Therearemanyfactorscontributingtotheneedforgreenhousecoolingandventilationequipment.Theprimary sourceofheatinagreenhouseissolarradiation.Toreducegreenhousetemperatures,airremovalisrequiredandits rateofremovalisafunctionofthefloorarea.Asimplifiedmethodforsizingandselectingequipmentforgreenhouse temperaturecontrolisincludedinthisbrochure.Formoredetailedinformation,seeAcmecatalogC7.

TABLE1

Elevation,feetabovesealevel

feet Under100010002000300040005000600070008000

F Elev(e) 1.001.041.081.121.161.201.251.301.36

TABLE2

MaximumInteriorLightIntensity,footcandles

FC 5000550060006500700075008000900010,000

F Light(l) 1.001.101.201.301.401.501.601.802.00

TABLE3

HouseTemperatureaboveOutdoorTemperature°F

°F 18 17161514131211109

F Winter(w) .83.88.941.001.071.151.251.371.501.67

SELECTINGFAN-JET:

Fromcharts1and1A,locatethegreenhousesizeusingthe “equivalentwidth”fromtheformulabelowandtheactual lengthofthegreenhouse.

ACTUALWIDTHxFe xFl xFw =(EQUIVALENTWIDTH)

DONOTEXCEED30’INACTUAL HOUSEWIDTHWITH ONEFAN-JET.

SelecttheFan-Jet(s)withintherangeshown.IftheFan-Jetis tobeusedfordistributingheat,includetheheataccessorykit togowiththeFan-Jet.Selectthepropermodeloftubing accordingtothelengthofthegreenhouse.Impropertube punchingwillnotprovideuniformairdistribution.

SELECTINGEXHAUSTFANS:

WinterVentilation: (usedinconjunctionwithFan-Jet) Between11/2 and2CFMpersquarefootoffloorareais requiredforwinterventilation.

LENGTHXWIDTH x2xFe xFl xFw =WINTERCFM

TABLE4

InlettoFanTemperatureVariation,T°F

°F 10987654

F Temp(t) .70.78.881.001.171.401.75

TABLE5

InlettoFanDistance,feet feet 2025303540455055

F Vel(v) 2.242.001.831.691.581.491.411.35

feet 6065707580859095100

F Vel(v) 1.291.241.201.151.121.081.051.021.00

DONOTEXCEEDTHECAPACITYOFTHEFAN-JETWITH EXHAUST.

EitherincreasethesizeoftheFan-Jetorreduceexhaust belowtheFan-JetCFMrating.

SummerVentilationandCooling: Approximately8CFMper squarefootoffloorareaisrequiredformaximumventilation andcooling.

LENGTHXWIDTH x8xFe xFl xFt = SUMMERCFM. Iffansandpadsarelessthan100feetapart,adjustments mustbemadeforairvelocity.

LENGTHXWIDTH x8xFv = CFMFORSUMMER.

Selecttheexhaustfanstoprovidethehigher ofeitherCFM forconditionsor CFMforvelocity.

Kool-Celismostefficientwithairvelocityof250fpm. Therefore,formaximumefficiencyaddthetotalexhaust selectedanddivideby250togetthesquarefeetofpad required.Dividethesquarefeetofpadbytheavailablelength ofruntogettheheightofKool-Celrequired.Roundofftothe nearestfoot.

Thepadsare4”x12”x24”,36”,48”,60”&72”.Usingthetall padsupport,theymaybestackedtoprovide60”,72”,84”, and96”highpads,ThenumberofKool-Celpadsrequiredis equaltothelengthofrun.

Selectthedistributionsystemthatmatchesthelengthofrun upto100’.(50’inPDRsystems.)

Selectthewaterpumpaccordingtothelengthofthe distributionsystem.Use#15pumpforsystemsupto40’,#30 upto70’,and#60upto100’.

WinterVentilation:TheinletshuttersizesforFan-Jetsystems arelistedwiththeFan-JetsonPage10.

SummerVentilationandCooling:TheinletareaforKool-Cel padsshouldbecontinuousandatleast2/3ofthepadheight. Innocaseshouldthevelocityofairinletforsummercooling orventilationexceed400fpm.DividetotalCFMby400toget squarefeetofinletrequired.Selectinletshuttersusingthe openingareashownontheinletshutterchart.(Page9).

TypicalExample:

A25’x100’greenhouselocatedinanareawithlessthan1000 feetelevationand5000f.c.oflight.Thisexampleisbasedon 15degreewinterinsidetemperatureaboveoutside temperatureand7degreerisefrompadtofaninsummer.Air flowwillbeendtoendand,therefore,fantopaddistanceis 100’.

ActualWidthxFe xFl xF w =(EquivalentWidth)

25’x1.0x1.0x1.0=25’ (25’islessthan30’;therefore,oneunitisOK)

Winter: LxWx2xFe xFl xFw =CFM

100x25x2x1.0x1.0x1.0= 5,000CFM

Summer: LxWx8xFe xF xFt =CFM

100x25x8x1.0x1.0x1.0= 20,000CFM

21,120CFM÷250=84.48sq.ft.

85÷20(lengthofpad)=4.25(use48”)

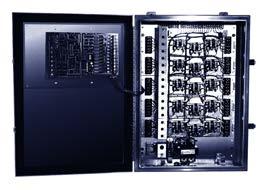

Becauseofnon-residentmanagementofgreenhouse operationstoday,automaticcontrolsbecomeanecessity. Ifsimpleoneortwostepheatingorcoolingisrequired, thermostatswillsatisfactorilyoperatetheequipment.Butto conserveenergy,stagingequipmentisrecommendedtouse minimumequipmentwhileachievingdesiredtemperatures. TheACC-Ihaszero,one,two,orthreestagesofheat,one stageofcirculationandfour,five,six,orseven cooling/ventilationstages.

TheGrotronIIhastwostagesofheat,oneforcirculationand fivestagesofcooling/ventilation.Morefeaturesareapartof theGrotronIIsystemandaredetailedonPage19andin BrochureC46.

BothGrotronIIandACC-Iarelowvoltage(24volts) controllersandrequire24voltcontrolrelays.Selectone PB90ER24-1relayforeachpieceofequipmentandone PB90ER24-1andPB90ER24-2relayforeachtwospeedor twodirectionalmotor.(Inletshuttersmaybegroupedand operatedwithonerelay.)

Fan-Jet

1-RCA24Ffromchart#1;WAAC333MTfrompage10performancedata;100 feet24”tubepunched“BP”frompage11.TubeSelectionChart;1-100’support package;13hangersandrings(100’÷8= 13);24”heataccessoryifheatisto bedistributedbytheFan-Jet.

ExhaustFans

2-DCA36Gfansat.05”SP=11,065CFMeach;oneis2speed,(lowspeedfor winterventilation);thereforeselect1-DCA36Gand1-DCA36G-2Seachwithslant wallhousing,shutterandguard.(Note2spd.Max.=10,055CFM);(TotalCFM= 11,065+10,055=21,120)

Kool-CelSystem

20-48”Kool-Celpads

1-20’DistributionandReturnSystem

1-#15SPump

1-PlumbingPackage InletShutters

Winter....................................................................................................................................SeeFan-JetAbove

Summer................................................................................................................................Abalanceofbothpadheightandlengthofrunisrequired.

21,120 400=52.8sq.ft.

4x15.4=61.6sq.ft.4-WAAC6340MT@15.4sq.ft.each Controls

Automaticoperationsrequired

Onerelaypereachpieceofequipment

2-heaters(assumed),1-Fan-Jet.

1-Fan-Jetshutter,2-fans, 1-pump,1-grouppadinletshutter

1-Twospeedfan

1-GrotronllorACC-1

9-RelayPB90ER24-2

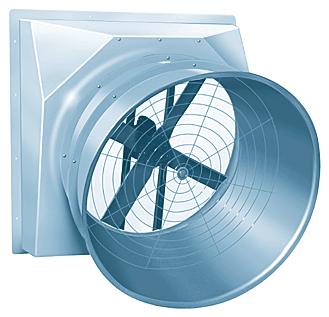

• Six-bladedpropellerutilizingacambered-twistbladedesignedwitha uniquedihedraltipforhigherairflowcapacitiesatlesshorsepower.

