Renewable Natural Gas (RNG), also known as biomethane, is a sustainable fuel that has been upgraded to meet natural gas pipeline quality standards.

RNG is produced through the processing of organic waste materials, such as food waste, animal excrement, and sewage.

The organic waste undergoes anaerobic digestion (a biological process where bacteria break down the biodegradable material in the absence of oxygen). This process produces biogas, which is a mixture primarily composed of methane and carbon dioxide.

The biogas is then processed and upgraded by removing impurities like moisture, hydrogen sulfide, and carbon dioxide. This purification process results in a renewable fuel source that has a very high methane content, similar in quality and properties to conventional natural gas.

RNG can be used for many of the same applications as conventional natural gas, such as heating, electricity generation, and transportation fuel. It is considered a renewable and low-carbon energy source that can help diversify energy supplies and reduce reliance on fossil fuels.

Using Renewable Natural Gas contributes to the reduction of greenhouse gas emissions and the transition towards a more sustainable and circular economy by using organic waste as a valuable energy resource.

Four industries primed to produce RNG:

• Landfills (LFG)

• Organic Waste

• Water Wastewater

• Livestock Waste

Raw biogas is mainly methane and carbon dioxide with traces of other elements such as water, hydrogen sulfide, siloxanes, nitrogen, and oxygen.

Waste products, such as sludge, food waste or manure are processed in a biodigester.

The biodigester breaks down the organic material to create biogas a mixture of methane and other elements.

The biogas can then be processed and conditioned leaving behind RNG, which can be used interchangeably with traditional natural gas.

This RNG can be used where it is produced for things like generating electricity or fueling vehicles, or it can be injected into a utility pipeline for transportation to other customers.

Reduced greenhouse gas emissions compared to fossil natural gas

Ability to use existing natural gas infrastructure

Utilization of organic waste streams as a valuable resource

Improved waste management and reduction of landfill usage

Facilities are now required by law to continuously measure flow and gas quality with a gas chromatograph (GC) for raw biogas and finished RNG.

Many RNG producers do not meet the new ruling and will need GCs on raw biogas streams. This also applies to different flow measurement applications.

FUEL PATHWAYS NEED TO BE AMENDED BY JANUARY 1, 2025 to comply with the new RFS rule.

NEW PATHWAYS REGISTERED AFTER JULY 1, 2024 MUST COMPLY IMMEDIATELY.

CONTINUOUS MEASUREMENT means the automated measurement of specified parameters of biogas, treated biogas, or natural gas recorded according to the following frequencies:

In-line Gas

Chromatograph (GC)

Automated measurement recorded at least every 15 minutes

Flow Meter

Automated measurement every 6 seconds, with weighted totals recorded at least every minute

Other meters

Automated measurement occurring at a frequency specified at registration

The EPA requires specific standards that must be used when measuring biogas properties, as stated in § 80.155 and shown in the chart below:

In-line Gas Chromatograph (GC)

