INDUSTRIAL SOLUTIONS

TURBINE SYSTEMS | ENGINE SYSTEMS | POWER MANAGEMENT

Rocky Mountain Technology & Innovation Center

This facility allows Woodward to perform in-house testing that a majority of controls manufacturers typically outsource to expensive testing laboratories. The extensive testing performed at the Tech Center ensures Woodward products operate in harsh environments for their intended life.

ADVANCED ON-ENGINE TEST CAPABILITES

ENVIRONMENTAL PRODUCT TESTING MACHINING, FABRICATION, & MODIFICATION

Winn-Marion + Woodward

Woodward is recognized as the world’s leading manufacturer of engine and turbine control systems. For over 150 years, Woodward has focused its resources and expertise on delivering proven systems that perform under incredible demands.

Understanding that system reliability is a major requirement for oil and gas, petrochemical, and process plant industries, Woodward’s control, actuation, valves, and protection systems are designed to meet the high level of dependability and redundancy required across intensive industrial applications.

The company also solves challenges associated with global efficiency initiatives – from reducing emissions, to increasing energy efficiency, to introducing alternative energy sources.

As a premier partner for over 20 years, Winn-Marion’s factory-trained experts are available to install, calibrate, repair and field-service all Woodward products.

In addition to being a Woodward parts distributor, Winn-Marion is the only Woodward factory-authorized repair facility in the Rocky Mountain region, providing comprehensive repair and remanufacturing needs.

Proven Steam Turbine Control Solutions

ANY SIZE, ANY APPLICATION.

Purpose-built for steam turbines, Woodward’s powerful controllers have the performance and accuracy required for today’s steam turbine applications. Steam turbine OEMs utilize Woodward’s turbine controllers to ensure their packages meet steady-state stability and fast transient responses required by petrochemical plant processes and utility grid regulatory commissions.

Self Cleaning. Dirt Tolerant.

The patented technology of Woodward's VariStroke actuators ensure greater overall reliability of your steam turbine. Their superb accuracy and resolution make them ideal for steam valve control and related turbine speed and load control.

CPC-II / CPC-DX

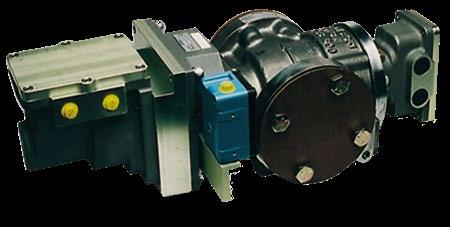

Electro-Hydraulic Actuator Control

CPC-II and CPC-DX Redundant Converters are electro-hydraulic pressure regulating control valves used to position single-acting steam turbine valve servos/actuators. These versions accept 4- 20 mA pressure demand signals and accurately controls oil pressure to precisely position single-acting steam turbine governor-valves.

MAGNETIC PICKUPS

Speed Sensing

Magnetic pickups (MPUs) are speed sensors that detect the speed of a prime mover, typically an engine or turbine. These fieldverified and compatible speed sensors provide a complete turbine control solution when combined with our turbine controllers and actuators.

Unit-To-Unit Compatibility

Woodward designs its line of steam turbine control products to be easily integrated together, simplifying system design and assuring unit-tounit compatibility. This integrated approach reduces installation costs and allows customers to scale their system components.

Custom Configurations

Woodward’s platform of steam control solutions covers the complete industry driving blowers, pumps, compressors, and generators. From custom Integrated Turbine Compressor Control (ITCC) to the reliable and robust performance of off-the-shelf configurable controls, Woodward has your solution.

Proven Gas Turbine Control & Protection Solutions

PURPOSE BUILT, PUTTING YOU IN CONTROL.

Purpose-built for gas turbines, Woodward’s turbine controllers, fluid control systems, and actuators ensure packages meet the rapid start, steady-state stability, and fast transient responses required by distributed power generation, utility grid regulatory commissions, and pump/compressor applications.

Purpose-Built Fluid Control Systems

A full line of fuel, water, air metering and shutoff valves and actuators are Woodward's solution to the required performance, precision, speed and safety requirements of gas turbine control products. Their leading-edge integrated actuator and valve technology is the chosen solution for OEM's, packagers and end user design to provide accurate, responsive and highly reliable fluid metering products.

SYSTEM INTEGRATION

Maximize Power & Simplify System Design

Woodward designs its line of gas turbine control products to be easily integrated, maximizing power and productivity, simplifying system design, and assuring compatibility.