• Non-overloadingdesignmaintainshorsepowerwithincatalograngeofstatic pressure,resultinginlowermotorloadandreducedoperatingcosts.

• Streamlinedorificeinsureshigherairflowcapacity.

• Availablemountedineitherslantorsquarewallhousing.

AcmeEngineeringandManufacturingCorporationcertifiesthatthe SuperWindmasterDCshownhereinislicensedtobeartheAMCA Seal.Theratingsshownarebasedontestsandprocedures performedinaccordancewithAMCAPublication211andAMCA Publication311andcomplywiththerequirementsoftheAMCA CertifiedRatingsProgram.

• Prelubricatedoversizeballbearingsaredouble sealed,requirenoservice.

• Improved,moreefficientdriveassemblyand super-dutyneoprenebeltsprovidelongerservice life.

• Heavydutytotallyenclosedmotorswithshielded ballbearingsaredesignedforcontinuouswork load.

• Availableintwospeed.

• Built-inthermaloverloadforlow-linevoltageprotection onallsinglephasemotors.

AcmeWindmasterFansarelistedbyCanadian StandardsAssociationTestingLaboratoryas approved.

1.Allsinglespeedsinglephasemotorsaredualvoltage(115/230)except¼ horsepower.

2.All¼horsepowersinglephasemotorsaresinglevoltage(115or230).

3.Two-speedmotorsaresinglevoltage(115or230)andnotavailablein 1½horsepower.

4.Lowspeedcapacityoftwospeedfansisapproximatelyonehalfof maximum.

5.Allthreephasemotorsaretriplevoltage(200-230/460).

DC24H-2S 3/4 87574250.6910.871950.6910.469550.7010.168250.709.966850.709.6.375

DC30F 1/3 52984750.4020.179850.4118.674000.4217.070100.4216.165600.4115.2.200

DC30G ½ 60797250.6115.993050.6115.088400.6213.385700.6313.682550.6313.1.250

DC30G-2S ½ 54687450.4419.782750.4518.377200.4616.873650.4616.069500.4615.2.200

DC30H 3/4 686109900.8712.7106200.8812.1102300.8911.5100150.9011.297800.9010.9.300

DC30H-2S 3/4 647103650.7314.299700.7413.595500.7512.893100.7512.490400.7612.0.300

DC36F 1/3 431102550.3528.395700.3625.287900.3822.383000.3820.876600.3918.9.150

DC36G ½ 495117800.5222.4111900.5420.5105550.5618.7102000.5717.898050.5717.0.200

DC36G-2S ½ 463110150.4325.5103900.4523.196800.4620.892650.4719.687950.4718.4.200

DC36H 3/4 575136800.8216.8131750.8415.7126500.8614.8123750.8714.3120850.8813.8.300

DC36H-2S 3/4 511121600.5821.2115950.6019.6109850.6118.0106400.6217.2102600.6316.4.250

DC36J‡ 1634150851.1014.0146301.1213.3141601.1512.6139151.1612.3136651.1711.9.300

DC42G ½ 385144450.5426.5135500.5624.1124900.5821.5118300.5820.1111100.5918.7.150

DC42G-2S ½ 356133550.4331.0123850.4427.7111250.4624.1104100.4722.196100.4820.1.150

DC42H 3/4 442165800.8220.4158150.8419.0149700.8617.6144750.8716.8139150.8816.0.250

DC42H-2S 3/4 511154950.6723.4146700.6921.5137250.7119.6131450.7118.6125200.7217.4.300

DC42J‡ 1485181951.0817.2175001.1016.2167601.1215.2163501.1414.7158901.1514.2.300

DC48G ½ 308174700.5531.8162200.5728.4146500.5824.9136300.5922.9121600.6119.9.150

DC48G-2S ½ 276156550.3939.5142300.4134.4122300.4328.6100750.4522.1---.125

DC48H 3/4 354200800.8324.4190050.8622.3177950.8720.5170650.8819.4162250.8918.3.200

DC48H-2S 3/4 314178100.5831.0165850.6027.9150800.6224.6141050.6222.7128650.6420.3.150

DC48J‡ 1382216701.0421.2206751.0719.8196001.0918.3189801.1017.6182851.1116.8.200

DC48K 11/2 44425,1851.6316.424,3351.6615.523,4501.6914.522,9801.7114.122,4751.7213.8.300

DC54-4J‡ 1355263951.1424.0245601.1721.7226601.1919.7216551.1918.8205701.2017.7.200

DC54-4K 11/2 398295901.6119.6279601.6418.2262951.6616.9254301.6716.2245401.6815.6.250

‡Availablewithtwo-speedmotorin230/1only.

SoundratingsonModelDCareshowninCatalogC2. PerformanceshownisinstallationtypeA-Freeinlet,Freeoutlet.

* Power(BHP)doesnotincludedrivelosses.

Performanceratingsdonotincludetheeffectsofappurtenancesinthe airstream.

CFMperWattdoesnotincludedrivelosses.C/Wratingsarenotlicensedtobear theAMCAseal.

WARNING!DONOTuseinHAZARDOUSENVIRONMENTSwherefan’s electricalsystemcouldprovideignitiontocombustibleorflammablematerials unlessunitisspecificallybuiltforhazardousenvironments.

CAUTION!Guardsarestronglyrecommendedwhenthefanisinstalledwithin seven(7)feetofthefloor,workinglevelorwithinreachofpersonnel.Guards complyingwithOSHAregulationsareavailableasoptionalequipment.Review OSHACodesandobtainaquotation.

US GLOBAL RESOURCES

Toll-free: +1-888-334-1440 | Ph: +1-830-755-4768

Website: www.usgr.com | Email: usgr@usgr.com

• Allaluminumconstruction

• Six-bladedpropellerutilizingacambered-twistbladedesignwithaunique dihedraltipforhigherairflowcapacitiesatlesshorsepower.

• Non-overloadingdesignmaintainshorsepowerwithincatalograngeofstatic pressure,resultinginlowermotorloadandreducedoperatingcosts.

• Streamlinedorificeinsureshigherairflowcapacity.

• Availablemountedineitherslantorsquarewallhousing.

AcmeEngineeringandManufacturingCorporationcertifiesthatthe SuperWindmasterDCAasshownhereinislicensedtobearthe AMCASeal.Theratingsshownarebasedontestsandprocedures performedinaccordancewithAMCAPublication211andcomply withtherequirementsoftheAMCACertifiedRatingsProgram.

• Prelubricatedoversizeballbearingsaredouble sealed,requirenoservice.

• Improved,moreefficientdriveassemblyand super-dutyneoprenebeltsprovidelongerservice life.

• Heavydutytotallyenclosedmotorswithshielded ballbearingsaredesignedforcontinuousworkload.

• Availableintwospeed.

• Built-inthermaloverloadforlow-linevoltage protectiononallsinglephasemotors.

1.Allsinglespeedsinglephasemotorsaredualvoltage(115/230)except¼ horsepower.

2.All¼horsepowersinglephasemotorsaresinglevoltage(115or230).

3.Two-speedmotorsaresinglevoltage(115or230)andnotavailablein11/2 horsepower.

4.Lowspeedcapacityoftwospeedfansisapproximatelyonehalfof maximum.

5.Allthreephasemotorsaretriplevoltage(200-230/460).

