power demand

the

power demand

the

Our acoustic enclosures provide exceptional noise reduction, transforming disruptive environments into focused, productive spaces. With over 40 years of experience, we have successfully delivered customized acoustic solutions to more than 1,000 clients worldwide.

We let the silence speak. For itself and for us.

Publisher/Sales DIrector Neb Saric neb@wipmagazines.com

Publishing & Events Director Richard Teasdale richard@wipmagazines.com

Managing Editor Aidan Turnbull aidan@wipmagazines.com

Accounts Manager Alison Williams accounts@wipmagazines.com

Business Development Manager Kurt Ellmer power@wipmagazines.com

Far East Sales Bob Liu Shanghai, China bob.liu@ronco.com.cn

US Sales & Subscriptions

Jelena Milojevic power@wipmagazines.com

Austrian & German Agent Mario Dobresko power@wipmagazines.com

Power Media International Group, Power Media International Group Ltd First Floor Suite 1 5 Sanford House Medwin Walk Horsham West Sussex RH12 1AG, UK

Phone Number +44 (0) 1403 332888

Mobile No +44 (0) 7539 791169

Power Media International Group,

www.powermediagroup.co.uk

© Worldwide Independent Power (ISSN 1468 7100)

Denmark is building the world’s first energy islands, making the most of its abundant wind energy resources in the North and Baltic Seas.

The Danish government says these energy islands will form a crucial part of a hub-and-spoke grid, “facilitating smart electricity distribution between regions across the two seas”.

Key entities behind the US$1.6 billion energy islands, as well as the Danish government, include the Danish Energy Agency, Danish system operator Energinet and private sector partners, as well as the VindØ Consortium. Ørsted and ATP have announced plans to bid for the North Sea island project.

The energy islands mark the beginning of a new era for the generation of energy from offshore wind, aimed at creating a green energy supply for Danish and foreign electricity grids. Operating as green power plants at sea, the islands are expected to play a major role in the phasing-out of fossil fuel energy sources in Denmark and Europe.

The plan envisages the establishment of at least one artificial island in the North Sea to serve as a hub for offshore wind farms supplying 3-4 GW of energy, with a long-term expansion potential of 10 GW.

The first energy island in the Baltic Sea will be Bornholm, where electrotechnical facilities on the island will serve as a hub for offshore wind farms off the coast supplying 3GW of energy.

“

DENMARK’S PROJECT IN THE BALTIC WILL COST US$30 BILLION & BE COMPLETED BY 2036.”

Denmark has a long history of exploiting the strong winds from the sea to produce electricity and the Danish Energy Agency is playing a key role in leading the project that will transform the two energy islands from a vision to reality.

The islands are a pioneer project which will necessitate the deployment of existing knowledge into an entirely new context. Working together with wellestablished companies in the industry and the highest level of expertise in the field. A spokesman comments: “The goal is to find the best solutions to the aspects of the project which remain unsolved. We are exchanging knowledge, performing quality assurance on solutions and working every day to further the green transition and ensure a reliable supply of electricity to Danish power sockets.”

The artificial island is likely to take the form of a sand island, steel platforms, or a large container lowered into place and filled with stone material, and would be located approximately 80 kilometres (50 mi) west of Jutland, at a water depth of 26–27 metres (85–89 ft). This should provide a stable base on which to build a hub on the natural island of Bornholm. This, in turn, will be able to serve up to 3GW of offshore wind farms.

The project will be the largest construction project in Denmark’s history. Current projections suggest that the site will be completed by 2036 at cost of US$30 billion.

AIDAN TURNBULL Managing Editor

GENSET MARKET WORLDWIDE 2025-36

Business Research Company’s latest report suggests that the diesel generator market size has grown strongly in recent years. It will continue to grow from $20.52 billion in 2024 to $21.82 billion in 2025 at a compound annual growth rate (CAGR) of 6.3%, reports BRC.

The growth in the historic period can be attributed to strong economic growth in emerging markets, rapid industrialization, an increase in energy demand and consumption, and a rise in focus on electricity generation using fossil fuel energy sources.

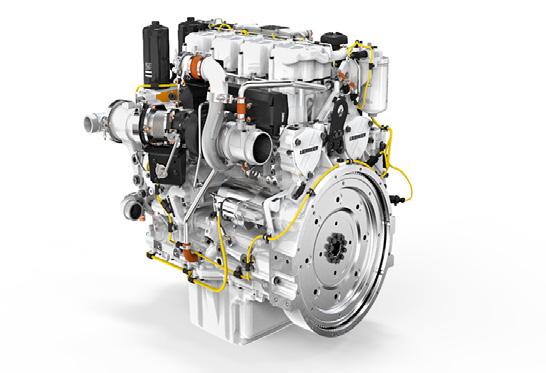

NEW AMMONIA-FUELLED ENGINE DEVELOPED WITH POTENTIAL GENSET APPLICATIONS

As a ‘proof-of-concept’ Liebherr’s experimental ammonia engine relies on ammonia as a power source for dual-fuel internal combustion engines. The results -says the company - ‘clear the path for further development of the solution’. Green ammonia serves as a key hydrogen carrier, offering benefits of reduced transportation.

ADVANCED ENGINE DEVELOPMENT RUNS ON DIESEL, METHANE AND HYDROGEN

The XCursor 13 is FPT Industrial’s first multi-fuel single base engine designed to run on diesel, methane and, in the future, hydrogen. It is compatible with a wide range of market requirements and easily adaptable for different vehicle installations.

The XCursor 13 is a primary contributor to achieving CO2 emissions targets, and is one of the most relevant parts of the group’s decarbonisation program.

75 YEARS OF DELIVERING FOR CUSTOMERS AND DRIVING PIONEERING PROGRESS

Celebrating 75 years of innovation and reliability, Woodlands Power, under the leadership of Managing Director Jack Preece, forges a bold path ahead with alternative power solutions and a commitment to industry leadership.

CHP PLANT IN THE EIFEL REGION, GERMANY, INSTALLS TWO NEW GENERATOR SETS

Bitburger Braugruppe has a CHP plant with two MWM gas generator sets at its headquarters in the Eifel region in Germany. This year, following more than 60,000 hours of operation, the two MWM TCG 2020 V20 generator sets will be replaced with newgeneration TCG 3020 V20 engines.

4 X 750 KVA DIESEL GENSET FOR A LARGE SHOPPING MALL CENTRE IN SOUTH AFRICA

South Africa’s generator set company NEW WAY has provided four 750kVA diesel gensets for a large shopping mall based in Eastern Cape, South Africa. These gensets all feature advanced Baudouin engines and Leroy Somer alternators. A NEW WAY company spokesman commented on the 3MVA package provided: “Our team was commissioned to design and supply 4x 750 KVA Sync to loadshare generator sets for this hybrid power solution.”

SOUTH KOREA’S LARGEST DATA CENTRE INSTALLS EIGHTEEN 3,750 KVA DIESEL GENSETS

Cummins Inc. has supplied 18 x Cummins QSK95 gensets with a 60 Hz standby rating of 3750 kVA to the the Gak Sejong data centre in South Korea. In addition to the gensets, Cummins has also supplied a DMC8000 digital master control system for the gensets, designed to provide best-in-class resiliency and system uptime during outages.

MARKET IMPROVEMENTs IN RECENT MONTHS MIDDLE EAST GEN-SET ASSOCIATION has gone from strength-to- strength with 50 + companies taking advantage of the new membership joining options, including Bahmani, Jubaili, Technopower, Staunch Machinery plus many other OEMs. For more details on how to apply for membership to the Association please see page 28.

MEETING TODAY’S ENERGY CHALLENGES INVOLVING SUBSTATION INSTALLATION

In 2024 Lucy Electric provided a 500kVA package substation with a National Grid RMU, Lucy Sabre VRN2a TLF unit to NGED Specification and Lucy AcuLok LV cabinet with an 800A ACB. InstaVolt, renowned as the largest and most reliable EV charging network in the UK, was involved in the project.

UK GEN-SET & CHP ASSOCIATION PowerEx Live Midlands 2025, will be held on Thursday, July 3rd, 2025. It aims to probe and discuss all the trends, opportunities and challenges for the GENSET, CHP & ENERGY industries. Before this important day the UKGSA is backing an Tournament which will be held the day before the PowerEx Live (July 2nd, 2025). See page 29 for details..

Bornholme, The Baltic.

03

EDITOR’S LETTER

03-14

NEWS REPORTS (p.8-12).

