THE SAFETY NET

A look at some environmental news for safety professionals. In the past week, I’ve started to feel more capable and reassured. I can keep tottering for work-life balance. I can lift heavier weights. I can tackle this big project. It’s a mindset

One other thought that has propelled me is that I am part of things: Mother Nature, a community, a circle of given and chosen family. Feelings of connectedness help me remember I am but a player of a larger team—and that while I don’t have to carry a metaphorical weight on my back, I do have to play my part.

That simple phrase has allowed me to recommit my efforts so I can continue to show up for others.

I hope that regardless of where you are, what you’re doing and what you’re working toward, you find some way to reconnect, recharge and refocus so you can channel your energy into doing the most good for the world.

Until next time, stay safe, be well and be kind!

FOOD SAFETY

There has been a lot of activity, sometimes contradictory activity, from Washington the past few months. Food Processing, a sibling publication of EHS Today, explores the downstream effects of tariffs with Mexico and Canada on food safety.

I found this article interesting because it goes far beyond acknowledging that costs of certain imported would rise with tariffs. Author Benjamin Miller explains how domestic growers and manufacturers could experience such severe production pressures that food safety measures are knowingly or unknowingly followed. For the former, this could include not properly training new employees and the latter could include extended production runs between sanitation cycles.

Miller also explains that such price strains could give rise to sophisticated black market food supply chain operations and undisclosed substitutions or dilutions to consumers. It’s not hard to imagine many such scenarios—spoilage, traceability difficulties or undisclosed food allergies—that could put consumers at risk.

It seems to me that the greatest concern about tariffs at the grocery store is not merely more expensive avocados, tomatoes, meats, cheeses and tequila, among other items; it’s a more fundamental issue of whether we can continue to trust the safety and security of the food that we buy and eat.

Read the full article here

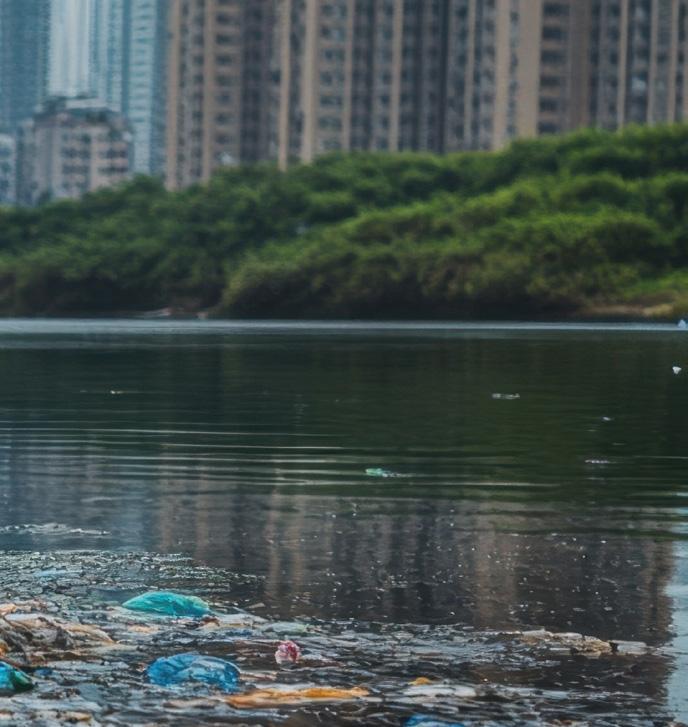

SEWAGE DISCHARGE

The Supreme Court of the United States ruled on March 4 that it had sided with the city of San Francisco and against the U.S. Environmental Protection Agency (EPA) in a matter related to the Clean Water Act.