3/4 9497400.938.37195.947.96985.957.66875.957.56760.967.3.300

DCA24H-2S 3/4 8756820.738.46600.748.06365.757.66245.757.56115.767.2.250

1/2 6079375.6614.58990.6713.78580.6912.78340.7012.28065.7011.8.250

DCA30G-2S 1/2 5468430.4814.88005.4913.87515.5112.47210.5111.96820.5211.1.200

DCA30H-2S 3/4 64710015.8111.19660.8210.69290.849.99080.859.68855.859.4.250

DCA36F 1/3 43110005.3229.99345.3426.28555.3920.98035.3820.27330.3221.9.150

DCA36G 1/2 49511585.5123.211065.5321.410475.5519.510110.5618.59670.5817.1.200

DCA36G-2S 1/2 46310730.3823.910055.4120.79310.4417.98880.4516.78685.4615.4.200

DCA36H 3/4 57513325.7318.912785.7717.212225.8115.711930.8314.911615.8414.4.300

DCA36H-2S 3/4 51111845.5120.911235.5518.410585.5816.410225.5915.69835.6114.5.200

DCA36J‡ 163414560.9915.3141751.0314.3137751.0713.4135601.0912.9133251.1012.6.375

DCA42G 1/2 38514690.5825.913635.6222.512465.6519.611775.6618.310920.6616.9.200

DCA42G-2S 1/2 35613585.4625.012435.4921.411105.5218.010235.5216.68970.5314.3.150

DCA42H 3/4 44216710.8320.915940.8519.515190.9017.514725.9216.614165.9315.8.250

DCA42H-2S 3/4 51115615.6820.614800.7029.013950.7416.913385.7615.812700.7615.0.200

DCA42J‡ 1485182951.1117.1176201.1416.1169801.1914.8165751.2014.7161251.2014.0.250

DCA48G 1/2 30817490.5433.116215.5629.614495.5925.113420.6122.512005.6319.5.150

DCA48G-2S 1/2 27615675.3934.014215.4129.312045.4423.110190.4519.1---.125

DCA48H 3/4 35419775.7926.018825.8223.817625.8521.516770.8720.015770.9018.2.200

DCA48H-2S 3/4 31417540.5528.716445.5625.514805.6121.813675.6319.512415.6417.4.150

DCA48J‡ 138221380.9822.7204401.0121.0194201.0519.2188301.0618.5181301.0817.4.250

†DCA54-4J‡ 1356255701.1523.1238701.1721.2219201.1919.1207901.2018.0196001.2116.8.150

†DCA54-4K 11/2 405290901.6918.2276101.7217.0260001.7415.8251101.7515.2241301.7614.5.200

‡Availablewithtwo-speedmotorin230/1only.

PerformanceshownisinstallationoftypeA-Freeinlet.Freeoutlet.

*Power ratings(BHP)doesnotincludedrivelosses.

Performanceratingsdonotincludetheeffectsofappurtenancesintheairstream. †Thesemodelsfeatureafour-bladedpropeller

CFMperWattdoesnotincludedrivelosses.C/Wratingsarenotlicensedtobear theAMCAseal.

WARNING!DONOT useinHAZARDOUSENVIRONMENTSwherefan’s electricalsystemcouldprovideignitiontocombustibleorflammablematerials unlessunitisspecificallybuiltforhazardousenvironments.

CAUTION!Guardsarestronglyrecommendedwhenthefanisinstalledwithin seven(7)feetofthefloor,workinglevelorwithinreachofpersonnel.Guards complyingwithOSHAregulationsareavailableasoptionalequipment.Review OSHACodesandobtainaquotation.

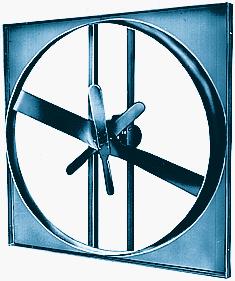

• Constructedofheavygaugegalvanizedsteeloraluminum.

• ForModelDC,DCA,FQandFNFans.

• EnergySavings-withinsideshuttersavesupto3750 BTU/HRheatlossperfan.

• HighFlowCapacity-shutterdirectsairtofan. Selectfanat.05”sp.insteadof.10”.

• WeatherProtected-slantarrangementprotectsmotorand drivesfromelements.

• OutsideMounting-keepsequipmentfromblockingaisles.

• Assembledtofanforquick,easyfieldinstallation.

• Includes1”x½”guardonoutletside.

• Shutterandinletguardheldinplacewithquickrelease clips.

• Wiringknockoutincludedtoallowallwiringconnectionsfor motortobemadeinsidethebuilding.Forfanapplication, seepages4and5forWindmaster® (DCorDCA)andpage 8forDynaMaster® (FQandFN).

CAUTION! Guardsmustbeinstalledwhenfaniswithinreachofpersonnelor withinseven(7)feetofworkinglevelorwhendeemedadvisableforsafety.

• Constructedofheavygaugegalvanizedsteel.

• ForModelDCandDCA.

• Providesconvenientmeanstoinstallfanandshutter.

• OutsideMounting-keepsequipmentfromblockingaisles.

• MountingFlangesforattachingtowallandtoattachshutter.

• Assembledtofanforquick,easyfieldinstallation.

AllGuards:forwallhousingshave1”x ” weldinggalvanizedwireinaluminumframefor inletsideofwallhousing.Outletguardsare includedonWSwallhousingsasstandard equipment.

Inletguardsaremountedwithquickrelease clips.

Master-ExDDPfansareengineeredanddesignedto withstandcorrosioninhorticulturalenvironments.

• Housing -Heavygaugeplastic14"-24";fiberglass36"-50” housing.Slantdesigneasytocleanandassistsrun-off.

• Propeller -14”-50”stainlesssteelcamberedtwistblades.

• Motor -Highefficiencydualvoltage(115/230)totallyenclosed; DDPS48J8-Csinglevoltage(specify);allsizesexcept36”-48”and 50”aresuitableforvariablespeedwithoptionalcontroller.

• Frame/Guard -Stainlesssteelverticalsupportframe,heavygauge coatedfrontguard.

• DiffuserCone -IncreasesairflowwithsameH.P.

DDPS14B4-C 1/101720159312.51620158011.41500156610.2128015548.5.20

DDPS14D4-C 1/5215016429.2202016388.5184016357.777016533.5.20

DDPS18B4-C 1/102720147816.32430144913.92060141211.3159013748.4.20

DDPS18F4-C 1/34180163811.04000163210.4381016259.7361016179.1.30

DDPS24G6-C 1/27360109714.46900109113.06500108612.06070108010.8.30

DDPS36G8-C 1/21109085322.61026084619.4946084017.0857083314.4.30

DDPS361G8-C 1/21154086423.91078086121.0999085518.5934085216.4.30

DDPS36G-C 1/21300063823.11241063620.81186063619.21118063517.4.30

DDPS48J1-C 12240050526.02140050423.22030050220.91910050218.7.30

DDPS48J-C 12150046526.82040046523.91910046421.31740046218.3.30

DDPS48J8-C 12140085326.11990085223.11820084619.91650084317.3.30

DDPS48K-C 11/22410054321.62320054219.72230054118.12130053916.6.30

DDPS50J1-C 12590048124.42460047921.72340047719.72200047517.7.30

DDPS50J-C 12530046324.92380046122.02260044920.02080045717.7.30

DDPS50J3-C 12520046825.32390046822.92270046620.52120046518.5.30

DDPS50J3L-C 12160039732.72010039728.31840039624.51620039620.8.25

DDPS50JL-C 12120038733.51970038629.51780038525.61540038321.1.30

DDPS50K-C 11/22700050222.12600050120.22470050018.52330049816.8.30

DirectDriveFans

PerformanceshownfromtestsperformedatBessLabs.

**RPMshownisnominalandtheperformanceshownisbasedonactualspeedoftest.

Performanceshownisfor14"through50"unitswithaluminumshutter,diffuserandoutletguard(noinletguard).

HIGHEFFICIENCYDIRECTDRIVEFANS

Acme’s42”and48”modelsfeatureanewunique,high airflow,energysaving(2x4)propeller.Thisuniquenewdesign providesdurability,efficiencyandrealoperationaleconomy. Usersofthe(2x4)areprovidedwithoutstandingperformance, enduranceandsavingsonenergycosts.

