9 minute read

Alumni in Action

The Ultimate STEM Playlist

Music Video Project Celebrates Love of Science

By Micaela Myers

Back in 2014, three best friends and University of Wyoming civil engineering undergraduates decided to enter a video contest promoting the field, starting a music video tradition that continues to this day.

“We were always up for an adventure,” says Britton Hammit Johnson. “We were all a part of American Society of Civil Engineers. Sierra Johnson is an extremely talented musician. Katie Sitler is the most creative person I know and was in the marching band. I think I brought the energy and the video-editing experience.”

The creative result of their efforts was a medley of popular songs with lyric changes and choreographed dance routines all over the Engineering Building. Associate Dean for Undergraduate Education David Mukai’s daughter joined them, representing the young women they want to help recruit to the field. Other engineering students participated, and members of the marching played backup.

Songs and lyric changes included: “Thrift Shop”— “I’m gonna draw some plans, only got a straight edge in my pocket”; “Life is a Highway”—“I design highways, airports, bike lanes, railroads”; “All About That Bass”—“I ain’t no chem-e, but I know reactions that they will never see”; “Single Ladies”—“All the geotech”; “Party in the USA”—“Now put your hands up, we’re civil engineers, the best job in the world”; and “Stacy’s Mom”—“Engineers have got it going on; civil is great, it’s been around for so long.”

They had so much fun creating the video their senior year that they never stopped. Together with a fourth friend and UW alumna, Lisa Johnson Mallon, they’ve continued to make music videos as they travel, visit one another and attend one another’s weddings.

“We’ve danced through London, Dublin, Glasgow, Edinburgh, Lyon, Montpellier, Barcelona, Berlin, Munich, Dresden, Vienna and continued that with many other videos where we road tripped through Wyoming, did the manikin challenge all over Washington, D.C., rafted down a river in Montana on an air mattress, and took a tour bus up to Niagara Falls and Toronto,” Britton says.

All three women have gone on to successful careers. Britton, originally from Prescott, Ariz., went on to earn her master’s degree and Ph.D. from UW. She works at KimleyHorn, a civil engineering consulting firm in Massachusetts, as a traffic engineer with a focus on data analytics, intelligent transport systems and traffic simulation modeling. Last year, Britton and her husband started the process for an endowment fund for UW engineering students. Sierra, originally from Laramie, went on to earn her master’s degree from University of Colorado Boulder and works at Corona Environmental Consulting in Colorado as a water process engineer, helping to optimize water treatment. Katie earned her master’s degree from Colorado State University and works at Golder, a civil/environmental engineering consultant firm in Colorado, in the mine waste group, with a focus on civil design of mine waste containment and heap leach facilities.

They are contemplating a remake of their original video for its upcoming 10-year anniversary. Whether that happens or not, they will continue to stay friends, making music videos of their many adventures.

Katie Sitler and Sierra Johnson “hooding” Britton Hammit Johnson at her Ph.D. graduation.

WATCH THE ORIGINAL VIDEO AT BIT.LY/ASCE-VIDEO

How CEAS Students Utilize 3D Printing

Platforms By Riley Box

3D Printing is Changing the World! As technology and the need for speedy creation increase, the interest of new manufacturing also increases. The U.S. Advanced Manufacturing Initiative has openly stated that new technologies are needed, as they actively promote research in new manufacturing. 3D printing has been exactly that. 3D printing is used for much more than creating three-dimensional toys and gadgets. 3D printing has used high-performance materials to revolutionize the research and prototype process of aerospace and biomedical engineering. 3D printing is starting to be used in many other engineering fields as well, such as wind energy and nuclear energy. Both are two fast-growing energy sectors in Wyoming, enabling economic diversification during its energy transition from fossil to sustainable sources. 3D printers have also been introduced into classrooms worldwide to help integrate technology into the curriculum and promote learning through tactile technology.

A Professor in the Center of it All Xiang Zhang is an assistant professor in the department of Mechanical Engineering at the University of Wyoming. Zhang graduated with his Ph.D. in civil engineering at Vanderbilt University prior to his postdoctoral research experience in aerospace engineering at the University of Illinois at Urbana-Champaign. Since coming to UW

in 2019, Zhang has used his research and methods to help future students and doctors make positive changes in the field. He currently directs the Computations for Advanced Materials and Manufacturing Laboratory, where he has four Ph.D. students and three undergraduate students collaborating to explore new avenues in engineering. One focus of his team is to use a combination of computational modeling and experimental study to advance the use of 3D printing in the field of engineering.