San Francisco’s Oceanside Water Pollution Control Plant has been accused of discharging huge quantities of raw sewage into the Pacific Ocean during big storms for years, as the city runs stormwater and sewage through the same pipes . The city would have needed to spend billions to upgrade its infrastructure to be in compliance with the Clean Water Act, which it said was too expensive. That’s no longer necessary as the ruling make a permittee responsible for the quality of the water discharged—not the water quality’s “end result.” “[The EPA’s] reliance on the Combined Sewer Overflow Policy is misplaced as that policy authorizes narrative limitations

but not end-result requirements,” writes Justice Samuel Alito in the majority opinion.

Going forward, the EPA must be more specific about what permit holders can and cannot do.

Miranda Willson and Pamela King write for E&E News , an environmental and energy focused subsidiary of Politico, that: “At issue in the case are permits issued under EPA’s National Pollutant Discharge Elimination System, a key Clean Water Act tool for safeguarding rivers, lakes and streams nationwide. The ruling allows EPA to continue to use narrative permit language pertaining to water quality in some cases, instead of only numerical limits, but sets up a massive workload for the agency and other permit writers.”

Beyond the ruling for the city of San Francisco’s wastewater treatment plant, there are serious concerns for public health nationwide due to more sewage pollution in waterways that could increase the risk of waterborne diseases , such as typhoid fever, cholera, giardiasis, E. coli, Hepatitis A and salmonella.

Read more about the court’s ruling here

CLIMATE CHANGE IN PICTURES

Last year, I had the privilege to visit the Rocky Mountain National Park. Throughout our time there, my partner and I reflected on how we were treading on such a vast amount of preserved land. Perhaps why this story from The New York Times caught my eye.

Author Kim Beil, an art historian who teaches at Stanford University, was part of a small group led by geology professor Jeff Munroe that backpacked into the Uinta Mountains in Wyoming to recreate a series of photographs William Henry Jackson captured in 1870 for the United States Geological Survey. Munroe had re-photographed the path in 2001. They went back in 2024 to see how much of the landscape has been altered due to climate change.

Beil writes: “When I asked Jeff, before our trip, about why he planned to rephotograph these sites again just 23 years later, he explained that the pace of climate-driven changes is accelerating. ‘If I had looked at this landscape between 1950 and 1975, it might have changed a little bit,’ he said. ‘But I think between 2001 and 2024, it’s going to have changed a lot more, in roughly the same amount of time.’”

I don’t want to give too much away, so I encourage you to see the photos and read about their journey here .

Ladder Safety Regulations Have Changed— Here’s How To Stay Compliant

01.30.2025 | Diversified Fall Protection

In 2016, OSHA introduced significant updates to its walking-working surface standard, marking one of the most extensive revisions in decades. These changes included new requirements for employee training, routine system inspections, and, notably, enhanced ladder safety regulations. One of the most impactful changes was the requirement that all new fixed ladders over 24 feet be equipped with a personal fall arrest system, such as a vertical lifeline system. This regulation applies to ladders installed after 2018. However, for ladders installed before that date, OSHA provided a phased compliance approach, allowing businesses until 2036 to transition away from traditional ladder safety systems like cages and wells in favor of personal fall protection systems.

ALTERNATIVES TO A LADDER CAGE

Ladder cages were originally designed to provide limited protection by preventing workers from falling backward or sideways off a ladder. However, realworld incidents have shown that cages are largely ineffective at preventing serious injuries or fatalities from

falls. As a result, OSHA no longer considers them a compliant standalone safety solution for ladders.

The modern and safer alternative to a ladder cage is a personal fall arrest system specifically designed for ladders. These systems typically come in the form of vertical lifeline systems, which allow a worker to attach to the system before climbing. If a fall occurs, the system detects the fall and arrests it quickly, minimizing the risk of injury. Compared to ladder cages, these systems offer superior protection and are now considered the best practice for ladder safety.

ARE LADDER CAGES REQUIRED ANYMORE?

No, ladder cages are no longer required if the ladder is over 24 feet and is equipped with a personal fall arrest system. The updated OSHA regulations have effectively phased out ladder cages as a primary means of fall protection, requiring the use of more effective personal fall arrest systems instead.

