We are fascinated by surfaces and their fundamental significance for products and objects. Driven by this fascination, we transform and refine surfaces.

We focus on developing technologies and applying our expertise to add value for our customers. We aim to create products that improve our customers’ lives and exceed their expectations. This applies to all types of surfaces and application technologies and inspires us to always set new standards in surface coating.

The perfect mix of practical tips, interesting industry insights, useful instructions, exclusive competitions and much more relating to the professional trade. Sign up now.

Need to find a product manual easily? Visit our document centre to find manuals & brochures for current and obsolete products.

wagneraustralia.com.au/newsletter-signup/

wagneraustralia.com.au/document-library/

Important tips and tricks for optimum handling and perfect spraying results.

wagneraustralia.com.au/press-tips-tricks/

2,000 employees

19 operational companies, including 5 production plants

Around 400 international agencies

A 1,500 m² Technology Centre in Markdorf, Germany and a further 7 throughout the world

Worldwide service directly on site

Wagner is a technology based, global manufacturer of leading edge equipment and systems for the application of coatings. We are driven by an outstanding passion for innovation since 1947.

In order to best respond to the needs of our customers, our portfolio of products is organised into two divisions. The Decorative Finishing division develops tools that are tailored specifically to the needs of contractors and do-it-yourself enthusiasts, while the Industrial Solutions division manufactures industrial surface coating products and systems for a range of industry sectors.

We are proud of our legacy and committed to supporting the Josef Wagner foundations, which Josef set up to guarantee the continuation of his company and his life’s work. Having had no children of his own he transferred all his shares in the company and his personal fortune to the Foundation.

The Foundation’s returns fund non-profit and charitable endeavours including youth care and welfare, single parents and families in need, university students and other childrens’ charities, hostels, nursing homes and care homes and child care centres. To date the Foundations have donated over $20M to the related charities.

Wagner Australia has been operating since 1977, celebrating over 45 years with our head office and warehouse based in Melbourne. We offer a full suite of DIY, trade and industrial products to suit all application requirements. The business has grown to incorporate the brands featured below.

Industry, contractors and do-it-yourself enthusiasts - our customers benefit from our comprehensive expertise, profitable innovations and our many years experience as one of the leading international manufacturers of coating technology for the finishing of surfaces.

For do-it-yourself enthusiasts, Wagner has developed a wide range of user-friendly home-improvement products.

For contractors use our reliable and economical tools with a range of technologies including airless to apply paint, coatings and plaster. For industry, we offer technologically advanced equipment and systems for the application of fluid coatings, powder coatings and paint to surfaces.

With our innovations and highly efficient, reliable and user-friendly, top-quality solutions, we set new standards in surface technology - and in doing so make the advantages of the latest technology of real benefit for our customers.

Freecall: 1800 924 637 or (03) 8586 5190

Fax Orders: (03) 9587 2444

Email Orders: info.aumb@wagner-group.com

For all product information & technical specifications visit our website www.wagneraustralia.com.au

To assist our DIY customers to navigate our extensive DIY sprayers range, direct them to sprayerselector.com

For product videos, tutorials and general in-use videos, visit our YouTube channel, as well as latest product news and events on Facebook, Instagram & TikTok.

Room

For us, innovation is not a buzzword, but the heart of our business - since we started out in surface technology with the development of the first spray gun for serial production in 1953. Innovation is set deep in our mindsets. It forms the basis of our vision and is underpinned by our company strategy of 'WINNOVATION.' Pioneering developments such as dynamic 3D-coating and process-led, industrial powder-coating of woodbased MDF sheets, as well as the use of HVLP technology in the do-it-yourself segment that raised DIY spraying to a professional level, are characteristic of our talent for innovation.

Above all, our customers benefit from our technological expertise. The innovations go directly into our tools and components for do-it-yourself enthusiasts, contractors and industry. They are also used in the modern, comprehensively equipped WAGNER technology centres. Our brand new Innovation Training Academy facility is located in Hallam; allowing our customers and their products come into contact with solid expertise of our application specialists, enabling the optimal coating solution to be designed and tested in a realistic production environment.

On-site service & technical resolution

Innovation beyond the core business: Aerocar and SkyTrac

Josef Wagner, who studied aero and car manufacturing and whose career saw him working in various positions at the airplane manufacturer Messerschmitt, culminating in the role of technical director, set himself a particularly demanding task in the sixties: the development of a private, affordable gyrocopter. Because it was envisaged for a range of civil tasks, it was intended to be very easy to drive on the street and to fly.

Josef Wagner developed a particularly innovative technology that had never existed up to that point in the sector: two counter-rotating rotors, positioned one above the other, which render the otherwise typical tail rotor superfluous, and with flying characteristics that make the helicopter particularly easy to fly. While at the same time leading his coating technology company, Josef Wagner, in just a few years, successfully obtained the first approval for a helicopter in Germany - long before the famous German aircraft manufacturers.

In 2022, Wagner Spraytech Australia proudly celebrated 45 years of servicing the equipment and coatings industries. Over that time, the need and drive for the business from an innovation and logistical perspective has grown and changed. This prompted the move to our new facility at Dansu Court in Hallam, Victoria.

As part of the 45th anniversary, the Grand Opening in late 2022 began a new era for Wagner Australia. The facility features an open-plan office environment with plenty of natural light, from the Josef Wagner Boardroom to training rooms and meeting spaces. The property also now boasts the new state-of-the-art Innovation Training Academy featuring open and closed spray booths, blast rooms, on-site service and technical support and training.

Wagner Australia has a wide range of equipment and accessories suitable for use in industrial applications such as powder, liquid, adhesives, and sealants. For professional trades, we have the equipment to suit large and small projects that can save you time and money. For home DIY applicators, Wagner has a range of popular DIY sprayers including the Flexio range and the Control Pro Series.

A new era has begun with Wagner Australia, and we look forward to sharing the journey with you.

Supported by a nation-wide distribution chain

Features a state of the art Innovation Training Academy for on-site demonstrations & support

Expert service on site

Oil based semi gloss/ gloss top coat

Semi gloss/gloss interior woodwork

Ceiling acrylics Intumescent coatings

Synthetic resin varnishes, PVC lacquers, 2K lacquers

Exterior water-based paints

Water and oil-based primers and sealers

Interior acrylic low sheen/satin walls, interior undercoats

Roof coatings, floor coatings, thin membrane coatings, adhesives, sealants

Structural waterproofing, bituminous coatings, thick membranes Plaster

FEATURES

Rugged housing

Heavy duty housing

Reversible seat and replaceable ball

Spring assembly isolated from fluid path

Next generation shut-off

Extra light trigger

‘All Day’ trigger

Exchangeable grip in different sizes

FingerPrint+ Grip - fully adjustable

Built in wrench for easy filter access

Filter in handle

Improved swivel joint

One finger lock

Note: Dilution may be

*Can spray metallic coatings

#Level 5 plaster filler only - No aggregate coatings This is a guide only, multiple factors may impact spray experience

As a market-leading manufacturer, Wagner offers a wide range of products equipped with different technologies. From robust piston pumps to low maintenance diaphragm pumps, to entry-level low pressure devices and worm driven pumps for the application of plaster. Below is an overview of our different technologies:

Low pressure spraying uses a high volume of air under low pressure. With HVLP, the atomised air generated in the turbine flows through an air hose to the paint tank where it then builds up pressure. The transported material then reaches the nozzle where it’s atomised with remaining air. XVLP achieves even greater atomisation due to 60% higher air volume.

• Perfect as an entry level sprayer or for small projects

• Easy to use

• Can be easily adjusted to suit any object/surface

• Variety of spray attachments

• Very fine spray pattern, even with water based materials

• Easy to clean

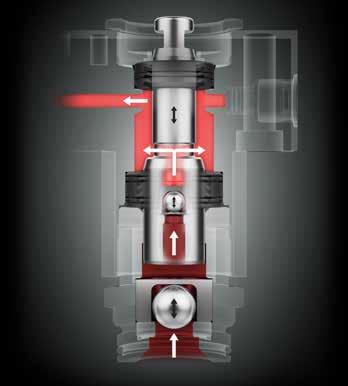

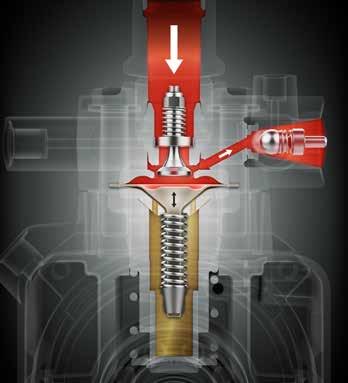

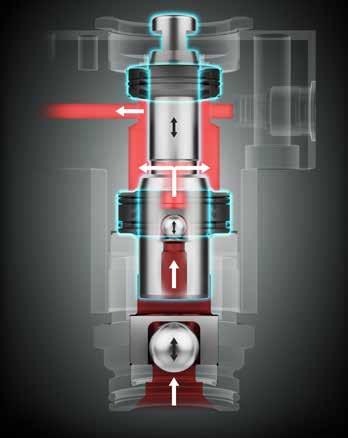

Piston pumps transport the material by means of a stroke movement in the piston. This creates high suction performance, making them ideal for highly viscous materials. Some piston pumps are operated pneumatically. Wagner hydraulic piston pumps offer even greater performance and can also be petrol operated.

