HEIDELBERG SMART PRINT SHOP WITH PRINECT

LEADING THE INDUSTRY FOR OVER 70 YEARS IN PRINT | SPRINTER.COM.AU MAY 2023

with

production

Heidelberg

Ricky Richards’ Kelly Morgan in Women in Print

Gallery: The 9th annual Diemen Awards

Having environmental responsibilities in print

I wish to say a huge thank you for accommodating all our crazy orders over the past fortnight, your brilliant service made it possible to reach all the deadlines.

Lizzie

Thanks for your help with these cards. The parcel arrived yesterday and they look great! We’re looking forward to pushing the raised foil more this year so we’ll pass some more jobs across soon.

Doug

The Guide looks beautiful! Gorgeous print and colours, thank you again for organising the press check and paying such close attention to our work.

Caroline

The print is amazing - even better than I expected. Everything went so smoothlyyou were so prompt to respond to me, the tracker you have with the daily and update emails is fantastic, even the courier service you use has such good tracking info.

Ellen

The folders look fantastic. Thank you so much for your help and tireless efforts getting them through for us. You are such a legend and fill us with confidence knowing you’ve got our backs.

Sarah

Printing has already dispatched – thank you!!! I always feel confident sending an urgent job your way, and in this online world where you rarely get to deal with a real live human, I really appreciate that.

Mel

YOU

OF OUR NEW CLIENTS ARE REFERRALS

CAN SEE WHY... AUSTRALIA’S BEST TRADE PRINTER

MAY 2023

6-12 NEWS: Australian Printer’s comprehensive industry news

14-16 HEIDELBERG OPTIMISES PRODUCTION WITH ITS INTELLIGENT SYSTEMS: Heidelberg enables print shops to stay competitive and profitable using its systems

18 WOMEN IN PRINT: Ricky Richards’ Kelly Morgan

20 LARGE FORMAT PRINTERS: Canon Production Printing launches new modular Colorado M-series

22-25 THE 9TH ANNUAL DIEMEN AWARDS: Tasmania’s Mercury Walch wins Grand Diemen Award for print, and pictures from the event

26 INSTALLATIONS: Victoria’s Revolution Print automates its business with printIQ technology

28-40 SUSTAINABILITY & ENVIRONMENTAL RESPONSIBILITIES: Real impact, real change

28 Currie Group 36 Lithocraft

30 Durst 38 Bailey Print Group

32 HVG 39 Carbon8

34 Konica Minolta 40 Sunprint

41 THE REAL MEDIA COLLECTIVE: Sustainable green print – the industry standard

42

43

44

PRINT EXPERTISE: Giving them a reason to keep your prints

MEQA SMITH: Jobs are products now

DEBORAH CORN: Five signs you're a print junkie – 2023 edition

45 FELLMAN CLASSICS: People will pay for performance

46-50 WIDE FORMAT +PLUS: Australian Printer’s comprehensive wide format news, powered by Wide Format Online

51 PRINT DIARY: All the upcoming events

52-58 CLASSIFIEDS: The Australian print industry’s biggest marketplace

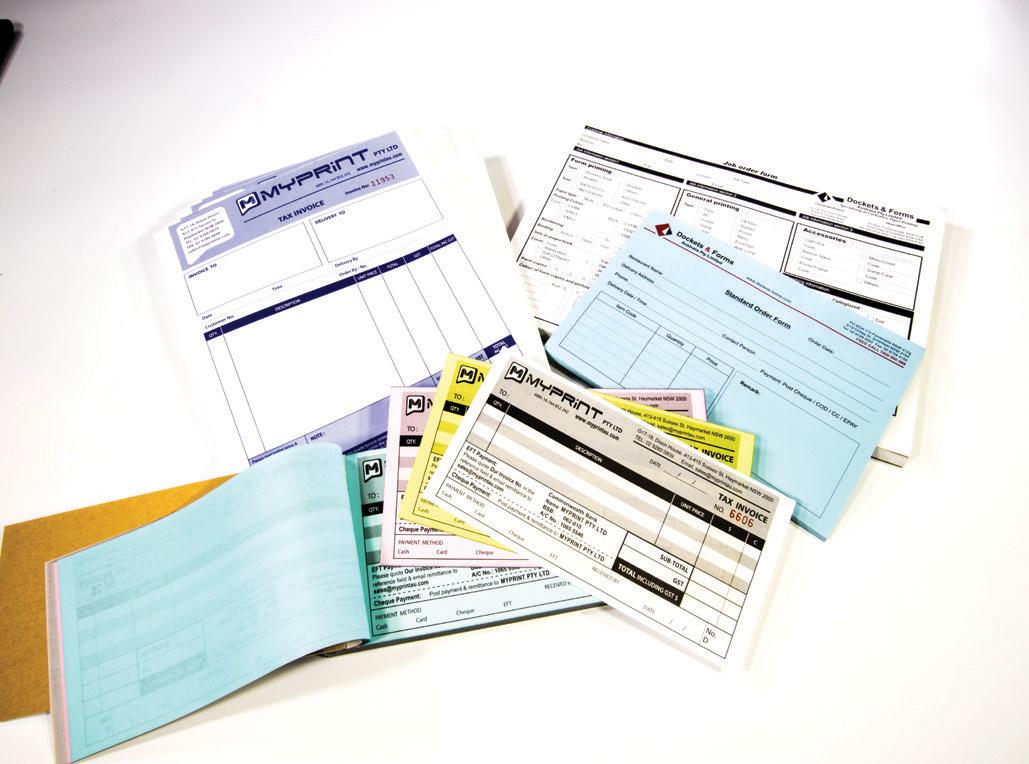

CONTENTS ABC Copier Solutions 52 All Work Crane Services 58 Allkotes 58 Bottcher Australia 51 Canon Production Printing Australia 21 CTI Colour Printer 55 Currie Group 29 Cyber (Aust) OBC D & D Mailing 56 Dockets and Forms Australia 54 Durst Oceania 31 FUJIFILM Australia 5 Gecko Sticker Signage 53 Graph-Pak 57 Heidelberg Australia OFC, 14, 15,16, 17 Hero Print 2,3 Hilton Laminating 23 HVG Graphics 33 Jet Technologies 7, Insert JTS Engineering 54 Konica Minolta 35 Label Line 54 manroland GOSS 11 National Auctions 58 Penrith Print Museum 52 Periodical Press 52 Print Logistics IBC printIQ 27 Printmac Corporation 55 ProPrint Awards 8,9 Screen GP (Aust) 13 Stick On Signs 19 Top Line Binding 52 Wholesale Magnets Insert Advertiser’s Index

advertise call Carmen on

450 or carmen@proprint.com.au

To

0410 582

14-16 OPTIMISING PRODUCTION WITH HEIDELBERG

18 WOMEN IN PRINT: RICKY RICHARDS’ KELLY MORGAN

22-25 THE 9TH ANNUAL DIEMEN AWARDS

SPRINTER.COM.AU 4 | AUSTRALIAN PRINTER MAY 2023

The new blueprint for wide format

The new blueprint for wide format

A true flatbed with a unique and exceptional design.

A true flatbed with a unique and exceptional design.

Fujifilm to showcase expanding Acuity range at FESPA 2023 with a new printer to be unveiled at the show and more details of historic FujifilmBarberan partnership to be revealed.

The IF Design Award winning Acuity Prime offers high quality printing on a range of rigid and flexible media across five dedicated vacuum zones. Using our Uvijet HM LED UV inks and jettable primer, bold graphics and fine text can be reproduced with variable drop sizes from 7 to 21 picolitres for near photographic quality.

The IF Design Award winning Acuity Prime offers high quality printing on a range of rigid and flexible media across five dedicated vacuum zones. Using our Uvijet HM LED UV inks and jettable primer, bold graphics and fine text can be reproduced with variable drop sizes from 7 to 21 picolitres for near photographic qualit y.

Following the huge success of Fujifilm’s ‘New Blueprint for Wide Format’ appearance at FESPA 2022 in Berlin, Fujifilm will use FESPA 2023 to present developments to its existing Acuity models, as well as unveiling an entirely new machine in the line-up. Additionally, Fujifilm will present more details on its partnership with industrial manufacturer Barberan, to bring single-pass inkjet to the sign and display market.

Click on the QR code to obtain your discounted ticket to FESPA

Visit acuit yprimeseries.com for more information or contact your local FUJIFILM representative to request print samples and organise a demonstration.

Use code FESuewDLD75

Visit acuityprimeseries.com for more information or contact your local FUJIFILM representative to request print samples and organise a demonstration.

FUJIFILM Australia1300 650 504

FUJIFILM Australia1300 650 504

https://avolio.swapcard.com/fespa2023/registrations/Start%20Exhibitor%20Visitor%20Tickets?_pc=FESuewDLD75

FUJIFILM Australia 1300 650 504

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM Business Innovation Australia 13 14 12

FUJIFILM and Fujifilm Value from Innovation are trademarks of FUJIFILM Corporation. ©2021 FUJIFILM Corporation. All rights reserved.

FUJIFILM and Fujifilm Value from Innovation are trademarks of FUJIFILM Corporation. ©2021 FUJIFILM Corporation. All rights reser ved.

FUJIFILM and FUJIFILM Value from Innovation are trademarks of FUJIFILM Corporation. ©2023 FUJIFILM Corporation. All rights reserved.

Stand B10 Hall A1 | 23-26 May 2023 | Messe Munich

The case for sustainability is real. No longer is it just a ‘green’ buzzword or just the tick of a box for businesses to show that they are doing something in that space.

The industry genuinely cares for the well-being of the earth and the future generations that will be born into it. It has and continues to take the necessary steps to ensure that it has a wholesome sustainability and environmental responsibility plan in place – and in some cases, has implemented out-of-the-norm strategies. As a result, not only are many businesses within the industry decreasing their impacts on the environment, but they are also leading the way in educating customers and other industries about ways that sustainability can be done right.

This issue of Australian Printer looks at how some of these businesses have improved their environmental responsibilities and introduced sustainable systems within their companies.

There’s plenty in this issue for everybody to learn from. We hope you enjoy the read.

FESPA Aust sets vision for 2023, welcomes IVE’s Bianca Martin as

new board member

By Colleen Bate

FESPA Australia has announced its vision for 2023 and the re-appointment of its existing board members, along with the appointment of Bianca Martin to the position of public relations director.

IVE Brand Activations commercial manager Bianca Martin brings a wealth of experience in the printing industry, and the Association said her communications and media relations expertise will be a valuable asset to FESPA Australia as it continues to promote the industry and its members.

