Aramark Repair Guides USA-CLEAN 1-800-USA-CLEAN NationalAccounts@usaclean.com 2803 N. 22nd St. Decatur, IL 62526

Table of Contents Kaivac 1750 ......................................................................... 1 Replacing the Vacuum Motor 1 Check for Clogs.......................................................................... 3 Replacing the HEPA filter 5 Cleaning/Replacing the Solution Filter 6 Cleaning/Replacing the Chemical Injector Valve ................... 7 Replacing the Unloader Valve 9 ProCarpet 45 ....................................................................... 11 Replacing the Brush Motor Belt .............................................. 11 Replacing the Shackles 13 Replacing the Shoe 15 Replacing the Vacuum Motor .................................................. 17 Swingo 350E ........................................................................ 103 Replace the Brush ..................................................................... 103 Replace the Front Wiping Blade 104 Replace the Squeegee Blades ................................................. 105 Replace the Vacuum Motor ..................................................... 106 Clean/Replace the Solution Filter 108 Jet 38 .................................................................................... 19 Adjust Brush Height .................................................................. 19 Check Brush for Wear 19 Check for Power to Brush Motor ............................................ 20 Check Micro switch for Brush Motor 21 Check the Belt 22 Check the Brush Roll Ends ....................................................... 23 Check Carbon Brushes - Brush Motor 24 Check the Roller Support 25 Check the Transmission Support ............................................ 26 Replace the Belt 27 Replace the Brush Roll ............................................................. 29 Replace the Vac Motor Filter.................................................... 30 Replace the Carbon Brushes in the Brush Motor 31 Replace the Micro switch for the Brush Motor ..................... 33 Replace Roller Support 34 Replace Transmission Support 35 Check Base Wiring .................................................................... 37 Check Cord Plug 38 Check Cord Condition 38 Check Micro switch ................................................................... 39 Check Brush Motor 40 Check Primary Terminal Block ................................................ 41 Check Carbon Brushes - Vac Motor ........................................ 43 Check Curve Support 45 Check the Switch ....................................................................... 47 Terminal Block Continuity 49 Check Wiring - Base Plug and Terminal Block 51 Check Wiring - Switch and Connector .................................... 53 Check Wiring - Terminal and Vac Motor 55 Check Wiring - Terminal Block and Curve Support 57 Check Wiring - Terminal Block and Switch ............................. 59 Replace Carbon Brushes - Vac Motor 61 Replace Damaged Base Wiring ............................................... 64 Replace Circuit Board ............................................................... 65 Replace Micro switch 66 Replace Brush Motor ................................................................ 67 Replace Cord Plug 69 Check and Clean Filter 72 Replace Curve Support ............................................................. 73 Check the Filter Bag 76 Replace Main Switch 77 Replace the Power Cord ........................................................... 79 Replace Primary Terminal Block 81 Replace Terminal Block ............................................................ 83 Replace Vac Motor .................................................................... 85 Locate and Remove Clog 88 Swingo 350B ........................................................................ 109 Replace the Battery Charger 109 Replace the Control Panel ....................................................... 111 Replace the Filter Screen ......................................................... 112 Replace the Pump 113 Clean/Replace the Solution Filter ............................................ 114 Replace the Solution Tank 115 Replace the Squeegee Vacuum Hose 117 Replace the Float ....................................................................... 119 Check the Fuse 120 Replace the Fuse 121 Replace the Brush ..................................................................... 122 Swingo 855B ........................................................................ 123 Replace the Brush Belt 123 Replace the Brush Pulley ......................................................... 126 Check Brush for Damage 129 Replace the Wheels .................................................................. 130 Check the Brush Pulley ............................................................ 131 Check the Belt Tensioner 132 Check Battery Cables ................................................................ 135 Replace the Battery Cables 136 Replace the Casters 138 Replace the Filter Screen ......................................................... 140 Replace the Drain Hose 141 Replace the Squeegee Blades - Series 1 142 Replace the Vacuum Hose ....................................................... 144 Replace the Vacuum Motor 145 Replacing the Tank.................................................................... 148 Combimat Swingo 2500 ..................................................... 151 Replace Brushes 151 Test Circuit Breaker for Continuity 152 Replace Circuit Breaker ............................................................ 153 Check Battery Cables 155 Replace the Control Panel ....................................................... 156 Clean the Filter Screen ............................................................. 157 Clean the Recovery Tank Sensors 158 Replace the Filter Screen ......................................................... 159 Replace the Vacuum Hose 160 Replace the Squeegee Blades 161 Clean/Replace the Solution Filter ............................................ 163 Replace Wiring - Switch and Connector ................................. 89 Replace Wiring - Terminal Block and Switch 91 Replace Wiring - Terminal Block and Motor .......................... 93 Replace Wiring - Base Plug and Terminal Block 95 Replace Wiring- Terminal Block and Curve 97 Replace the Filter Bag ............................................................... 100 Replace Vac Motor 101 i. Checklists 164

Dear Aramark Customer,

For over thirty years, we have had a passion for helping others keep their floor equipment in top shape with quality aftermarket parts and exceptional service, and we are proud of our record of providing the kind of technical expertise that allows our customers to save money by taking maintenance of their equipment into their own hands.

Our partnership with Aramark - now approaching fifteen years - is no exception. While we have an extensive network of service technicians across the USA, we also strive to make machine repairs accessible to our valued customers. This book is one small way in which we aim to offer you useful guides for troubleshooting and repair that are simple, clear, and easy to follow.

Enclosed within is an extensive but not exhaustive selection of guides to help you identify and correct major issues that will keep your equipment from working optimally to keep your facilities clean and spotless. Each guide specifies any needed equipment to complete the task as well as detailed, step-bystep instructions accompanied with pictures and illustrations to make the job that much easier. We hope you find these guides not just useful but invaluable for your cleaning operations.