• Perfect for high viscosity materials

• Optimal suction performance

• High delivery volumes

• High material pressure

• Long hose lengths possible

• Use of large tip sizes possible

• Extra durable packings for long life

In diaphragm pumps the material is transported by means of a stroke movement in the diaphragm. Products featuring this technology are robust and yet easy to handle on a construction site or workshop. Achieve smooth pressure regulation for high quality finishes.

• Flexible material intake

• Use a hopper for smaller projects or apply directly from the can

• Pressure can be continuously regulated

• Low maintenance and very low wear

• Low operating costs

• Long stroke technology and extremely robust design

Double diaphragm pumps transport material by means of a stroke movement of two diaphragms working in opposite directions. This creates a very low-pulse, smooth flow of material. This also allows you to work with materials which are sensitive to shearing and moisture, and with pre-mixed 2K products. Operated by compressed air.

• Flexible material intake

• Use a hopper for smaller projects or apply directly from the can

• Pressure can be continuously regulated

• Low maintenance and very low wear

• Low operating costs

• Long stroke technology and extremely robust design

Wagner's relentless pursuit of innovation has been centred on the development of advanced technologies and the application of our expertise to enhance value for our customers. Our meticulously crafted products not only elevate the quality of our customers' lives but also go above and beyond their expectations. As part of our dedication to safeguarding surfaces, Wagner has ventured into a new category, Outdoor Clean & Care, introducing a range of user-friendly home improvement products.

Compatible with Bosch Professional 18V, Bosch ProCORE 18V batteries and AMPShare platform (2429183).

Compatible with Bosch POWER FOR ALL Alliance 18V platform (2458099).

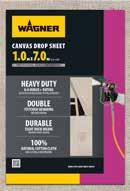

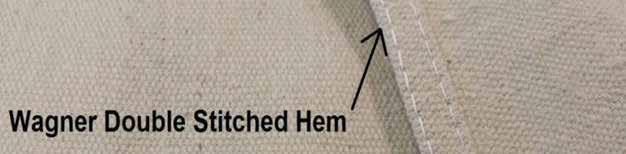

Wagner is the market leader in the supply of heavy duty canvas drop cloths, and our range of drop cloths are the highest quality available in the market. Made of 100% natural cotton, Wagner heavy duty canvas drop cloths are a premium contractor grade product, and are stronger and more hardwearing than other similar products in the market. Double stitched hemming adds to their durability and testing proves the tight weave of the fabric provides superior absorption and protection.

Heat Tools are versatile for many uses around the work site, home, workshop as well as many hobby and craft projects. Powerful heat flow helps simplify many tough jobs or tedious tasks such as removing paint, stripping labels, forming plastics, re-applying adhesives, drying, shrinking and much more. The possible uses are endless! The FURNO range of DIY & trade heat guns have a range of handy features and the digital display on the Furno 750 makes it very easy to control.

Dual heat settings: Tackle a range of applications with precision.

Three working positions: Adjust for balance and comfort while working.

Fold-out wire stand: Enables convenient, hands-free operation.

Thermal shut-off: Built-in safety for peace of mind.

Ergonomically designed to feel balanced at all times, reducing fatigue.

Two temperature settings with stabilisers for upright support ensuring safety in stationary applications.

Removable cordset allows for easy storage.

Memory function, cool down mode, 6 air flow settings, removable heat shield, rear stabilisers for upright support, removable cordset for workbench style, and sturdy carry case.

Accessory kit includes concentrator nozzle (spot jet), glass protection nozzle, hook nozzle, wide nozzle and 5-in-1 detailed scraper tool.

Stripping wallpaper with an electric steamer is so quick and convenient, and the handy, user-friendly equipment from Wagner makes it simple: Fill with water and connect to power. Hold the steamer plate against the wallpaper. The long working hose and light weight steamer plates guarantee trouble-free working. These efficient units even manage problem areas such as ceilings, corners and angles with ease.

The SteamForce Speed Pro Wallpaper Steamer is a professional wallpaper steamer, ideal for use in hire departments and for commercial use. This professionally rated system is hard wearing and durable. Combined with a patented, unique built-in step, providing a strong working platformthere is no need for a ladder to reach those difficult areas. The extra large anodised aluminum water tank can carry up to 5.1 litres of water with one fill. This enables up to 95 minutes of steam time, allowing continuous stripping of paper on larger projects. A handy exterior water level indicator shows when the tank needs refilling. The tough yet lightweight steam plate can penetrate through several layers of wallpaper at a time for speedy paper removal.

Control Pro 350 Extra Skid

Ideal for medium to extra large sized projects, new work or small renovations.

with HEA technology for up to 55% less overspray.

Wagner provides a range of painting solutions that extend beyond traditional spray applicators. In addition to their innovative spray products, Wagner has developed specialised rollers that are specifically designed to handle painting tasks in situations where spraying is not practical. These rollers are engineered to make painting projects faster and easier, eliminating the need for messy paint trays. With Wagner's versatile range of products, you can tackle any painting project with ease and efficiency.

Wagner Wood & Metal Sprayers use High Volume Low Pressure Technology (HVLP) and are classified as a finishing tool. These sprayers atomise paint under very low pressure (around 4 to 12 psi).

Wood & Metal Sprayers are ideal for high-quality precision painting applications where finish and control matter.

There are many projects around the house and garden that are best suited for using an HVLP sprayer, including gutters, doors, furniture, shelving, pipes, frames, appliances, cabinets, shutters, porcelain, architraves, trims, multi-colour finishes and much more.

Why is HVLP so effective?

The warm envelope of air that surrounds the paint jet allows for precise, clean work with great control. The high air rating of the nozzle and the paint flow rate together create very fine atomisation – and this is in spite of the low electrical current consumption. Great for painting areas that a brush or roller typically can’t reach, with a superior finish.

Suitable paints and materials

Suited for water based (acrylic) and oil-based primers and paints, aluminium paints, wood preservatives, polishes, oils, stains, hammer finishes and special effects paints. Some paints/materials may require some dilution when necessary, dependent on paint viscosity. Thin oils such as corrosion protection and cleaning fluids can also be sprayed.

Wagner HVLP models have been designed for use with the patented Click & Paint® System.

This system allows for the front spray attachment to be quickly and easily removed from the gun in under 5 seconds.

The Click & Paint® System is great when using different colours and materials or where a specialty attachment is required for your application.

A dream for DIY enthusiasts, the Flexio sprayers enable sprucing up the home in no time! From interior walls and ceilings, doors, window frames and indoor furniture, to wooden fences, garden furniture, sheds and much more. Projects can be primed, lacquered, varnished, oiled, sealed, preserved or simply given a new colour with a Flexio.

The powerful X-Boost™ turbine means that most conventional coatings can be applied without being diluted. With adjustable air pressure, the power of the turbine can be varied to suit any coating perfectly, for precise control. The volume of paint can also be adjusted to suit the material being sprayed and the project type. With an average working speed of 3m2/min, a standard room can be sprayed in around 12 minutes, or an outdoor chair in just a few minutes!

Wagner’s unique i-Spray nozzle is a technical innovation. It allows interior acrylic paints to be atomised finely to achieve even paint coverage and a perfect finish on your walls and ceilings. Thick exterior acrylics can also be sprayed onto coarser surfaces. Instead of applying two coats of paint with a brush or roller, paint fast with Flexio and spray the same amount of paint in less than half the time.

Wagner Flexio models have been designed for use with the patented Click & Paint® System. This system allows for the front spray attachment to be quickly and easily removed from the gun in under 5 seconds. The Click & Paint® System is great when using different colours and materials or where a specialty attachment is required for your application.

(2420174)

Ideal for those larger-sized projects around the house, including interior and exterior walls, weather boards, wooden fences, garage doors, window shutters, lattice work, pergolas, cane furniture and much more. The Control Pro range of pumps will spray both water based and solvent based materials. Whether painting a fence or an entire house, Control Pro sprayers provide simplified operation and clean up, with the technology to provide years of trouble free operation.