The remaining existing board members were re-appointed, with Nigel Davies remaining as president, David Asker as vice-president, Mark Brooks as treasurer, Keith Ferrel as honorary secretary, and Matt Ashman as supplier director.

FESPA Australia said their wealth of industry experience and leadership will be essential in guiding it towards its goals for 2023.

“I am excited to have Bianca on board,” FESPA Australia president Nigel Davies said.

“As well as her commercial skills and relationships, as a FESPA Future Leaders program graduate, she has the unique insights which will drive success in our Mentoring, Training and the 2023 Future Leaders Program.”

Durst Oceania managing director Matt Ashman said, “I’m really proud that the FESPA board has allowed me to continue in my role

for another two years. FESPA is the premier trade organisation that globally represents the best interests of all industry professionals within our market segment.

“It is also great to have Bianca join us from an exciting business such as IVE. I’m really looking forward to working with her to grow FESPA Australia’s membership and deliver more support and innovation to our members.”

At the Annual General Meeting on 26 April, FESPA Australia also presented its plans for 2023 and beyond.

The Association said it will build on the success of its inaugural Future Leaders program and Conference with a stronger emphasis on networking and facilitation. Working with the Future Leaders cohort and FESPA global associations, it will focus on attracting and retaining new people in the industry with a new training initiative.

With a strong leadership team and a clear vision for the future, FESPA Australia added that it is committed to advancing the industry through collaboration between suppliers and print service providers on the issues that matter to it.

The FESPA Conference for 2023, which co-locates with the ProPrint Awards, will be held on 3 November.

Australian Printer is published bi-monthly by Printer Media Group (a division of Charted Media Group and The Intermedia Group). This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken n the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication.

DISCLAIMER

This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information.

All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2023 — Charted Media Group Pty Ltd

SPRINTER.COM.AU 6 | AUSTRALIAN PRINTER MAY 2023

NEWS

FESPA Australia’s new public relations director Bianca Martin

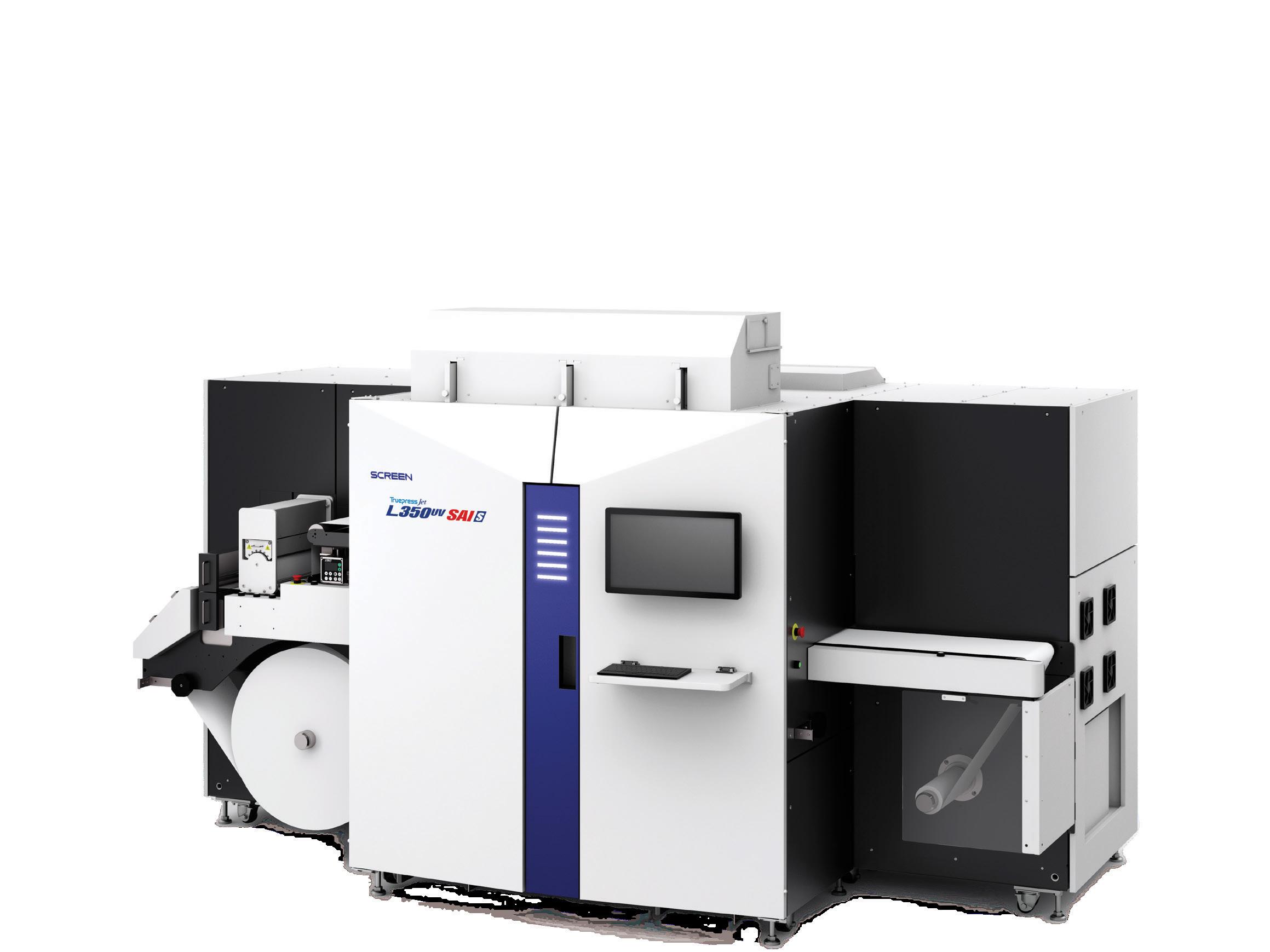

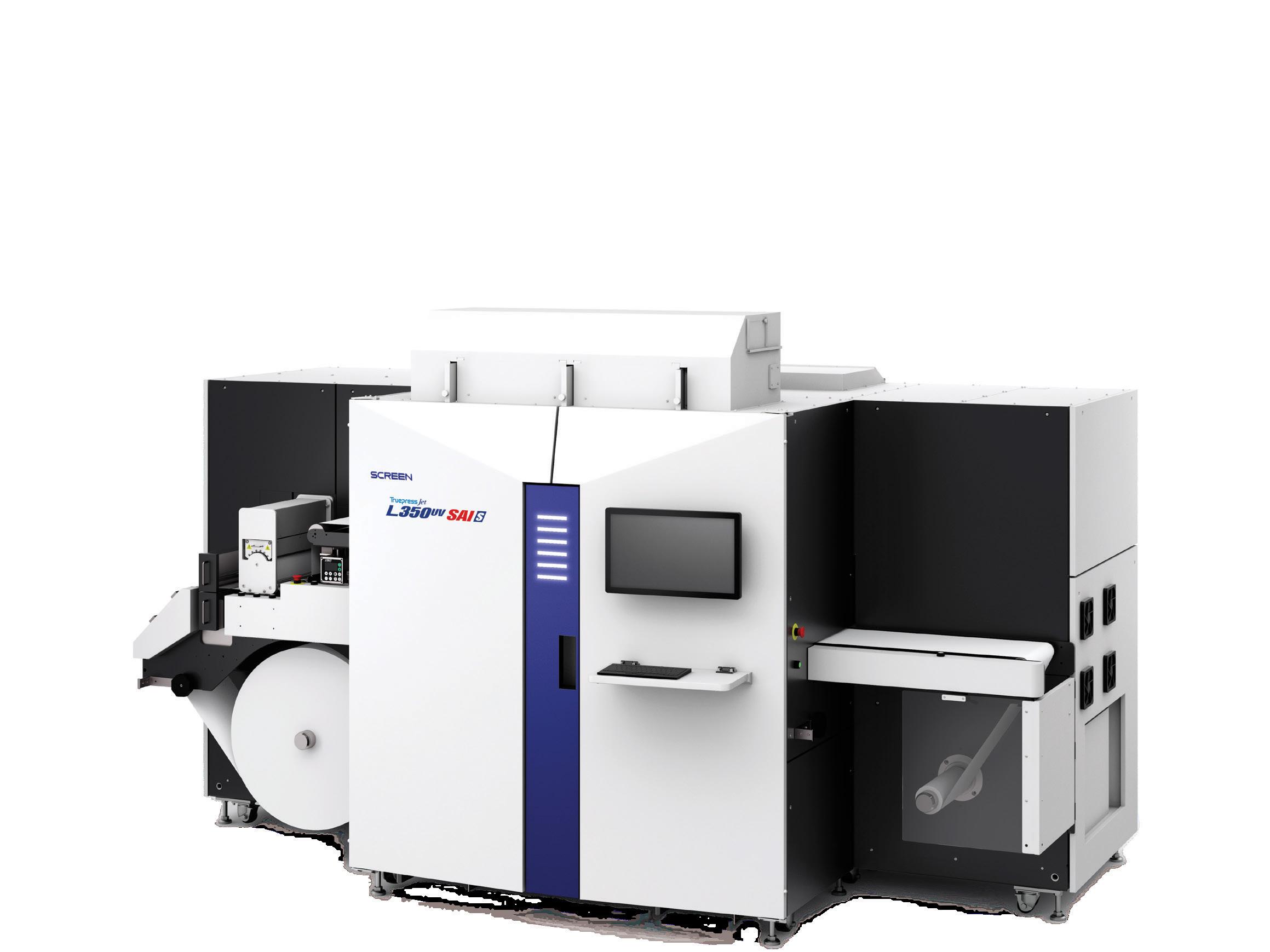

THE BEST-SELLING INKJET PRESS

in Australia, New Zealand, & SE Asia

TAKE A FRESH LOOK AT L350UV SAI

Screen L350UV SAI series deliver:

• NEW High opacity white

• Industry-leading productivity (up to 60m/min)

• Highest reliability (>93% Uptime)

• Ability to upgrade on site

• Chiller for thin and heat-sensitive substrates

• Reverse feed (material saving)

For more information, please contact us here:

David Reece

• Expanded colour gamut

• Up to 7 colours including blue, orange & white

• Hybrid integration ready

• Fully supported by local factory-trained technicians

• User-friendly EQUIOS workflow integrates with MIS

P: +61 2 8399 4999 M: +61 488 190 290 dreece@jet-ap.com / 19 Rosebery Ave. Rosebery, NSW, 2018

