VCE's state-of-the-art facility combined with our expert staff enables us to repair all cryogenic pumps on the market within 24 hours at competitive rates.

We build the most reliable automated system for high pressure demand. The Veite Laser GS4000 is an automated system for filling and maintaining a high pressure storage bank at a set pressure. The system monitors minimum and maximum set points for the storage vessel to supply high pressure nitrogen, oxygen, carbon dioxide or argon.

Veite Cryogenic has designed and installed compressed gas fill plants, and cryogenic equipment for more than 55 years. We have a reputation for high quality work with increased safety. We know how to build and maintain reliable, hard-working fill plants for oxygen, nitrogen, argon and other compressed gases.

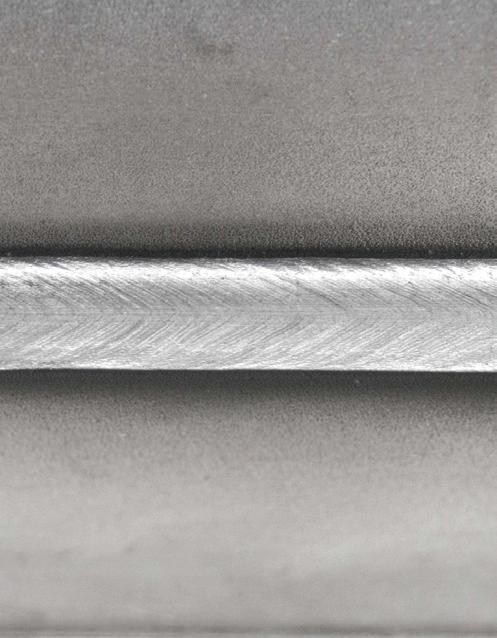

VCE specializes in orbital welding. This is a very specific technique used on items that would be very difficult to weld manually, such as pipes. This is an ideal welding technique for use on items where a strong weld is hard to achieve due to welding positions and size.

EXECUTIVE EDITOR

John Ospina jospina@gawda.org

PUBLISHER

Bill Brod billb@gawdamedia.com

EDITOR IN CHIEF

Steve Guglielmo steveg@gawdamedia.com

CONTRIBUTING EDITORS

Natasha Alexis nalexis@gawda.org

Andrea Levy alevy@gawda.org

DESIGN DIRECTOR

Robin Barnes robinb@gawdamedia.com

VICE PRESIDENT, SALES

Tim Hudson timh@gawdamedia.com

ACCOUNT MANAGER

Lesli Mitchell leslim@gawdamedia.com

RESEARCH & DEVELOPMENT COORDINATOR

Athena Cossette athenac@gawdamedia.com

GRAPHIC DESIGN

Jeannine Papelino

72

Tech Trends & Takeaways

A Look at GAWDA’s Technology Committee Ahead of SMC 2025

BY STEVE GUGLIELMO AND HECTOR VILLARREAL

82 A Guide to Digital Transformation Investments for Distributors

BY MIKE MARKS

86 Customer Expectations in 2025

BY ART WASKEY

88

Combating Brain Drain and Building the Future

Sustaining a Resilient Culture

BY RANDY SQUIBB

92

Search Engine Trends for the Gases and Welding Industry

Welding & Gases Today (USPS 22-975) is published quarterly: Winter, Spring, Summer and Fall, with additional publications in Spring and Summer. • Non-member subscription rate is $195 per year. • GAWDA members (key contacts and branch locations) receive the magazine as part of their dues. • GAWDA members can order additional yearly subscriptions (4 issues) for $40. • Welding & Gases Today is published by Data Key Holdings, LLC on behalf of the Gases and Welding Distributors Association. • Periodicals postage paid at Ft. Lauderdale, FL, and at additional mailing offices (ISSN 1558-5344). • Editorial correspondence should be sent to Editors, c/o editor@gawdamedia.com. Advertising correspondence and materials should be sent to William Brod, Data Key Holdings, LLC, 19 Albany St., Suite 2E Cazenovia, NY 13035; telephone (315) 445-2347, fax (315) 422-1721. • Postmaster: Send address changes to Welding & Gases Today, Gases and Welding Distributors Association, One Oakwood Blvd, Suite 195, Hollywood, FL 33020 • Welding & Gases Today is the official journal of the Gases and Welding Distributors Association (GAWDA) and carries news and announcements concerning GAWDA. • It is not responsible for contents or opinions other than association activities. • Contents are copyright ©2025 Data Key Holdings, LLC. • All rights reserved. • Nothing may be reproduced in whole or in part without written permission of the publisher. • Questions and comments can be sent via e-mail to Editors, c/o editorial@gawdamedia.com. • Data Key Holdings, LLC reserves the right to print portions of or all of any correspondence mailed to the editors without liability on its part and no such correspondence will be returned. • Visit Welding & Gases Today Online at www.GAWDAmedia. org. Statement of Ownership Publication Title Welding & Gases Today. Publication number 22-975. Filing date 09/2024. Issue frequency quarterly + 2 special issues. # of issues published annually: 6. Subscription price part of member dues. Mailing address of known office of publication and headquarters: One Oakwood Boulevard, Suite 195, Hollywood, FL 33020. Headquarters address same. Publisher: William Brod, Data Key Communications, 9 Albany St., Suite 2E Cazenovia, NY 13035. Editor: John C. Ospina, GAWDA Executive Director, One Oakwood Boulevard, Suite 195, Hollywood, FL 33020. Editor in Chief: Steve Guglielmo Data Key Holdings, LLC, 9 Albany St., Suite 2E Cazenovia, NY 13035. Owner: GAWDA, One Oakwood Boulevard, Suite 195, Hollywood, FL 33020. Average net press run 1803/1875. Outside county paid/requested mail subscriptions 1850/1875. In-county paid/ requested mail subscriptions 0/0. Sales through dealers and carriers 0/0. Requested copies by other mail classes 0/0. Total paid and or requested circulation 1775/1803. Outside county nonrequested copies 0/0. In-county nonrequested copies 0/0. Nonrequested copies distributed through USPS by other classes 0/0. Nonrequested copies distributed outside the mail 150/400. Total nonrequested distribution 150/400. Total distribution 1850/1875. Copies not distributed

• NEW FOR 2025 – HP Type 2 Carbon Fiber Wrapped Cylinders

• Industrial, Acetylene, Medical Co2 and more

• Cylinder Refurbishing and Hydro service from our Midwest facility

• Liquid Cylinders – limited sizes

• Cryogenic Repair Services

Hydrocarbon Gas packaging for cannabis extraction

Eric Wood is GAWDA’s 2024-2025 President as well as COO of O.E. Meyer Company. He can be reached at 419-6253054 or by email at ewood@oemeyer.com

Hello GAWDA Members, and thank you for taking the time from your day to read this article and for checking out this issue of Welding & Gases Today. This issue and article coincide with our SMC in Dallas, Texas, and I am so excited to spend time with our members and volunteers and share my theme and vision for 2025.

My theme for 2025 is “Sustaining a Resilient Culture.”

I find relevance and examples of resilience in the GAWDA organization and in the companies we represent. It goes without saying that change is ever-present.

The changes and challenges we experience are many. The most difficult changes that can affect a company’s culture can be the disruptions in our business related to changes in ownership and/or leadership changes within our companies. Leadership transitions are an unavoidable part of any organization, but their influence on company culture can be significant. Whether a company is going through a planned succession, an unexpected leadership change, or a shift in business strategy, the way new leaders integrate into the organization can either enhance or disrupt the workplace culture. Effectively managing these transitions is crucial for ensuring stability, keeping employees motivated, and achieving longterm success.

Here at the SMC, we will hear from Aaron Brandt and Evan Smith from Hypertherm. They will discuss and share with us the Hypertherm culture and Hypertherm’s recent leadership transition and share some of their thoughts regarding the challenges with a change of such magnitude.

This year, GAWDA celebrates its 80th anniversary. It takes resilience, effort, and generosity for a trade organization such as ours to succeed and continue to grow for 80 years. Despite the challenges we’ve faced, our industry remains strong, and partner companies continue to contribute regardless of the headwinds we face.