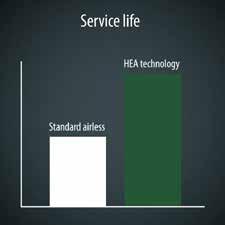

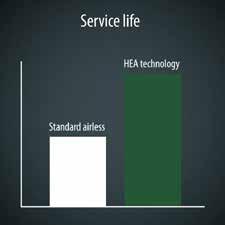

Wagner’s unique High Efficiency Airless spray technology has revolutionised the way we spray today. Available in the Control Pro range, this innovative pump and tip technology is a game changer.

With an innovative spray tip design and a very efficient pump, this ground-breaking technology enables the user to spray with significantly reduced pressure and maximum control – resulting in a softer spray pattern and up to 55% less over-spray when compared to conventional airless technology. There are many benefits to this technology, especially when spraying indoors. Less overspray results in more efficient usage of paint since less paint is wasted when spraying.

Tip angle

The tip angle determines the width of the spray angle, e.g. in this case 50°.

Specific octagonal handle tip made for the Control Pro range.

Orifice diameter

The orifice determines the flow volume (the amount of paint that will be applied).

= 0.015” thou

Ideal for medium residential, commercial and maintenance applications. Features a quick-release fluid section that can be changed in seconds and an intelligent high efficiency brushless motor for demanding jobsites.

The ultimate tool for the painting professional

This latest generation turbine was developed with quality and functionality at the forefront. With 60% higher air volume and 30% greater coverage than other low pressure devices, Wagner’s XVLP units provide excellent atomisation performance.

Wagner XVLP sprayers (consisting of a turbine and various spray attachments) allow for varnishes, high viscosity lacquers and standard water based paints to be sprayed with a quality finish that a painting professional would expect.

Optimum atomisation of lacquers and stains. Compatible with all XVLP front ends. Allows for full directional spray control.

The spray attachment can be cleaned quickly and easily. Additional spray attachments are available which allow for a wide range of materials and objects to be sprayed on the job.

Finely adjustable air flow and material flow regulation enable precise application. The spray level and fan width settings allow additional adjustment to suit the object being sprayed.

High-efficient brushless DC motor for maximal power and durability.

Powered by Bosch Professional AMPShare battery system.

Wagner FinishControl sprayers can be used for a broad scope of applications, and can spray oil based paints and stains as well as high viscosity acrylic paints. There are 3 spray attachment options: StandardSpray, FineSpray and WallSpray. The unique Click & Paint® system enables the attachments to be changed quickly and easily.

SPRAY ATTACHMENT

Varnish | low-viscosity materials

Standard enamels and lacquers

High-viscosity enamels and lacquers

Gloss/Semi Gloss acrylics and water based paints

Wagner Recommends Limited Suitability

The FinishControl Range is Click & Paint® compatible, meaning the front end can be swapped out in seconds!

Compatible with Bosch Professional 18V, Bosch ProCORE 18V

The ultimate choice when it comes to painting, touch-up or renovation work. Solvent or water based paints, stains, varnish, impregnations, oils and primers can be applied. With additional spray attachments, it is also possible to use emulsion paints, making this handy paint sprayer very versatile. Doors, windows, stairs and other surfaces can be coated fast.

HVLP spray technology operates by harnessing the airflow produced by the turbine to move into the container and then to the gun nozzle. The incoming air compresses the air in the paint container, propelling the paint through the suction tube toward the nozzle. Through a combination of high air volume and low air pressure, the paint is atomised into fine particles at the nozzle outlet forming the spray jet. The air stream enveloping the paint particles acts as an air jacket, reducing spray mist to ensure better coverage and minimal material loss offering significant advantages for the user. The solvent-resistant HVLP gun Ultra is designed for applying standard solvent-based and water-thinnable paints.

Integrated storage box

Ideal for needles, air caps, tools and cleaning accessories

Improved HVLP Ultra Gun

Adjustable air and material volume directly on the gun

For HVLP guns with gravity feed cup (gun with gravity feed cup available as separate accessory)

Ideal for work breaks, storage and transport

The spray jet can be perfectly adjusted to the object to be coated

Indicates when the filter needs cleaning or replacement

Easily accessible filters with large surface for optimal atomisation

A great additional accessory ideal for spraying inside cabinets and other hard to reach areas. Takes the weight of the pot away from the hand for fatigue-free spraying. Less re-fills required due to double pot size.

Comes complete with 2 litre pressure pot, 1.5m air and material Whip Hose.

Master any of your painting or staining projects with this gun. Provides the finest atomisation in the industry.

Choose from 3 spray patterns with click-in guided air cap for perfect pattern alignment. Comes complete with non-bleeder gun with two-stage trigger, stainless steel needle and nozzle and #2 projector set.

Convert your air compressor to a HVLP system! (minimum 1½ HP 5 SCFM @ 90 psi required)

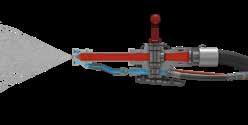

Experience the best of both Airless and Air Spray with Wagner AirCoat Fine Finishing Systems. Achieve mirror finish projects effortlessly and efficiently. These systems offer low pressure airless paint atomization through a fine tip, along with the added benefits of air to optimize the spray pattern and provide fan control. Elevate your finishing game with these ultimate tools for superior finishes in all applications.

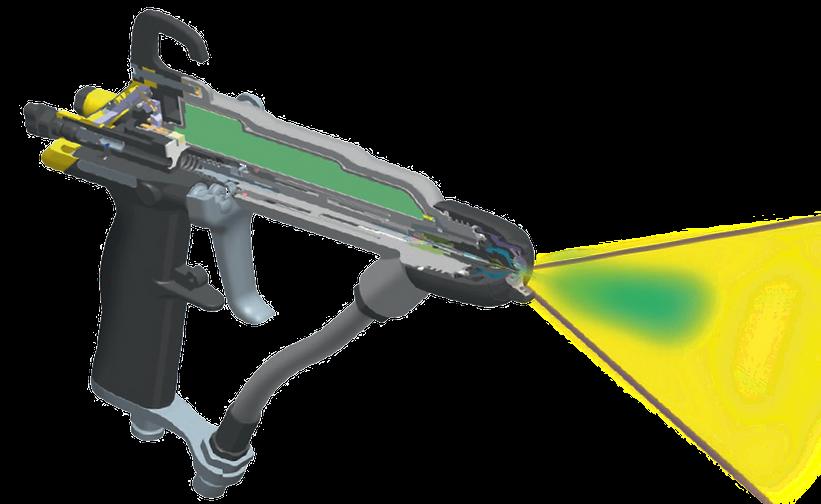

In the AirCoat process (air assisted airless atomisation) the material is pushed through the tip at a relatively low pressure (435 - 1,740 PSI) using a piston pump or a diaphragm pump, and supported by compressed air (7.25 - 36.25 PSI) in the atomising process. This is made possible by the central air feed (air cap) which is fitted immediately at the tip bore and surrounds the material being sprayed like a sheath. This directs the spray to the surface with minimal overspray. Adjustment in the spray pattern of up to 50% is possible.

- The

The combination of an innovative Tip and three different Air Caps makes the Wagner AirCoat gun range a high grade all round system for the application of all water based and solvent based lacquers (such as acrylic, 2-component, lacquer, stains and varnishes). The perfect combination to help achieve a superior finish.

BENEFITS

High coating speed

Uniform application of material

Soft run out at edges

Less overspray than with airless or airspray products

Reduced working pressure of 870 psi

Ergonomic guns with many extras for greater working convenience

Designed for maximum reliability with perfectly matched features to suit a huge variety of applications. From smaller pumps for lighter work right up to larger pumps for higher viscosity materials, larger work sites or for running multiple guns, you will find the right pump in the Wagner ProSpray/HeavyCoat range. Features include Digital Electronic Spray Control, brushless DC motor, Auto-Oiler, self-adjusting packings, high pressure filter, and more. The smaller skids now come with Wagner HEA Pro Tips for optimised performance, with the larger units also able to be used with HEA tips.

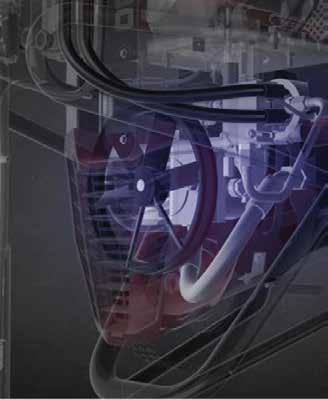

The innovative, Brushless DC Motor* provides improved performance and efficiency and requires minimal maintenance. Continuous pressure measurement automatically controls the motor speed, ensuring constant material pressure. In the event that the motor approaches a temperature that could cause damage, the EPC will reduce the current to slow down the motor until the temperature stabilises.