Acme’spreciseengineeringhasmatchedacamberedtwist propellerwithcontinuousdutymotorstoformhighairflowand lowenergyconsumptionfans.Combinedwithcorrosion resistantgalvanizedorificeandframes,thesefansofferthe usermaintenancefree,longlastingequipmentsuitedforuse inhorticulturalenvironments.Checkthesefeatures:

• GalvanizedConstruction - Corrosionresistant,longlasting.

• CamberedTwistPropeller -Highairflow,lowenergycost,high CFM/watt.

• TotallyEnclosedMotors -Gasketedandshieldedagainstdust andmoisture.

• VerticalSupportFrame -Maintainsproperalignment.

• MotorWireLeads -forquickhook-up.

• QuietOperation

• DirectDrive -Nodrivelosses,nobeltstoslip.

• Available

• inw.s.slantwallhousing.

• Easytoinstall.

• Smartstreamlinedconstructionincludesbackguard(motorside) asstandardequipmentwhenorderedwithoutwallhousing.

• Frontguards(propellerside)alsoavailable.

• Availablewithgalvanizedsteelwallhousing.

• Aluminumpropeller,epoxypaintedsteelorifice.

• Totallyenclosedmotorwithballbearings.

• Variablespeedwithsolidstatecontrols.(Page17)

AcmeEngineering&ManufacturingCorporationcertifiesthatthe DynaMastershownhereinislicensedtobeartheAMCASeal.The ratingsshownarebasedontestsandproceduresperformedin accordancewithAMCAPublications211and311andcomplywith therequirementsoftheAMCACertifiedRatingsProgram.

†Whenusedwitha2-speedswitch,speedreductionisapproximately30%for lowspeed.

PerformanceshownisforinstallationtypeA-freeinlet,Freeoutlet. *Powerrating(BHP)doesnotincludedrivelosses. Powerratingsdonotincludetheeffectsofappurtenancesintheairstream. CertifiedSoundRatingsforFQ&FNModelsshownincatalogS-4. ModelFN18E4isnotlicensedtobeartheAMCASeal.

Provideslargeopeningarea aroundthefullperimeterfor efficientairflowthroughthe ventilatorwheninstalledona standard8”highcurb.Hinged foreasyaccesstomotorand drive.Preassembledforquick, easyfieldinstallation.

Foreasymountingofbackdraftdamper insidefieldconstructedroofcurb.

AcmeEngineering&ManufacturingCorporationcertifiesthatthe DynaMastershownhereinislicensedtobeartheAMCASeal. Theratingsshownarebasedontestsandprocedures performedinaccordancewithAMCAPublications211and311 andcomplywiththerequirementsoftheAMCACertifiedRatings Program.

ForusewherewallspaceisunavailableforconventionalwallmountedWindmasterfans. Mountedonfieldconstructedcurbopeningonroofofhouse.

Ifpossible,installonnorthendofroof.

PerformanceshownisforInstallationTypeA:Freeinlet,FreeOutletPower Rating(BHP)doesnotincludedrivelosses.Performanceratingsdonotinclude theeffectsofappurtenancesintheairstream.Thesoundratingsshownfor ModelECisloudnessvaluesinfansonesat5feet(1.5m)inahemispherical

freefieldcalculatedperAMCAStandard301.ValuesshownareforInstallation TypeA:FreeInletfansonelevels.

Acme’spreciseengineeringhasmatchedtheproperpropeller withacontinuousdutymotortoformahighairflowandlow energyconsumptionfan.Thisfanofferstheuser maintenance-free,long-lastingequipmentsuitedforusein horticultureenvironments.

• Propeller -Aluminumbladesheldsecurelyinplacebyasteel spiderandhubprovidequietoperation.

• Motor- Heavy-dutyPSC,totallyenclosedmotorwithautomatic thermaloverloadprotectionandballbearingsisenergyefficient. HAF20A4motorcanbeusedwithvariablespeedcontrolformore preciseairmovement.

• Guards- TwopiecewireguardforeasyaccesshasawhitePVC plasticcoatingtoresistcorrosion.

20”HAF20A415731/15115/1119.52475

20”

*Wattreadingiscorrectedtostandardairdensity. † Fantestedwithbothguardsinplace. Notavailablewithvariablespeedcontroller.

• Corrosionresistantheavygaugealuminumframe.

• Precisioncounterbalancedaluminumbladesopeneasier,widerto permithigherfancapacity.

• Nylonbearingsthroughoutarecorrosionprooftohelpprevent sticking.Suitablefordustyorhumidapplications.

• Stainlesssteelhingepinswillnotrust,insureeasypositiveblade action.

• Allshutterbladesarereinforcedwithpolishedgalvanizedsteel rods,andequippedwithdoubletie-rods.

• Automatic-Usedwithexhaustfans;opensautomaticallywhenfan ison,closesautomaticallywhenfanisoff.

• Keepsoutwind,rainandbackdraftswhenfanisnotinoperation.

(Seefanselectionforshuttersizes)

• Newcampulleyoperator-provideslonglifetomotor-corrosion resistant.

• Motordrawsonly17watts.

• WAACmodelsarecenterpivotedtoopeneasieragainsthouse staticpressures.

• Motorsareavailablein24v,115v,230v,460v,(SpecifyVoltage Required).

Mildweatherdistributionoffreshairisaccomplishedthrough highefficiencystreamlinedinlet,inletshutterand custom-punchedtubing.Exhaustfandrawsinfreshairfor draft-freeventilation,andsystemmaybeequippedwith motorizedshutterforautomaticoperation. FRESHAIRTUBEVENTILATION

• Installation- Twopiecerotationalbracketprovidesalockingtilt adjustmentforproperangleofairflow.“S”bracketprovidestwo differentdimensionalmountings.

• Wiring- Motorcomesfactory-wiredonthe“A4”withasix-foot, threeconductorcordwithgroundingtypemoldedplugforeasy installation.The“F4”motorhasthespecifiedcordshipped unattached.

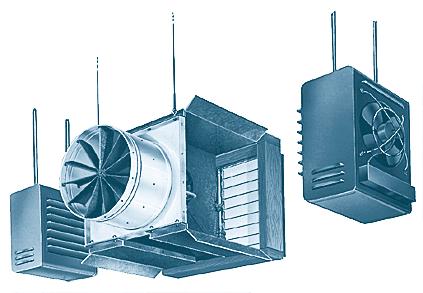

TheuniqueFan-Jetisaspecialtubepressurizingfanwith curvedstationarydischargevanes(statorvanes)thatrecover therotationalenergyofdischargingairtoincrease performancecapacityandefficiency.

LOWCOST: Fan-Jetpowersmoreairatlesshorsepower forbestresultsatlowoperatingcosts.

QUALITY: Fan-Jetisfullyassembledatfactory,testrun andinspectedandthenshippedreadytoinstallwithbrackets andfasteners.

QUIET: Fan-Jet’slowsoneratingsareanAcmetradition.

DIRECTDRIVEMODELS -RC12,18

RCP12,18,24

Directdrivemodelsarecapableofvariablespeedcontrol. (SeeControlsonPage17)

BELTDRIVEMODELS -RC24,30;RCA24, 30

Beltdrivemodelsfeatureno-servicesealedfanshaftball bearingscapturedinauniquecastingtomaintainproper alignmentandspacing.

BUILTTOUGH: ThesteelmodelRCisavailablein12”, 18”,24”and30”sizesandisrustprotectedwithametalwash processandabaked-onfinish.AluminummodelRCAis availablein24”and30”sizesandproducedfromheavy gaugealuminum.TheRCPplasticmodelincorporatesABS plasticconstructionwithastainlesssteelframe.