To further aid your efforts, we have also provided some links below to our model pages on USAfix™, where you can find replacement parts and our ever-growing library of support materials from diagrams to manuals to even more troubleshooting and repair guides like these.

As always, we stand ready to assist you with any of your floorcare needs, including our outstanding customer service team, accessible by phone (1-800-USA-CLEAN), Email (info@usaclean.com), or chat (usaclean.com).

Your friends at USA-CLEAN

by Jon-Don

Introduction ii.

Kaivac 1750

ProCarpet 45

Jet 38

Swingo 350E

Swingo 350B

Swingo 855B

Combimat Swingo 2500

Kaivac 1750

Replacing the Vacuum Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

4. Turn the key at the top of the black box to remove the box from the machine. Lift the black box from the machine and lay upright to expose the vac motor.

1

Surface Cleaner

2. Remove the 2 yellow capped wing nuts from the wheel bracket (1 wing nut on each side).

3. The bracket is now disconnected from the tank.

A. Flat tip screwdriver

B. 11mm Socket wrench

1. Locate the black box on the machine.

6. Using an 11mm socket wrench, remove the 3 bolts holding the vacuum motor to the black box.

5. Locate the vacuum motor.

7. Locate the black wire and disconnect it from the white wire at the connector.

Surface Cleaner

Table of Contents

Kaivac 1750

Replacing the Vacuum Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

2

10. Pull the vacuum motor gently to remove it from the machine.

9. Pull the black cover off the vacuum motor.

8. Locate the black wire that goes to the control panel and pull the wire connector to disconnect it.

11. Using a flat tip screwdriver, loosen the hose clamp on the vacuum hose.

13. The vacuum motor is now free from the machine. Reverse the process to install a new vacuum motor.

12. Pull to remove the vacuum hose.

Kaivac 1750

Check for Clogs

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

2. Place 2 fingers in the vacuum inlet without blocking it. If you feel air flowing, check the hose or squeegee head (steps 9-12). If no air flow, proceed to step 3.

Table of Contents

3

Surface Cleaner

3. Pull to remove the recovery tank cover.

A. Phillips screwdriver

1. Pull to remove the vacuum hose.

4. Locate the float.

6. Pull the float cage from the machine.

5. Using a Phillips head screwdriver, remove the two screw holding the float cage to the machine.

7. Turn the float hose to remove it from the machine.

Table of Contents

Kaivac 1750

Check for Clogs

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Rinse the float hose under water to remove dirt and debris.

9. Unwrap the hose from the machine to check for a clog or any trapped water.

10. If the hose is still clogged, remove the vacuum inlet and place on the muffler (HEPA filter) outlet to blow the clog/ water out of the hose.

11. Check the squeegee head for a clog.

12. Check the hose for damage and replace if needed. Reverse the process to re-install all parts.

4

Surface Cleaner

Kaivac 1750

Replacing the HEPA Filter

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

1. Locate the HEPA filter cover at the bottom of the machine.

Table of Contents

2. Remove the wing nut by turning it counter clockwise.

5

Surface Cleaner

3. Pull to remove the cover.

4. Remove the wing nut by turning it counter clockwise.

5. Pull to remove the bolt.

7. Pull to remove the HEPA filter cover.

6. Remove the bottom wing nut by turning it counter clockwise.

8. The HEPA filter will now slide out. Reverse the process to install a new filter.

Table of Contents

Cleaning/Replacing the Solution Filter

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

1. Locate the solution tank.

2. Lift the solution tank cover out of the machine.

3. Locate the solution filter at the bottom of the tank. Turn the filter counterclockwise to remove.

4. Rinse the filter under water to remove debris. Reverse the process to install a new filter.

6

Surface Cleaner

Kaivac 1750

Kaivac 1750

Cleaning and/or Replacing the Chemical Injector Valve

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

7

Surface Cleaner

2. Using a 1/2 inch Allen wrench, loosen the set screw on the chemical knob.

3. Pull the chemical knob to remove it.

A. Crescent wrench

B. Needle nose pliers

C. Phillips screwdriver D. 1/2 inch Allen wrench

1. Locate the chemical knob on the control panel.

4. Using a Phillips screwdriver, remove the four screws from the control panel.

6. Using a crescent wrench, remove the brass ring from the knob.

5. Pull the control panel up to access the brass knob.

7. Locate the chemical injector valve.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Using needle nose pliers, squeeze the hose clamps to loosen them.

9. Using a wrench, remove the brass elbows from the chemical injector valve.

10. Remove the tip slowly and carefully so you don’t lose the inner parts. Set aside the spring and ball.

11. Use a paperclip or small Allen wrench to clean the tip. Reverse the process to re-install or replace the chemical injector valve.

Surface Cleaner 8

Kaivac 1750 Cleaning and/or Replacing the Chemical Injector Valve

Table of Contents

Kaivac 1750

Replacing the Unloader Valve

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

4. Turn the key at the top of the black box to remove the box from the machine. Lift the black box from the machine and lay upright to expose the solution pump.

5. Locate the two bolts on the outside of the machine. Using an 11mm socket wrench, remove the two bolts attached to the pump bracket.

6. Pull to remove the pump from the inner wall.

7. Pull to disconnect the unloader valve from the black hose.

9

Surface Cleaner

2. Remove the two yellow capped wing nuts from the wheel bracket (1 wing nut on each side).

3. The bracket is now disconnected from the tank.

A. Crescent wrench

B. Socket wrench

C. Flat tip screwdriver

1. Locate the black box on the machine.

Surface Cleaner

Table of Contents

Kaivac 1750

Replacing the Unloader Valve

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

10

10. The unloader valve is now free from the machine and can be moved to a workplace surface.

9. Pull to remove the hose from the unloader valve.

8. Using a flat tip screwdriver, loosen the screw holding the hose clamp in place.

11. Using a crescent wrench, remove the hose from the unloader valve.

12. Using a crescent wrench, remove the brass fittings from the unloader valve. Reverse the process to install a new unloader valve.