*Available on ProSpray PS 3.23 and up

The tilting cart feature allows for quick and easy change over of paint containers.

Wagner’s practical Self-Adjusting Quad+™ Packings lead to less wear and are very simple to change.

The superior seal design provides 50% longer service life as the packings keep tension even as the piston wears, which means significantly lower maintenance costs over the life of a machine.

Maintenance is made easy with the Auto-Oiler*. With the push of a button before each use the piston is oiled and the packings are lubricated. The “Easy Glide” machine oil can be refilled easily and forms a protective film around the cylinder and piston, protecting the unit against premature wear.

*Available on ProSpray PS 3.21 and up

FLUID SECTION

Quick change of the fluid section is possible without tools eliminating the need for costly downtime on site.

*PS 4.23, 3.34 & PS 3.39 only.

The low position of the PS 3.39 inlet valve improves the suction power for extremely high viscosity materials.

The next generation ProSpray piston pumps, featuring IntelliSync technology, offer seamless Bluetooth connectivity with the SprayManager app. This integration unlocks enhanced app functionality, providing users with advanced digital support for optimal paint spraying performance.

With IntelliSync technology, Wagner devices connect effortlessly to the SprayManager app via Bluetooth. Compatible devices appear automatically in the app’s “MyFleet” section, and a bright Bluetooth symbol on the device shows connection status. IntelliSync ensures a stable, secure link— giving users full control whether nearby or working remotely.

ProStart makes setup easy by guiding users through each step—from preparation to documentation. When connected to an airless device, it automatically applies the correct pump settings. The pump can then be controlled remotely via smartphone, wherever you are on site.

Managing multiple sprayers can be complex, but MyFleet simplifies oversight—even across different brands. Devices with IntelliSync integrate automatically, enabling usage tracking and service reminders based on material flow. For non-connected units, maintenance records can be updated manually.

Worn tips waste material and produce poor spray patterns—but wear isn’t always visible. TipAware solves this by checking tip condition in real time, similar to a battery tester. Just insert the tip, spray water into a bucket for 30 seconds and the app displays its status. Integrated into ProStart, TipAware continuously monitors tip quality while you work.

Wondering if your material is sprayable and how to set up your device? Scan the Can gives you instant answers. Just snap a photo of the can and the app displays recommended settings like tip size, spray pressure and dilution. With one tap, you can also open the full product data sheet.

While ProStart automatically logs all workflow steps, manual data entry is also available— eliminating handwritten reports and simplifying handovers. This boosts team efficiency and ensures reliable documentation without lengthy briefings.

The cordless spray solution designed for professional contractors who demand flexibility, effciency and professional-grade results. Use it as a backpack, stationary or side-carry.

Built-in 4.7 litre hopper enables high area coverage. The two batteries provided in the kit are capable of delivering more than 30 litres of paint.

The PS 3.20 Skid offers excellent value for money. This affordable unit is ideal for those who only spray occasionally or who need a reliable pump for spraying small areas. Although compact in size, the PS 3.20 is robust and durable with user-friendly features all wrapped into a practical design.

• 5.7 Litre Hopper accessory also available.

Ideal for small jobs or as a second unit. A compact solution for small to medium airless applications.

• 5.7 Litre Hopper accessory also available. Comes complete on skid with flexible suction system, high pressure filter, HEA pressure gauge, inlet valve depressor, Vector Grip airless gun, 15 metre airless hose, 517 HEA Pro tip and base, tool kit and pump protection start-up pack.

•

•

•

Tilt

•

• Long stroking piston

• Retractable telescopic handle for compact storage

• Angled cart design for one man loading and unloading

• New tilt cart feature for easy change over of paint drums

Suitable for projects requiring more than one gun to be used.

• Innovative brushless DC motor

• Long stroking piston

• Retractable telescopic handle for compact storage Angled cart design for one man loading and unloading

• Quick-release fluid section (without tools)

• Tilt cart feature for easy change over of paint drums

Ideal for large production residential, roofing, commercial, maintenance, industrial applications and projects requiring more than one gun to be used. Can also spray high viscosity materials such as nonaggregate texture coatings and plaster based products, including filling compounds.

• Innovative brushless DC motor

Long stroking piston

• Retractable telescopic handle for compact storage

Angled cart design for one man loading and unloading

Quick-release fluid section (without tools)

• Direct immersion inlet valve providing greater intake power

Tilt cart feature for easy change over of paint drums

Wagner’s patented QLS (quality long stroke) technology provides superior performance, eliminating pulsation for smooth application. The longer stroke of the diaphragm allows the application of a wide range of materials, from thin stains and lacquers to higher viscosity coatings. The low stroke frequency puts less stress on internal components, significantly extending the service life and keeping maintenance costs low. The valves are made from wear-resistant carbide and the diaphragm is made of solvent resistant polyamide.

Highlighted parts on each pump show the number of parts that may need to be serviced in the lifetime of each respective pump.

Diaphragm pumps use fewer parts - diaphragm, inlet & outlet valve - compared to the piston pump -piston, packings, inlet & outlet valve - with the packings tending to wear out quicker due to the friction caused by the piston pumping material out of the pump. Diaphragms can be serviced using a quick change valve set, whereas pistons are required to be taken to a service centre for service.

DIAPHRAGM

Versatile and robust, the perfect all-rounder for multiple application types.

Compact - smallest in its class, mobile and lightweight.

Robust - ideal for demanding construction site use.

An optional DN3 7.5m hose is available. Perfect for laquers and varnishes (9984583)

The latest generation of Vector airless paint sprayer guns from Wagner has been meticulously engineered to provide top-notch performance. These professional-grade guns are incredibly versatile, as they can accommodate water, oil, and solvent-based materials, making them suitable for a wide range of applications. The super light trigger action, 1-finger trigger lock, and smooth swivel ensure that these guns are extremely easy to use, providing unparalleled convenience for the user.

One of the notable advancements in the Vector series is the Vector Grip, which is an improvement over the Pro model. It introduces an industry-first exchangeable, ergonomic grip feature. For added comfort and adaptability, these comfortable grips are available in three sizes, catering to various hand sizes and preferences.

Moreover, the Infinity model takes user comfort to the next level with its fully adjustable handle, offering a custom fit tailored to the user's needs. The 'All Day' Trigger feature ensures exceptional comfort during extended use, making it suitable for prolonged spraying tasks. With a pressure rating of 5000 psi, the Infinity model stands out as the optimal choice for high-production applications that require continuous spraying.

FEATURES

Rugged housing

Heavy duty housing

Reversible seat and replaceable ball

Spring assembly isolated from fluid path

Next generation shut-off

Extra light trigger

‘All Day’ trigger

Exchangeable grip in different sizes

FingerPrint+ Grip - fully adjustable

Built in wrench for easy filter access

Filter in handle

Improved swivel joint

Wagner have developed a range of products to enable you to maintain your Wagner pumps in peak condition with the minimum of fuss. A well looked after pump will perform better and give you a longer pump life increasing your productivity.

Save valuable working time with this practical accessory for piston and diaphragm pumps.

Wagner PumpRunner prevents valves from drying out and sticking in between use. It provides an airtight seal and is very quick and easy to install and remove. PumpRunner is simply placed over the suction tube, filled with water or EasyClean and clamped on airtight. Assists with clean transportation.

Suits ProSpray high boy units from PS 3.25 up and SuperFinish pumps.

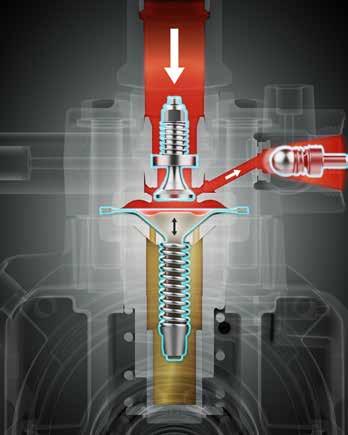

Wagner's patented HEA (High Efficiency Airless) tip technology incorporates a Pre-Tip that is strategically positioned ahead of the atomisation tip. This innovative design allows the Pre-Tip to atomise the material at the same delivery volume and working speed as traditional airless devices. The unique structure of the HEA tip generates a soft, feathered spray pattern, resulting in enhanced coverage of overlapping strokes, minimising paint build-up, and an overall higher surface quality. These characteristics make the HEA tips exceptionally user-friendly, cost-effective, and guarantee a flawless finish, making them an excellent choice for various painting applications.

