Structural Sequencing

The centre utilises a CLT construction system, making the main interior walls part of the load bearing structure of the buildings, and the interior walls will act as the secondary reinforcing structure.

In order to achieve the spans across the main workshop space a small glulam frame has to be erected in the main workshop space, this is so the structure can support the floor slabs and maintain the permeable threshold between the classrooms and main workshop.

The tertiary support comes from the existing façade materials

Technical Detail

The CLT structure is insulated by a retrofitted layer of rockwool insulation, due to the existing brick wall only being cavity insulated, the interior is covered in cork insulation for both noise and fire reasons. The cladding is either the existing gratified brick, or Yakisugi

Fire Strategy

The centre was designed in accordance with approved document B. When making the building comply with these regulations I decided that it was to be an institutional building because it has the strictest regulations (18 meters to a fire exit)

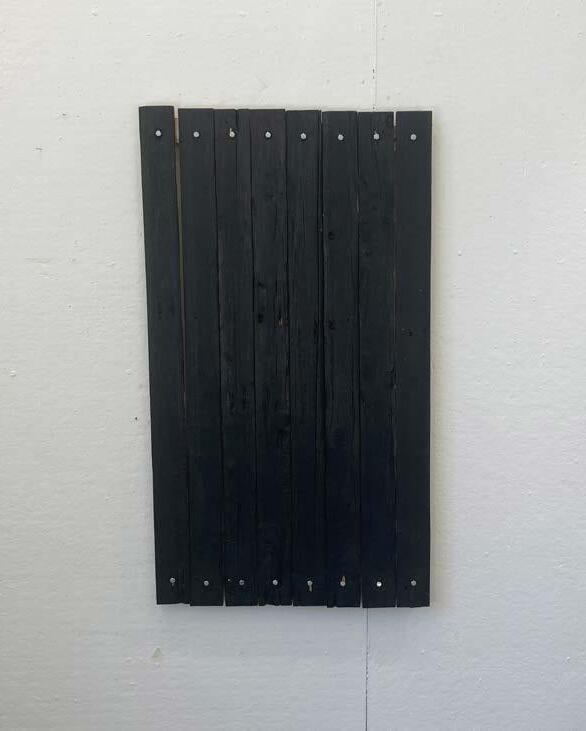

DIY Cladding

My research will be looking into how I would be able to make Yakisugi myself, as well as researching methods of mounting the cladding in a way which would allow for simple maintenance, repair, and replacement if any op the panels are damaged, and for when the yakisugi will need to be re-oiled.

Considering that much of my design will be utilising the existing brick cladding I decided that the Yakisugi should utilise this same concept of re-use and recycling. I chose to investigate the possibility of using pallets due to their ubiquity when considering how much they are littered around back alleys and kerb sides in Newcastle. On one short walk between the Newcastle Uni Student’s Union and Haymarket Metro, I found 15 pallets left, to be only used once, and then to be destroyed.

Considering this I decided to use palette wood for the material for the centre’s Yakisugi. I decided that each of these panels should be 15mm thick, 70mm wide, and 1000 mm long. I worked out from my experimentation that you could get around 7 panels from each palette. 105 panels in total which could cover up to 73.5m2 of façade on my building,

For what I made it took me the this long to do the following:

Stripping: 25 minutes

Sanding: 10 minutes

Trimming: 10 minutes

Charring: 45 minutes

Brushing: 5 minutes

Oiling: 10 minutes (not including drying time of 1 hour)

Drilling: 20 minutes (including marking out holes)

Insertion: 8 minutes

Mounting: 3 minutes

Total: 136 minutes (2 hours and 16 minutes) (3 hours and 16 if including drying time)

Per Panel: 17 minutes (77 minutes with drying time)

Panels per Hour: 3.5 panels

This means that to clad the main building it will take 16 workers a combined 986 hours (or 42 straight days) to make the 6629 panels which are required for the project. However, if the centre were at it’s capacity of 64 people, the time would be quartered (just over 10 days). Also these timings are based off an individual making the system, I estimate there are time saving measures which could shorten production by 33%, making the time 165 hours, or a little under a week.

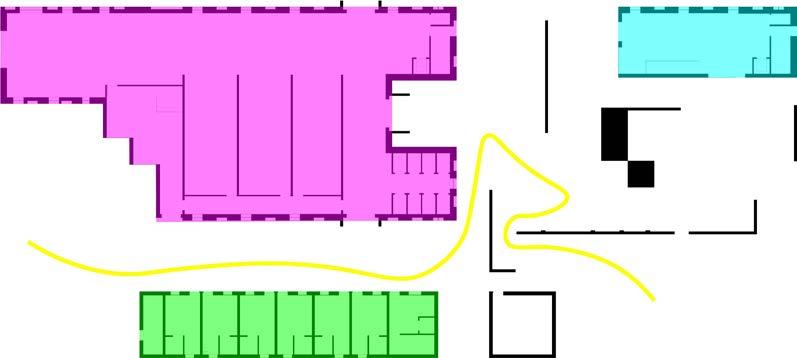

Zoning the Centre

Similarly to the earlier precedential studies I undertook I analysed how each of the differing spaces in the centre would interact, this is to help better understand how to enforce these feelings of transition

