The elegance of Champenoise MILLÉSIME stems from the striking contrast of an opulent body, extending into a curved shoulder and a long thin neck. Its sober dimensions and its cylindrical body, make it a container much appreciated by those handling it.

Inc. | www.saverglass.com

For those marketing, distributing or selling fine wine, the tariffs the U.S. has threatened to place on Mexico and Canada as of press time will be disruptive and may bring unintended consequences. Canada is the largest export market for U.S. wine and Ontario’s liquor control board, the LCBO, already pulled California wines from shelves. In addition, tariff hikes will raise costs for bottles, boxes, winery equipment, and more.

Grape growers have a different perspective on this, though, because low-cost imports of bulk wine have made it even more challenging for them to survive.

While we’ll be following the tariff story with interest, much of this issue focusses on grape growing and winemaking.

Powdery mildew is the top vineyard disease and is an issue with many crops. It’s been estimated that more than 100 million pounds of chemical fungicides are used each year in the U.S. to suppress powdery mildew—all while resistance to fungicides is increasingly an issue. Ultraviolet light is beginning to emerge as an effective, new tool for defeating powdery mildew in the vineyard and has been a long time coming.

The trick to making UV light work as a remedy is to apply the right dose without damaging the crop, now done at night. Researchers with Washington State University are working toward making the widespread use of UV light for managing grapevine powdery mildew more of a reality.

Sparkling wine is time consuming and costly to produce so many smaller wineries don’t make bubbles or outsource their sparkling winemaking. That said, more wineries are making sparkling themselves, and that requires the right equipment. This issue includes a look at sparkling wine equipment specifically for the small winery.

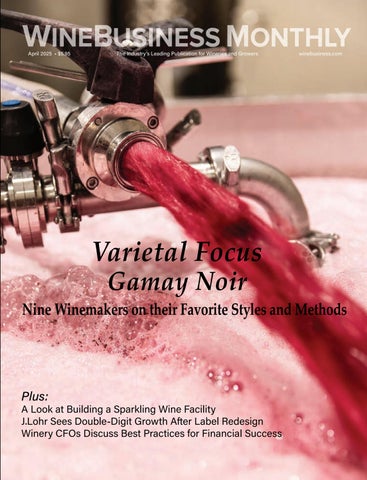

Whether you call it Gamay or Gamay Noir, winemakers say it is delicious and fun to make. Gamay is typically associated with Beaujolais but according to the WineBusiness Analytics database, 146 wineries are making it in North America. One third of these wineries are in Oregon, where Gamay is trending, while wineries across Canada make it, and to a lesser extent, other wineries produce it in California, Washington and New York.

Whether you’re considering making Gamay or are just drinking it, check out this month’s Varietal Focus report. Our Varietal Focus articles delve into clones, rootstocks, soil types, what winemakers are doing to express terroir, and how fermentation techniques affect style. The discussion helps readers assess how winemakers achieve their goals. Chances are we’ve produced a Varietal Focus report for you. More than 20 Varietal Focus reports are available for download at winebusiness.com/wbm.

2025 • Volume XXXII No. 4

Editor Cyril Penn

Managing Editor Erin Kirschenmann

Assistant Editor Katherine Martine

PWV Editor Don Neel

Eastern Editor Linda Jones McKee

Copy Editor Paula Whiteside

Contributors Bryan Avila, Mark Battany, Richard Carey, Lance Cutler

Design & Production Sharon Harvey

Editor, Wine Analytics Report Andrew Adams

Staff Writer Sarah Brown

Events Director Danielle Robb

Web Developers Burke Pedersen, Peter Scarborough

Marketing Specialist Katie Hannan

President & Publisher Eric Jorgensen

Associate Publisher & Vice President of Sales Tamara Leon

Chief Commercial Officer Dave Bellon

ADVERTISING

Account Executives Laura Lemos, Ashley Powell, Bonnie Magid

Account Support Representative Aidan O’Mara

ADMINISTRATION

Vice President – Data Management Lynne Skinner

Project Manager, Circulation Liesl Stevenson

Financial Controller Katie Kohfeld

Data Group Program Manager Rachel Cunningham

Research Assistant Sara Jennings

Public Relations Mary Jorgensen

Office Manager/Customer Support Maggie Cline

Chairman Hugh Tietjen

Publishing Consultant Ken Koppel

For editorial or advertising inquiries, call 707-940-3920 or email info@winebusiness.com

Copyright 2025 Wine Communications Group, Inc. Short passages can be quoted without permission but only if the information is attributed to WineBusiness Monthly

Cyril Penn - editor

WineBusiness Monthly is distributed through an audited circulation. Those interested in subscribing for $39/year, or $58 for 2 years, call 800-895-9463 or subscribe online at subs.winebusiness.com. You may also fill out the card in this magazine and send it in.

CEO, Bright, Inc., “Experts Discuss Balance Sheet, KPI Best Practices to Ensure Financial Success,” page 72

“It is incumbent upon us all as we enter this cycle of the industry, knowing the challenges that are out there, to take that time to pull your head out of the day-to-day.”

professor, viticulture extension specialist, Washington State University, “Trials & Troubleshoots - Ultraviolet-C light v. Powdery Mildew in the Vineyard,” page 46

“The best program for disease management in any crop is to have options. In the last few decades, we’ve likely over-relied on highly effective fungicides and this overreliance has resulted in the rise of fungicide resistance. This means having efficacious, non-chemical options can be a game changer for grape powdery mildew control.”

vice president of marketing, J. Lohr Vineyards & Wines, “Consumer Research Lends Perspective to Successful Brand Redesign,” page 66

“You have to adapt to what the consumers wants and needs and otherwise, brands will get left behind. The other packaging served its purpose—but it was time to evolve and address what the consumer wants.”

grape growing advisor, “Springtime Cover Crop Management Decisions and Frost Risk,” page 54

“For sites that have never needed any type of active frost protection measure, the extended presence of cover crops after budbreak may necessitate the addition of tools such as wind machines or sprinklers to prevent frost damage.”

general manager, Pellegrini-Olivet Lane Winery and Vineyard, “Varietal Focus: Gamay Noir,” page 12

“My family imported Beaujolais for some years. I fell in love with a specific small winery in Saint-Amour that used a submerged cap fermentation to achieve juiciness with softer tannins. When we found a supply of Gamay Noir, we decided to use submerged cap as well.”

In February, Napa County Superior Court Judge Mark Boessenecker ordered Napa Valley winery Hoopes Vineyard to close temporarily, ordering the family-owned business to stop serving wine to the public as well as halt the sale of items such as books, soap and wine openers, according to an injunction. Under the court order, the winery had two weeks to move animals, including chickens and horses, in its sanctuary off of Washington Street. The order was filed amid a legal battle between the county and the winery over what it can and cannot do on its property. Owner Lindsay Hoopes had filed a notice of appeal. In the order, the judge ruled that winery activities that don’t comply with county rules had to be halted until the winery obtains a “valid use permit.” The legal issues for the winery began in 2022 when the county filed a complaint against the winery.

Marchesi Antinori purchased the Arcadia vineyard in the Coombsville AVA from the family of late vintner, Warren Winiarski. The 135-acre property has 84 vineyard acres planted to 58 acres of Cabernet Sauvignon, 23 acres of Chardonnay and three acres of Merlot. Public records obtained by WineBusiness indicate the purchase price was $21 million. Warren Winiarski purchased the vineyard from Mike Grgich’s partner Austin Hills in 1996. After Stag’s Leap Wine Cellars was sold in 2007 to a partnership between Marchesi Antinori and Chateau Ste. Michelle, the Winiarski’s retained Arcadia vineyard. Antinori fully purchased Stag’s Leap in 2023.

New York-based Skurnik Wines & Spirits acquired the wine-on-tap Gotham Project brand including its national distribution rights and production operations. Gotham provides high quality wines in kegs for either bars, restaurants or other hospitality venues. Skurnik has been a distribution partner for the brand since its start, helping to build the category with initial sales based in New York. Bruce Schneider and Charles Bieler are the founders of the Gotham Project and with this acquisition, Skurnik will help transition current partners and customers while also looking into growth opportunities for the Gotham Project.

In late February, Bronco Wine Co. acquired key assets from Wine Hooligans at an auction. Bronco has been a majority shareholder in Wine Hooligans since 20023, and now it will fully control several brands including Portlandia, Shortbread, Broadside and Sea Monster, as well as Wine Hooligans’ and BevZero production facilities located in Santa Rosa, Calif. According to a press release from Bronco, most Wine Hooligan employees will continue to support the operations of the brands as new Bronco employees.