HIGHPERFORMANCEPROPELLERS:

Thepropellersarematchedtothesize,performanceand constructionoftheFan-Jet.RCfanpropellersarewelded steelwithabakedonfinish.RCAfanpropellersarewelded heavygaugealuminum.RCP12fanbladesarepolycarbonate attachedtoaglassreinforcednylonhubwithanaluminum hubcore.RCP18-24bladesaremadeofstainlesssteel.

ModelsRCandRCParelistedbyCanadianStandards AssociationTestingLaboratoryasapproved.

ENERGYEFFICIENT: Allmotorsaretotallyenclosed, highefficiencydesignwithshieldedballbearingsandinclude thermaloverloadprotectiononsinglephasemodels.

Fan-Jet Model HPRPM Tube Size System CFM

▼ Motorized ShutterModel Heat Accessory

†RC12D4 1/8172512”1180/780WAAC1818NotAvailable

‡HeatingCapacityWithHeatKitBTU/hr.Output HeaterTemperatureRiseof 40°50°60°70°

NOTAPPLICABLE

RC18E6 1/4116018”3120WAAC2626HT18112,000138,000163,000186,000

RCA/RC24F 1/373524”5420WAAC3333HT24172,000212,000250,000287,000

RCA/RC30G ½60730”8550WAAC4040HT30278,000342,000403,000463,000

RCP12B4 1/10162512”1100WAAC1818NotAvailable

NOTAPPLICABLE

RCP18B4 1/10162518”2140WAAC2626PHT1877,00095,000112,000128,000

RCP18F4 1/3162518”3050WAAC2626PHT18109,000135,000159,000182,000

RCP24G6 ½107524”5115WAAC3333PHT24162,000200,000236,000271,000

†RC12D4hasa2-speedmotorthereforetwodifferentsystemCFM’s ▼ OrderCAMmotorizingkitsseparately.

‡TheOrderratingforgasfiredheatersis80%oftheirinputBTUratings.

Toll-free:

Website: www.usgr.com

TUBE MODEL TUBE LENGTH TUBE MODEL TUBE LENGTH TUBE MODEL TUBE LENGTH TUBE MODEL TUBE LENGTH

HFT10’-20’HFY18’-20’HKX24’-27’HKT39’-42’

HLT20’-25’HDY20’-22’HJX27’-30’HJT42’-47’

HRT25’-30’HCY22’-25’HHX30’-33’HHT47’-52’

HLW30’-35’HBY25’-27’HFX33’-37’HFT52’-58’

HMW35’-40’HKN27’-30’HDX37’-41’HDT58’-66’

HLY40’-50’HJN30’-33’HCX41’-45’HCT66’-77’

HRY50’-60’HHN33’-36’HBX45’-48’HKS77’-84’

HMZ60’-75’HFN36’-40’HKP48’-53’HJS84’-94’

HRZ75’-100’HDN40’-45’HJP53’-59’HHS94’-104’

HCN45’-50HHP59’-66’HFS104’-116’

HBN50’-55’HFP66’-73’HDS116’-129’

HKA55’-61’HDP73’-81’HCS129’-145’

HJA61’-68’HCP81’-90’HBS145’-163’

HHA68’-76’HBP90’-101’HKU163’-183’

HFA76’-85’HKI101’-112’HJU183’-206’

HDA85’-96’HJI112’-126’ **HHU206’-232’

HCA96’-108’HHI 126’-142’HFU232’-263’

*HBA108’-121’HFI142’-160’ *HDU263’-305’

**HKE 121’-138’ **HDI 161’-182’HCU305’-348’

HJE138’-154’ *HCI 182’-206’HBU348’-405’

HHE154’-177’HBI206’-233’

HFE177’-205’HKO233’-269’

HJO269’-311’

HHO311’-360’

*MaximumtubelengthforFreshAirConvectionTubeSystem.

**MaximumtubelengthforFan-JetwithHeatKit.

+When12”tubingisusedforPerimeterHeatingtheTubeModelisprefixedbytheletterP.

HEATKITS foroverheadheating

CAUTION! Toavoidcombustionmalfunctionswhentwoheatersareused withoneFan-Jet;theminimumheaterdistancefromFan-Jetopeningmust bemaintained,bothheatersmustoperatesimultaneouslyunlesscenter baffleisused,andthedischargelouversmustbedirectedtowardthetopof theFan-Jetopening.

WEATHERHOOD:

Galvanizedsteel,withbird screen.Flangesfitmotorized shutterframesforeasy installation.

Alltubesareengineeredforuniformdistributionandproper mixingofairtoproducethebestaerodynamiceffectin greenhousestructures.

• Furnishedinclear4milthickUVstabilizedpolyethylene material.

• Eachtubeiscustompunchedtomatchtheselected Fan-JetUnitwitheachspecifichouse.Sincetubesare custompunched,ordersalreadyprocessedorshipped cannotbecancelledorreturnedforcredit.

Uniquehangerclampsontotubingfor easyattachmenttooverheadsupportwire withsnapring.

12”Tubingevery10ft. 18”Tubingevery10ft. 24”Tubingevery8ft. 30”Tubingevery6ft.

Wiresupportkits,availablein50’,100’,150’,200’and300’lengths,include sixstrand10gaugewire,turnbuckleand2securingclips.

*CAUTION! Thistubing,foruseingreenhouses,doesnotcontain fireretardants.Duecareshouldbetakenduringinstallationand operationtokeepawayfromopenflame.

AcmeHeatKitsallowuseofgasfired,electric,steamorhotwater unitheaterswithoutoutsideairpassingthroughtheheatexchanger. WhenusedwithFan-Jet,HeatKitskeepcoilsandelementsoutofthe airflowroute,thussavingenergy.Eachkitconsistsoftwobaffle plateswithairscoopsattachedhorizontallytothetopandbottomof theFan-JetUnitandtotheframedopeningofthemotorizedinlet shutter.KitsalsocomewithaFan-Jetmotorshieldtopreventheat build-up.Acenterbaffleaccessoryisincludedforusewhenopposing heaterstriggerseparately,preventingblow-throughofhotairand possiblemotordamage.

*Theunitheaterlouversshouldbeatthesameelevationasthe Fan-Jetinletopeningandspacedaproperdistancefromit,withthe axisoftheunitheaterdischargeopeningdirectedtowardtheFan-Jet inletopening.Iftheheatermustbepositionedbelowthelevelofthe Fan-Jetinletopeningtomaintaintheproperspacing,thelouvers shouldbeadjustedtodirecttheheatedairupwardtowardthetopof theinletopening.

IftheFan-Jetendofthebuildingiscolderthantheremainderofthe house,thisconditionusuallycanbecorrectedbyadjustingoneortwo ofthelowerlouversoftheheaterstoadownwardpositiontodivert partoftheheatedairtotheendwallarea.

CAUTION! Guardsarestronglyrecommendedwhenthefanis installedwithinseven(7)feetofthefloor,workinglevelorwithin reachofpersonnel.GuardscomplyingwithOSHAregulationsare availableasoptionalequipment.ReviewOSHACodesandobtain aquotation.

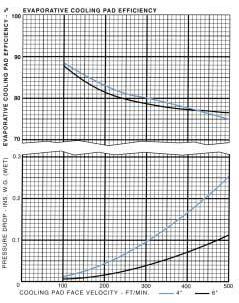

Kool-CelPads

Kool-Celpadsarecellulosecoolingcells4”and6”deep,12” wideandavailablein12”incrementsfrom24”to72”tallwith twopiecesof4”combinedtomake84”and96”tallpads.The coolingcellsaremadefromaspeciallyformulatedcellulose paperimpregnatedwithinsolubleanti-rotsalts.Itisdesigned withanexclusivecross-flutedconfigurationwhichinduces highlyturbulentmixinginsidethepadbetweenthewaterand theair,andcontributestotheevaporativeefficiency.The cross-fluteddesignmakesKool-Celastrongself-supporting padwithhighevaporativeefficiencyandlowpressuredrop (resistancetoairflow).