International News + details on PowerEx Live Midlands and PowerEx Live London Exhibition. PowerEx Live Midlands 2025 will be held in the UK on Thursday, 3 July, 2025 (with a Golf Tournament the day before). We also feature details on PowerEx Live 2025 which will be held again at London’s Park Plaza Hotel, Westminster, London, UK, on Thursday 11th December, 2025

17

MARKET REPORT - GLOBAL GENSET MARKET

WIP looks at predictions for the genset market 2025-36.

28-30

ASSOCIATION NEWS

Associations: MEGSA, UKGSA, EGSA, Europgen and JENDER.

32

NEW PRODUCTS & WORLD DIARY OF EVENTS (p.26)

Don’t miss some of the best new products for March 2025 (page 32).

33

CLASSIFIED DIRECTORY OF EQUIPMENT & SERVICES

Listings of key companies in the industry.

34

ENGINE MANUFACTURERS GUIDE

OEMs manufacturing engines today.

GOLF DAY & POWEREX LIVE MIDLANDS 2025

Mecc Alte’s highly reliable and highly efficient alternators offer critical protection solutions to many data centre operators. Our extensive experience in the power generation industry, as well as our diligent studies and thorough research, has led to the development of our full alternator range. In-built features and highly customisable products allow our alternators to provide peace of mind when power is needed.

As data centre alternators manufacturer, standard products are performance enhanced with rich designs in order to meet the demands of the applications in which they operate. These features are standard across the ranges allowing peace of mind to our customers who need reliable power supply.

RELIABLE BACKUP POWER SOLUTIONS FOR DATA CENTRES

The 20M55 Generator Set boasts an industry-leading output of 5250 kVA, making it one of the highest-rated generator sets available worldwide. Engineered for optimal performance in demanding data centre environments.

HIGHEST RATINGS AVAILABLE ON THE MARKET | UPTIME INSTITUTE COMPLIANCE

ISO-8528 G3 LOAD ACCEPTANCE PERFORMANCE | BEST LEAD TIME

The battery manufacturer Northvolt has sold its industrial battery pack division to long-term partner Scania.

PowerEx Live Midlands 2025, will be held on Thursday, 3 July, 2025. This event aims to probe and discuss all the trends, opportunities and challenges for the GENSET, CHP & ENERGY industries.

PowerEx Live Midlands 2025 will be hosting some of the foremost energy speakers in the country with the most recent and cutting-edge content within the energy industry. This regional UK event - with an associated Golf Tournament [see page 29] held the day before the event (July 2, 2025) - offers all key sector players in the North of England an opportunity to assess new trends, connect and develop all under 1 roof over the course of 1 day.

The Midlands event features 8+ Speakers and 28+ companies will be there. To reserve a table and/or take on sponsorship visit https:// lnkd.in/d8nApVtU https://lnkd.in/ewP7Fhui or send email to power@wipmagazines.com

Scania, controlled by Volkswagen’s commercial vehicles arm Traton Group, depends on Northvolt for battery cells for for its e-trucks and owns a stake in the Swedish green tech player. The company invested US$100 million in Northvolt as part of the U.S. deal last year. Scania is Northvolt’s top investor with a 21% stake. Since November 2024, Scania provided members of staff for work at Northvolt’s Ett plant in Skelleftea, 200 kilometres below the Arctic Circle, a move which reflects Scania’s support strategy for the green tech player. The plant employs around 2,500 people. Northvolt has faced significant financial stress in recent years, including the need to seek emergency funding.

The event is sponsored by UK Gen-Set & CHP Association with the Data Centre Alliance. The Conference is being held at a top-class venue offering optimal trade opportunities to meet both regional and global buyers, specifiers, OEMs, equipment distributors and contractors/ installers. The venue is at the Belfry Hotel and Resort in Royal Sutton Coldfield, West Midlands.

For more details on the 2025 Powerex Live Midlands Conference please visit: www.powerexlive.co.uk/midlands

IT’S NEVER TOO EARLY TO TAKE YOUR PLACE AT POWEREX LIVE LONDON 2025,

PowerEx Live 2025 will be held again at London’s Park Plaza Hotel, Westminster, London, UK, on Thursday 11th December, 2025.

PowerEx Live 2025 aims to offer perfect networking opportunities for international professionals across the Genset, CHP, Data Centre and Consultancy industry sectors.

With 24 conference speakers at the top of their respective fields attending GEN-SET, CHP & ENERGY LIVE you can be sure to glean some valuable insights into the industry at this special One-Day Event. The three conferences are held alongside premier display space in a world class venue. The conferences will run parallel with prime exhibitor space available in adjoining rooms. Do not miss this opportunity for networking with experts in all fields of CHP, Data Centres, Consultancy and Gensets.

PowerEx Live 2025 will feature 3 Conference Rooms this year. Topics are as follows:

*Room 1: Data centres: (Power Growth), AI, Energy Efficiency, Grids, Intelligence and infrastructure.

*Room 2: Gen-Sets, Battery & Energy Storage, Batteries& UPS, Hydrogen, Solar Power for Clean Energy Transition.

*Room 3: CHP, Renewables, DH, Biogas, Heat Pumps/ Networks, Distributed & Decentralised Energy, Carbon Emissions, Efficiency for a Carbon NET Zero sustainable FUTURE.

The conferences are held alongside premier display space in a world class venue. This event has earned its reputation as a priority show for all those in the power and energy markets. Book your Exhibition Tabletop or register as a delegate now by visiting: www.powerexlive.co.uk

ComAp recently partnered with EJT New Energy in Dubai, UAE, to commission an energy storage solution for Al Shola Transportation Co., LLC, an equipment rental and transportation company.

This solution was commissioned to facilitate the successful integration of EJT New Energy’s battery packages with the customer’s existing gen-set.

As one of the first equipment rental companies in the UAE, Al Shola Transportation sought to import EJT New Energy’s battery packages from China for use alongside their rental equipment, taking a pragmatic approach to stay ahead of trends in the power generation rental industry.

However, to achieve this, Al Shola Transportation needed to ensure that they would be able to seamlessly integrate the new battery packages with their conventional fleet.

In co-operation with EJT New Energy’s Research and Development team and Al Shola operations, a new control system operated by ComAp’s BESS controller for battery energy storage systems was implemented.

The InteliNeo 530 BESS enables direct integration of the Battery Management System (BMS) with the Power Conversion System (PCS) within a BESS, while also providing control, monitoring, and protection of auxiliary systems, facilitating the safe integration of the batteries with the fleet’s diesel genset.

Logan City Council’s Australian-first biosolids gasification facility is revolutionising human waste disposal while reducing harmful carbon emissions and saving Council millions of dollars per year. The gasifier, designed and delivered by the Council’s water business, Logan Water, in partnership with Downer, WSP and Stantec, thermally treats biosolids (human waste) to produce reusable gas, and an environmentally-friendly, charcoal-like product called ‘biochar’. The innovation has been a game-changer for the growing South East Queensland city, which previously – like many local government areas disposed of its biosolids by treating, then trucking the waste thousands of kilometres for use on non-edible crops. All a considerable expense to the authority.

A US DoE report shows that in 2023 biomass accounted for about 5% of U.S. energy consumption, or about 4,978 trillion British thermal units (TBtu).

The types, amounts, and the percentage shares of total biomass energy consumption in 2023 were:

Biofuels—2,662 TBtu—53%

Wood and wood waste—1,918 TBtu—39%

Municipal solid waste, animal manure, and sewage—398 TBtu—8%.

The industrial sector accounted for the highest total annual U.S. biomass consumption in 2023 in terms of energy content and percentage share. The wood products and paper industries use biomass in combined heat and power plants for process heat and to generate electricity for their own use.

The transportation sector accounted for the second-highest amount and percentage share of biomass (as biofuels) consumption in 2023.

The residential and commercial sectors use firewood and wood pellets for heating. Commercial sector biomass consumption in the US includes biogas produced and consumed by municipal sewage treatment facilities and waste landfills. In conclusion the report notes that U.S. total biomass energy exports exceeded total biomass energy imports in 2023.

Land’or, a key player in the Tunisian cheese industry, has made a strategic choice by adopting a trigeneration solution to optimise its energy operations. Land’Or’s choice to partner with Clarke Energy for the supply, design, installation and maintenance of its trigeneration plant. This represents a significant step towards more efficient, sustainable and economically advantageous cheese production .

By combining diversified energy benefits with a long-term partnership, Land’or is positioned to thrive in a competitive environment while making a positive contribution to the environment.

