2 minute read

PORUR RESIDENCE

a family’s love for their land, re-discovering agricultural heritage in an urban sprawl

“It within It is in the roots, not the branches, that a tree’s greatest strength lies ”

Advertisement

Intent Of The Architects

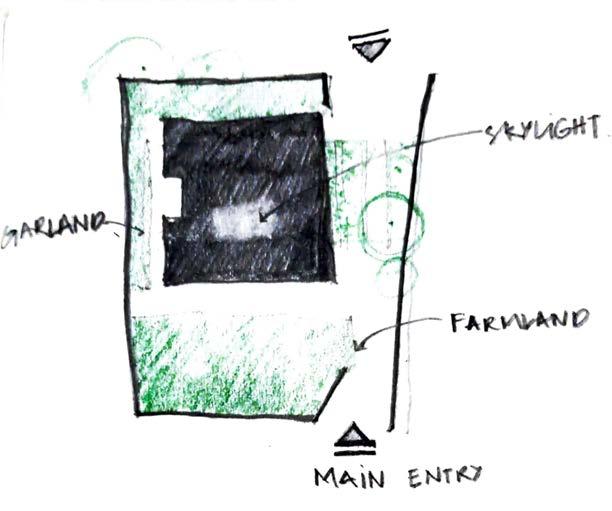

A residence that’s all about celebrating the family’s love for their land and their agricultural heritage, situated amidst residential pockets of Chennai, India. On account of this neighborhood experiencing urban sprawls and extents of farmlands being turned into commercial plots, there has been significant change in the residents’ wayof-life.

The brief aims to revert to a grounded lifestyle set up through a design that captures the essence of being connected to one’s roots. The client’s understanding of the significance of landscape and the design team’s conscious effort to integrate that with the activities inside built spaces guide the project decisions.

Landscape

The landcape almost seems to hug the building from all sides.

The green is spilled in pockets of different natures. The green pockets double up as catchment areas.

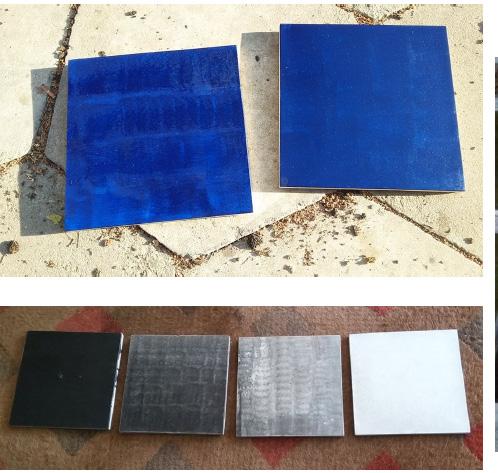

Materials

A Simple yet bold aesthetic.

The yellow and the wood balance the rawness of concrete.

The Athangudi tiles and blue accents add pops of colour.

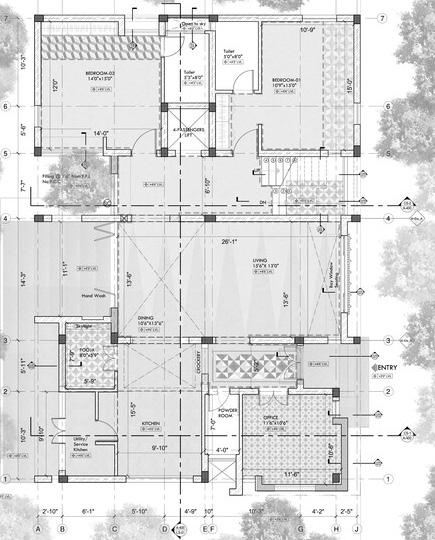

Zoning

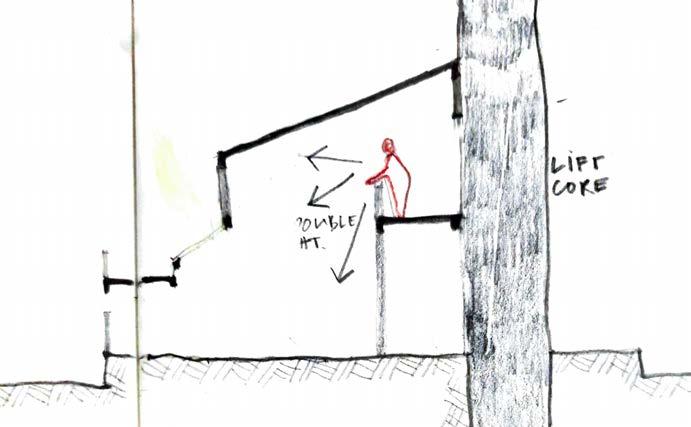

A home office sits in front, buffered from private zones.

Living spaces and bedrooms are designed with strategic openings and cut outs that act as uncompelled visual linkages

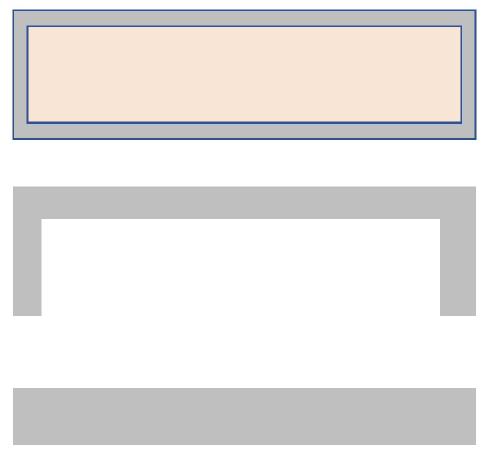

DETAIL STUDY compound wall

material study

GFRC composite concrete

glass fibre reinforced concrete is a new age take on the timeless material, pushing the limits through simple chemistry

