EVERYTHING TESTED OUT OF THE FACTORY CHEETAH 30 IS EVERYONE'S FRIEND THE IMPORTANCE OF SHARP KNIVES

EVERYTHING TESTED OUT OF THE FACTORY CHEETAH 30 IS EVERYONE'S FRIEND THE IMPORTANCE OF SHARP KNIVES

The well-known Jaguar 40 wood chipper is now also available on a tracked chassis. This makes hard-toreach places, such as wet areas or where there is limited space to work, also accessible. In addition, the machine can be used on sloping terrain and the 5-speed gearbox makes it easy to choose the right speed such as extra slow when loading and unloading on the trailer. With the option of a wood crane, material can be fed in easily and without heavy physical strain. New is the optional turn table. This turn table hydraulically rotates the machine 270 degrees, allowing it to quickly and easily turn the infeed towards the material. The advantage is that material is faster processed and thus more efficiently. Finally, the machine has a large ground

New to the range is the Greentec front weight bumper. This bumper has a basic weight of 860 kilograms and is expandable with 3 weights of 220 kilograms.

At the top, the bumper is fitted with a lid under which tools can be stored. Due to width of 2.3 metres it also allows longer tools, such as shovels and rakes. The bumper is connected to the tractor by a three-point linkage (cat.2) and is fitted with lighting and wide-beam headlights.

On the underside of the bumper, a rubber slide made of 30 mm thick rubber with steel insert is fitted. Finally, the front bumper features a towing hitch.

With a renewed saw wheel for the Greentec Forestcutter 370, the sawing result has improved promoting regrowht. Despite the fact that the cutting pattern of the Greentec Forestcutter was already highly refined, the sawing wheel has been further developed. The new saw wheel is equipped with 16 cutting tooth instead of 12. The result of this development is that the machine has an even thinner saw wheel of 42 mm instead of 58 mm, which leaves minimal marks when cutting.

An additional advantage is that this saw wheel has

The front bumper is made of 25 mm thick steel, making it the most robust bumper on the market. The bumper is 2.38 metres wide, 1.20 metres deep, 1.05 metre high and available from stock■

much less resistance when working in heavy logs, reducing fuel consumption and keeping the saw wheel running easily. The new saw wheel is now standard on the Greentec Forestcutter■

clearance between the tracks, making it easy to drive over obstacles such as stumps■Luchtenberg Tree Care from Barneveld has become an established name in the field of all common activities surrounding the care of trees. Since last year, the Greentec Cheetah 30/80 wood chipper with crane was added to the product range in order to expand the range of services even further.

There is currently no shortage of work at Luchtenberg Tree Care. The company is active in taking care of, replanting, pruning and felling trees and also provides advice on these topics. The regular maintenance work ensures that the machines are currently heavy used and so does the Cheetah 30/80. This machine can generally be found behind the Volvo truck where the wood chips are immediately collected. The combination of truck and machine ensures that various activities can be taken on whereby this chipper combination can also be moved quickly over long distances. Especially for this, the Cheetah 30/80 is equipped with a chassis with air brakes.

Activities with the machine vary at Luchtenberg from pruning tree-lined avenues to felling trees. When pruning tree-lined avenues along roads and paths, a telehandler is used where the Cheetah 30/80 ensures that the cut branches are chipped quickly.

As a result, these jobs are efficiently performed and the workplace can be left clean at the same time.

"The machine amazes me every

With the purchase of the Cheetah 30/80, a machine that was chosen to move quickly and also for its very high capacity, work is done a lot faster. In addition, in terms of operation, the machine appears to have lots of possibilities. That is why in the beginning it got a little time to get used to all these setting options on the machine. Compared to the previous chipper everything goes a lot faster now. "Jobs were taken on based on the old shredder, but soon the capacity turned out to be a lot bigger, the machine really devours everything it gets in its mouth. The Cheetah continues to amaze me every day with its performance"

An additional advantage, is that the machine is equipped with a large and powerful TG FB63T crane. The crane supports the operator efficiently with turn away logs, loading logs or feeding material into the machine. This way of working is not only faster but also many times more labour-friendlier. "The crane is an absolute added value! It tackles really anything and thicker logs are handled like they were nothing. The machine remains nicely stable, partly thanks to the support legs"