NEW

www.jet-ap.com

Connect with us

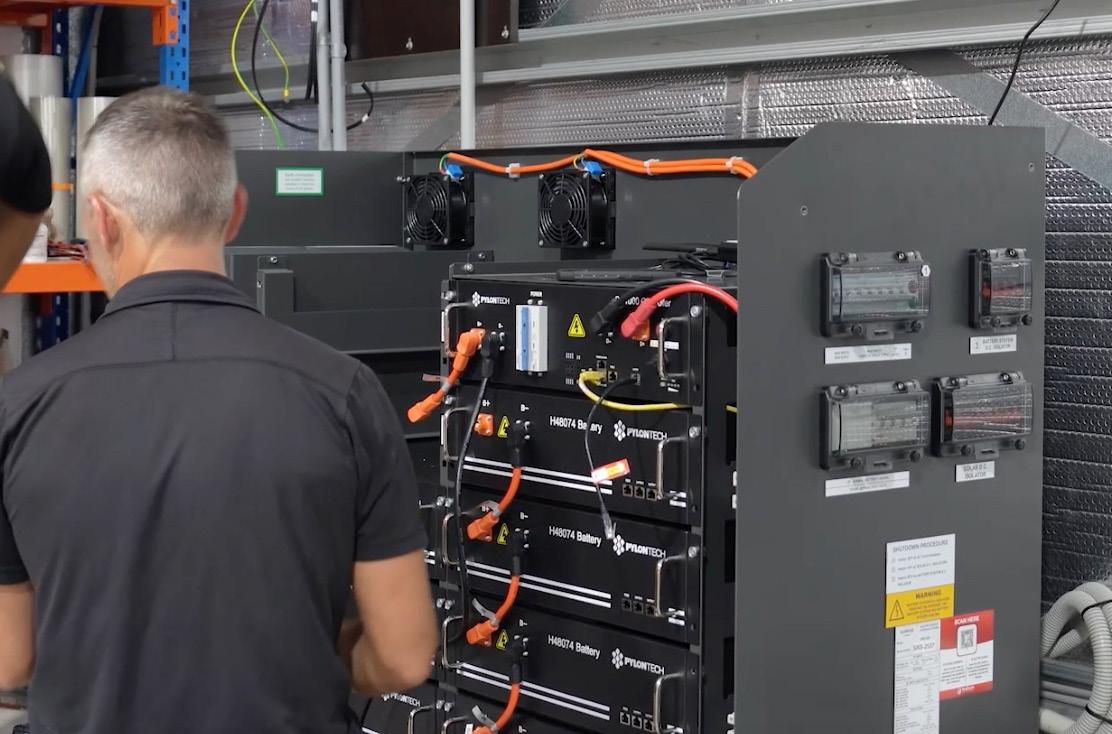

Perth’s Kingman Group wraps RAC’s new electric vehicles

By Hafizah Osman

Perth-based signage company Kingman Group recently completed the wrap of RAC’s new electric vehicles and its driverless bus, known as the RAC Intellibus.

The RAC Intellibus is a new machine that uses a combination of technologies, including a 3D mapping system, to create a comprehensive understanding of the surrounding environment.

“We take pride in working with RAC to create environmentally friendly solutions for its business. Our team at Kingman Signs is experienced in designing and installing vehicle wraps that are visually appealing, durable, and effective in promoting our client’s brand. We understand

that businesses are continually evolving, and we are here to help them stay ahead of the curve,” Kingman said.

“We believe that these initiatives from RAC are a step towards a more sustainable future and will encourage more people to consider electric vehicles as a viable and economical option. Thanks again to RAC for entrusting us with this project.”

Kingman has had an ongoing partnership with RAC, having completed signage for many of its parks and resorts, office buildings and RAC Arena.

“At Kingman, we are delighted to have been involved in both

projects as they align with our values in the support of sustainability. Our team of experts worked tirelessly to complete the wraps for RAC’s electric vehicles, ensuring they looked stylish and professional,” Kingman said.

“The EVs are being used for an exciting and innovative project at RAC, where they’re giving 50 of their members the opportunity to trial one of the EVs for a week.

“This trial aims to give more Western Australians the chance to experience life with an EV, share their learnings and help RAC understand how it can support its members with the transition to low or zero emissions vehicles.”

Kingman has also manufactured and installed its own EV charging station, offering customers custombuilt, environmentally friendly charging ecosystems that can provide shade, solar, seating and more.

A complete range of certified EV chargers for businesses is available, including the Apollo, featuring a fully integrated 55-inch digital screen.

Kingman is also the exclusive supplier and installer of Hydra’s range of AC and DC Electric Vehicle Chargers in Australia. Hydra chargers were designed to meet the growing global demand for electric vehicle infrastructure and have been installed in over 5,000 locations globally.

NEWS

SPRINTER.COM.AU 8 | AUSTRALIAN PRINTER MAY 2023 Nominations open now TICKETS ON SALE NOW

RAC’s new electric vehicle, wrapped by Kingman

Breen Printing celebrates 50th anniversary in style

By Colleen Bate

By Colleen Bate

Breen Printing has turned 50, with the company celebrating the milestone at the Healesville Amateur Race Club, where friends, family and VIPs who have supported them on their incredible journey shared in the festivities.

Among the guests were Lindsay Banks who has been involved with Breen Printing over the three generations; Chris Gander who has helped the company

employ three key staff in recent years; Tim Mahoney from Spicers and Peter Broman who trained Breen Printing’s joint MD Kirsty Woodhead as an apprentice 23 years ago.

“We’d like to thank all of those who celebrated with us. The weather was perfect, the company was friendly, and the day was thoroughly enjoyed by all,” Kirsty Woodhead said, acknowledging

the company’s two generations of owners in attendance, including Peter Breen, involved from 2 April 1973 and Derek and Merinda Jones, involved from 1 July 1987.

Kirsty and Luke Woodhead have been working at the company since 1 July 2020.

“Luke and I are proud to be the third generation running Breen Printing. We’re privileged to be able to celebrate such a big milestone with a great community who have been a big part of our journey. Breen has continued to grow and evolve with this everchanging industry and has been proudly located in Healesville for the entire time,” Kirsty said.

“I’m honoured to be part of Breen Printing’s story and thrilled to be celebrating such a significant milestone with some amazing people,” Luke said.

“Breen Printing is a great little business with huge potential. I’m proud of what our team have achieved in the short time we’ve held the reins and I’m excited about what Breen Printing will become in the future.”

Kirsty also extended a special thanks to all current team members, partners, clients, and suppliers helping build “what Breen Printing will become in the future”.

“We can’t wait to see where this part of the journey takes us. Cheers to you and the next 50 years!” she said.

NEWS

SPRINTER.COM.AU AUSTRALIAN PRINTER MAY 2023 | 9 For more information about becoming a sponsor and to nominate please visit: www.proprintawards.com.au Sponsors announced so far

Platinum Gold Silver

Breen Printing’s joint managing directors Kirsty and Luke Woodhead

Foxcil ceases all production and closes its doors

By Hafizah Osman

NSW-based label, flexibles and point-of-sale printer and manufacturer Foxcil has ceased all production and has closed its doors as its owner Roger Kirwan exits the industry.

Kirwan said the company decided to cease production and manufacturing as it could not keep up with the costs associated with retooling using the latest technology and equipment.

“Over the past 10 years, it has been my privilege to build and grow the Foxcil business with some of our industry’s most driven and innovative people,” he said.

“Innovation and retooling are essential in print to remain current and continue producing exceptional results. Sadly, the costs associated with [it] is something we at Foxcil can no longer keep up with.”

All of Foxcil’s outstanding customers have been transitioned over to its friendly rival Guru Labels, with Foxcil general manager Carl Butchard joining the Guru team to continue to ensure the needs and expectations of Foxcil customers are met moving forward.

“Meeting our customers’ ongoing needs and expectations has always been at the heart of what we do, and to that end we have asked our friends and trusted print partner Guru Corporation to step in and service our customers’ needs going forward,” Kirwan said.

“Guru is one of Australia’s most trusted and innovative label manufacturers that operate a state-of-the-art print facility in

Lithocraft’s Kevin Pidgeon named as PVCA deputy president

By Hafizah Osman

By Hafizah Osman

Lithocraft co-founder Kevin Pidgeon has been named as the new Print & Visual Communication Association (PVCA) deputy president for 2023.

Pidgeon replaces Spot Press managing director John Georgantzakos who held the title previously.

Lisarow on the NSW Central Coast. Nick and the team have over 22 years of print experience and have recently invested heavily in the latest label technology.

“For these reasons, and for the synergies in print and finishing equipment between our businesses, they have been uniquely chosen to service the Foxcil customers. Foxcil customers can continue to contact and deal with Carl directly going forward. All existing Foxcil communication channels remain open and will feed into Guru.”

Foxcil’s existing plant and equipment, including its digital label presses, CI solvent press, label finishing equipment and factory fittings, were auctioned off in midto late-April with Grays Australia online.

“I am saddened that this is how Foxcil will end, but I am very pleased that this has resulted in the ongoing employment of my friend and “right hand man” Carl. Our remaining Foxcil staff have been assisted in finding new roles within the industry, whilst some are taking the opportunity to travel or open exciting new chapters in their lives,” he said.

“I would personally like to thank all my staff for their loyalty and hard work over the past 10 years. For me personally, after being in senior management print positions for over 20 years, the time has come for

me to call time on this chapter in my life. I would like to thank Nick and his team for stepping in, welcoming Carl, and ensuring Foxcil customers have continuity of supply.

“I have loved the industry, and I value the many connections and friends I have made through the years.

“It is time for a new chapter in my life, most likely outside of the industry.”

Guru Labels owner Nick Lowe said the company is saddened to see the Foxcil business finalise in this way but is humbled to be approached to look after Foxcil’s customers moving forward.

“Guru and Foxcil have been responsible for pushing both businesses to excel over the past decade, providing everything from healthy competition through to cooperative joint ventures,” Lowe said.

“We have always held Roger and his team in high regard, and they should be proud of the business they have created in the digital label space.

“We are thrilled to welcome Carl to the team and we look forward to extending his journey in the print industry by continuing to promote quality label products and service under Guru Corporation.”

last year, with IVE Group CEO Matt Aitken resuming his role as PVCA president.

Lamson Group CEO Rodney Frost and The Label Factory managing director Stuart Fysh have again taken on the roles of treasurer and honorary secretary respectively.

