is abandoning the familiar

The industry leaders of tomorrow are already moving to secure the future of their facilities. And while motivations differ across sectors and geographies, the benefits are similar.

“There are many advantages to operating a facility remotely,” says Karen Sobel, President for the Americas region at Worley.

“Safety is always a priority, and by reducing the time people spend at these facilities, we can expect better safety performance. That’s not only considering the risk of injury or illness at a facility, but also the risk of travelling to and from it.

“Economics are also driving this shift,” continues Sobel. “COVID-19 is impacting all the industries we work in, but a common theme among all of them is the need to reduce operating costs. Often, that means getting people back into a central location where costs are more contained.

“We’ve seen this in an offshore project in North America in harsh conditions, where our customer wants to run their facility with minimum coastguard requirements. This means fewer people on site for a facility of this kind, and yet it’s safe and economically competitive.” The benefits extend beyond safety and cost savings. As Sobel explains, operating facilities remotely can also lead to higher output.

“Whether it’s mining equipment or an offshore rig, efficiency is everything. And preparing a facility to operate with fewer or no people requires establishing the digital infrastructure to monitor, automate and predict outcomes. And this information is critical to keeping facilities running and producing more product.”

What it takes to make remote operations work

So, what needs to be in place to support successful, remotely operated sites?

“Communications infrastructure is everything,” says Purvis. “Distance isn’t a concern, so long as you have high-speed and stable communication, such as a fiber optic cable to the facility. Some facilities may be hundreds of miles offshore, but a fiber optic cable connected will allow for quick and reliable decisions to keep things running.

“You also need equipment that is specifically selected to run for a long period of time without maintenance,” continues Purvis.

“That means buying equipment that doesn’t require regular servicing, and then setting up sensors to evaluate its performance and handle failures before they happen.

“The other critically important consideration is security. Without a human presence on site, and more information travelling to and from the facility, the risk transfers to the digital environment. This means it’s imperative to have a cyber security system in place, which prevents hackers from acquiring information, shutting down or even damaging the facility. It also means that more accessible facilities may still need security personnel on site, even if they’re not involved in operating the facility itself.”

However, operational considerations are only part of the story.

“You can’t just flick a switch and expect people to accept that a multibillion-dollar facility is going to run fine with nobody on it,” laughs Purvis. “People need to trust that this is going to work, which comes from an understanding of the technology behind it.

“It’s always going to be a leap of faith. But we have the technology, and now it’s about trusting that we’re in control.”

READ MORE POSITIONING OUR CUSTOMERS FOR A DIGITAL FUTURE

23 worley.com REMOTE OPERATIONS

22 REMOTE OPERATIONS

WE CAN EXPLORE DIGITAL TWINS THROUGH AUGMENTED OR VIRTUAL REALITY, JUST LIKE WE WOULD A REAL SITE.

ONE STEP FORWARD, NO STEPS BACK

How can we harness the momentum that COVID-19 has given clean technology to make sure it's here to stay?

WORDS BY HAYLEY SUTTON

As the world comes together to combat climate change and decarbonize our world, the energy industry has taken center stage. The result? A new wave of innovation and technology to help us get there faster and more efficiently. From utility-scale energy storage to online platforms that help you design distributed energy systems 90 per cent faster, the mission is on to change the way we power our planet.

“Everyone is taking the conversation around climate change and the energy transition very seriously,” says Roy Brown, Senior Director, Technology Ventures at Worley. “There’s a lot of interest in clean technology such as the circular economy, energy storage and renewables. And venture capitalists, private equity firms and corporations are starting to make some pretty big investments in this area of technology.”

However, this isn’t the first-time that clean technology was on the top of investor’s portfolios. It was only a decade ago that everyone was focused on technologies such as solar, hydrogen and wind. But the financials were so far off that you needed large subsidies, or a government prop up to break even.

So, what’s changed?

The timing is right

When the first wave of clean technology investment came through, venture capitalists quickly shifted their focus from software to energy. As Cory Steffek, Managing Director at Ara Partners, a private equity firm specializing in industrial decarbonization investments recalls, there was a lot of money being raised for investments that venture capitalists at the time didn’t understand.

“Coming from the software industry, they didn’t have much experience in the energy sector from an entrepreneurial and investor level,” says Steffek. “As a result, investments were too narrow and there was an underestimation of how long it takes to innovate in this space.”

