We strive to build the most robust, reliable and efficient machines on the market and producing versatile brick lined machines allow us to do this.

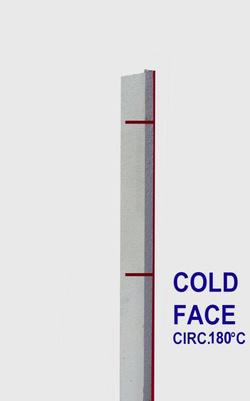

• Interlocking brickwork: Brickwork is bonded together therefore there are no steel anchors to burn out.

• Twice the thickness of competitors linings: enabling us to be up to 40% more efficient on fuel usage.

• High Purity Low Porosity bricks & mortars: Super low porosity means far less liquid ingress than conventional low grade cast linings.

• Impact & Abrasion high strength block retaining system: The ADDFIELD Capping block has been designed combat mechanical damage through loading, help retain brick structures and combat general wear and tear.

ADDFIELD BRICK REFRACTORY:

Abrasion/ impact resistant seal blocks

180mm thickness

10mm steel work

Three layers of purpose built refractory materials

COMPETITORS CONCRETE

Heat conductible steel anchors precariously close to the hot face.

70-100mm thickness

One layer of concrete

5mm steel work

Source: Thermal Evaluation 2014 Cobb Lloyd Refractories Inert brick anchors

- Radiant heat causes more thermal loss and burners have to work twice as hard. -- Heath and safety implications.

With over 41 years experience in the incineration and cremation industry our references include: - The UN

-The World Food Programme

-MSF

-The Red Cross

-The Medical Research Council

-European Union Commission

-BQP – The largest pig producer in the UK

-Sukarne – The largest cattle producer in Central America

-Cargill – One of the largest poultry producer in world

-Marine Harvest – The largest aquaculture producer

-Mars – One of the largest chocolate and food producers

And many, many more……

World Wide Export

We currently export to 147 plus different countries world wide and we have a machine on every continent.

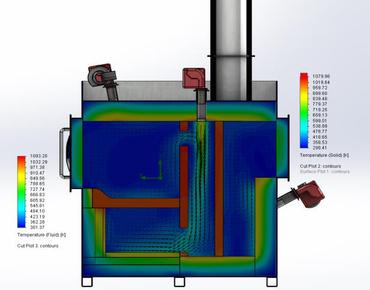

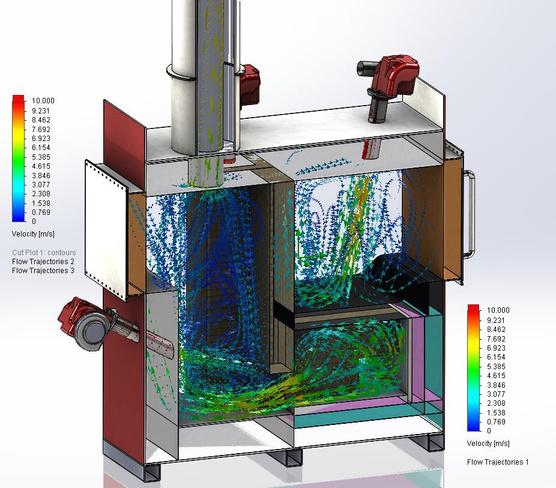

Computational fluid dynamic (CFD) modelling is a testing technique used to visually render gas flows and velocities within an incinerator machine. It is the same technique used for modelling aircraft, cars and power stations.

We use it at Addfield to ensure:

-100% destruction of waste.

-That we make best use of all the heat generated.

-The designing out of hot and cold spots.

-The machine is thoroughly stress tested – before it is sent to a customer.

-A two second retention time in the secondary after chamber.

This is one of the only ways to measure the correct after chamber size to ensure a compliant two second gas retention time. If this is not done correctly, an incorrect after chamber can lead to dioxin reformation which can be harmful to human health.

Addfield MP-100 CFD Modelled, Showing steel and refractory temperatures

Addfield MP-100 CFD Modelled, Showing gas velocities

Addfields machines utilise a robust two pack paint system, this is the same technology found in modern car

manufacturing. The paint systems are highly durable and designed to withstand the harshest of environments.