These office bearers will hold the above-mentioned positions for the 2023 calendar year.

The election processes were administered by the Australian Electoral Commission.

The announcement was made alongside the election of the rest of the PVCA board office bearers, who were elected from and by members of the PVCA board. Pidgeon is the only new board office bearer from

PVCA formally appointed Kellie Northwood as its CEO in October last year, following the recent merge with The Real Media Collective.

NEWS

SPRINTER.COM.AU 10 | AUSTRALIAN PRINTER MAY 2023

Rog er Kirwan (centre) and the Foxcil team

Lithocraft co-founder Kevin Pidgeon

Graph-Pak appointed as Australian agent for Yoshino

By Colleen Bate

Graph-Pak has been appointed as the local agent of Yoshino, the largest perfect binding manufacturer in Asia. Currie Group was the local agent of Yoshino in the 1980s.

Yoshino complements Osako’s book binding products, which have been distributed locally by Graph-Pak since the company took over distributorship from Print & Pack in November last year. Yoshino and Osako products are manufactured in Japan.

“Osako is a well-established brand in Australia, so our customers were pleased to hear that we have taken over the local distributorship of Yoshino products too,” Graph-Pak managing director Tom Ralph said.

He explained that the agreements between Graph-Pak, Osako and recently Yoshino, were seamless and came about “fairly quickly”.

Graph-Pak currently sells Osako’s Tener and Tener Alpha high-end saddle stitching machines, which Ralph said improves bookbinding efficiency by enhancing inspection equipment and automation with additional expanded value.

Ralph said he is excited that Graph-Pak is also bringing Yoshino’s Sirius and WB 18 machines to the Australian market for the first time.

“Sirius is a small-sized perfect binder, which is equipped with a two-roller gluing system, has a clamp equivalent to a large-sized model and operates at a speed of 5000 rph,” he said, pointing out that in contrast, the WB18 is a spacesaving perfect binder which offers a one- or two-roller gluing system, and operates at a speed of 6000 rph.

Ralph said there has already been quite a lot of interest in Yoshino’s products from Graph-Pak’s existing customers.

“I have 13 projects planned between the two brands at the moment, which isn’t too bad,” he mentioned.

As the Yoshino’s book binding machines are huge and take up around 30 square metres in space, Ralph said potential buyers may have to travel to Japan to inspect one, and that the machines are basically purchased “spec on demand”.

He pointed out that this is not the case with the Osako brand, however – there are currently 20 Osako Tener machines installed in Australia, which he said makes it easy for GraphPak to arrange viewings for interested parties at local customer sites.

“We will be offering some good prices to launch these Yoshino machines in Australia,” he added, confirming that Graph-Pak will also be selling factory refurbished machines, which “look like new”, include a warranty and are about 30 to 40 per cent of the price of a new machine.

ROLAND 700

Technological powerhouse.

The widely acclaimed ROLAND 700 EVOLUTION litho press deploys an array of innovative technologies to give unprecedented levels of efficiency, productivity and print quality.

SPRINTER.COM.AU AUSTRALIAN PRINTER MAY 2023 | 11 NEWS

manrolandsheetfed.com The Evolution of Print. manrolandGoss - Australasia Tel: +61-2-9645-7900 info.au@manrolandgoss.com

ManRo_PM_Leopard_88x258_23-08-19.indd 1 23/08/2019 17:02

Graph-Pak managing director Tom Ralph with a Sirius perfect binder

ACM heavily downsizes its newspaper portfolio

By Hafizah Osman

Australian Community Media (ACM) has further consolidated its newspaper portfolio as the company gets impacted by increased newsprint costs and a shift in advertiser spending.

The company has shut down or sold nine more mastheads, in addition to the four regional Western Australian newspapers that ceased in the week of 24 April.

According to The Sydney Morning Herald, when the announcement was made, an email was sent to staff with ACM managing director Tony Kendall telling them that the business “was in the process of selling seven titles in the NSW centralwest and south-west regions after receiving an approach by Provincial Press Group”.

In addition, the report also identified that this move follows the sale of several titles in Queensland and South Australia to newspaper company The Star Group.

ACM has also confirmed the closure of its Queensland community mastheads the Jimboomba Times and Redlands City Bulletin via their respective websites.

As for the closure of the four regional Western Australian newspaper mastheads, the Mandurah Mail, Bunbury Mail, Busselton-Dunsborough Mail and Augusta-Margaret River Mail newspapers are the affected publications, and all issued statements on their respective websites on why the publisher ceased printing in April.

They said ACM had briefed staff about the changes and informed them about plans to retain journalists to continue to work on local news coverage via the Mandurah Mail and Bunbury Mail’s websites.

The publications added that “increased newsprint costs and a shift in advertiser spending” were the reasons for the decision to stop printing the newspapers.

“This decision has not been made lightly as these newspapers have been serving these communities in south west WA for many years,” ACM managing director Tony Kendall said in the reports.

“Unfortunately, the rising costs of newsprint and the shift of advertising spending to digital platforms has made these titles unprofitable.”

An ABC report also indicated that a Mandurah printing facility run by IVE, which prints ACM’s closing newspapers, will soon be closed.

In May 2021, ACM’s executive chairman Antony Catalano mentioned that the company was moving towards digital and away from manufacturing.

That same month, ACM announced that it was turning off its presses at North Richmond at the end of June, leaving an association that represents regional newspapers in NSW “assessing options” about where it will send its publications to be printed.

SPRINTER.COM.AU 12 | AUSTRALIAN PRINTER MAY 2023 IVE MAY 2022 1.0 1.5 2.0 2.5 3.0 MAY 2023 NEWS CORP MAY 2022 22 24 26 32 30 28 MAY 2023 AGFA MAY 2022 2.0 2.5 3.0 3.5 4.0 MAY 2023 UPM MAY 2022 1.0 1.5 2.0 2.5 MAY 2023 NEWS: BUSINESS

Amcor 16.52 0.49 19.03 15.94 IVE 2.41 0.41 2.76 1.38 News Corp 26.00 3.53 30.74 21.89 oOh!media 1.66 0.10 1.72 1.04 Redbubble 0.39 0.78 1.56 0.38 Adobe 377.67 36.28 451.15 274.73 Apple 165.02 2.14 176.15 124.17 Canon 22.31 0.28 25.79 20.84 Fujifilm 51.26 5.40 57.75 44.30 News Corp 17.44 0.01 21.86 15.15 Xerox 13.76 3.90 19.40 11.80 Agfa 2.89 1.02 4.16 2.44 Heidelberg 1.71 0.43 2.36 1.09 Koenig & Bauer 19.00 3.13 23.70 10.70 Metsa Board 8.28 0.06 20.15 10.70 UPM 29.64 1.96 37.14 28.32 NYSE (US$) ASX (AUD$) DAX (EURO) PRINT STOCK WATCH: APR 01 TO MAY 01 Price Price Price Change Change Change Year High Year High Year High Year Low Year Low Year Low

XEROX MAY 2022 12 14 16 18 20 MAY 2023 FUJIFILM MAY 2022 45 50 55 60 MAY 2023

ACM has shut down or sold several of its newspaper mastheads in Australia

Labels, Flexible Packaging High Volume Digital ComputerTo-Plate Automated Workflow

SCREEN Truepress Jet 520HD with SC inks – the digital inkjet press that prints superb colour on standard offset stocks.

SCREEN Truepress Pac 830F Digital flexible packaging using aqueous inks across 830mm web.

SCREEN Truepress Jet L350UV SAI digital label press. Up to 7 colours inc. White & High Opacity White. 60 m/min across 350mm web.

SCREEN GP Australia Pty Ltd Tel: +61-(0)2-9016-3400 • Toll Free: 1300 305 118 • sales@screenaust.com.au • www.screenaust.com.au

SCREEN PlateRite 8600NII New generation 8-page thermal CtP with fiber laser diodes. Up to 32 B1 plates/hour.

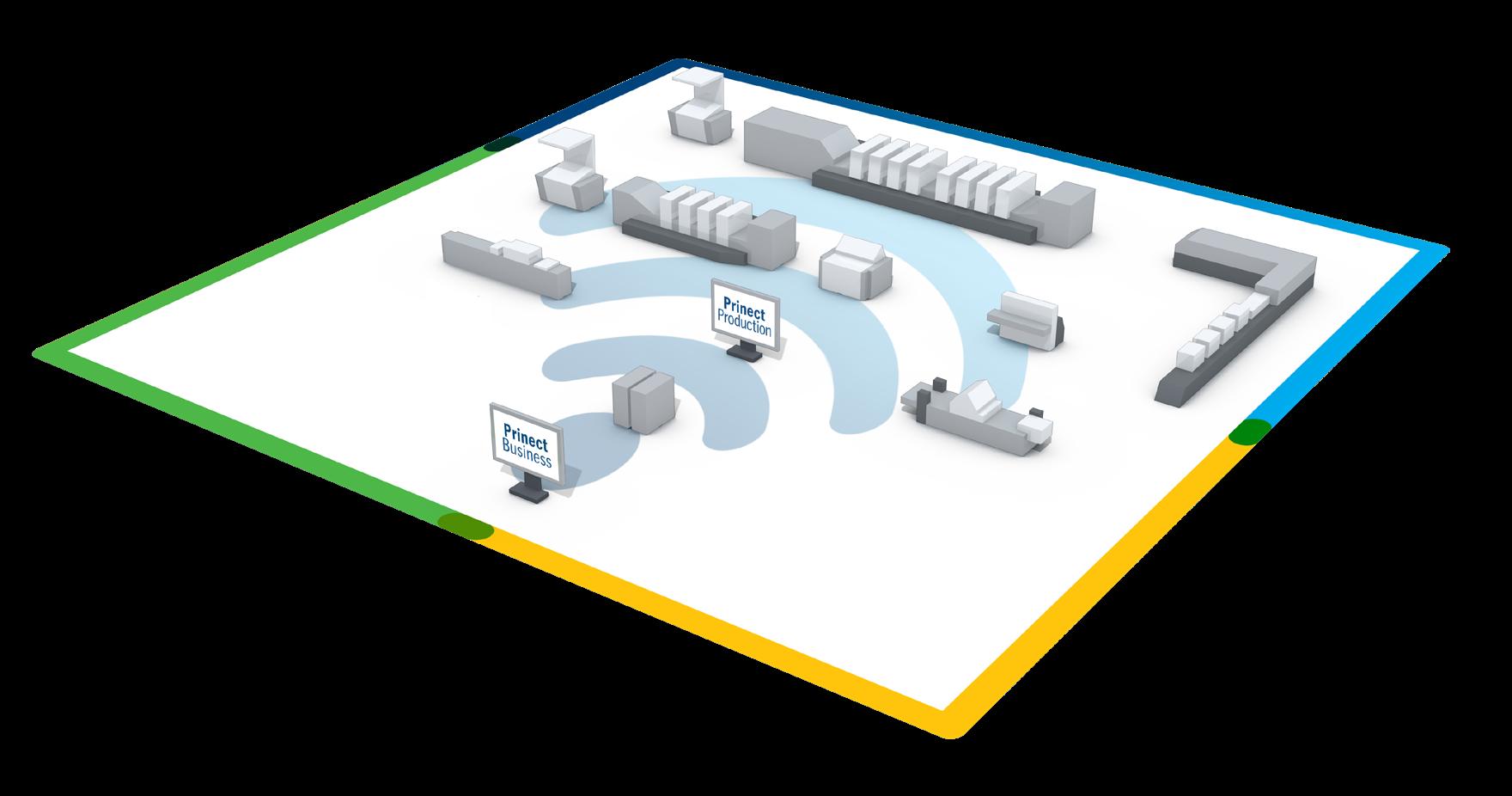

Heidelberg’s Prinect workflow allows its customers to stay ahead and benefit from a digitised world