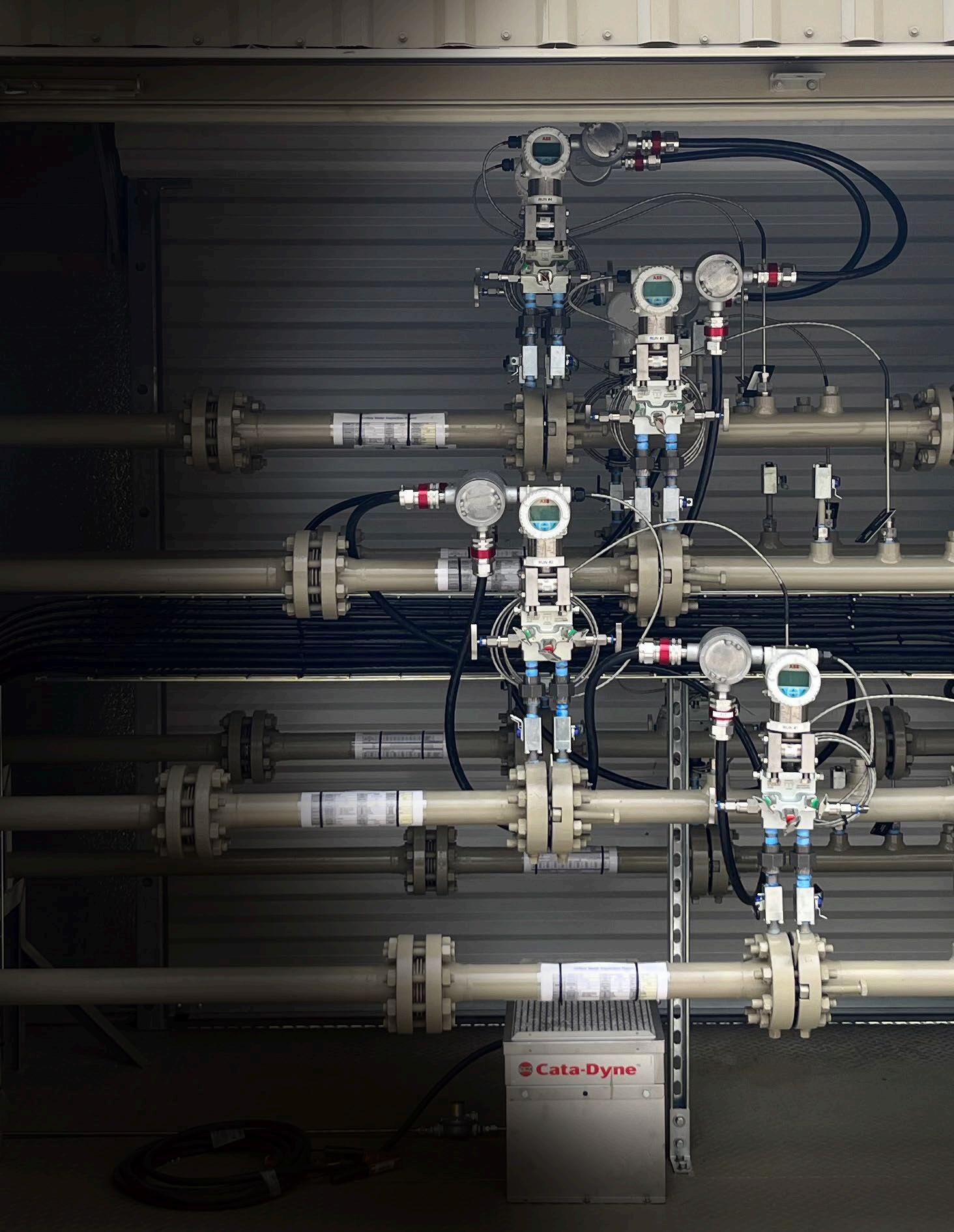

Winn-Marion has trusted ABB instrumentation to develop quality custom solutions for almost 40 years. ABB products have consistently demonstrated reliability, accuracy, and ease of maintenance to customers around the world for over a century.

A company with a long-standing reputation for delivering top-tier solutions, ABB takes pride in offering one of the most complete and competitive instrumentation portfolios in the market, designed to meet the diverse needs of various industries. Their commitment to innovation and digitalization provides customers with state-of-the-art technology and reliable performance.

Custody Transfer/Metrology Quality GC for Heating Value and Composition

The NGC8206 enables remote analysis of natural gas composition from N2 to C6+ and format the information for output to most 3rd -party systems. One simple-to-operate device provides total energy measurement at every point along the natural gas supply chain.

The NGC8203 gas chromatograph features a dedicated column designed for the analysis of components present in low Btu "Landfill" gas. Sometimes this is mixed with higher Btu components like propane to enhance its quality, enabling it to be introduced into a transmission pipeline.

o Performs on-site gas analysis and heating value computation.

o This truly “transmitter-like” gas chromatograph takes up no more room than most multivariable transmitters.

o The integral stream selector allows sampling up to 4 different natural gas streams. Up to 2 of these sample streams can be designated as the “calibration/validation sample”.

o Optional sample conditioning modules are available to address natural gas streams that need additional filtering and “speed loops.”

Modular design for easy maintenance

32 bit digital, low-power controlling electronics, using Windows CE®

Lithium battery-backed RAM

Two remote serial digital communications ports; one local port

Comprehensive diagnostics and wizards available to users

Three-level security for user access control

Audit-quality historical data; date and time stamped

VortexMaster flowmeters accurately measure the flow of gases, liquids and steam over a wide range of temperatures. Vortex meters are ideal for use on all kinds of gases, low viscosity liquids, and demineralized water, and for direct, cost-effective steam mass flow measurement.