For eight decades, GAWDA has been a pillar of strength in our industry. We’ve grown, adapted, and thrived because of our commitment to those values, and we will continue to do so. GAWDA is strong, and together, we’ll ensure it stays strong for the next 80 years.

Throughout 2025, as we celebrate this big milestone, you can expect plenty of moments to reflect on GAWDA’s rich history and all that we've achieved together. But it won’t just be about looking back; we’ll also be looking ahead, focusing on how we’ll keep building and strengthening the resilient culture that’s made us who we are today.

One last point on resilience and culture. GAWDA Gives Back is celebrating its 25th anniversary this year. For 25 years, the GAWDA organization and its members have created and embraced a culture of generosity and a culture of resilience. Members have continued to be charitable and generous regardless of our current economic cycles, contributing astounding amounts to those in need. For this, we are also resilient!

In the past 25 years, GAWDA Gives Back has changed the lives of many people and organizations. I thank our predecessors for making GAWDA Gives Back so impactful, and I find the opportunity to choose one very humbling. I can’t think of a better way to contribute and sustain our generous culture as GAWDA president than by choosing a worthy cause in which we can make a difference.

At Lincoln Electric, we maintain a commitment to innovation in everything we do. From the new POWER MIG® 262P, to the Elevate™ SLi Battery Powered Welder, we are driven to deliver new products that make your customers’ welding experience easier, more productive, more efficient – in a word, better. As the world leader in the engineering, design and manufacture of advanced arc welding equipment and solutions, we are proud to offer a full lineup of innovative products, backed with the expertise and support you can trust.

GAWDA provides resources to help members make sense of the ever-changing stream of information.

John Ospina is GAWDA’s Executive Director. He can be reached at GAWDA Headquarters in Hollywood, FL, via telephone at 844-251-3219 or via email at jospina@gawda.org.

GAWDA is working to develop programs to keep up with the overwhelming stream of information we face today.

GAWDA has launched our new LMS and is now hosting the updated GAWDA University modules. Each member company can open an account where a designated person in your company serves as the manager that can assign user privileges to employees. This person can track employee progress and see who has completed and passed the assigned courses. These courses come with a certificate of completion for your HR records. In the 30 days since we launched, there have been more than 30 companies and 109 users signed up for the program.

GAWDA is now hosting all 13 CGA eLearning modules on the new LMS. Prior to this change, the modules were only open to distributors. Under the new agreement, the eLearning modules are now open to all member companies through the members-only site.

Since the beginning of the year, we have seen all kinds of changes coming out of Washington D.C. that are impacting businesses. Our consultants are swamped with questions on a regular basis with members trying to keep up with the ever-changing landscape. Trying to keep up with the constant changes is like drinking out of a fire hydrant.

To help clarify some of the questions, we were able to provide GAWDA members access to a special webinar on April 8th hosted by the National Association of Wholesale Distributors (NAW) on “Navigating Tariffs: Strategic Insights for Wholesaler-Distributors in 2025.” For those of

you who missed it, we also added the host of that webinar, Brian Wild, Chief Government Relations Officer, National Association of Wholesaler-Distributors (NAW), to the SMC speaker lineup. Brian will break down the latest developments on tariffs and their real-time impact on the gases and welding industry. With clarity and insider insight, he’ll explain how trade policy decisions are made, what to expect next, and what GAWDA members can do to protect and position their businesses in this evolving economic climate.

At the 2025 Annual Convention, Alex Chausovsky, Director of Analytics and Consulting at the Bundy Group, and Eugene Chausovsky, Senior Director for Analytical Development for New Lines Institute, which is a foreign policy think tank based in Washington D.C., will present on the impact of geopolitics on business. During this presentation, they will discuss the effects of geopolitical policies and how they impact the way we do business. They’ll cover tariffs, global trade issues, conflict hot spots, and other trends that could affect your business.

During our 2026 SMC, Alex Chausovsky and Eugene Chausovsky will be back to host a series of simulation exercises on crisis management scenarios based on geopolitical and economic trends of that time. These exercises are designed as an interactive way to look at potential problems and develop ways to work through them and find creative solutions.

There’s no question that we need to be prepared for whatever may come. GAWDA is committed to help you face these and other new challenges coming our way.

Steve Guglielmo is GAWDA Media’s Editor-in-Chief. He has more than a decade of experience working with industrial associations. He can be reached at steveg@gawdamedia.com.

In the Q1 Issue of Welding & Gases

Today, my editor’s column was entitled “Building a Culture that’s Worth Sustaining.” I love this year’s theme of “Sustaining a Resilient Culture,” but, as I explored in that Q1 Issue, I also find it fascinating to explore how strong cultures are built in the first place.

One of my all-time favorite movies is Field of Dreams, and its most famous line —“If you build it, they will come”—feels especially relevant as GAWDA celebrates its 80th anniversary. Over the past eight decades, this association has built an incredible culture. And, as we set new attendance records with each passing show, the axiom proves true. But, as this year’s theme reminds us, it’s not enough to build something great. You have to keep building to keep it great.

This principle applies not just to GAWDA’s culture but to the way we have always embraced innovation and change. Internally, we always refer to the Q2 issue as “The SMC Issue,” because it debuts on-site at the Spring Management Conference. But, looking at this edition’s content, it might be more fitting to call it “The Technology Issue” or “The AI Issue.”

As you will read in our interview with Technology Co-Chair Hector Villarreal on pages 72, the committee was created to tackle AI, cybersecurity, and e-commerce—three areas our Board of Directors identified as critical for our mem-

bers. As Hector explains, “There is no finish line in e-commerce. There’s no finish line in cybersecurity. You always have to be evolving.”

That point hit home for me. If you build it, they will come. But if you don’t keep building it, they won’t stay. And that idea is echoed throughout this issue, as you’ll read in articles like “A Guide to Digital Transformation Investments for Distributors” (page 82), “Customer Expectations in 2025” (page 86), and the Member Profiles of Haun Welding Supply and SafTCart.

Art Waskey wrote in his article on page 86, “The overarching goal of a successful distribution business is to provide the best possible customer value, products, and services with ease and efficiency. Becoming more productive with AI tools allows you to grow and prosper.

These tools are the next frontier for our members. And I’m so proud that GAWDA is once again on the cutting edge in bringing those tools and education to our members.

I’m so excited for this year’s SMC, and I’m even more excited to be celebrating GAWDA’s 80th Anniversary throughout the year. The continuous innovation and evolution have allowed GAWDA and our members to have built and continue to build “Resilient Cultures” that are worth sustaining.

• Over 90 Locations in 19 states

• Now one of the largest independent distributors in the US

Please visit www.meritusgas.com/become-a-partner for more information today!

In my GAWDA (then NWSA, National Welding Supply Association) President Year of 1993, time was the currency and speed was the base, as the internet was rapidly accelerating business methods and Peter McCausland was consolidating our association membership under the Airgas marquee. We had the initial wave of Baby Boomers joining the industry, and I had the honor and fun of serving NWSA alongside Jack Dammann, Randy Squibb, Dan Paris, Jim Robertson, Gary Armstrong, Bill Higley, Chip Valentine, Dave Mahoney, and current GAWDA Hall of Famers Bob Roberts and Wally Brant. My Fab-Five mentors of Ken Thompson, John Beringer, Bob Jackson, Larry Kissler, and Andy Castiglione Sr. imprinted on me their industry actions and behavior. I was a lucky 41-year-old in 1993 with a team of industry titans supporting me.

Our spring meeting theme was “Why Technology? Because it Works!” and in Maui in the fall, I suggested “Chart A New Course” to turn headwinds to tailwinds as the internet, gas manufacturing and distribution safety, Total Quality Management, and NWSA membership consolidation were hot topics for our industry. Our Executive Committee of two Jacks, Randy, John, and Dan with enlisted Board Vice Presidents Jim Robertson (safety), Gary Armstrong

(technology), and Bill Higley (training /education) met in Nashville, Indianapolis, Baltimore, Reno, and Fort Worth throughout the year with about 200 people at each meeting. We created two learning forums: The “Industry Forum,” where supplier CEOs shared their technology and safety ideas, and “Operation Interchange,” where NWSA distributors shared best practices about specific new technologies. The great people skills of our speakers, combined with our members’ willingness to share, made “Why Technology? Because it Works!” an exposé of industry success stories and near misses. The Baby Boomers were stepping up, and our NWSA mentors kept challenging us with difficult assignments. The Great Generation was passing the baton to the Baby Boomers, and it was inspirational to follow behind these trailblazers.

