THE SAFETY NET

IT’S ALWAYS SAFETY FIRST.

October Is Hearing Awareness Month 06.24.2022 | Healthy Hearing by Joy Victory

While not all types of hearing loss are preventable, there are steps you can take to lower your risk of developing age-related hearing loss and/or noise-induced hearing loss.

SAFE T Y FIRST.

Austin employees have worked 5,110,293 hours without a Lost Time Accident through 8/2022.

LOCATION CONSULTING DESIGN & ENGINEERING DESIGN-BUILD CONSTRUCTION & CONTRACTING OCTOBER 2022 VOLUME 16 ISSUE 10

CONSULT • DESIGN • ENGINEER • CONSTRUCT

8 WAYS TO PREVENT HEARING LOSS

It’s never too early—or too late—to begin wearing hearing protection around loud noises. And adopting a healthy lifestyle and following your doctor’s advice can go a long way to protecting your hearing health .

We can’t stress enough the importance of reducing your exposure to loud noise (more on that, below) but there are other healthy habits that will also help you preserve your hearing as you get older:

8 LIFESTYLE TIPS TO HELP PREVENT HEARING LOSS

Your inner ear contains delicate hair-like cells that are quite sensitive to changes in blood flow, they are vital to how we hear . If these cells are damaged, you experience hearing loss. The healthier you are overall, the better you can prevent hearing loss —or preserve the residual hearing you do have, if you already have hearing loss.

1. MANAGE YOUR BLOOD PRESSURE AND CARDIAC HEALTH

High blood pressure and heart disease can damage the fragile mechanisms inside your ear that help you hear. If you have high cholesterol or blood pressure, follow your doctor’s treatment orders to get it under control.

2. STOP SMOKING AND VAPING, AND LIMIT DRINKING

Studies definitively show that cigarette smoke —whether directly, secondhand, or even in utero—can have a big impact on a person’s hearing health. Likewise with heavy alcohol use , which can create a toxic environment in the ear. Vaping and hearing loss isn’t as well-studied, but there are anecdotal reports linking it to sudden hearing loss.

3. KEEP DIABETES UNDER CONTROL

Research has shown that people with diabetes are twice as likely to have hearing loss . Just as with high blood pressure, diabetes can damage the cells in your inner ears. Keep your blood sugar under control and follow your doctor’s orders for managing diabetes.

4. EXERCISE AND PRACTICE STRESS REDUCTION

What isn’t exercise helpful for? Exercise improves blood flow and helps your body—and your ear health—in countless ways. (Just be careful about loud music and incorrect weightlifting at the gym ; both are linked to hearing damage.) And because chronic high levels of stress aren’t good for your hearing (or the rest of you), do what you can to keep stress levels under control.

5. EAT FOODS HIGH IN CERTAIN VITAMINS AND MINERALS

Did you know that several vitamins and minerals , especially B12, potassium and magnesium are vital to good hearing? Iron-deficiency anemia is linked to losing your hearing, so try to eat a diet rich in iron.

6. KNOW YOUR FAMILY HISTORY

While knowing your family history won’t directly prevent hearing loss, it will help you know if you’re at elevated risk. Catching it early can reduce your risk of the negative impacts of hearing loss, such as cognitive decline, depression and social isolation.

7. BE AWARE OF DRUGS THAT CAUSE HEARING LOSS

Hundreds of over-the-counter and prescription drugs are linked to hearing loss. These ototoxic drugs range from ordinary, over-the-counter medications like aspirin to chemotherapy drugs and IV antibiotics. In some cases, you may be able to take an alternative drug to reduce your risk of drug-related hearing loss.

8. LAST BUT NOT LEAST, LOWER YOUR RISK OF NOISEINDUCED HEARING LOSS (NIHL)

Even if you’re as healthy as an Olympian and eat salads all day long, you still risk hearing damage if you don’t protect your hearing in noisy environments. Regardless of your age

or your hearing status, it’s always a good idea to protect your hearing when you’re going to be exposed to loud sounds. Simply put, there is nothing more damaging to your hearing.

COMMON SOURCES OF DAMAGING NOISE

Noise-induced hearing loss can have many sources. Blasts, like gunfire or fireworks , can cause immediate hearing loss. Less explosive sounds, such as airplane engines, rock concerts, or even high-pitched dentist drills, still cause damage, just more slowly. Either way, the damage is almost always irreversible and cumulative.