Integrated Gas & Compressor Control

Woodward ‘s integrated IGCC systems with qualified compressor cores drive productivity, efficiency, optimization, and safety in turbine and compressor performance.

Compressor Control & Protection

Our integrated turbine-compressor and motor-compressor control systems maximize availability and performance in upstream, midstream and downstream oil and gas applications, helping owners run their compression systems and process at peak efficiencies. All of our systems meet industry standards for machinery control and safety and are fully tested in a dynamic simulation environment.

Integrated (ITCC) Or StandAlone Compressor Controls

Woodward's line of integrated (ITCC) and standalone compressor control and anti-surge systems operate in the most demanding environments in the industry . These field-proven compressor control cores drive productivity, efficiency, optimization, and safety in turbine, motor and compressor performance.

CONFIGURABLE CONTROLS

Anti-Surge Protection

Woodward’s advanced technologies enable maximum protection for your compressor. Leading-edge process control logic optimizes performance and productivity to reduce surge events. When a process disturbance does occur, Woodward’s advanced surge management system provide the performance needed to avoid trips and enable optimization of process control points.

PEAK PERFORMANCE

Advanced Technologies

Woodward has developed surge preventive techniques that help compressor users achieve peak performance of their process and minimize process disturbances. Woodward’s patented rate PID algorithms provide anticipative opening of anti-surge valves during process upsets to minimize overshoots and allow safe operations with minimal safety margins. Compressor turndown is maximized, and higher product yields are achieved.

Electrical Power Generation & Distribution Solutions

Our power management systems for diesel, natural gas, and alternative-fueled engines successfully address strict EPA emissions regulations while providing reduced overall cost of system ownership. These technologies have helped us maintain preferred supplier status in the diesel- and gaseous-fueled power generation industry, plant control systems operation, and the wind power generation industry.

Benefits of Woodward's Control Technologies

- Seamless integration of protection and control products

- Performance to meet demanding applications

- Fuel efficiency and emissions compliance

- Reliable products for increased uptime

Command Your Complex System

GENSET

EASYGEN-3000XT SERIES

One Unit. Infinite Possibilities.

EASYGEN-3000XT REMOTE PANEL

Remote Control & Visualization

RGCP-3400 REDUNDANT CONTROL For Mission Critical Applications

EASYGEN-2000 SERIES Simple Paralleling

EASYGEN-1000 SERIES For Automatic Mains Failure Applications

EASYGEN-100 SERIES For Single Genset Applications

SYNC

/ SWITCH

SPMD-2 SERIES Reliable Synchronization

MSLC-2 / DSLC-2 Multifunction Load Sharing

PLAYS WELL: PROTECTION RELAYS

HIGHPROTEC-2 SERIES

Reliable Power System Protection

The Woodward HighPROTEC-2 line offers an outstanding solution for reliable medium-voltage protection of distribution, generator, substation, and motor assets. The innovative PC tool minimizes commissioning and training costs. The high degree of proven reliability guarantees the availability of electrical grid and equipment. Each model has the flexibility to handle all variations that can be encountered in a specific application.

LS-5 SERIES Complex Power Management

DTSC-200/50 CONTROLLER Automatic Transfer Switch Control

Power Solutions

Complete System Integration & Service Packages

Woodward’s 40+ years of project experience in the power business, combined with the application of state-of-the-art methods and technology, makes them a reliable partner for customers. And right from the initial tender stage, the experienced team at Winn-Marion will consult with you to ensure the best possible solutions. No matter what application combined heat and power plant or HFO power station our engineering department will provide a customer-oriented solution individually tailored to your specific requirements.

• - Dual-Fuel Power Applications

• - Generator Control Applications

• - Turbine / Generator Systems

• - Smart Grid Applications

CONSULTING, ENGINEERING, & COMMISSIONING SERVICES

EXPERIENCE IN CUSTOMER CO-OPERATION & CUSTOMIZED SYSTEMS

HIGHLY EFFICIENT & FLEXIBILE ENGINEERING SUPPORT

Complete System Control & Protection

We make sure that data is acquired and processed locally, providing adaptation of set values and securing the long-term operability of the system. All solutions rely on approved components from long-standing suppliers to ensure the highest degree of reliability.

• Genset Control Systems

• Engine Control Systems

• Turbine Control Systems

• Generator Control Systems

• Generator Protection Systems

• Genset Aux Control Systems

• Engine Safety Systems

Power Plant Supervisory System

The efficient use of the primary energy source is an important factor for overall efficiency. The essential values of the prime mover are monitored, sampled, and transmitted to a databased visualization system for continuous screening.