Our in house dedicated spray booth coats the exterior steel work with a protective layer of paint. The paint is then baked on at 70°C to ensure complete adhesion to the steel.

Addfield are one of the few manufactures who can use this technology, due to our brick lined refractories and cooler exterior steel temperatures. Alternatives such as enamel based high temperature paints typically utilised on machines with “CAUTION HOT” signs denoted on their exterior are far less durable, especially when used on external applications causing early, machine failure.

The electronic systems found on addfield machines are all plug and play, this reduces costly site time required for commissioning and simplifies future electronic troubleshooting, as parts are hot swappable.

Electronics are all in accordance with BS7671-17 and weather proof to IP65.

Addfields door and lid systems consist of a compressible low thermal mass ceramic. Many machines built to a price point will use a concrete lined lid. When the aperture closes, concrete on concrete doesn't seal effectively. A low thermal mass ceramic lining creates a very tight window frame seal, it retains heat extremely well and prevents any influx of exterior air that could effect the burning process.

Progressive lid clamps positioned on the front of the machine ensure a tight seal on the day of delivery, but also for years to come due to their adjustability.

The EcoCycle™ badge is an accumulation of energy efficient technologies developed by Addfield, culminating in some of the most fuel efficient and eco friendly incinerator and cremator machines on the market today.

The technology incorporates:

•180mm-221mm of refractory wall thickness that locks the incinerator heat inside the machine.

•Twin brick lined refractories: Hot face bricks that reflect heat back into the chamber whilst insulation bricks behind prevent heat from escaping.

•Pulse firing burners that turn off once the machine is up to temperature to save fuel and aid a cleaner burn process.

•Intelligent PLC controls, automatic high and low burn cycle settings that effectively allows the waste to burn its self (intermittently) without fuel.

•Computational Fluid Dynamics

Did you know?

•Addfields steel work is precision laser cut to an accuracy of 10 micrometers.

•We use a robust 8mm and 10mm thick steel plate for the primary chambers.

•The steel work is acid etched to prevent corrosion from the incineration process.

•Integrated into many of Addfields larger machines is a tough front protection ram guard.

•We operate from two factories, Hollies Park and Addfield Fabrications

This enables us to:

-Ensure quality throughout the manufacturing process.

-Construct bespoke machine.

-Customise existing designs to meet customers specific requirements.

The high quality materials used within the construction of Addfields machines ensure long term use with minimal maintenance.

Addfields machines are built in such as way that maintenance can be performed on site quickly, economically and effectively with almost every single part.

A good examples of this is Addfields brick lined refractory. Machines available on the market, built from a price point utilise a concrete refractory. Brick refractories are serviceable on site – simply by changing a brick. A damaged concrete refractory will require a specialist former to be constructed and a complete reline will be required to make an effective repair, this is typically conducted at the manufacturers factory.

The refractory materials found on Addfields machines are the same robust, reliable and efficient components you will find in a human crematorium. You will never find a concrete lined human crematorium because they cannot afford the downtime concrete brings, ultimately you should have the same assurances.

We recommend an annual service of the machines, this involves changing of burner parts including a fuel filter, blast tubes, diffusers and nozzles. We use ECOFLAM manufactured burners within our machines, as we believe them to be the most robust and reliable on the market. ECOFLAM operate from over 60 different countries world wide, as such spare parts are widely available via an established distribution network. We also have a spare parts

availability guarantee of 5 years.

DEFRA TYPE APPROVED The UK ‘Department for Environment Food & Rural Affairs’ have Type Approved Addfields machines for use.

ISO International Organisation for Standardisation. We are ISO 9001 and ISO14001 certified. CE COMPLIANCE

Conformité Européenne [European Conformity]:

•BS E7N4 6-2:1997 (Industrial thermo processing equipment - part 2)

•73/32/EEC Low voltage directive

•89/336/EEC EMC Compatibility Regulations

•89/392/EEC Machinery Directive.

EU WID Compliance: Our emission levels have been MCERTS tested and are compliant with the EU Waste Incineration directive 2000/76

UK Midlands Manufacturer Of The Year: finalist 2014/15 (results to be held 20/02/2014)