ProCarpet 45

Replacing the Brush Motor Belt

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

4. Open the tank and lean it back.

Warning: Be careful not to lift the tank too fast or hard so you do not damage the plastic solution elbows.

5. With the solution line removed, tilt the solution tank all the way back.

6. Locate the brush motor cover. Using a 5mm Allen wrench and T20 torx remove the three screws holding it to the base and pull up to remove the cover.

7. Looking at the machine from the front, the belt is located on the right. Using a 10mm ratchet socket, loosen the two locknuts on the pulley tension.

11

Extractor

2. Remove the recovery tank from the solution tank.

3. Using a Phillips screwdriver, remove the two screws connecting the tank to the base of the machine. Note: One on each side.

A. Phillips screwdriver

B. T20 torx

C. 5mm Allen wrench

D. 10mm ratchet socket

1. Remove the two suction hoses on the top of the tank.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Pull back the tension pulley by either lifting up on the tab above the pulley or by pushing in on the tab opposite the pulley.

9. Remove the belt by sliding it off the top motor pulley first and then the bottom pulley. Install the new belt by placing in on the bottom pulley first and then the top.

10. After the new belt is on, push down on the tab to place tension back on the belt and tighten the two lock nuts to hold the tension pulley and belt in place.

Reassemble the machine and test.

Extractor 12

45

Table of Contents ProCarpet

Replacing the Brush Motor Belt

ProCarpet 45 Replacing the Shackles

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Note: There is one screw on each side.

3. Pull open the solution tank and lean it back. Remove the solution line.

Warning: Be careful not to pull too fast or hard so the elbow fittings on the solution line do not get damaged.

Table of Contents

4. With tank pulled open, locate the brush motor hood.

5. Remove the 3 screws with a T20 torx and 5mm Allen wrench that hold the hood to the frame and remove the hood by pulling it up and off.

6. Lower the brush and shoe by pressing forward on the foot pedal.

7. Using a

screwdriver, remove the two screws holding the shackles together.

Note: There are 4 screws total and interchangeable.

13

Extractor

2. Using a Phillips screwdriver, remove the two screws holding the tank to the frame.

A. Phillips screwdriver

B. T20 torx

C. 5mm Allen wrench

1. Remove the recovery tank from the solution tank and set aside.

Phillips

Replacing the Shackles

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

8. Pull the shackles apart to remove them from the shoe and frame.

9. Reverse steps 1-8 to install new shackles.

Extractor 14

Table of Contents ProCarpet 45

ProCarpet 45 Replacing the Shoe

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

3. Pull open the solution tank and lean it back. Remove the solution line.

Warning: Be careful not to pull too fast or hard so the elbow fittings do not get damaged.

4. With the solution line removed, tilt the solution tank all the way back.

5. Remove the 3 screws with a T20 torx and 5mm Allen wrench that hold the hood to the frame and remove the hood by pulling it up and off.

6.

remove the screws

are holding the shackles to the shoe and base. Remove the shackles.

Note: There are four screws total (two on each side).

15

Extractor

1. Remove the recovery tank from the solution tank and set aside.

2. Using a Phillips screwdriver, remove the two screws holding the tank to the frame. Note: There is one screw on each side.

A. Phillips screwdriver

B. T20 torx

C. 5mm Allen wrench

D. 8mm socket

E. Snap ring pliers F. Vice grips

Using a Phillips screwdriver,

that

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

7.

11. To reassembly reverse steps 1-10.

Note: There is one on the bottom side of each hose.

8. With the shoe removed, remove the brush

9. Hold the shaft in place with vice grips and remove the bolt on top using an 8mm socket

Extractor 16

ProCarpet 45

Table of Contents

Replacing the Shoe

adjustment knob.

Using a 5mm Allen wrench, remove the six Allen head screws that hold the shoe hoses to the shoe.

wrench.

10. Using snap ring pliers, remove the snap retaining ring and slide indicator disc off and then the shaft slides out of the other sides.

ProCarpet 45 Replacing the Vacuum Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

4. Pull open the solution tank and lean it back. Remove the solution line.

Warning: Be careful not to pull too fast or hard so the elbow fittings on the line do not get damaged.

17

Extractor

2. Remove the recovery tank off of the solution tank and set off to the side.

3. Using a Phillips screwdriver remove the 2 screws (one on each side) that hold the tank to the frame.

A. Phillips screwdriver

1. Remove the two vac hoses from the top of the recovery tank.

6. Trace the vac motor wires back to the 120V contactor and remove them.

5. Remove the top part of the noise absorber.

7. Remove the vac motor from the bottom noise absorber.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

8. Remove the vac cover and set off to the side.

9. Remove the vac motor from the bottom cover.

10. Reverse steps 1-10 to install the new vac motor.

Extractor 18

of Contents ProCarpet 45 Replacing the Vacuum Motor

Table

Jet 38 Adjust the Brush Height

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

1. Locate the orange dial on the top of the base. Turn the dial to Adjust the brush height.

Jet 38 Check Brush for Wear

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

1. Lay the vacuum back on the handle. Locate the brush roll under the base. Visually inspect the brush for wear.

Table of Contents

Vacuum 19

Table of Contents

Vacuum

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

4. Locate the 2 red wires on the circuit board. Put one lead on each wire connector. Make sure the machine is plugged in and turn power on. Activate the brush motor. Set the volt meter to voltage. Volt meter should read approx. 120 Volts.