One common source of hearing damage you might not even realize? Your earbuds and headphones , especially if you don’t take the right precautions when you listen to music.

HOW CAN YOU PROTECT YOUR HEARING?

Plan to use hearing protection like earmuffs and earplugs anytime you’ll be immersed in loud sounds. (Gun enthusiasts should wear both!) Not only do you reduce your risk of hearing loss, you may also stave off tinnitus, or ringing in the ears . If you work in a noisy place—for example, at a hair salon with blow dryers constantly in use and music blaring in the background—find out if your employer offers noise protection, or bring your own. You’ll thank us later!

3

...continued on next page

WHEN IS IT TOO LOUD?

Signs your hearing is at risk

HOW TO KNOW IF IT’S TOO LOUD

Anything over 85 decibels can cause hearing loss. That’s roughly equivalent to standing in city traffic or pushing a lawnmower. If you’re out and about and have a smartphone, these apps can help you measure the sound around you . And the following guidelines are good to keep in mind:

If a situation feels too loud, it probably is. Beyond that, watch for these signs:

• You need to raise your voice to be heard

• You are unable to hear someone three feet away from you

•

Speech around you sounds muffled or dull after leaving a noisy place

• You experience pain or ringing in your ears (tinnitus) after being in a noisy place

GET A HEARING TEST

Preventing hearing loss means being proactive in your approach to hearing health. If you wouldn’t hesitate to have your eyes or teeth checked, it is time to add regular hearing exams to your list of check-ups. If your test indicates you already have some hearing loss, you can begin taking action to prevent it from getting worse. If you need hearing aids , your hearing professional can discuss the best options for your hearing loss, lifestyle and budget.

Lifelong hearing health starts with you.

Pay attention to noise levels at work and at play. There’s no need to stop enjoying the hobbies you love if you can take reasonable steps to protect your ears from noise.

If you need a baseline hearing test, or if you suspect you may already have some hearing loss, visit our extensive directory to find a dedicated hearing healthcare professional near you.

Definitions Key to Understanding Permit Space Entry

09.12.22 | JJ Keller

OSHA’s standard for permit-required confined spaces often raises questions on the difference between a “confined space” (also called a non-permit space) and a “permitrequired confined space” (also called a permit space).

OSHA defines a confined space as one that meets the following criteria:

• Large enough for an employee to enter and work;

• Limited or restricted means of entry and exit; and

• Not designed for continuous occupancy.

OSHA doesn’t regulate employees in non-permit spaces.

Those areas may be awkward to work in, but they don’t pose a significant threat. On the other hand, a permit space is a confined space that has one or more of the following:

• Contains or has a potential to contain a hazardous atmosphere;

• Contains a material that has the potential for engulfing an entrant;

• Has an internal configuration that could trap or asphyxiate an entrant by inwardly converging walls or a floor which slopes downward and tapers to a small cross section; or

• Contains any other recognized serious safety or health hazard.

Employers must identify any permit-required confined spaces and inform exposed employees by posting signs or using other effective means to identify the existence and location of (and the danger posed by) the permit spaces.

If employees will enter a permit space, the employer must develop a program to protect them from those hazards.

A permit space program regulates entry and outlines the conditions that must be met to allow employee entry.

ENTRY OR NOT?

Be aware that “entry” does not necessarily mean crawling into the space. OSHA says that “entry” occurs “as soon as any part of the entrant’s body breaks the plane of an opening into the space.” Even reaching an arm into a permit space could be considered “entry.”

If employers do not allow entry, they must take steps to prevent employees from entering permit spaces. They must still inform workers about the spaces, evaluate non-permit spaces following changes in their use or configuration, and cooperate with contractors who will enter the permit spaces.

A good practice is to bar or lock the potential entry portals.

In fact, OSHA has said that posting signs is not required if the only means of access requires using tools or keys, provided the employees expected to gain entry (if any) are trained.

5

The One Thing You Need to Know about Workplace Safety

Start by identifying what is the one most important safety initiative you want to make progress on this year.

In The ONE Thing: The Surprisingly Simple Truth About Extraordinary Results by Gary Keller and Jay Papasan, the authors share physicist Dr. Lorne Whitehead’s work demonstrating that a domino is capable of knocking down another domino one-and-a-half times its size. What that means is that a domino that is just 5 millimeters tall can knock down a domino 7.5 millimeters tall, which then could knock down a domino 11.25 millimeters tall. In such a manner, it would only take 29 dominoes to knock down the Empire State Building.

