LOCATION CONSULTING DESIGN & ENGINEERING DESIGN-BUILD CONSTRUCTION & CONTRACTING NOVEMBER 2022 VOLUME 16 ISSUE 11 SAFE T Y FIRST. Austin employees have worked 5,166,191 hours without a Lost Time Accident through 8/2022. Every year in November, child health and welfare advocates organize resources and spend the month raising awareness about childhood safety. THE SAFETY NET IT’S ALWAYS SAFETY FIRST. CONSULT • DESIGN • ENGINEER • CONSTRUCT November is Child Safety Protection Month 10.20.2022 | EVOLVE

Most of the information shared during Child Safety Protection Month is directed toward infants, toddlers, and school age children. Safety experts offer helpful tips and advice about things like crib safety, kitchen safety, and bathroom safety. Meaning, really, all the things you worry about when you’re the parent of a little tyke.

For information and tips on keep young kids safe around the house – and in public places like swimming pools – read this article here . We recommend parents of older kids read it too. There are some good reminders there, like keeping medication safe and away from kids, storing hazardous cleaning chemicals properly, and other basic commonsense things everyone can brush up on.

All that’s important information. But when we began to do a little research for this post, we realized that safety is something parents need to keep in mind throughout adolescence, as well.

Why?

Because accidents are the leading cause of death for people age 18 and under. That probably got your attention.

ACCIDENTAL DEATH AND INJURY IN THE U.S.

We’re not saying that to be alarmist, or to scare you, or to get you to click a link and sign up for something that costs money. We’re saying it because data from the Centers for Disease Control (CDC) says it in black and white. Click this link to read the CDC Child Safety page.

We’ll summarize the key data points, starting with the overall numbers for children and adolescents, age 0-18:

• Around 9,000 deaths from accidental/preventable injury occur each year

• One child dies every hour from accidental/ preventable injury

• One in five child deaths are the result of accidental/ preventable injury

Now we’ll break those numbers down by accident type:

• Car Crashes: 4.564

• Suffocation: 1,160

• Drowning: 983

• Poisoning: 824

• Fires/Burns: 391

• Falls: 151

The primary reason to pay attention to these numbers is because although it’s true that accidents do happen, and no life is accident- or injury-free, many accidents –and therefore many fatalities caused by accidents –are preventable

KEEP YOUR TEENS SAFE

Adolescents are neither toddlers nor school kids, and they should not be treated like them. All parents of teens know most of them hate being treated like babies. But.

Despite how mature and adult-like teenagers may act, they are not adults.

The teen brain is not fully developed, which can create safety risks. Without diving deep into developmental neurobiology – you can do that by reading our article

What Parents Should Know About Teenager’s Brains – we’ll just say that the part of the brain that assesses risk and modifies behavior based on that assessment doesn’t finish developing until around age 25.

That’s why teens do impulsive things that seem absurd to adults, and totally logical to them.

That’s also why parents need to protect their teens. Poor decision-making increases the chance of accidents, which increases the chance of accidental injuries. Which, in some cases – over 9,000 a year, in fact – can lead to death.

So, what kind of things can you do to protect your teen , while simultaneously allowing them to live a full life, make mistakes, and learn hard lessons on their own?

We’ll offer a list based on the types of accidents that cause the most harm to adolescents. For each item below, think through what your teen knows about the risk area. Have you taught them about these things yourself, or have they learned them elsewhere?

For instance, you may not have taught your teen to swim, but they’ve been on the swim team for years. And last summer they earned a lifeguarding certificate – so you can cross “swimming safety” off your list.

Identify any gaps in your teen’s knowledge that may exist, and work to fill them with accurate and practical information that gives them the best chance of making smart, safe choices.

TEEN SAFETY: HOW TO MITIGATE ACCIDENT RISK

1. Cars and Driving. Make sure you and your teen are one hundred percent clear on your expectations about driving and riding in cars with other people. Make firm rules, logical consequences, and follow through on them every time, no matter what.