Martinez Orchards, a supplier of grapevine plant material, acquired Guillaume Grapevine Nursery. The nursery was established in 2006 in Knights Landing, Calif. and produces certified grape varietals and rootstocks. With a history of grapevine grafting that dates back to France in 1895, the Guillaume family has passed down to generations its experience and innovation in grapevine cultivation. Martinez Orchards was founded in 1969 in Winters, Calif.

Lance Cutler

IN SPITE OF A LONG history that dates back to the 14th century, Gamay Noir has been—and remains—a very small player in the world of wine. As of 2021, less than 91,000 acres of the grape existed in the entire world, and 75% of that was planted in France, with Beaujolais accounting for 62% of the world’s supply. DNA analysis shows that Gamay is a member of the Pinot Noir family hooked up with an obscure white grape called Gouais Blanc. True Gamay, known as Gamay Noir à Jus Blanc, has been growing in Burgundy since the 14th century. Records of Gamay Noir started to appear in Burgundy shortly after the Black Death epidemic. It was easier to grow than Pinot Noir and delivered larger yields, so local farmers were all in on the grape.

In 1395, the Duke of Burgundy, Philippe the Bold, banned the cultivation of Gamay in Burgundy because he felt it was inferior to Pinot Noir, saying that Gamay wine was full “of a very great and horrible harshness.” He insisted that the space be used for Pinot Noir, declaring that it produced a more elegant wine. Later, another Duke of Burgundy, Philippe the Good, banned cultivation of the grape again, citing the need to maintain the reputation that Dukes of Burgundy had for producing the “finest wines in all of Christendom.”

Even after being persecuted by the bans, Gamay Noir remained firmly entrenched in Beaujolais, just south of Burgundy and north of Côtes du Rhône. It is the only red grape grown in Beaujolais. Starting in the 1970s and 1980s, Beaujolais Nouveau became all the rage. This wine went straight from the fermentation vat to be rushed around the world on the third Thursday in November. The wine itself tended to be fruity, tart and was served chilled, but hurrying it to market had a detrimental effect on the wine quality which seriously wounded the reputation of Gamay Noir wine.

Largely, Beaujolais Nouveau has fallen out of favor although it still accounts for close to 50% of all Beaujolais wine. Instead, Cru Beaujolais wines from 10 different communes attract wine aficionados to a world of delicious, reasonably priced wines. Starting in the north and heading south, you pass through Saintt-Amour, Juliénas, Chénas, Moulin-à-Vent, Fleurie, Chiroubles, Morgon, Regnié, Brouilly and Côte de Brouilly. These Cru Beaujolais wines always exhibit good acidity with red fruit flavors, notes of purple flowers and some soft earthy hints on the palate.

Gamay is also grown in the Loire Valley where it is often blended with Malbec and Cabernet Franc. It is the second most popular red grape variety in Switzerland and has made inroads in Oregon, as well as Washington state. Gamay does well in the Niagara Peninsula and other parts of Canada. Gamay Noir has devotees in California, Australia and eastern European countries, like Kosovo, Croatia and Serbia.

For this Varietal Focus on Gamay Noir, it took some real searching to find producers. We were fortunate to find California Central Coast winemakers Scott Caraccioli and Chris Vita at Caraccioli Cellars, Tim Fulnecky of Mr. Brightside Wines and Jeremy Leffert from Tooth and Nail Winery. Farther north in Napa and Sonoma we invited Alexia Pellegrini from Pellegrini Wine Co., Chris Pittenger at Gros Ventre Cellars and Blair Guthrie from Guthrie Family Wines. We went to Oregon to bring in Jay Somers from Anne Amie Vineyard, Brad McLeroy from Ayres Vineyard and Matt Berson from Love and Squalor Wine.

winemaker for Croma Vera Wines and

Jeremy Leffert was hired as director of winemaking for Tooth and Nail Winery in 2015. Leffert went to college at the University of Vermont but followed his parents out to California upon graduation. He developed an interest in wine while working at Trader Joe’s and enrolled in the master’s program in Agriculture and Viticulture at Cal Poly San Luis Obispo. He spent five years, as winemaker, for Hearst Ranch Winery before taking over the reins at Tooth and Nail. Along with his duties at Tooth and Nail, he also works as consulting winemaker for Croma Vera Wines and Old Creek Ranch Winery, among others.

According to the winemaker:

“My stylistic goals are to create a vibrant and energetic Gamay with concentrated dark fruit and serious complexity. The main goal is to have volume on the mid-palate with elevated mouthfeel and texture supported by bright acidity. I’m looking for richness with a sense of weightlessness.

can. Typically, the first SO2 additions are made in April/May the following year. Our barrels are 100% neutral 228L French oak, and the wine rests there for eight months. We rack only to bottle. The wine is bottled unfiltered and sealed with DIAM 10 corks. We bottle-age for 60 days before release.”

“This Stasis Gamay Noir is a blend of two different vineyards: 86% from Rancho Real, AKA Murmur Vineyard, and 14% from Nolan Ranch Vineyard. Murmur Vineyard is lower in elevation, about 775 feet. Soil at Murmur Vineyard is 50% sand, 30% loam and 20% clay farther down the hill. Murmur is planted with 8x5 foot spacing while Nolan Ranch is 8x4 foot spacing. Both are on 1103P rootstock, which works well in the sandy soil but was chosen because it was the only one available. Both vineyards are planted with Clone 358. Murmur Vineyard is farmed organically (but not certified), and both vineyards are irrigated. Production is usually between three and four tons per acre.

“In caring for the vineyard, we do light tunneling for leafing and dropping fruit to alternate one cluster, then two clusters per shoot. Third clusters are always dropped. We generally make our picking decisions based on pH and flavor, looking for pH around 3.2 to 3.3 which results in a Brix range of 23 to 24.5, depending on the vintage. With Murmur I look for slightly underripe flavors because, if I wait for it to taste delicious, it has gone too far. With Nolan Ranch I can wait for flavors to develop and for the acid to drop a bit.

“Grapes are picked by hand, at night. All are destemmed, but no SO2 is added at the crusher. We use non-saccharomyces yeast for bio protection at the time of destemming. Grapes sit at ambient temperature of about 60°F for 24 hours, waiting for native yeast to begin fermentation. We added 240ppm Fermaid O at 1/3 Brix depletion. Wine is fermented in headless neutral 500L puncheons and one four-ton concrete tank. The puncheons hold 1,000 pounds of grapes each and get punched down once a day. They lend nice structure to the wine, along with good grip. The concrete tank takes longer to get going, usually five to six days, but both fermentations are quick, eight to nine days. High temps in puncheons are 80 to 82°F and about 75° in the concrete tank.

“We press when we are satisfied with color and structure, usually around dryness. Press juice is separated from free run. The wine gets pumped to a tank for settling where we inoculate for malolactic before racking to barrels. We want ML to finish quickly, and we hold off SO2 additions as long as we

Leffert: Aromatically, I get nice market berry fruit on the verge of being ripe, and I get cool savory notes, like white pepper and a sage component as well. On the palate it bursts with front end acidity that carries into nice dark red fruit on the mid-palate. It has a long finish and a nice frame to it. While there is no new oak, there is some minerality/reduction that I really like about Gamay.

How the other featured winemakers described the wine: Nice purity of fruit with black cherry on the nose, with earthiness and a bit of rusticity. Acidity upfront with prominent tannin, giving it that mineral center, so I’m surprised there is no whole cluster. The fruit rides nicely on the tannin. It has lovely sour cherry aromas with savory notes, like white pepper. On the palate, amazing acid upfront and dark red and blue fruit flavors. There is a long, soft silky tannin that is beautiful. Whole cluster aromatics of herbal red fruit. It shows bright acidity and red fruit. Big ripe nose with raspberries and fennel. Tobacco with firm tannin but still balanced. Higher tannins but still lush. Stem inclusion was necessary to balance the ripeness.

Arthur C. Clarke wrote: “Any sufficiently advanced technology is indistinguishable from magic.” Introducing StaVin Pure, Nature and Express Oak, untoasted and toasted liquid tannins made from three-year seasoned oak. An incredibly simple way to impart refined structure, mid-palate mouthfeel, and an elegantly extended finish to any wine. Achieve the benefits of fermenting on oak without the labor, wine loss, and difficulties. And prepare to reap an astonishing result. Magic? No. Alchemy? Yes.

2022 Zabala Vineyard Gamay Noir, 630 cases, $20

Tim Fulnecky started as a cellar worker in 2015, working with Andrew Jones of Field Recordings Wine. In 2016 he started his own Mr. Brightside Wines focused exclusively on Gamay Noir.

According to the winemaker:

“I am not so much trying to make a particular style of Gamay, instead, each year I try to represent the vintage these wines come from while still expressing the terroir and the varietal. Every vintage presents different chal lenges and opportunities. For us, 2022 was a very hot year, including a heat spike that lasted eight days with temperatures over 100°F. I watered heavily for the first five days and then stopped.