My father, Butler Gas founder John A. Butler (Jack), always taught me that luck is the crossroads of preparedness and opportunity, and NWSA received a bolt of luck in the early 1990s. As our NWSA Safety Committee, led by Jim Robertson and Bonnie Stanage, was rapidly developing new safety and compliance manuals to meet federally mandated deadlines, we met Rick Schweitzer on this safety journey, and the rest is history. Our early 1990s NWSA Safety Committee evolved from basic manu-

als to the industry’s first publications of advanced safety and compliance procedures rooted in established CGA standards. This journey took less than 365 days. Jim, Bonnie, and Rick created this 1993 safety quantum leap for the entire packaged gas distribution industry.

When my daughter, Abydee, became GAWDA President at 33-years-old in 2020 and 2021, it was more eventful and exciting than my year in 1993. Abydee had the COVID Pandemic, with the collapse of in-person collaboration, to deal with in her years, so my brush with the early internet hassles seems pale by comparison. My wife, Elissa, and I were so proud of Abydee’s leadership during these unforgiving times, and thanks to Wally Brant, Gary Halter, and Indiana Oxygen Company, a shuf-

fling of the GAWDA Officer terms was implemented, and Abydee had a second presidential year in 2021 to have in-person Conventions. Thank goodness for the GAWDA Consultants and PPP-funding during these years. Our business and association were lucky to have Abydee lead during these tough times with her innovative thinking, volunteering skills, and industry network across GAWDA, IOMA, and CGA.

My father told me on his deathbed, “Become a lifetime learner; get active in these associations, they will help you and teach you the business,” and obviously, we followed his advice for generations. Abydee and I believe that Butler Gas’s active engagement in GAWDA, IOMA, CGA, BIG, IWDC, and the University of Pittsburgh IEE (Family Business Center) is our secret sauce for continuous improvement over the last 77 years. We participate and volunteer actively, meet friends for life, and have fun as we keep sharpening the saw, utilizing associations to train our colleagues, and learning best practices and new ideas.

At Butler Gas, we strive to be the region’s best gas manufacturer and distributor, excelling as the packaged gas supplier of choice by driving sustainable customer growth and relationships, exceeding our 100-Year Plan. We believe customers do not have to sacrifice service for capabilities. We are a safe, customer-focused manufacturer and distributor of packaged gas products and mutually profitable business solutions. GAWDA enables the secret sauce.

Back home at Butler Gas in Pittsburgh, Abydee is leading our talented team, growing our 100-Year Plan of striving daily for 100% safety, nurturing our colleagues and empowering them to succeed, wowing our custom-

ers, and earning responsible levels of profit for continual investment in the business. Our family business succession plan is 3rd-gen-complete with Abydee as President and CEO, alongside Elissa’s and my active roles as Treasurer and Chairman, respectively. At 73 years old, I still enjoy the competition of the game of business, and the fun from actively coaching and mentoring. My job is being the “Head Scout and Tribal Knowledge Coach,” and I still sell wholesale gases (acetylene, specialty gases, hydrogen, and helium) to many industry friends whom I’m grateful to also call customers. I have fun analyzing gas-centric continuous improvement projects, but my favorite duties now involve my granddaughters, Ivy and Coda. I am Papa; Elissa is Gramme,

and we try to bring our A-game to cherish our 7-year-old and 4-year-old next generation. Being Papa is my new passion, and we all know that time is much more important than money, so I am taking time to smell the roses. You will see me and Elissa chasing Ivy and Coda at GAWDA and IWDC as they network with their “industry sisters and brothers,” as Ivy calls her new friends. Butler Gas is a business-first family business, and we all travel well for networking and learning.

Our GAWDA Officers are all next-gens just like our NWSA team back in 1993. It has been so cool to watch Woody, Allie, Kevin, and Colleen sprout their wings during my career and become such strong industry leaders and public speakers, too. GAWDA has great next-gen talent now, and these four rising stars are ready for prime time

cial intelligence, FDA/DOT/EPA rising regulations, and Technology? Because it Works!” and “Chart A New Course”

CTR offers a wide variety of gas control manifold options, including:

CTR offers a wide variety of gas control manifold options, including:

CTR offers a wide variety of gas control manifold options, including:

• Standard industrial pressure control

• Standard industrial pressure control

• Cabinet (optional)

• Cabinet (optional)

• Standard industrial pressure control

• Pressure temperature control

• Pressure temperature control

• Pressure temperature control

• High-pressure applications

• High-pressure applications

• High-pressure applications

• Medical gas controls

• Medical gas controls

• Medical gas controls

• Large stainless-steel manifolds with flows greater than 500,000 SCFH

• Large stainless-steel manifolds with flows greater than 500,000 SCFH

• Right or left-hand control manifold assemblies

• Large stainless-steel manifolds with flows greater than 500,000 SCFH

• Right or left-hand control manifold assemblies

• Right or left-hand control manifold assemblies

• Cabinet (optional)

• Local signal alarm control panels

• Local signal alarm control panels

• Local signal alarm control panels

• Systems sizing for appropriate product pressures and flow rates

• Systems sizing for appropriate product pressures and flow rates

• Cylinder reserve manifolds

• Systems sizing for appropriate product pressures and flow rates

• Cylinder reserve manifolds

• Custom designs

• Cylinder reserve manifolds

• Custom designs

• Custom designs

All manifolds are cleaned, bagged and tagged for use in oxygen

and all designs adhere to the latest NFPA 99 standards.

All manifolds are cleaned, bagged and tagged for use in oxygen service, and all designs adhere to the latest NFPA 99 standards.

All manifolds are cleaned, bagged and tagged for use in oxygen service, and all designs adhere to the latest NFPA 99 standards.

Our main focus is to reduce customer cost by limiting the product footprint, minimizing maintenance, and extending product life.

Our main focus is to reduce customer cost by limiting the product footprint, minimizing maintenance, and extending product life.

Our main focus is to reduce customer cost by limiting the product footprint, minimizing maintenance, and extending product life.

A new administration brings new regulatory priorities.

BY TOM BADSTUBNER, MARILYN DEMPSEY, MICHAEL DODD, RICK SCHWEITZER AND STEVE GUGLIELMO

The First Quarter Issue of Welding & Gases Today discussed the theoretical regulatory changes and priorities that would come with the new Presidential administration and Congress. Now, with both underway, the priorities are becoming clearer. Here to break down what has changed and what it means for GAWDA members are GAWDA’s Consultants. Between the four of them, GAWDA’s Consultants bring more than 150 years of industry-specific experience to the association.

The GAWDA Consultant Program is a GAWDA member benefit that is included as part of your member dues to the association. It is consistently rated as one of the most valuable member benefits that GAWDA provides. Thank you to Tom Badstubner, GAWDA’s FDA and Medical Gases Consultant; Marilyn Dempsey, DHS, EPA, and OSHA Consultant; Mike Dodd, DOT Consultant; and Rick Schweitzer, Government Affairs and Human Resources Consultant, for lending their time and expertise to discuss these important topics. The following is a lightly edited transcript of that conversation.

Those attending the 2025 GAWDA SMC in Dallas should be sure to attend the Consultant Roundtable during the Educational Track Sessions from 10:30 a.m. to 11:30 a.m. on Tuesday, May 6, 2025.

WELDING & GASES TODAY: Since we last spoke for the Q1 Issue of Welding & Gases Today, is there anything that has changed or that is going on with the various agencies that is important for GAWDA members to be aware of?

MIKE DODD: For DOT, there hasn’t been anything new. It’s been very quiet. I like it.