The Land’Or trigeneration plant is equipped with an INNIO Jenbacher type JMS 416 gas engine powered by natural gas, with an electrical power of 1.2 MWe, with a thermal capacity of 574 kWth and a cooling capacity of 600 kWf. ulti-Purpose Power Generation: Electricity, Heat, and Cooling (CCHP)

Trigeneration allows Land’or to simultaneously generate electricity, heat in the form of steam at 9 bars produced by the boiler, and cold in the form of chilled water. This versatility meets the plant’s multiple energy needs. The trigeneration plant also has an absorption unit to produce cooling, i.e. 600 kWf of chilled water. This cooling is essential to regulate and improve product quality Obtained.

The in-house production of electricity, heating and cooling reduces dependence on external energy sources, thus minimising production costs and strengthening Land’or’s competitiveness in the market.

The residual gases from the trigeneration can be exploited for other thermal needs, thus minimising energy waste and helping to reduce current operational costs.

A flour factory recently installed a 8.5 MW power plant in Sierra Leone, located on the southwest coast of West Africa. This new biomass-based power plant has been designed to supply the site with electricity and feed excess energy back into the power grid, contributing to the region’s development.

The power package - designed to operate in the demanding climatic conditions found in West Africa - includes stateof-the-art engines with optimised consumption to ensure optimal performance, adapted to the environment. An extra fuel tank has been installed and adapted to suit the client’s specific needs.

Once complete the flour mill will use heavy electricallypowered equipment to grind the grain into different types of flour - whole wheat, all-purpose, bread flour - and to run conveyor belts, safety monitoring equipment, lighting, security, fire prevention and ventilation systems. Both the flour and wheat products will be shipped to grocery stores and other food retailers in Sierra Leone.

We’ll help you navigate change.

With 150 years of innovation under our belt, we offer comprehensive service from planning to operation. We work with you to develop futureproof energy solutions based on our proven gas generator sets. Get in touch – we’re raring to go!

Fetis Group has developed a hydrogen-powered hybrid generator set. The new genset range is based on an internal combustion engine specially designed to run on all types of hydrogen, including white hydrogen.

Nomad Solar Energy, a mobile renewable energy solutions provider based in Madrid, Spain, showcased its solar technology at PowerGen International, Feb. 11-13, in Dallas, Texas. The company is well-known for its deployable solar panel systems designed for off-grid power generation, with and without storage capabilities.

The Nomad Energy Box is available in 47-kWp and 107-kWp versions and allows for parallel scalability up to 1 GW at a range of worksites. Designed for quick deployment, whether grid connected or standalone, the solar generators come ready to use and fully pre-wired, including the mounting structure, inverter and electrical panel.

The range is comprised of two solutions. The H150-ICE hybrid unit, which incorporates a battery pack, optimises energy management and meets high-dynamic requirements. It has a rated output of 150 kVA and a maximum output of 195 kVA. This new solution replaces diesel generators for events and rental applications, as well as for renewable energy installations. It can be used when the carbon footprint and/or exhaust emissions are an issue; or to convert waste hydrogen produced as a byproduct from industrial processes (known as fatal hydrogen) into electricity.

The Energy Box enables efficient solar panel deployment, energy collection, storage and consumption using intelligent battery load balancing, the company stated. It said units have been deployed in humanitarian environments and industrial self-consumption projects and are emerging as an option for agri-food irrigation and mining excavations requiring temporary energy supply.

“Solving mobile energy supply challenges and contributing to environmental decarbonization are at the core of our strategy,” said CCO Lorenzo Jourdain at Nomad Solar Energy. “With increasing global energy demands, our scalable and efficient solar solutions allow

Rolls-Royce is to launch an upgraded 50 Hz version of the mtu Series 1600 gen set platform. This follows on from the introduction of the related 60 Hz model in 2023.

“At the heart of these gensets is the proven mtu Series 1600 engine, which we have further developed in terms of performance, flexibility, life-cycle costs and sustainability for the new generation, and with which we are setting new standards,” said Tobias Ostermaier, president of the Stationary Power Solutions division at Rolls-Royce Power Systems.

He continued: “Serving a wide variety of applications in the lower end of our power range, the Series 1600 will expand our strong position in the power generation market, as part of our growth strategy to support the world’s power needs.”

The 12V1600 Gx1 engine is said to have the highest power density in its class. It offers ‘outstanding’ load acceptance and reliability. The engine can deliver nearly full power at high ambient temperatures and in high humidity locations. The new platform is said to produce up to 40% more power than the model it replaces. This translates to an electrical output of between 590 and 996 kVA.

Mtu Series 1600 gen sets are approved for synthetic diesel fuels that meet the EN 15940 standard, such as hydrotreated vegetable oil (HVO). Using HVO can reduce CO2 emissions by up to 90%.

Caterpillar has announced that it has received DNV Approval in Principle of the Cat 3500E methanol-ready main and auxiliary engines.

The DNV approval and class notation validate Caterpillar Marine’s methanol-ready dual-fuel engine solution. The Cat 3500E engines are available in 12-cylinder (up to 1901 kW) and 16-cylinder (up to 2525 kW) configurations. Caterpillar will provide update kits for the 3500E in addition to offering new methanol-burning engines to satisfy the timing and requirements of any project.

“Caterpillar Marine is pleased that the DNV review was successful, as it marks an important product development milestone for us,” stated Caterpillar Marine Vice President and General Manager Brad Johnson. “Methanol will play an important role in the industry’s energy transition efforts, and we look forward to providing operators with high-quality methanol solutions.”

Cat 3500E methanol-ready engines will have a significant impact across all maritime segments, especially tugs and other vessels that require high-power propulsion for heavy loads. This innovative solution will enable operators to use methanol as a fuel to help reduce greenhouse gas (GHG) emissions.

“The DNV review marks an important product development milestone for us,” says Caterpillar Marine Vice President and General Manager Brad Johnson.

The Business Research Company’s latest report suggests that the diesel generator market size has grown strongly in recent years. It will continue to grow from $20.52 billion in 2024 to $21.82 billion in 2025 at a compound annual growth rate (CAGR) of 6.3%, reports BRC.

The growth in the historic period can be attributed to strong economic growth in emerging markets, rapid industrialization, an increase in energy demand and consumption, and a rise in focus on electricity generation using fossil fuel energy sources.

Diesel generator market expansion forecast from 2025-2037

The diesel generator market size is expected to see strong growth in the next few years. It will enlarge to $28.28 billion in 2029 at a projected compound annual growth rate (CAGR) of 6.7%.

This phenomenal growth can be attributed to the expanding construction industry, thriving growth of the manufacturing industry, and remote work revolution.

Major trends in the forecast period include improving the efficiency of diesel generators, developing rental generators, hybridization of diesel generators, designing compact and mobile solutions, and integration of advanced technologies such as remote monitoring, predictive maintenance, and data analytics.

The expansion of the construction industry is expected to be a key driver of the growth of the diesel generator market in the forecast period.

As construction projects expand, reliable power sources are essential to maintaining operations in various stages of development, and diesel generators serve as critical backup power solutions, ensuring uninterrupted operations in construction sites where grid power may be unreliable or unavailable.

According to a report published by the U.S. Census Bureau, a primary agency of the United States Federal Statistical System, in August 2023 construction expenditure accounted for $1,938.4 billion in June 2023, indicating a 3.5% percent increase from the estimated expenditure of $1,873.2 billion in June 2022.

According to Oxford Economics, a UK-based provider of global economic forecasting and econometric analysisthe global construction output is estimated to grow from $9.7 trillion in 2022 to $13.9 trillion by 2037.

Industry analysts have indicated that the expanding size of the construction industry will - in turn - drive the growth of the diesel generator market going forward into the 2040s and beyond.

“ANALYSIS SUGGESTS THE GLOBAL DIESEL GENERATOR MARKET SIZE WILL GROW FROM US$20.52 BILLION IN 2024 TO US$21.82 BILLION BY THE END OF 2025 AT A CAGR OF ROUND 6.3%.”

The remote work revolution is expected to propel the growth of the diesel generator market in the forecast period.

The practice of remote working, often referred to as telecommuting or teleworking, has gained significant traction in recent years and was further accelerated by the COVID-19 pandemic.

As more people work remotely, businesses may seek reliable backup power solutions to ensure continuous operations, especially in areas with unreliable grid power.

Ultimately this contributes to the need for backup power sources such as diesel generators to maintain productivity during power outages and enhance their market demand.

For instance, in June 2023, according to Forbes, a US-based renowned business publication, 12.7% of full-time employees were operating in a remote work model.

Additionally, 28.2% of employees have embraced a hybrid work approach.

By 2025, projections indicate that around 32.6 million American professionals, or roughly 22% of the workforce, will be engaged in remote work.

Therefore, the remote work revolution will drive the growth of the diesel generator market in the forecast period. Major companies operating in the diesel generator market are

focused on providing technologically advanced solutions such as ultrasilent generators to strengthen their market position.