Distributed Energy Resources (DER)

Woodward enables the integration of electrical power systems, which means distributed generation, medium- and low-voltage distribution, and the use of electrical energy in an IT-connected infrastructure.

“No-Worry” Power Distribution Systems

Woodward specifies and integrates complete MV and LV distribution systems to the entire power station. This saves time during assembly and enables customers to save money from the beginning while ensuring elements fit perfectly, providing seamless plant start-up.

Prefabricated Power Control Rooms

Prefabricated power control rooms help speed up on-site commissioning and construction. The modules are pretested and just need to be connected to the entire system. A 20/40 feet container format can be easily assembled for a turnkey power control room and power distribution cell.

Large Engine. Integrated System Solutions.

HIGH-SPEED INDUSTRIAL / MEDIUM-SPEED INDUSTRIAL

Woodward integrated systems are based on a foundation of key technologies − electronic controls and software, fuel and air delivery, and combustion control. With Woodward’s fully integrated control system architectures, costs are significantly reduced while performance and external communications are enhanced.

Spark Ignited Gas Applications

Woodward spark-ignited gas solutions are developed for a wide range of industrial stationary or mobile engines used in power-gen, oil and gas compressor, and marine auxiliary/propulsion. Solutions include low-pressure (TecJet) to medium-pressure (SOGAV) and high-pressure gas engines designed to operate under all kinds of gases.

HIGH SPEED INDUSTRIAL Spark Ignited Gas

MEDIUM SPEED INDUSTRIAL Spark Ignited Gas

Benefits

WIDE RANGE OF APPLICATIONS

• Standard integrated solutions

• Rich and Fuel Blending

• Preliminary engine calibration

• Demonstrate engine targets set by the customer

• Demonstration of emissions certification

Key Components

RELIABLE & ROBUST PARTS

• Product validated and tested under harsh environment specs and onengine conditions

• Used on multiple OEM engine platforms

• Engine mounting design reduces overall system cost, speed of installation, and ease of application

SYSTEM OFFERING & PROTECTION

• Components optimized to maximize system capability

• Tamper proof: Mass flow control valves are not field adjustable

• Pre-ignition detection using accelerometer and pressure sensors

• Monitoring of peak pressure

Diesel Gas Applications

Controlling all engine parameters in relation to operating conditions is essential for low emission and high efficiency of a diesel engine. Woodward’s diesel control systems manage the complete diesel engine combustion process and gas exchange cycle. The systems provide control of the charge air or combustion air through compressor bypass, turbo waste gate, exhaust gas recirculation (EGR) or variable turbine area or geometry turbo chargers

Benefits

WIDE RANGE OF APPLICATIONS

• Gas and dual-fuel operation ranks as one of the most innovative technologies for a more flexible, more efficient and loweremission use of large engines

• Applications can be operated with inexpensive gas as well as with liquid fuel

• Injection systems with the unique multineedle nozzles are a key prerequisite for the dual-fuel process

Key Components

RELIABLE & ROBUST PARTS

• The same design base for all commonrail pumps from high-speed to 2stroke engines

• Modular design allows simple adaptation

• One complete system – one solution. With all components perfectly matched for optimal control.

• Reduced exhaust and noise emissions, lower fuel consumption, outstanding reliability and durability

CUSTOMIZED SOLUTIONS

• The goal is to set new standards in terms of quality, durability, fuel consumption, and emissions

• Close collaboration throughout the development process

• Collaboration allows for fewer program changes and quicker development time

Dual Fuel Applications

The Dual Fuel System has been developed for any industrial stationary or mobile diesel engines with protection as priority. This system is designed to reduce diesel consumption by substituting gas for diesel and therefore significantly reduce the operating costs of new and existing applications. The new torque-based control strategy allows customers to maintain the desired gas/diesel ratio throughout the load and speed range of the engine, simplifying the calibration effort while in the field. Original engine performance is maintained with minimal changes to the base diesel engine. The DRDF System will always maintain the ability to return to full diesel operation at any time or when gas is not available, therefore always keeping the engine operational

Benefits

WIDE RANGE OF APPLICATIONS

• Standard application for mechanical, electronic and common rail fuel injection engines

• Standard applications for Powergen, oil and gas generator, oil and gas compressor, and marine propulsion

• Ready for pipeline gas, LNG, field gas

Key Components

MEDIUM SPEED INDUSTRIAL

Dual Fuel Multi Point Pilot Injection

SAFE OPERATION AT THE HIGHEST GAS SUBSTITUTION RATE

• Tamper proof: Mass flow control valves are not field adjustable

• Pre-ignition detection using accelerometer and pressure sensors

• Monitoring of peak pressure

RELIABLE & ROBUST PARTS

• Product validated and environment tested

• Used on multiple OEM engine platforms

Dual Fuel Engine

Primary Engine To Complete System Control

LECM (LARGE ENGINE CONTROL)

Rapid Development Controls & Software

Woodward‘s software control solutions offer fast development cycle times, high flexibility and customer ownership of intellectual properties The suite of controller products, software tools and application engineering expertise, you can build production controls in a flash.