Heidelberg optimises production with its intelligent systems

Heidelberg has equipped its solutions with the most intelligent systems to enable print shops to optimise every aspect of their production

Today’s printshops are facing increasing challenges, such as shorter run lengths, faster turnaround times, increasing costs, competition for talent and declining print prices. Therefore, it’s important now, more than ever, that print shops are optimise every aspect of their production to stay competitive and profitable.

To help print shops alleviate these challenges, Heidelberg has fitted its solutions with intelligent systems that control the harmonious interaction of six key factors:

1. The integration of customers

Web portals simplify communication and automate workflows. The result that print shops get is more efficiency, more customer service and in turn, more turnover.

2. The reduction of touchpoints

Fewer touchpoints and more automation unleash unrealised potential. This results in visible throughput increases.

3. The increase in productivity and operating time

Efficient planning and automatic data availability increase the operating time and productivity. This means profits for print shops increase.

4. The reduction of paper waste and warehousing

The use of optimal materials ensure reproducible production. When this occurs, paper waste decreases.

5. The optimisation of consistency and reproducibility

Standardisation provides certainty and

consistency. As a result, production becomes more predictable.

6. Having business intelligence

Having insight into business intelligence delivers sound information for print shops to utilise. This means they can make decisions based on real facts.

BENEFITS OF DIGITISATION

Digitisation offers the printing industry a great many opportunities. But anyone looking to harness these opportunities need to actively shape this process of change.

As such, Heidelberg’s Prinect Production solution reorganises the production workflow, ensuring the basis for increased cost-effectiveness, consistently high

COVER FEATURE

SPRINTER.COM.AU 14 | AUSTRALIAN PRINTER MAY 2023

performance, and outstanding quality. Many processes are completely automated, thus providing a smart boost to the success of a print shop.

In addition, Heidelberg’s Prinect workflow allows customers to stay ahead and benefit from a digitised world.

Two leading Australian print companies provide their comments on how they have benefitted from using Heidelberg’s digitisation solutions:

Southern Impact managing director Rod Dawson said, “Prinect gives us a lean production workflow, a consistent quality outcome, accurate repeatability, and transparency across the entire production – which in turn helps to identify any bottlenecks and uncover potential areas for further improvements”.

NEO general manager Clinton Daley said, “A print company’s workflow is the beating heart of its manufacturing process that has enormous ramifications on output – both in speed and quality.

“When it came to aligning ourselves with a business, we felt that Heidelberg was the natural fit. My family’s relationship with Heidelberg would be getting close to a hundred years. The choice of Prinect was simply a natural evolution of this long-standing relationship and we knew in Heidelberg that it was a company that would help us grow and share the same industry-leading mentality that we as a company strive to have.”

ENHANCING PRODUCTION

Prinect Production offers enhanced performance thanks to intelligent processes. It digitises a print shop. In addition, it automates production and colour and quality management while also providing key data for analyses and reporting. It keeps customers coming back and maximises performance with a smart workflow.

The new Heidelberg philosophy

Push to Stop is Heidelberg’s idea of a smart print production. It is based on networked processes and intelligent

machines that organises and works through print jobs independently with full autonomy. The operator only has to intervene if necessary. Print shops can increase the overall effectiveness of their machines and can almost double their net productivity, enabling them to become a Smart Print Shop.

Save time and money with Prinect

For Push to Stop to become reality, new and improved processes are required that provide all the necessary production data. Prinect is the tailored solution for successfully implementing this philosophy of the Smart Print Shop with Push to Stop. Prinect Business supports printers in the automation of their commercial processes and production. Prinect Production covers the actual production workflow – from the pre-press modules through to offset and digital press to post-press.

A decisive step that puts a printer ahead of the competition

Whether a company is small or large, or whether it is a commercial or packaging printer, Prinect reduces all touchpoints.

COVER FEATURE

SPRINTER.COM.AU AUSTRALIAN PRINTER MAY 2023 | 15

Prinect Production keeps customers coming back and maximises performance with a smart workflow

Wit h Prinect, users always have an overview of the workflows, the utilisation, and the economic efficiency of their print shops

In other words, the process steps and manual interventions involved in order acceptance, data transfer, or post-processing is kept to a minimum. Users always have an overview – of the workflows, the utilisation, and the economic efficiency of their print shops – and can react directly.

The perfect solution for the Smart Print Shop

Prinect Production transforms a print shop’s workflows. Manually controlled operations involving a wide range of touchpoints are replaced by intelligent networking and automated processes. Touchpoints are reduced and flexibility increased.

With Prinect Production, printers are closer to their customers and integrate them directly into the workflow. Data entered online controls processes throughout production and quality management. Digital approvals speed up production times and increase productivity. Moreover, as efficiency increases, so too does the satisfaction and loyalty of their customers.

It also lets printers reduce waste and storage through standardised quotations, perfectly coordinated consumables, and defined processes. This means printers can use their time, machines and materials more efficiently, while simultaneously optimising consistency and repeatability. Pave the way for Push to Stop by using intelligent machines that organise and work through the production process independently. With Prinect Production, most operations can be carried out based on navigated or autonomous control.

Prinect Production also makes it possible to unlock the full potential of a print shop. Integrated business intelligence functions can be used to produce reports for corporate management and production that are intuitive to understand.

Accurate data and sound analyses reveal error sources before damage occurs. Real-time data capture and evaluation ensure you are always up to date on current processes.

Printing was never so easy. How Prinect Production increases your productivity

• Offers portal functionalities to optimise selling and communication process

• Enables powerful job setup, planning and presetting, eliminating manual intervention that keeps presses up and running

• Includes fully-automated plate production including pre-flighting, imposition and more

• Has press room and finishing integration, delivering best data to drive Push to Stop production philosophy

• Provides significant analysis and reports, changing the way printers make their business decisions

• Offers maximum freedom with one workflow, whether a printer produces with toner, inkjet or printing plate

• Provides everything needed and much more – no matter where a print shop wants to extend its business, Prinect Production is ready for commercial, packaging and labelling.

That is Prinect – Driving the Smart Print Shop Prinect Production Manager provides a full suite of software productivity tools that help printers attain the highest levels of productivity in their print shops through an easy monthly subscription fee. Some of the benefits include:

• Low initial startup costs that lets users take advantage of Prinect Production Manager solutions without the big upfront capex or the need for financing

• Simple subscription model: Complex, expensive license models are a thing of the past with an easy and transparent monthly usage fee that follows a printer’s production volume.

• All the latest upgrades and new technology from Prinect Production Manager with the monthly subscription. This is safety that a print business deserves.

• Scalability of workflows and introduce new Prinect solutions into a print shop at a printer’s own pace.

• Return on investments from productivity and efficiency gains with powerful workflow tools like presetting, multi-colour, gang printing, smart automation and more.

Printshops are rapidly adopting Prinect Production Manager on the road to building a Smart Printshop. Currently, Heidelberg has more than 2,000 Production Manager subscribers worldwide, with 65 of them based in Australia and New Zealand. Heidelberg continues this growth by adding 400 new systems globally every year.

COVER FEATURE SPRINTER.COM.AU 16 | AUSTRALIAN PRINTER MAY 2023

Prinect Production Manager provides a full suite of software productivity tools that helps printers attain the highest levels of productivity

Being an approachable person

closely with her over the past five years, and I look up to her greatly as a woman in a leading role.

“She may not even know she has equipped me with some of these skills, but I watch her and listen to her and see her capabilities first-hand – this makes her the successful general manager that she is today.”

As a woman in print, Morgan also finds inspiration in some of Ricky Richards’ female customers.

“Some of the print customers we work with are owned and run by females and I love knowing that in an industry that is quite often mistaken for a man’s line of work, that the females I know here are smashing goals and producing print designs, products and highly-regarded projects that are next-level,” she said.

Having joined the industry by chance in 2010, Kelly Morgan compares herself to an “excitable puppy” when it comes to learning about all that print and visual communications has to offer.

As the marketing and events executive at specialised textiles and wide-format print media company Ricky Richards, Morgan enjoys the diversity in her role and the cross-over of dealing with people in other industries.

“I started working at Ricky Richards in July 2010 after the company was introduced to me by a friend. I was in between jobs, having worked for nine years before that at the charity Jeans for Genes Day on events and the fundraising campaign itself. I literally fell into the textiles and printing industry without much thought and have never looked back,” she said.

“My printable product knowledge has developed while working with the team at Ricky Richards, but overall, I am still like an excitable puppy when I see or hear about designs on these products coming to life during and after the printing process. The most interesting elements of my job are the diversity in my role – no two days are ever the same – but also the crossover of industries that I work within. At Ricky Richards, I am fortunate

that working in the marketing team permits me to work in all our three divisions.

“This includes the Technical Textiles division where we supply textiles for the likes of projects and applications featured all around Australia, the Sun Control division which is primarily highend outdoor fabrics for blinds, awnings, and upholstery, and our Printable Products division which slots me into this printing industry.”

Morgan said the changes in the printing industry has kept her on her toes and that she’s constantly learning about the new and improved. But more importantly, the professional relationships that she has forged have taught her aplenty.