Ultra-silent generators are designed to operate with minimal noise, making them ideal for use in noise-sensitive environments while providing reliable power output.

Digital technologies have boosted the diesel generator market and manufacturers are investing in R&D to develop sophisticated diesel generators that integrate advanced technologies such as remote monitoring, predictive maintenance, and data analytics for better optimization of fuel efficiency. Asia-Pacificis considered to be the largest and most lucrative region in the diesel generator market in 2024.

The Business Research Company provides diesel generator market statistics, including details on diesel generator industry global market size.

Celebrating 75 years of innovation and reliability, Woodlands Power, under the leadership of Managing Director Jack Preece, forges a bold path ahead with alternative power solutions and a commitment to industry leadership.

Founded in 1950 by Fred Preece as a civil engineering firm, Woodlands Power has consistently evolved to meet the changing needs of its customers.

In the 1970s Woodlands Power established itself as a leader in generator rental and sales, driven by the energy crisis that highlighted the importance of dependable temporary power.

Over the years, the company has powered iconic projects such as Live Aid and has partnered with the Royal Navy to support nuclear submarines across Europe.

Today, the company provides mission-critical power solutions across healthcare, data centres, manufacturing, construction, and defence, delivering trusted, high-performance power solutions while driving innovation, reliability, and tackling the challenges of an ever-changing energy landscape.

Leading the company into the future is Jack Preece, Managing Director of Woodlands Power and the third generation of the Preece family to head the business. With over a decade of experience across various roles within the organisation, Jack is equipped with a deep understanding of the industry and a forward-thinking vision.

Under Jack’s leadership, the company rebranded as Woodlands Power in 2020 to reflect its full-service capabilities and broaden its range of power-related products.

“The reason for the rebrand was to enable us to delve deeper into power specialisms, particularly in critical and standby applications,” Jack explains.

“This shift allows us to continue delivering innovative, reliable solutions tailored to our customers’ energy needs.”

As industries demand more sustainable and resilient power solutions, Woodlands Power continues to adapt. The company integrates advanced technologies such as battery systems and load bank services while embracing future fuels like gas, biofuels, and hydrogen.

Managing Director Jack Preece

Woodlands Power also focuses on utilising advanced technologies such as alternative fuels, hybrid systems, and battery energy storage solutions to address the growing demand for sustainable and efficient energy.

Simultaneously, the company remains committed to providing exceptional service and delivering dependable solutions that meet its customers’ unique requirements. These advancements reflect a commitment to providing engineered solutions that combine proven reliability with cutting-edge sustainability.

“Within our industry, there is a significant push to decarbonise and move towards net zero,” notes Jack.

“Our customers rely on us to deliver robust solutions that exceed sustainability standards.

Transparency is at the heart of what we do – ensuring every solution is fit for purpose while engineering alternatives that balance hybrid technologies to meet specific requirements.”

Woodlands Power’s commitment to providing cutting-edge solutions is exemplified through its role as the primary UK partner for HIMOINSA’s newly launched HGY Series generators.

Developed by HIMOINSA, part of the YANMAR Group, the HGY Series is a high-performance power solution designed specifically for missioncritical applications. It integrates advanced power generation, storage, and control technologies to ensure superior reliability and efficiency, even in the most demanding environments.

Jack states, “Through this partnership, we can better assist industries such as data centres, healthcare, and manufacturing, delivering tailored technology that ensures success in

even the most challenging conditions.”

With capacities ranging from 1250kVA to 3500kVA, the HGY Series reinforces Woodlands’ dedication to providing a range of dependable solutions. The design of these generators excels in protecting IT infrastructure, maintaining hospital continuity, and maximising industrial performance.

Built to perform in harsh and high-demand environments, the HGY Series also incorporates noise-reduction features, aligning with Woodlands’ focus on operational efficiency and customer satisfaction.

By partnering with HIMOINSA on this next-generation power solution, Woodlands Power continues to lead the way in delivering innovative, high-performance energy solutions for industries that demand nothing but the best.

Woodlands Power combines industry-leading capabilities with an unwavering commitment to delivering resilient, high-performance energy solutions across key industries.With a proven track record, the company continues to provide tailored power solutions across a variety of key industries, ensuring reliability and efficiency where it matters most.

In healthcare, Woodlands has a 20-year partnership with the NHS, recently delivering a 1260kVA containerised generator and fuel management system to ensure uninterrupted power while meeting stringent standards.

Similarly, in data centres, Woodlands has recently deployed several multi-megawatt load banks for real-world load testing at Tier 3 facilities, strengthening backup power systems and ensuring operational continuity.

For more details on these and other projects, visit: woodlandspower.com/case-studies

On your path to net zero

INNIO Group’s flexible, scalable, and resilient Jenbacher CHP and CCHP energy systems deliver power, heat and/or cooling for your local site while supporting your decarbonization efforts. Yielding up to 95 % total efficiency, cogeneration can reduce your energy consumption and CO2 emissions by more than 30 % compared to the separate generation of power and heat, significantly lowering your energy costs. Combined with heat storage, you can operate your asset flexibly. Jenbacher CHP and CCHP systems run on a wide range of gases with the option of converting to H2* operation once hydrogen is more readily available.

Let us support your transition journey. jenbacher.com

* In general, “Ready for H2” Jenbacher units can be converted to operate on up to 100% hydrogen in the future. Details on the cost and timeline for a future conversion may vary and need to be clarified individually.

Jenbacher is part of the INNIO Group

The UFR1001E system-disconnection relay monitors voltage and frequency in single or three-phase networks.

Presetting per G99/98, values as per the standard pre programmed

• Under and overvoltage monitoring 40…520 V

• Under and over frequency monitoring 45…65 Hz

• Monitoring of Rate of Change of Frequency (ROCOF, df/dt) Monitoring the voltage quality (10 minute average value)

• Response time adjustable 0.05 … 130.0 s, individual setting for each limit

• Fail-safe, with monitoring of the connected section switch (can be switched off) 2 automatic restarts on error

• Supports the mains synchronisation when using generators

• Measurement 3 phase 3 or 4 wire systems or single phase Self-test

• Third Part Independently tested Compliant to G99/98 by Bureau Veritas

As you would expect, Liebherr’s ammonia engine concept relies on ammonia as a power source for dual-fuel internal combustion engines.

The results -says the company - ‘clear the path for further development of the solution’.

Green ammonia serves as a hydrogen carrier, offering the benefits of reduced transportation and storage costs.

Generators and potential off-road powertrains fuelled by green ammonia could provide low- or zero-emission solutions for supplementing onsite power supplies. This engine will offer a high efficiency density power in line with the requirements of the mining industry, for example.

The engine produces zero CO2 emissions and has lower emissions than gas-powered engines. The ammonia engine is a significant step towards achieving the goal of reducing carbon emissions and promoting sustainable transportation.

Liquid ammonia is a clean-burning fuel which produces almost no carbon emissions when burned. This makes it an attractive alternative to gasoline and diesel, which are major contributors to air pollution and climate change.

A combustion engine works by mixing liquid ammonia with air, which creates a clean-burning fuel that powers the engine. The ammonia is stored in a specially designed tank that is kept at a low temperature to prevent it from evaporating.

Liebherr also equips its combustion engines with a catalytic converter which reduces nitrogen oxide emissions, which are a major contributor to air pollution.

Dual-fuel internal combustion engines combined with ammonia

D9612 with 12 cylinders in-V arrangement

Another innovation shown at Bauma is the D9612 with 12 cylinders in-V arrangement and a displacement of 27 L can deliver a maximum power output of 950 kW (1,274 hp).

Key to the engine is an integrated centrifugal water pump and closed crankcase ventilation system, ultrafine fibre oil filter, fuel fine filter on engine.

This includes a twin scroll turbocharger which can provide - Liebherr says - considerably improved fuel consumption.

The engine is best suited for demanding off-road applications, including rugged applications in

agriculture, industry and construction which demand equipment which can survive rugged environmental conditions.

The D9612 delivers a maximum power output of 950 kW and combines robust performance with high efficiency.

A spokesman comments: “The engine is designed to operate reliably under challenging conditions and offers notable improvements not only in fuel consumption, but also in the reduction of emissions.”

www.liebherr.com

Since 2014, Bitburger Braugruppe has a CHP plant with two MWM gas generator sets at its headquarters in the Eifel region in Germany. This year, following more than 60,000 hours of operation, the two MWM TCG 2020 V20 generator sets will be replaced with new-generation TCG 3020 V20 engines.