“Zabal Vineyard is Alluvial Granitic Sandy Loam with a fair amount of manganese. The elevation is 250 feet. Rows are planted with 4x8-foot spacings. We have two clones: 358 and 5, and both are planted on 1103P rootstock. The vineyard is irrigated. We are practicing organic but not certified. We average 3.75 tons per acre.

“The Arroyo Seco Valley is fairly arid and often windy, so leafing is kept to a minimum. We do a green drop usually a couple of weeks after veraison. Typically, I harvest more based on pH and flavor than sugar content. I am always looking for brown seeds that separate easily from pulp, good lignification in stems (because I ferment partially whole cluster) and developed flavors, lacking any bitterness or green flavors. I often wait for pH to rise, hopefully, up to 3.3.

“Grapes are hand-harvested into half-ton bins and sorted in the vineyard. No SO2 is used at crush. I ferment in one-ton open top fermenters, dumping the Clone 5 fruit whole cluster on the bottom of the bins and then destem whole berries of Clone 358 on top. I dig a hole in the destemmed fruit to access some juice and add dry ice daily. Once spontaneous fermentation begins, I foot-tread for the three days and then punch down once daily. No nutrients or acid were added. No cooling was used to control temperatures. The peak fermentation temperature was 82°F.

Fulnecky: Aromatically, it is like falling into a wild raspberry bush, along with brambly aromas. It has a stem character and white pepper as well. When it hits the palate, the fruit is darker, maybe overripe or cooked raspberry, then a very mineral mid-palate but a more tannic finish, due mostly to the more lignified stems I got with this vintage.

“This wine got 10 days’ maceration, and then both free run and press juice were pressed to a tank for 48 hours’ settling. From there it was racked to 100% neutral French oak barrels where native malolactic fermentation finished. Once ML finished, I added 45ppm SO2. The wine sat in barrels for nine months and was racked again for bottling with another 25ppm SO2 addition. It was crossflow-filtered, bottled using DIAM closures and received four months’ bottle aging before release.”

How the other featured winemakers described the wine: Mostly red fruit with nice savory notes. It is definitely on the riper end of the spectrum. I get red apple skin aromas. Driven with a candy note red fruit flavor. Bright red fruit also shows the spicy savory side of Gamay. I get dried herbs, thyme and a touch of oregano on the nose. Quite giving on the front, then savory and with the stem tannin structure on the finish. Good body and varietal character of red fruits and dried herbs.

® Things are changing, and fast. The old ways of doing things aren’t always the best ways anymore. Everyone knows barrel alternatives can save a winemaker big money with considerably less impact on the environment. StaVin barrel alternatives can actually help one to build a better wine, too. Our Barrel Fingerprinting Program utilizes nuanced combinations of oak concentrations, toast levels, micro-oxygenation and blending procedures. Finally offering unheard of mastery over wine.

2023 Escolle Vineyard Gamay Noir, 307 cases, $45

Chris Vita is the son of winemakers Greg and Diana Vita. He started working in various cellars with his parents. He thought it was a good career to pursue, so he got a degree in enology and viticulture at UC Davis. He is a wine maker and consultant, primarily in Monterey County. He attempts to balance science and tradition by using modern technologies to support traditional winemaking.

According to the winemaker:

“We want our Gamay to show an incredible purity and depth, as well as bright acidity and fruitiness. The wine must have heightened aromatics that are both intensely fresh and layered. We are looking to achieve some perfumed florality with juicy red fruit and a small component of earthiness from the stem inclusion. We want the wine to have moderate tannin and richness, but light enough to be accessible.

“Escolle Vineyard is comprised of Granitic Metamorphic Schist and soils of Chualar Sandy Loam and Alluvial Sandy Loam. The vineyard is farmed traditionally but uses mechanized weeding. Sitting at an eleva tion between 220 and 500 feet, vines are planted with 8x4 foot spacing. Rootstock is 1103P with 65% Clone 358 and 35% Clone 5. The vineyard is dry-farmed, and we use no herbicides. We perform a light leafing before veraison and often do three crop drops. Ideally, the crop is thinned to one cluster per shoot, which still gives us a yield of close to four tons per acre.

temperature is 85°F. We inoculate for malolactic at the end of fermentation while wine is on the skins. Then we press, separating free run from press juice. “Malolactic finishes in barrel. We use neutral French oak puncheons, and 41% of the blend went into a concrete egg for six months. Wine is racked and blended after malolactic and gets a total of seven months’ aging in the vessels. We rack again four weeks before bottling and then bottle unfiltered. We use Portacork Icon to seal the bottles and give the wine eight months bottle age before release.”

“Pick dates are determined off chemistry, flavor and historical data. With Gamay we look for a sugar right at 23° Brix with an acid around 8.0 g/l and a pH in the 3.3 range. We want the fruit to be ripe enough to give its full expression while still maintaining the signature freshness of the variety. We look for fruit flavors to transition from crunchy red to blue fruit, and we look for partially lignified stems.

“Fruit is hand-picked into FYV lug boxes at night and sorted. It gets sorted again at the winery, and we add 35ppm SO2 at that time. We have the luxury of taking in enough Gamay to separate lots into small two-ton fermentations. There is no formal cold soak, but there is a two- to three-day lag before the start of fermentation. We add no nutrients or acid, and fermentations are carried out with both native and Rhône 4600 yeast. One 600-gallon Olavin tank gets sealed with 95% whole cluster to ferment carbonically for three to four weeks before being pumped over until completion. We use dry ice and CO2 gas for 20 to 30 days then pump over daily for about five days.

“We use two two-ton Westec open-top tanks for the other fermentations. With Clone 358 we alternate lug boxes between whole cluster and destemmed fruit to get a good mix, finishing with 50% whole cluster. That gets pumped over once a day until dryness. Clone 5 gets fermented with 25% whole cluster, also with one pump-over daily until dryness. Maximum fermentation

Vita: Right upfront you get some bright cherry, red fruit notes and the stem inclusion adds a bit of an herbal component that we describe as like peanut butter, which I like. There is a nice concentration upfront, and I like the juiciness behind that. It is fresh and satisfying with a richness at the center of the wine. Then there is stem tannin on the back end that gives it some structure.

How the other featured winemakers described the wine: Darker black berry and raspberry aromas and a borderline mineral or saline component. In the mouth it explodes with black fruit and has a mineral line from start to finish, which complements the tannin beautifully. Very lifted with high tone dark red, raspberry aromas with a savory element, like pepper, thyme and bay. Red flavors with beautiful acidity. Love it. It’s a banger. I’d drink it all day. Plush texture with polished acidity. Sweet red fruits with a touch of herbs. Perfectly picked with bright fruit but with ripe character as well. I like the balance of fresh vibrancy. Well integrated at an early age. Bright cherry and raspberry with soft mouthfeel with slate character coming through.

Tooth and Nail Winery

Wine 2022 Stasis Gamay Noir

Case Production

Price

$25

Winemaker Jeremy Leffert

Style Goals

Vineyard

Vibrant, energetic Gamay with concentrated dark fruit, serious complexity and volume on the mid-palate. Rich with a sense of weightlessness

86% Murmur Vineyard, 14% Nolan Ranch Vineyard

Appellation Santa Barbara County

Clones Clone 358

Farming Methods

Harvest Practices

Winemaking Data

Organic(not certified); irrigated

Hand-picked at night

When to Pick pH around 3.2-3.3 and Brix 23°-24.5°; slightly underripe flavors

Sorting De-stemmed

SO2

Destemmed?

Cold Soak

Yeast

Fermentation

Temperature

None at crush

At 60° F for 24 hours

Non-Saccharomyces at destemming, native for fermentation

80°F to 82°F

Fermentation Technique Punch-down once daily

Press Regimen

Nutrients

Acid Addition

Caraccioli Cellars Mr. Brightside Wines

2023 Gamay Noir

$45

Chris Vita

Purity and depth, bright acidity and fruitiness. Moderate tannin, richness and light enough to be accessible.

Escolle Vineyard

Santa Lucia Highlands

65% Clone 358, 35% Clone 5

Conventional; dry-farmed; no herbicides

Hand-picked

23° Brix, 8 g/L acid, 3.3 pH; blue fruit and partially lignified stems

2022 Gamay Noir

$20

Tim Fulnecky

Not trying for a particular style, just to represent the vintage.