“There is always something new happening in this industry. Sure, the technology has changed, and the printable products have gotten better and more sustainable,” she said.

“But besides that, the people in this industry are often fast-paced individuals that are forward thinking and always developing the next project before they finish one. I’ve learnt plenty from them.

“There is no one that has taught me more about leadership than our own general manager, Kathryn Polgar. I have worked

“Ricky Richards always seems to have females in leading roles. In all the industries we cross over, we have always had the largest group of females working for us and they are all very inspiring individuals.

“The number of women in print that I see now is a high number that continues to grow. I am proud of this and love seeing it evolve this way.”

According to Morgan, supporting the next generation of females wanting to work within this industry is important and is one way that those in print and visual communications can give back.

“It is all about educating everyone on what working in this industry involves and what it can become so it never dies out. The easy start is to just share this knowledge with the people that we know, be it our family or friends.

“Women are also more proactive in getting the message out there about how good it is to work in the printing industry. It is a lot of fun, and the younger generation and those outside of the industry need to be exposed to this.

“I would like to be an advocate for the print industry but also be a person that the people I work with trust. I would like to be seen as someone that they can approach for a chat if they need advice or just someone that can lend a listening ear for anything, really.”

WOMEN IN PRINT

SPRINTER.COM.AU 18 | AUSTRALIAN PRINTER MAY 2023

Ricky Richards marketing and events executive Kelly Morgan

As the marketing and events executive at Ricky Richards, Kelly Morgan finds that the changes in the printing industry has kept her on her toes

CREATION OF NEW DIMENSION IN DIGITAL PRINTING

Mark McEwan, Director of Label Concepts, is the proud owner of the Dimense printer.

Said Mark: “From the outset, I’ve enjoyed the candour and engagement with Abe Weiszberger, and the passion both he and Phillip Bouchard have shown towards achieving a successful outcome for our business. This product is an absolute game changer, and I look forward to our respective businesses growing in the surfaces market”.

dimense.com.au

Canon Production Printing launches new modular Colorado M-series

Canon Production Printing (CPP) has expanded its roll-to-roll printers portfolio with Colorado M-series, a modular 1.6m machine with two speed configurations and Canon UVgel white ink support.

The new large format printer has been developed to boost productivity and substantially expand the range of applications, supporting business growth with diverse graphics and décor applications.

Retaining Colorado’s industrial build quality, the new M-series design is based on a single platform that can be configured to customers’ needs and grow alongside their business with easy in-field upgrades.

The scalable series includes M3 and M5, two base models offering a choice of an output cruising speed of 29sqm/h and 40sqm/h and maximum print speed of 111sqm/h and 159sqm/h, respectively. Both printers can be easily upgraded to W versions for white ink (M3W and M5W).

Introducing a white UVgel ink maximises performance for a full spectrum of premium graphics and décor applications, such as window graphics, labels and wallpaper.

The Colorado M-series also features new media detection sensor technology for easy media handling, offering customers expansion of their typical product with heavy structured, transparent, coloured, reflective and magnetic materials.

The unique gel formulation of Canon UVgel ink translates to a fast build-up of dense and opaque white images in fewer passes than with conventional printing technologies, with printed output maintaining its original whiteness over time.

According to CPP, it also eliminates many production issues commonly associated with white ink, such as nozzle cleaning and maintenance, offering smooth, errorfree printing and minimising ink usage and waste while maximising productivity.

Customers can also choose the FLXfinish+ option to add matte, gloss or mixed matte and gloss on the same print without additional varnish. High-volume customers can automate the print-to-finish process with a UVgel Print Factory or

Like previous Colorado models, the M-series is designed to handle the workload of multiple legacy roll-to-roll printers

UVgel Wallpaper Factory configuration, which integrates the Colorado M-series printer with cutting, rewinding, taping or sheet stacking to manage volumes of at least 50,000sqm per year with minimal operator time.

“Ever since they burst onto the market, Colorado printers with UVgel ink have set the highest bar for speed, quality and all-round productivity,” Canon Production Printing Oceania managing director Craig Nethercott said.

“On top of these business-critical performance criteria, customers today want to make smart, environmentallyresponsible investments in large format graphics printing solutions that can evolve with them and help them tap into lucrative creative applications, products and markets.

“With the addition of an easy-care white ink option, the new modular Colorado M-series is the growth engine that businesses need to level up their capabilities and turn ideas into reality.”

CPP said UVgel ink delivers pin-sharp image quality and consistent colour, while its instant drying properties enable immediate

According to the company, compared to other ink technologies, such as latex or eco-solvent inks, UVgel technology consumes up to 40 per cent less ink to build up the same image quality and colour intensity.

The low-heat, energy-efficient LED curing system and instant-on operation reduce energy use compared to other technologies. With UVgel technology, customers can print on environmentally responsible materials, even uncoated, PVC-free, paper-based media. This means the Colorado M-series printer fits perfectly in a sustainability-conscious organisation.

Like previous Colorado models, the M-series is designed to handle the workload of multiple legacy roll-to-roll printers, with industrial-grade round-theclock reliability and unattended printing with minimal operator intervention.

It is supported by PRISMAguide software and designed with a low total cost of ownership and rapid return on investment in mind, thanks to the low operating costs, the ability to produce high-value applications, and the modular upgrade options.

The Colorado M-series is available via accredited partners and CPP’s regional direct sales organisations.

LARGE FORMAT PRINTERS

The new large format Colorado M-series is equipped with UVgel Ink support, including optional white ink, amongst other stellar features

SPRINTER.COM.AU 20 | AUSTRALIAN PRINTER MAY 2023

WHITE INK WITHOUT WORRY

Are you ready for the next level in productivity, creativity and profitability? With the Colorado M-series, now including white ink, say ‘yes’ to more jobs, create stunning applications and promise short turnaround times. It’s field upgradeable to grow with your business, and designed for a low cost of ownership.

DISCOVER MORE >>

Colorado M-series

Tasmania’s Mercury Walch wins Grand Diemen Award for print

The award was handed out at the recent Tasmania Diemen Awards, now in its ninth year, which recently took place at the Town Hall in Hobart

• Mona – The Best of Our Worst Reviews project – cinematography category

• Inclusive Creatives – BOFA Film Festival 2022 project – brand ID

• Studio Decade – Moonah Hotel & Cellars project – typography

Advertising/Communications

• Mona – The Mush Room project – ambient

• Red Jelly – Loud and Proud project – creativity for good

• Mona – Mona Foma project –art direction

• Inclusive Creatives – Be Open to Autism project – creativity for inclusion

• Advocacy Tasmania – ‘They Would Tell You’ project – copywriting

Mercury Walch has taken the top Grand Diemen Award in the print category for its Dorrie and Nobby Booklet, beating finalists Foot and Playsted and Mona for the win. The Diemen Awards, supported by diamond sponsors Print & Visual Communication Association (PVCA) and Media Super, and other sponsors, celebrate excellence in the Tasmanian creative and craft industries in four major categories: print, design, advertising/communications and digital.

In the advertising/communications category, Mona took home the Grand Diemen gong for its The Best of Our Worst Reviews project, which also won Judge’s Choice. Studio Decade won the Grand Diemen Award in the design category for its Moonah Hotel & Cellars project, while Adam Walker Film nabbed the Digital Award for its TasWater –Water Surety project.

Keynote speakers on the night included Kellie Northwood representing Media Super and PVCA, Zaidee Jackson from Ball & Doggett, Paul Fallon from Document Management Tasmania and Jens Kraeft from Southern Cross Austereo.

In a tribute to the late PVCA president Peter Clark, his son and daughter Richard and Sarah were presented with a special Diemen Award. Adam announced that the Print Apprentice of the Year Award would be renamed the Peter Clark – Print Apprentice of the Year Award to honour Clark’s legacy. This year’s Award went

to Hannah Coleman from Flying Colours. Other emerging talent were also recognised at the awards ceremony, with Mitch Williams from UTAS winning the Student of the Year Award, Jessica Stennings winning the Inclusive Work Award and Mark Acheson from Kindly winning the Young Executive of the Year Award. The other non-Grand Diemen Award winners include:

Print

• Foot and Playsted – West Coast Wilderness Railway Booklet –4-colour print

• Mercury Walch – Moulin Rouge Invitation – print embellishments

• Mercury Walch – Mercury Walch Pty Ltd project – book (offset)

• Mercury Walch – Dorrie and Nobby Booklet – book (digital)

• Flying Colours (Tas) – House of Fudge 100gm – packaging production

• Mercury Walch – Mary Poppins Opening Night Collateral – point-ofsale print production

Design

• Mona – Moo Brew Stout project –photography category

• Sam Lyne Illustration & Design –Eden Whisky project – illustration

• Angela Pelizzari –Deborah Wace Brochure – brochure, catalogue, booklet or publication

• Flying Colours (Tas) – House of Fudge 100gm – packaging production

• Mona – Mona Foma project –poster and large format outdoor

• Mona – The Best of Our Worst Reviews project – mobile

• Inclusive Creatives – Be Open to Autism project – radio

• Mona – Art Critic Dog Skivvy project – point-of-sale

• Cathy McAuliffe Design –MACQ-01 project – wild card

• Tom Chapman – Film Opening the Gate – King Island project –online video category

• Red Jelly – Believe Tasmanian project – effectiveness category

• Mona – The Best of Our Worst Reviews project – television or cinema

• Advocacy Tasmania – ‘They Would Tell You’ project – newspaper/ magazine category

• The20 – ‘The Shake Up’ project – social change

• The20 – ‘Let’s love our water’ project – integrated campaign

Digital

• Mona – the Mush Room project – innovation category

• The20 – ‘Let’s love our water’ project – social category

• The20 – Women in Construction project – website category

• Adam Walker Film – TasWater –Water Surety project – animation and visual graphics

• Mona – The Best of Our Worst Reviews project – sound design category

THE 9TH ANNUAL DIEMEN AWARDS

SPRINTER.COM.AU 22 | AUSTRALIAN PRINTER MAY 2023

Mercury Walch takes home the top Grand Diemen Award in the print category

Hilton Laminating are now the proud distributors of Rilecart Australia. We look forward to assisting you with all things

hilton@hiltonlaminating.com.au 1800

819 970

Gatsby themed spectacular at the 9th Annual Diemen Awards

The Tasmanian industry gathered to celebrate the best of the best at the Hobart Town Hall

The recent 9th Annual Tasmanian Diemen Awards saw winners across the categories of Advertising and Communication, Digital, Design and Print celebrated at the magnificent Hobart Town Hall. A Gatsby themed spectacular celebrated winners across each category as well as emerging talent.