Bitburger Braugruppe is a family business. Now run by its seventh generation of owners, it employs roughly 1,600 staff. It owns the Bitburger, König Pilsener, Köstritzer, Licher, Königsbacher, and Nette brands.

The brewery group, based in the Eifel region, is one of the world’s 40 largest brewery groups. When it comes to energy supply, this company relies on MWM gas gensets.

The first generator set was replaced in spring 2024, and the second will follow in Q4. In order not to disturb operations - especially during the summer months which see higher beer sales - the brewery group decided to replace the two generator sets at different times.

“We planned about five weeks for each engine replacement”, explains Bastian Hargarten.

As Head of Technical Infrastructure and Maintenance, Hargarten is responsible for the smooth replacement of the gas generator sets. “To meet this tight schedule, the mechanical work is carried out in two shifts,” he reports.

Additionally, in order to meet current and future emissions requirements, the new MWM generator sets have been installed with customised SCR catalytic converter pre-fitting solutions.

“The new generation of engines from MWM has long service intervals of up to 80,000 operating hours. They can also be retrofitted for operation with natural gas with a hydrogen admixture of up to 25 vol% or for mixed operation with biogas. This puts us in a good and flexible position for the future,”, explains Hargarten, highlighting the significance of the decision to replace the generator sets.

Current MWM gas generator sets can already run on natural gas with a hydrogen admixture of up to 10 vol%. In case Bitburger Braugruppe decides to retrofit its plant for a higher hydrogen admixture in the future, it can make use of the MWM 25H2 retrofit kit which enables operation with a hydrogen admixture of up to 25 vol%.

With this retrofit kit, MWM supports its customers in converting existing plants for operation with natural gas with higher hydrogen admixtures, thereby contributing to lower emissions.

Using heat efficiently

None of the cogeneration power plants of the brewery group, including the one in Bitburg, is equipped with an emergency cooler to protect the engine from overheating.

Instead, two heat storage tanks, each with a capacity of 200 m3, buffer the generated heat.

This ensures continuous efficient operation of the cogeneration power plant.

The plant also features a two-pass heat recovery steam boiler and two waste heat exchangers to provide a total thermal output of approximately 4 MW.

The generated heat is used for the provision of steam and hot water. For

this purpose, the various beer production processes were adapted to an inlet temperature of 98°C in 2014. The cogeneration power plant supplies about 18 consumption points.

“We work with a heat deficit in the hot water supply”, explains Hargarten.

“During production, we often need to provide additional heat in the form of steam.” For this reason, two new high-temperature heat pumps will be installed alongside the new gas generator sets in 2025.”

The two new TCG 3020 V20 gensets, with an electrical output of 2,000 kW and a thermal output of 2,066 kW, have an electrical efficiency of 43.2% and a thermal efficiency of 44.6%, giving an overall efficiency of 87.8%.

www.mwm.net

The XCursor 13 is FPT Industrial’s first multi-fuel single base engine designed to run on diesel, methane and, in the future, hydrogen. It is compatible with a wide range of market requirements and easily adaptable for different vehicle installations.

The XCursor 13 is a primary contributor to achieving CO2 emissions targets, and is one of the most relevant parts of the group’s decarbonisation program.

New air handling for down speeding and fast transient response along with improved combustion efficiency, with increased Common Rail and peak cylinder pressures.

State-of-the art technologies are incorporated such as new smart oil and water pump, advanced combustion control, thermal management, and friction reduction thanks to new connecting rod pins and crankpin materials.

The XCursor 13 offers a wide range of ratings for different applications, from 460 hp/2,300 Nm to 600 hp/2,850 Nm with long service intervals: oil change intervals of up to 150,000 km, and DPF change intervals of up to 600,000 km.

Sylvain Blaise, President of Iveco Group’s Powertrain Business Unit, presided over a special celebration recently at the Bourbon-Lancy plant in France with all the employees presenting a plaque recognizing the success of the FPT Industrial XCursor 13 engine.

This multi-fuel engine recently earned a prestigious Alternative Engine Award. This honour - reports the company - highlights the crucial role of internal combustion engines in the decarbonisation journey.

“

THE XCURSOR 13 IS A PRIMARY CONTRIBUTOR TO ACHIEVING CO2 EMISSIONS TARGETS, AND IS ONE OF THE MOST RELEVANT PARTS OF THE FPT GROUP’S DECARBONISATION PROGRAM.

THERE IS NEW AIR HANDLING FOR DOWN SPEEDING AND FAST TRANSIENT RESPONSE.

STATE-OF-THE ART TECHNOLOGIES ARE INCORPORATED SUCH AS NEW SMART OIL AND WATER PUMP, ADVANCED COMBUSTION CONTROL, THERMAL MANAGEMENT & FRICTION REDUCTION.”

to the Bourbon-Lancy team, emphasizing that this achievement would not have been possible without the dedication and hard work of every FPT Industrial employee.

What else is special about the engine?

The XCURSOR 13 features a new electric turbo control (eWG) and new EGR system. This is designed to offer increased engine efficiency and reduced exhaust temperature, thanks to the state-of-the-art technologies involved, reports the mnufacturer.

The engine offers high reliability thanks to Nickel-Resist cast-iron exhaust manifold, water cooled eWG, and Compacted Graphite Iron (CGI) cylinder head.

The new XCURSOR 13 NG offers two ratings for different applications

– 500 hp/2,200 Nm and 520 hp/2,500 Nm, with extended oil change intervals of up to 100,000 km. It offers best-in-class in performance, power output of up to 520 hp and torque of up to 2,500 Nm.

Best-in-class features

FPT Industrial further reports it provides best-in-class in braking power too - up to 260 kW - thanks to the new valvetrain system.

The engine’s turbocharger is a e-VGT (Electronic Variable Geometry Turbo) 2stT (Twin-Stage Turbo) and a WG (Fixed Geometry Turbocharger with Waste Gate valve). In addition there is an EVGT BB (Electronic Variable Geometry Turbo Ball Bearing) & eWG electronic (Fixed Geometry Turbocharger with Waste Gate valve).

www.fptindustrial.com

South Africa’s generator set company NEW WAY has provided four 750kVA diesel gensets for a large shopping mall based in Eastern Cape, South Africa. These gensets all feature advanced Baudouin engines and Leroy Somer alternators.

A NEW WAY company spokesman commented on the 3MVA package provided: “Our team was commissioned by a renowned renewable energy specialist to design and supply 4x 750 KVA Sync to loadshare generator sets for this hybrid power solution at second largest shopping mall centre in the picturesque Eastern Cape province.

“A special mandate was issued against noise pollution due to surrounding residential area. Our design and production team got this build down to a sound level of 64dBA at 7m.

“The package features durable, robust, built-to-last Baudouin 6M33G2D0-S engines, Leroy-Somer alternators and DSE8610MKII controllers packaged into our super silent container design. This was an incredible project and we are ‘super stoked’ to have been part of this journey.”

Baudouin 6M33G2D0-S engines

PowerKit engines like these are a popular choice at the centre of continuous (COP) applications. Installations without connection to an electrical grid rely on power generation equipment to supply reliable and stable primary electrical energy. PowerKit engines are used to power equipment providing constant base load power for installations such as remote mining sites, large retail centres, sensitive industrial processes and rural

“

OUR TEAM WAS COMMISSIONED BY A RENOWNED RENEWABLE ENERGY SPECIALIST TO DESIGN AND SUPPLY 4X 750 KVA SYNC TO LOADSHARE GENERATOR SETS FOR THIS HYBRID POWER SOLUTION AT SECOND LARGEST SHOPPING MALL CENTRE IN THE PICTURESQUE EASTERN CAPE PROVINCE. SPECIAL MANDATE WAS ISSUED AGAINST NOISE POLLUTION DUE TO SURROUNDING RESIDENTIAL AREA. OUR DESIGN AND PRODUCTION TEAM GOT THIS BUILD DOWN TO A SOUND LEVEL OF 64DBA.”

through excellent fuel consumption, proven durability and long service intervals, economic dependability is ‘why customers choose Baudouin PowerKit engines for COP applications’, says the company.

The DSE8610MKII controller fitted to the gensets represents the latest in complex load sharing and synchronising control technology. Designed to handle the most complex grid type generator applications the DSE8610 MKII control module is packed with multiple features and benefits which are ‘unrivalled across the generator control industry’, reports the manufacturer.

Key load-sharing features of the DSE8610 MKII include:

• Peak lopping/sharing (with appropriate DSE mains controller)

• Sequential set start

• Manual voltage/frequency adjustment

• R.O.C.O.F. and vector shift protection

• Generator load demand

• Automatic hours run balancing

• Mains (Utility) decoupling

• Mains (Utility) decoupling test mode

• Dead bus sensing

• Bus failure detection

• Direct governor and AVR control

• Volts and frequency matching

• kW and kvar load sharing

• Dead bus synchronising New Way is one of Africa’s largest suppliers of bespoke prime & standby power solutions and is a wholly-owned subsidiary of the JSE-listed enX Group.