To help readers identify their own first domino, the book suggests they ask themselves the following question: “What’s the ONE Thing I can do such that by doing it everything else will be easier or unnecessary?”

Inspired by the book, the author surveyed and interviewed safety professionals and company leaders and discovered a few common themes and patterns about their ONE Thing across four main categories:

1. Their upcoming safety initiatives,

2. Targeted safety practices,

3. The role of senior leadership in safety and

4. The beliefs of those on the frontline of performing the work safely.

SURVEY RESULTS

Respondents represented a wide range of industries including safety consultancy, utility, manufacturing, government, construction, mining, oil and gas, military, and health care. Below is a summary of their responses to four questions.

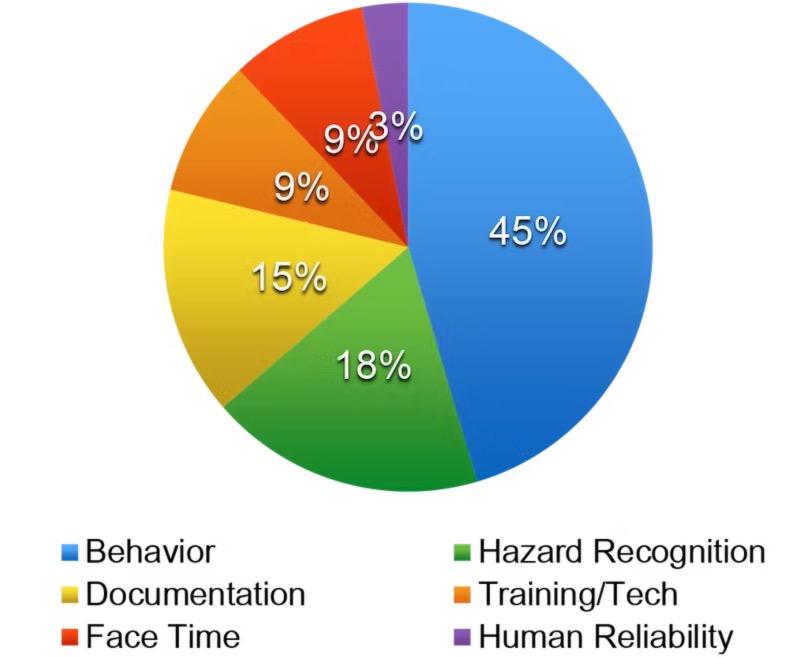

What is the one most important safety initiative you want to make progress on this year?

Most respondents (Figure 1) reported initiatives targeting behaviors such as improving reporting, critical thinking, planning, or psychological safety. Many responses in this category referred to ownership and culture in general. Next most common were behaviors targeting employees’ hazard recognition or risk acceptance skills. Several

08.23.2022 | EHS Today

organizations reported focusing on centralizing and streamlining their documentation for employees or for certification purposes. Others had software or training rollouts in progress.

What is the one thing you really wish your senior leadership understood about safety?

Many respondents (Figure 3) reported that they work for leaders who “get it.” Others mentioned how critical it is for leaders to understand just how much they influence safety. Whether or not they lead by example or give mixed messages drives results and behaviors down the line. They also want their leaders to appreciate the complexity of safety: it impacts the organization in many ways, there are many root causes, it’s difficult to measure, and it takes time to see results. So, invest in programs and safety staff.

Figure 1

What is the one strategy, tool, or behavior your team needs to adopt to improve safety?

While most respondents (Figure 2) reported they would like to generally target behaviors that improved ownership or culture, there was not often a specific behavior identified that would help accomplish that goal. Communication behaviors were the next most common with respondents wanting to improve job planning dialogues, storytelling and info-sharing. They also reported the need to be continually recognizing, anticipating and mitigating hazards. Leadership behaviors such as coaching, seeking feedback and strategic thinking were also mentioned.

Figure 2

Figure 3

What is the one thing the frontline needs to understand about your safety program?