His personal research includes “developing sophisticated multiscale and multiphysics methods in conjunction with data-driven methods for modeling, design and manufacturing of high-performance materials and advanced-manufacturing

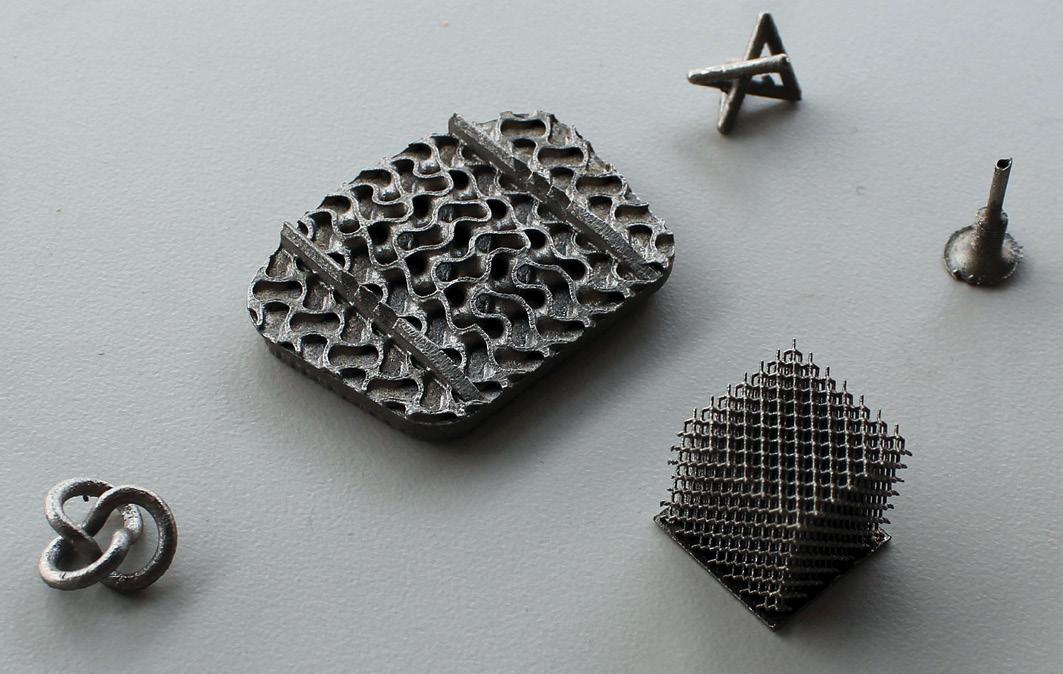

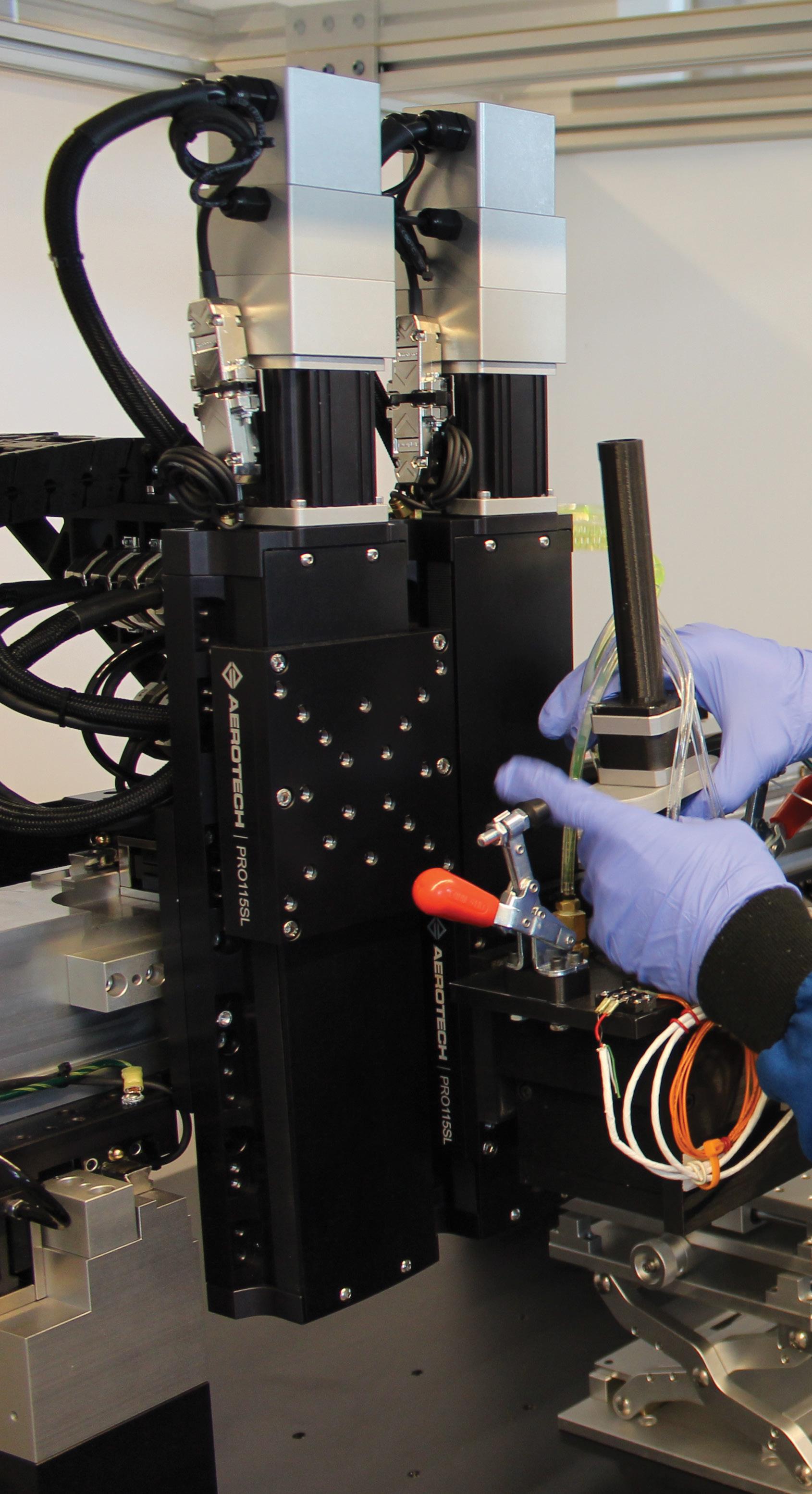

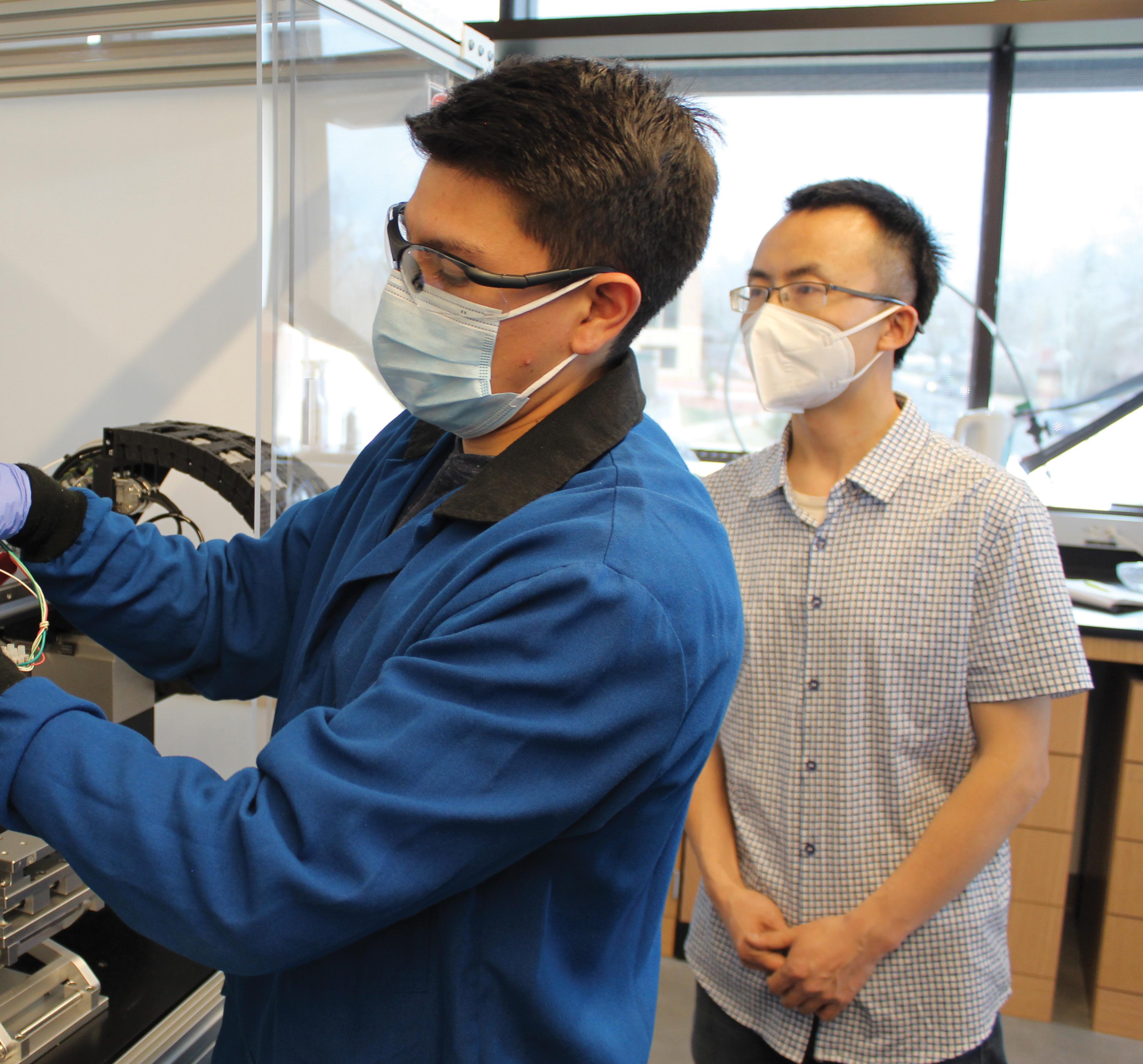

Far left: Metal 3D models created by graduate student Matthew Jones shows the initial possibilities of a metal 3D printer. Above: Undergraduate student Aaron Vigil demonstrates his knowledge of creating 3D printer ink by showing Xiang Zhang and his peers.

PHOTOGRAPHY BY RILEY BOX

TOUR OTHER AREAS OF UW’S MECHANICAL AND ENERGY SYSTEMS ENGINEERING DEPARTMENT, INCLUDING THE INNOVATION WYRKSHOP AT BIT.LY/CEAS-SYSTEMS-TOUR