A spokesman comments: “We forge lifelong relationships with our clients to satisfy their power requirements, supported by a highly skilled support team and a range of strategic partners including Moteurs Baudouin, John Deere and Mitsubishi. “New Way is committed to technological innovation in providing total energy solutions from one of the largest dedicated assembly facilities in Africa.”

He concludes: “New Way is a proud member of the JSE-listed enX Group Limited, being a wholly-owned subsidiary. We tackle challenges head-on through technological innovation and development.”

www.newway.co.za baudouin.com

www.deepseaelectronics.com

In 2024 Lucy Electric provided a 500kVA package substation with a National Grid RMU, Lucy Sabre VRN2a TLF unit to NGED Specification and Lucy AcuLok LV cabinet with an 800A ACB.

With the RMU to DNO spec and Transformer/LV to IDNO specs for the company InstaVolt, renowned as the largest and most reliable EV charging network in the UK, setting the industry standard for rapid charging solutions.

With a reputation built on excellence and reliability, InstaVolt’s commitment to providing top tier charging experiences means any new site must meet exacting standards. In last year’s project Lucy Electric and Lucy Zodion worked together to meticulously integrate essential service elements into its end-to-end solution for InstaVolt.

An innovative back-to-back main supply pillar was designed to minimise the footprint and optimise space, ensuring the site could accommodate the required 6 x 160kW chargers.

The pillar incorporates earth leakage protection, residual current protection, provisions for metering, surge protection, anti-condensation heaters, and service lights for enhanced safety and user experience. Finished off in black paint, to seamlessly integrate with the rest of the site visually.

Alongside this a comprehensive package substation solution was designed, tailored to seamlessly integrate medium and low-voltage power distribution while ensuring efficiency and compliance with industry standards.

The centrepiece of this solution is a 500kVA package substation featuring a National Grid Ring Main Unit (RMU), meticulously engineered to DNO specifications, enhancing connectivity to the grid.

The integration of Lucy Sabre VRN2a TLF unit further ensures adherence to NGED specifications, guaranteeing reliable performance and interoperability. Complementing this, the inclusion of a Lucy AcuLok LV cabinet equipped with an 800A ACB aligns with IDNO standards, providing flexibility and choice in transformer-mounted LV equipment.

Beyond the technical specifications, both Lucy Electric and Lucy Zodion were proud to provide a holistic approach, providing end-to-end solutions from initial specification to delivery on-site.

This includes the flexibility to accommodate various transformer manufacturers and third-party equipment requests, which underscores a commitment to meet diverse requirements while maintaining compliance with all DNO, IDNO, and general industrial specifications, reports the company.

By harnessing cutting-edge technology and expertise, InstaVolt continues to set the benchmark for user-friendly, reliable, and sustainable charging solutions.

With installations at Cliff Court and Camphill Village Trust – Taurus Crafts, communities across the UK will benefit from convenient access to rapid charging facilities, driving the widespread adoption of electric vehicles and contributing to a greener, more sustainable future.

Tim Douglas, Head of Delivery at InstaVolt commented: “We are thrilled to collaborate with Lucy Electric and Lucy Zodion to advance EV charging infrastructure in the UK.

“Our partnership signifies a shared commitment to driving the electric mobility revolution forward, making EV charging an integral part of everyday life for communities

across the country.”

He explains: “Lucy Electric’s expertise in crafting specialised charging solutions perfectly complements InstaVolt’s dedication to delivering top-tier charging experiences.

“Together with Lucy Zodion, we are pioneering innovative solutions that not only meet but exceed the evolving needs of EV drivers and site owners.

“Our collaboration ensures that our charging units are not only future-proofed but also optimised for future scalability, to allow us to continue to meet increasing demand for fast charging.

“ Just as reliability is paramount in our commitment to delivering 24/7 service, the robust solutions provided by Lucy Electric and Lucy Zodion help us to guarantee dependable performance and user satisfaction.

He concludes: “Through our collective efforts, we are driving towards a greener, more sustainable future, where electric vehicles play a central role in reducing emissions and shaping a cleaner, brighter tomorrow.”

www.lucyelectric.com

LUCY ELECTRIC’S EXPERTISE IN CRAFTING SPECIALISED CHARGING SOLUTIONS PERFECTLY COMPLEMENTS

INSTAVOLT’S DEDICATION TO DELIVERING TOP-TIER CHARGING EXPERIENCES. WE ARE PIONEERING INNOVATIVE SOLUTIONS.”

installation at Camphill Village Trust

With a deep understanding of the unique pressures faced by end users, Cabel goes beyond standard repair, rewind, servicing and maintenance of industrial alternators. No matter the application, we enhance and optimise performance to ensure the reliability of the key components of critical power generation.

Cummins Inc. has supplied 18 x Cummins QSK95 gensets with a 60 Hz standby rating of 3750 kVA.

With soaring traffic on its platform, Naver embarked on the project to construct one of Asia’s largest data centres which will be developed over six phases using a substantial volume of generator sets.

The first phase of the Gak Sejong data centre features 18 Cummins QSK95 gensets with a 60 Hz standby rating of 3750 kVA. At the heart of the genset is Cummins’ most powerful diesel engine, a 95-litre V16 noted for its power density, fuel efficiency and low emissions capability.

In addition to the gensets, Cummins has also supplied the DMC8000 digital master control system for the gensets, designed to provide best-in-class resiliency and system uptime in any potentially disruptive scenario.

Located on a 294,000-square-metre site, the Gak Sejong data centre is all about Naver’s big push to secure its supremacy position in fast-growing artificial intelligence.

Launched as an online platform in 1999, Naver was the first South Korean web portal to develop its own search engine. Today, it has 48 million daily users using the mobile web and PC search engine.

“

GAK SEJONG REPRESENTS NAVER’S SECOND DATA CENTRE, FULLY COMPLEMENTING THE TECH GIANT’S EXISTING FACILITY IN CHUNCHEON, WHICH HAS BEEN OPERATIONAL SINCE 2013. THIS ALSO FEATURES CUMMINS GENSETS – A TOTAL OF EIGHT 2500 KVA UNITS WHICH ARE POWERED BY CUMMINS’ QSK60 ENGINE PROVIDING BACKUP POWER FOR THE FACILITY.”

When all six phases of the Gak Sejong data centre have been built it will be fully capable of hosting more than 600,000 servers.

Data storage capacity will be 65 exabytes, or 65 billion gigabytes – more than one million times the capacity of the National Library of South Korea.

“The collaboration between the Cummins teams – sales, engineering, supply chain and service – has been crucial to the success of the Gak Sejong project,” said Homyun Choi, who has headed up the project for Cummins South Korea.

“Brad You, who worked on the logistics side, faced the daunting task of getting the 30-tonne QSK95 gensets from the US to Korea, but he succeeded in keeping the project on schedule.

“Above all, our partnership with Naver highlights Cummins’ commitment to providing best-inindustry customer support and also the ability to meet the stringent demands of prestigious data centre projects.”

Gak Sejong represents Naver’s second data centre, fully complementing the tech giant’s existing facility in Chuncheon, which has been operational since 2013 and which features Cummins gensets – eight 2500 kVA units powered by Cummins’ QSK60 engine – for backup power. At the opening of Gak Sejong, Naver CEO Choi Soo-yeon said:

“Hyperscale data centres recently have gained recognition as the core infrastructure for technological innovation, but Naver has been preparing for hyperscale data centres since the opening of Gak Chuncheon 10 years ago.

“The hyperscale data centre Gak Sejong will become an engine for technological innovation not only for Naver but also for all industries.”

Sustainability is a focus for Gak Sejong. The centre employs a selfdeveloped air conditioning system which cools server rooms using natural wind and optimises energy efficiency by reusing waste heat for central heating, snow and ice melting systems on facility roads and floor heating.

Naver is aiming for platinum certification under LEED V4 Platinum (Leadership in Energy and Environmental Design) which is the most widely used green building rating in the world. Platinum is the highest possible rating. To maximize operational efficiency in the vast facility, Naver has implemented various technologies, including AI, robotics and driverless shuttle buses.