Zabala Vineyard

Arroyo Seco Valley

Clone 358, Clone 5

Organic (not certified); irrigated

Hand-picked and sorted

pH around 3.3 and flavor, brown seeds and good lignification of stems

In vineyard and again at winery At harvest

35 ppm

95% whole cluster

None, though 2-3 day lag before fermentation

Native, Rhone 4600

Max 85° F

Ferment carbonically for 3-4 weeks, then pump-over until finished

Press juice separated from free runFollowing ML, press and free run separated

240 ppm Fermaid

None

Malolactic Inoculate prior to racking

Oak Program 100% neutral 228L French oak

None

None

Inoculate while on skins

Neutral French oak puncheons, 41% of wine in concrete egg

None

Whole cluster for Clone 5, whole berries for Clone 358

10 days

Native

Max 82° F

Foot-tread for 3 days, then punch-down once daily

Straight to tank for 48 hours settling

None

None

Post-racking, in barrel

100% neutral French oak

Barrel-aging 8 months 7 months 9 months

Filtration Rack to bottle; unfiltered

Unfiltered

Closure DIAM 10 Portacork Icon

Bottle-aging 60 days 8 months

Cross-flow filtered

4 months

Guthrie Family Wines Gros Ventre Cellars Pellegrini Wine Co.

Wine 2023 Gamay Noir

Case Production

Price

$36

Winemaker Blair Guthrie

Style Goals Akin to Cru Beaujolais, with depth and structure. A more natural approach.

2021 Rancho Coda Gamay Noir2022 Gamay

$38

$40

Sarah and Chris Pittenger Alexia Pellegrini

Lighter wine that balances red, lifted fruit aromas with bright acid and crunchy tannins; Versatile and food-friendly.

Deep expression, rich, dark fruit and spicy with bright acid and light tannin.

Vineyard James Creek Vineyard Las Cimas (nee Rancho Coda Vineyard) Turner Vineyard

Appellation Sonoma Valley Sonoma Coast Knight's Valley

Clones Unknown Clone 358

Farming Methods

Harvest Practices

Winemaking Data

When to Pick

Sorting

SO2

Organically

Hand-picked at night

Acidity and intuition; rain forced pick this vintage

Hand-sorted

Destemmed? Whole-cluster

Unknown

Organically; drip-irrigation, no tillingSustainable; dry-farmed, no fungicides or herbicides

Hand-picked

Ripe, but not too ripe; between 21.5°23° Brix

Hand-sorted

Hand-picked at night

Drop in acid, brown seeds, blue fruit

Hand-sorted

50% destemmed; 50% 1/2 whole-cluster 100% destemmed

Cold Soak 5 days of carbonic fermentation3 days at 55-60° F 2 days at 55°F

Yeast Native Native Xpure

Fermentation Temperature High 70°s-low 80°s Max 82° F Max 84°F

Fermentation Technique

Press Regimen

Foot-stomped 5 days

Punch-down 1x daily at cold soak; 2x daily during fermentation

Combined to rack, then Poly EggAt 0° Brix direct to barrel

Nutrients None

Acid Addition None

Malolactic Native on lees

Fermaid O, DAP if needed

None

Inoculated

Oak Program Poly eggs 100% neutral French oak

Pump-over 1x daily; délestage at yeast add; pump-over every other day until negative Brix

Mazzola basket press direct to barrel

Fermaid O, DAP as needed

None

Inoculated

20-25% new French oak

Barrel-aging 10 months 9 months 10 months

Filtration Cross-flow

Unfiltered

Cross-flow and sterile-filtered Closure

Love and Squalor Anne Amie Ayres Vineyard

Wine 2022 Gamay Noir

Case Production

Price $25

2022 Gamay Noir

$35

2021 Gamay Noir

$28

Winemaker Matt Berson Jay Somers Brad McLeroy

Style Goals

Vineyard

Exude fresh red fruit with dark fruit undercurrent. Crunchy bright berry fruits with plenty of acid. Voluptuous and graceful.

40% Methven Vineyard, 30% Sunnyside Vineyard, 30% Jubilee Vineyard

Balance, an Old World-style that emphasizes focus, length and balance.

Cerise Vineyard

Same as Pinot Noir. Raspberry and Cranberry aromas,bright with medium body and soft tannins.

Palimpest Vineyard

Appellation Eola-Amity Hills and Willamette Valley Willamette Valley Chehalem Mountains

Clones Unknown Clone 358 Clone 282

Farming Methods

Harvest Practices

Winemaking Data

Dry-farmed

Hand-picked at night

When to Pick Soft berry flavors, some lignification of stems

Sorting

Organic (not certified); dryfarmed

Hand-picked

Taste and pH, with no astringency and good acid

Field-sorted N/A

LIVE-certified; dry-farmed

Hand-picked

Dried herb character, brown seeds

Field-sorted with additional sort at winery SO2 None

Destemmed? Whole cluster 100% destemmed 100% destemmed

Cold Soak 14 days carbonic macerationNatural

None

Yeast Native Natural Native

Fermentation

Temperature Unknown

Fermentation Technique

Max 88°- 90°F

Pump-over if ferment slow to startPigéage at start; punch-down no more than 1x daily

Press Regimen Full delestage and press at half-dryness Gentle press to tank

Nutrients None None

Acid Addition None None

Malolactic In barrel Native, in barrel

Unknown

Pump-over daily

Pressed back to a fermenter

Fermaid O in early ferment

None

N/A

Oak Program 100% neutral French oak 100% older French oak 100% neutral French barrels

Barrel-aging

Filtration Unfiltered Cross-flow Unfiltered

Closure Natural cork CWINE agglomerated corkScrew cap

Bottle-aging

Born in Christchurch, New Zealand, Blair Guthrie has a degree in enology and viticulture. Starting as a harvest intern with BK Wines in Australia, he then moved to California and worked for Paul Hobbs Winery. He spent three years as assistant winemaker for Kunde Family Wines in Sonoma before taking over as winemaker for Stewart Cellars in Napa Valley. Guthrie started Guthrie Family Wines with his wife Caroline to get more involved with eclectic grape varieties.

According to the winemaker:

“In general, we opt for a more natural approach to winemaking, forgoing the addition of grape concentrates or synthetic chemicals. Instead, we use minimal ingre dients with native whole cluster fermen tation of the sugars and acids and add no more than homeopathic amounts of sulfur and tartaric acid.

“With our Gamay Noir, I was looking to make a style more akin to Cru Beau jolais. I used carbonic maceration, foottreading and blended in 5% Carignan to give more depth and structure. This Gamay came from James Creek Vineyard in Sonoma Valley. The vines were six years old and were being sold as Pinot Noir. Once they realized it was actually Gamay, I was able to buy some. The vineyard is Raynor clay and mixed volcanic soil at an elevation of 700 feet. The vine spacing is 6x8 feet, but both the clone and rootstock are unknown. Vines are cane-pruned with no weeding. We pulled leaves toward the end for exposure and dropped fruit. Grapes are farmed organically, and yield is three to four tons per acre.

“I pick based primarily on acidity and intuition. These grapes had some virus, so I waited for development but was forced to pick before it rained. Grapes were hand-picked at night. They were hand-sorted and whole cluster-fermented in 1.7-ton bins after adding 30ppm SO2 We added neither nutrients nor acid. We added CO2 during five days of carbonic fermentation, and then we foot-stomped for another five days. Juice fermented with native yeast in a warm room with temperatures in the high 70s to low 80s. At that point we pressed the skins, combining free run and press juice. After settling for 24 hours, juice was racked to Poly eggs, which breathe like a barrel but churn the fermentation like concrete eggs. All the suspended solids help the fermentation finish.

“The wine finishes fermentation and undergoes native malolactic on lees in the Poly eggs. Once the wine is dry and ML has finished, I add

SO2. The wine sits on the lees, with no stirring for 10 months. I crossflow-filter for safety because I am in a custom crush facility. Bottles are sealed with DIAM corks and aged three months before release.”

Guthrie: I get traditional raspberry, strawberry and rose petal push, probably from the carbonic fermentation. It is pretty on the nose with bright red cherry. On the palate, there are a lot of earth tones, and I love that forest floor character you get from Gamay. Nice gravelly tannins, not too silky. Gamay can be so easy to drink; I think those rocky tannins help make it more interesting.

How the other featured winemakers described the wine: Some good slight reduction, vibrant palate with crunchy finish adds structure and backbone to what is a very pretty wine. Great acid with grip and awesome energy. Beautiful aromatically with floral notes, bit of stem character. Begins very crunchy on the palate. It is a fresh, young, vibrant wine. It has an ethereal character and vibrancy. Vibrant and driven by dark fruit with a beautiful natural sweetness and serious structure on the back. Nice clarity and purity of aroma. Fresh fruit with stemmy slightly green component. Very juicy and still light. The nose matches the palate. Lots of whole cluster character and green character. Ripe enough to lose some varietal character. We’ve been tasting a darker profile but different from others. Showing some sweetness in the mouth with mostly raspberry and pomegranate flavors.

