THE WATER ISSUE/

Minimizing Freshwater Consumption in Hydraulic Fracturing Operations By Temi Yusuf, Schlumberger

H

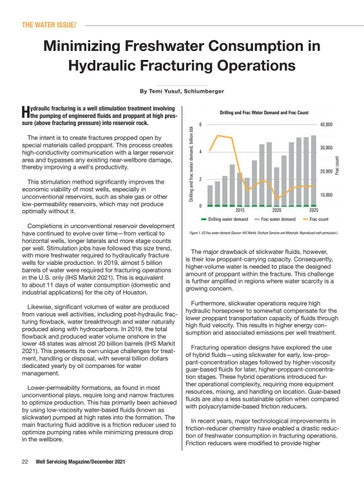

ydraulic fracturing is a well stimulation treatment involving the pumping of engineered fluids and proppant at high pressure (above fracturing pressure) into reservoir rock. The intent is to create fractures propped open by special materials called proppant. This process creates high-conductivity communication with a larger reservoir area and bypasses any existing near-wellbore damage, thereby improving a well's productivity. This stimulation method significantly improves the economic viability of most wells, especially in unconventional reservoirs, such as shale gas or other low-permeability reservoirs, which may not produce optimally without it. Completions in unconventional reservoir development have continued to evolve over time—from vertical to horizontal wells, longer laterals and more stage counts per well. Stimulation jobs have followed this size trend, with more freshwater required to hydraulically fracture wells for viable production. In 2019, almost 5 billion barrels of water were required for fracturing operations in the U.S. only (IHS Markit 2021). This is equivalent to about 11 days of water consumption (domestic and industrial applications) for the city of Houston. Likewise, significant volumes of water are produced from various well activities, including post-hydraulic fracturing flowback, water breakthrough and water naturally produced along with hydrocarbons. In 2019, the total flowback and produced water volume onshore in the lower 48 states was almost 20 billion barrels (IHS Markit 2021). This presents its own unique challenges for treatment, handling or disposal, with several billion dollars dedicated yearly by oil companies for water management. Lower-permeability formations, as found in most unconventional plays, require long and narrow fractures to optimize production. This has primarily been achieved by using low-viscosity water-based fluids (known as slickwater) pumped at high rates into the formation. The main fracturing fluid additive is a friction reducer used to optimize pumping rates while minimizing pressure drop in the wellbore.

22

Well Servicing Magazine/December 2021

The major drawback of slickwater fluids, however, is their low proppant-carrying capacity. Consequently, higher-volume water is needed to place the designed amount of proppant within the fracture. This challenge is further amplified in regions where water scarcity is a growing concern. Furthermore, slickwater operations require high hydraulic horsepower to somewhat compensate for the lower proppant transportation capacity of fluids through high fluid velocity. This results in higher energy consumption and associated emissions per well treatment. Fracturing operation designs have explored the use of hybrid fluids—using slickwater for early, low-proppant-concentration stages followed by higher-viscosity guar-based fluids for later, higher-proppant-concentration stages. These hybrid operations introduced further operational complexity, requiring more equipment resources, mixing, and handling on location. Guar-based fluids are also a less sustainable option when compared with polyacrylamide-based friction reducers. In recent years, major technological improvements in friction-reducer chemistry have enabled a drastic reduction of freshwater consumption in fracturing operations. Friction reducers were modified to provide higher