TOM BADSTUBNER: The new Medical Gas regulations were released last summer and become effective this December 18. We're looking at the impact of new regulations on our operations. We have already drafted the SOPs that go along with the new requirements. We are asking members to take the next couple of months to look over the SOPs and plan implementation strategies. The implementation process just needs to be completed before December.

Just last week, the FDA sent out a survey, Form 4003, to medical gas manufacturers across the country. The survey has a dozen questions in it, and some are difficult to answer. The FDA is asking for a lot of information, including the last six months of sales of medical gases and where they went, how much was sold, etc. This is a massive request. We have developed a sample response template for members to use when answering the FDA Form 4003. Contact jodie@asteriskllc.com for a copy of the response template.

The interesting thing that they've done with this latest one is that they're actually asking for things that are required under the new rules (Supplier NDA/NADA, etc.). We haven't implemented all the new rules yet, so some of the answers will be based on the old rules, and some will be based on what we expect for the new rules. So, contact us if you get one of these 4003 forms and you want some suggested ways on how to respond to some of those questions.

MARILYN DEMPSEY: I think when the Trump administration placed a “Regulatory Freeze Pending Review” on all proposed or recently published (but have not taken effect) until the rule has been reviewed by the department or agency head is huge, not only for our industry, but all businesses operating in the U.S. This freeze includes: “Heat Injury and Illness Prevention in Outdoor and Indoor Work Settings,” OSHA’s “Walkaround Rule” and the “Emergency Response Standard.

RICK SCHWEITZER: For me, unlike with Mike, the answer is everything! The biggest thing is that EPA Administrator Lee Zeldin announced that the agency was either rescinding, reconsidering, or rolling back 31 separate programs or rules

Whether you agree or disagree with these policies, they are noteworthy because they represent a 180-degree change in the regulatory approach of this administration compared to the two prior Democratic administrations.

that came out of the Biden administration or, in some cases, the Obama administration. This includes things like Advance Clean Trucks waiver that was granted to the California Air Resources Board, or the California waiver for the Omnibus Nitrogen Oxide rules on trucks. It also includes the Greenhouse Gas Phase Three final rule that came out of the EPA. It includes the calculation of the social cost of carbon, which is an objective

calculation that underlies a number of EPA clean air rules, but has varied dramatically between the Obama, Trump, and Biden administrations.

They're also going to go back and reconsider the 2009 determination that greenhouse gas, itself, is harmful to public health and reassess the analysis that went into that determination and see if they can either rescind it or revise it in some way.

Whether you agree or disagree with these policies, they are noteworthy because they represent a 180-degree change in the regulatory approach of this administration compared to the two prior Democratic administrations. This is simply the opening salvo in what is going to be an ongoing legal and policy battle in Congress and in the courts. Some of these changes will require submissions to Congress under the Congressional Review Act. And, there is even a legal question as to whether the Congressional Review Act applies to EPA waivers under the Clean Air Act.

There will also be fights in courts as to the extent to which the EPA can reconsider or justify its right to reconsideration of a number of rules. They will need to go through rulemakings to undo several of these items.

This is a long way from over. It’s an amazing change in policy that will affect everything that the EPA does.

WGT: When we spoke in December for the Q1 issue, it was all theoretical. We knew there was going to be a new President, we knew there was going to be a new Congress, and we could speculate as to what that was going to mean. Now we’re in March, and we know for sure the direction of things, as it pertains to DOT, FDA, etc. Have we seen any shift in policy or specific focus from those agencies as it pertains to audits or to directives or anything like that?

RICK: Yes. At DOT, we have. Just last week, the acting general counsel at the DOT issued a memo on their enforcement policy, and it is much more business-friendly. It says that their enforcement activities, which include enforcement of safety regulations for HAZMAT, for trucks, and for all modes of transportation, have to be based on due process. They have to be fair, they have to, for instance, provide you with exculpatory evidence, if they have any. And you don't even have to ask for it. They have to make sure that those people who are involved in prosecuting the enforcement action are not the same people advising those who are the decision makers. So there is a separation of functions between the judge and the prosecutor, which has not always been the case.

It also says that there has to be fair warning and an explanation of the regulations that you're being held accountable to, to make sure you know exactly what it is that you're supposed to comply with and that there is supposed to be compliance assistance, as well as enforcement, so as to bring you into compliance as much as to punish you for non-compliance.

In all, it's a remarkable document. You can read more about that document in the April 1, 2025, issue of the GAWDA Connection.

WGT: Mike, has this made its way into the practical application of audits that we've seen?

MIKE: No, it hasn't yet. The stuff Rick sees is ahead of time. As far as DOT’s impact on the distributor, their record keeping, their drivers, trucks, cylinder filling, requalification, etc. Everything is status quo. Nothing has changed there. And I don't expect it to.

TOM: So far, the FDA is auditing about the same as before. This new FDA Form 4003 request discussed above might influence the FDA’s strategy for which firms to visit.

MARILYN: I believe the freeze on the “Walk Around” rule is the biggest change for OSHA, and it may become a permanent freeze. This would be a significant win for businesses like ours because no outsider should be permitted to participate in an OSHA inspection unless they are directly involved in the reason for the inspection.

WGT: Rick, this will be our third administration since we’ve started doing these round tables. You hear the 24-hour news cycle talk about how polarized things are. When the Presidency or Congress changes parties, there will obviously be a change in priorities. But is it normal, in history, for the changes to be this drastic each time? Or is this more whiplash than usual?

RICK: No, this is more whiplash than we're used to.

MIKE: This is more than normal.

RICK: We've been doing this for a long time. We've sat through a number of changes in administrations and changes of parties. The last couple of changes: from Bush to Obama, from Obama to Trump, from Trump to Biden, and now, from Biden back to Trump, there have been 180-degree changes in policies because of the polarization of the electorate.

We have, basically, a 50/50 deadlock in the electorate. Both sides see the government’s function very differently. To represent the side that elected you, you have to have a policy approach that is diametrically opposed to what your predecessor did. And we’re seeing that again here.

Similar to what I said with the EPA programs, we’re going to see fights in the courts between the Trump administration and a number of, at least district court, judges over the administration's ability to control spending and fire federal workers. We are going back and forth on whether we can have particular programs defunded, whether particular agencies can furlough or fire some of their employees, or, in some cases, all of their employees. Ultimately, the appellate courts are going to have to decide a number of these very fundamental issues.

WGT: The reason I ask is not to make a judgment or to bring up politics. But it seems like it must be difficult to do business in an environment where every four years, or in some cases even two years, the environment shifts so

rapidly. How does a GAWDA member operate when the ground shifts so dramatically every 2-4 years?

RICK: You have to pay attention to what's going on. That’s the best thing I can say. You have to do the best you can with the information that is available to you. Each administration is going to have its priorities. The Biden administration's priorities were environmental regulation, including things like environmental justice, labor issues, supporting workers and the unionization of the workforce, and climate change. Those priorities are no longer the priorities of the Trump administration. They are promoting energy independence and trying to promote business. We'll see how that goes. But you have to roll with it as a business owner and pay attention to what the priorities are and where you need to change your practices to comply with them.

MIKE: I don't think it's going to change the delivery of product, the delivery of cylinders, the filling of cylinders, etc. But what I do anticipate is that there's very likely going to be some supply issues from their vendors, for hard goods. They’ll

to ship! Recognized as the gold standard for quality & durability

• Industry-leading 7 year warranty

• Service & repair facilities

- McCarran, NV

- Richburg, SC

• Composite Super Insulation™ reduces product losses

• ISO 9001:2008, ISO 14001:2004 compliant to meet highest quality standards

• Patented load ring protection enhances cylinder longevity

www.ChartPackagedGases.com 1-800-400-4683

have to deal with that and find alternative sources. And I’m sure they’re doing it right now.

RICK: A number of members are dealing with the fallout of the tariffs or the threat of tariffs, at least, right now. Things like petroleum products, LPG, but also cylinders, hard goods, depending on where they're sourced. That's going to be, at least on a temporary basis, and maybe even longer. That is going to be an issue for members.

WGT: Shifting away from Washington, we are coming up this month on the 5-year anniversary of the first consultant safety webinar online. The webinars were started, initially, because of the COVID lockdowns. They were never supposed to be a permanent thing; they were supposed to get us through COVID because of all the uncertainties with doing business during that time. Can you reflect back on the safety calls and what it means to continue to do them, and the good that has come out of them now, five years later?