2021 Rancho Coda Gamay Noir, 63 cases, $38

Sarah and Chris Pittenger founded their Gros Ventre Winery in 2009. Chris has loads of winemaking experience, having worked in Napa, Australia, Sonoma and New Zealand. He learned the craft at wineries like Robert Biale, Torbreck, Williams Selyem and Marcassin. They spent several years in Placerville (where Chris was founding winemaker at Skinner Vineyards) and fell in love with the high elevation vineyards there. They now live with their two children in Healdsburg, Calif., where Chris is also the winemaker at Limerick Lane Cellars.

According to the winemaker:

‘With all my Gamays I am looking for a lighter-styled wine that balances red lifted fruit aromas, bright acidity and crunchy tannins. I want the wine to be versatile and food-friendly and to show well when served slightly chilled. This 2021 Gamay has a deeper, denser quality, but it is still fresh and lively.

“The grapes come from Rancho Coda Vineyard (now called Las Cimas). The soils are Yorkville and Sutter Series: chlorite and sandstone schist with chunks of quartz. Elevation is 750 to 950 feet with an east facing aspect. Vine spacing is 5x8 feet. Vines were grafted to Clone 358 and are on 101-15 rootstock. The vineyard has drip irrigation and is farmed organically with no tilling; [there are] cover crops, hedgerows for beneficial insectaries and sheep grazing every few years. The vines have small clusters; the soils promote self-regulation, keeping production to 2 to 2.5 tons per acre.

“I decide when to pick by looking for ripe flavors but not too ripe. Usually, I pick between 21.5 to 23° Brix and get by with natural acidity. The grapes are hand-harvested at night and passed over a sorting table. I add 20 to 25ppm SO2 at harvest and maintain that level post-ML until bottling. One bin is 100% destemmed; for the other I sandwich 50% whole cluster between the destemmed fruit to retain the carbonic quality. The grapes get a three-day cold soak at 55 to 60°F and, after five days, are warm enough for native yeast to start fermentation. I never add acid but will add Fermaid O and DAP, if needed, to maintain a healthy ferment.

“Wine ferments in Macro S bins. I punch down once daily during cold soak and at the end of fermentation, then twice daily during peak fermentation. Temperatures are typically in the upper 70s, topping out at 82°F. I press at 0° Brix directly to barrel and separate free run from press juice. I inoculate with malolactic because I want it to finish quickly so I can get SO2 into it for protection. I use 100% neutral French oak barrels. I age in barrels for nine months and rack only for bottling. Wine is unfiltered and sealed with natural cork. It is bottle-aged six months before release.”

Pittenger: Red fruit is mellowing and softening on the palate. The acidity is still prevalent, but wine has transitioned into a more polished mouthfeel with the additional year in the bottle. There is some nice mushroom and forest floor, along with darker cherry notes. The structure has softened into a mouth-watering finish. It is one of my darker, most extracted Gamays which I attribute to the vintage.

How the other featured winemakers described the wine: Bright, cherry aromatic notes. Gorgeous texture with flavors of red fruit and baking spice. Maybe a touch of new oak on this. Enjoyable red fruit sweetness. Round and soft and fills up the palate. Baker’s chocolate and heavy red fruit on aromatics, reminds me of Seguin Moreau barrels but really enjoyable. I appreciate the body and grip of the tannins. I see the stem influence of the tannins. Orange rind, marzipan with gravelly tannins. Full-bodied, lush with earth tones and Christmas cake with delicious acidity. A little closed on the nose, opening up to red fruits and herbs.

With the Flavy X-Treme, you can effortlessly filter your wines, juice lees during vintage, and effectively manage fermentation and fining lees throughout the year. This all-in-1 system guarantees the preservation of quality while delivering added value by recovering additional wine juice at each stage of production, ultimately optimizing your return on investment.

Discover the efficiency and reliability of the Flavy X-Treme today. Contact us to schedule a demonstration.

Contact Bucher Vaslin North America

bvna@buchervaslin.com (707) 823-2883

bvnorthamerica.com/filtration-ro

Alexia Pellegrini is a fourth-generation vintner. Her family has produced Sonoma County wine and grapes since 1925. They also imported French and Italian wines. Alexia says she comes from a long line of bootleggers. Her first harvest internship was at Penfolds in 2000. She has worked in all phases of the business, since then, earning an MBA in wine business at Sonoma University in 2017. She took up the reins general manager of Pellegrini-Olivet Lane Winery and Vineyard that same year. According to the winemaker:

“In Gamay we are looking for deep expression,rich,dark-fruitedandspicywinewith bright acid and light tannin. My family imported Beaujolais for some years. I fell in love with a specific small winery inSaint-Amourthatusedasubmerged cap fermentation to achieve juiciness withsoftertannins.Whenwefounda supply of Gamay Noir, we decided to use submerged cap as well.

“ The Turner Vineyard is in Knight’s Valley and has Red Hill clay loam soil. The elevation is 500 feet. Rows are planted to 6x6-foot spacings on St. George rootstock. The clone is unknown. The vineyard is old vines, dry-farmed and sustainable with no fungicides or herbicides. Production is two tons per acre. Inner canopy leaves are pulled, before bunch closure, to avoid unnecessary sprays. Before calling the pick, we look for a drop in acid down to approachable levels, seed browning and a change in fruit profile from reds to blue. Grapes are hand-picked at night into barred micro bins and delivered to our winery by 7 a.m. Grapes are handsorted and 100% destemmed, adding 30ppm SO2 at the destemmer. We cold soak for two days at 55°F. We inoculate with Xpure yeast and wait for the cap to rise before installing the submergible cap rack at the best depth for holding the skins below the fermenting juice. A couple days after yeast add, we add Fermaid O and DAP as needed. Typically, no acid is needed.

“We pump-over once a day until the cap rises, délestage at yeast add and pump over every other day until negative Brix. Fermentation temp peaks at 84°F. Wine is negative Brix within 12 days. We press skins via a Mazzola basket press and barrel down directly the from fermenter without settling for additional sur lie impact.

“Malolactic finishes in barrel, usually by mid-December. We use a mix of Mallard, Nadalie and Claude Gillet French oak barrels with 20 to 25% new

oak. Gamay loves to show oak and punishes those who overdo it. Learning how much and which kind of oak to use is paramount. We use barrels that show acid, tension and red fruit to ensure the wine doesn’t become brooding. We barrel-age for 10 months, stirring the lees twice a month, until January, to help finish ML. The only racking occurs two weeks before bottling. The wine iscrossflow-andsterile-filtered.TheclosureisTCA-freenatural cork, and the wine is bottle-aged for three to six months before release”

Pellegrini: This is the ripest vintage we have made from this vineyard. Eff ects of the submerged cap come through with the brambly cherry aromas with cinnamon and black pepper. Less breaking of the skins throughout fermenta-tion makes for an exceptionally soft texture upon the palate, which reminds me of the Saint-Amour Beaujolais; that was my goal.

How the other featured winemakers described the wine: I get baked lemon, orange and cherry that caramelizes when you bake it in the oven. It is full, plush with a broader palate but still retains the nice gravelly tannins that keep it textured. A dead ringer for old vine Zinfandel on the nose and palate. Great purity of fruit. Juicy and concentrated. This smells like grapes. Really enjoyable wine but not typically Gamay. Good acid with soft structure. I get those Christmas baking spices but with a very polished mouthfeel. Really pleasurable wine with well-managed oak. Red fruits with a touch of herbs.

CRIVELLER GROUP

The Multi-Purpose Automatic Crossflow Lees Filter is engineered to meet the evolving needs of winemakers worldwide. It boasts key innovations including:

Stainless Steel Membrane(s)

High Solids Handling Capabilities

Exceptional Flow Rates

Filter Wine and Juice With Presence of Clarifying Agents

Eliminate The Usage of Filtration Aids Such As Perlite or D.E. Powder

Juice and Decanted Juice Lees

Lees from Treatment with Bentonite, Carbon,

Spirits RECOVER MONEY FROM YOUR LEES

Gelatin, and Other Clarifying Agents

Barreling Down

Flotation Lees

Wine and Hard Cider

Matt Berson worked in the restaurant business in San Francisco until he met a bunch of Oregon winemakers in 2003 where he worked a harvest. He traveled to New Zealand, Germany, Argentina and Napa Valley to learn about grape growing and winemaking. By 2006 he made a small batch of wine to sell and needed a name. Reading J.D. Salinger, he picked Love and Squalor as the name for his winery. In 2019 he moved into his new winemaking facility, Portland Wine Company Winery.