HMI for easy meter set up

Integrated RTD for temperature compensation

Digital outputs for pulses, frequency and alarm signal

Remote transmitter with up to 98 ft. cable length

Stainless steel transmitter housings

Enhanced meter diagnostic

o Basic meter for volume flow applications.

o Available in flange-mount and wafer-type designs.

o Uses a two-wire transmitter with leading edge DSP-technology.

o Intuitive operation directly through the glass makes it very user-friendly.

o Drift-free sensor provides long term stability; no recalibration required over the lifetime of the meter for most applications.

o Temperature and pressure compensated flow available via internal temperature sensor and external pressure input.

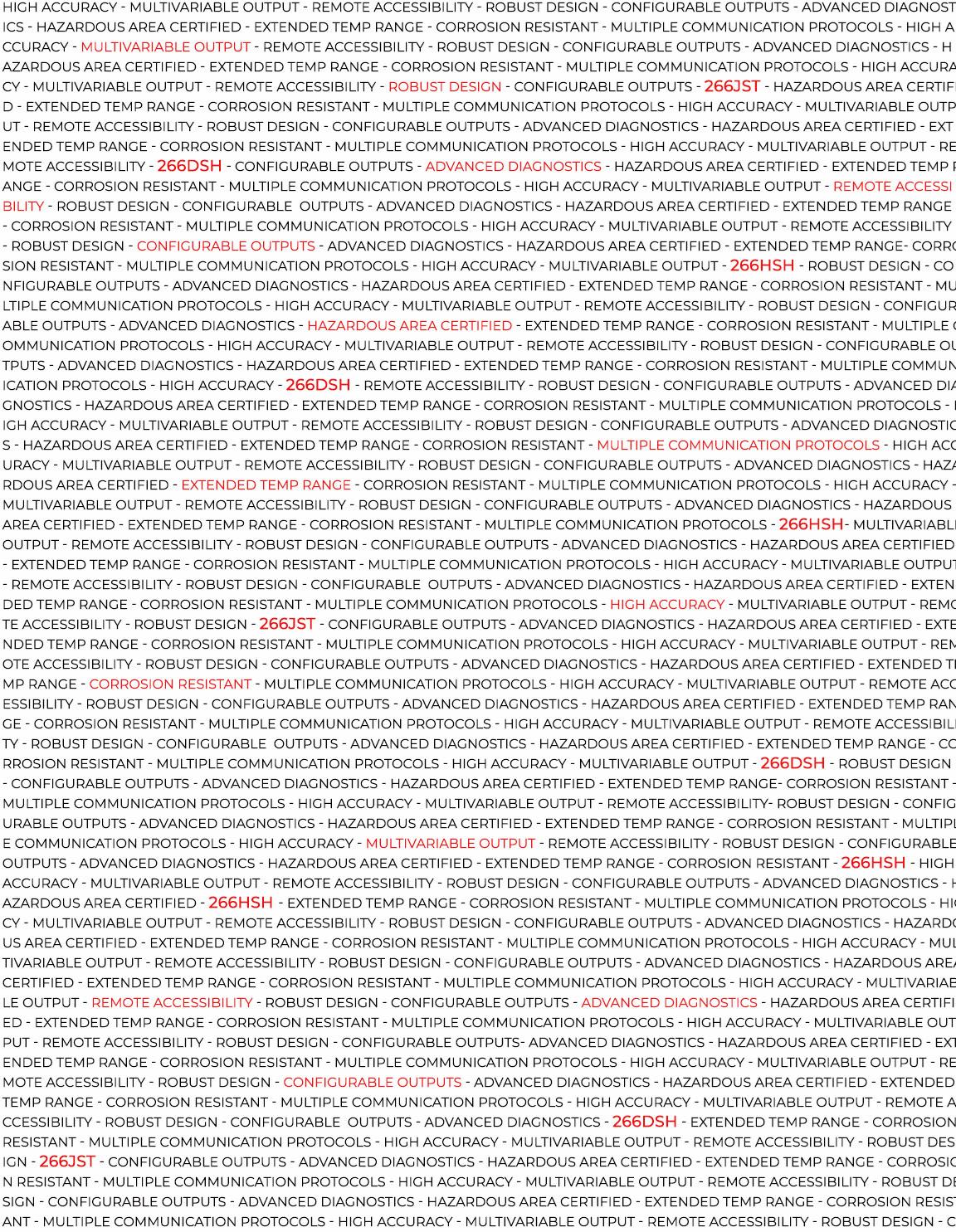

Replace up to 3 individual sensors with 1 Modbus® Multivariable

The multivariable 266JST offers an advantage in that only a single device needs to be used for the measuring point instead of several transmitters. This reduces purchase and installation cost and increases reliability due to fewer devices and less wiring.