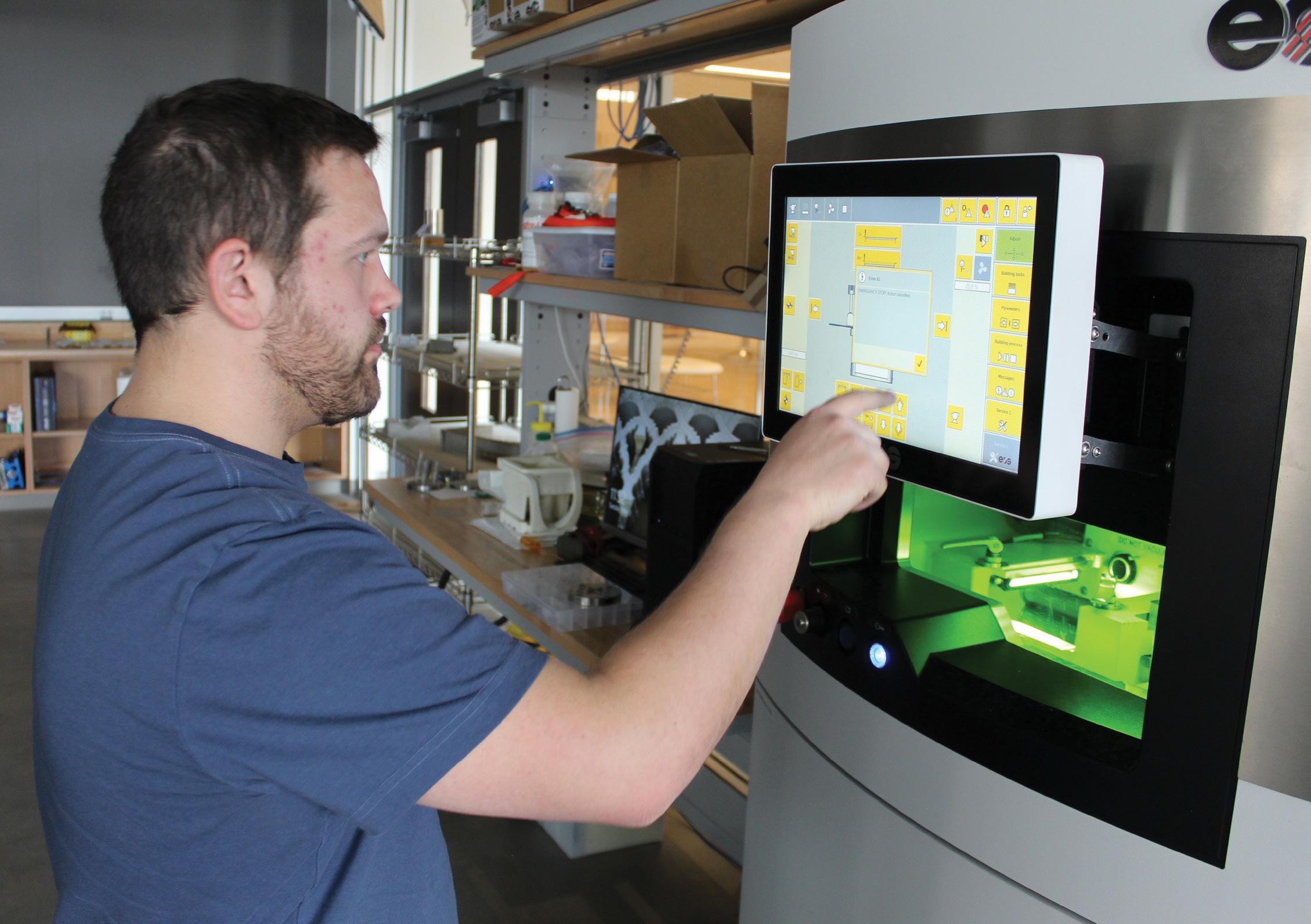

Ph.D. candidate Matthew Jones operates on the EOS M1000 3D printer in the Engineering Education and Research Building.

processes,” says Zhang. Zhang focuses his graduate students on three goals. According to Zhang, the three goals are:

“1. modeling of failure and deformation in advanced materials under extreme condition, such as high-performance alloys and composites used in nuclear and aerospace engineering; 2. modeling of manufacturing process including composite and ceramic 3D printing to guide the printing process; 3. 3D printing and testing of titanium and aluminum alloys. Currently, I also have three undergraduate students working with me developing a 3D printing platform and pursues various applications.”

Zhang continues to come to work every day to take on any new challenges that present themselves. He gets excited each day to work with his students, exchanging ideas with them, and researching with them and other researchers. Zhang hopes to make significant advancements within the engineering community and address important issues in the field with the assistance of his team.

Successes of the Whole As previously mentioned, Zhang works with four graduate students and three undergraduate students. Zhang is proud to admit that his group has been extremely successful in gaining ground within the engineering community and more specifically through 3D printing.

One of the most important stories to come out of the group this last year is from Zhang’s graduate student Matthew Jones, who transferred into Zhang’s group just last year. Jones is the first student at UW to get the metal 3D printer running and print titanium and aluminum alloy parts. Jones works with a company called DJO, which donated $10,000 to support his research for 3D printed titanium implants. Jones is supported by a WSGC Graduate Research Fellowship and a WSGC NASA ESPCoR Seed Grant.