THE 9TH ANNUAL DIEMEN AWARDS

SPRINTER.COM.AU 24 | AUSTRALIAN PRINTER MAY 2023

Adam Glover, Isobel (Flying Colours) representing Hannah Coleman (inaugural Peter Clark – Print and the Year recipient), Sarah and Richard Clark and Amr Elsayed

Amr Elsayed and Adam Glover with Doug Hagger and Sam Moffat – Studio Decade (centre) – Design Grand Diemen winner

Mit chell Williams - Student of the Year, Mark Acheson - Young Executive of the Year, Isobel Clark, accepting for Hannah Coleman - Print Apprentice of the Year and Inclusive Work Award winner - Jess Stennings

Adam Glover, Mark Acheson (Young Executive of the Year), Kellie Northwood and Amr Elsayed

Heath Collins (Cummins and Partners), Allan Didus, Zaidee Jackson, Michael and Carolyn Childs (Ball & Doggett), Kirsten Taylor (Taylor’d Press) and Phillip Mariette (Sierra Delta)

THE 9TH ANNUAL DIEMEN AWARDS SPRINTER.COM.AU AUSTRALIAN PRINTER MAY 2023 | 25

The Grand Diemen Awards

Amr Elsayed and Adam Glover with Gary Nilsson – Mercury Walch (centre) – Print Grand Diemen winner

Adam Glover, Jardin Anderson from Mona (Judges Choice winner), Mark Ringer and Amr Elsayed

Ball & Doggett’s Zaidee Jackson

Amr Elsayed and Adam Glover with Adam Reed – Adam Walker Film (centre) – Digital Grand Diemen winner

Amr Elsayed and Adam Glover with Michael Blake – Mona (centre) – Advertising Grand Diemen winner

Diemen co-chairs Amr Elsayed and Adam Glover with Diemen chair of judges Mark Ringer (centre)

Kerri and Sharon (Spicers Paper) with Adam Colgrave from Flying Colours (centre)

PVCA CEO Kellie Northwood

Adam Glover, Mitch Williams (Student of the Year), Kellie Northwood and Amr Elsayed

Hannah Coleman (Flying Colours) –Inaugural Peter Clark Apprentice of the Year

Sarah and Richard Clark with Adam Glover accepting the special Diemen Award for services to the Tasmanian Print Industry on behalf of their late father Peter Clark

The spectacular Hobart Town Hall

The awards were held at the Hobart Town Hall in Tasmania

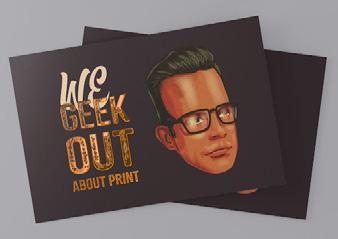

Victoria’s Revolution Print automates its business with printIQ technology

Revolution Print director Leon Wilson shares the company’s journey of how it went from being a bricks and mortar business to one that has embraced automation

Revolution Print, located in Alfredton, Victoria, has seen greater success since it started using printIQ and other tools to automate its business processes. The company, which was started in 1902, transitioned into the digital space about 18 years ago.

Its director Leon Wilson said the business was using an older MIS software and although it had a separate solution for an online print website that worked well, the two systems did not communicate with each other and provided no capabilities for production management.

Revolution Print then explored four different software solutions but could not find one that met all its needs until it came across printIQ about eight years ago.

The company implemented the system internally in about a year and launched it externally for trademarked locations and customers in what it calls its “corporate cloud” soon after.

Today, 70 per cent to 80 per cent of all orders for Revolution Print come through printIQ.

To further automate its processes, Wilson drove more functionality with tools such as Enfocus Switch.

How this works is, orders flow in from printIQ and the accepted job information is then moved into the production process, where artwork and impositions are automatically routed into the necessary “hot folders” to move to the next step in production.

This process allows the business to even receive orders on the weekend, which

staff can action when they come into the premises on Monday morning – the stack has about 400 jobs ready to be produced.

Running alongside the software investments, Revolution Print is one of only three installations in the whole of Australia with a B2 sheet-size digital inkjet press in the Konica Minolta AccurioJet KM-1.

It has also invested in equipment from MGI to offer digitally embellished finishing options. These capabilities have enabled the company to accept new businesses during the COVID-19 pandemic, especially when one of the largest printers in the world contacted it about producing premium luxury products that it wanted to offer as a reseller.

This capability brought in over $1 million in additional revenue each year for Revolution Print, with over 200 additional orders per day.

Making concrete decisions

Revolution Print’s confidence in the printIQ platform is strengthened by its accuracy with job costing, which allows the company to pull up any job and analyse the actual timing from start to finish, including the equipment used and the people that worked on it.

This type of analysis allows it to adjust its quoting for future jobs to increase profitability. The reporting functionality inside printIQ provides custom-built reports that are auto-generated and emailed every morning with the previous day’s job production totals and performance, allowing Revolution Print to focus on the big things instead of the small ones.

Wilson said he sees the software as an organic, living, breathing thing that is never complete.

“As it is software, there is always room for improvement with the upgrades. It has been exciting to explore even more ways that printIQ can integrate with platforms for pre-press, ganging, and imposition,” he said.

“Revolution Print is on a pathway to realistically improve our automated processes upwards of 10-fold, aiming to scale up for the ability to effectively handle over 1000 orders per day with the same or even less time than it currently takes to do less volume.

“printIQ is the core piece of our ability to empower our customers to order premium products with luxury stocks and finishes without any intervention needed on the front-end of our team.”

According to Wilson, printIQ is a “complete game-changer” and is “groundbreaking technology”, and the only way to create the future of print is by embracing software and technology and putting it in the hands of smart people.

“Although investments in automation are not cheap, it is a long-term investment that will ultimately make things easier for our clients and for our business,” he added.

INSTALLATIONS

SPRINTER.COM.AU 26 | AUSTRALIAN PRINTER MAY 2023

Revolution Print’s premises in Victoria

What Revolution Print is capable of producing using printIQ’s technology on the back-end

Leon Wilson and John Schreenan with the KM-1

SURFACE YOUR DATA AND AUTOMATE YOUR BUSINESS

IQ ACCOUNTS MODULE

Connectivity to accountancy packages like Sage, Xero, QuickBooks and others. Saves hours of double data entry, eliminates errors. Invoice creation and consolidation status shared with customers automatically.

PAYMENT GATEWAY

Online credit card payments, share links, track payments. Custom branded site for customers displays job lists, allows payment and download of invoice in one transaction.

QUOTE INTELLIGENCE

Simplifies the estimating process, making it easy for businesses to quote complex jobs. The quote drives the business and knows the production routes and material costs that have already been allocated to the job.

INVENTORY MANAGER

Multi location warehouse support with barcodes. Delivered items scanned into stock using supplier barcodes auto updating inventory levels and logging their position within the warehouse.

OUTSOURCE MANAGER

Full transparency and control over supplier relationships allowing them to interact with you. Check progress and Win/Loss ratio, award purchase orders, share artwork, upload invoices all in one place.

WORKFLOW MANAGER

Lean manufacturing routing while calculating other print processes. Compares digital to litho, stores calculations for jobs life, intelligent capacity planning. Calculates best production routes saving planning time.

JOB TRACK

Enables account handlers’ fast access to information and locate jobs, view current status, customer progress updates and ETA’s. Customers can selfserve via standard web browsers.

SHIPPING MANAGER

Visibility and control over dispatch for single items, multi-location deliveries and a range of couriers. Handle mass shipping, automatically, lodge consignments, retrieve tracking information via a digital trail, view remotely on a mobile device, 24/7.

BOOK

A DEMO

Helping print service providers achieve their sustainability goals

HP Indigo and its local distributor Currie Group are helping their customers by driving some of the most aggressive and comprehensive sustainability goals in the industry

method Life Cycle Assessment (LCA). The statistics found that 20,729 tons of CO₂ emissions were avoided through offsets for all HP Indigo press production. In FY22, 12.1 per cent of all products packaged and shipped were made of renewable, recycled, or reused sources.

• Reduce set up waste by up to 90 per cent

• Increase production time by implementing smart tools such as PrintOS OEE, Color Beat and Jobs API (Application Programming Interface).

It’s no secret that the global community is challenged by a wide range of social and environmental problems. Some of them, like social and gender inequality, education and the changing climate can be addressed if businesses adopt sustainable practices.

HP strives to create lasting value by integrating sustainable solutions into the entire value chain, from sourcing materials to the printed product, and supporting product circularity, by focusing on these three goals:

• Reduce (waste, logistics, partnerships, compensation)

• Redesign (product recyclability, energy, inks, supply chain)

• Regenerate (forest, water, plastic).

As for HP Indigo, it continues to focus on the three areas listed above to achieve the following goals:

• Creating higher solid content ink tubes to reduce the carbon footprint associated with production, packaging waste, ink tube replacement and logistics across the supply chain

• Developing a high-speed printing process for our presses, increasing life span of supplies, resulting in energysavings and reduction in supplies waste

• Developing the widest ink portfolio including functional inks that reduce multiple stages in the product production flow.

HP Indigo presses have also been certified by a third-party, multinational assurance, inspection, product testing and certification company, Intertek, under its Green Leaf program. In addition, HP Indigo has been measured Cradle-to-Gate – according to the environmental footprint

HP Indigo and its local distributor Currie Group have partnered with Close the Loop since October 2018 to deliver a world-class product stewardship program to treat used HP Indigo imaging consumables. Since its inception, the HP Planet Partners Program has seen tremendous participation and continued growth with more than 58 tonnes of HP Indigo canisters being diverted from landfills, and more than 19 tonnes of HP Indigo BIDs recovered and returned to Israel for remanufacture.

HP Indigo supports its PSPs in their sustainability efforts

First, HP Indigo’s printed product sustainability focus is to comply with worldwide circularity standards by providing PSPs with data, programs and regulation statements. HP Indigo supports its customers with product circularity via collaboration with partners all over the world to reinvent, innovate, and drive life cycle thinking across the industry.

For example, in terms of product circularity, HP Indigo enables PET wash-off labels, flexible packaging mechanical recycling, folding carton recyclability and flexible packaging product compostability.

HP Indigo presses support printing on responsibly-sourced media, such as recyclable, recycled content, postconsumer waste; FSC-certified media; reduced weight labels and rPET liners; and mono-material flexible packaging.