Composite Materials

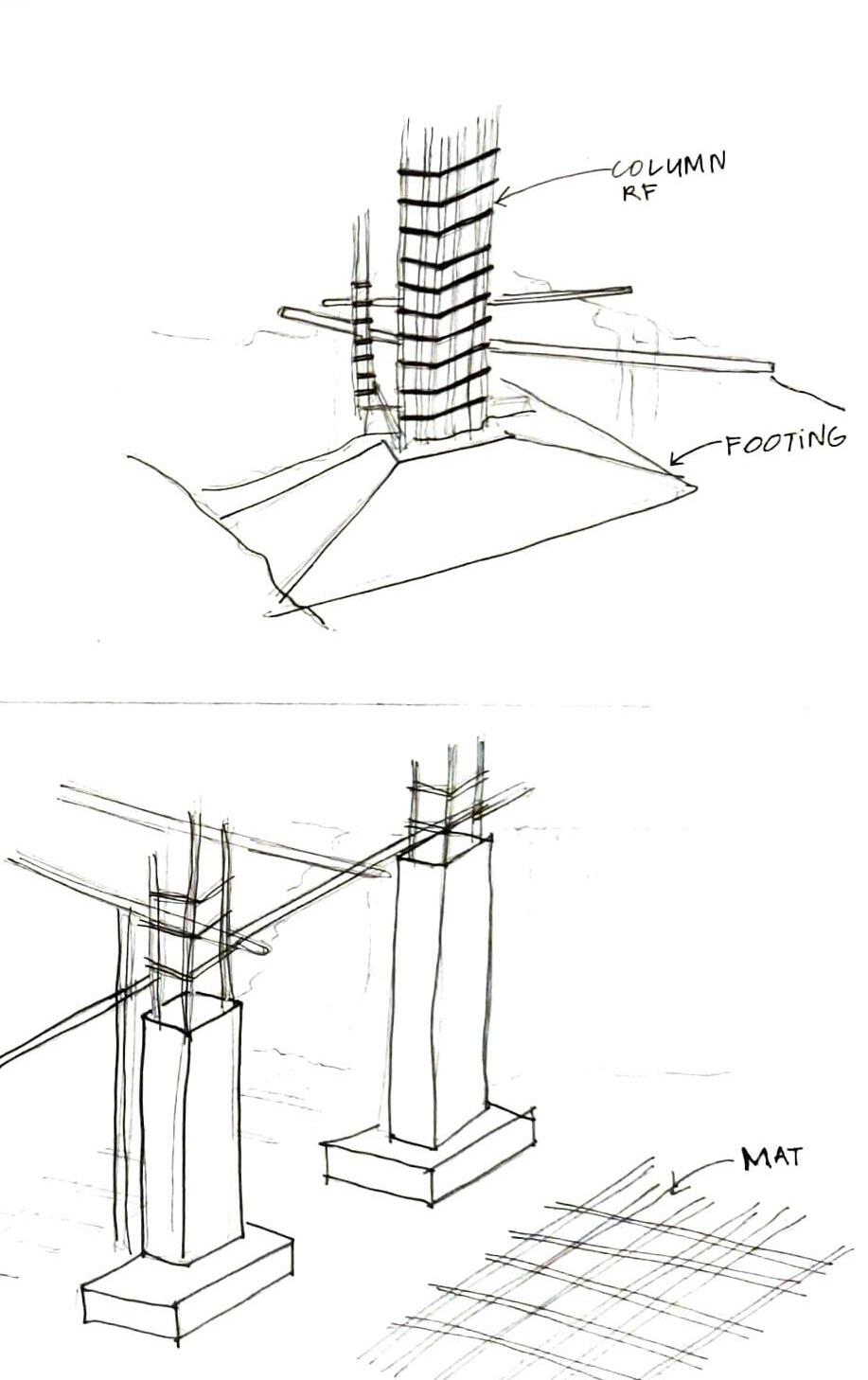

Composite materials are on a strong upsurge as demands in the construction industry rise up. Wood and plastic are pressed and moulded together in compression. Steel rebars are embedded in a concrete matrix to form a rigid reinforced material. As technology advances, so does the building material.

Gfrc System

1” thick cementitious skin reinforced with alkali resistant glass fiber

Different Types Of Sections

Construction Of Parametric Wall

Evolution

The concept of using fibres as reinforcement is not new. Historically, horsehair was used in mortar and straw in mudbricks. In the 1900s, asbestos fibres were used in concrete but due to health risks, a replacement was needed.

In the late 50’s and early 60’s E glass and C glass were being proposed as reinforcements for concrete in Russia and China. Very high tensile and flexural strength glass fibre aspects made it a good reinforcement for concrete, which is inherently brittle. But it was concluded that glass fibres were not stable in concrete due to the high alkalinity of the matrix.

In Europe, approaches focused to make the glass itself alkali resistant, and at the end of the 1960’s, Zirconia (Zr02) containing glass formulation was invented, and after exhaustive trials it’s content was optimised at approximately 17%. In the 1970’s the technology was developed to produce alkali resistant (AR) glass fibres and the GFRC industry was born.

FACILINI DESIGN LAB’S TECHNOLOGY

• Alkali Resistant Glass

• Simple Cementitious Binder/ Polymer Modified Cementitious Binder

• Admixtures and Chemicals

• Aggregates

For almost 50 years of ongoing development, the industry now presents better quality glass fibres with a wider variety of sizing, new pozzolans to enhance the overall GFRC properties, low alkali cement to reduce the attack on the fibres, improved and diversified equipment, and more manufacturing methods. Today GFRC has become one of the most versatile building materials available to architects and engineers.