MIKE: The first 6-7 months were about understanding COVID, taking care of employees, preventing the spread of COVID, and keeping businesses open. From my perspective, the last 4 years have been training sessions. I've been using my piece to do microburst training sessions of all the different things inside DOT.

MARILYN: The roundtable calls started within the first month of my becoming a GAWDA Consultant, and it was a crazy time. Like Mike said, the first 6-9 months, it was survival of the business. Now, the calls are another means for members to receive good, pertinent information in a very expedient manner.

TOM: I think that’s what the members continue to expect the consultant webinars to be moving forward. These webinars are opportunities to discuss the latest agency actions, regulatory enforcement, and policy revisions. Also, they are a good training opportunity for current issues. I think the webinars are a great way to keep in touch with the members.

RICK: I think back on the first year of COVID, and I remember saying, “We’re just making it up as we go along." And that was true of those who deal with the government, but it was also true of the government itself. We’re finding out even more how much that was true. This was uncharted territory. We were trying to deal with a pandemic of the likes we have never dealt with before. We tried to come up with a rational government/business response and a rational social response. No one wanted to get sick and die. We didn't want our employees to get

sick and die. We didn't want our businesses to go under. So, we were trying to come up with some way to deal with that, and we all did the best we could.

As Mike and Tom said, it's morphed into just keeping the members apprised of what is going on on a day-to-day basis. As you mentioned, Steve, now we're dealing with a ping-pong back and forth between administrations and the politics of all of the policies that change every 2-4 years. I still see a continuing need to have these monthly sessions. I think it has strengthened the membership and helped them to do business better.

WGT: We're coming up on the SMC. This will be at the SMC in Dallas. You will have a panel discussion during the educational track sessions. Is there anything you specifically plan on touching on for the Q&A portion that you can preview or get people excited about?

TOM: I think a subject that will come up during the roundtable for FDA compliance is “what's a rational strategy for implementing new regulations?” What's the best way to do that?

MIKE: I'm not planning to present anything specific. I'm going to be asking questions from the audience about any topic they want to talk about: drivers, trucks, cylinder filling, cylinder requal. Hopefully, there will be questions. Tom and Rick will mostly talk about the new stuff coming in. Rick will be talking about hanging on, and this is what is going on as of today.

RICK: One new regulation that is going to come into effect that I want to address that I talked about last week at the safety managers conference is the EPA ban on products containing methylene chloride. There is a May 5th deadline on that for sales by retailers. I want to reemphasize that. That also appeared in the April 1st GAWDA Connection.

Just to let them know that there are, even GAWDA members, who have alternative products in the marketplace already. There are a lot of antispatter products that have methylene chloride in them that you won't be able to sell anymore. There are some other things you can use.

MARILYN: I’m going to talk about the “Lessons Learned” from the GAWDA Safety Committee and the information to mitigate those experiences.

• Manufactures a full line of atmospheric LIN/LOX/LAR bulk tanks

o 1500 to 15,000 gallon

o Vertical or horizontal

o 250 and 500 Psig MAWP

o Thermosiphon

• Manufactures vacuum jacketed, SS inner vessel LCO2 tanks

o 6 ton to 50 ton

o Standard internal refrigeration coil for hook-up to external systems

• Offers a standard 5 year vacuum warranty

Offers 40 years of cryogenic manufacturing expertise

• Proudly partners with WesMor Cryogenics as our exclusive distributor in the US

• Serves as the sales, service and warranty distributor for CRYOLOR products

• Offers over 100 years of combined service expertise in the cryogenic industry

• Provides complete rehab and repair services on existing bulk tanks and trailer fleets

• National board “R” stamp, DOT & TC registered for MC & TC 331 & 338 repairs

BY MICHAEL DODD, GAWDA DOT CONSULTANT

GAWDA DOT & Safety

Consultant Michael Dodd is president of MLD Safety Associates in Poplar Bluff, MO. Members can reach him at 573-718-2887 and at MLDSafety@hotmail. com.

The following is an excerpt from the GAWDA Safety Organizer, a monthly bulletin sent to GAWDA members. For more information on the GAWDA Safety Organizer, or to read past issues, visit the GAWDA.org Members-Only Section.

Here is a compiled list of all required DOT training, documentation, and frequencies.

A HAZMAT employer must train, test, and certify (sign the training documentation form) every HAZMAT employee who, in the course of employment, has any function that directly affects hazardous materials transportation safety. The HAZMAT employee must be trained in General Awareness, Safety, Function Specific, and Driver issues as applicable to the employee’s duties.

Function-specific items for our industry would include:

• Cylinder filling of high-pressure, cryogenic liquids, liquefied gases such as carbon dioxide, LPG products, and acetylene.

• Cylinder requalification, such as high-pressure (hydrotest), low-pressure gases (visual inspection), and acetylene.

177.816 says that the driver must receive training on the safe operation of the motor vehicle that will be transporting hazardous materials. This section goes on to describe in detail the issues the driver must be trained on. Please note: 177.816 (c) states: The driver training requirements may be satisfied by compliance with the current requirements for a Commercial Driver’s License (CDL) with a tank vehicle or hazardous materials endorsement.

GAWDA has an excellent Driver Training Manual available. This would be an excellent source for driver safety meetings. It is set up into six short training modules, with each module having its own test. Then, there is a final overall test covering all the topics in the manual. Each of these modules would make an excellent driver safety meeting training session of a few minutes each. If a company did one module every two months, they would cover the complete manual in the year and could start back over again the following year with refresher training.

• In-depth training on the written plan: HAZMAT employees of employers who are required to have a security plan must receive in-depth security training on the security plan and its implementation. In-depth security training must include company security objectives, specific security procedures, employee responsibilities, actions to take in the event of a security breach, and the organizational security structure.

• Security Awareness training: Each HAZMAT employee must receive security awareness training. This training must include an awareness of security risks associated with hazardous materials transportation and methods designed to enhance transportation security. A component covering how to recognize and respond to possible security threats must be included.

I have a HAZMAT general awareness, safety, and security awareness test and certification if you wish to use it. Just ask, and I will email it to you. If you need to do only the security awareness portion with certain employees, then you just scratch through the other portion of the answer page and just do the security part of the test questions and answers.

A record of current training, inclusive of the preceding three years, must be created and retained by each HAZMAT employer for each HAZMAT employee for as long as that employee is employed by the employer as a HAZMAT employee and for 90 days thereafter.

The record must include:

• HAZMAT employee’s name;

• Most recent training completion date of the HAZMAT employee’s training;

• Description, copy, or the location of the training materials used to meet the training requirements;

• Name and address of the person providing the training;

• Certification that the HAZMAT employee has been trained and tested. (This is where someone within the company signs the training documentation.)

• 382.601 covers two important points: a written policy and distributing that policy to your drivers. Drivers are not required to undergo formal training. However, the employer must provide a copy of the company’s written drug and alcohol policy to each driver. Written notice of the availability of these materials must be provided to union representatives. These materials must be distributed prior to the start of alcohol and drug testing. Each driver must sign a receipt that he/she has received a copy of the materials. The JJ Keller pamphlet, product code 38797, does a great job of this.

• 382.603 covers training for driver supervisors. Each employer shall ensure that all persons designated to supervise drivers receive at least 60 minutes of training on alcohol misuse and receive at least an additional 60 minutes of training on controlled substance use. The training will be used by the supervisors to determine whether reasonable suspicion exists to require a driver to undergo testing under §382.307 (reasonable suspicion testing). The training shall include the physical, behavioral, speech, and performance indicators of probable alcohol misuse and use of controlled substances. Recurrent training for supervisory personnel is not required.

• This training is available on the GAWDA University website.

The HAZMAT (general awareness, safety, function-specific (which includes driver training), and security awareness) must be done at least every three years.

The security in-depth training is required every three years unless you update your security plan, and then you must train on the changes to the plan.

The supervisor drug and alcohol awareness training is only one-time training, but I suggest that you conduct this training every few years to keep the supervisors aware of the requirements.