2. Swimming, Boating, and Water Recreation. Water awareness and water safety start at a young age, when children first learn to swim or first encounter water of any kind, outside of the bathtub. If you don’t come from a swimming or boating family, your teen needs to understand this simple equation: wherever there’s water, there’s a risk of drowning. And where there’s a boat –especially one with a motor – the risk of an accident that leads to drowning increases exponentially.

3. Chemicals and Poison. It’s likely you’ve been on top of this for years, beginning with storing cleaning chemicals out of reach of children, childproofing kitchen and bathroom cabinets, and taking other similar household precautions. Now that your teen is actually using cleaning products to do their chores (hint hint), it’s time to make sure they know – without a doubt – that ingesting toxic chemicals is a serious health risk, and can result in severe, permanent disabilities, such as brain damage and blindness, and in some cases, death.

4. Fires and Cooking. Some families start fire awareness early. Camping trips mean campfires and the basics of fire safety, including open fire cooking, are part of family culture. Other families don’t camp or have backyard firepits. It’s similar with cooking. In some families, kitchen rules and safe cooking habits happen because families spend time together in the kitchen, while other families don’t. For both fire and cooking, identify what kind of family you are, what your child knows, and fill in the gaps with practical knowledge. It’s worth repeating that rules around safety issues should be crystal clear. Any consequences should be enforced every time exactly as described. These are, quite literally, matters of life and death. Loose rules or shifting lines can result in teens not taking safety seriously, which could lead to mistakes no one wants to think about.

3

...continued on next page

Being Active During Leisure Time Can Make You More Engaged At Work: Study

Oulu, Finland — “Even light physical activity may foster work engagement,” researchers in Finland are saying after studying on- and off-the-job data for more than 6,800 workers.

The researchers analyzed questionnaire-based and clinical data from a 46-year follow-up study to the Northern Finland Birth Cohort 1966. Study participants answered questions about the types, frequency and duration of leisure-time physical activity. Meanwhile, nearly 5,900 participants took part in clinical exams that involved wearing an accelerometer on the wrist for 14 days.

The participants who either self-reported or exhibited higher levels of leisure-time physical activity and sports participation scored higher on a measure of work engagement, including the subdimensions of dedication, vigor and absorption. In contrast, more sedentary time was linked to lower work engagement.

Encouraging employees to be physically active, the researchers note, is beneficial to workers and employers, “possibly by promoting general psychological well-being and recovery from work.” They say the benefits include improved employee health, increased job performance and decreased absenteeism.

The study was published online in the Journal of Occupational and Environmental Medicine.

10.04.22 |

Family Safety and Health

America’s Safest Companies 2022: Hunter Site Services

Safety is more than a day’s work. It’s a long-term commitment to employees, clients and the public.

Once a quarter, production stops at Hunter Site Services. Employees come together to celebrate birthdays and work anniversaries. Meals are provided, and so are cookies or cake. But that’s not the main focus of those gatherings; rather, it’s to focus on safety.

Safety Days are an opportunity for all employees—including management—to conduct required compliance training as well as focus on team building, behavior-based safety observations (BBSO) and inspections, and review policies and any changes. At the end of the day, there’s even a competitive game to reiterate what employees were just trained on.

“The whole day is geared toward getting our employees involved and engaged in our safety program,” says JoAnn DeLaO, HSE manager.

Safety Days also include recognizing employees who have turned in quality BBSOs, completed equipment inspections, and gone above and beyond with regards to safety. They all receive a $5 gift card. Prior to a Safety Day, management reads all BBSOs and chooses those (usually four or five) who will be entered into a drawing for bigger prizes, such as $50-75 gift cards, Milwaukee pack out accessories, Bluetooth speakers and ice chests.

“Engaging and recognizing our employees lets them know we value them,” DeLaO says. “In turn, they will value us and will go the extra mile for safety.”

5

10.05.22 | EHS Today - Nicole Stempak

...continued on next page

That’s especially important since Hunter Site Services is a specialty installer of blast resistant buildings, which are used as safe havens in case of explosions.

The company, which was previously named one of America’s Safest Companies in 2016, continues to push the safety needle. The company constantly evaluates its processes and procedures and also reviews policies annually. Every two years, a team of safety professionals from other industry organizations audits the company’s books, its field safety and DeLaO’s performance.