Afacevelocityof250feetperminutefor4”and400feetper minutefor6”isrecommendedforthemosteconomicalcost andoperationoftheKool-Celsystem.

SizingKool-CelPad

DetermineTotalSummerCoolingRequiredinCFM,then dividebyvelocitytoobtainpadareainsquarefeet.Thepad areadividedbythelengthwilldeterminetheheightinfeet.

TotalPadarea,sq.ft.= TotalSummerCooling Required(CFM)

Velocity(250-4”400-6”)

Kool-CelonGreenhouse

Kool-CelandCeldek

4”KOOL-CELPAD

The4”Kool-Celpadisconstructed withairflowatequal45°angleswhich allowsairflowtoenterfromeither sideofthepad.

The6”Celdekpadcontainsflutes organizedintwoangles,onewith steeppitchandtheotherlesspitched. Theairmustenterthepadfromthe sidewiththesteeppitch. 6”CELDEKPAD

MI-T-Edg ®

Optionalcoatingononeorbothsidesofthepads reducesalgaegrowthandenableseasypadcleaning andmaintenance. MI-T-EdgisaregisteredtrademarkofMuntersCorporation.

Website:

• Availableinstainlesssteel

• CustomSizing-sectionsavailableinonefootincrements(5’-50’) tomaximizeefficiencyandpreventadditionalinstallation requirements

• Fullyprefabricated

• Preassembledguttersectionsreduceinstallationcosts

• Tallpadsupports-provideadditionalsupportfor4”systemswith padsover48”tall

Thesystemcomescompletewithawaterdistributorand cover,returngutter,strainer,pumpandmiscellaneousfittings andfastenerstocompletetheassembly.

Thecellsaresupportedattheirbasebythespecialsupport builtintothegutter.Thewaterdistributoriscomposedofrigid PVCpipewithmeteredoutletholes.Flush-outplugsand connectionteesareprovidedtofacilitatecleanoutandwater connection.Allhardwareandfittingsareprovidedtoeasethe installation.

Thealuminumsystemutilizesquicksnaptogether componentsforeasyinstallationusingaminimumof hardware.Theheavyextrudedgutterandsupportare designedtosupportthepadsandcarrythewaterbacktoa sumpwithcapacitiesforan8’x100’systemin4”padandan 8’x80’systemin6”pad.Thealuminumtopcoverismadein twopiecestofacilitatecleaningthePVCpipeifclogged.

Acme’s8”PVCtransitionpumptankisidealforinstallationin rockyareas.TheAcmehighefficiencysystemismadeupofa coveredpolyethylenetransitionpumptank,couplingandend capfor8”PVCpipe(suppliedbyothers)andafloatvalve andbracketassembly.

Thereturnguttersupportsthecellsthatwhenwetweigh2¾ lbs.(4”)or4lbs.(6”)persquarefootand,therefore,shouldbe adequatelyreinforcedandsupported.

Thesepumpsareheavyduty centrifugal,selfprimingtypefeaturing highvolumeandlowheadpressure performance.

Thesepumpsaresubmersibletype withcastironhousing,polypropylene baseandpolycarbonatecover.They includealifetimeoilsupplyand non-clogpumpingheadandimpeller.

#30Centrifugal1/3115/230/142GPM70’55’

#60Centrifugal½115/230/155GPM100’80’

#15SSubmersible1/4115/129GPM40’35’

#30SSubmersible1/3115/142GPM70’55’

#60SSubmersible½115/163GPM100’80’ Thepumpsshouldbesizedtoprovide ½ gallonperminutefor4”and 3/4 gallonperminutefor6”offlow perlinearfootofpadtoinsureadequatewetting.

Kool-Celpadsareverydurableandlonglasting.Tomaximizethe lifeofyourpadsandkeeptheefficiencyoftheoriginalinstallation, correctanyconditionsthatmaybedetrimentaltothepad.

APhofrecirculatingwater(fromsump)mustbemaintained between6and9(7ispurewater).Iftheselimitsare exceeded,thestiffeningagentsinthepadwillleachoutand destroythepad.

B.HardwaterresultinginCalciumCarbonatedepositsonthepad isnotharmful,butshouldbekeptwithinlimits.

C.SodiumChloride(saltwater)concentrateabove50,000ppm (approx.)willdepositsaltonthepadandreduceairflow.Keep saltconcentratesbelow50,000ppminrecirculatingwaterand below40,000ppminmake-upwater.

D.Algaewillgrowonanysurfacethatiswetandexposedto sunlight.Tohelppreventalgaebuildup,followthesetips.

1.Donotdrawmake-upwaterfromanopenpond.Use wellwaterorchlorinatedwaterfromcitysystems.

Theplumbingpackageisdesignedforuse withallthepumpsfortheKool-Celsystems andincludesthenecessaryplumbing fittingsandvalvetocompletethe installationfromthesumptothedistributor andalsocontainsthewaterstrainerand floatvalve.

Thesumptankcoverandtankfittingsare furnishedbyothersandshouldbesizedto provide¾gallonpersquarefootof4”pad areaand1gallonpersquarefootof6”pad area.

2.Coverthesumptoavoidexposuretosunlight andairborneparticles,andtokeepanimals fromdrinkingit.

3.Keepthefansrunningafterthepumpisshut offtodrythepads,thuskillingthealgae sporesleftonthepad.

4.Isolatethewatermake-upsystemfromany othersystem.

5.Padsshouldbeshadedfromdirectsunlight.

E.Ifairbornedustandbugstendtoclogtheairflow passages,properoperationofthesystemwill normallywashawaytheclogging.

F.WhenKool-Celisinstalledwithinreachofpoultryor livestock,itshouldbeguarded.

G.Bleed-Off-Sincethewateriscontinuously evaporatingandbeingreplacedbyfreshwater,the saltsandmineralsareleftbehindinthere-circulating water.Toreducethebuildupofdepositsandscale,a bleedofffortherecirculatingwaterisprovided.

• RuggedPVCconstructionisrustproof,lightweightandeasytoinstall

• Availablein5’sections

• Uniquedesignrequireslesswater

• Entiresystemeasilyremovedfromthebuildingandstoredduring coolermonths

Padsareeasilyinstalledinexisting2”systemswithlittleor nomodifications.

Availablein34’rollsandavarietyofwidthsorin preassembled12gaugecoatedwirecages.

Wirecagesystemeliminatestheneedforamiddlestringer ormiddlesupportsysteminoriginalinstallations.

Unique,rigidblownpolyesterfiberconstructionisdurable, lightweightandunaffectedbysoftwaterorchlorine.

Easilycleanedandmaintainedwithoutremovingthepads fromthesystem.

Madefromby-productsoftheoilrefiningprocess,the uniquespunpolyesterpadmaterialisbiodegradableand environmentallysound.

AquaCelPlusisabondedplasticfiberpadthatiscoated withanabsorbentplasticcellularfoam.Itisunaffectedby continuousexposuretomoisture,disinfectants,chlorine, traditionalwatertreatmentchemicals,orwaterpH.Soft waterorwatersoftenerswillenhanceAquaCelcooling performance.

AquaCelPlusrequires 1/4 to 2/5 gallonsperminuteperlineal footofpadtooperateatpeakperformance(i.e.,a100foot longcoolingsystemwouldrequirebetween25to38GPMof water)dependingonthegeographiclocationandcurrent environmentalconditions.

TheT115N.E.M.A.4Xthermostatisdesignedspecificallyfor useinNationalElectricalCode(N.E.C.)Article547 applicationsrequiringarugged,weatherresistant,durable controlforbothheatingandcooling(ventilation)in agricultural,industrialandcommercialenvironments.The T115issuitableforuseinpoultryhouses,hoghouses, livestockbarns,brooderhousesandgreenhousesaswellas factories,warehouses,garagesandgymnasiums.

• N.E.M.A.4XenclosurecomplieswithN.E.C.Article547when usedwithappropriatewatertightconnections.