HP Indigo technology’s unrivalled speedto-market and removal of minimum order quantities also help PSPs to:

• Develop leaner, more agile, just-in-time packaging supply chain solutions by reducing waste from artwork changes due to regulatory or legal reasons.

• Focus on short-runs and low volume SKUs

• Reduce costs while eliminating the need to produce plates and cylinders

PSPs can also help brands with their sustainability goals by using HP Indigo technology and services. For example, they can implement just-in-time inventory management with PrintOS Supply Inventory Manager application.

HP Indigo’s PrintOS is a cloud-based print management system that enables print service providers to offer printas-a-service to their customers. This model reduces waste and promotes a circular economy by allowing customers to print only what they need, reducing overproduction and unnecessary waste. This application helps brands reduce up to 26 per cent of packaging waste while eliminating 65 per cent to 80 per cent of CO₂ emissions while printing.

The result is that the more brands use digital print with HP Indigo, the faster they can reach their ESG (sustainability) goals – by reducing packaging, print, waste and energy consumption.

HP is driving some of the most aggressive and comprehensive sustainability goals in the industry. Since everything has an impact on the environment, it’s on a mission to reduce it across its entire value chain.

HP Indigo has been making changes to its presses to ensure they abide by current sustainability standards. HP Indigo strives to meet HP Inc.’s ambitious global strategy, according to the following goals:

• 50 per cent CO₂ emission reduction by 2030

• Net-zero carbon emissions by 2040.

So far, HP Inc. has managed to avert 2.93 million tonnes of CO₂ across the HP value chain since 2019. The baseline set in 2019 has been reduced by 59 per cent compared to the 2015 baseline. HP also aims to achieve 75 per cent circularity for HP products and packaging by 2030, of which we have achieved 39 per cent circularity by weight.

SUSTAINABILITY & ENVIRONMENTAL RESPONSIBILITIES

SPRINTER.COM.AU 28 | AUSTRALIAN PRINTER MAY 2023

By HP sustainability and industrial application manager Regina Guslitzer

www.curriegroup.com.au

Durst Oceania implements a multifaceted approach to sustainability

Durst Oceania has a clear direction in mind that is aligned to that of its global headquarters when it comes to sustainability, and has been leading the way with its approach

interventions, using a combination of great hardware with outstanding reliability and remote monitoring software, Durst Analytics, installed on all new machines and being retrofitted to older units. This software enables us to monitor the machine at a sensor level to ensure maximum uptime, and works in combination with smart algorithms and AI to predict when an intervention will be needed.

In addition, our machines are always under review, as far as software goes, to reduce power consumption and for energy efficiencies. That is to do with the likes of how long the machine takes to power up and down. Durst had systems in place, even with its older machines, where we can address this post-install; it’s not a feature just for new printers.

By

Being sustainable means having a more defined and clearer strategy than being environmentally friendly or being ‘green’. It is a better way of addressing the needs of a modern business that is taking the necessary steps to be environmentally aware and is a more realistic and quantitative approach.

Being ‘green’ was a trend, whereas sustainability involved a clear path forward in balancing the needs of the environment and the needs of a business. It also involves a more scientific way of how we use resources, how we look after our staff and how we take care of our customers.

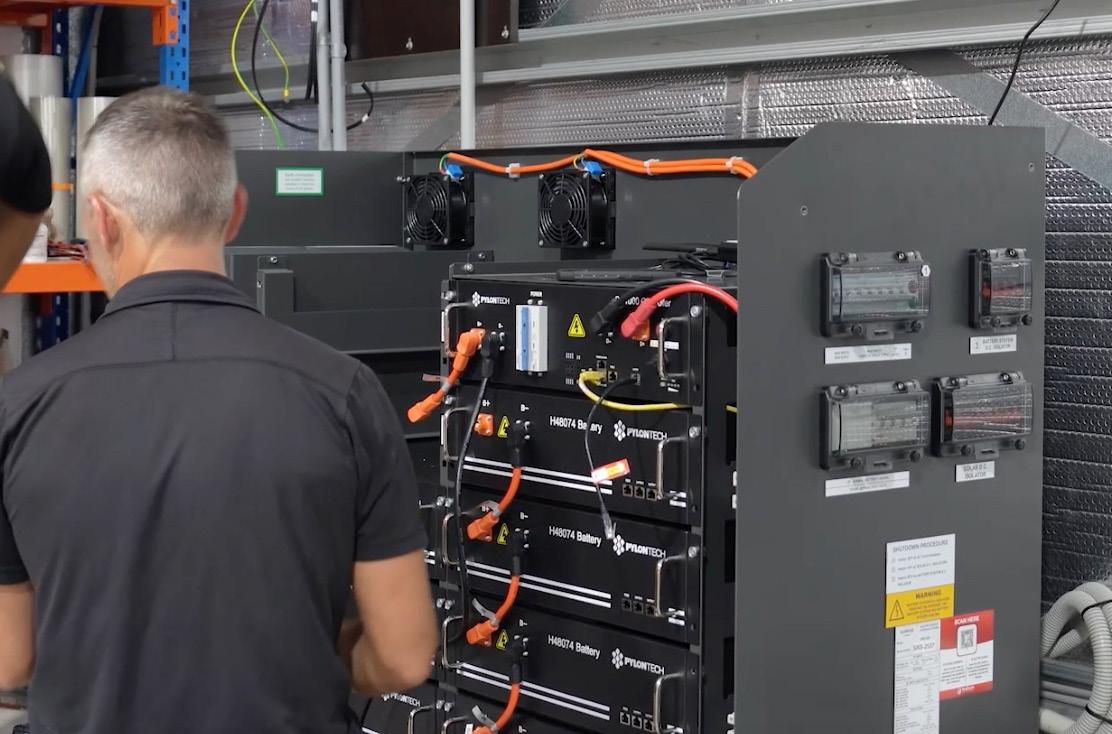

Durst Oceania has a multi-faceted approach to its sustainability and environmental responsibility that was started pre-COVID. The business has now deployed an electric-powered car fleet in the Australian market to pursue internal sustainability targets.

All company-owned vehicles at Durst Oceania are now 100 per cent electric. I think we are the first in our sector to do so. The transition to an entirely electric fleet of company cars represents the first phase in our path to sustainability and brings us in line with the strategy

of the Durst Group, to explore all ways to become more sustainable.

We have plans to move to a bigger and more sustainable local headquarters in the next 24 months. This will also meet our expanding needs as we enter new markets. However, we will remain in Melbourne.

Currently, we are using an electricity supplier that guarantees electricity from renewable resources. However, the next phase of our path to sustainability and reducing pollution will be inspired by our head office in Brixen, Italy, and this will be to move to a new premises with electric charging stations fed by solar panels, as well as battery storage on site.

Our head office in Brixen already offers car charging using energy from solar panels with gigawatts of power stored each year, as well as e-scooters free for staff and visitors to buzz around on errands locally.

Thirdly, due to the global nature of the business and the huge distances we must transverse, we will still be flying, and renting cars locally, but this is the first of many steps we are actively pursuing towards neutrality. Our transport policy will encourage staff to think twice about the options for local transport options, and if the trip is 100 per cent required.

This feeds into our global aim to have as near to zero unplanned service

Last year, we also introduced new packaging from our Melbourne office using zero plastic and no harmful adhesives. The boxes are reusable, and we encourage our customers to reuse them.

Our next big step is to try to look at how we deal with our waste, and ways to repurpose and recycle incoming packaging. Also, on a grander scale, we aim to reduce the level of on-site visits to customers but at the same time ensure that we continue to provide them with the stellar levels of support that they’re accustomed to. Our ultimate goal is to have zero unplanned interventions.

When it comes to having a sustainability strategy, my advice to the print industry is to firstly look inward within your business before you launch a truly sustainable initiative. Otherwise, it becomes something that does not benefit the business, customers, suppliers or the environment.

The definition of long-term sustainability is true sustainability. It’s a process that requires you to take baby steps. Every small step forward to being sustainable today will make your business sustainable in the long-term.

Be a forerunner; an early adopter. Don’t be afraid to roll out initiatives that no one else has. Always be in consultation with your stakeholders and the people who work for you about how you can be more sustainable because you never know where the next great idea will come from.

SUSTAINABILITY & ENVIRONMENTAL RESPONSIBILITIES

SPRINTER.COM.AU 30 | AUSTRALIAN PRINTER MAY 2023

Durst Oceania managing director Matt Ashman

Durst Oceania’s entirely electric fleet of company cars

PRODUCTION EXCELLENCE

P5 350/HS

The hybrid printer that elevates the efficiency in your production cycle.

For more information, please visit durst-group.com/p5350

P5 TM

Creating a lasting, competitive advantage with sustainability

As more customers align themselves to the circular economy, it is becoming vital that print service providers also share the same vision and meet their demands

ecological values and meet sustainability industry standards.

Our sustainability roadmap helps us achieve goals that create financial, social, and a sustainable environmental approach. Our plans are reviewed regularly to preserve or improve our systems, ensuring our business practices are sustainable.

Innovation and problem solving is also a key part of planning. It’s important that we engage with our suppliers, customers and staff to achieve the necessary outcomes to reach our sustainable targets.

converters, print service providers and end users. Coming together, they need to consider all aspects of sustainability, such as energy, waste, recycling and reusing. In addition, they should collectively lobby to local and Federal Governments to provide incentives for recycling schemes to encourage investment in all aspects of recycling in what is a very complex area.

By HVG Graphics Media general manager Richard

Sustainable business strategies are essential for long-term viability of a business. Studies from the Harvard Business School show that the most sustainable companies today are also the most profitable.

As businesses desire to work with other like-minded organisations who take being kind to the planet seriously, the bottom line of a sustainable strategy should also measure environmental and social impact.

Today, environmental sustainability in business involves the following:

• A business that operates in a sustainable manner, causing minimal damage to the environment and using renewable resources where possible. It evaluates where supplies come from and how they are made as part of the cycle

• Working with environmentally responsible suppliers to source materials that have a reduced carbon footprint

• Minimising any negative effects that products or services have on the environment

• Considering any unnecessary packaging and managing stock production to reduce waste.

HVG Graphics Media is constantly evolving the company’s product range, ensuring that we are intentional in our sustainable product offerings. Our range of environmentally conscious products continue to grow, as we align our

Some of HVG Graphics Media’s sustainability efforts include:

• Partnering with suppliers who actively pursue manufacturing practices towards a more sustainable future