Faculty in Action

UW Center Breaks Ground for Char Demonstration By Christine Reed The Center for Carbon Capture and Conversion (CCCC) in the University of Wyoming’s School of Energy Resources (SER) recently broke ground on a demonstration house made of coal-derived carbon building materials and char bricks. The house is being built in tandem with a second house made from conventional building products and Pacific Clay bricks. The coal-derived bricks are made using low-energy, ecofriendly process technologies developed in the CCCC. “The goal of the project is to see how the coal-derived building materials, especially char bricks, stand up to different environmental conditions and compare to conventional building materials that are currently used in the market,” says ChooiKim Lau, the civil and architectural engineering and construction management graduate student leading the project. “Our team will evaluate performance characteristics, such as the mechanical integrity, thermal resistance, weight, fire resistance, toxicity and electromagnetic radiation tolerance, with comparative durability, noise resistance, moisture absorption and weathering.” Originally from Alor Setar, Malaysia, and now resident of Laramie as a U.S. citizen, Lau is working alongside undergraduate students Noah Scott and Jonathan Scott, of Cheyenne. They work under the direction of Kam Ng, an associate professor in the Department of Civil and Architectural Engineering within the College of Engineering and Applied Science. Focusing on the future of Wyoming coal, the project is part of the 12 • Foresight

Carbon Engineering Initiative in the CCCC dedicated to discovering and advancing new uses for coal by making commodity products that are nonenergy and fuel based. The goal of the demonstration is to showcase the various building materials that are made from Wyoming coal and, in particular, the coal-derived char bricks. In the summer of 2021, the team manufactured over 4,000 coal-derived char bricks in the span of 30 days using basic tools and equipment. The bricks were produced using a zero-waste construction method in which they can be manufactured, transformed and recycled in a comprehensive life cycle, minimizing residual materials.

According to Lau, the initial findings regarding the properties of the char bricks show attributes that are superior to clay bricks. They are lighter weight, provide better insulation and have the ability to regulate the moisture content in the building. “The porosity and thermal properties of the coal char bricks are such that they have the ability to absorb moisture from inside buildings on humid days, and release moisture on dry days, which mean that the building is consuming less energy,” Lau says. “Additionally, according to the industry-standard fire endurance test, char bricks receive a rating of Class A, which is the highest score possible.” The char bricks are more economical

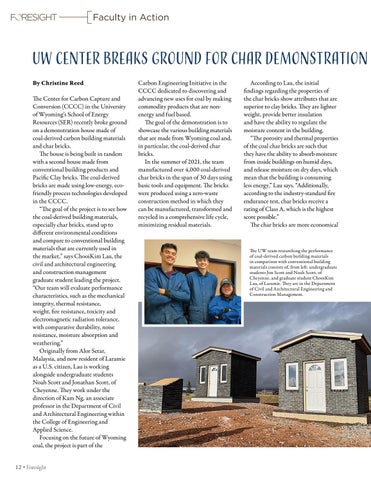

The UW team researching the performance of coal-derived carbon building materials in comparison with conventional building materials consists of, from left: undergraduate students Jon Scott and Noah Scott, of Cheyenne, and graduate student ChooiKim Lau, of Laramie. They are in the Department of Civil and Architectural Engineering and Construction Management.