Vacuum 20 Table of Contents Jet 38

Check for Power to the Brush Motor

2. Stand the machine up and pull up on the base cover to remove it.

3. Locate the circuit board in the base. Pull up on the circuit board to remove it.

A. Phillips screwdriver

B. Volt meter (True RMS capable)

1. Lay the machine down and remove the 7 screws from the base bottom.

Jet 38

Check Micro switch for Brush Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

6. Locate the

switch. Move the neck up and down. If the micro switch clicks, the micro switch is okay.

21

Vacuum

Table of Contents

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

blue micro

5. Flip the base back over and pull up on base cover to remove it.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

6. Locate

and visually inspect it for damage such as cuts, shredding, and wear.

Vacuum 22 Table of Contents Jet 38 Check the Belt

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

the belt

5. Flip the base back over and pull up on base cover to remove it.

Jet 38

Check the Brush Roll Ends

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Table of Contents

23

Vacuum

3. Slide the brush roll and roller support out of machine.

4. Pull the brush roller support off the brush roll.

2. Lay the machine down on its handle.

5. Visually inspect the brush roll ends for damage such as cracks and wear.

1. Slide the brush roll cover up to remove it.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

4. Flip the base over. Remove the 7 screws.

5. Flip the base back over and pull up on base cover to remove it.

6. Locate the brush motor. Visually inspect the carbon brushes located between the 2 white wires as shown. The lead end on the carbon brush should be touching the coil.

Vacuum 24 Table of Contents Jet 38 Check the Carbon Brushes - Brush Motor

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

Jet 38

Check the Roller Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 25

Table of Contents

3. Slide the brush roll and roller support out of machine.

4. Pull the brush roller support off the brush roll.

2. Lay the machine down on its handle.

5. Visually inspect the brush roller support for damage such as cracks and wear.

1. Slide the brush roll cover up to remove it.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

6. Turn the

brush. If brush turns freely, transmission support is okay.

Note: The transmission support is on the belt side of machine.

Vacuum 26

Contents Jet 38

Table of

Check the Transmission Support

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

roller

5. Flip the base back over and pull up on base cover to remove it.

Jet 38

Replace the Belt

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

27

Vacuum

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

6. Remove the 2 screws holding the transmission support.

5. Flip the base back over and pull up on base cover to remove it.

7. Pull the transmission support from the machine.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

Vacuum 28 Table of Contents Jet 38 Replace the Belt

8. Remove the belt from the transmission support.

9. To replace the belt, first slide the belt between the base and brush motor pulley. Reverse steps 1 through 7 to install a new belt.

Jet 38

Replace the Brush Roll

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Table of Contents

29

Vacuum

3. Slide the brush roll and roller support out of machine.

4. Pull the brush roller support off the brush roll.

2. Lay the machine down on its handle.

5. Reverse steps 1 through 4 to install a new brush roll.

1. Slide the brush roll cover up to remove it.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

1. Slide up on the bag cover latch. Pull the bag cover from the machine.

2. Push in on the red lever on the right side to unlock the bag.

3. Pull the bag down off the intake hose.

4. Slide the yellow cage out of machine.

5. Locate the vac motor filter in cage.

6. Open the cage and remove vac motor filter.

Reverse steps 1 through 7 to install a new vac motor filter.

Vacuum 30

Jet 38

Table of Contents

Replace the Vac Motor Filter

Table of Contents Jet 38

Replace the Carbon Brushes in the Brush Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

31

Vacuum

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

B. Flat tip screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

6. Remove the 2 screws holding the brush motor.

5. Flip the base back over and pull up on base cover to remove it.

7. Pull brush motor from the base.

Replace the Carbon Brushes in the Brush Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

12. The carbon brush is now out of the brush motor. Repeat steps 10 and 11 for the other carbon brush.

13. Reverse steps 1 through 11 to install new carbon brushes.

Note: When installing new brushes, push spring down and hold it. Slide the metal tab on wire over spring until it clicks in place.

Vacuum 32

Jet 38

Table of Contents

10. Push in tab on carbon brush while pulling wire out.

11. Pull the spring and carbon brush out of motor.

9. Disconnect all the wire connectors from the brush motor. Record wire sequence for reinstalling brush motor.

8. Slide the belt off the brush motor.

Table of Contents Jet 38

Replace the Micro switch for the Brush Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

4. Flip the base over. Remove the 7 screws.

5. Flip the base back over and pull up on base cover to remove it.

6. Disconnect the 2 red wires on the micro switch.

7. Remove the screw from the micro switch. Reverse steps 1 through 7 to install a new micro switch and to reassemble the machine.

33

Vacuum

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

Replace the Roller Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 34

Jet

Table of Contents

38

3. Slide the brush roll and roller support out of machine.

4. Pull the brush roller support off the brush roll.

2. Lay the machine down on its handle.

5. Reverse steps 1 through 4 to install a new brush roll support.

1. Slide the brush roll cover up to remove it.

Table of Contents Jet 38

Replace the Transmission Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

35

Vacuum

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

6. Remove the 2 screws holding the transmission support.

5. Flip the base back over and pull up on base cover to remove it.

7. Pull the transmission support from the machine.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Pull the belt off the transmission support.