• Ruggedweatherresistantenclosuremadeofcorrosionresistant materialsforlonglife.

• Lowmass,highsurfaceareaofstainlesssteelcoiledsensor providesrapidresponsetotemperaturerange.

• Large,readilyvisibledialwith40°-110°Ftemperaturerange.

Note:Whenproperlywettedyoushouldnotseewater“runningdown” thepadlikeawaterfall.Infact,thepadshouldappearsomewhatdry, butwhentouchedwiththebackofthehanditshouldfeellikeasponge saturatedwithwater.

• Multi-positionalmountingoffersflexibilityineitherneworexisting installations.

• Onecontrolforbothheatingandcoolingapplications.

• UnderwritersLaboratories(U.L.)listedandCSACertified.

Rating 120VAC240VAC277VAC480VAC

FullLoad16.0AMP12.0AMP10.0AMP

LockedRotor80.0AMP60.0AMP50.0AMP

Non-Inductive25.0AMP25.0AMP22.0AMP5.0AMP

PilotDuty125VA125VA125VA125VA

Allcontrolsaremountedtocorrosionresistant,fireretardant, UVstabilizedABSplasticboxesandcovers.Thesespacious boxesincludeanoutsidemountingplateincorporatedintothe boxandthecoverisgasketedtoinhibitmoistureanddust penetration.Pre-moldedknockoutsareinfivehandylocations forfast,easyfieldwiring.

ThesecontrolsarelistedbytheCanadianStandardsAssociation TestingLaboratoriesasapproved.

Thesethermostatsusereliable,timeprovensensingand switchingcomponentswithhighercapacityforusewithlarger HPmotors.Furtherprotectionagainstcorrosionincludesa plasticcoatedcoilwithgrommetconnectionthroughthebox andasealedsettingdialknobthroughthecover.

Theseindustrialqualityrelayshave highcapacitycontacts,yetlowcoil currenttoadapttoanycontrolsystem. Push-onterminalsreducefieldwiring timeandcosts.

SwitchTypeSPDTSPDTDPDT

CoilVolts24VAC115VAC230VAC

CoilPower2.7vamaximum,continuousduty

Contact Rating

1HP@115VAC;1½HP@230VAC (Willhandle24VACasslaverelay)

Thisswitchisusedtochangethefanmotor operatingspeedfromhightoloworlowto highinmanualoperation.

Thejunctionboxisoversizedformultiple connectionsthroughfivepre-molded knockouts.Easytomount,itincorporates thesamemoistureanddustprotection features.

Thisdisconnectswitchisusedtoswitchfan motorsintoautomaticelectronicand/or mechanicaltemperatureregulating equipmentcircuits.Thedisconnectswitch canalsobeusedtoswitchtomanual operationortodisconnectpowerforfan servicing. OPTIONAL

Water-tightconnectors areavailableforuse withrubberjacketed2 and3wirecable.

DesignedforusewithPSCorsplit phasefanmotors,themanualspeed controlshaveaninternallowspeed adjustment.Theknobissealed throughthecoverformoistureand dustprotectionandsetsthecontrolin off,highandvariablelowspeed settings.Colorcodedwiresassure safeandeasyconnections.

Thismanualvariablemotorspeedcontrolisdesignedfor heavydutyserviceandcanadjustfanmotorspeedfromnear 20to100percentfullspeedwithsoftstartingtoeliminatehigh startingcurrents.

TheStandardEMSisdesignedtocontrolthebasic greenhouse.TheSEMScomescompletelyconfiguredand wiredreadyformountingonthewall.

• ACCIEnvironmentalController

• 10PowerRelays

• BypassSwitchesforPowerRelays

• Safe24VACControlWiring

• PrewiredatFactory

• TemperatureSensorwith75FT.Cable

• PhotocellOption

• DehumidificationOption

• SealedFiberglassEnclosure

• EnvironmentallyProtected

• HingedEnclosureforEasyAccess

• Fan-JetorHAF

• BenchHeater

• TwoStagesofOverheadHeat

• 2ExhaustFans(includingone2speed)

• GableShutter(firstcoolingstage)

• ShutterorEndVentAirInlet

• EvaporativePadCoolingSystem

EMS istheintegrationofclimate controlequipmentwithuniquecontrol apparatustoregulatethebuilding climateforsuitableproduction.

• Stagedenvironmentalcontrol

• Greenhousemanagement

• Centralfacilitycontrol

• Overridecircuitsallowingexclusionofspecificoperationsduring otherstages-forexample,ventilationduringtheHEATstage

• MechanicalHumidistat

• Allcomponentsfactorywiredreadytoacceptfieldwiring.Reduces installationtimetoamerefractioncomparedtoinstallingandwiring relays,switches,andcontrolsindividually

• Quickeasyconnectterminalsforfieldwiring

• Easyinitialsetup

• Simplefrontpanelsetpointadjustments

• Availableinmanyconfigurationstomeettheneedsofmost horticulturaloperations

• Remotesensormount(upto500feetfromcontroller)

• Rainanddusttightenclosures withgasketseal

• Hingedaluminumenclosureswill notrust

• Bypassswitchesprovidedfor eachpowerrelay

• 6,9,12,or15Heavydutypowerrelays. ACCIController(SeeBrochureB112).GrotronIIController (SeeBrochureC61)

• Availablewithvariouscontrollers

• Dualtemperaturesensinglocations

• PhotocellInput

• NEMA4xEnclosures-Raintight

• ExternalMountingTabs

• SolidState

• Compact

• WiringTerminals

• Relayscapableofhandlingupto 2HP

• Relayboxavailablewithoutthe controllerforusewithexistingor othercontrolsystems(RCC model)

• FahrenheitorCelsiusoperation

• 8StagesofControl-0,1,2,or3Heat,1Circulation,4,5,6,or7 Cool

• RemoteTemperatureSensor-allowsconvenientlocationfor ACC-I

• OptionalAuxiliaryTemperatureInput-tomonitoroutside temperatureorselectedtemperatureinaselectedareaofthe structure

• OptionalAuxiliaryInputforFreshAir-tocontrolfumesorhumidity

• OptionalDay/NightControl-allowscontroltoswitchbetweentwo differenttemperatures

• LCDDisplayforProgrammingandDisplayingTemperatureand Stage

• StageDifferentialsSelectablefromTenPrograms

• Hysteresis1°FOffsetfromontooffsignaltopreventcycling

• SelectableCycleTimer5or10minutesforfreshairwith5%to 95%programmableontime

• LowTemperatureCoolingLockoutwhenoutsidetemperaturefalls belowselectedminimum

• SeparateDay/NightSettingswhenPhototerminalisusedwith optionalPhotoSwitch

• StepThroughprogrammingandreadingstatusofsensors

• 24VoltControlforsafe,lowcostwiring

TheACC-IincludesoneACCI-TStemperaturesensorto drivethesystem.Toimplementauxiliarycontrol,additional sensingdevicesarerequired.

ACC-I-TS-TemperatureSensor(additional)tomeasure outsidetemperatureandactivatelowtemperaturecooling lockout.

Humidistat(optional)-(on/off)toactivatede-humidificationcycle duringSetPointorHeating.

(Byothers)Ammoniastat(digitaltype-on/off)toactivatefreshair cycleduringSetPointorHeating.

(Byothers)TimeClock(24hour)toactivateday/nightcontrol.

TheACC-Iisapilotdutycontrolandthereforeshouldnotbewired directlytoequipment.24voltcoilrelaysmustbeusedasmotorand equipmentstarters.Accessoriesareavailabletocompletethe controlsystem.(Seepages15and17).

24voltpowersourceisrequiredtopowertheACC-Icontroland equipmentrelays.IftheACC-Iistobeusedinanewinstallationorto replaceanexistingcontrolthatisnot24volts,atransformeris requiredtosupplytheproperpowertothesystem.

Humidistat 0-90%R.H.