Another graduate student, Pengfei Shen, has also been developing computational models to stimulate the fatigue behavior of 3D printed Titanium. This research helps his team “develop proposals to NSF and NIST on studying the fatigue behavior of AM parts,” says Zhang.

Teaching and student engagement have been large points of

emphasis for Zhang. He has had a total of five undergraduate students work with him; currently he has three. One student co-wrote a paper with him, four students won the WSGC NASA Undergraduate Research Fellowship, and one student won a UW INBRE award in the summer 2022. Needless to say, Zhang allows his students to succeed with him.

Another major effort at Zhang’s group is developing a 3D printing platform that is based on a novel curing strategy called frontal polymerization. Based on this 3D printing technique, they are working toward 3D printing composites targeting aerospace application and ceramics for nuclear propulsion, and biomedical application. According to Zhang himself, “several NASA researchers expressed their interest for using this technique for in-space-manufacturing of composites and manufacturing ceramics for nuclear propulsion application”. Due to this, Zhang and his team have developed two different proposals and submitted to NASA in order to further their research on 3D printing. Both applications are still pending.

Making Changes Locally UW has embraced the art of 3D printing. As a part of the Tier-1 Engineering Initiative, the Engineering Education and Research Building has dedicated “3,500 square feet of lab space and houses over $1.4 million worth of state-ofthe-art equipment and technology,” says Zhang. Among the equipment is a multitude of 3D printing facilities from basic 3D printers to highly advanced metal 3D printers housed at the Innovation Wyrkshop in EERB. Zhang says: “We recognize that the Wyrkshop has been using these 3D printing resources to support and foster innovation and collaboration among students and faculties, and offers tremendous outreach activities to the community”. Zhang hopes for further advanced manufacturing research and course opportunities at UW.