“We take all the feedback and opportunities to grow and create goals to get where we need to be,” she says.

That need to educate and train—and the desire to improve safe operations—is what led to the creation of Safety Days

in the first place. DeLaO says Hunter Site Services used to train on paper, read aloud or show PowerPoint presentations. Now, the company invites subject matter experts to come in and present on topics such as heat stress and excavation. They offer hands-on training for matters such as fall protection, hand tools and equipment certifications. They’re also trying new methods for delivering that training, such as adult learning theories, games and VR training. They’ve even started offering third-party training for supervisors with a focus on soft skills to teach them how to coach and lead better.

“I think we are setting new standards,” DeLaO says.

Photos courtesy of Hunter Site Services

7 OSHA’s Top 10 Violations Announced: Fall Protection Tops List 09.21.22 | OSHA.gov Preliminary data show some changes in Top 10 rankings 1. OSHA’s Top 10 list of most frequently cited standards for fiscal year (FY) 2022 was announced on September 20 by Patrick Kapust, deputy director of OSHA’s Directorate of Enforcement Programs, at the 2022 National Safety Council (NSC) Safety Congress & Expo. 2. Preliminary data show that fall protection once again topped the list. While the Top 10 generally includes the same standards from year to year, the rankings tend to move around. TOP 10 MOST FREQUENTLY CITED VIOLATIONS – FY 2021 Ranking Standard Standard Number 1 2 3 4 5 6 7 8 9 10 1926.501 1910.1200 1910.134 1926.1053 1926.451 1910.147 1910.178 1926.503 1926.102 1910.212 Fall Protection – General Requirements Hazard Communication Respiratory Protection Ladders Scaffolding Lockout/Tagout Powered Industrial Trucks Fall Protection – Training Requirements Personal Protective and Lifesaving Equipment – Eye and Face Protection Machine Guarding

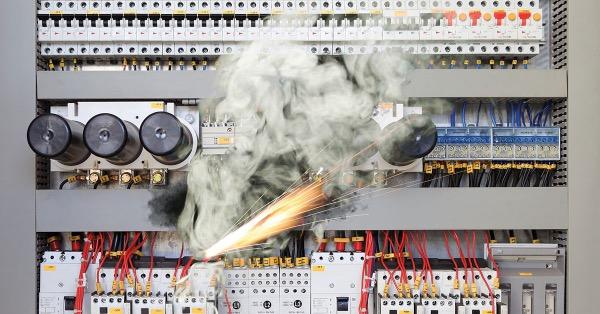

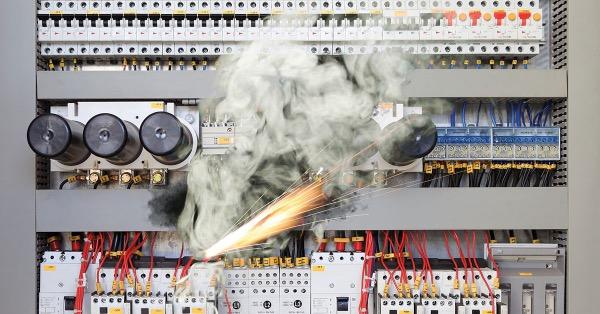

Protecting Workers From Electric Shock Hazards

09.19.2022 | JJ Keller

09.19.2022 | JJ Keller

An electric shock can cause anything from a slight tingling sensation to immediate cardiac arrest. The severity depends on the amount of current, the current’s path through the body, the length of time the body remains in the circuit, and the current’s frequency.

Electrical burns are caused when current flows through tissues or bone, generating heat. A severe shock can cause damage to blood vessels, nerves, and muscles that won’t be visible. Anyone who receives a shock should seek emergency medical help immediately.

A shock may cause muscles to contract, preventing the person from pulling free. This increases the length of exposure, creating a greater risk of serious injury. Longer exposures at even low voltages can be just as dangerous as short exposures at higher voltages. Low voltage does not imply low hazard.

If a person is “frozen” to a live electrical contact, shut off the current immediately. If this is not possible, use boards, poles, or sticks made of wood or other nonconducting materials to push or pull the person away from the contact. It’s important to act quickly but remember to protect yourself as well from electrocution or shock.