• Through-the-glass key technology

• Dynamic compensation of pressure and temperature

• 0.04% accuracy of calibrated DP span

• 0.05% accuracy of calibrated SP span

• Large range down ratio of up to 100:1

• Utilized in all market segments

• Modular design

• Isolated electronics for better noise resistance

• Mounting brackets available

o Measures differential and absolute pressure.

o Measures temperature of liquid, vapor and gas via an external RTD.

o The MODBUS® protocol allows the ability to communicate in a wide variety

o of products (not just ABB).

o ABB’s open architecture design allows for use with most any RTU, Flow Computer or system on the market. Full transparency is given with the complete Modbus mapping details included in the 266JST operating instructions, as well as pre-programmed mapping selections.

266DSH is a differential pressure transmitter featuring standard DP-Style design. Characterized by long stability and high performance, this transmitter represents ABB commitment in satisfying customer needs.

• Through-the-glass key technology

• Integral display with integral keypad

• Base accuracy 0.06 % of calibrated span (optional 0.04 %)

• Large range down ratio of up to 100:1

• Two–wire 4 to 20 mA, user-selectable for linear or square root output

• Utilized in all market segments

• Surge protection

• Modular design

o The 266DSH transmitter features an in-field replaceable electronics module dramatically improves plant productivity.

o Intuitive plug-and-play display with easy setup saves time and lowers maintenance and inventory costs.

o Plugged impulse line detection (PILD) generates a warning via communication (HART, PA, FF) and can be configured to drive the output to “Alarm current” or set a status “BAD”.

The Gauge pressure transmitter portfolio from ABB offers a broad variety of communication possibilities. With a long-term stability, 266HSH grants lasting performances even in extreme ambient and process conditions.

• Through-the-glass key technology

• Digital LCD integral display with integrated keypad

• Base accuracy 0.06 % of calibrated span (optional 0.04 %)

• Large range down ratio of up to 100:1

• Utilized in all market segments

• Modular design

• Mounting brackets available

• Surge protection

o High overload gauge pressure transmitter with a maximum working pressure up to 105 MPa, 15225 psi suitable for measuring liquid, gas or steam pressure in a pipe or on an open tank. Communication options now include Modbus®, along with 4-20mA HART and 1-5V HART.

o Features an in-field replaceable electronics module that dramatically improves plant productivity.

o Intuitive plug-and-play display with easy setup saves time and lowers maintenance and inventory costs.

Renewable Identification Numbers (RINs)

The Renewable Fuel Standard (RFS) program, administered by the Environmental Protection Agency (EPA), requires a certain volume of renewable fuels be blended into the nation's transportation fuel supply each year.

Renewable Identification Numbers (RINs) are tradable credits used for compliance with the RFS program in the USA.

To demonstrate compliance, refiners and importers of gasoline and diesel must accumulate and surrender a certain number of RINs every year.

STEP 1

STEP 2

Each batch of renewable fuel produced or imported receives a unique 38-character RIN assigned by the EPA.

STEP 3

When the renewable fuel is blended with gasoline or diesel, the RIN can be separated and used for compliance or traded.

STEP 4

Obligated parties (refiners, importers) must accumulate sufficient RINs to meet their share of the year's blending requirements.

RINs can be traded on an open market, allowing obligated parties to buy RINs from others if they don't have enough from blending activities.

STEP 5

At the end of each year, obligated parties must retire the required number of RINs with the EPA to demonstrate compliance.

The Sensi+ analyzer is a reliable new solution that simplifies and reduces the cost of operation and maintenance. It enables safer, easier, and more efficient monitoring and operations through a single device that can analyze up to three contaminants in any natural gas stream accurately and in real time. Its fast response also enables quick reaction to process upsets, thus helping to reduce waste and methane emissions.

ABB's Integrated Cavity Output Spectroscopy (ICOS) laser absorption technology has been used for over 15 years in the world's most reliable gas analyzers, providing advanced spectroscopic analyses that offer unparalleled accuracy, precision, sensitivity, and reliability compared to other TDL analyzers.

• Single device for continuous, simultaneous measurements of H2S, H2O and CO2 contaminants in natural gas streams for custody transfer, tariff compliance, and process monitoring (O2 to be available late 2024).