GrotronII PatentPending

11”X11”X3”HingedLeft, 12VA,24VacSupply 24VacControl

WARNING Acmeproductsaredesignedandmanufacturedtoprovidereliableperformancebutthey arenotguaranteedtobe100%freeofdefects.Evenreliableproductswillexperienceoccasional failuresandthispossibilityshouldberecognizedbytheUser.Iftheseproductsareusedinalife supportventilationsystemwherefailurecouldresultinlossorinjury,theUsershouldprovideadequate back-upventilation,supplementarynaturalventilationorfailurealarmsystem,oracknowledge willingnesstoaccepttheriskofsuchlossorinjury.

WARNING DONOTuseinHAZARDOUSENVIRONMENTSwherefan’selectricalsystemcould provideignitiontocombustibleorflammablematerialsunlessunitisspecificallybuiltforhazardous environments.ComplywithalllocalandnationalsafetycodesincludingtheNationalElectricalCode (NEC)andNationalFireProtectionAct(NFPA).

CAUTION Guardsmustbeinstalledwhenfaniswithinreachofpersonnelorwithinseven(7)feet (2.134m)ofworkinglevelorwhendeemedadvisableforsafety.

DISCLAIMER TheCompanyhasmadeadiligentefforttoillustrateanddescribetheproductsinthis literatureaccurately;however,suchillustrationsanddescriptionsareforthesolepurposeof identification,anddonotexpressorimplyawarrantythattheproductsaremerchantable,orfitfora particularpurpose,orthattheproductswillnecessarilyconformtotheillustrationsordescriptionsor dimension.

WARRANTYANDDISCLAIMER: AcmeEngineeringandManufacturingCorporationextendsthis limitedwarrantytotheoriginalbuyerandwarrantsthatproductssuppliedbytheCompany,shallbe freefromoriginaldefectsinworkmanshipandmaterialsfortwoyearsfromdateofshipment(exceptfor thewarrantyperiodsnotedforproductslistedbelow),providedsamehavebeenproperlyhandled, stored,installed,serviced,maintainedandoperated.Thiswarrantyshallnotapplytoproductswhich havebeenalteredorrepairedwithouttheCompany’sexpressauthorization,oralteredorrepairedin anywaysoas,intheCompany’sjudgment,toaffectitsperformanceorreliability,norwhichhavebeen improperlyinstalledorsubjectedtomisuse,negligence,oraccident,orincorrectlyusedincombination withothersubstances.TheBuyerassumesallrisksandliabilityforresultsofuseofallproducts.

Evaporativecoolingpadsarewarrantedtobefreeofdefectsinmaterialsandworkmanshipforaperiod oftwoyearsfromdateofshipmentprovidedsamehavebeenproperlyhandled,stored,installed, serviced,maintainedandoperated;andfurther,notsubjectedtoexcessiveheat,corrosiveagentsor chemicals,ormechanicalabusethatmaycausetearing,crushingorunduedeterioration,norusedon asystemorinamannerotherthanthatforwhichitwasdesignedasexplainedintheproductliterature.

Thefollowingproductsarewarrantedtobefreeofdefectsinmaterialsandworkmanshipforthe periodsshownfromdateofshipment:Acme’sexclusiveduplexsplitpillowblockbearingsandshaft fiveyears,beltsoneyear,Polyethylenetubing90days,AIR40Heaterwarrantyoneyear,AIR40 EmitterwarrantythreeyearsandDDPfanlifetimewarrantyonitspropeller,cone,andhousing.

LIMITATIONOFREMEDYANDDAMAGES: Allclaimsunderthiswarrantymustbemadeinwriting anddeliveredtoP.O.Box978,Muskogee,Oklahoma,74402,within15daysafterdiscoveryofthe defectandpriortotheexpirationoftwoyearsfromthedateofshipmentbytheCompanyoftheproduct claimeddefective,andBuyershallbebarredfromanyremedyifBuyerfailstomakesuchclaimwithin suchperiod.

Photocell Day/NightControl

Transformer100VAClass2, 115Vac-Primary, 25Vac-Secondary

VaporCapsule

AmustwhentheGrotronII isinstalledinagreenhouse. Replaceeachyear.

AspiratedSensor

24voltfandrawsairacrosssensortoobtaina moreaccuratemeasureofairtemperature. Usewhenlittleaircirculationisobtainable aroundthetemperaturesensor

SensorWire Special18-2twistedpairwithjacket (donotuseregular18-2wireforsensor).

Otheraccessoriesrequiredtocompletethecontrolsystemare available.Seepages16and17.

Within 30 days after receipt of a timely claim, the Company shall have the option either to inspect the product while in Buyer’s possession or to request Buyer to return the product to the Company at Buyer’s expense for inspection by the Company. The Company shall replace, or at its option repair, free of charge, any product it determines to be defective, and it shall ship the repaired or replacement product to Buyer F.O.B. point of shipment; provided, however, if circumstances are such as in the Company’s judgment to prohibit repair or replacement to remedy the warranted defects, the Buyer’s sole and exclusive remedy shall be a refund to the Buyer of any part of the invoice price, paid to the Company, for the defective product or part.

The Company is not responsible for the cost of removal of the defective product or part, damages due to removal, or any expenses incurred in shipping the product or part to or from the Company’s plant, or the installation of the repaired or replaced product or part. Implied warranties, when applicable, shall

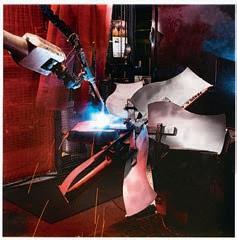

IndustryLeadership Foundedin1938,AcmeEngineering andManufacturingCorporationis knownworldwideasaleaderinthe manufactureoffans,blowers,and ventilationequipment.Acme'sgrowth overthepasthalfcenturyisatributeto superiorquality,customerloyalty,and dedicatedemployeesandsales representatives.

Today,fromitsheadquartersin Muskogee,Oklahoma,Acmeserves customersworldwidewithhighquality airmovementandcontrolproducts.

Manufacturing

Withapproximately350,000squarefeetof manufacturingspace.Acmeproducesoneofthe broadestlinesofairmovingequipmentinthe industry.State-of-the-artmanufacturingequipment andawelltrained,experiencedworkforceisthekey toAcme'stimelydeliveryofqualityairmoving products.

EveryAcmeFanisbackedby afull2-yearcomprehensive productwarranty.Fora completecopyofthewarranty statement,seeformACS27or writetoAcmeEngineering& ManufacturingCorp.,P.O.Box 978,Muskogee,OK74402.

InadditiontoAcme’sstandard 2-yearcomprehensive warranty,Acmeoffersa 5-yearwarrantyontheshaft andbearingassemblyin everyAcmeFan.

Acme’scorrosionresistant Master-Ex® DDPfansoffer anadditionallifetime warrantyonthepropeller, coneandhousing.

The Acme Research and Development Center operates both air and sound laboratories. The Center houses four wind tunnels with a data acquisition system, a reverberant sound room with the latest sound analyzer equipment, and a structural laboratory for stress and vibration analysis. Solid modeling, and finite element analysis support product research and development. The Center also houses a fully equipped prototype facility enabling Acme to develop and introduce new products to the market in the shortest time possible.

DISTRIBUTED BY:

Sales&Service

Afactory-trained,knowledgeable Acmesalesorganization addressestheneedsofmany diverseanddistinctmarkets. Customersaroundtheworldare servicedbyacompletesystemof salesrepresentatives,equipment distributorsandlocaldealers supportedbynationwide distributioncentersandbackedby astaffofsalesandmarketing professionals.

AhighlytrainedProduction staffsets thestandardfordependable, qualityairmovingproducts.Byusingthe latestcomputertechniquesforresearch anddesign,andrigorousqualitycontrol standardsAcmecanofferoneofthebest warrantyprogramsintheindustry.Our exclusive2/5yearlimitedwarrantyprovides ourcustomerswithconfidence...YearAfter Year.