24 25 worley.com worley.com TECHNOLOGY

TECHNOLOGY

EVERYONE IS TAKING THE CONVERSATION AROUND CLIMATE CHANGE AND THE ENERGY TRANSITION VERY SERIOUSLY.

Then the 2009 recession hit and investments in clean technology stopped as quickly as they had started. But as interest and activity in clean technology takes off again, Brown believes that this time, it’ll continue to increase.

“Investment will continue because the financials are there, and money can be made from these technologies,” he explains. “We now have a more diversified mix of investment, the technology has matured, and the cost curves have come down. Then add a global pandemic to the mix, which has made us question the status quo and accelerated the uptake of new technology.”

The rate of adoption has increased

When COVID-19 turned our lives upside down at the start of the year, Steffek and his team held their breath. “In 2009, I saw the entire clean technology sector go upside down in a six- to 12-month window,” recalls Steffek. “If history repeated itself, it would mean clean technology initiatives within corporations would be pushed aside. The good news is, this hasn’t been the case with COVID-19 because the momentum to innovate and decarbonize our global economy isn’t dying down. If anything, it’s the opposite.”

TECHNOLOGIES THAT WERE ONCE THOUGHT TO BE DECADES AWAY ARE NOW BECOMING A REALITY IN THE NEAR TERM.

“In a matter of weeks, we had to shift the way we lived and worked and adopt new technology and processes,” Brown adds. “If you consider how technology moves through the market development curve from early adopters to laggards, we essentially crushed this model down where the majority are more willing to test new technology even if it hasn’t been completely proven.”

Technologies that were once thought to be decades away at the start of the year, are now becoming a reality in the near term. “There’s more of a willingness to adopt progressive technology that would have otherwise gone through a lengthy and traditional adoption curve,” explains Brown. “But they still need to be economically viable if they’re going to become a reality.”

27 worley.com TECHNOLOGY

26

IF HISTORY REPEATED ITSELF, IT WOULD MEAN CLEAN TECHNOLOGY INITIATIVES WITHIN CORPORATIONS WOULD BE PUSHED ASIDE. THE GOOD NEWS IS, THIS HASN’T BEEN THE CASE WITH COVID-19 BECAUSE THE MOMENTUM TO INNOVATE AND DECARBONIZE OUR GLOBAL ECONOMY ISN’T DYING DOWN. IF ANYTHING, IT’S THE OPPOSITE.

TECHNOLOGY

If it’s not clean, it won’t get funded

Millennials and Gen Z are the fastest growing portions of the global workforce. They’re bringing with them a new set of values and expectations for corporations, which is influencing energy technology investment decisions.

“The next generation is demanding energy and technology that’s environmentally and ethically responsible,” says Brown. “They’re more aware of what they’re consuming and how their buying behaviors affect their future environment. As the largest demographic, they have a massive purchasing power to influence demand and what companies invest in. That’s why, if a technology can’t help lower emissions, or if it adds to our emissions, it’s unlikely that it’ll get funding.”

Corporations are planning for a cleaner future

Almost every company, no matter what it does, has announced that they’re going to reduce their carbon footprint. Earlier this year, Microsoft announced that it will be carbon negative by 2030. BP set a new ambition to be a net zero company by 2050 or sooner. And Amazon revealed its US$2 billion dollar Climate Pledge Fund that will focus on technology investments across energy, storage and manufacturing to reduce the impact of climate change and support sustainable development.

“What this means is that these companies are going to start to make some big investments in the clean technology space,” says Brown. “Whether it be infrastructure investment, partnerships or adopting new technologies to reduce carbon emissions across their operations.

“The playing field is completely level right now and it’s likely that we’ll start to see more technology firms come into the energy industry. They have the capital to place some pretty big investments and get into the industry very quickly.”

Our window of opportunity is now

But as other industries start moving in, how do the energy, chemicals and resources industries keep pace?

“We need to start to figure out what our position is, and decide how we want to progress forward,” says Brown. “Things are changing fast and this window of opportunity is limited. The steps we take today don’t always have to be perfect. But they need to be forward.”