In a nutshell, respondents want the frontline to know that the safety department isn’t responsible for safety (Figure 4). The frontline has to own the program, follow the guidelines, and reach out for guidance from the safety department when they need it. Many respondents want the frontline to understand just how much they care about going home in the same condition and that the purpose of the safety department is to make that happen. If safety procedures are too burdensome or not helping, then collaborate with safety to make it better.

7 ...continued on next page

4

INTERVIEW INSIGHTS

For a deeper understanding of the ONE Thing across these four questions, the author interviewed safety professionals and company leaders from the manufacturing, maritime, military, utility, construction, environmental inspection, pharmaceutical, and oil and gas industries. Based on these interviews, here are four principles to help take your organization’s safety to the next level.

1. EMBRACE METRICS

Across the board, there was significant frustration and lack of clarity when it came to metrics that accurately conveyed an organization’s level of safety or risk. The safety professionals we spoke with understood that having statistics for their leaders was important, but they also found it really hard to do.

In the past, there was a lot of focus on lagging indicators around injury rates and lost time, but those statistics don’t provide information on what is causing a problem. Nor do they tell if an organization is safe or if it’s just that all the holes in their Swiss cheese haven’t lined up yet. Nevertheless, there is still a lot of pressure on those metrics.

On the one hand, safety professionals are feeling that these lagging indicators are inadequate, but on the other, they can’t let them go. Part of the reason they can’t let them go is because there aren’t good replacements. During our interviews, we collected over 3 0 potential candidates for leading indicators

Despite these difficulties, it’s important to embrace metrics because time and money are finite. When invested in one area, they can’t be invested someplace else. Knowing if

an investment was worthwhile and should be continued requires some kind of way to measure success.

2. EMBRACE BUY-IN

Time and time again, safety professionals expressed the belief that workplace safety was not solely the responsibility of the safety department and that every person in the organization played a role in it. Safety professionals said they wanted more buy-in from other departments. They wanted employees to take ownership of their own personal safety.

Safety culture, ownership and accountability are driven by buy-in. Buy-in comes from at least three places. The first happens when employees connect the dots for themselves about how some change the organization wants to make to a process, a piece of equipment, or a behavior is important to them. It’s much easier to write a memo or stand in front of a classroom and tell people why it matters. But it’s much more powerful when they realize for themselves how it protects something they want to protect or helps them accomplish something they want to accomplish.

Buy-in also happens when employees participate in the problem-solving process. Adults like to feel a sense of autonomy, and they want to apply tools and strategies in ways that make sense to them and accommodate their experiences. Involve employees in crafting the solutions, and they will be significantly more bought in. During our trainings, employees always craft their own plan of action on how they will apply a new behavior into their own work day.

The third place buy-in comes from is leadership. Are they allowing the time and investing in the structure that allows employees to connect the dots and be a part of the solution? Are they communicating mixed messages about safety? Are they undermining employees’ sense of autonomy or respect with authoritative or dismissive communications?

3. EMBRACE A HOLISTIC APPROACH.

Many organizations are finding that the quick wins and easy solutions are already addressed. To reach the next level of safety performance, they have to dig deeper and address multiple areas to have an impact. It requires both developing resilient systems so that employees are protected when errors are made and improving how employees behave within the systems.

When it comes to changing how employees behave, organizations have to appreciate how difficult that is. Human beings are complicated. Employees don’t

Figure

leave work at work or home at home. Their physical and emotional well-being matters, so improving workplace safety means investing in programs that help employees create healthy personal well-being habits. Leadership and communication skills are important at every level in an organization, but they are most often neglected in the frontline supervisors who can have the greatest impact on workplace safety. Getting employees to adopt these new skills requires both good training and embracing the next principle: focus.

4. EMBRACE FOCUS

Returning to the domino analogy, the domino is the initiative to learn a new technology, tool, or behavior that will make the biggest improvement and set you up to knock down the next domino. Unfortunately, knocking over a domino takes so much more time and effort than we would like.

One of the biggest struggles mentioned in the interviews was how hard it was to maintain focus long enough to see results from an initiative. Organizations have so many other priorities to address. There’s always the next training that has to get done, the next initiative it’s time to launch, and that

next e-mail that needs to get sent. As a result, organizations have moved on before employees have incorporated new knowledge, tools and behaviors into their existing habits. In order to get long-term measurable results, we recommend organizations plan to spend at least 60 days after the launch focusing on the knowledge, tools and skills they want employees to retain. Plan ahead of time the micro lessons that will revisit key topics and takeaways from different angles or with different examples. Set up a structure that helps employees practice new skills until it becomes a natural part of their day.