Due to the many hours the machine operates for Luchtenberg, there may of course be the occasional machine breakdown. It is therefore important to be able

to adress these quickly so work can continue. "After 1 year of full chipping, breakdowns are really minimal. The breakdowns that are there can resolved by phone with Ufkes Greentec. This is a strong plus and increases the reliability of the machine"

At the moment, Ruben is mainly running the machine. One of his employees is also getting a truck driving license, being able to also hit the road with the Cheetah. As for the user-friendliness of the machine, that should not be a problem either■

Ruben Luchtenberg Barneveld 2017 Permanent team of 4 and permanent freelancers Highly specialised work

Owner Place Founded Employees Activities

Ruben Luchtenberg Barneveld 2017 Permanent team of 4 and permanent freelancers Highly specialised work

Owner Place Founded Employees Activities

This Greentec 962 track side-infeed is specially developed to process logs up to 65 centimetres quickly and well processed intowood chips. The heavy-duty track chassis, 60 cm wide, ensures that the machine is usable in various circumstances.

It is a very complete machine and is equipped with a 425 HP John Deere Stage 5 engine. With a very spacious opening of 650x910mm, the closed feed chain and 5 feed rollers, the material is quickly and powerful transported to the chipper drum. The large chipper drum (960 mm diameter, 40 mm thick-walled and approx. 1450 kg) continues to chip thick logs well, even when

the blades become slightly blunted. The special design counter blade cuts fine branches at a different angle, resulting in better chipping quality thus higher yields.

The machine is also equipped with a heavy-duty splitter to split thicker logs. It has a dozer blade for levelling and provides the machine with additional stability during when using the crane.

This machine is equipped with a Palfinger M70F101 crane combined with a labour-friendly cab with extra space both lengthwise and width wise, which includes equipped with heating, air conditioning and an airsuspension seat. From spring 2023, we can also fit this machine with a 780 hp MAN engine■

Ties says: "I have been working at Ufkes Greentec in Drachten for many years and I have seen rapid growth of the company. We make wood chippers, stump grinders and tree saws for maintaining and felling trees, for the professional market worldwide. When I arrived, we supplied machines to the Benelux, now also in Germany and France and much further. We have 4 fully equipped service vans. As a service engineer, I drive an average of 60,000 kilometres a year. Sometimes I am on the side of the motorway, the other time in the middle of a forest, or in the workshop at an agricultural contractor. I love the variety. My heart is really in the field. This MAN TGE 3.180 I received new at the beginning

of this year and is completely to my own liking. The interior of the bus is as good as the workshop, only the overhead crane is missing, but otherwise all the tools and equipment are there! Customers are happy to see me arrive, and even happier when I leave, because then the machine is up and running again and they can move on. Because I cover so many kilometres it's nice to have a bus with an 8-speed automatic transmission, airsuspension seat and 180 hp. Then I arrive everywhere trouble-free and fresh."■

"That variety, I love"

Ufkes Greentec has a team of enthusiastic employees who work hard on quality machines and good service every day.

VIDEO:

VIDEO:

Cheetah 30 Track with crane

Technical specifications

CB 100hp Ecomax 448-TC 4.8lit. CS

Infeed opening (mm) 300 x 580 Feed opening channel (mm) 300 x 320 Disc (mm) Ø 960 x 58

Number of anvil knives 3 Max. chip length (mm) 22

Number of knives on disc 2 Revolutions disc (rpm) 750 Infeed speed up to (m/s) 0,6 Capacity up to (m3/hour) 40

Specification tracks

Track length total 2000 mm, width rubber track 300 mm, rubber tracks Drive 4200 Nm. 5-speed, with integrated negative brake.

Remote control chipper TG 3163 wood crane GR30 Rotator incl. radio remote control (SCAN) and hydraulic dozer blade

Greentec 942/14 Rear infeed

2 infeed rollers

Infeed opening (mm) 520 x 710

Feed opening channel (mm) 450 x 710 Max. infeed hardwood (mm) Ø 300 Max. infeed softwood (mm) Ø 450

Drum size (mm) Ø 960 x 730

Top roller (mm) Ø 430 x 710

Bottom roller (mm) Ø 300 x 710 Chipper knives 3 Anvil knives 1 Max. chip length (mm) 22

Power requirement (hp) 100 / 220 Capacity up to (m3/hour) 100

Model Tandem, 4-wheel braked Container volume (m3) 14 Gross weight (tonnes) 18,5 Loading capacity tandem axle (tonnes) 16 Discharge chute: 340 gr rotation