28 29 worley.com worley.com TECHNOLOGY TECHNOLOGY

AS THE LARGEST DEMOGRAPHIC, THE NEXT GENERATION HAVE A MASSIVE PURCHASING POWER TO INFLUENCE DEMAND AND WHAT COMPANIES INVEST IN. THAT’S WHY, IF A TECHNOLOGY CAN’T HELP LOWER EMISSIONS, OR IF IT ADDS TO OUR EMISSIONS, IT’S UNLIKELY THAT IT’LL GET FUNDING.

READ MORE WORLEY TECHNOLOGY VENTURES

Out of office

COVID-19 forced many companies to switch quickly to remote working. Here’s how we used it as an opportunity to innovate and change the way we work, forever

WORDS BY MEHREEN YUSUF

When the world went into lockdown at the start of 2020, companies had two choices. Quickly switch to remote working or stand people down until the right infrastructure was set up to support working from home.

“The first few weeks of the pandemic were challenging for everyone,” reflects Vance WilsonMay, Group Director of Global Infrastructure and Operations at Worley.

“But looking back, we were better prepared than we anticipated. In just three weeks we moved 80 per cent of our workforce to remote working.”

Finding solutions in existing information systems

For WilsonMay, our existing information systems were a key part of our success.

“We already used Citrix to give people remote and secure access to work applications, allowing them to work on the same data from different locations. So, we had the technology ready to respond to the pandemic.

“But, while we used the software for remote access before the lockdown, it was only for a minority of our people. There was little requirement for the majority to have remote access, and there was no effective solution in place for engineering applications.”

That might have been a more challenging situation, if it wasn’t for one key thing. “Because our systems were built in the cloud, we had the agility to expand quickly. We added engineering application capability and increased network VPN capacity in key locations to allow the majority of our people to work from home as soon as possible.”

For people working on site, it was a different story. They continued to work on site, with social distancing guidelines, additional sanitation measures and extra personal protective equipment, such as masks. Work schedules were also changed to minimize risks and new safety processes, such as temperature checks, were introduced.

Shifting over 80 per cent of our workforce to remote working

Ben Bredin, Director for Global Workspace at Worley, had one priority in the first 48 hours after countries began going into lockdown.

“We needed to provide our people with a virtual desktop environment – a desktop experience that is consistent, no matter where that desktop is located. We knew it was vital to do this so that our people could continue to work while at home.”

To do this, Bredin knew he needed to create new connections between each of our people and their devices.

“We’ve been using remote-working software successfully for over 15 years, so we were confident that we could support that many connections for our people around the world.”

He also knew that, out of everyone at Worley, the engineers would find it most difficult to work from home. “Engineers make up large percentage of our workforce. They rely on local servers to access their modeling programs,” explains Bredin. “They need to work with large amounts of data every day without any kind of slow down or delay.’

“So, we increased our virtual private network (VPN) capacity to ensure secure and fast connections. We also began to use a software that gave our engineers access to their graphic-intensive applications securely and remotely, allowing them to deliver value to customers.”

Building a new global support team of 350 specialists

Once the solutions for the workforce were prepared, the hard work really began. Bredin embarked on establishing a new remote support model and training 350 desktop support specialists on the newly deployed solutions.

“We set up a schedule of crash courses to train the support team. It was important they knew how to assist our people working remotely by troubleshooting any problems they had. We also made sure that people could access our support team 24/7.”

30 31 worley.com worley.com REMOTE WORKING

REMOTE WORKING

For Bredin, the biggest challenge was to make sure that all the computers in the offices remained powered on. “With the lockdown in place we knew we wouldn’t be able to physically access sites to power computers on if they were inadvertently switched off. If that happened, nobody would be able to work remotely, so it was critical that they were not powered off. We got around this by removing the shutdown option entirely.

“In just a week we transitioned from a team of five to an extended team of 350, who could support a remote working environment. The initial five-person team created 25,000 remote connections, and the 350-person team provided daily support to everyone in our new work-from-home community.”

Swapping physical offices for digital data centers

With the company’s efforts in increasing utilization of office space, more people will be working flexibly from home going forward. “Because of our efforts in getting most of our people working remotely, we’re much less reliant on bricks and mortar,” says WilsonMay. While some offices remain closed, others need to stay open to support the business for customer interactions as well as storing engineering applications on local servers. These applications are demanding from a server point of view.