9. Reverse steps 1 through 8 to install a new transmission support

Vacuum 36 Table of Contents Jet 38

the Transmission Support

Replace

Check Base Wiring

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Vacuum 37

Contents

Table of

Jet 38

2. Stand the machine up and pull up on the base cover to remove it.

3. Visually inspect all wiring for damage such as cuts, splitting or melting. Make sure all wire connectors are tight.

A. Phillips screwdriver

1. Lay the machine down and remove the 7 screws from the base bottom.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

1. Visually inspect the cord plug for damage such as cuts, cracks, and bare wires.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

1. Visually inspect the power cord for damage such as cuts, fraying, etc.

Vacuum 38 Table of Contents Jet 38 Check Cord Plug

Jet 38 Check Cord Condition Vacuum

Table of Contents

38

Check Micro switch

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

6. Locate the blue micro switch. Move the neck up and down. If the micro switch clicks, the micro switch is okay.

Vacuum 39

Table of Contents Jet

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

5. Flip the base back over and pull up on base cover to remove it.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

4. Locate the 2 red wires on the circuit board. Put one lead on each wire connector. Make sure the machine is plugged in and turn power on. Activate the brush motor. Set the volt meter to voltage. Volt meter should read approx. 120 Volts.

Vacuum 40 Table of Contents Jet 38 Check Brush Motor

2. Stand the machine up and pull up on the base cover to remove it.

3. Locate the circuit board in the base. Pull up on the circuit board to remove it.

A. Phillips screwdriver

B. Volt meter (True RMS capable)

1. Lay the machine down and remove the 7 screws from the base bottom.

Table of Contents Jet 38

Check Primary Terminal Block

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

41

Vacuum

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

A. Phillips screwdriver

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Locate the 5 screws on the back of the vacuum (visible after removing the bag). Remove the 5 screws.

7. Remove the screw holding the brush tool holder.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 42 Table of Contents Jet 38 Check Primary Terminal Block

10. Remove the back panel on the handle assembly.

11. Pull the terminal block up out of the handle. Visually inspect it for damage. Make sure all wire connectors are tight.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vacuum.

Check the Carbon Brushes - Vac Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

43

Vacuum

Table of Contents Jet 38

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

A. Phillips screwdriver

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

10. The vac motor is located in the top of the lower vac housing. Visually inspect the carbon brushes for wear. The lead part of the carbon brush should be touching the coil. Check the length of the carbon brushes by looking in the hole. If the hole is black the carbon brushes are worn and need replaced. If the hole is orange, the length of the carbon brush is okay.

Vacuum 44 Table of Contents Jet 38 Check the Carbon Brushes - Vac Motor

9. Pull up on the top of the upper vac housing to separate it from the lower vac housing.

8. Loosen the 2 screws holding the guide housing.

Table of Contents Jet 38

Check the Curve Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

45

Vacuum

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

A. Phillips screwdriver

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 46 Table of Contents Jet 38 Check the Curve Support

10. Locate the curve support in the bottom of the vac housing. Visually inspect it for damage such as cracking.

9. Pull up on the middle vac housing to separate it from the lower vac housing.

8. Loosen the 2 screws holding the guide housing

Table of Contents Jet 38 Check the Switch

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

47

Vacuum

A. Phillips screwdriver

B. Volt meter (True RMS capable)

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

7. Remove the screw holding the brush tool holder.

5. Pull the bag down off the intake hose.

4. Push in on the red lever to unlock the bag.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

12. Insert 1 lead into the green/ yellow wire at terminal block.

13. With the other lead, touch the wire connector of the green/yellow wire at the connector. Set the volt meter to continuity. If the volt meter beeps, the wire is okay.

14. Locate the blue wires on the switch. Insert 1 lead into the wire connector of one of the blue wires.

15. Trace the blue wire to the connector at the bottom of the handle. Touch the wire connector of the blue wire at the connector. Set the volt meter to continuity. If the volt meter beeps, the switch is okay. Repeat step 14 and 15 for the other blue wire.

Vacuum 48 Table of Contents Jet 38 Check the Switch

10. Remove the back panel on the handle assembly.

11. Slide the cover off the connector at the bottom of the handle.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.

Terminal Block Continuity

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

49

Vacuum

Table of Contents Jet 38

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

A. Phillips screwdriver

B. Volt meter (True RMS capable)

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Loosen the 2 screws holding the guide housing

9. Pull up on the middle vac housing to separate it from the lower vac housing.

10. Locate the terminal block on the bottom of the middle vac housing. Insert 1 lead into the terminal block and insert the other lead in the terminal block directly across from the first lead. Set the volt meter to continuity. If the volt meter beeps, the terminal block is okay. Repeat this process with the other 2 openings on the terminal block.

Vacuum 50 Table of Contents Jet 38 Terminal Block Continuity

Table of Contents Jet 38

Check Wiring between Base Plug and Terminal Block

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

51

Vacuum

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

A. Phillips screwdriver

B. Volt meter (True RMS capable)

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Loosen the 2 screws holding the guide housing

9. Pull up on the middle vac housing to separate it from the lower vac housing.

10. Locate the base plug on the bottom of the middle vac housing.

Note: the 3 prongs are labeled in the pic. Place lead 1 on the first green prong.

11. Insert the other lead into the terminal block of the corresponding wire (green/ yellow wire). Set the volt meter to continuity. If the volt meter beeps, the wire is okay. Repeat steps 10 and 11 for the 2 blue wires.

Vacuum 52 Table of Contents Jet 38 Check Wiring between Base Plug and Terminal Block

Check Wiring between Switch and Connector

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

53

Vacuum

Table of Contents Jet 38

A. Phillips screwdriver

B. Volt meter (True RMS capable)

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

7. Remove the screw holding the brush tool holder.

5. Pull the bag down off the intake hose.

4. Push in on the red lever to unlock the bag.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

12. Locate the connector at the bottom of the handle. Slide the cover off the connector. There are 3 wires, 2 blue and 1 green/yellow.

14. Trace the blue wire to the connector. Place the other lead on the blue wire at the connector. Set the volt meter to continuity. If the volt meter beeps, the wire is okay. Continue this process for the other blue and the green/yellow wire.