Unlike the earlier studies I have turned “community” into “connecting”, and “connecting” into “linking”, the interacting shapes have also been abandoned, rather using dots, and shapes which fill the spaces

The programme for the centre is:

Connecting: Social Bar area (ground), residents kitchen (1st floor)

Mending: Resident Accommodation (ground and 1st floor)

Linking: Outdoor exhibition area, and gardens

Making: Workshop and classrooms (ground floor), arts studios (1st floor), Therapists offices (2nd floor)

Grid Based Thinking

When designing the centre much of the design was set up on a 3 x 3 meter grid. The orange sections in this drawings all owe their form to the grid system inspired by Fujimoto and O’Donnel and Tuomey

DOWNTAKING PLAN 1:500 A3

EXISTING

PROPOSED

DEMOLISHED

1:1000 A3 WIDE

Materiality

To carry on the theme of care within conflict, the materials that will clad the building will be the existing gratified brick, and the aforementioned Yakisugi. These have both been chosen because of their aesthetic qualities but also because of the unconventional idea of protection they convey

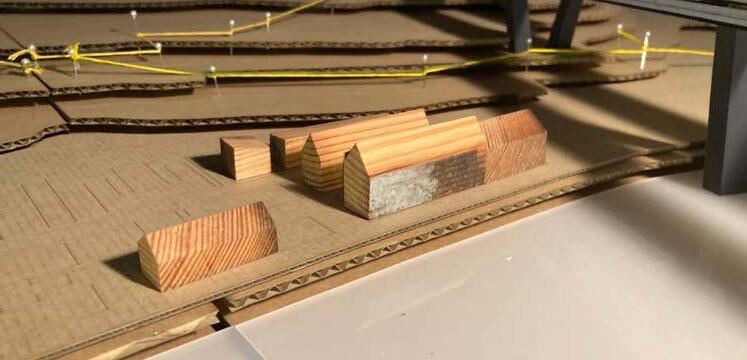

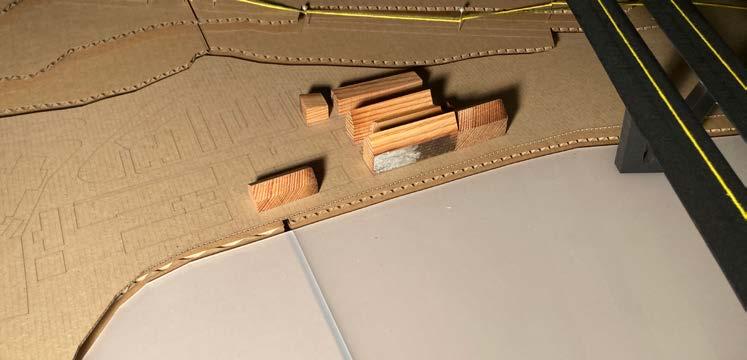

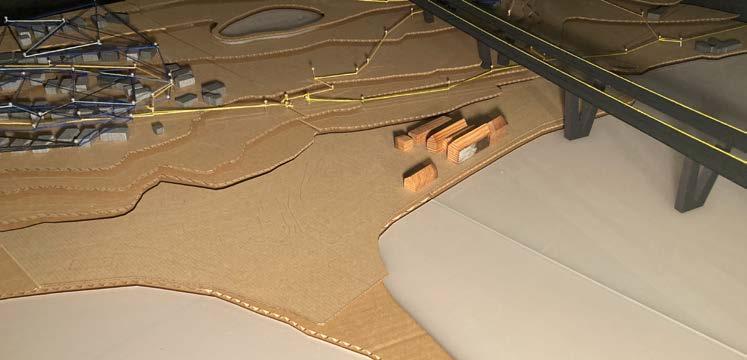

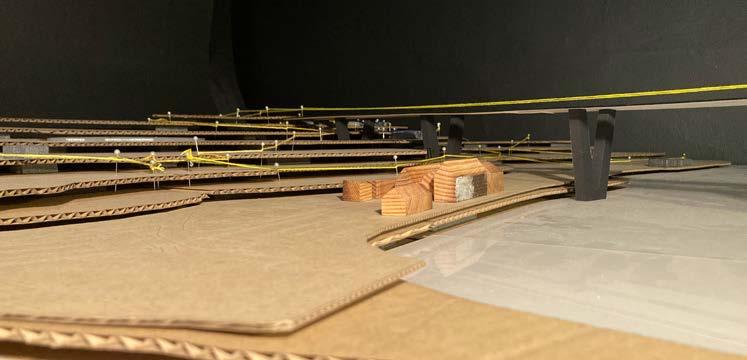

Modelling

To reinforce the notion of making and mending I chose to represent my spaces with handmade models. Modelling also enabled me to understand and reinforce the principles of Peter Zumthor which I investigated earlier in the project. I modelled the main interior spaces at 1:50, and the exterior spaces at 1:100

The Classroom The Studio

The Classroom The Studio

The Therapy Room

The Bar

The Therapy Room

The Bar

The Workshop

The Workshop