• Fast response time

• Minimizes interferences using high-resolution diode laser

• Reduced cost of ownership

• Low sample flow, lowering the environmental impact and financial loss due to venting of natural gas

• No need for periodic calibration

• Internal performance metrics for asset health monitoring

HoverGuard combines the world’s highest performance laser sensing technology with advanced data analytics and ABB Ability to allow customers up and down the natural gas value chain to detect, find, and quantify leaks quickly to increase public safety and improve human health and the global environment.

Combining patented LGR -ICOS laser technology, wind velocity and GNNS sensors, and advanced data analytics, the HoverGuard solution allows our ABB service team to detect leaks far from hard-to-reach sources in minutes.

Enables detection and mapping of methane leaks while flying with unprecedented speed, accuracy and reliability.

The ABB Ability leak detection service is a cost- effective solution with the ability to locate leaks more easily at lower costs, resulting in more efficient repair and lower overall emissions.

Distribution pipelines

Gathering lines

Odor investigation

Post disaster evaluation

Public gatherings Landfill monitoring

Agricultural studies Research studies

Woodward is recognized as the world’s leading manufacturer of engine and turbine control systems. For over 150 years, Woodward has focused its resources and expertise on delivering proven systems that perform under incredible demands.

Understanding that system reliability is a major requirement for oil and gas, petrochemical, and process plant industries, Woodward’s control, actuation, valves, and protection systems are designed to meet the high level of dependability and redundancy required across intensive industrial applications.

The company also solves challenges associated with global efficiency initiatives – from reducing emissions, to increasing energy efficiency, to introducing alternative energy sources.

As a premier partner for over 20 years, Winn-Marion’s factory-trained experts are available to install, calibrate, repair and field-service all Woodward products.

In addition to being a Woodward parts distributor, Winn-Marion is the only Woodward factory-authorized repair facility in the Rocky Mountain region, providing comprehensive repair and remanufacturing needs.

Update Your Engine Control Systems to Better Burn the Biogas Produced

Winn-Marion offers industry leading Woodward gas engine and dual fuel control solutions. Producing BTUs costs money to capture, compress, or flare. Convert the excess into valuable power to increase your bottom line.

Woodward’s engine control unit (ECU) is designed with high-speed, on-engine processor and control algorithms to assess pressure for each cylinder, each cycle, and convert the information into metrics such as center of combustion, rate of pressure rise, and peak pressure. With this data, the ECU can control combustion phasing in reactivity-controlled compression ignition (RCCI) combustion. Additionally, the combustion metric feedback can be used to maintain good combustion phasing during changes in substitution rates and when the fuel quality changes.

Woodward E6 Gas Engine Control Module a Powerful Core Controller

• Closed-Loop Emissions compliance

• Optional Speed/load control

• Optional High Energy Ignition and timing control

• Optional FFT Knock Detection and Detonation Mitigation

TecJet Characterized Fuel Metering Valve

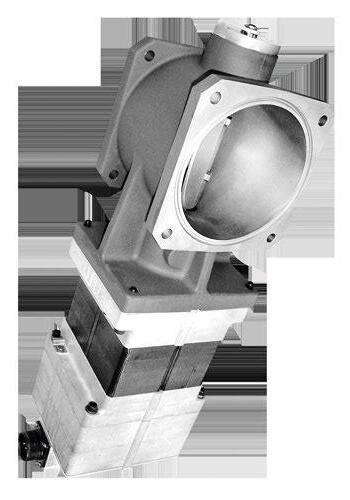

P-Series (ProAct) Actuators and Integrated Throttle Bodies

F-Series (FloTech) Integrated Throttle Bodies

R-Series Actuators and Hot Valve Systems

StableSenseTM Hazardous Location Exhaust Gas Sensors

LECM High-Energy/High-Voltage Ignition Coils

LECM High Voltage Plug Extenders

FTI – Fast Turbulent Igniter Pre-Chamber Spark-Plugs

Integration with easYgen Power Management product line

Arizona (480) 968-9344

Denver, CO (303) 778-6767

Casper, WY (307) 381-6866

Gillette, WY (307) 686-9196

Loveland, CO (970) 339-9211

Midland, TX (432) 563-8151

Montana (406) 259-9234

New Mexico (575) 725-5484

North Dakota (701) 586-3184

NE Pennsylvania (272) 223-7355

PA, Ohio, WV (412) 319-7392

San Antonio, TX (210) 263-1853

Utah (801) 676-0155