MAKING A DIFFERENCE

Now it’s your turn. What is the ONE Thing you can do such that by doing it each of your efforts to create a safer workplace will be easier or unnecessary? As you’re answering that question, take a holistic approach to look at the entire organization and the many facets of your employees’ lives. Involve employees in strategizing how to knock the domino over, identify the metrics by which you’ll determine the success of the initiative, and then focus on it long enough to make the difference you want see.

9

What To Do When OSHA Shows Up At Your Project

09.06.22 | Weeklysafety.com

What are the do’s and don’ts when it comes to OSHA visits? Do all employees know what to do if an OSHA Compliance officer shows up without calling first? If not, they should, because their first reaction might not be the best one.

OSHA may make inspections to any work site and rarely will advance notice be provided. These inspections may cover the entire workplace or just a few operations.

Why OSHA may select a company for inspection:

1. Imminent Danger, when there is a good chance that a hazard could result in death or serious harm.

2. Fatal or Catastrophic Accidents, all work-related fatalities must be reported within 8 hours and all workrelated inpatient hospitalizations, amputations, or losses of an eye must be reported within 24 hours.

3. Employee Complaints of unsafe working conditions or alleged safety violations.

4. Program Inspections in industries that have a higher than normal accident rate.

5. Special Emphasis Programs that are currently being targeted by OSHA, like Excavations for example.

6. Follow-up Inspections to verify that cited violations have been corrected (abated).

OSHA inspectors are referred to as Compliance Officers and they may have training on safety hazards or health hazards (or both).

WHEN AN OSHA COMPLIANCE OFFICER ARRIVES ON SITE, here is what all employees and managers should know about ahead of time.

1. Notify the person responsible for the site, such as the supervisor, manager, project superintendent or owner.

2. Request identification, write down the Compliance Officer’s name and ID number, and ask which area office they represent.

3. The purpose of the inspection should be stated by the Compliance Officer before or during an opening conference at the beginning of the visit.

4. A manager should escort the Compliance Officer at all times.

5. During the walk-around inspection, the Compliance Officer is permitted to take notes and photographs and shall comply with the safety and health rules required at the job site.

6. Employees may be interviewed or written statements may be requested.

7. A company representative should take notes and photos of all inspection activities.

8. A closing conference will be arranged to allow the Compliance Officer to review any violations observed and refer to applicable OSHA standards.

9. Instructions on follow-up procedures will be provided at the end of the inspection.

During the inspection, everyone on site should follow these guidelines:

• Be cooperative.

• Do not evade questions or try to hide anything.

• Answer questions truthfully, but do not speculate.

• Do not be sarcastic or argumentative.

• Do not volunteer information, answer only the questions asked.

• Do not volunteer an admission of guilt.

• Take notes, measurements and photos.

• If possible, fix any violation immediately.

OSHA Standard 1926.3(a)(1) states that any authorized representative shall have a right of entry to any site of contract performance … to inspect or investigate the matter of compliance with the safety and health standards…

Can the foreman or supervisor of the work site refuse to let the Compliance Officer on site? Yes, but it is not recommended. It is always best to cooperate with any OSHA compliance officer.

Does the Compliance Officer need to show a warrant? No, but entry can be refused until a warrant is provided. However, cooperation with OSHA is always recommended and granting immediate entry will get the inspection off to a good start.

Can an employee refuse to be interviewed? Yes, but cooperation by all employees is advisable. An employee can ask that they have another person with them during the interview.

If hardhats or PPE are required in the work area, can the Compliance Officer refuse to comply with the PPE requirements since they work for OSHA? No, the Compliance Officer must wear any PPE required in the work area they are inspecting.

What can happen if the company receives a citation? If a violation is recorded, OSHA will require a corrective and preventive action plan, the violation will be on the company’s public record and there may be a financial penalty assessed.