DO I NEED TO REMOVE MY LADDER CAGE AFTER INSTALLING A LADDER FALL ARREST SYSTEM?

Technically, OSHA does not mandate the removal of existing ladder cages if a compliant fall arrest system is in place. However, there are considerations to keep in mind. OSHA states that ladder cages may remain “provided that the cage or well does not interfere with the operation of the system.”

While OSHA provides a grace period for compliance, businesses that proactively implement personal fall arrest systems demonstrate a commitment to worker safety and reduce the risk of accidents. Investing in modern fall protection solutions now can help prevent injuries, lower liability, and create a culture of safety within the organization.

Some safety professionals argue that ladder cages can interfere with the proper function of a fall arrest system. For example, a cage might impede or slow the activation of the system, which could delay or prevent a proper arrest. Additionally, there is a risk that a falling worker may strike the cage, leading to secondary injuries such as head trauma or broken limbs. Due to these concerns, many companies opt to remove ladder cages after installing a vertical lifeline or other fall arrest system to ensure optimal safety and proper functioning of the new system.

PROACTIVELY UPDATING LADDER SAFETY SYSTEMS

Employers that take worker safety seriously should not wait until the 2036 deadline to update their ladder safety systems.

Additionally, updating safety systems early can spread out costs over time and prevent the last-minute rush to comply as the deadline approaches. Forward-thinking employers recognize that workplace safety is an ongoing responsibility, not just a regulatory requirement.

FINAL THOUGHTS

The landscape of ladder safety has changed dramatically in recent years, and companies must adapt to these new standards to protect workers and remain compliant. Ladder cages, once seen as a safety measure, are now considered outdated and ineffective. The industry best practice is to install a compliant personal fall arrest system on any fixed ladder over 24 feet and consider removing existing cages that may interfere with these systems. By taking proactive steps now, employers can ensure a safer working environment while staying ahead of regulatory deadlines.

Your plan may look great on paper but if it’s not being put into practice, this is a compliance trouble spot!

Survey Reveals Top EH&S Challenges

03.17.2025 | JJ Keller

Developing and maintaining environmental health and safety (EH&S) programs, keeping up with regulatory changes, and training and evaluating workers were the top three challenges faced by safety professionals who responded to an EH&S benchmark study conducted by J. J. Keller & Associates in late 2024. The study aimed at understanding the state of the industry and the challenges faced by EH&S professionals.

What could safety professionals do to alleviate these challenges?

DEVELOPING AND MAINTAINING EH&S PROGRAMS

Written safety plans (or programs) are records of how an establishment is protecting or plans to protect employees overall for safety or health hazard. Writing an effective safety and health plan helps keep your training program organized and shows a good faith effort to comply with the regulations. Written safety plan requirements are found throughout 29 CFR 1910 for general industry and 29 CFR 1926 for construction. Most regulations have a scope and applicability section(s), so if you find that the regulation applies to your situation, check if there’s a written plan requirement within it.

Be sure to review your written plans when there are changes to work processes or procedures, and at least annually to ensure they’re working the way you intend. Your plan may look great on paper but if it’s not being put into practice, this is a compliance trouble spot!

KEEPING UP WITH REGULATORY CHANGES

Although OSHA’s regulations generally move slowly through the pipeline, state-plan states tend to see more frequent regulatory activity, particularly California, Washington, and Oregon. Environmental regulations are much more active, particularly at the state and local levels. Ideas for keeping on top of changes include:

• Visiting state and federal regulatory agency websites, such as osha.gov, and follow them on social media (e.g., LinkedIn). Most have an active social media platform to keep the public informed. Set a calendar reminder to make it a regular habit.

• Joining industry associations and your local safety council. These groups host meetings and events that provide regulatory updates and best practices.

TRAINING AND EVALUATING WORKERS

Building training time into an already busy workday can be a challenge, particularly when you have multiple locations. Are you training too many employees? While more than 70 construction and general industry regulations have training requirements, it’s likely that not all of them apply to the work your employees are performing. Likewise, if there’s not an annual training requirement it may not be necessary to repeat your entire training program, but instead use toolbox talks or brief refresher trainings throughout the year.