Vacuum 54 Table of Contents Jet 38 Check Wiring between Switch and Connector

10. Remove the back panel on the handle assembly.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.

13. Place 1 lead on one of the blue wires at the switch.

11. Locate the switch. There are 2 blue wires and 1 green/ yellow wire.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

55

Vacuum

Table of Contents Jet 38 Check Wiring between Terminal Block and Vac Motor

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

A. Phillips screwdriver

B. Volt meter (True RMS capable)

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Loosen the 2 screws holding the guide housing

10. Locate the 3 wires attached to the vac motor. 2 blue wires and 1 green/yellow wire. Insert 1 lead into a blue wire on terminal block. Follow the wire to the vac motor. Insert the other lead into the wire connector of the blue wire. Set the volt meter to continuity. If the volt meter beeps, the wire is okay. Continue this process with the other blue wire and the green/ yellow wire.

Vacuum 56 Table of Contents Jet 38 Check Wiring between Terminal Block and Vac Motor

9. Pull up on the middle vac housing to separate it from the lower vac housing.

Table of Contents Jet 38

Check Wiring between Terminal Block and Curve Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

57

Vacuum

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

A. Phillips screwdriver

B. Volt meter (True RMS capable)

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8.

10. Locate the terminal block on the bottom of the middle vac housing. Insert 1 lead in the terminal block and 1 lead on the curve support. The curve support is located on the bottom of the lower vac housing. Set the volt meter to continuity. If the volt meter beeps, the wiring is okay. Repeat this step for the remaining wires in the terminal block.

Vacuum 58 Table of Contents Jet 38 Check Wiring between Terminal Block and Curve Support

9. Pull up on the middle vac housing to separate it from the lower vac housing.

Loosen the 2 screws holding the guide housing.

Check Wiring between Terminal Block and Switch

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

59

Vacuum

Table of Contents Jet 38

A. Phillips screwdriver

B. Volt meter (True RMS capable)

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

7. Remove the screw holding the brush tool holder.

5. Pull the bag down off the intake hose.

4. Push in on the red lever to unlock the bag.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 60 Table of Contents Jet 38 Check Wiring between Terminal Block and Switch

10. Remove the back panel on the handle assembly.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.

11. Locate the blue wire on terminal block. Insert a lead into the terminal block. Insert the other lead on the wire connector on the switch for the blue wire. Repeat for other blue wire and green/yellow wire. Set the volt meter to continuity. If it beeps, the wire is okay.

Table of Contents Jet 38

Replace Carbon Brushes - Vac Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

61

Vacuum

2. Unhook the vac hose from the hose hook.

3. Locate the button on the back of the machine. Slide the button to open.

1. Remove the power cord from the hook.

6. Push in on the red lever on the right side to unlock the bag.

7. Pull the bag down off the intake hose.

A. Phillips screwdriver

B. Flat tip screwdriver

4. Lift up on the upper assembly to remove it from the base.

5. Slide up on the upper assembly to remove it from the base.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this

**Before you begin: Turn the machine off.

Vacuum 62 Table of Contents Jet 38 Replace Carbon Brushes - Vac Motor

8. Remove the 4 screws holding the upper vac housing.

9. Pull the upper vac housing up to separate it from the lower vac housing.

machine.

11. Pull up on the middle vac housing to separate it from the lower vac housing.

10. Loosen the 2 screws holding the guide housing

12. Locate the vac motor under upper vac housing.

13. Pull the wire connectors to disconnect the 2 blue wires from the carbon brushes.

15. The carbon brush spring will pop out once all 3 tabs are moved.

14. Push all 3 tabs, holding the carbon brush spring, up and out.

Replace Carbon Brushes - Vac Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

16. Break the bottom white tab away from the carbon brush.

17. Push up on the carbon brush to remove it from the vac motor.

18. Push down on new carbon brush to install.

19. Note: New carbon brush is recessed and has to be pushed out once installed in vac motor.

20. Insert screw driver in carbon brush below the spring. Push in on screw driver and the lead on the carbon brush will pop out and touch coil. Repeat steps 14 through 20 to replace the other carbon brush.

21. Repeat step 13 to reattach the wires. Reverse steps 1 through 11 to reassemble the machine.

Vacuum 63

Table of Contents Jet 38

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Vacuum 64 Table of Contents Jet 38 Replace Damaged Wiring in Base

2. Stand the machine up and pull up on the base cover to remove it.

3. Locate bad wiring. Disconnect wiring at terminal block. Trace wiring to component. Disconnect wiring from component. Install a new wire with wire connectors.

A. Phillips screwdriver

1. Lay the machine down and remove the 7 screws from the base bottom.

Jet 38

Replace the Circuit Board

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

7. Disconnect all wire connectors from circuit

Reverse steps 1 through 7 to install a new circuit board.

65

Vacuum

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

6. Locate the circuit board in the base. Pull up on the circuit board to remove it.

5. Flip the base back over and pull up on base cover to remove it.

board.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Reverse steps

Vacuum 66

Jet 38

Table of Contents

Replace the Micro switch

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

6. Disconnect the 2 red wires on the micro switch.

5. Flip the base back over and pull up on the base cover to remove it.

7. Remove the screw from the micro switch.

1 through 7 to install a new micro switch and to reassemble the machine.

Jet 38

Replace the Brush Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

67

Vacuum

2. Lift up on the body to disconnect it from the base.

3. Lay the neck down parallel to the base.

A. Phillips screwdriver

1. Locate the unlock button on the back of the machine. Slide the button to open.

4. Flip the base over. Remove the 7 screws.

6. Remove the 2 screws holding brush motor.

5. Flip the base back over and pull up on base cover to remove it.

7. Pull brush motor from the base.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

8. Slide the belt off the brush

9. Disconnect all the wire connectors from the brush motor. Reverse steps 1 through 9 to install a new brush motor.

Vacuum 68 Table of Contents Jet 38 Replace the Brush Motor

motor.