According to the winemaker:

“For me, aromatics are super important. It’s what draws you into a wine. I want my Gamay to exude fresh red fruit with an undercurrent of dark fruit. We want crunchy, bright berry fruits on the front palate with plenty of acid to keep it fresh and salivating. We don’t want it to get too dried out or heavy on the finish. We want something voluptuous and graceful.

“This wine is made from three distinct vineyards: 40% Methven Vineyard, EolaAmity Hills, 30% Sunnyside Vineyard, East Salem, Willamette Valley and 30% Jubilee Vineyard, Eola-Amity Hills. The three vineyards share

and sit at elevations between 400 and 600 feet. There are various rootstocks and clones, and they are unknown. The vineyards are all dry farmed. We drop fruit as needed and pull morning side leaves to bring in sunlight and air flow. Production is two to three tons per acre.

“I try to pick when the grapes taste good. That means the cutting acid softens and the green flavors of peach and banana soften into berry aromas and flavors. Gamay ripens late, so we look for some lignification of stems, and we are willing to let the fruit hang a bit for the late ripening bunches to

“Grapes are field sorted on the vine before picking into half-ton macro at the crush pad. Grapes go whole cluster directly into 1.5-ton open top fermenters. The fermenters are covered airtight and dosed for carbonic maceration. After 14 days, we unwrap the fermenters and stomp on the caps to allow the start of regular fermentation. We pump over if the ferment is slow to start. We do a full délestage and pressing when half dry. The wine finishes fermenting in a tank until it is dry. From there it is transferred to neutral French oak barriques and undergoes

natural malolactic. Élevage is 10 to 11 months. Post-malolactic, we add 50ppm SO2 and then adjust, as needed, in barrel. Wine is bottled unfiltered at 15ppm free. The wine was sealed with natural Amorim cork and aged one month before release.”

Berson: Cherry and blackberry aromas with hints of orange peel. The citrus notes persist on the palate, along with berries and dried herbs. There is some black pepper on the long light finish.

How the other featured winemakers described the wine: Bright and juicy with Gamay character of red fruit and herbs. There is some baking spice, clove and cinnamon in the nose, along with riper strawberry fruit and some savory notes. It lifted with red fruit and some VA. There is crunch on the palate, but it resolves into one note and ends abruptly. Some VA lift on the nose with one-dimensional red fruit. It has the ripest nose and darkest fruit. Supple mouthfeel but with less acid. This has a natural wine profile with VA prominent. Nice nose, ripe character and some mint. Lacks a little varietal character.

Jay Somers is a native Oregonian who has been making wine in the Willamette Valley for more than 30 years. He has worked with his mentor, John Paul, of Cameron Winery and spent time at Adelsheim in Oregon and Dry River in New Zealand. With his wife Ronda, he established the J. Christopher brand in 1996. He also works as director of winemaking at Anne Amie Vineyards in the Yamhill Carlton AVA.

According to the winemaker:

“The only goal in all my wines is to achieve balance between all the elements of the finished wine. I try to produce wines in an Old-World style that emphasizes focus, length and balance. In short, wines that are complete. I try to be patient, to not rush things and allow the wines to develop naturally at their own pace with minimum intervention. I tend to focus on pH, as it relates to acidity, because I appreciate a long finish that invites another sip more than a dramatic mid-palate sensation.

“The Cerise Vineyard soils are Loess over Basalt. The vineyard sits at 560 feet, and vine spacing is 5x8 feet. Clone 358 has been grafted onto Riparia Gloire rootstock, and the organic (but not certified) vineyard is dry farmed. On the Gamay we thin clusters so none are touching, remove wings and pull leaves on the east side of the canopy. The yield averages 3.5 tons per acre.

“The pick decision is based on taste and pH. I want green character and astringency to lessen and give way to some fruit character while still maintaining good acidity. I need that acidity to achieve the finish structure I want for the wine. Grapes are handpicked and 100% destemmed. We add 50ppm SO2 at the destemmer and another 44ppm post-malolactic, shooting for 25ppm free at bottling. We do a natural cold soak, waiting for native yeast to begin fermentation. We added neither nutrient nor acid to this wine. We add no enzymes, tannins or other weird things. The wine fermented in two- and three-ton open-top stainless-steel fermenters. We pigéage when fermentation begins and then punch down no more than one time a day. After that, the wine tells us what it needs. It is not a recipe, so some days we’ll skip punching down altogether. Fermentation temperature tops out at 88 to 90°F.

“As the wine goes dry, we wait for the cap to relax but not sink. This small amount of extra time on the skins helps prevent reductive issues. Wine gets gently pressed to a tank where it settles overnight before getting racked to 100% older French barrels. We combine free run and press fractions. It undergoes native malolactic in barrel. Early in its time in barrel, we stir the lees once to get some air into the wine; then it ages in barrel for 10 months before

getting racked for bottling. We crossflow-filter. The wine closure is CWINE agglomerated cork, and the wine rests in bottle for six months before release.”

Somers: Aromas of earth, raspberry, black tea, potting soil, tobacco, violets and blueberry. On the palate it is medium-bodied with balanced mid-texture. Flavors tend to black currant, tart blackberry, coffee, and cocoa nibs and fruit. The finish is long and acid driven.

How the other featured winemakers described the wine: This is a beautiful, hedonistic wine with rose petals and brambly dark fruit and lots of extraction. There is some brambly reduction and complex Gamay herbal notes. There is good palate structure, density and texture. Floral with ripe fruit. It is extracted with heavier weight and richness. A lot of tertiary characters on the nose. Seems like it went through a heat wave. Lacks some varietal character. Most balanced of the trio with nice palate feel with nice fruit tannins. Elegant and complex, but more like an elegant Pinot Noir. Shows darker fruits with spice and a hint of dried leather.

2021 Gamay Noir, 200 cases, $28

Brad McLeroy owned a wine shop in Kansas City, Missouri. Upon his arrival in Oregon, he sold wine for a small distributor and honed his winemaking skills at the famed Domaine Drouhin Oregon, where he worked harvest from 2000 through 2006, serving as the cellar master for the last three years. In 2006 he took on the full-time winemaker position at Ayres Vineyards.

According to the winemaker:

“For the most part, I make Gamay the same way I make Pinot Noir. While Pinot Noir shows an elegant bent, Gamay has a bit of ‘wild child’ about it. I like rasp berry and cranberry aromas accompanied by dry herbs, like thyme, tobacco and anise. I want the wine to be bright with medium body and soft tannins.

“Palimpest Vineyard is made up of Marine Sedimentary soils. The elevation is 350 feet, and the row spacings are 4x8 feet. Vines are Clone 282 on 3309 rootstock and are dry farmed, using traditional methods, no herbicides or pesticides. We are LIVE-certified. Our Gamay is late ripening and usually the last fruit we bring into the winery. We fruit drop near veraison and pull leaves to enhance air flow through the vines. Even at our usual 3.5 tons per acre, the grapes maintain acid good. I want the flavors to develop away from green to a drier herb char acter. I wait for brown seeds but don’t concern myself with stem lignification because I am not doing any whole cluster fermentation.

“Grapes are picked into five-gallon buckets and dumped into micro bins. There is some field sorting of bunches and more sorting at the winery. Everything gets destemmed and receives 50ppm SO2. We ferment in open top micro bins with native yeast. There is no cold soak, but it takes a few days for fermentation to begin. I add Fermaid O early in the ferment to ensure healthy yeast and a completed fermentation. No acid is needed. I pump over daily to oxygenate the wine and keep the yeast healthy, but I also punch down the cap once a day which I think gives me better structure.

McLeroy: Accompanied by vibrant floral notes of violets, this wine features a harmonious blend of red raspberry, anise, leather, and white pepper. Its luscious and ripe character is complemented by a natural acidity that enhances its overall balance.

“I wait for the wine to go dry and then allow it to sit on the skins for about a week. From there it is pressed back to a fermenter, with press and free run juice being combined. It settles for three to five days before getting racked to barrel. I use all neutral French oak barrels. The wine ages for 10 months. It gets one racking for bottling with no filtration. We seal with screw caps and try to get three months bottle age before release.”

How the other featured winemakers described the wine: Older wine, with a nice dusty character and a good balance between freshness and density. Super soft and granular tannins at the finish that’s enjoyable. A bit confusing whether nose is from extra age or time in barrels, but really beautiful with dark, rich fruit and plum. Red fruit driven. Big structure on palate with drying tannins, but I like it. Seems like oak influence on nose but could be age. Love the acidity but ripe. I like the high acidity but also get some oak character. It is dark and rich with earthy notes and a darker fruit profile. Blueberry Pop-Tart is what comes to mind. Vanilla character as well. Spot on.