Although OSHA doesn’t require that you give a quiz after training, it’s a great way to determine if employees understand the material. Follow-up observations, safety incident statistics, and safety observation reporting are among ways to ensure employees apply training on the job.

EHS TODAY’S EDITORS REFLECT ON THE DEFINING DEVELOPMENTS IN OCCUPATIONAL HEALTH AND SAFETY OVER THE PAST 25 YEARS.

Those chairs are still occupied as organizations feel more comfortable tying ROI to safety. Evaluation of the function has expanded from prevention of workplace injuries to creating a safety culture that is now an integral part of every company’s strategy. Safety culture has specific goals and actions with industry recognition based on the effectiveness of this culture.

The basis for this reorganization has been building over the past 25 years as safety has been baked into every job. The workforce is continually trained in improved safety methods and held accountable for safety records. Most managers’ performance reviews now include safety components. And investment in the culture has included capital expenditures on safety technology, through robots performing “unsafe” jobs, as well as analytics to better manage incident rates. The number of stakeholders who are involved in safety analysis is increasing. Inside the building employees view safe working conditions as a term of employment. Outside the building, it’s a recruiting tool. And in the general economy, Wall Street views safety in its company valuation

WHATEVER HAPPENED TO ENVIRONMENTALISM?

Let’s go back further than 2000 for a moment—back to the 1970s, when Earth Day got its start, when ecology and pollution were frequent topics on the nightly news, and when environmentalism was a distinct political force. In 1970, under the watch of Republican President Richard Nixon, the Environmental Protection Agency was launched, an agency with a clear mission: to protect human health and the environment. The EPA got off to a quick start with a lot of impressive goals and accomplishments: cleaning up the burning Cuyahoga River, establishing the Clean Air Act and then the Clean Water Act, banning DDT as a pesticide, and similar efforts to make living conditions safer for everybody. The push to reduce pollution shifted to protecting the ozone layer to reducing carbon emissions to protecting the planet itself from global warming (or as it is now known, climate change).

Of course, from the very beginning of the movement businesses started challenging the EPA and other environment-focused initiatives for meddling in the affairs of private industry—and not just meddling, but tacking on significant costs to their bottom line. Over the years, new terms emerged to try to breathe new life into environmentalism: the green movement, sustainability, corporate social responsibility and more recently, environmental, social and governance (ESG). But as with just about everything that can be politicized, in the 21st Century it’s been one step forward, one step backward, and occasionally one step sideways in the monitoring and regulating of emissions, wastewater, hazardous chemicals and other nasty things that nobody in their right minds would want in their communities. At this writing, President Trump has pulled the US out of the Paris Agreement on climate change (for the second time; he did the same thing in 2017), pingponging President Obama’s agreement to participate and President Biden’s reversal of Trump’s first pullout.

Right now, with President Trump focusing on deregulating just about everything, the future of ESG as a standard for business investing is very much in doubt. What is not in doubt, at least if you put any faith in public polling, is that consumers are very much in favor of buying products that are environmentally and socially responsible; according to a recent McKinsey /NielsenIQ study, consumers prefer products with ESG-related claims over those that don’t. In a separate study of corporate CEOs, consulting firm KPMG discovered that sustainability initiatives improves financial performance for companies, particularly when it comes to access to new capital and customer loyalty.

While the term “ESG” itself is a political hot potato, consumers—especially, young consumers—are likely to continue to champion its cause. And EHS professionals, who of course are tasked with ensuring safe and clean environments for their employers, will continue to play an outsized role in fulfilling their companies’ sustainability initiatives.

...continued on next page

TECHNOLOGY OFFERS AN EXPONENTIAL LEAP IN SAFETY

The walk across the factory floor today, as compared to 25 years ago, reflects the myriad ways technology has improved safety. Employees are outfitted with wearables that monitor their movements to improve ergonomics. They wear augmented reality glasses that provide training videos on how to correctly operate machinery. And those same glasses are teaching new workers, the group most likely to be injured, how to do their jobs properly.