If there are any questions regarding this Traffic Bulletin, please contact me.

BY TOM BADSTUBNER, GAWDA FDA CONSULTANT

GAWDA’s FDA and Medical Gases Consultant Thomas L. Badstubner is president of AsteRisk, LLC in Lewisville, TX. Members can reach him at 508-883-0927 and tom@asteriskllc.com

The following is an excerpt from the GAWDA Safety Organizer, a monthly bulletin sent to GAWDA members. For more information on the GAWDA Safety Organizer, or to read past issues, visit the GAWDA.org Members-Only Section.

The GAWDA Medical Gas SOPs have long been the industry standard procedures for medical gases. The procedures are practical methods to comply with FDA regulations and current enforcement. They are consistent with CGA positions on FDA compliance. Revision Schedule – we have rewritten the SOPs to be compliant with the new medical gas regulations (21 CFR 213). These new procedures are available now. You have until 12/18/2025 to become compliant with the new regulations. In addition to the new SOPs (version 7), we are also supporting the latest updates to the old regulations (version 6.5) until they expire in December. Consider when, this year, you wish to migrate your medical gas compliance from the old regulations to the new regulations.

Annually, we digitally sign the current version and issue an update. This annual update, along with the update training, occurs during the January GAWDA Medical Gas Roundtable (1/31/2025). (A recording is available in case you missed the Roundtable.) The signed old procedures for version 6.5 will be valid until 12/18/2025. The signed new procedures will be valid until the end of the following year (i.e., up to 12/31/2026). This gives you plenty of time to migrate your SOPs to the most flexible, compliant, and up-to-date version.

Paper - Years ago, we distributed the procedures only in printed manuals. This was difficult to maintain and update. (FYI – we can still get the SOPs to you on paper if you prefer.)

FDATechSupport.com – This website allows us to better deliver the content you need. If you do not already have a user account on FDATechSupport.com, please let us know.

Customized Procedures - We can also deliver your own customized PDF version of the GAWDA Medical Gas SOPs. The consolidated PDF file will have your logo, and it will contain only the procedures that you need. If you have not already received your customized SOPs, contact tom@asteriskllc.com or andre@asteriskllc.com. We will get the SOP selection tool to you.

You have access to free compliance and operations training. Please let jodie@asteriskllc.com know if you would like the link to the following training resources:

• Administrative Personnel –CGMP Training

` Food and Medical Gas – CGMP Training for Administrative Personnel

• Food Gases

` Food Gas – Qualified Facilities and submitting the FDA Attestation

` Food Gas – CGMP Training for Pumpers

` Food Gas – For Owners and Managers

• Medical Gases

` Medical Gas – CGMP Training for Pumpers

` Medical Gas – CGMP Training for Drivers

` Medical Gas Liquid Container Valve Outlet and Labeling Regulations

• Specialty Gases

` Hazards and Precautions for Mixtures Containing Both Carbon Monoxide and Carbon Dioxide in Steel Cylinders

• CGA Resources

` FREE e-Learning Resources from CGA

` CGA Safety Posters

Scan this QR code to visit the GAWDA.org Members-Only Section, where you can access exclusive content for GAWDA members.

BY PAUL BERNIER, ASP

Paul Bernier, ASP, is the Safety Products Manager at General Air Service & Supply. He is also an Authorized OSHA Instructor. He has worked in the welding and gas industry since 1996. Paul is Vice President of Southern Colorado ASSP (American Society of Safety Professionals) Chapter.

Paul can be reached at 719-761-7076 or pbernier@generalair.com

One of the most common injuries on a worker’s body is related to the hand. We use them nonstop in almost every industry, especially ours. From administrative workers to drivers and cylinder fillers, we depend on our hands to get the job done.

However, even knowing how important our hands are, they are injured all the time and in situations that can almost always be avoided. In fact, accidents involving hands are the second leading type of injury on the job. Here are some recent statistics:

• Annually, there are approximately 110,000 lost time cases due to hand injuries.

• More than one million workers are treated each year for hand injuries.

• 70% of workers who experienced hand injuries were not wearing gloves.

• Another 30% of workers who wore gloves and were injured were wearing the wrong type or damaged gloves.

Lacerations are the most common type of hand injury, followed by crush injuries, then fractures. Since crush injuries are common in our industry, with workers handling cylinders, this article is mostly directed at the new ANSI impact standard and what it means to us.

In 2019, ANSI standard 138-2019 was developed by the International Safety Equipment Asso-

ciation (ISEA) and approved by the American National Standards Institute (ANSI). Although this standard has not yet been adopted by OSHA, it could fall into the “General Duty Clause,” which basically requires employers to recognize possible hazards and protect their employees from injuries and sickness.

The standard establishes the testing procedures that manufacturers must follow, the classification criteria, and the label requirements.

The ANSI 138 standard aims to protect workers’ dorsal side of their hands by using impact-resistant gloves. The impact-resistant gloves are specifically designed to focus on the knuckles, fingers, and thumbs from forceful injuries. The standard establishes different levels of measurement to resist the impact and possible crushing injury.

The gloves are placed on an anvil, then a weight is dropped on the glove and recorded in kilonewtons (kN). A lower number indicates better resistance to impact, and a higher number means less impact resistance or protection. This test is repeated several times to ensure accuracy. The test will measure the impact on the thumb, knuckles, fingers, and finger joints.

The results of the test divide the gloves into three categories of impact resistance. In other words, the ratings indicate how well the gloves will offer protection against impact. The glove performance is then assigned an impact-rating level.

• Level 1: Less than 9 kN transferred through the glove, offering some protection

• Level 2: Less than 6.5 kN transferred through, offering mid-level impact rating

• Level 3: Less than 4 kN transferred through the glove, offering a high impact rating

This testing and rating system makes it easy for the consumer to know which glove is needed for the risk and possible hazards of a specific job.

This is what a glove label may look like, and it has a lot of information for the consumer.

• ANSI/ISEA 138 depicts the impact level that the glove provides and was successfully tested to.

• The ANSI A4 Cut explains the cut resistance at which the glove was tested and passed; cut resistance levels are A1 through A9, with A9 offering the best cut protection.

• EN388 is the “European Nations” ratings, which have been adopted by most glove manufacturers, showing a lot of information, 4X41D

This document is provided solely for the purpose of proofing and is not to be considered the final artwork.

` 4 is abrasion resistance (1-4), 4 being the most protection.

` X means the glove was not tested for cut protection using ANSI 105; they decided to use the more accurate EN388 or ISO test, which is depicted in the last digit.

` 4 is the tear resistance (1-4), 4 being the highest level.

` 1 is the puncture resistance (1-4), 4 being the highest.

` D is the EN388 cut resistance level (A-F), F offering the highest protection.

In general, if a person is working around falling objects, objects that could fall, or working with heavy objects or equipment, that worker is at a high risk for impact injuries to their hands. In our industry, moving heavy non-forgiving cylinders around could cause impact injuries to the hands, and many such injuries have been recorded. In fact, a close member of my family lost part of his finger in a crushing injury while moving cylinders.

I almost always end these articles with “if you’re not providing these safety items to your customer, then who is?” But since this is a general safety article explaining how gloves can protect workers who encounter this type of hazard, it is

also directed at workers in our industry. Cylinders are notorious for having poor handles, making them difficult to move around, thus causing many possible hazards to workers who handle them. Very common ones we can address are “caught between” and “crushed by” cylinder injuries. Remember the OSHA General Duty Clause, and protect your workers the best you can against risks that can cause injuries, sickness, or death.

Paul Bernier appeared in the April Episode of GAWDA TV as part of “The Safety Episode.” To see the full interview with Paul, scan the QR Code.

Tube Trailers, ISO-Containers, CO2 Transports, Ground Storage

For superior product quality and performance, call on Weldship! We have met virtually every global standard or code, and have the engineering, technical and manufacturing experience to assure you the right size and configuration for your gas product transports and containers. Weldship is now ISO 9001 Certified.

All of our products are available for lease or purchase. In addition, we provide a complete testing service for required container certification.