11

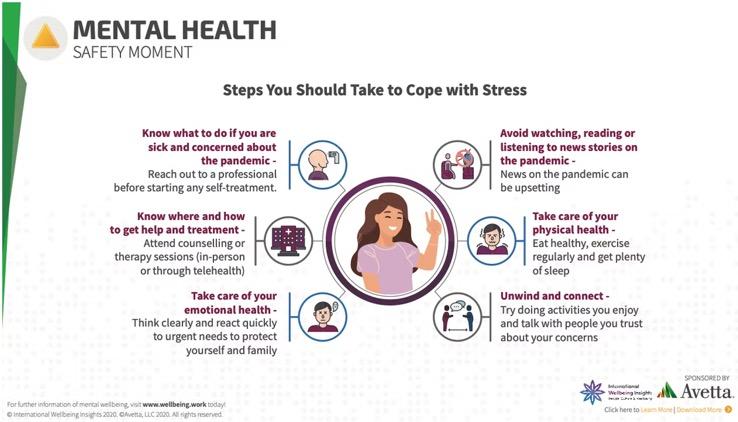

How to Reduce Stress and Improve Mental Health in the Workplace

09.13.22 | EHS Today by Richard Parke

09.13.22 | EHS Today by Richard Parke

Companies need to develop a new understanding of stress and help people feel connected and supported.

Most often, stress has a negative connotation. We associate stress with headaches, sweating, rises in blood pressure and other physical symptoms.

In reality, however, stress serves to help and protect us. The stress response is part of our evolutionary biology since our earliest human ancestors depended on it for survival. When we face serious threats or danger, stress creates adrenaline and a boost of energy and gives us the extra brain power to focus on what’s needed.

The problem is that, in today’s environment, there are too many stressors. We’ve just been through a pandemic that caused us to miss a lot of events and stay home for longer than we’ve been used to. National and world events have only added to that stress.

The American Psychological Association regularly polls Americans about their stress levels. In March, more than 80% of respondents said the biggest stressors of their lives included all of these concerns: inflation, supply chain issues, global uncertainty and Ukraine. The report stated that while we are doing remarkably well in coping with these issues, we are reaching “unprecedented levels of stress.”

The report also notes that diminished social support during the pandemic made coping with stress much more difficult. It’s time we reverse these trends, and it starts with us as leaders. We don’t have to perpetuate negative and stressful environments any longer, especially in the workplace. There are changes you can make in your organization to reduce stress and improve mental and physical health for all. You can start by developing a new understanding of stress, creating a long-term strategy for your organization, and helping people feel connected and supported.

CHANGE YOUR OUTLOOK ON STRESS

In his seminar on building personal resilience against stress , Neil Shah, the chief de-stressing officer of The Stress Management Society and founder of International Wellbeing Insights, helps us understand stress in a few different ways. Stress can be represented as an equation: force divided by area equals pressure. That is, to reduce pressure (or stress), you must spread the weight over a larger surface or reduce the load.

Another way to view this explanation is to think of people as bridges: If there is a large load of heavy trucks piled in a single spot on the bridge, the bridge might collapse.

However, if the trucks are spread out across the bridge, the bridge will stand.

The key is to find the balance between the amount of stress and a person’s ability to handle it—too little stress and people get bored and depressed; too much stress and people get burned out and breakable.

MAKE A LONG-TERM STRATEGY

To make lasting changes in your organization, you need more than just “initiatives”; you need a long-term strategy. Shah compares organizational change to a GPS: In order to get anywhere, you need to know where you currently are and where you want to end up. Then you can see the path that will take you there.

You can evaluate where your organization stands in terms of mental health through interviews, surveys, focus groups and visits. The vision of where you want to be can be created through leadership visioning exercises and goal mapping. The steps to get there might include training, workshops and policy changes, to name a few.

It is worth noting that many employees would love to see more mental health benefits at work. A 2022 report by PeopleKeep shows that 63% of employees value mental health benefits (one of the most valued benefits), yet only 5% of employers offer such benefits. That leaves a lot of

CONNECT WITH AND SUPPORT PEOPLE

Finally, in the increasingly virtual world, we are losing our connection with each other. There are fewer opportunities for “water cooler conversations,” and people can lose interest in each other’s lives.

One way to combat this is to ask more questions about how people are doing—and not just the basic “How are you?” Which merits the canned response, “I’m fine.” Shah encourages people, especially leaders, to always follow up with a second question , such as “How are you?”

“What’s the latest with your life?” or “Are you sure you are ok?” To get genuine answers, you must also be honest about your life and cultivate an open, vulnerable dynamic.

It is also important to make sure people feel supported and have access to all the resources they need when dealing with stress or mental health challenges. Make the resources easy to find, and use signs and emails to communicate so everyone knows what is available.