• Simpler, faster development and lower cost for fleet testing

• Better testing using real production hardware

• Develop, analyze, and enhance software features in Simulink

• Direct access to the production I/O from Simulink

• Readable documentation of system design

• Real-time simulation capabilities GOVERNOR LINE

Hydraulic-Mechanical Governors & Actuators

Woodward hydraulic-mechanical governors provide reliable and precise control of engine speed and output in virtually every type of engine application. Available in work output ratings from 10 8 inch-pounds up to 500 foot-pounds, Woodward governors are used in power generation, marine, pump, compression, and vehicle applications.

Emissions & Efficiency

Precision Control In Harsh Environments

Woodward has coupled R-Series actuators with its newly-designed Glo-Tech hot valves to precisely control the flow of high-temperature gases up to 780°C . The R-Series actuators in the Glo-Tech system are sized to match the valve, minimizing the electrical power required while providing fast, precise valve positioning.

TECJET FUEL METERING

Mass Flow Control Technologies

Woodward’s TecJet valve is an electronic gas metering valve for single-point injection. Its integrated sensors and electronics provide the correct gas flow under all conditions, enabling the engine to run very lean with low emissions. Its ability to be used with many gas qualities from methane to landfill gas to coal gas makes it among the most flexible and accurate gas metering devices on the market.

HPCR LINE

High-Pressure Common-Rail Pumps & Injectors

Woodward designs, develops and manufactures high-pressure common rail systems for industrial high- and medium-speed engines. They are designed and developed to meet the challenges of future engine design, and the requirements for increasingly higher injection pressures, to support the need to improve engine performance and durability while meeting the relevant emissions targets.

THROTTLES & ACTUATORS

Fast-Acting & Precise Positioning

The Woodward engine throttle family consists of a group of throttle valves able to operate in a variety of gaseous media. The throttles are designed to operate in boosted environments with valve sizes from 16mm to 180 mm. These fast-acting actuators with internal power drivers precisely position fuel pumps, fuel valves, throttle valves, and wastegates.

SOGAV SERIES

Solenoid-Operated Gas Admission Valves

The SOGAV valve is designed to be used as the valve portion of an overall gaseous fuel admission system delivering precise gas mass flow metering per cylinder. This enables gas engines and dual-fuel engines to operate more efficiently while reducing emissions.

Small Industrial / Commercial Engine Solutions

Woodward offers completely integrated control systems as well as individual control component technologies that integrate easily with others to provide total engine equipment control that meets user requirements for efficiency, emissions, performance, and reliability. These technologies have been proven in a range of mobile and stationary engine equipment, including natural gas buses and trucks, construction and agricultural equipment, material handling, electric power generation, pumping, and welding applications.

BETTER PERFORMANCE & RELIABLITY

LOWER EMISSIONS

INCREASED SYSTEM EFFICIENCY

Small Engine Solutions

Woodward small engine components easily integrate with other controls to provide total engine equipment control that meets user requirements for efficiency, emissions, performance, and reliability.

OH COMMERCIAL VEHICLE SYSTEMS Spark Ignited Gas Engine

POWER GENERATION SYSTEMS Spark Ignited Gas Engine POWER GENERATION MOBILE INDUSTRIAL OFF-HIGHWAY Small Diesel Engines

Gas Engine Components

INTEGRATED THROTTLES

ELECTRONIC FLOW REGULATOR (EFR)

FUEL METERING VALVE (FMV)

INTEGRATED EGR MODULE

PROPORTIONAL FLOW AREA VALVE

Diesel Engine Components

HEAVY DUTY SMART COIL ON PLUG

Because it absolutely has to be right, depend on Woodward.

WHY WOODWARD?

Exceptional solutions and systems expertise in specialized technologies.

A 150-year reputation for delivering high-quality, reliable systems that perform as expected.

Close customer collaboration to develop innovative solutions that move your technology forward.

Positive impacts on reliability, safety, energy efficiency, and emissions reduction.