PROTECTING WORKERS

Methods to protect against shock include insulation, guarding, grounding, electrical protective devices, and safe work practices.

• Guarding involves enclosing electric equipment to prevent contact, along with warning signs such as “Danger/High Voltage/Keep Out.”

• Grounding involves creating a low-resistance path to the earth. It reduces the risk of shock, especially when used with other safety measures. An equipment ground helps protect the operator by providing a path for the current to pass from the tool or machine to the ground.

• Circuit protection devices limit or stop the flow of current automatically in the event of a ground fault, overload, or short circuit in the wiring system. Examples include fuses, circuit breakers, ground-fault circuit interrupters (GFCIs), and arc-fault circuit interrupters. GFCIs are used in wet locations, construction sites, and other high-risk areas. They interrupt the flow of electricity to prevent electrocution.

Employees who work directly with electricity should use any personal protective equipment required for the jobs they perform. This may include rubber insulating gloves, hoods, sleeves, matting, blankets, and protective helmets designed to reduce electric shock hazard.

Using appropriate and properly maintained tools protects workers also. Workers should check each tool before using it. If they find a defect, they should immediately remove the tool from service and tag it so no one will use it until it has been repaired or replaced.

TRAINING

Train employees in the safety procedures for their jobs, including how to inspect equipment for defects. When working on electrical equipment, basic procedures to follow include:

• Deenergizing the equipment,

• Using lockout/tagout to ensure the equipment remains deenergized,

• Using insulating protective equipment, and

• Maintaining a safe distance from energized parts.

In short, preventing electric shock requires delivering training on the hazards, safe work practices, and protections adopted by the employer.

9

US DEPARTMENT OF LABOR CITES MISSOURI CONTRACTOR IN FATAL DUDLEY TRENCH COLLAPSE

Lethal construction industry hazard buries worker under thousands of pounds of soil in seconds

DUDLEY, MO - A federal workplace safety investigation alleges that a Dexter construction contractor might have prevented a pipelayer’s fatal injuries in a trench collapse on April 8, 2022, if the company had used trench safety protection measures as required by law.

The worker was installing storm water drainage in an 8-footdeep trench along Old Highway 60 in Dudley when the tragedy occurred.

Trench collapses are among the construction industry’s most lethal hazards. In the first six months of 2022, the U.S. Department of Labor’s Occupational Safety and Health Administration reports 22 workers suffered fatal injuries in trenching and excavation work.

Following its investigation, OSHA determined Brown Construction Co. Inc. failed to use a trench box, or to

shore or slope the trench walls to prevent collapse. The company did not provide a required means to exit the 80-foot-long trench. It also failed to train employees about excavation hazards and safety precautions and did not have a competent person inspect the trench daily for potential hazards.

OSHA cited Brown Construction Co for four serious violations of federal trenching and excavation standards , and proposed penalties of $58,008.

OSHA NEWS RELEASE - REGION 7

OSHA

Since 2009, Charm Builders Ltd. cited 12 times for exposing workers to deadly fall hazards

WHEELING, WV – A Millersburg, Ohio, contractor with a long history of disregarding workplace safety standards now faces more than $1 million in penalties after an inspection by the U.S. Department of Labor’s Occupational Safety and Health Administration found their employees working at dangerous heights without fall protection, this time at a West Virginia work site.

Responding to a complaint from roofing workers atop a two-story office building without fall protection on March 29, 2022, OSHA found Charm Builders Ltd. allowing

employees, some at heights up to 28 feet, to work without required protection, and exposing them to the construction industry’s most deadly hazard.

OSHA issued citations for 12 violations – six egregious-willful, five repeat and one serious – for failing to ensure the use of fall protection, not training employees on fall hazards, allowing unsafe use of portable ladders, and not making sure workers used safety glasses. This marks the 12th time that OSHA has cited Charm Builders since 2009 for violations related to fall hazards. OSHA has placed the contractor on its severe violators list.

The agency has proposed $1,090,231 in penalties.