UP TO

Tip angle

The tip angle determines the width of the spray angle, e.g. in this case 50°.

The ideal distance from the object is always around 300 mm.

Bore diameter

The bore diameter (in this case, 0.017 inch) determines the flow volume and thus the amount of paint applied.

Extra durable

The high-quality stainless steel tip cylinder, as well as the carbide tip insert, reduce wear and allow a constant spray angle.

The lower spraying pressure reduces overspray by up to 55%.

Free in the set: purchase a HEA tip and receive the matching gun filter and a double seal for FREE.

Wagner HEA tips are reversible and can be cleaned in a matter of seconds. Simply twist the tip and spray - and the tip is clean, without the need for any tools. Easy to clean for easy insertion of the tip seal.

MAXIMUM CONTROL

The gently feathered spray pattern ensures better coverage and avoids hard edges.

Reduced strain on the sprayer and its components mean HEA tips can be used for twice as long as conventional airless tips.

Patent-registered dual tip technology

Two tip bores, one directly after the other, guarantee a perfect spray pattern with high material output, even in low pressure ranges. Overspray is reduced to a minimum.

FATIGUE-FREE WORK

Low pressure spraying ensures low gun recoil for ease of use.

Even coverage provides excellent surface quality, with little to no back-rolling required.

The TradeTip 3 (TT3) stands as the focal point of Wagner airless spraying technology. It operates by pumping paint at high pressure through the tip, where the tip core atomises and shapes the spray fan. Wagner tips are highly durable, crafted from carbide and stainless steel to minimise wear and maintain a consistent spray angle. Additionally, Wagner tips are easy to clean - simply twist and rinse without the need for any tools. Each set of Wagner tips is accompanied by a bonus matching gun filter and a double seal for added convenience.

Understanding Spray Tips: 517 = 10 inch Fan & 17 thou Orifice

The first digit on the tip indicates the nozzle angle. It is also used as a guide to work out the fan width; simply double the number:

4 = 40° 8 inch

5 = 50° 10 inch

6 = 60° 12 inch

Includes Seal & Filter (Yellow Tip)

The next two digits indicate the nozzle or orifice diameter. This determines the flow volume (the amount of paint that will be applied).

17 = 0.017” (17 thou orifice)

The Fine Finish Tip uses a pre-atomising process which slows down the speed of the paint to provide more control, less overspray and a superior finish. With a double special core for ultrafine droplet formation for achieving incredibly high-quality surface finishes. The Fine Finish tip offers optimal atomisation even in the low pressure ranges and is ideal for particularly high grade finishes. The spray pattern of Fine Finish

provides soft run-out at the edges providing first class results.

Seal & Filter (Purple Tip)

Offers extra wide spray pattern (24”) for high production jobs. Will allow you to complete your broad spraying jobs with fewer passes and minimum feathering. Tip core made from the highest quality tungsten carbide for extra durability.

Includes Seal & Filter (Yellow Tip)

A unique tip for high quality line painting and marking projects. Now with an even larger selection of tip sizes with different spray jet widths, the spray pattern of the Line Finish tip will result in precise, clean lines.

Includes Seal & Filter (White Tip)

Gun filters prevent tip blockages

The airless gun push-in filters from Wagner are made of non-rusting steel and come in various mesh sizes, depending on the application. Plasma welded joints ensure they are highly stable against mechanical stresses of all kinds. Quality Wagner filters offer durability and consistency that painters value.

FINE - YELLOW for exterior water based paints, interior acrylic & interior undercoats

MEDIUM - WHITE for ceiling acrylics, thin membranes, roof & floor coatings

COARSE - GREEN for thick membranes, intumescent coatings

*Check product data sheet for specific recommendations.

Filters should regularly be removed from the gun, cleaned and inspected for wear.

Note - Application speed should be increased by ‘up-sizing’ tip rather than increasing pump pressure. Check product data sheet for specific recommendations.

Wagner high-pressure filters are used to prevent downtime due to blockages.

Suction Filters limit foreign bodies from entering the pump section providing greater protection and

Heating instead of diluting!

All TempSpray heating systems incorporate an electric heating element located inside the hose, directly within the paint flow. This design ensures uniform heating of the paint material to the desired temperature along the entire length of the hose, with smooth regulation from 20° to 60° C. This results in reduced viscosity and enhanced paint application. The heating system maintains the coating materials at the ideal working temperature, irrespective of temperature fluctuations. This eliminates the need for dilution of coating materials to make them sprayable. Additionally, the heating hose system not only reduces the need for solvents but also allows for increased applied film thicknesses. These innovative systems offer several advantages.

-Ideal for any painting and undercoating jobs.

-Constant paint temperature even at low outside temperatures.

-Considerably better working of high viscosity coating materials.

-Increase in the atomisation quality.

-Easily adapted to all Airless units.

-Excellent edge coverage.

-Increase in the flow characteristics.

-Paint savings due to minimised overspray.

-Lower equipment wear since a lower material pressure is needed.

• Ideal for any painting and undercoating jobs

• Easily adapted to all Airless units

• Low weight Heating instead of diluting!

Constant paint temperature even at low outside temperatures.

• Considerably better working of high viscosity coating materials.

• Increase in the atomisation quality.

• Excellent edge coverage.

• Increase in the flow characteristics.

• Paint savings due to minimised overspray.

• Lower equipment wear since a lower material pressure is needed Heating instead of diluting! Easily

• Constant paint temperature even at low outside temperatures.

Considerably better working of high viscosity coating materials.

• Increase in the atomisation quality.

• Excellent edge coverage.

• Increase in the flow characteristics.

• Paint savings due to minimised overspray.

• Lower equipment wear since a lower material pressure is needed

Perfectly balanced gun in a compact and organised case set for mobile use. Features a secure grip on the gun with excellent ergonomics and a fully electronic control module. The Special funnel beaker with various inclination angles to allow virtually any powder type to flow until completely used.

Screw driven machines for aggregate based products such as acrylic based renders, textures, waterproofing, grouting and fireproofing compounds.

The application of organic and mineral materials can be incredibly demanding, especially in multi-storey buildings where materials need to be manually transported over several floors. This often results in unavoidable mess and debris on construction sites. Fortunately, Wagner texture and render machines offer a solution by efficiently pumping materials to heights of up to 30 meters.

The versatile PlastCoat units are capable of a wide range of applications, including thermal insulation, textured plaster and paint, acrylic-based renders, smoothing and structuring, waterproofing, concrete repair, and more. These units are designed to deliver consistent and high-quality coatings across various surfaces.

When material is applied using PlastCoat units, it is fed from the hose to the spray lance via a spiral/screw pump . When compressed air is injected at the spray lance , the heavy material is atomised to ensure uniform application. Screw pumps use a displacement worm drive mechanism to deliver the material through the rotor and the stator . The equipment is exceptionally durable and low-maintenance.

retardent, corrosion protection, adhesives

Fillers, concrete coatings

Structural waterproofing, bituminous coatings

Plaster, concrete, contact primer

render, thermal insulation, adhesives/fillers

Ultra high build coatings, including coatings with grain size up to 0.3mm

Suitable for use with PC 830, PC 1025 Pro & PC 1030, the PlastMix 15 continuous flow mixer is very user friendly with simple controls.

Easy to dismantle for fast cleaning and maintenance. The high performance drive motor with direct transmission and high torque ensures optimal start-up even with a full hopper (60ltr). Height adjustable from 95cm to 116cm and available in four variants; with steel or PUR mixing tube, and with or without booster pump. Mixing rate of 15 l/min with a maximum grain size of 5mm. Suitable for cement-based, dry bags render, texture & fire retardant coatings.

The number 1 brand in the USA when it comes to airless spray technology. When your business depends on the tools you use, you need to be able to count on the people who make them. Titan’s relentless commitment to helping every professional painter be their best leads to better work, improved ROI and growing business.

Since their introduction almost half a century ago, Titan PowrTwin hydraulic piston sprayers have a well-earned reputation for durability and dependability among serious contractors for large scale residential, commercial and industrial applications and multi-gun usage. Featuring Titan’s slow-stroking hydraulic Speeflo® HydraDrive™ for extreme power and reliability. The PowrTwin’s Severe Service™ 900 Pump features a cylinder and piston rod that are tempered with a proprietary heat-treating process that increases pump life by 150% over competitive pumps. Self-adjusting packings resist over-tightening and help prevent premature wear.

Long and slow stroking piston maximises power and durability.

Proven Titan technology with 45 years in the field.

Field serviceable with easy to remove/replace fluid section.

Extremely efficient cooling system: fan and shroud maximise cool air flow over warm areas and radiator style active cooling hydraulic tank.