Automated guided vehicles ferry materials across the factory floor, eliminating the physical wear and tear on employees. Exoskeletons aid employees with various tasks, protecting their muscles. And robots can do the heavy lifting in the warehouse, as well as performing repetitive tasks such as picking.

The ability to use sensors and cameras to provide real-time monitoring to identify potential hazards has been a game changer as it can provide environmental monitoring. Sensors can detect harmful fumes, noise levels and dangerous temperatures. They can trigger shutdowns to prevent harm. The technology also is able to detect body issues, such an improper use of PPE, stress levels and fatigue.

Smart helmets are keeping construction workers safety, while drones are busy inspecting dangerous areas. Drones are also keeping lone workers safer.

On top of these day-to-day operations, technology has given EHS professionals the ability to analyze data. Staffing and time constraint limit the ability to comb through massive amounts of data, yet algorithms are up to the job. Artificial intelligence , the latest step in rapidly advancing technologies, will be able to identify trends and ultimately prevent injuries.

SAFETY IN NUMBERS

Over the past 25 years, collaboration between organizations to address specific issues has been increasing. The ability to share data, offer best practices and advocate for standards improves outcomes.

OSHA is involved in this trend creating programs such as the Alliance Program, the OSHA Strategic Partnership Program the popular Voluntary Protection Programs .

Associations have expanded their reach as well. The American Society of Safety Professionals (ASSP), which changed its name from the American Society of Safety Engineers in 2018, works with the National Institute for Occupational Safety and Health (NIOSH), the International Safety Equipment Association (ISEA), Mechanical Contractors Association of America , The National Electric Contractors Association and the U.S. Army Corps of Engineers , among others.

Collaboration also takes the form of assessment tools. The National Safety Council (NSC) joined with Avetta to launch the Safety Maturity Index, which offers a systems-based approach to target health and safety weaknesses within the supply chain to help avoid serious injuries and fatalities.

Sharing data on technology is a more recent form of collaboration. The NSC’s Work to Zero program , created in 2021 with Safetytech Accelerator, shares cutting-edge research through pilots that incorporate data analytics,

artificial intelligence and computer analytics. The initiative includes a free online assessment tool.

Creating coalitions is another tactic. The NSC’s Road to Zero Coalition, created in 2025, is a traffic safety alliance dedicated to eliminating roadway fatalities.

Advocating for policies, such as increasing awareness of the need for naloxone in workplaces, has led organizations to speak up on congressional bills as well as create internal programs, as the NSC did with its Respond Ready Workplace

The greater cohesion among safety professionals, the safer the workplace becomes.

THE ROI OF SAFETY

Back at the turn of the century, Rick Fulwiler, president of Transformational Leadership Associates and formerly worldwide director of health and safety for consumer products giant Procter & Gamble, published an article in this magazine that set the tone for the EHS profession in the 21st Century. As Fulwiler observed then, and which still very much is the case today, regulatory pressures tend to ebb and flow depending on how the political winds are blowing at any given time. What matters most to companies, and what should matter most to the EHS professionals leading their companies’ safety initiatives, is the three-legged stool of People, Public Trust and Profit. Keeping workers safe not only makes it easier to attract and retain employees, and it not only builds a positive reputation, but it also (and this is when the C-suite starts to pay attention) delivers a substantial financial payback— what we call “the ROI of safety.”

competition was to honor companies that went above and beyond the appearance of minimum-required compliance to “protect their employees and their bottom line through

effective, well-defined safety programs, innovative solutions to challenges, a belief that safety is the ‘right thing to do,’ mutual respect between management and employees, and management commitment.”

The conventional wisdom holds that for every dollar spent on workplace safety, a company can expect at least a fourfold savings in terms of reduced workman’s compensation costs, reduced productivity when a worker is injured or work is suspended, lost revenue from negative publicity and difficulty in attracting new workers due to a poor safety reputation, and various other bad things avoided by focusing on establishing and maintaining a culture of safety.