“It is unconscionable when construction contractors put workers at risk and undercut law-abiding companies by failing to invest in basic, life-saving protections,” said Assistant Secretary for Occupational Safety and Health Doug Parker. “We will use all of our available legal powers to hold accountable employers like Charm Builders who continually put people in serious jeopardy.”

In fiscal year 2021, the agency issued citations for fall protection failures in the construction industry more than any other workplace safety standard. OSHA reports that 351 of the 1,008 construction workers who died on the job in 2020 were victims of falls from elevation.

11

NATIONAL NEWS RELEASE

OHIO CONTRACTOR CONTINUES TO DEFY FEDERAL FALL PROTECTION SAFETY RULES, CITED FOR EGREGIOUS WILLFUL VIOLATIONS, FACES $1M IN FINES AFTER WORKPLACE INSPECTION

SLC 2022 Preview: Take Charge of Safety

09.30.2022 | EHS Today, Nicole Stempak

Regardless of your background or years of experience, there’s always something new to learn and ways to improve. That can be both exciting and terrifying for safety professionals. Here’s how to embrace change and be an effective leader.

It’s not easy being in charge. For one, everyone assumes you know everything. And two, you’re responsible for everyone. And three, you need to figure out a way to get through to people before something catastrophic happens.

EHS Today spoke William Gibson, ASP, safety specialist of the Del-Co Water Company, about ways safety professionals can further their own knowledge of safety and grow in their career, all while making sure workers take your safety program to heart.

Gibson will speak at the 2022 Safety Leadership Conference , being held in Cleveland from Oct. 18-20. Below is a preview of what to look forward to this fall.

EHS Today: Your presentation is geared toward safety professionals at all levels: those new to the field, a new role or those who are accepting more responsibilities. Regardless of title or years of experience, what is the first thing someone who has been handed the safety reins should do?

Gibson: In my opinion, the first thing someone should do is walk the floor and meet everyone. Although many might choose to assess the workplace or round up past OSHA 300 data, I think first impressions make the biggest impact. You might not remember their name after the first meeting, but a smile or a laugh is something they’ll remember. Management skills don’t come naturally and being good at your job or having subject matter expertise doesn’t automatically make you a great leader. What other misconceptions do organizations have about safety leadership?

One of the biggest misconceptions I’ve noticed is that the safety professional is responsible when an employee is injured. Although our job is to educate and provide the tools necessary to complete daily tasks in a safe manner, each employee is even more responsible for making the right decision, in addition to utilizing the provided training and tools.

What misconceptions do safety professionals have about what it means to be a leader?

Many feel that being a leader means you have to know everything. Even when they don’t, they’ll pretend to. It’s OK if you don’t know everything. It’s OK to ask for help. It’s OK to be wrong. When your employees are able to provide

feedback—or even stump you—it’s a great thing, because it means they’re engaged and are thinking about safety.

Whether safety professionals have been in the field for 5 months, 5 years or 25 years, there’s always something new to learn, try or do. How can safety professionals embrace an environment of constant change?

Some people either have patience or they don’t. If you’re unable to embrace change, this might not be the profession for you. There is always a fire (not always literal) to put out, always a question and always the risk of an injury (or worse). Safety professionals must be ahead of the game by staying up to date with current trends while attempting to bring some innovation to the table. Just because you haven’t done it before, doesn’t mean you can’t now—or in the future.

Safety professionals come from different backgrounds, with some having formal education credentials and others having more real-world experiences. Regardless of background, how can they continue to develop and grow as a leader?

By pushing themselves outside of their comfort zone. Opportunities such as speaking at this conference will likely unlock new opportunities [for me] while enhancing my confidence. Whether it’s through networking or future speaking engagements, it’s important to take what you’ve learned and pass it on. [However, it] doesn’t always have

to be in front of hundreds of people. Even if it’s one new idea, it could make all the difference for someone else’s safety program.

How can safety professionals make safety more fun and accessible?

My biggest impact comes when I visit jobsites to work, not just to observe. Sure, it’s not my job to get down in a hole or operate a forklift, but when my employees see me getting dirty or hitting a cone during my forklift assessment, it shows I’m just like them. When they see your true character, they’ll not only be willing to put up with your 30-minute training about bloodborne pathogens, they’ll [also] be willing to walk with you and buy into what you’re trying to achieve. The psychology here is HUGE.

