Our game-changing automated formatting process can help you optimize your commercial production performance.

There’s never been a thermoplastic bias-ply formatting process with greater precision, less material waste, or faster production rates. Our newest innovation, Precision BiasPly™, opens exciting new opportunities for aerospace and space applications that utilize off axis slit tape layups with AFP, wide-width master rolls, laminated blanks, or ply kits.

Lighter-weight airframes

Take advantage of the latest aerospace thermoplastic composites and CCM (continuous compression manufacturing) to gain production speed, structural, and cost benefits.

Dramatic waste reduction

Custom-width tapes, spools, and pad sets virtually eliminate waste (compared to 30% losses of the past).

Optimal buy-to-fly ratios

Higher yields, custom formats, and unmatched quality help you document and deliver on “green aviation” and supplier goals.

Proven at the highest level

With more than 11 billion linear feet of thermoset slit tape on board some of the most high-profile projects in the sky, you can rely upon the Web Industries/Omega Systémes team for the “personal touch” that supports real progress.

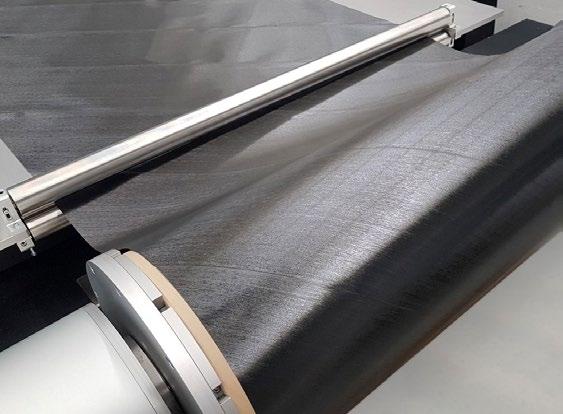

Web Industries’ Precision BiasPly™ process is a patented method of producing advanced bias-ply composites (TCPs) at commercial scale.

1

UD Prepregs are automatically positioned, cut, and seamed to create master rolls at +/- 45° and 90° orientations.

2

Master rolls are precision slit to customerspecified width, spool or pad size, or sheeted to virtually eliminate waste.

3

Incremental slit widths can create superior edge alignment for processes such as CCM opening up new manufacturing options for composite stringers, supports, and beams.

Our automated placement, cutting, and edge seaming technologies are a “game changer”. Current hand seaming and manual cutting operations limit the viability of bias-ply material and manufacturing methods.Automated bias ply parent rolls, combined with customized formatting, significantly improve production throughput.

We start by making wide-width master rolls of up to 127 cm across. Then our precision slitting and ultrasonic seaming capabilities do the rest. We can create custom tapes, spools, pads, laminated blanks and ply kitted materials that fit your application—with near-zero waste.

Whether you need to demonstrate more sustainable manufacturing (less material waste, better recycling, lighter-weight) or simply need to get to market faster, Precision Bias Ply™ is a powerful tool, delivering immediate advantages.

• Customized incremental-width tapes designed for your lines

• Bias-ply parent rolls up to 50” wide

• Automated alignment and 100% weld inspection at 1mm tolerances

• Precision assembly at +/- 45° and 90° orientations

• Ultrasonic seaming at nominal 1.5 mm overlap

• Pad and roll output formats

New opportunities for designers & engineers to:

• Reach target material cost savings

• Improve buy-to-fly ratios

• Support a greener supply chain

• Achieve the highest economic performances throughout the entire industrialization process.

Web Industries’ “personal touch” approach to strategic partnerships offers a trusted solution to sourcing these innovative materials. This enables you to incorporate bias-ply materials at the design phase to achieve the highest performance at the lowest total cost compared to existing manufacturing methods.