Taking that three-pronged model of people, public trust and profit as the formative premise, in 2002 EHS Today launched the America’s Safest Companies competition. As we described it then, the goal for the new awards

Beginning with the Class of 2002 (which included such companies as Alcoa, General Electric, Georgia-Pacific and John Deere), to date more than 250 companies have been recognized as being one of America’s Safest Companies, which among other things means they’ve all substantiated the financial benefits of the safety process, while achieving injury and illness rates lower than the industry average. Since winning the ASC award in 2015, industrial manufacturer Victaulic Company opted not to sit on its laurels but instead invested more than $10 million on various safety technologies, doubled the number of full-time safety professionals, and began covering the cost of training for all employees interested in becoming emergency responders. The company was again named an ASC winner in 2024 , and as William D’Amico, global director of safety and health, explained, “The ROI in these investments is not only financially measurable, but the signal sent to the employees on these investments is priceless.”

DIGITAL TRAINING

From dial-up internet on a device the size of a carryon suitcase to lightning-fast WiFi on a device that can

...continued on next page

fit in your back pocket, it’s safe to say that we couldn’t have foreseen the rapidity with which technology would develop and evolve. Nor could we have fathomed what was possible. Technology has redefined our way of living, including how we learn.

Until the 21st century, all safety training was essentially delivered in a classroom or hands-on apprenticeship setting, under the watchful tutelage of an experienced instructor. Workers either had to physically go to the training or have the training brought to them. Both options were disruptive, timeconsuming and costly.

That’s radically different now, thanks to computers, tablets, smartphones, virtual reality (VR) headsets, smartwatches and smart personal protective equipment (PPE).

Whether it’s through the internet, cloud, software or an app, there are an ever-increasing number of ways to deliver safety training digitally, both synchronously and asynchronously. You can remotely participate in an entire degree program, hourslong certification, microlearning, periodic refreshers, gamified learning modules or 60-second safety moments.

All of this is to say that EHS professionals have many options for how best to teach and reinforce safety training for a diverse workforce using a variety of different learning styles that are minimally disruptive to operations.

It’s not an either-or mindset, but a yes-and mindset. These digital devices don’t replace training; rather, they are another tool that EHS professionals can use to enhance, reinforce or supplement existing safety training offerings. Thanks to digital training, EHS professionals have the ability to reach more people, including those who work by themselves or in remote areas. That’s allowing organizations to stretch their dollars and potentially free up more resources for additional trainings, take more proactive measures and ultimately make workplaces safer for more people. There are seemingly limitless opportunities for digital training, but its effectiveness, engagement rate and long-

term retention levels with employees still require a watchful eye and judicious implementation.

“It’s a time saver and a money saver, and I know a lot of inhouse EHS professionals that couldn’t live without it because they don’t have enough time in the day to do what they do,” says Natalie Fox, principal scientist at Roux , and a speaker at Safety Leadership Conference 2024 . “But you can’t rely on it as your only training source.

“I really do think that all these different schools of thought need to be working together. [By delivering safety training through multiple methods], you hopefully touch on enough learning styles, so everybody takes in the knowledge they need to.”

LEADING AND LAGGING INDICATORS

Businesses have long been required to report data surrounding the number of work-related injuries and illnesses to OSHA and, in some instances, the Bureau of Labor Statistics. These metrics are lagging indicators because the numbers reflect incidents that have already happened.

Lagging indicators are one way to benchmark and compare the safety of a given business or industry with another. They helped improve safety in U.S. workplaces during the 20th century, but only to a point.

“For decades, companies have relied primarily on lagging indicators, such as total recordable injury rate, to measure safety performance,” says Perry Logan, senior director of networks at NSC. “While this approach has contributed to reducing overall injuries, it has not significantly decreased serious incident and fatality (SIF) figures, which have remained stagnant over the past decade across all industries.”