Power requirements: 140/ 280 hp High tipping bunker 13m3 left hinged

Greentec Piranha stump grinder

Grinding wheel diameter 870 mm

Grinding wheel thickness 40 mm Teeth 2 x 22

Weight 1565 kg

Swivelling range 250 cm, telescopic 40 cm

Above ground 50 cm In ground 70 cm Up to 250 hk

Rubber screens Electric joystick control

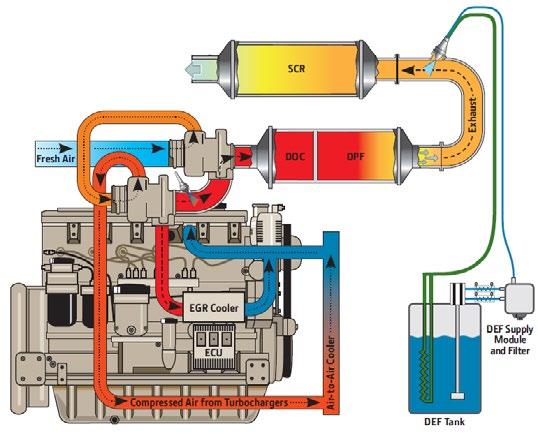

European emission standards for diesel engines have gradually become more stringent since the introduction of the Stage I standard in 1997. Currently, the Stage V engine is the cleanest diesel engine and is applied to all Ufkes Greentec motor machines. The Stage V legislation was proposed in 2014 where the focus is on emitting less soot particles. By limiting the number of soot particles emitted, in order to achieve the Stage V standards, it is almost always necessary to, in addition to a particulate filter to fit the engine with AdBlue (SCR) and a specific catalytic converter (DOC). Often, exhaust gas recirculation (EGR) is also used.

By applying the impressive aftertreatment system, there is not only much lower emission, but the engine noise is also greatly reduced compared to the previously applied engines. The latest generation of Stage V engines bring the necessary advantages. Thus, the engines not only have higher power outputs (for the same engine the same engine capacity), but by using the dual and variable turbocharger (for 300-425 hp engines), there is also more torque at lower speed. Resulting in stable power delivery, over a wide speed range. Ideal for application on a Greentec wood chipper.

By making smart choices regarding operating speeds of our chippers, a lower fuel consumption is realized. Most shredders are even equipped with an ECO mode. In this mode, the machine runs at a lower speed, making the machine not only more economical but also more quiet. Finally, this adaptation offers the advantage of complying to the newest requirements and thus be able to tender for new works.

Ufkes Greentec deliberately chooses to use stage V

engines from Kubota, Doosan as well as John Deere engines. The reason for this is the long-term relationship with these brands with the added value of reliability, the modern technology and the good cooperation with the global service network. Depending on the machine and associated expectations of the machine, a specific engine is built up to then ensure a powerful, reliable and clean drive■

The Ufkes test centre ensures that the quality is guaranteed and the customer can use the machine as expected. All machines, from large to small, are subjected to a thorough test. Small and large wood chippers, wood chipper combinations but also stump grinders, forestcutters and three-point linkage machines, as well as wood cranes pass the test centre. The start of each test is a visual inspection of the machine. Parts, customer-specific wishes and options are optically checked. The outcome of this first stage is whether all parts are fixed and whether the machine is complete.

After the first step the machine is, if required, re-adjusted and re-programmed. Finally, the machine is connected to the simulation unit which simulates the rear end of a tractor. This unit is complete with hydraulics, PTO, air brakes and lighting. Once connected, the machine operates through a specially designed test module where various functions and situations are simulated. This includes simulating harsh conditions and safety settings and the adjusted values of, for example, the lifting force of the crane are checked.

Before testing, the oil in the machine is brought to operating temperature, after which testing and adjustment begins. Adjustment of, for example infeedspeed or chip length with a machine at operating

At Ufkes Greentec, all products, which are made in our own factory, are extensively tested before they are handed over to the customer.

temperature has the advantage that the machine will fully meet expectations like in daily work. The warmer oil has added value when making precise adjustments. We can also open the floor during testing to inspect the machine from the bottom. There is extra attention to cabling, hydraulic hoses, ground clearance and any leaks.