Large 12” pneumatic tyres make it easy to move around job site.

Front mounted motor/pump assembly is easy to access for simplified maintenance and service.

The PowrTwin DI units with submersed foot valve create the most efficient siphon system on the market today, allowing the spraying of very heavy coatings. The EZ Swing Frame makes this the most efficient and convenient to use petrol hydraulic system. Additionally, the EZ Swing Frame allows for less spillage during paint changes and lower height (and centre of gravity) of unit for easy transportation.

The PowrTwin 12000 Plus DI is the flagship of the lineup for very large scale projects where up to 6 guns may be needed, or application of very heavy coatings. Very portable and user friendly!

Titan PowrTwin hydraulic piston sprayers have a well-earned reputation for durability and dependability among serious contractors for large scale residential, commercial and industrial applications and multi-gun usage. With accurate pressure control ranging from 400 to 3300 psi to spray low viscosity primers to heavy-bodied finish paints. Featuring vented hydraulic fill and dip stick for easy access and less mess, and easy-remove filter: only 3 turns to remove, and a wrap around frame for extra strength and stability.

Smooth, slow-stroking hydraulic drive provides extreme power and reliability.

Cylinder and piston rod are tempered with a proprietary heat-treating process that increases pump life 150% over competitive pumps.

Self-adjusting packings resist over-tightening and help prevent premature wear.

Bridges, water tanks, roofing, waterproofing, foundations and other large projects require the kind of hydraulic piston power only a Hydra can deliver. It is the ultimate sprayer for any job where maximum power is required and dependability is critical.

Unmatched durability and performance powered by electronically controlled hydraulics.

Versatility to spray heavy and light bodied coatings without burning out clutches.

Hydraulic motor is optimised with one moving part, reducing heat and extending life.

Equipped with two cooling fans to maximise air flow over hydraulic system.

Large reservoir holds up to 23 litres of fluid.

Automotive style radiator provides efficient cooling.

Perform effortless drum changes with the electric AutoLift™ system that raises and lowers the fluid section with the touch of a button.

Ideally suited for new construction, residential repaint and small commercial projects where electricity is not readily available. This high performance, petrol-powered airless sprayer will apply all standard architectural primers and paints quickly, easily and efficiently.

Compact and portable for total flexibility, with 12” rugged, pneumatic wheels.

Designed and built for contractors who are serious about completing large scale painting projects quickly and profitably. The PowrTwin 4900 Plus is ideal for professionals who want the slowstroking power and maximum durability that only the PowrTwin 4900 Plus can deliver. Connect up to 3 guns to keep a crew spraying.

for professionals who

the

stroking

and

durability that only the PowrTwin 6900 Plus can deliver. Take a step up in power delivering 8.5 litres per minute and connect up to 4 guns to keep a crew spraying.

complete on cart including pressure gauge, rigid suction system, 15 metre airless hose, RX-Pro airless gun, SC-6+ reversible 517 tip and base.

The flagship of the DI series, this model is recommended for very large scale projects where up to 6 guns may be needed, or application of very heavy coatings. The most portable roof sprayer ever.

Comes complete on heavy duty EZ swing frame, Speeflo® HydraDrive™ piston pump with Severe Service™ fluid section, RX-Apex non-filtered premium airless gun, 15 metre 3/8” hose, SC-6+ reversible 517 tip and base. Recommended for 1800+ L/week.

Max Tip Size 1 Gun 0.058” Max Tip Size 2 Guns

The new Hydra X roofing and protective coatings sprayer combines the power and pressure needed to spray the toughest coatings. Built to last with HydraStroke® technology and Severe Service™ fluid section which maximize durability.

Additional, new key features like the new AutoLift™ system and quick change fluid sections make jobsite life easier and more productive.

The new Hydra X roofing and protective coatings sprayer combines the power and pressure needed to spray the toughest coatings. Built to last with HydraStroke® technology and Severe Service™ fluid section which maximize durability.

Additional, new key features like the new AutoLift™ system and quick change fluid sections make jobsite life easier and more productive.

Comes complete on heavy duty balanced cart with 12" pneumatic types, HydrastrokeTM technology piston pump with Severe Service™ fluid section. AutoLift™ system to raise fluid section easily to change drums or pails.

Note - Hydra X 7230 comes bare, customer may choose desired hose and gun detailed on following page. Max Tip

Wagner’s SuperFinish diaphragm units are the perfect base for an efficient, reliable and cost-effective crack injection system. Complete with everything you need to start working!

THE BENEFITS

• Precise, user-friendly and efficient in crack filling and redevelopment.

• QLS - Quality Long Stroke diaphragm pump ideal for both high and low viscosity materials.

• Suitable for a range of materials: epoxy, polyurethane (PU), SPUR foam and aqueous solutions.

• Suitable for use in concrete repair works.

Professional crack injection unit for concrete repair work.

Suitable for a range of materials including epoxy, polyurethane (PU), SPUR foam and aqueous solutions.

Versatile and robust, the perfect all-rounder for multiple application types. Compact – smallest in its

Professional crack injection unit for concrete repair work.

Suitable for a range of materials including epoxy, polyurethane (PU), SPUR foam and aqueous solutions.

Versatile and robust, the perfect all-rounder for multiple application types.

Compact – Mobile and lightweight.

Robust – ideal for demanding construction site use.

Specifically designed for use as a pump for crack repair, masonry restoration; for combatting moisture and water damage, and for concrete restoration.

The stainless steel pump head and the diaphragm have been specially adapted to the special loads for use in crack repair and grouting.

Features a robust frame for the tough environments with easy, prime and spray gate valve.

Professional crack injection unit for concrete repair work.

Suitable for a range of materials including epoxy, polyurethane (PU), SPUR foam and aqueous solutions.

Versatile and robust, the perfect all-rounder for multiple application types.

Robust – ideal for demanding construction site use.

Added features include large, shock absorbing wheels, robust single-position cart with built-in tool box.

optional hose reel is great to keep your hose organised when not in use and available on page 71.

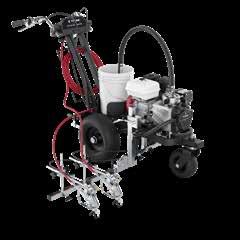

Precise lines, curves and circles, without retouching or time consuming manual marking. Now the choice in line marking equipment could not be easier. Titan’s versatile range of petrol powered piston, hydraulic piston and diaphragm pump line markers provide the professional contractor with all the power, reliability and options needed to get the job done on time with minimum fuss.

The PowrLiner range of line marking equipment has many innovative features including: remote locking front wheel, adjustable handlebars, quick gun release for stencilling, solvent and water based paint compatibility, self-propulsion option, adjustable/foldable gun rack (SmartArm™ - on 4500S+ models), parking brake, easy to reach engine and pump controls.

Backed by the industry’s best 4 year Wear Guard Warranty - see page 125 for details.

For medium sized projects on all parking lots and sports fields.

The revolutionary PowrLiner 5500, built with technology that delivers a best in class stripe with sharp and consistent line quality even on the toughest surfaces. Designed to withstand the rigors of steady, everyday use on pavement, fields and turf. It’s the perfect intermediate line striper for contractors who need a maneuverable, medium-duty line striper for projects where the big machines just aren’t profitable to operate.

require more power and output. PL6955 & 8955 are the workhorse machines of the industry, for major projects that require maximum performance with minimum downtime and maintenance.

Take a load off and increase productivity up to four times. An economical way to grow your business. Compatible with PowrLiner 3500 and up as well as Graco® 3900 and up.

kit (S-3 gun, hose and tip kit for wider or dual lines), flexible suction system, 419 TR1 Line Striping tip, tip guard, 15 metre airless hose with hose rack and quick release gun holder for stencil work.

Includes 200-watt lamp coil charging system, engine protection bumper bar, heavy-duty pneumatic tyres, multi-position seat (forward/back, side to side) and height adjustable foot pedals.

Tow hitch and coupling included.

Honda® GX200 motor.

Hitches for LazyLiner Elite ride on drivers.

Includes hitch (290180), mounting hardware and instructions. 0537935 also includes bracket adapter (537513).

XLT units require axle with pre-drilled holes (0290489A) and Hitch Kit for 495X/695X/895X (2430599)

Innovative and proven technology. The exciting PowrCoat range has been designed with a hardened chrome fluid section. The three-step hardening process makes this one of the hardest, most durable fluid sections in the market today.

The lubricated motors last longer, are more efficient and even quieter. The use of our AirCare product not only lubricates but also minimises icing. Maintenance is simple and inexpensive. All pumps in this range are sold as bare units on a trolley with the inclusion of a wall mount frame, flexible suction hose, high pressure filter (50 mesh), prime spray valve, air regulator with water trap and auto drain, automatic air motor lubricator, earthing wire and clamp.