A growing number of organizations have started turning their attention from this historical measure of safety that sits in a binder, spreadsheet file or governmental database to trying to predict the future using new tools and technologies.

“To drive meaningful improvement in SIF prevention, organizations are shifting focus to proactive risk reduction strategies,” Logan says. “These efforts prioritize identifying and mitigating high-hazard activities and conditions, fostering strong leader and employee engagement, and cultivating a culture of safety ownership.”

In 2012, NSC’s Campbell institute surveyed safety leaders about leading indicators. Ever since, safety professionals have been mired in discussions about leading indicators. There’s consensus that preventing workplace injuries and

fatalities is a good thing but, as is often the case, the devil is in the details.

What constitutes a good leading metric? How do you determine the ROI for machine guarding a piece of equipment? How do you calculate the potential reduction in musculoskeletal disorders as a result of a new ergonomics initiative? How do multinational companies roll out meaningful change with metrics that need to be highly personal and specific to a given job or facility?

Safety professionals find themselves beholden to lagging indicators because they are a requirement and allow for easy comparison while struggling to make meaningful progress on leading indicators, because they are, by their very nature, a constantly moving target. And until or unless there is widespread agreement on how to get there, there’s going to be more attempts to raise the floor—and simultaneously reach for the stars.

TOTAL WORKER HEALTH

During the Industrial Era, workers endured long hours, low wages, dangerous working conditions, little protections and no benefits. Labor conditions improved ;in the 20th century thanks to governmental reforms, worker advocates and efforts by organizations such as the American Society of Safety Professionals (ASSP), which was founded in response to the deadly Triangle Shirtwaist Factory fire.

Today’s workers have benefited from these hardwon protections, but occupational safety and health programs have long focused on worker’s physical safety. That begun to change in 2006 with a revolutionary new concept: total worker health.

This approach, brought forth by the National Institute for Occupational Safety and Health (NIOSH), prioritizes a hazard free work environment as well as worker well-being. Total worker health focuses on employees’ physical, mental and emotional health. It also “considers health influences that arise from outside the workplace, including interactions between work and non-work demands and circumstances,” according to NIOSH’s FAQ page.

The concept of total worker health underscores that workers need to feel seen, heard, understood and respected to perform their best work. Total worker health supports psychological safety, the belief that workers can’t be productive if they don’t feel comfortable being themselves or the ability to speak freely. Instilling both requires buy-in, investment and a commitment to creating a culture of safety.

Indeed, total worker health is more than a singular idea. Rather, it’s an inclusive belief in wholeness and unity, both within an individual and across the organization. It’s recognizing the role of work within the totality of a person’s life.

In other words, total worker health recognizes that workers are human beings who are more than just their ability to perform consistent labor during their hourslong shifts. It recognizes that workers’ worries, frustrations, fears and concerns about what happens in their personal lives don’t disappear when they clock-in.

Can A Mask Detect Respiratory Health?

03.18.2025 | EHS Today

A prototype smart mask can check for asthma, COPD, and post-COVID infections.

It is generally accepted that your wearable can help you with health concerns. And there have been instances of a smart watch alerting a wearer to an abnormal heart beat that lead to life-saving procedures.

Well now professor of medical engineering at Caltech, Wei Gao, has developed a prototype for a smart mask that can monitor respiratory health.

It can check for a range of conditions including asthma and COPD (chronic obstructive pulmonary disease), and post-COVID-19 infections.

It does this by monitoring physical changes such as temperature, humidity, or rate of breathing.

To test the masks, the breath of patients with asthma or COPD were monitored for nitrite, a biomarker for inflammation in both conditions. The results showed that the masks accurately detected the biomarker, indicting inflammation in the patients’ airways.

“These first studies are a proof of concept,” says Gao,in an article. “We want to expand this technology to incorporate different markers related to various health conditions. This is a foundation for creating a mask that functions as a versatile general health–monitoring platform.”