Gamay Noir, as a variety, is a winemaker’s dream. First, there isn’t much of it around, so you must look for it or plant it yourself; it’s always an adventure. It is prolific in the vineyard and delivers high-quality fruit even at three to four tons per acre. Keeping the crop size within reason almost guarantees that you can make good wine. It hangs onto its acid naturally and rarely is plagued with astringent tannins.

It allows winemakers a wide variety of approaches. You can use whole cluster, destem and ferment, run carbonic maceration, submerged cap, or mix and match anything that strikes your fancy. The winemakers in this varietal focus tried all of the above and more. Generally, it ferments clean without acid additions. You can make a serious wine and still have fun at the same time.

Gamays almost always have great color. Most often they have red fruit flavors, like sour cherry, raspberry, currants, red plums and strawberries. They also have flavors of violets, rose petals, white pepper and a distinct minerality and earthy character. Because of the high natural acidity, there is a long thread of bright fruit flavor on the tongue, mid-palate and well into the finish. That acidity, paired with low tannin, makes Gamay the perfect wine for almost any food.

It’s fun to make and a delight to drink, yet for some reason it doesn’t get the respect it deserves. That could be due to decades of mediocre Beaujolais Nouveau, flooding cafés every November. It could be centuries of royalty that declared Gamay a poor cousin to Pinot Noir. Whatever the cause, discovering

true Gamay is a delight for any wine lover. Tasting your way, through the 10 communes of Cru Beaujolais, is enlightening and educational. Comparing iterations of the grape from Oregon, Canada, California or Australia presents variations anchored in the French version of the grape. Gamay presents the perfect wine pairing for virtually any food; and because it doesn’t get proper respect, you can still get bottles that will charm your wallet, as well as your palate. WBM.

seguinmoreaunapa.com

THE NUMBER OF WINERIES producing sparkling wines in the United States has risen dramatically since 2019 (TABLE 1 )—there are now over 1,000 wineries in 30 states that produce sparkling wines, according to the WineBusiness Analytics Database.

The expansion of the sparkling wine sector over the last several years has been driven by two factors. First, the rise in interest and sales from the end consumer. On the production side, the pinpoint carbonator has opened the door to more wineries because it can increase the quality of the direct carbonation of wine without the significant cost of other expensive pieces of production equipment. Mobile bottling companies that offer counter pressure filling lines can come to a winery with pinpoint carbonators and fill, in real-time, a sparkling wine into a bottle.

It’s been several years since the last report on the status of sparkling wine equipment for producing method traditionnelle sparkling wines (formerly Methode Champenoise, which is now used only for sparkling wines in certain regions of France) appeared in WineBusiness Monthly. This article will explore new information on the long-term aging of sparkling wines and the impact of expensive upfront costs for production of those wines, as well as review relevant material from two prior WBM articles on sparkling equipment.

In the December 2013 issue, Patricia Howe wrote an extensive article titled “Product Review: Specialized Sparkling Wine Equipment for Small Production.”1 Six years later, the November 2019 issue included an article by Jim Gordon2 that focused on mobile packaging systems, along with updates on other aspects of sparkling wine production.

There are three types of sparkling wine: methode traditionnelle, the Charmat process, and carbonation. The carbonation process uses either a bright tank or an inline carbonator that injects carbon dioxide that dissolves into the wine in a way that is similar to the production of canned sodas.

It may seem to be a simple trivial process to infuse CO2 into wine, but it has significant tax consequences. Because of the difficulty of producing sparkling wine, in the past it was only the wealthy who could afford to make the wine. Consequently, taxes were levied on sparkling wine. Today, it is not difficult to inject CO2 into wine, so tax agencies now stipulate how much

is OK to have in wine with no additional taxes, as well as how much to tax the CO2 above that level. It is difficult to remove all CO2 after fermentation and, in some cases, a small amount can act as an acidulant. Therefore, any way of introducing or leaving carbon dioxide from fermentation in a wine above what is known as one volume of CO2 (or 0.392g/100 ml), is taxed at the luxury rate of $3.40 per gallon.

There are several important decisions winemakers must make when deciding what type of sparkling wine to produce and how willing they are to invest in that process. Much of what follows this brief discussion and explanation of sparkling wine production was eloquently written by Patrica Howe in her 2013 article and really cannot be distilled into simpler or different terms than her original publication. For purposes of convenience and clarity, much is reprinted here because it is not out of date. Most of the manufacturers making this equipment come from Europe and have various distribution companies in the United States (SEE DIRECTORY ).

For many winemakers, producing sparkling wine will be a labor of love, especially if starting from scratch. Reaching for the luxury level can take generations. The reason has to do with texture of the sparkling wine and the flavor development when in yeast lees contact for years before releasing. One has to have the ability to invest in that time before revenue comes in. It is for that reason the starting point here is to begin with the sparkling wine process with the shortest time from jumping into the sparkling pool and creating a final product.

In its various configurations, this method will get a winery into the sparkling wine production business with the least capital. Fortunately for this part of the business, one can be reasonably close to the traditional method of making the wine with one critical purchase: an inline carbonator. This is not a soda

The Best Wine Deserves the Best Bottles

You always know where your grapes come from. With Gallo Glass, you will always know where your bottles come from. Our glass is sourced and manufactured exclusively in California, by our skilled local workforce. Gallo Glass has a broad and reliable selection of bottles to meet your needs. We can’t wait to partner with you.

MODESTO, CA | GALLOGLASS.com

Speak with a team member today | 209-341-4527 (GLAS)

pop carbonator, but one with precise technology for dissolving the CO2 into the wine. These pinpoint carbonators are not inexpensive for the best ones ($5,000/$10,000) from companies such as GW Kent, Pentair and Wittemann.

The pinpoint carbonator infuses CO2 into the wine that mimics in the bottle fermentation and produces a mousse that has the crémant of in the bottle fermentation. It still requires bright tanks and the associated refrigeration requirements for Charmat production, but not the time for the CO2 to integrate into the wine. With this type of entry, once the wine is ready, a mobile bottler can come to the facility to bottle using a counter-pressure filling bottling line.

Within this sector of direct carbonation, another way is to use the bright tank as the carbonation vessel and gradually infuse the CO2 into the wine using the sintered stainless-steel stones. Because volumes are large and time is not on the side of cost savings, this type of carbonation is usually much more coarse than pinpoint carbonation. Other wineries may take the time for the Charmat process and also can be close to the traditional method by holding the wine under pressure for longer periods of time.

In the Charmat process, a winemaker creates the same base wine for the style selected. After primary fermentation, the wine is placed in a bright tank where the secondary fermentation can occur. In this scenario, one can handle the wines in much the same way as the traditional method, without the difficulties of disgorgement equipment, fill levelers, etc. that are needed during the conversion from aging to finishing and bottling. A winery can certainly take advantage of mobile bottling equipment as well.

However, both paths have the advantage of enlisting a mobile bottler that has all the intricate equipment that is described below for transposing a carbonated beverage into a bottle. Even with the simplest counter-pressure filler, such as the one from GAI that starts at about $250,000 and produces slightly more than 1,000 bottles per hour, the winery still needs to have wire hooders and foil crimpers, etc. to handle packaging.

There are four stages for sparkling wine production using the traditional method that necessitated many pieces of specialized equipment.

“The production of base wines and their ‘tirage’ bottling with sugar, yeast and fining agents or additives requires simple winemaking equipment; the most challenging aspect is the biduling and crowning of the special bottles. Most wineries can use their existing bottling equipment by buying the change parts for lines to fill the size bottles for this primary bottling but need some way to seal them. This “tirage” bottling is traditionally done in the early spring following harvest.”

Assembling the “tirage” has two parts:

Primary Fermentation

• Fermentation of traditionally low alcohol, low tannin, high acid still wines (“base wines”).

• Blending and stabilizing the base wines for sparkling wine production. “Tirage” Bottle Filling

• Mixing blending base wines, sugar, yeast and adjuvants.

• Transferring into special sparkling wine bottles.

• Sealing the bottle with bidules (small plastic caps filled with the second fermentation yeast) and crown caps.

“The fermenting, aging and riddling of sparkling wines can range from just a few months for fast turnover wines to many years for special, extended yeast contact wines. True autolysis of the yeast and the resulting complex chemical reactions begin at about 18 months of yeast contact. There are no regulations for American wines on minimum aging times.”

“Aging” in two parts:

Second Fermenting

• Secondary fermentation in the bottle (three to 12 weeks) Aging

• Aging on the yeast lees (6 months to more than 8 years) on the bottle’s side

• Typical times of 11months to 2 years for standard, three years for reserve, five years for special wines

Riddling

• Riddling the spent yeast sediment into the neck of the bottle (four to 40 days)

• Further aging on the bottle’s “point”

The final bottling process of “disgorging” involves multiple steps, all done in immediate succession. This process is unique and thus requires much specialized equipment.