They have a database on the back end, and the front end is located at an engineering workstation with graphics card acceleration. For companies like Worley, this equates to needing physical offices just for local access to hardware and data.

“Our goal is to move engineering applications from our remaining physical offices to our multi-cloud environment, removing the need for local servers,” explains WilsonMay. “That would enable us to support the business better without relying on physical infrastructure.”

Any device, anywhere, anytime

For WilsonMay, the future will be a hybrid of working from home and working from a shared office space. “If you look at our journey, it began by expanding our existing software. Now, what we’re doing a piece at a time, is moving from people needing to be at home with a Worley device, to being able to work from any device anytime, anywhere.”

Eventually, WilsonMay is confident that our people will be able to access any program from any device in any location. All they’ll need is their multi-factor Worley log in.

“Imagine the flexibility that will bring – people will be free to choose how and where they work. That’s what the future looks like.”

32 worley.com REMOTE WORKING

WE’RE MOVING FROM PEOPLE NEEDING TO WORK REMOTELY WITH A WORLEY DEVICE, TO BEING ABLE TO WORK FROM ANY DEVICE, ANYTIME, ANYWHERE.

Analyze risks. Understand opportunities. Navigate the energy transition. Advisian Carbon Risk Index Service... coming soon

READ MORE LIVING FOR TODAY, PLANNING FOR TOMORROW

5 minutes with…

Cameron Druery

We caught up with Cameron Druery, Product Manager for waterRIDE™ to find out more about this flood analysis tool and its role in climate change resiliency

What is waterRIDE?

waterRIDE is a software tool for the floodplain and flood emergency management industries. It presents complicated flood information in a visually appealing and easy to understand way. This means anyone can analyze flooding data – not just flood modelers.

Why is waterRIDE so important?

Floods are among the most frequent and destructive natural disasters in the world. Over the last decade, flood events have increased by more than 50 per cent. Communities are set to face increasing flood severity as climate change progresses. It’s vital that we understand the implications of these changes to help secure climate change resiliency.

Traditionally, flood studies are delivered as static information. But in reality, a flood is dynamic – it builds up over time. With waterRIDE, users can easily see how that will happen. It not only shows them which areas will be inundated, but how these areas will be affected as a flood evolves. Our solutions help communities and businesses plan for and manage flood events.

How does waterRIDE help with climate change resiliency?

waterRIDE is part of Worley’s suite of health, safety and environment products. Its functionality helps users understand which areas and assets are vulnerable to flooding –and to plan suitable responses.

Using our platform, communities can arrange evacuation plans well in advance of a flood occurring. Governments can see which areas are most at risk and put processes in place to help people deal with the effects of climate change. Businesses and utilities can minimize the interruption to their operations.

In the last 15 years, waterRIDE has helped more than 250 organizations across government, insurance, and energy and resources understand the impacts of flooding.

What’s new for waterRIDE?

This year we launched waterRIDE CLOUD. It allows our users to distribute, manage, and work with their flood information from one place securely, anytime, anywhere.

It also means flood information and insights can be shared instantly with stakeholders directly from our platform, creating a more resilient and agile flood management system. And because our flood datasets are centralized in the cloud, critical information can be spread more quickly among communities so they can prepare and evacuate before flooding occurs.

Users can manage their data themselves, or take up our new ‘waterRIDE as a Service’ managed data service offering and have us do it for them. All we need to know is when a new flood study has been completed and a link to the datasets. We’ll then provide an automatic notification when the updates are ready to use on waterRIDE CLOUD.

The bottom line? Simple, hassle-free and fast data sharing using waterRIDE CLOUD means better understanding, flood resiliency, mitigation and emergency response.

What are you most excited about with waterRIDE?

It has to be waterRIDE’s ability to help people understand their flooding problems and the associated consequences. We strive to give people the tools they need to make the best planning and management decisions that will drive a safer community, and ultimately, save lives.

READ MORE HOW WATERRIDE WORKS

34 worley.com

INTERVIEW

INTERVIEW

35 worley.com

SUSTAINABLE SOLUTIONS

Let’s focus, together

Sustainable Solutions is our new approach to reducing the carbon footprint of our customers’ projects. It helps us to have conversations, generate ideas, measure emissions avoided, make change – and build sustainability into everything we do.

COMING SOON TO A PROJECT NEAR YOU