Jet 38

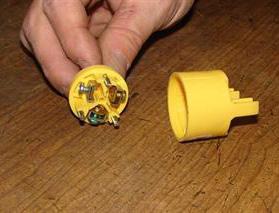

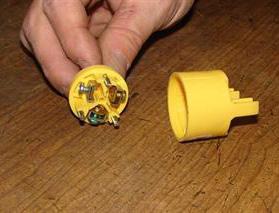

Replace the Cord Plug

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Note: If any wires are cut, cut that part of

Table of Contents

Vacuum 69

2. Carefully cut through the wire covering on the power cord. Be careful not to cut any of the wires.

the cord off and start over.

3. The wires are now visible.

A. Phillips screwdriver

B. Wire cutters

1. Cut the bad plug off the cord.

4. Carefully cut the wire covering on each wire. Cut about a half inch off.

6. Set the power cord aside. Loosen the 2 screws on the cord clamp on the new plug.

5. The 3 wires should now look like this.

7. The new plug has 3 parts shown here.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 70 Table of Contents Jet 38

Replace the Cord Plug

8. Loosen the 3 screws on the prong part of the plug.

9. Pull the prong part of the plug off the bottom part of the plug.

10. Slide the bottom part of the plug on the power cord.

11. Loosen the 3 screws on the prong part of plug. Insert each wire into the plug and tighten the screws. Note: Green wire to green screw, white wire to silver screw, and black wire to brass screw.

12. The prong part of the plug should look like this.

14. Tighten the 3 screws on the prong part of the plug.

13. Slide the bottom part of the plug up to connect it to the prong part of the plug.

15. Put the 2 parts of the cord clamp on the power cord at the base of the plug and tighten the 2 screws.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

16.

17. Plug the machine in and turn on

Note: If machine doesn’t power on, go back and recheck wire is connected correctly and tightly.

Vacuum 71 Table of Contents

Jet 38 Replace the Cord Plug

Put the 2 parts of the cord clamp on the power cord at the base of the plug and tighten the 2 screws.

power.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine.

**Before you begin: Turn the machine off.

1. Locate the brush motor filter cage on the bottom back of the vac, Push down on the latch to it.

2. Visually inspect the brush motor filter for damage such as wear and/or tear.

3. Pull the filter out of the cage. Shake the foam filter to remove dust and debris. You may also clean filter with water. Rinse the filter under water and lay flat to dry. Replace the clean filter and close the cage.

Vacuum 72 Table of Contents Jet 38 Check and Clean the Filter

Jet 38

Replace the Curve Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

73

Vacuum

2. Unhook the vac hose from the hose hook.

3. Locate the button on the back of the machine. Slide the button to open.

1. Remove the power cord from the hook.

6. Push in on the red lever on the right side to unlock the bag.

7. Pull the bag down off the intake hose.

A. Phillips screwdriver

B. Flat tip screwdriver

4. Lift up on the upper assembly to remove it from the base.

5. Slide up on the upper assembly to remove it from the base.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 74 Table of Contents Jet 38 Replace the Curve Support

8. Remove the 4 screws holding the upper vac housing.

9. Pull the upper vac housing up to separate it from the lower vac housing.

11. Pull up on the middle vac housing to separate it from the lower vac housing.

10. Loosen the 2 screws holding the guide housing

12. Remove 1 screw holding hose support to the lower vac housing.

13. Pull to remove hose support.

15. Remove the 2 screws holding the curve support to vac housing.

14. Locate the curve support in the lower vac housing.

Replace the Curve Support

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

16. Pull the hose apart to separate the 2 pieces.

17. Pull the bottom hose away from curve support.

18. Trace the wires from the curve support to the terminal block on the middle vac housing. Loosen the 3 screws on the terminal block. 1 yellow/ green wire, 1 black wire and 1 white wire. Pull to remove the 3 wires from the terminal block. Reverse steps 1 through 18 to replace the curve support and to reassemble the machine.

Vacuum 75 Table of Contents

Jet 38

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

1. Locate the bag cover on the back of the vac. Slide the bag cover latch up.

2. Pull the bag cover from the vac.

3. Make sure the bag is locked in place by checking the red lever. Visually inspect the bag for damage such as rips, wear, and tears. Check bag to see if it’s full.

Reverse steps 1 and 2 to reassemble the bag cover.

Vacuum 76 Table of Contents Jet 38 Check the Filter Bag

Jet 38

Replace the Main Switch

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

77

Vacuum

A. Phillips screwdriver

B. Volt meter (True RMS capable)

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

7. Remove the screw holding the brush tool holder.

5. Pull the bag down off the intake hose.

4. Push in on the red lever to unlock the bag.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 78 Table of Contents Jet 38 Replace the Main Switch

10. Remove the back panel on the handle assembly.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.

11. Disconnect the wire connectors on the 4 blue wires and the 2 white wires, Pop the switch out. Reverse steps 1 through 11 to install a new main switch and to reassemble the machine.

Jet 38

Replace the Power Cord

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

79

Vacuum

2. Unhook the vac hose from the hose hook.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

A. Phillips screwdriver

B. Flat tip screwdriver

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

7. Remove the screw holding the brush tool holder.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

Replace the Power Cord

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

12. Using a small screwdriver, pry the white terminal block out of the handle.

Note: When reconnecting the wires, put green on left, black in middle and white on right

15. Reverse steps 1 through 14 to install a new

Vacuum 80

Jet 38

Table of Contents

10. Remove the back panel on the handle assembly.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.

11. Remove the 2 screws from the power cord clamp.

14. Pull the power cord out through the top of the handle assembly.

13. Loosen the top 3 screws in the top row of the terminal block.

power cord.