What’s one thing you hope attendees learn from your session at the Safety Leadership Conference?

I hope they learn that safety isn’t about being the enforcer so much than it’s about being a real-life person who truly cares about the people you serve. That’s the key word: serve. Yes, we are tasked with running a program that ensures that our organization is compliant. But more importantly, we are here to serve our employees by making sure we not only listen to their feedback, but act on it because it’s the right thing to do.

13

When Training Workers To Use Equipment, Teach Them To Identify Defects

10.03.2022 | JJ Keller

Employers must train workers to properly use equipment but should also explain how to spot problems. You likely have employees who use equipment that they aren’t responsible for inspecting on a regular basis, but they should still be able to identify defects. Here are a few examples: Dockboards: Employers must inspect all walking-working surfaces regularly and as necessary, including dock boards, but they probably don’t need a daily inspection. Employees who use dock boards should know how to properly position them but should also be able to spot defects such as cracks or loose bolts. In addition, if damage occurs during use, employees should report any problems and avoid using the damaged or defective dock board.

Storage areas: Defective storage racks pose a threat to anyone in the area. Potential problems might include bent or sagging shelves, loose bolts where the rack is secured to the floor and bent or damaged uprights. If a rack got bumped by a forklift, for example, employees should recognize any damage and report the problem. A sign or tag may be needed to warn against using the rack until repairs are completed.

Removeable guardrails: Elevated working areas should be protected by guardrails, but may include gates, chains, or removable sections so that forklifts can deliver pallets to the upper area. When not in use, the gate must be closed or the chains must be secured. In addition, a defective guardrail (such as one that wobbles) creates a fall hazard, and workers should report those problems.

Ladders and stairs: Employees who use ladders must inspect them before the first use on each shift and after any incident that might cause damage, such as the ladder falling over. This requires training on what defects to look for that require removing the ladder from service. Employees should inspect fixed ladders and mobile ladder stands before use as well. Even stairs could have defects such as loose handrails or worn tread. Employees should notice and report such defects.

Maintaining a safe work environment requires ongoing vigilance, which is one reason OSHA requires employers to conduct regular inspections. Even if employees aren’t responsible for conducting those inspections, they should be able to recognize defects and report any problems such as damage that occurs during use.

Globally Harmonized System (GHS)

Weeklysafety.com, Volume 2, Issue 154

OSHA’s Hazard Communication Standard (HCS) is now aligned with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

• When OSHA made this update to the HCS in 2012 they enacted a universal and easier-to-understand approach to classifying chemicals and communicating hazard information on labels and safety data sheets (SDS).

• The U.S. HazCom standard (HCS), that now matches the international HazCom standard (GHS), is better for businesses and creates a safer work environment for employees.

HOW HAZARD COMMUNICATION WORKS

Chemicals are classified by their hazardous properties.

Chemicals are labeled.

Chemicals have a prepared safety data sheet.

Chemicals are received with labels and safety data sheets.

A written communication program is created.

A list of the hazardous chemicals in the workplace is prepared.

All hazardous chemicals are labeled for safety.

For all hazardous chemicals, safety data sheets are available and easily accessible.

Training is provided on chemical hazards and protective measures.

15

MANUFACTURERS, IMPORTERS, &

DISTRIBUTORS EMPLOYERS EMPLOYEES ...continued on next page

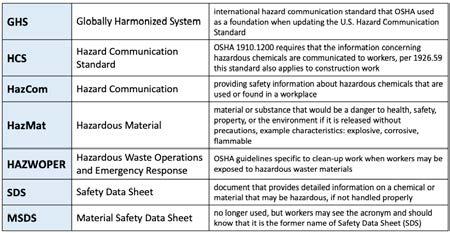

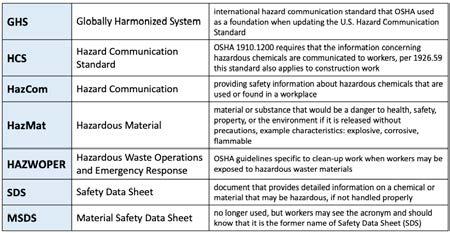

When referring to hazard communication, there are several acronyms and abbreviations that are often used, and sometimes it can get confusing. Here are the basics:

• Workers have the right to know and understand the hazardous properties of the chemicals in the workplace to which they may be exposed.