No organization will function well when its workforce is stressed and burned out. If you want people to perform well and thrive at work while staying healthy physically, mentally and emotionally, it is worth taking steps to transform your organization. In your efforts to create a less stressful organization, realize that you don’t need to create

For further information of mental wellbeing, visit www.welllbeing.work today! © International Wellbeing Insights 2020. © Avetta, LLC 2020. All rights reserved.

Beat The Heat: 6 Creative Ways to Cool Teams Down on a Hot Worksite

06.30.2022 | HRMorning.com by Alison Roller

As the temperature rises, so do incidences of heat-related illness, especially for employees in higher-risk professions. HR needs to help employees prevent heat exhaustion, dehydration, heat stress, heat stroke and other ailments that comes with the hot weather.

For employees that work in a warehouse or somewhere that is hard to keep cool, heat-related illness can cause hospitalization or even death. The problem has become so prevalent that OSHA has recently announced a new program to help protect employees from heat hazards.

There are many ways for employers to prevent heat exhaustion and ensure employees are staying safe during a heatwave or the dog days of summer.

In 2019, there were 43 work-related deaths due to environmental heat exposure, and 90% of heat-related deaths occurred between May and September. So, what can you do to help prevent these illnesses?

INCENTIVIZE HYDRATION

The importance of hydration can’t be overstated. Although just drinking water won’t fully prevent heat-related illness, it’s a good foundation to ensure employees are staying

safe in the heat. There are many ways to help boost hydration, such as frequent water breaks and signs to remind employees to stay hydrated.

One way to boost the amount of water your employees are drinking is to incentivize it. For example, maybe employees get a raffle ticket for every water bottle refill or a companywide goal and incentive is set for the amount of water bottle refills.

You may also want to encourage employees to continue staying hydrated outside of work. Starting the day hydrated and continuing to hydrate after you clock out can help prevent dehydration.

ACCESSIBLE COOLDOWN SPACES

If your employees work in a warehouse or another place that makes it hard to keep employees cool, consider making temporary “cooldown rooms.” A cooldown room could be as simple as a tent with a few cooldown items inside, such as:

• An A/C unit or dehumidifier

• Industrial fans

• Coolers with ice, water bottles and Gatorade

• Fresh fruit or frozen snacks, such as popsicles

COOLING APPAREL

Cooling apparel can help ensure workers are staying as cool as possible in the heat.

Encourage clothing that is moisture-wicking, quick-drying and breathable. If you are providing employees with cooling clothing, such as cooling gaiters, make sure your employees know how to use them properly.

The wrong type of clothing, such as thick fabrics, can raise body temperatures and intensify the effects of heat.

If possible, consider relaxing your company’s dress code during the summer months to encourage cooling clothing and light, breathable fabrics. Keep the dress code specific, so employees know what is and isn’t allowed.

You may also want to encourage workers to keep an extra set of clothes on the worksite to change into if need be.

KEEP COOLERS CONVENIENT

Water coolers are a no-brainer for helping to keep employees safe and cool, but you need to ensure that they are accessible and plentiful around the workplace. Coolers tucked away in a corner or break room down the hall can deter workers from using them if they are busy or distracted. Keep them in plain sight and put them in multiple places around the office to make sure workers are using them frequently.

If you have the means, bringing in a refreshing treat like ice cream on an especially hot day can help boost motivation and keep them cool at the same time.

KEEP VENTILATION EFFICIENT

A functioning and efficient ventilation system can help ensure your workplace and your employees are safe. Although updating ventilation can come with a hefty price tag, a properly functioning HVAC system can make a huge difference for your employees and prevent heat-related illness. Misters and fans can also help boost ventilation around the workplace. However, if your employees work in a warehouse, be sure to keep the misters contained to prevent inventory damage.

CREATE A CULTURE OF SAFETY

Make sure your employees know the true dangers of heat exposure. You may even want to put up signs around your workplace that provide warning signs of heat-related illness

and action steps for what to do if an employee seems to be showing these signs.

Creating a culture of safety is more than just education, though. Put that education into action by creating a rapid response plan in case of illness or exhaustion.