Contact us today to keep your product safe, your fleet moving… and your profits rolling!

www.weldship.com

Designed to

Transform your work with 3M’s Solution of Abrasives and Personal Protective Equipment and help your team reach new levels of productivity, confidence, and safety.

Transform your work with 3M’s Total Solution of Abrasives and Personal Protective Equipment and help your team reach new levels of productivity, confidence, and safety.

Transform your work with 3M’s Total Solution of Abrasives and Personal Protective Equipment and help your team reach new levels of productivity, confidence, and safety.

Transform your work with 3M’s Total Solution of Abrasives and Personal Protective Equipment and help your team reach new levels of productivity, confidence, and safety.

For process efficiency and safety, even in the most demanding work environments, 3M is constantly delivering technical expertise and invaluable partnerships.

Discover the next generation of heavy grinding & welding solutions from 3M: Sustainably Forward When

Transform your work with 3M’s Total Solution of Abrasives and Personal Protective Equipment and help your team reach new levels of productivity, confidence, and safety.

For process efficiency and safety, even in the most demanding work environments, 3M is constantly delivering technical expertise and invaluable partnerships.

For process efficiency and safety, even in the most demanding work environments, 3M is constantly delivering technical expertise and invaluable partnerships.

When using these products together to undertake an end-to-end welding process 40% MORE SPEED * Boost welding capacity while helping to improve comfort and safety. Designed to

Transform your work with 3M’s Total Solution of Abrasives and Personal Protective Equipment and help your team reach new levels of productivity, confidence, and safety.

For process efficiency and safety, even in the most demanding work environments, 3M is constantly delivering technical expertise and invaluable partnerships.

For process efficiency and safety, even in the most demanding work environments, 3M is constantly delivering technical expertise and invaluable partnerships.

For process efficiency and safety, even in the most demanding work environments, 3M is constantly delivering technical expertise and invaluable partnerships.

When using these products together to undertake an end-to-end welding process 40% MORE SPEED *

Discover the next generation of heavy grinding & welding solutions from 3M: Sustainably Forward

Discover the next generation of heavy grinding & welding solutions from 3M:

Discover the next generation of heavy grinding & welding solutions from 3M:

of

Discover the next generation of heavy grinding & welding solutions from 3M: Sustainably Forward

MFG:: Taylor-Wharton

SERIAL #: M705-0010GQ

SERVICE: Med N2

RETEST

DATE: 12/23/2004

MODEL NO. XL 65

PART NO. HP65-OC 14 M

SER. NO. M705-001-GQ

TEAR WEIGHT 388 lbs, 176.1 kg

DOT-4L 292 PSI

Tired of manually setting up new accounts, logging cylinder information, and calculating rental costs? Save time, eliminate human error, and achieve cost savings with the introduction of new Datacor AI technologies, to be rolled out in stages over the next 12 months. The following information is a summary of an interview with Lou Zhang, Senior Lead, Data Science at Datacor who is a key contributor to the Datacor AI initiatives.

The first AI feature to be rolled out in 2025 includes the use of a cell phone camera to input information quickly and easily into Datacor software. Things like inputting cylinder/asset information will now be a simple picture that assigns a digital barcode to the asset and sets it up in your system with relevant information like manufacture date, manufacturer, pressures, retest dates, and any other data to capture for your records. The best part is that the hardware cost is minimal, as this feature will be available on any iOS or Android phone, eliminating the need for a distributor to purchase or rent dedicated handhelds.

This same camera feature will also enable users to simply take a picture of a purchase order or invoice, updating the customer account in the system, adding products to production,

and facilitating delivery, all in an instant. The system also saves time setting up new accounts, as the AI can extract account information from a picture to populate as many fields as possible, all while eliminating human error. This time-saving measure will have a positive impact on production throughout the business, while also feeding the database with better, more timely, and relevant information that will contribute to future forecasting, preventative maintenance schedules, and recertification dates.

Data Integrity checks and balances are implemented by setting rules that enable the system to monitor data and highlight any potential issues for double-checking. Example of the scanning capability. Cylinders look different but the reader still works with high accuracy in beta testing.

Ordering Recommendations Based on Futures Commodities

Another AI feature that Datacor believes will set them apart from other software companies is their state-of-the-art sales forecasting and supply chain optimization. This will take forecasting to the next level by incorporating profitability optimization through analysis of all supply chain levels. Datacor will provide recommendations based on commodity futures to help distributors buy products, molecules, and raw materials at the optimal time through a recommendations feature that analyzes the costs of the goods sold. Distributors being able to buy some molecules up to 24 months in advance, this feature can help guide a distributor to buy at the right time while still selling at market prices.

Sales forecasting will include all the regular data points, including current trends, seasonality, historical invoice data, sales promotions, while accounting for current costs and pricing, helping you easily map and track sales to ensure year-over-year growth, keeping your sales team focused and organized while harmonizing production, ordering, asset utilization, and staff efficiency.

Distributors will now have access to a business calculator to ensure that all costs and profits are accurately reflected in all products, including rental contracts. Streamline quotes while ensuring price integrity, saving time and administrative work for your sales staff and allowing them more time to build new and strengthen existing relationships with customers.

Aside from rental business quoting, Datacor software includes price intelligence features that analyze the distribution of prices for your customers, allowing you to see how much they have paid for each product over time. This provides valuable insights, including the mean, median, and mode, as well as the percentiles for the prices. With this at hand, you’ll have a far better idea of how much a customer should pay for each specific product you offer.

One of the primary factors that companies consider when evaluating software is ROI. The return on investment for these offerings will be most evident in increased productivity across different departments at all levels of an organization. These AI features are sure to streamline daily tasks for drivers, administrators, purchasing personnel, warehouse staff, accountants, sales managers, Vice Presidents, and all the way up to the C-Suite and beyond.

Datacor products have demonstrated significant advancements in recent years, thanks to acquisitions and the recruitment of industry-leading software engineers. For GAWDA members, Trackabout and Infonetics are among the commonly used solutions for asset tracking, point of sale, and accounting among welding and gas distributors. Datacor has been able to harness the best of those offerings, combined with acquisitions from outside this industry, to deliver the best software experience for both gas distributors and mid-size to small manufacturing and wholesale distribution companies on the supplier side of the GAWDA Membership. Many of the supplier companies have similar needs to the distributors because their products and operations are of a similar size.

If you are a GAWDA Distributor or Supplier Member looking for effective and practical software solutions to run your business, consider Datacor to be your complete software and asset tracking partner. Visit www.datacor.com to learn more.

The purpose of Ask Your Board is to ask common business questions that all GAWDA members might be dealing with and to see how GAWDA’s Board of Directors are dealing with these issues within their own companies. To submit a question for GAWDA’s Board Members to consider, please email steveg@gawdamedia.com

In their Forecast Responses in Q1, many members expressed reservations related to the impact that potential tariffs might have on the supply chain and the economy. How is your business preparing for any possible impacts or opportunities these tariff changes might present for supply chains, pricing, and operations, and what conversations, if any, have you had with customers about these potential effects?

PRESIDENT

ERIC WOOD O.E. Meyer Company

Our company is actively taking steps to minimize the potential effects of tariffs on our operations. We are closely keeping an eye on trade policy changes and meeting often to review and discuss any developing changes. Furthermore, we are assessing our pricing strategies and cost structures to ensure competitiveness without losing gross profit dollars, while not sacrificing the quality of our products or services.

We continue to monitor the supply chain and are keeping a higher stock of essential components on hand when needed to reduce any potential disruptions and continue to purchase capital assets such as cylinders and bulk tanks before the tariffs are implemented. Our objective is to remain flexible and responsive in this dynamic trade landscape.

We are assessing our pricing strategies and cost structures to ensure competitiveness without losing gross profit dollars, while not sacrificing the quality of our products or services.

Earlbeck Gases & Technologies

We have selectively boosted inventory levels for key items, ensuring we have enough on hand to weather

short-term disruptions. We have also explored broadening our supplier pool to help stabilize pricing in the case where there is a domestic alternative and keep supply channels available if one vendor’s costs surge due to tariffs or if there is a shortage.