• Workers have the right to all pertinent information that will enable them to work with or around such chemicals in a safe manner.

The Hazard Communication Standard (HCS), that aligns with the international standard (GHS), has key requirements that help to ensure chemical safety in the workplace.

• Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import and prepare labels and safety data sheets (SDS) to convey the hazard information.

• When a workplace or jobsite has hazardous chemicals, those materials must be identified with proper labels and safety data sheets (SDS) must be readily available for workers.

• Workers must be trained on the safe ways they are expected to handle hazardous materials. Employee training must include information on the hazards of the chemicals in their work area and the measures to be used to protect themselves.

OSHA Standard 1910.1200(h)(1) Employers shall provide employees with effective information and training on hazardous chemicals in their work area at the time of their initial assignment, and whenever a new chemical hazard the employees have not previously been trained about is introduced into their work area.

Workers that handle chemicals or are in a work environment where chemicals are used, have a right to know the dangers of those chemicals.

• Employees should be trained on how to read an SDS. Because all Safety Data Sheets are written in the same manner, once employees are trained on how to read the document, they should be able to understand any SDS.

• There are 16 required sections that can be found on every SDS, that provide information on the hazardous chemical including 1) what it is, 2) what are the hazards, and 3) how do you prevent the hazards from becoming dangerous and how do you protect yourself from those hazards.

• The HCS (based on the GHS) requires the Safety Data Sheets to be in a uniform format so that each of the 16 sections are always in the same order to ensure that employees reading the document can quickly get the information they need.

• The SDS format is the same as the ANSI standard format which is widely used in the U.S. and is already familiar to many employees.

• SDSs must be readily accessible to employees.

OSHA Standard 1910.1200(g)(8) The employer shall maintain in the workplace copies of the required safety data sheets for each hazardous chemical and shall ensure that they are readily accessible during each work shift to employees when they are in their work area(s).

The Globally Harmonized System (GHS) and the Hazard Communication Standard (HCS) require universal pictograms to be displayed on labels to alert users of the chemical hazards to which they may be exposed.

• The GHS (international standard) has 9 pictograms that are used on hazardous products.

• OSHA’s HCS requires 8 of these pictograms on hazardous chemical labels. The Environment pictogram is nonmandatory because environmental hazards are not within OSHA’s jurisdiction.

• Each pictogram consists of a symbol on a white background framed within a red border and represents a distinct hazard or set of hazards.

• Workers should become familiar with these images and the hazards they represent.

• Labels on hazardous chemical containers must remain legible and should not be defaced or removed.

COPYRIGHT AND DISCLAIMER

This material is the copyrighted property of Weeklysafety.com, LLC. Purchase of this material from Weeklysafety.com, LLC grants the owner the right to use this material for workplace safety and education purposes only. Use of this material for any other purpose, particularly commercial use, is prohibited. This material, including the photos, may not be resold. Weeklysafety.com, LLC does not warrant or assume any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed in these materials. Photos shown in this presentation may depict situations that are not in compliance with applicable Occupational Safety and Health Administration (OSHA) safety requirements. These materials are meant for informational purposes only and it is not the intent of Weeklysafety.com, LLC to provide compliance-based training. The intent is more to address hazard awareness in the construction and related industries, and to recognize the potential hazards present in many workplaces. These materials are intended to discuss Federal Regulations only, as individual State requirements may be more stringent. Many states operate their own state OSHA and may have standards that are different from information presented in this training. It is the responsibility of the employer and its employees to comply with all pertinent OSHA safety rules and regulations in the jurisdiction in which they work.

PHOTO ACKNOWLEDGMENTS

Unless specified below, all photos are the copyrighted property of Weeklysafety.com, LLC and may not be used in any other training materials or resold for any purpose.

17

09.19.2022 | JJ Keller

09.19.2022 | JJ Keller