Safety protocols: Keeping track is easier said than done

“Safety first” — an adage as old as time. Safety inspections are essential in ensuring that both the equipment and processes that vessel crew members handle are of satisfactory quality, to not only reduce the risk of costly damage to vessels, but to safeguard the health and well-being of our crew members.

Yet, keeping track of safety protocols is often easier said than done.

The busy and unpredictable nature of work onboard can make it difficult for ship operators and crew members to find time to update checklists of the necessary tasks and conduct safety checks necessary to ensure that welding equipment and tools are kept in safe working conditions.

Without a streamlined process in place, safety checks can be very time-consuming. Pair that with having a sea of items to check and complying with the latest regulations and vetting inspections such as UK MCA Code of Safe Working Practices for Merchant Seafarers (COSWP), OCIMF Ship Inspection Report (SIRE) Programme and RightShip Inspection Ship Questionnaire (RISQ), it may suddenly become overwhelming.

That’s why we’re here to make it easier.

Welding Safety Inspection service

Our WSI service, performed by our Port Service Engineers, is enabled by our improved WSI 3.0 app built to generate a confidential report that documents and presents inspection findings to enable easy identification and rectification of welding safety blind spots.

Grouped by risk categories, the WSI Report can effectively highlight critical safety risks that require immediate attention. Each inspection point not only comes with photographs and detailed explanations in cases of safety shortfall, we go one step further and provide recommendations for you to remedy the issue.

This is how our WSI service works:

1

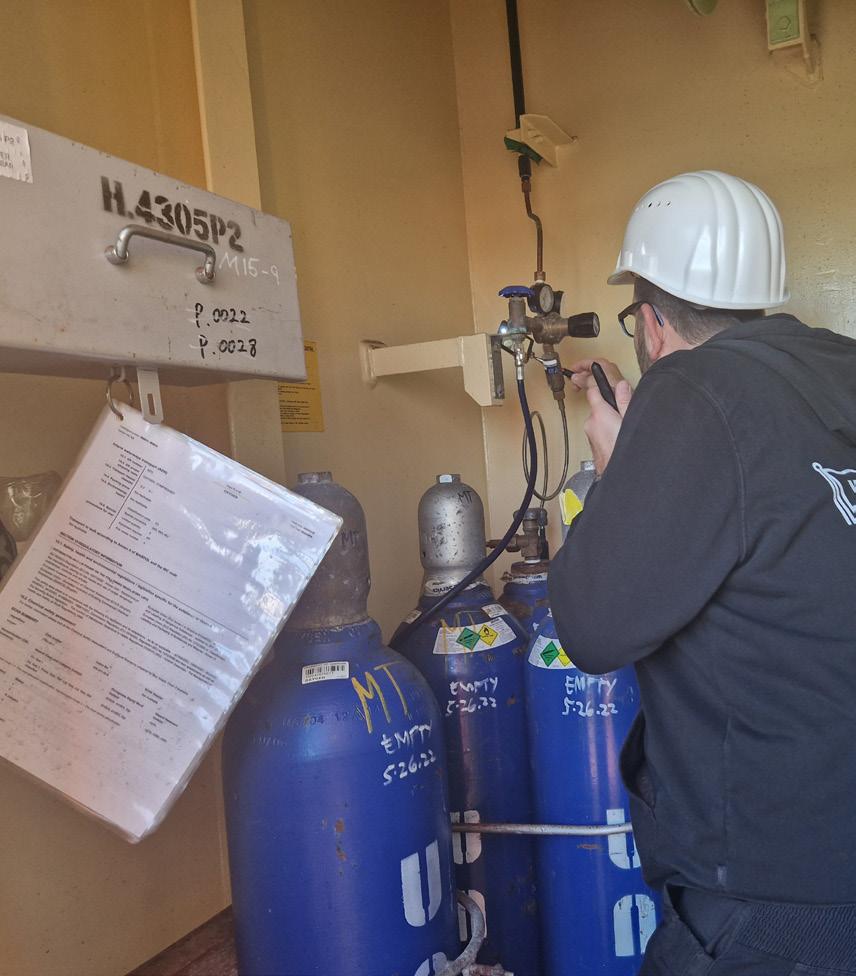

One of our trained Port Service Engineers (PSE) goes on board to conduct a safety inspection using the WSI app.

2

PSE will create a report based on their findings and will work with your Account Manager / Technical Sales Manager to fine-tune the report.

3

The Account Manager/ Technical Sales Manager will present the report to you, along with key findings and important next steps to ensure safety and compliance.

Safety could never be easier

Our detailed WSI report captures all the important points that can help to mitigate safety risks. Here is how we achieve that:

Proven approach

Enable safer management of Hot Work on board due to extensive checks conducted by our PSEs.

Create a documented understanding of common safety risks to look for based on comprehensive and structured safety inspections.

Customer testimonials mention that WSI recommendations are helpful in educating crew members on the importance of playing their part in safety.

Assurance

Product incompatibility can contribute to potential safety risks. WSI can recommend standardisation of compatible products.

Save on unexpected costs by preventing equipment damage and accidents to crew and vessel by making the welding environment on board safer.

Safety is a commitment, made every day

Have peace of mind with the understanding that active steps are being taken to ensure that safety is taken care of.

By efficiently documenting welding safety improvements, you can enable a safe welding environment on board by preventing accidents to crew and vessels. We are here to help you create a work environment on board that is compliant and safe for everyone.

Reach out to your WSS Account Manager or Technical Sales Manager for more information on our Welding Safety Inspection service solution. For more information, scan the QR code below.