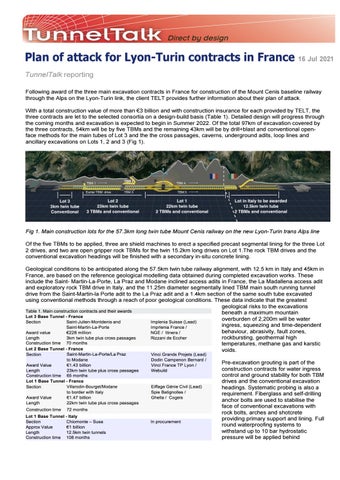

Plan of attack for Lyon-Turin contracts in France 16 Jul 2021 TunnelTalk reporting Following award of the three main excavation contracts in France for construction of the Mount Cenis baseline railway through the Alps on the Lyon-Turin link, the client TELT provides further information about their plan of attack. With a total construction value of more than €3 billion and with construction insurance for each provided by TELT, the three contracts are let to the selected consortia on a design-build basis (Table 1). Detailed design will progress through the coming months and excavation is expected to begin in Summer 2022. Of the total 97km of excavation covered by the three contracts, 54km will be by five TBMs and the remaining 43km will be by drill+blast and conventional openface methods for the main tubes of Lot 3 and the the cross passages, caverns, underground adits, loop lines and ancillary excavations on Lots 1, 2 and 3 (Fig 1).

Fig 1. Main construction lots for the 57.3km long twin tube Mount Cenis railway on the new Lyon-Turin trans Alps line Of the five TBMs to be applied, three are shield machines to erect a specified precast segmental lining for the three Lot 2 drives, and two are open gripper rock TBMs for the twin 15.2km long drives on Lot 1.The rock TBM drives and the conventional excavation headings will be finished with a secondary in-situ concrete lining. Geological conditions to be anticipated along the 57.5km twin tube railway alignment, with 12.5 km in Italy and 45km in France, are based on the reference geological modelling data obtained during completed excavation works. These include the Saint- Martin-La-Porte, La Praz and Modane inclined access adits in France, the La Madallena access adit and exploratory rock TBM drive in Italy, and the 11.25m diameter segmentally lined TBM main south running tunnel drive from the Saint-Martin-la Porte adit to the La Praz adit and a 1.4km section of the same south tube excavated using conventional methods through a reach of poor geological conditions. These data indicate that the greatest geological risks to the excavations beneath a maximum mountain overburden of 2,200m will be water ingress, squeezing and time-dependent behaviour, abrasivity, fault zones, rockbursting, geothermal high temperatures, methane gas and karstic voids. Pre-excavation grouting is part of the construction contracts for water ingress control and ground stability for both TBM drives and the conventional excavation headings. Systematic probing is also a requirement. Fiberglass and self-drilling anchor bolts are used to stabilise the face of conventional excavations with rock bolts, arches and shotcrete providing primary support and lining. Full round waterproofing systems to withstand up to 10 bar hydrostatic pressure will be applied behind