Jet 38

Replace the Primary Terminal Block

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

81

Vacuum

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Locate the 5 screws on the back of the vacuum (visible after removing the bag). Remove the 5 screws.

7. Remove the screw holding the brush tool holder.

A. Phillips screwdriver

B. Flat tip screwdriver

Replace the Primary Terminal Block

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8.

to

12. Loosen the screws to all 6 wires. Pull wires to remove them from the terminal block.

Reverse steps 1 though 12 to install a new terminal block and reassemble the machine.

Vacuum 82

Jet 38

Table of Contents

10. Remove the back panel on the handle assembly.

11. Remove the screw holding the terminal block to the machine. Pull up on the terminal block to remove it.

9. Lay the handle assembly down and remove the 4 screws.

Pull

remove the handle assembly from the vacuum.

Jet 38

Replace the Terminal Block

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

83

Vacuum

2. Unhook the vac hose from the hose hook.

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

6. Remove the 4 screws holding the upper vac housing.

7. Pull the upper vac housing up to separate it from the lower vac housing.

A. Phillips screwdriver

B. Flat tip screwdriver

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

8. Loosen the 2 screws holding the guide housing.

9. Pull up on the middle vac housing to separate it from the lower vac housing.

10. Locate the terminal block on the bottom of the middle vac housing. Loosen the screws and pull to remove the wires. Remove the terminal block screw. Pull terminal block from machine. Reverse steps 1 through 10 to install a new terminal block and to reassembly the machine.

Vacuum 84 Table of Contents Jet 38 Replace the Terminal Block

Jet 38

Replace the Vacuum Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

85

Vacuum

2. Unhook the vac hose from the hose hook.

5. Slide up on the bag cover latch. Pull the bag cover from the machine.

1. Remove the power cord from the hook.

6. Push in on the red lever on the right side to unlock the bag.

7. Pull the bag down off the intake hose.

A. Phillips screwdriver

B. Flat tip screwdriver

4. Lift up on the body to disconnect it from the base.

3. Locate the unlock button on the back of the machine. Slide the button to open.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Vacuum 86 Table of Contents Jet 38 Replace the Vacuum Motor

8. Remove the 4 screws holding the upper vac housing.

9. Pull the upper vac housing up to separate it from the lower vac housing.

11. Pull up on the middle vac housing to separate it from the lower vac housing.

10. Loosen the 2 screws holding the guide housing.

12. Remove 1 screw holding hose support to the vac motor housing.

13. Pull to remove hose support.

15. Remove the 2 screws holding the curve support to vac motor housing.

14. Locate the curve support in the vac motor housing.

Replace the Vacuum Motor

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

16. Remove the curve support from machine and pull the hose apart to separate the 2 pieces.

17. Pull the bottom hose away from curve support.

18. Locate the terminal block on the lower vac housing. Loosen the 3 screws on the right side (closest to vac motor) of terminal block. Pull to remove the wires from the terminal block.

19. Disconnect the 3 wires from the

20. Line the carbon brushes up with notches in the vac housing. Slide the vac motor out of the vac housing. Reverse steps 1 through 21 to install a new vac motor and to reassembly the machine.

Vacuum 87

Contents

Table of

Jet 38

vac motor. 1 green/yellow and 2 blue wires.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

1. Pull hose out from upper housing. Insert a coat hanger or long screwdriver into hose to feel for a clog.

2. Locate the unlock button on the back of the machine. Slide the button to open.

3. Lift up on the body to disconnect it from the

4. Pull the neck on base down parallel with base. Flip the base over. Insert a coat hanger or a long screwdriver to feel for a clog.

5. Insert a coat hanger or a long screwdriver into the neck on base to feel for a clog.

Vacuum Table of Contents 88 Jet 38 Locate and Remove Clog

base.

A. Phillips screwdriver

Table of Contents Jet 38

Replace the Wiring between Switch and Connector

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

89

Vacuum

2. Unhook the vac hose from the hose hook.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

A. Phillips screwdriver

B. Flat tip screwdriver

C. Wire crimper

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

7. Remove the screw holding the brush tool holder.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

12. Locate the connector at the bottom of the handle. Slide the cover off the connector. There are 3 wires, 2 blue and

14. Follow the bad wire to the connector at the bottom of the handle. Pull up on wire connector to remove it from its slot. Replace the wire and/or

Vacuum 90

of Contents Jet 38

the Wiring between Switch and Connector

Table

Replace

10. Remove the back panel on the handle assembly.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.

11. Locate the switch. There are 2 blue wires and 1 green/ yellow wire.

connector.

13. Loosen the screw in the terminal for the bad wire.

1 green/yellow.

Jet 38

Replace the Wiring between Terminal Block and Main Switch

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

Tools Needed

Table of Contents

91

Vacuum

2. Unhook the vac hose from the hose hook.

1. Remove the power cord from the hook.

4. Push in on the red lever on the right side to unlock the bag.

5. Pull the bag down off the intake hose.

A. Phillips screwdriver

B. Flat tip screwdriver

3. Slide up on the bag cover latch. Pull the bag cover from the machine.

7. Remove the screw holding the brush tool holder.

6. Locate the 5 screws on the back of the vac (visible after removing the bag). Remove the 5 screws.

These are general maintenance guidelines. Please consult your owner’s manual prior to performing any repairs or maintenance on this machine. **Before you begin: Turn the machine off.

12. Follow the wires to the switch. Pull to disconnect the wire connectors on the 2 blue wires. Replace the wire and wire connectors. Reverse steps 1 through 12 to reassemble the wires and machine.

Vacuum 92 Table of Contents Jet 38

Replace the Wiring between Terminal Block and Main Switch

10. Remove the back panel on the handle assembly.

9. Lay the handle assembly down and remove the 4 screws.

8. Pull to remove the handle assembly from the vac.