On the customer side, our customers are well aware of the potential impacts of tariffs. We’re working closely with them to map out upcoming projects, ensuring we can ramp up supply or place large orders in advance of any cost or leadtime pressures.

VERSATILITY AND POWER IN TWO NEW MACHINES

250 MP PRO:

• Portable and powerful, delivering high amperage and extended duty cycles

• Designed for professional use with MIG, Flux-Core, Stick and TIG capabilities

• Dual-voltage and generator compatibility for adaptability on job sites, including remote locations

• Trilingual LCD screen

Minneapolis Oxygen

We first focused on our backend systems, particularly pricing and billing. We’ve added clear wording and a separate line item on invoices to account for tariff-related charges. We’re in ongoing discussions with affected vendors to understand their tariff strategies, which will help shape our customer communications. Our approach is to address the issue early, frequently, and transparently. While we’ll provide options for customers, clear communication will be essential in navigating these challenges together.

250 MP PRO

190 AC/DC MP:

• Ultimate versatility with AC/DC TIG, MIG and Stick capabilities

• Handles welding on various metals like aluminum, steel and stainless steel

• Designed for versatility in multiple welding applications

190 AC/DC MP

Contact your Industrial Pro representative at 1-888-889-1889 or industrialpro@forneyind.com

In an effort to prepare for potential tariff impacts, Noble has been enhancing our current sourcing strategy. Unfortunately, tariffs are not something Noble can completely avoid. Our reaction has to be creative. Where we can, we will shop the market for alternative suppliers, both domestic and international. Noble will also evaluate how much we can absorb in the short term vs. what we need to pass on to our customer base. Strengthening our core service offering will help maintain customer loyalty. Also, having open, transparent conversations with our customers always helps in times like these.

In our industry, supply chain management is a constant challenge, with shortages shifting from one product line to another. During times of disruption, distributors with strong processes and relationships can turn challenges into opportunities by stepping in front of those less prepared. At CK Supply, we

take a proactive approach with open communication with key vendors and customers to anticipate potential disruptions and adapt accordingly. We closely monitor orders and inventory with a strong focus on ensuring accurate, up-to-date cost information for both our employee-owners and customers. It is important to stay calm, as experience has taught me that yelling at the TV and complaining about forces beyond my control won’t get product into our warehouse any faster!

Willard C. Starcher, Inc.

There seems to be very little we can do to prevent disruption to our business because of the tariffs. The best we can do is try to keep up with the daily notifications of price changes by our vendors. We have increased the inventory of items that we feel may be critical to our customers during the next few months.

Keen Compressed Gas Company

As the political landscape has changed in 2025, along with other dis-

tributor companies, Keen has been forced to pay close attention to potential tariffs and unexpected price fluctuations. Internally, we are double-checking pricing from our suppliers prior to quoting customers and effectively communicating about the uncertainty of quoted prices changing. We have asked for additional support from our key suppliers toward any projected changes that can be forecasted, allowing us more time to react. The issue is fluid and seems to move in a different direction daily, but we are working to find opportunities within the changing environment to increase inventory levels where appropriate and maximize on immediate purchasing opportunities.

JASON KIRBY

Central McGowan, Inc.

Tariffs can significantly impact businesses by increasing costs, disrupting supply chains, and affecting pricing strategies. As we all know, higher tariffs can make imported materials and products more expensive, forcing companies to either absorb the costs, pass them on to customers, or seek alternative suppliers. This can reduce profit margins and competitiveness, especially in industries like ours that rely heavily on global sourcing. To stay ahead, Central

McGowan is looking at diversifying our supply chains, passing on the tariffs to our customers, and adding standard verbiage to all quotes stating, “All prices quoted are subject to applicable tariffs, which may vary based on regulations and market conditions. Final pricing will reflect any tariffs in effect at the time of purchase.”

The impact of tariffs has been a challenge that we are all currently navigating, whether it pertains to finished products or the materials used in fabrication. We anticipate that the situation will stabilize soon, and we are committed to maintaining transparency throughout this process. It is likely that domestic companies will also adjust their pricing in response to these circumstances. As such, our pricing now includes a footnote indicating that it is subject to tariffs or unforeseen charges. Should tariffs be lifted, we will promptly adjust invoices accordingly, ensuring we uphold the highest standards of integrity in our operations.

As part of its continued push to help GAWDA members get the most out of their membership dues in the association and stay on the front lines of emerging industry trends and hot-button issues, GAWDA has several volunteer committees devoted to specific areas of the industry. The volunteer committees include Government Affairs, Industry Partnering, Insurance & Benefits, Member Services, Safety, Technology, Women of Gases and Welding, and Young Professionals. This feature in Welding & Gases Today will update readers on the latest news and events from each committee. We thank all the committee chairs for their help and input, as well as their service to the association and its members.

If you are interested in enhancing your GAWDA experience and joining a committee, visit gawda.org/about/committees to fill out a GAWDA volunteer form today.

Co-Chair Chuck Beal, American Welding & Gas

Co-Chair Rick

Schweitzer, GAWDA Legal Counsel

The GAWDA Government Affairs Committee will meet in person during GAWDA's Spring Management Conference on Sunday, May 4, 2025, in Dallas, TX. The Government Affairs Committee will have a combined meeting with GAWDA's Safety Committee during the SMC. The Committee continues to work on its primary priorities:

1. The Food and Drug Administration issued a long-awaited final rule on medical gases on June 18, 2024. The new requirements went into effect on December 18, 2025, except for annual reports. The final rule includes regulatory changes for product labeling, Current Good Manufacturing Practices, product certification, and post-marketing safety reporting. CGA’s Medical Gas Committee is providing additional advice on how to handle these issues. Through Tom Badstubner, GAWDA has provided compliance information to members on the new final rule.

2. A federal court has enjoined implementation of the U.S. Department of Labor’s final rule increasing the threshold salary amounts for Executive, Administrative, and Professional employees to be exempt from overtime pay requirements. The final rule increased the standard salary level employee total annual compensation threshold on the rule’s effective date of July 1, 2024. The rule would have again increased the thresholds on January 1, 2025. The final rule also provided for future updates of these levels every three years to reflect current earnings data. The Trump Administration is not expected to defend the rule in court.

3. The Trump Administration has issued an Executive Order requiring federal agencies to withdraw ten final rules for each new rule or proposed rule from that agency. In addition, agencies have been directed to provide a list of existing regulations that may be withdrawn or modified to be consistent with current administration policy. The Administration has also ordered agencies to cease all activities of programs promoting Diversity, Equity, and Inclusion and Environmental Justice.

4. The Occupational Safety and Health Administration has issued a proposed rule to protect indoor and outdoor workers from heat illness and injury while on the job. If finalized, the rule would affect 35 million workers nationwide. The regulatory text shows that employers will have to have a written heat injury and illness prevention plan and monitor heat levels at each work site, both indoors and outdoors. OSHA would adopt two heat index thresholds that would apply nationally and would factor in humidity as well as temperature. One, at 80 degrees Fahrenheit, would require employers to provide drinking water and break areas that

workers can use as needed. Employers would also need to have a plan for new and returning workers to gradually increase their workload, allowing their bodies to adjust to the heat. More protections would kick in at 90 degrees, including monitoring for signs of heat illness and mandatory 15-minute rest breaks every two hours. Employers would be required to check on people working alone every few hours and to issue a hazard alert, reminding their workers of the importance of staying hydrated. The deadline for comments was January 14, 2025.

5. The EPA Administrator has asked Congress to rescind waivers previously granted to the California Air Resources Board to impose stricter emissions requirements for internal combustion engines for commercial trucks, and ultimately to ban the sale or operation of non-Zero-Emission Vehicles after 2036.

6. The Federal Motor Carrier Safety Administration plans to implement its final rule to integrate the driver’s medical examination results into the Commercial Driver’s License database at the State level as of June 23, 2025. The final rule,

2 gas and 3 gas mixers designed for: Ar, CO2, H2, He, N2, O2, SF6, N2O

Mixed gas flowrates up to 56,000 SCFH

Mixed gas pressures up to 520 PSIG

Explosion proof for mixing H2 with N2, Ar