Ideal for light industry, fabrication, cabinetry and applications where a superior fine finish is required.

So tough they are virtually indestructible. Severe Service means twice the life with half the maintenance. The durability, reliability, and ease of operation that you need are built in to each unit. PowrCoat sprayers have been used throughout the world, providing their owners with dependable, efficient operation.

So tough they are virtually indestructible. Severe Service™ means twice the life with half the maintenance. The durability, reliability, and ease of operation that you need are built in to each unit. PowrCoat sprayers have been used throughout the world, providing their owners with dependable, efficient operation.

Comes complete on a trolley (can be converted to wall mount) with flexible suction hose, high pressure filter (50 mesh), prime spray valve, air regulator with water trap & auto-drain, automatic air motor lubricator, earthing wire & clamp.

Includes 15m 3/8” airless hose with 1/4” whip, adapter 3/8" - 1/4", S-7 airless gun, 517 TR1 high pressure tip & high pressure tip base. Ratio 45:1 Stroke Length 4.75” Min Air Requirement 43 scfm Max Pressure 4500 psi Max

So tough they are virtually indestructible. Severe Service™ means

the

PowrCoat

N/A

Straight line fluid passage allows for max. flow rate. Angled handle for increased comfort .

Adjustable needle packing prolongs the life of critical wear parts.

Swivel allows freedom of movement without hose kinking. Lightweight metal construction.

Max

Rating: 7700 psi

In-handle

In-handle

Includes Seal & Filter (White Tip)

Creates a consistent fan pattern width from the first litre to the last that is a longer lasting HP Tip. TR1 tips spray a uniform paint thickness for the life of the tip creating less wasted paint. The max pressure for these tips are 7700 psi.

In the revolutionary AirCoat process, a unique combination of airless and air spraying techniques is expertly utilized to achieve uniform atomization of materials at a relatively low pressure, typically from about 870 PSI, depending on the material being sprayed. This process is made possible by the central air guide (air cap), which envelops the sprayed medium like a coat, effectively reducing overspray compared to traditional airless and air spraying methods. As a result, the AirCoat process delivers remarkable material savings of up to 15% compared to the airless process and up to 40% compared with air atomization. Wagner AirCoat tips are precision-engineered to the highest standards, and the improved geometry of the tip core has been successful in minimising tip and pump wear, ensuring a consistently soft and uniform spray pattern.

• AirCoat technology for high quality coating results

• Fast application

• Very low overspray

• Long service life

• Increased productivity

• Increased paint savings

• Soft spray pattern

• High transfer efficiency

• Precise adjustment for greater control

• Superior performance and finishing results

• Ergonomic and well balanced gun with light trigger pull

• Tool-free filter removal

The low pressure diaphragm pumps of the Zip range are first choice high quality pumps. Simple and powerful, the Zip range is ideal for feeding automatic and manual spray guns, transferring fluids, corrosive, adhesive and high-viscosity materials.

These pneumatically operated double diaphragm pumps work with extremely low pulsation. The pumps are equipped with the low icing “runner” air motor which is characterised by low air consumption with maximum reliability and performance.

THE BENEFITS

• High suction capacity

• Long life diaphragms

• Wide range of available models

• Suitable for many different materials

• Low noise level (integrated silencer)

• Safer than pressure pot systems

If you have to stop to refill your cup gun or pressure pot often, then it is time to think about a professional feeding system.

Zip 52 Eco Perfect Flow are ideal solutions for the continuous feed of manual and automatic applications in the following markets:

• Wood and furniture industry General metal industry

• Plastic finishing

• Leather and textile application

• Glass coating

The Tomcat gun is perfect for all coatings from thin to thick, stains to glue. Can also be used with internal mix nozzles as well as carbide tipped fluid nozzles for abrasives. This gun features a self-adjusting needle packing, inexpensive nozzle replacement and rugged construction.

• Compact design

• High flow rate

U731.PACK/SP5 N/A

Comes complete on stand with flexible suction system, 10m duplex hose, Tomcat 100 conventional gun with 2.2mm nozzle and 2167 aircap.

Ratio 1:1

Max Flow Rate 28 L/min

Max Pressure 116 psi

Air Connection G 1/4”

Material Connection G 1/4”

For the Zip 52/80, one of the following must be added.

Polypropelene Pump (Water Borne Products), PTFE Diaphragm, Stainless Steel Ball, and Seats

Polypropelene Pump (Solvent Based Paints), PTFE Diaphragm, Stainless Steel Ball, and Seats

Aluminium Pump (Solvent/Water Based Paints), PTFE Diaphragm, Stainless Steel Ball, and Seats

Aluminium Pump (Solvent/Water Based Paints), PTFE Diaphragm, Stainless Steel Ball, and Seats

Wagner electrostatic technology is used in many varied industries including automotive, furniture and steel manufacturing, as well as general on-site commercial usage for metal hand rails, steel doors, pipes and vents, etc.

The major attractions of this technology are the incredible labour and paint savings achieved. When coupled with the ease of operation and consistent film builds able to be achieved, this system is well worth considering.

An electrostatic field is generated between the electrode in the gun head and the grounded work object. The paint particles are charged and attracted by the grounded object. This effect increases the efficiency significantly compared to non-electrostatic systems. The “wrap-around” effect allows the operator to paint items such as pipes or hand rails without changing position.

Wagner has developed a unique multi-swirl system. As paint passes through the nozzle it starts a swirling motion. This produces a soft spray pattern with an increased “wrap-around” effect.

Covered in special treatment to reduce wearing

Wagner’s electrostatic atomisation process delivers a highly economical coating system, offering many advantages over conventional application techniques, in numerous areas of industry. For both manual and automatic application solutions.

THE BENEFITS

• Lower paint consumption

• Enormous time savings

• High surface quality

• Reduction in waste disposal costs

• Higher performance

• Innovative technology for any application

TYPICAL APPLICATIONS

• Metal protection & finishing

• Wood finishing

• Plastic finishing

• Aerospace industry

• Automotive components

• Motorcycle parts

TYPICAL FLUIDS

• Solvent and water based materials

• 1K and 2K paint

• Primer and top coat

• Low/medium/high solid material

• Paints and release agents

• PU and epoxy material

• Metallic paint

• UV paint

The Wagner 3-in-1 System combines the latest technology in electrostatic and aircoat applications with an airless system, all designed to produce the perfect finish. The system comes complete on a single trolley with three different gun and hose packages. This is the perfect mobile system for any painting contractor who uses all three types of technology on their projects.

Separate displays for: High-voltage

(set and

• Spraying current µA (actual figure when

•

• Earthing check

• Fault displays Adjustable high

•

• Max. cable length 80m

(kV)

• Enclosure Class IP 54

Control unit to drive the electrostatic manual guns GM5020 EAW and GM5020 EACW.

• Adjustable high voltage Recipe changes

• Safety monitoring & more

• Large cabinet for the electrostatic processing of water-based lacquers and separating agent with manual guns.

• Completely insulated construction with internal charging of the materials for manual spraying applications, AirSpray and AirCoat.

• Basic spray sets including cabinet & control unit, pump set, and guns available. Can also be customised.

Conventional spray guns use compressed air to atomise paint and apply it to a surface. Air and paint enter the gun through separate channels and are mixed using an air cap to form a controlled spray pattern. Paint can be fed to a conventional spray gun via different methods. These vary from a cup attached to the bottom of the gun which supplies the paint by suction (suction fed), or a cup on the top of the gun which supplies the paint by gravity (gravity fed). Gravity fed guns generally require less air than suction fed guns and generate less overspray.

Coating Atomization Technologies (C.A.T.) are part of Wagner. Founded in 1997, C.A.T. provides extensive years of experience in the design and manufacture of spray finishing equipment. Focusing their expertise, C.A.T. offers the most comprehensive line of precision atomising nozzles and aircaps available to complement its line of professional grade spray guns. Committed to quality and research, C.A.Technologies continuously strives to bring the latest innovations to the industrial and automotive spray finishing industries. The C.A.T. product range complements the existing Wagner industrial product portfolio.

The C.A.T. CPR gun’s Patented 12-point Balanced Plenum provides superior atomisation over competitive products:

The atomising air hits our 12-point fluid nozzle behind the air cap and is diffused. It surrounds the fluid in a uniform shroud of atomising air as it leaves the air cap.

Without 12-point diffusion, high and low spikes or hot spots exist as the air leaves the air cap and surrounds the fluid.

This results in more uniform SMALL particles. This results in very small and very LARGE particles.