A robotic automation system manages server assets, with robots monitoring and controlling the flow of assets in real time within the data centre.

www.cummins.com

2-3 April 2025

SOLAR & STORAGE LIVE ExCel London, UK

2-4 April

DATA CENTRE & STORAGE EXPO TOKYO Tokyo, Japan

3 April 2025

76th POWER LUNCHEON IPowerE Chelsea Harbour Hotel, London, UK

7-9 April 2025

MIDDLE EAST ENERGY 2025 Dubai, UAE

7-13 April 2025

BAUMA Germany

14 April 2025

BUDAPEST LNG SUMMIT Hotel Marriott, Budapest, Hungary

9-10 April 2025

LATIN AMERICA ENERGY SUMMIT Santiago, Chile, South America

14-17 April 2025

DATA CENTER WORLD 2025 USA Washington, DC, USA

6 –7 May, 2025, ELECTRICAL ENERGY STORAGE ees Europe Conference, ICM München Germany

6-9 May 2025

INTERSOLAR EUROPE Munich, Germany

7-9 May 2025

EMP- Power Europe 2025 - incorporating:

The European Power Distribution Systems Summit

The European Power Generation Strategy Summit Messe München, Germany

14-15 May 2025

ALL ENERGY Glasgow, UK

14-15 May 2025

MIX E (Europe’s Energy Transition) Lyon, France

20-21 May 2025

UTILITY WEEK LIVE

Flexible Energy/Sustainable Infrastructure Show

NEC Brimingham, UK

3-4 June 2025

Lisbon Energy Summit & Exhibition Lisbon, Portugal

3-4 June 2025

POWER SUMMIT 2025EURELECTRIC

Maison de la Poste, Brussels Belgium

3-5 June 2025

THE BATTERY SHOW EUROPE Stuttgart Germany

11-13 June 2025

G-POWER 2025

Shanghai New International Expo Center China

17-20 June 2025

AFRICA ENERGY FORUM

Cape Town, South Africa

2 July 2025

PowerEx Live Golf Day [sponsored by UKGSA] – Brabazon Course

The Belfry Hotel & Resort

Royal Sutton Coldfield, North Warwickshire, B76 9PR

3 July 2025

PowerEx Live Midlands 2025 Conference Event

The Belfry Hotel & Resort

Royal Sutton Coldfield, North Warwickshire, B76 9PR

9-12 September 2025

GASTECH EXHIBITION & CONFERENCE

Featuring: Energy, ClimateTech, Hydrogen Milan, Italy

19 - 20 Nov 2025

EMEX - The Net Zero & Energy Management Expo

ExCeL London, UK

11th Dec 2025

PowerEx Live London 2025 Conference & Exhibition Park Plaza London SE1 7UT, U

After a decade of engineering innovation, our next generation engine platform for industrial operations is here, ready for the challenges of today and tomorrow. More efficient, more powerful and more durable – all powered by cutting-edge technology. Scania has raised the bar.

Our new platform unlocks increased value from every drop. An up-to seven percent improvement in fuel consumption combined with an extended engine lifespan means you get more for longer. And reduced CO2 emissions across the range means you also get ready for sustainability regulation.

Step into the future of power solutions.

Richard Teasdale, President I CEO of the Association, explains: “MEGSA - MIDDLE EAST GEN-SET ASSOCIATION has gone from strength-to- strength with 50 + companies taking advantage of the new membership joining options, including Bahmani, Jubaili, Technopower, Staunch Machinery plus many other OEMs.

“Research shows that the Middle East Gen-set (Generator) market is expected to register substantial growth (3.7% CAGR) owing to the rising population and inadequate generation of power supply between 20222030.

“We continuously keep members abreast of the latest industry news within the Middle East sector. MEGSA has a real voice thanks to the Association’s links with various media & marketing entities. Accordingly, it can offer real & profitable Networking Opportunities. Make sure that you take advantage of the many benefits MEGSA has to offer.”

All enquiries - take up membership by visiting: www.megsa.org

* 1,250 KVA DIESEL GENSET FOR A WATER PUMPING STATION IN HATTA, UNITED ARAB EMIRATES

JUBAILI BROS of Dubai have supplied a 1,250kVA diesel genset. A company spokesman comments: “Maintaining a continuous water supply relies on consistent power, which is why infrastructure operators in Hatta choose us as trusted partners to provide electrical power. Jubaili Bros offer dependable power solutions and has a long history of supporting critical infrastructure operations, including water supply operations.

“Our recent deployment of a 1250 KVA power unit to a water pumping station in Hatta adds to our track record. We are proud to provide homes and businesses in the region with the peace of mind that comes from an uninterrupted water supply.”

Jubaili Bros is experienced in the design, supply, building, operation and maintenance of complete power generation plants, using generators with a prime unit range up to 5300 KVA for Diesel Powered and 1500 KVA for gas powered version. Jubaili engineers can synchronize up to 32 generators with different sizes for one power generation plant. The plant components (generators, synchronization controllers, and totalizing panels) are completely assembled by Jubalili bros under one roof, says the company.

A spokesman commented: “Our solutions for power generation plants, include both LV and MV systems, with different methods, by using step up transformers or using special –custom made- MV alternators.”

* 1,000 KVA ADDITIONAL BACKUP DIESEL GENERATOR FOR A BITUMEN FACTORY IN KARBALA, IRAQ

GMC (Ghaddar Machinery Co) has supplied a 1,000 kVA diesel generator with Cummins engine and Nidec alternator to a bitumen factory based in Karbala, Iraq.

This new deal has meant that Ghaddar Machinery’s Iraq Branch has effectively expanded the power station of the Bitumen factory in Karbala province.

Based on the excellent performance over the past two years of the two Ghaddar Generators 1000 KVA each powered by Cummins Engine KTA38-G5 and Leroy Somer Alternator TAL049E, an expansion of the power station was requested, and an additional unit was added to bring the total capacity of the station to 3000 KVA. The 3 Generators are operating in synchronization to power the factory.

The latest KTA range from GMC is a jacket water aftercooled design. Its inbuilt step timing control system ensures optimum engine timing at all combinations of load and ambient temperature, improving cold starting and reducing light load fuel consumption to greatly enhance engine efficiency, the company tells MEGSA..

* ABU DHABI GOVERNMENT HOSPITAL DEPLOYS GENSETS WITH EUROPEAN-MADE CONTROLLERS

Two 1100KVA Bahmani NGT1100 diesel gensets specially designed for standby applications were supplied by the Bahmani Group to one of the key government hospitals in Abu Dhabi. These sets have been providing vital backup power for the facility in case of a mains power failure in the local grid without any problems since their installation in 2023.

Producing reliable power at 1100 kVA, 50 Hz, each NGT 1100 GC diesel generator set is built to meet ISO 8528-5 transient response requirements and to accept 100% rated load in one step; this generator set type also offers a low fuel consumption system and accepts 100% Block Load and a demonstrated capability to pick up large onsite loads.

Each NGT Gen set is equipped with a DSE controller (DSE7320), made in the UK by one of the world’s top manufacturers. An advanced and user-friendly controller, it helps to maintain each set’s low fuel consumption, saving on fuel spend. Its compact and rugged design also saves on transport and storage costs.

The DSE7320 unit is described as a ‘feature packed Auto Mains (Utility) Failure Control Module’.

PowerEx Live Midlands 2025, will be held on Thursday, July 3rd, 2025. It aims to probe and discuss all the trends, opportunities and challenges for the GENSET, CHP & ENERGY industries.

Before this important day the UKGSA is backing an associated Golf Tournament which will be held the day before the PowerEx Live (July 2nd, 2025).

This special Golf Day on Wednesday, July 2nd, 2025, is known as the official PowerEx Live 2025 Golf Tournament and is being held at the Belfry Hotel & Resort at Royal Sutton Coldfield, West Midlands, UK. With 3 award-winning courses, decades of experience hosting golf tournaments and home to 4 Ryder Cupsmore than any other venue in the world.

The famous Belfry Brabazon Ryder Cup Course is a must play course for anyone who loves the game, so join us on Wednesday 2nd July 2025 for an unforgettable day.

Here’s what’s happening: 72 Player Shotgun start with the ENTIRE COURSE booked OUT. To confirm a ‘TEAM or Teams of 4, 3, 2 or even yourself for all places ‘BOOK EARLY’. On finishing all participant will come to the New and fabulous wooden veranda halfway area for “Cold beer buckets & drinks”, meeting & networking with others overlooking the famous Par 4 10th hole (there are 8 TEAMS already confirmed).

Why not come and challenge your industry peers?

Enjoy our ‘Very Reduced Green Fees’

Cost: £189.00pp Freshly-ground Coffee or Tea on arrival with Bacon Rolls served on a Brioche bun before playing with full sit down 3-course meal after golf in the Sutton Suite with presentation next to the famous Ryder Cup winning patio.

