Greentec WOOD CHIPPERS

Greentec WOOD CHIPPERS

Ufkes Greentec produce Wood chippers, Stump grinders and Grapple saws for sale to professionals worldwide. All stages of design, production and testing are done in house by the Ufkes Greentec Team. We offer full after sales service through our in house engineers and network of approved dealers worldwide.

wood chippers, stump grinders, forest mulchers, grapple saws and knife grinders for sale to professionals worldwide. All stages of design, production and testing are done in house by the Ufkes Greentec Team. We offer full after sales service through our in house engineers and network of approved dealers worldwide.

Our machines are entirely designed and produced in our state-of-theart factory located in Drachten, the Netherlands. Modern production factory

Displaying the extensive range of machinery available, while also providing product servicing and maintenance. Sales and Service - the Netherlands

In 2019 Ufkes Greentec opened a new Sales & Service facility in Sudern, Germany, providing convenient access to customers in this area. Sales and Service - Germany

Having spent years working in the design, sales and servicing of forestry and arboricultural equipment, in 2004 Jippe Ufkes used his extensive experience to start designing and producing his own equipment better able to meet the demands and requirements of professional users. A new factory was opened in 2009 in Drachten in the North of the Netherland. Since then the product range has expanded to include woodchippers in a wide variety of configurations, PTO, Trailer – with or without bin, engine powered, track and truck mounted as well as stump grinders, grapple saws, forestry mulchers and grinders. Additional facilities have been added over the years, a new dedicated production facility of 4400 m2 and a separate after sales and service department. grinders, forest mulchers and knife grinders. Additional facilities have been added over the years, a new dedicated production facility of 47500 ft2 and a separate after sales and service department.

Providing onsite service, maintenance and repairs, by our highly skilled team of professionals. Service

Parts

Because we produce our machines in house, we have all parts readily available.

The Greentec team

Our passionate and enthusiastic team is our greatest asset, providing a friendly, competent and complete customer service experience.

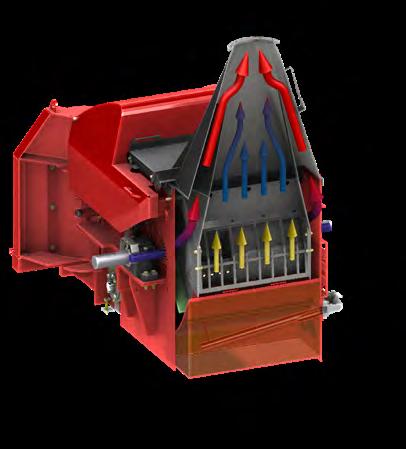

The Venturi blower system cools the Hydraulic oil Grate is easy to change

Replaceable bottom

Hardox wear plate

All functions on the chute can be controlled by the remote

The big drum, ø 24" cuts all material in the centre of the drum, the benefit of this is that all material is

The big drum, 600mm wide, cuts all material in the centre of the drum, the benefit of this is that all material is pulled in easily

Closed Hardox infeed chain covering the complete length of the infeedtable

The chute has replaceable Hardox wear plates

Hydraulic controlled slewing chute is equipped with ball bearings

Greentec machines are manufactured with S355 steel. Sandblasted and double powder coated.

The massive ø 24" heavy-duty drum with .8" wall, produces uniform wood chips from either heavy logs or branches.

The massive 600mm wide heavy-duty drum with 20mm wall, produces uniform wood chips from either heavy logs or branches.

The specially designed anvil cuts small branches and large logs at different angles, producing uniform wood chips. The wood chip size can be easily adjusted by changing the grate or by adjusting the speed of the infeed rollers.

The Venturi system in combination with the integrated blower system produces an extra powerful discharge of chips

Greentec drum chippers have an extra wide infeed opening, perfect for feeding in whole trees, logs and brash.

system left and right of the

A 400mm x 600mm infeed makes this machine suitable for a wide range of jobs

A 16" x 24" infeed makes this machine suitable for a wide range of jobs

The large 450mm diameter top feedroller is very aggressive and powerful

The large 18" diameter top feedroller is very aggressive and powerful

Quick change knives are fitted as standard

An optional infeed table makes chipping of brash and foliage very easy and efficient

An optional infeedchain table makes chipping of brash and foliage very easy and efficient

Chip size is controlled be a very easily accessible and changeable grate

A simple and logical user interface maximises output and performance and minimises maintenance costs

All wear parts are easily replaced minimising downtime.

Integrated hydraulic infeed rollers no open slits on either side

Standard equipped with quick change knives

Chip grade unit is easily changed

Cutting length up to 1" 1213

A disc chipper gives high production with relatively little power

All the material gets pulled in under an infeed angle of 50 degrees. Because of this the 2 knives also help with pulling in material, in combination with the 2 aggressive infeed rollers making the infeed of this machine very powerful

The large disc fitted with specially designed fanblades easily blow material through a 5 metre shoot over the cab of a tractor

The large fitted with designed fanblades easily material through a 200" shoot over the cab of a tractor

Two powerful aggressive vertically amounted feedrollers crush and feed branches easily

Heavy duty robust construction means the machine runs very smoothly and reliably for years

Lower RPM means the Cheetah 30 runs quieter.

Cutting length up to 25 mm 2,3" thick steel results in a lot of chipping

The large disc of 58mm thick steel results in a lot of chipping power/ momentum.

Special design to easily grab short material, bushes and branches to feed in as a as a whole

Crab in closed position for raking

Very compact construction allowing the Crab to come close to the feed rollers

Very high gripping force.

Easy to navigate digital system panel

Installed with 2 programs for chipping on 2 rev levels (eco-mode)

Standard with remote control

Stopping and possibly brief reversal of material to be fed in responds to disc/drum speed

Vulcanised controller with no moving parts, minimum chance on errors and making it durable against vibrational wear and tear

Minimal electronics = less down time

Radiographic remote (GCS1.1) chipper functions

Chip deflector up/down

Chute up/down

Turning of chute

Infeed rollers in/reverse

Lift and crush

Motor revs up or down

up/down. up/down. chute. in/reverse. Infeed rollers open and crush with extra downforce. down.

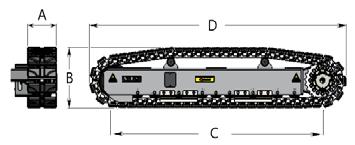

Chassis

One control, for the woodchipper, crane and diesel engine

Everything is on an easily programmable 7” touchscreen

4 program options to choose from: Heavy logs, Soft wood, Hardwood & Branches

The various settings adjust the infeed roller pressure & speed to accommodate different materials

Auto feed function (No stress) is designed to monitor the engine rpm and oil pressure simultaneously. This dual sensor system activates the infeed rollers ‘Stop & Reverse’ feature when either the engine rpm or oil pressure move out of their normal parameters

Eco Program option: runs the machine on a lower engine speed to save on fuel, reducing noise and produce bigger chips with less dust

Chip size can be adjusted at any time while the chipper is running

System can be set in 5 languages Dutch, English, French, German & Polish

Suitable for multiple operators, each with their own custom