Euro-Machines offers an all-encompassing range of equipment for sparkling wine production from top suppliers in the industry: TDD Grilliat, Petitdemange, SAS Chayoux and Stevial. With machines for riddling, neck freezing, disgorging, corking and bottle washing, we can meet the manual, semi-automatic and fully automated needs of any size winery.

Harvest is on the horizon. You need tanks and you need them now, but compromising on quality to get them fast is not how great wines are made.

We’re ready. Our Letina stainless tanks – jacketed, single wall, variable, you name it –are built in Europe and in stock in our Pacific Northwest warehouse, ready to ship.

Want more info? Call us today, or

Post-disgorging, dosing and restoring the volume to the correct fill level can be challenging: due to sparkling wine’s nature, it has a tendency to foam, bubble, and gush, resulting in loss of product.

“Disgorging” Bottling in six parts:

• Disgorging: Removal of yeast lees and crown caps/bidules

• Dosing: Addition of sweetening syrup (and SO2 or other additives)

• Fill leveling: Adjusting liquid level/volume in the bottle

• Corking: Sealing of a bottle with traditional sparkling cork

• Wiring: Securing the cork to the bottle with wire hood

• Mixing: Agitating the sealed bottle to integrate the syrup

The process of “Dressing” the finished wine bottle can take place immediately after disgorging or can be done as a separate process on days, weeks or several months later. It is not typical to wash a still wine bottle, and the special foil capsule requires a unique applicator. The labeling process may be identical to standard still wine equipment, assuming the machine can handle the bottle shape and size.

“Dressing” in three parts:

• Washing: Washing the exterior of the bottle

• Pleating and crimping: Applying the traditional foil capsule

• Labeling: Labeling

A rapidly produced and minimally aged, traditionally produced sparkling wine could be released within a year of harvest, but it will show little, if any, typical yeast autolysis characteristics and would more likely be a fresh and fruity style. Autolysis characteristics take about 11 months to 2 years of yeast contact, and it would take effort to get a wine with this minimum age out for the end-of-the-year holiday season two years after harvest. Many reserve style wines age for three to five years and will not be on the market until at least four years past the harvest year.

It is obvious that the scale of production decides the equipment necessary to fulfill the tasks of producing the final product. Sparkling wine production is not different, with an exception due to the variety of ways the complex processes need to be coordinated to produce the wine, and the intricate process steps the equipment must perform to achieve the final product. However, starting with the fermentation of the base wine, there is not much difference in the tasks at hand. Only the selection of the base wine is different

from still wine production, as sparkling wine base wines are low in sugar, high in acid and picked earlier than the more traditional types of wines.

Patricia Howe’s description of production scale is apt here: “For the purposes of the article, we will define small scale equipment as that which is appropriate for annual production from dozens to several thousands of cases of finished wine per year. Small-scale equipment corresponds to speeds of up to a maximum of 20 bottles per minute (bpm) or 1,200 bottles per hour (bph). Manual equipment uses human power alone; semi-automatic equipment uses either electric or pneumatic power for some parts of the operation; and automatic equipment can complete the whole process without human hands, including getting the bottle in and out of the machine. At very small scales, it is sometimes difficult to decide if a piece of equipment is fully manual or semi-automatic, and different manufacturers can use different definitions, which are subject to interpretation.”

“The combination of process and package results in types of equipment that are not needed for still winemaking but are needed for producing a bottle-fermented sparkling wine. These items can be grouped by the process into 13 specialized areas: biduling, crown capping, riddling, bottle freezing, disgorging, dosing, fill leveling, corking, wire hooding, mixing, washing, foil pleating and foil crimping. Many small-scale pieces of equipment do one, two or even three of these processes.”

“Biduling and crown capping are the steps used to seal the base wine, yeast, sugar and adjuvants into the bottle and are part of the primary ‘tirage’ bottling. The most basic versions of these processes involve fully manual operations. Placing a bidule in the neck of the bottle by hand and pushing it in with a rubber mallet then using a hand crown capper, such as the Grifo Manual Crown Capper “Supergrifo” TCSG, is the most manual approach. However, the realistic volume considerations and the inability to control the quality of the seal of the crown cap may become tiresome. Although many manufacturers produce low volume crown cappers, there are few automatic bidulers (such as the Espace Valentin BC Franval semi-automatic biduler with crown capper monoblock) available at low bottles per minute rates. The M.E.P. C500 crown capper is another small capping option and is typical of small benchtop pneumatic style cappers. The larger O.M.B.F. Mod. 2008S-TC/1 semi-automatic crowner for crown corks has a small magazine for the caps.”

WWW.BOUCHARDCOOPERAGES.COM sales@bouchardcooperages.com / (707) 257-3582

“Traditional riddling is done by setting bottles into angled wooden support racks (‘riddling racks’ or ‘pupitres’) and turning and bumping the bottles to encourage the yeast sediment to eventually end up in the neck of the bottle (inside the bidule, if one is present). Sawmills, such as Leban, produce and supply traditional racks of all sizes. Semi-automatic and automatic systems are available to meet the ‘small scale’ requirement and consist of two general types: the cage-based style where a metal cage that holds bottles is inserted into a controlled rotating system, and a bottle-based style in which individual bottles are inserted into a rotating/turning rack. The single cage gyro pallet from Oeno Concept is representative of the first type while the Aarest automatic riddling machine is one of the second type.”

“The second bottling operation in sparkling wine removes the crown cap and yeast sediment from the bottle, adds sweetening syrup (‘liquor’), restores any lost wine volume, inserts the traditional cork and wire hood and mixes the bottle to integrate the syrup into the wine. This series of steps is generally referred to as the ‘disgorging’ process although the term is technically specific to the step of yeast removal.”

“Once the bottle is riddled and the sediment is all located in the bottle neck, there are two ways to approach the specific step of disgorging. The first method involves removing the crown cap at just the right moment as the bottle is inverted from neck down to neck up. This allows all the yeast sediment and a very small amount of wine to be expelled due to the internal bottle pressure. This technique is called disgorging ‘on the fly’ and is the most basic manual method but requires skill and timing. Pull the cap too soon and large amounts of wine are lost; pull the cap too late and the sediment slides back into the bottle. To do this correctly, a special bottle opener called a disgorging key (clé à dégorger), which allows the worker to point the bottle away and pop off the cap with a small wrist movement, is used. These keys, which seem to be available at every farm supply store in European sparkling wine regions, are much harder to find in the U.S. The manufacturers and vendors known to produce

or carry them include Valentin, Cuñat, Ligapal and Station Oenotechnique de Champagne. The designs all vary slightly, and you may have something in the old toolbox that might work just as well.

“In contrast to the ‘on the fly’ method, the neck freezing method has become more common with automation and conveyer belts. This method involves inserting the bottle neck-down into an ice bath (of brine or alcohol) to freeze the wine (and the yeast sediment) in the neck. This allows a now upright bottle with a frozen yeast plug in its neck to travel on a conveyer or be moved by hand without risk of re-clouding the wine. Using the frozen neck method requires investment into some type of neck freezer. Small options for wineries exist, such as the 36-bottle freezing unit manufactured by Cuñat. There are a very diverse range of manufacturers and sizes for small units, from three to 124 bottle units.”

“Whether using ‘on the fly’ disgorging or neck freezing, the removal of the crown cap should produce an open bottle that contains only dry, clear sparkling wine. Dosing or sweetening (with a sweetened liquor typically of water, wine or brandy) and restoring the volume to the proper fill level (topping or equalizing) are the next two operations. These seemingly simple steps are a challenge because of the nature of sparkling wine, which have a tendency to foam, bubble and gush. On the most basic manual level, these sweetening and fill leveling operations can be done with food-grade volumetric dispensers to aliquot out the desired amount of sweetening syrup. Manual fill leveling can be done from bottle to bottle or by using a pressurized dispenser, such as a small soda keg. This entire process of transforming a neck-down riddled bottle of sparkling wine into an upright clear, sweetened and volume-equilibrated bottle can be done with several types of small-scale machines. Some of these units can perform only one of these tasks; others can do all of them.

“The pneumatic TDD Grilliat DLV-1 semi-automatic disgorger starts with a bottle placed neck down, then rotates and removes the cap (disgorging ‘on the fly’) and finally places a blocking cap (obturator) over the freshly opened bottle for a few seconds to reduce gushing. The Cuñat DL-1 Dosing and Fill Leveling unit is a very basic system that injects a specific amount of syrup from a storage vessel into the wine. There are many variations on this style, and some units include fill leveling options in addition to the dosage addition.