Accommodation: £169.00 per night +VAT (Single Occupancy rate). We only have 70 rooms booked with £100 approx. discount off the venue’s current prices.

These MUST be booked through ‘Power Media International Group’ to get these special reduced rates at only £169.00 per night +VAT.

What’s on offer on Wednesday July 2nd, 2025?

*Networking opportunities with many PowerEx Live companies and delegates.

*The evening will include a 3-course dinner with prize presentation.

* 72 players, Shotgun start and great price again at only £189.00pp x team of 4 = £756.00 (this is an Ideal opportunity to invite work colleagues, friends or

potential customers to what is definitely one of the most memorable days of the year.

* Over 63 players with 16+ teams have booked so far plus “CHAINERGY” Unlocking Sustainable RENEWABLE GENERATION for HPC

- already for ‘PowerEx Live Midlands Golf Day’ on 2nd July | “Brabazon Golf Course” @ The Belfry.

Cost: Only £189pp, including a 3course Evening Dinner with celebrity sporting guest presiding.

* At this same venue on next day3rd July - we are holding the PowerEx Live Midlands 2025 Event.

* 18+ Speakers have been confirmed and 28+ Companies will be there.

To reserve table and/or take on sponsorship please visit https://lnkd.in/d8nApVtU https://lnkd.in/ewP7Fhui or send email to power@wipmagazines.com

Both events are being sponsored by UK Gen-Set & CHP Association with the Data Centre Alliance.

* The Golf Tournament will take place on the 4 time Ryder Cup Brabazon Course at The BELFRY.

*Please reserve/confirm or provisionally book your golf team(s) of 4,3,2 persons - or even just

yourself. We hope there will be Play & an Afterdinner talk from BILLY FOSTER (he is a famous caddie to Garcia, Ballesteros, Bjorn, Darren Clarke, Westwood and - currentlyMatt Fitzpatrick).

ALSO this is your chance to beat the Ex Pro-Footballer/Celebrity playing - with Q&A session after dinner. Other competitons include:

- ‘Free Sponsored ball shot on famous 10th par 4 over water –Prizes for ‘hitting the green’.

- Nearest the Pins on All Par 3’s | 2 x Longest Drives | 2 x Nearest the Pin in two.

Making your booking: Don’t forget - the final deadline for booking: 26 April 2025.

The event will benefit 2 CHARITIES for the day : The Injured Jockeys Fund + (TBA).

We expect to be sold out on this event so BOOK EARLY and don’t miss your chance. This event is perfect opportunity to bring your partner or a guest along.

Please refer enquiries/bookings to :

richard@wipmagazines.com Tel. 0113 322 0007

WHAT DOES THIS ORGANISATION REPRESENT?

In 2024 EUROPGEN joined Orgalim as a new associate member. This membership is a significant step forward for us and brings numerous benefits, says the Association. These include:

-Leveraging Orgalim’s extensive network and connections with policy makers and stakeholders to ensure our voice is heard more prominently at the EU level.

-Working alongside other industries and associations on cross-cutting and common issues to protect and advance European industry as a whole.

-Strengthening our core mission of promoting the interests of the European generating set industry.

A spokesman comments: “We look forward to the opportunities this membership will bring and to actively contributing to and benefiting from Orgalim’s initiatives.”

Orgalim represents Europe’s technology industries, comprised of 770,000 innovative companies spanning the mechanical engineering, electrical engineering, electronics, ICT and metal technology branches. Together they represent the EU’s largest manufacturing sector.

Europe’s technology industries need a properly functioning European Standardisation System to be competitive.

Two years ago Orgalim joined key stakeholders from industry, national authorities, standardisation organisations and civil society on the High-Level Forum on European Standardisation (HLF). The HLF’s work includes identifying standardisation priorities in support of EU policies and legislation and discussing issues such as international leadership, education and skills.

As part of the HLF activities, Orgalim curated the drafting of a report on alignment between European and international standardisation, which HLF representatives validated. In Orgalim’s view, alignment between European and international standards is urgently needed to protect the competitiveness of our industries.

Among the recommendations included in the report, the HLF proposed

establishing a research project to develop a systematic data collection framework and a shared methodology to monitor alignment and decoupling of European and international standards, which currently don’t exist.

The group also highlights the importance of adjusting the harmonisation process to strike a balance between legalistic procedures and efficiency.

This will help achieve better alignment during standardisation development, avoid unnecessary deviations and ensure products comply with the essential requirements set out in the legislation.

Mette Peetz-Schou, HLF Sherpa Coordinator for Orgalim, Chair of the Orgalim Standardisation TF and Leading Senior Advisor, Danish Industry, comments: “Our industries need an aligned, coherent standardisation system to be competitive.”

He explains: “Fixing the European Standardisation System will help businesses by reducing compliance costs, enhancing market access, removing trade barriers and enabling them to benefit from economies of scale as products can be sold globally,”

The EU has been a leader in setting international standards for over 30 years.

This has helped its competitiveness and technological leadership. However, the rise of other regions in the international standardisation community has affected EU’s ability to lead in certain areas, causing divergences in standards for the EU market and damaging the competitiveness of our industries.

Now that the HLF’s report has been validated, Orgalim says it looks forward to its recommendations being implemented, starting with the development of a systematic data collection framework.

Jender operates to unlock the potential of diesel generator manufacturers in Turkey in global markets, strengthen the perception of the Turkish brand, and position these manufacturers as more effective players.

The generator manufacturers in Turkey boast a vast production network with over 20 main producers, more than 100 local manufacturers, and over 100 local businesses.

Supported by more than 1,000 suppliers providing key components and equipment, these manufacturers have established a significant presence in the global market by exporting to 145 countries. With a market share of US$800 million, Turkish generator manufacturers hold 5.7% of the global market and account for 24% of Turkey’s total exports.

Jender’s strategies focus on closely monitoring the generator market to provide operational ease to manufacturers, analysing market opportunities and global competition. It also keeps track of market and production standards, developing and implementing marketing strategies to meet Turkey’s export goals, delivering Turkey’s production power to target markets with the right messages, and making Turkish-standard production globally accepted.

The Electrical Generating Systems Association (EGSA) is the world’s largest organisation exclusively dedicated to On-Site Power Generation.

The Association is comprised of 500 companies - Manufacturers, Distributor/Dealers, Contractors/Integrators, Manufacturer’s Representatives, Consulting & Specifying Engineers, Service firms, End-Users and others - throughout the U.S. and around the world that make, sell, distribute and use On-Site Power generation technology and equipment, including generators, engines, switchgear, controls, voltage regulators, governors and much more.

SPRING CONFERENCE on 6-8 April, 2025, at Sheraton Le Meridien, Carlotte, North Carolina, USA.

A spokesman comments: “For Spring 2025, we are excited to welcome industry leaders and experts from related fields to share their best practices, insights, and stories of both failures and triumphs. Join us for an inspiring and educational experience as these titans of the industry provide valuable advice and knowledge to help you succeed.”

Attending the EGSA Spring 2025 Conference is a ‘valuable opportunity for anyone in the electric power generation industry’, says the Association.

Cummins Inc.’s Power Generation business has developed new Battery Energy Storage Systems (BESS) solutions to their global product line.

Fully integrated BESS containers for AC output, the development of this product represents a significant push towards helping customers reach their sustainability goals.

“The global shift for renewable energy sources is becoming more profound,” said Lucio Kroll, Senior Director New Energy Solutions of Cummins Power Generation. “We’re proud to expand our offerings to include BESS, staying in line with that shift and serving our customers with safe and reliable solutions that can help them meet their energy transition goals.”

Cummins Power Generation BESS solutions are available in two architectural designs: a 10ft container (200 to 400kWh) and a 20ft high cube container (600kWh to 2MWh).

Product features include proven lithium ferrophosphate (LFP) batteries for high cycle life, optimal liquid cooling thermal management designed to maximise battery life and reliability, complemented by a comprehensive three-tier fire safety approach.

Additionally, the products are completely selfcontained with plug-and-play functionality, making transportation and installation efficient and seamless.

This solution will respond to the power needs of industrial, commercial and mission critical markets operating in the 50Hz frequency range.

The three main use cases are off-grid (remote communities, mining sites, and remote industrial uses), energy management (EV charging infrastructure, commercial properties, and universities) and life-saving facilities (data centres, healthcare facilities, wastewater treatment plants). www.cummins.com

OmniOn Power has introduced its latest solution to the high-energy requirements of AI-driven workloads in data centres - the Osprey-series nonisolated DC/DC bus converters.

Engineered to support power-hungry AI applications, these converters deliver high power density with peak efficiencis exceeding 97%.