During testing, photos are taken of the machine and the testing process. The photos and the values of the test are collected and placed in the unique database of the machine. After delivery, this file is available to the helpdesk in order to retrieve all information of the machine if the customer has any questions about it later. The testing procedure is thorough and any adjustments which are desired are made. Finally, the machine is fully washed and prepared for delivery to the customer■

These compact and very strong mulchers for crane attachment is suitable for grinding unwanted storage, shrubs, stumps, wood residues and grasses. The forest mulcher is equipped with Widia teeth that cleave the material.

For determining the end product, the anvil knives can be easily adjusted. Hydraulic components and hoses are all safely concealed in the housing.

Thanks to its unique valve, the forest mulcher is virtually suitable for all cranes from 12-25 tonnes and it turns a very high torque at normal speed. Its compact construction and low weight, but strong due to Hardox housing and no V-belts, makes the machine reliable and fast in its work.

The forest mulcher is fitted with height adjustable glide runners and is available in two models, the 1300 and the 1500■

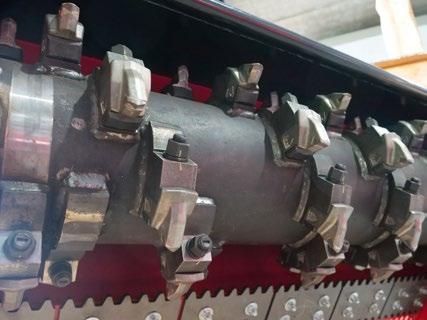

Sharp knives are essential for properly, quickly and efficiently chipping of material. Generally, knives last a long time but the lifespan depends strongly on the material thath is being chipped. In addition, the knives are losing its sharpness quickly through sand and soil.

Detection of blunt knives of a woodchipper is as easy as detecting a blunt chainsaw. The timely recognition of blunt knives ensures that the consequences for both the machine, the operations and the wood chips are minimized. In brief, the following four points are possible consequences of working with blunt knives. On which a closer inspection of the knives is recommended:

When knives are no longer sharp, they lose cutting power. As a result, the wood is not cut but the machine starts to 'pulverize/chop' causing a lot of dust in the chipping material. Especially for the sale of quality biomass chips this gives a lower financial value because the combustion of these shreds is far from ideal. In addition, a lot of dust in the material also creates a poor working environment for employees.

A second and highly visible landmark for blunt knives are the smaller, frayed shreds and long pieces. Again, blunt knives will pulverize the wood rather than cut. The chips are not cut properly, so the end result will consist

Picture: Blunt knivesof small and frayed chips as well as long pieces. The material is not nicely processed, causing decreased blowing power and this in combination with the long material, might result in blocking the pipe.

Blunt knives take longer for the logs to feed in because the knives pull the material in poorly. As a result, it greatly reduces the capacity of the machine and will require more time to process the same amount of material. An additional disadvantage is that a machine with blunt knives produces more noise, creating a combination of longer shredding time with more noise for the environment. It also has implications for the machine itself. Chipping with blunt knives causes vibrations throughout the machine and increased forces on the bearings of the chipper disc/drum so that they suffer.

Finally, much more engine power is required to run the machine. The blunt knives have considerably higher resistance, which means the machine requires more power demands from the drive unit. The consequence of this is that the engine produces more noise and in addition fuel consumption will increase substantially.

The chip quality, the production, the service life of the machine and job satisfaction thus depend very much on whether the knives are sharp. Therefore, advice is to check the knives daily. On a knifegrinder, knives are sharpened with cooling water at the right angle without affecting the hardness of the knives. This allows the knives to retain their sharpness for a longer period of time. Visit our website or scan the QR-code for more information on knifegrinders.

Chippers are fitted as standard with one extra set of knives which can be sharpened several times over a longer period. With multiple knife sets the knives can be changed quickly in the field after which the machine can return to work and the blunt knives can be sharpened.

More info:

Knives are wear parts and will eventually have to be replaced. When replacing the knives, it is recommended to also properly inspect studs, bolts, nuts and washers and also replace them if required. Reason for replacing the knives may be because the knives have been damaged, have cracks or pieces have broken off. Also, if the knife is too short to work safely with it, they should be replaced.

In short, with sharp knives:

- Much more chipping power

- Uniform quality chips

- Longer machine life

- Much lower fuel consumption

- Less noise

- More job satisfaction■

The Cheetah wood chipper is perhaps the fastest in its class! The machine processes complete logs up to a diameter of 30 centimetres. With the wood crane just one person easily processes 40 m3 per hour.