Zhang communicated with the Wyrkshop coordinator Tyler Kerr, and came up with a plan to provide an undergraduate course on additive manufacturing that will utilize 3D printing and other engineering developments. This project was awarded a Wyoming NASA Space Grant Faculty Education Grant. Zhang expects to finish the course development over the summer 2022 and start teaching the course in the fall 2022 semester or the spring 2023 semester.

With the advent of this course, Zhang hopes he can “handle the students’ interest and desire to learn 3D printing and help train skilled workforce with advanced manufacturing background to meet the state’s and the nation’s needs.”

In Conclusion… 3D printing is changing every facet of engineering. Due to its speed, cost and potential, there is no doubt as to why it has become a number one resource in the sciences. UW has gone all in to support the new developments of 3D printing and, with more interest, it could become a huge phenomenon in the state. Zhang and his team have worked tirelessly to utilize 3D printing to its full potential. With breakthroughs in running the metal 3D printer, interest from NASA, and a multitude of grants and research supporting these studies, UW is looking toward the future in more ways than one. Zhang still hopes for future progress in not only 3D printing at UW, but also the desire to learn about it from eager students.

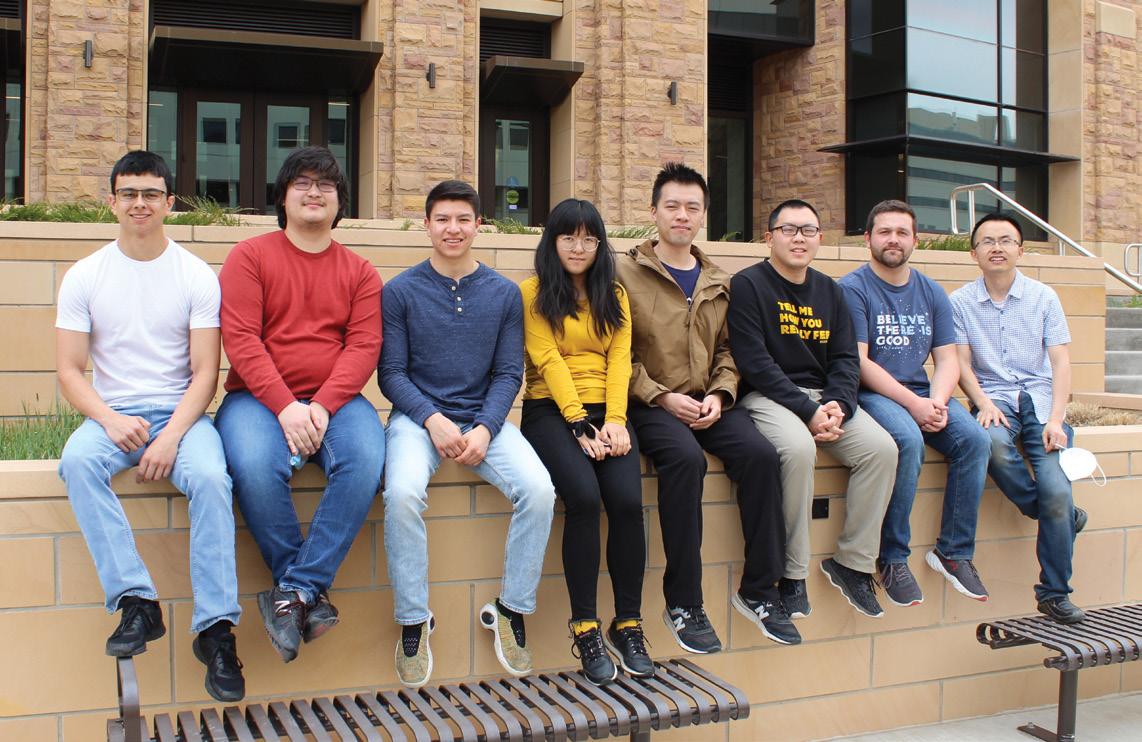

Xiang Zhang’s group includes both undergraduate and graduate students. (L-R) Ryan Ruiz, undergraduate; Max Condell, undergraduate; Aaron Vigil, undergraduate; Zhuoting Chen, graduate; Min Lin, graduate; Pengfei Shen, graduate; Matthew Jones, graduate; and Dr. Zhang.