The end result:

Tomcat 100 Conventional General Purpose

An economical general purpose conventional air spray gun for spraying a wide range of coatings. Designed for production use, the Tomcat is perfect for all coatings from thin to thick, stains to glue. Can also be used with internal mix nozzles as well as carbide tipped fluid nozzles for abrasives. This gun features a self-adjusting needle packing, inexpensive nozzle replacement and rugged construction.

A general purpose conventional air spray gun for the corrosion control market. Designed for spraying in harsh environments, this gun has the break-up power to atomise heavy, high solids coatings. The gun body is anodised PTFE to aid in clean-up and to extend the life of the gun.

The P200Z version of the Panther gun is a rugged conventional air spray gun designed for spraying zinc-rich coatings. It has a delrin tipped fluid nozzle to prevent plating and a unique leather/PTFE packing arrangement. Together these features increase spraying time before the gun needs to be cleaned.

The CPR range of guns combine the transfer efficiency of HVLP with the speed and finish quality of conventional air spray. All feature a stainless steel fluid passage. The nozzle requires 11 cfm at 29 PSI recommended inlet pressure. The CPR guns are available in both pressure feed and gravity feed versions and include the new CPR air cap and HVLP air cap, along with 3 different needle and nozzle sizes, multi-purpose wrench, nozzle wrench, and cleaning brush. These kits will also be available with your standard pressure and gravity cups or the popular 3M PPS.

The CPR-T3 gravity feed spray gun offers a less expensive economy version of the pressure reduced spray technology. The CPR-T3 combines the transfer efficiency of HVLP with the speed and finish quality of conventional air spray.

The CPR-FE spray guns are the lightweight and ergonomically designed versions of the CPR which combine the transfer efficiency of HVLP with the speed and finish quality of conventional air spray. All feature a stainless steel fluid passage.

Our pressure pots and tanks are constructed from a heavy gauge steel with a baked-on enamel. All pressure tanks come with wheels for manoeuvrability or optional stationary feet on request. All top outlet tanks come with a rigid liner and are designed for use with the C.A.T. range of conventional guns.

Simple in design and versatile in operation, this economically priced pressure pot is tough enough to hold up to daily industrial and automotive operation and is designed for easy use and cleaning. Comes with a convenient carrying handle and easy open screw lid.

10L Pressure Tank Manual Agitation

10L Pressure Tank Automatic Agitation

Complete with paint tank, pneumatic motor, air regulator, safety valve, outlet valve, paint exit hole. Seamless steel body construction of pressure tank for long durability. Teflon finish inside the inner tank for different viscosities. Air-actuated paint-stirring keeps paint from depositing at the tank bottom.

20L Pressure Tank Manual Agitation

20L Pressure Tank Automatic Agitation

Complete with paint tank, pneumatic motor ,air regulator, safety valve, outlet valve, paint exit hole. Seamless steel body construction of pressure tank for long durability. Teflon finish inside the inner tank for different viscosities. Air-actuated paint-stirring keeps paint from depositing at the tank bottom.

Modern high-performance corrosion protection and marine coatings are formulated with high and ultra high solid content, with most being 2-component based. These coatings require an accurate proportioning and mixing of the resin with the hardener to ensure the chemical reaction, which enables the mixture to harden and reach the expected chemical and mechanical properties.

The Protec & Helix range of 2K Systems are the future of electric dual component applicators. With unmatched accuracy and heating efficiency, and delivering performance, durability and innovation, they are loaded with features never seen before. The user-friendly design allows for simple operation and inexpensive maintenance.

The Wagner Protec 2K takes over the precise dosing of the components as well as the elaborate and time-consuming mixing. You will be surprised how easy the system is to use. It operates almost as simple as a 1K piston pump!

The Helix VR2.3 provides unmatched accuracy and heating efficiency. The key feature provides balanced pressure, less wasted material and direct heat from the system all the way to the gun. With user friendly design allowing for simple operation and inexpensive maintenance. The VR2.3 offers better results and increased ROI.

The new mixing and dosing unit WAGNER PROTEC 2K automatically determines the correct mixing ratio and thus guarantees the best possible coating quality. Only the exact amount of required material is mixed – this saves time and material. High power even with high viscosity materials and and high layer thicknesses – ideally suitable for applications in heavy-duty corrosion protection.

4:1 is standard, other ratios are available

Ratio 4:1

Electronically Controlled Dual System Proportioner Continual communication between pumps

ratio 64 times per motor revolution

lighter than most comparable equipment

3 Phase 70 Amp

gun & 30m hose set.

The TT1 & TT2 Transfer Pumps are designed to pump extremely viscous products. The Transfer Pumps are comprised of two components: an air motor and a fluid pump. The pneumatic-powered air motor drives a piston within the fluid pump that creates suction and can draw materials from large containers and deliver the material to an outside system.

The next generation of Wagner manual units and guns offers excellent finishing, perfect balance, optimal handling, and lightweight design (490g). The Sprint XE unit combines functionality and extraordinary design. All parameters can easily and quickly be entered in the EPG-Sprint X. By means of a central and dynamic knob, all parameters, grouped into four functional sections, can be easily set. The powder feeding is carried out directly from the original container for ease of use.

The PEM-X1 gun sets the standard and trend for all kinds of surfaces used today in powder coating. The product philosophy combines a balanced finesse on all levels with long life expectancy and optimal handling. Well-balanced ergonomics are based on experience - Wagner has incorporated this experience in the design of the guns, with the nozzle concept not only providing a perfect powder cloud, but also an improved finish. The flat spray can be easily adjusted for particular coating requirements using a sliding ring.

even more options. With the PEM-X1,

Sprint 2 is the new generation of our manual powder coating unit: The new development combines proven components of the previous product family with new, innovative components and assistance functions that offer even more options. With the PEM-X1, excellent manual coating results and high-quality surfaces can be achieved.

Work directly out of the carton. Ideal for small batches or frequent colour changes. Includes PEM-X1 manual gun.

- Constant and reliable coating performance

- Control unit with a regulated air volume cycle

- Quick colour changes

- A constant compressed air quantity despite fluctuations in the mains

- Fully electronic control unit for reproducible results

- Saving and accessing up to 50 coating recipes

- Diagonal position of the powder container ensures powder carton can be completely emptied

- Wheels for optimal agility

Ready to use set with your chosen device. With air pressure and powder supply, the device is ready to start powder coating. An ideal solution for small parts or mobile use, with excellent coating results. Compact, mobile, and always ready to use.

- Compact and organised case set for mobile use

- Perfectly balanced gun

- A secure grip on the gun with excellent ergonomics

- Fully electronic control module

- Store and query complete coating recipes

- Special funnel beaker with various inclination angles to allow virtually any powder type to flow until completely used.

Comes complete with Corona manual gun PEM-X1, control device EPG-Sprint XE, injector PI-F1, suction lance with fluid cap, device cart with vibrating table, gun cable & powder hose length 5m 7/16 in, power cord length 3m and grounding cable 10m.

Voltage 85-250 V

Comes complete in a carrying case with PEM-X1 CG, 4m pistol cable, 4m air hose pack, flat beam discharge system, round beam discharge system, control EPG Sprint X and funnel cup with lid.

Input Voltage 85-250V Input Frequency 47-440Hz Air Inlet Pressure 87-116 psi

Input Power 25 W Protection Class IP64

NEG Operating Temperature 43-113oC Weight 10 kg

Regular application of cleaning and disinfectant solutions is the key to infection control. Wagner ULV sprayers maximise application speed whether you are spraying out a small multi-room dwelling, police station or an entire office building.

• Airless sprayers provide high production rates to complete disinfectant jobs faster and with better coverage.

• HEA® (High Efficiency Airless) spray technology delivers the industry best wetting with a large fan pattern and small uniform droplets.

• Wagner has the right ULV sprayer for the job with flow rates from 0.5 LPM to 3.0 LPM.

• Delivers maximum ROI with high production rates, inexpensive equipment and ease of maintenance.

• Proven to spray approved products by Australian Register of Therapeutic Goods (ARTG) for use against COVID-19.

• The power of airless coupled with the control of HVLP.

• Easy to use and control with a maximum delivery rate of 0.50 l/min.

• Recommended Sprayers:*

–Flexio Elite

–FinishControl FC 4000 18V

• Choose from several one gun sprayers to get the job done.

• Portable and powerful sprayers from 1.25 l/min to 2.0 l/min.

• Recommended Sprayers:*

–Control Pro 350 Extra –ProSpray PS 3.20.

Alcohol Based Water Based

• Ethanol

• Isopropanol

• Aldehyde

• Phenolic

• Quaternary Ammonium Compounds