There are many different types of heat-related illnesses, including heat rash, heat exhaustion, and heat stroke. All employees must know what to do and who to call when someone starts showing signs of heat exhaustion. Plus, a lack of education or first-aid training on heat hazards can even lead to hefty fines by OSHA

It’s hard to avoid the heat in the summer months, but simple steps can help prevent serious illness and ensure your workers stay safe and productive, even with the rising temperatures.

In a recent study of more than 11,000 U.S. employees conducted by Mental Health America (MHA), nearly three-quarters (71%) of respondents said they find it difficult to concentrate at work due to stress and distractions of various kinds. The pandemic is no doubt a major contributor of stress and anxiety for all workers, considering that less than half (48%) responded the same way in a 2018 survey. Whatever the causes, employees are feeling overwhelmed

15

...continued on next page

like never before, and the situation doesn’t seem to be improving even as COVID recedes. In a Robert Half survey of 2,400 U.S. professionals, 41% said they feel more burned out now than they did a year ago. And here’s one more statistic to consider: 76% of workers report being frequently tired at work, according to a Zippia study of 1,500 U.S. workers, with stress and anxiety being the two leading causes.

Imagine, then, the challenges safety leaders face knowing a significant number of their employees—many of whom work in hazardous, high-risk situations—are stressed out, burned out, distracted and overtired.

Andrew Faas, founder of the Faas Foundation—a nonprofit that supports the creation of psychologically healthy, safe and fair workplaces—says there’s a need for leaders “to reduce, and ideally eliminate, the tremendous amount of unnecessary stress workers face, largely because the

conditions necessary for active and positive engagement do not exist in their workplace.”

The MHA’s 2022 Mind the Workplace report attempts to answer the question: How can companies meaningfully support employee mental health? The answers, as you would expect, are not quick fixes. However, they do directly address the reality of the situation: investment of time, intention and action from all levels of a company; employee empowerment; and full managerial support (see “What Can You Do?”).

The main takeaway from all of these recent studies is that safety professionals don’t need a degree in mental health counseling to help keep their employees out of harm’s way, nor do they need to be mind readers who able to peer into the deepest recesses of their employees’ psyches. They just need to do what they already do best: Pay close attention to their people.

Office Chair Safety

09.15.2022 | Weeklysafety.com

Sitting in and using a chair at work should not be dangerous, so don’t add unnecessary risk to a fairly safe activity.

• Always keep the entire base of the chair in contact with the floor. If the chair is wobbly, tilted, or unstable do not continue using the chair until it is fixed or replaced.

• Do not lean back in the chair by either lifting the front legs off the ground or forcing the back of the chair into a horizontal position. This can result in the chair slipping or sliding out from under you causing injury.

• Do not lean too far forward in the chair or sit too far forward on the edge of the seat because this can also result in an unexpected tip-over.

• Do not play pranks using anyone else’s chair and horseplay with chairs on wheels is prohibited. ➢ To prevent back injuries, avoid forceful twisting and turning motions while sitting. For example, don’t twist in your office chair to open a heavy filing cabinet behind you.

• Never run electrical cables (including extension cords) under rugs, in a high traffic area, or where chairs can roll over them. Cables that become damaged from a chair can cause electric shocks and present a fire hazard.

When it’s time to put together a brand-new office chair read the instruction manual first and follow all the directions for assembly.

• Ensure each piece of the chair is accounted for, put together in order, properly placed, and securely tightened.

• If not all the pieces were used during the chair assembly consult the instruction manual again because

a leftover part may mean the chair you just built is incomplete and unsafe.

• Before sitting in any newly assembled chair for the first time, double-check each wheel to ensure that they are all fully inserted into the base and securely attached.

• Once the chair is assembled and upright, make sure all the legs/wheels are in stable contact with the floor.

• If the chair has a tilting function, make sure it is tight enough for a controlled motion so the first try in the new chairs doesn’t send you flying backwards.

Always select chairs with a five-legged base as the safest choice with the strongest foundation. Chairs with four or fewer legs at the base may provide inadequate support and are more prone to tipping.

Every six months, or on a regular basis, make sure to check the chair you are using for wear and tear or damage.

• Tighten-up any parts that have come loose and replace any parts that have become worn out. Do not use any chair that is not safe any longer! Do not pass around a damaged chair because it seems funny.

• If you don’t know what the procedure is to get a chair removed from the work area or replaced if a new one is needed, please ask.

OFFICE CHAIRS ARE NOT STEP STOOLS

• Do not use any office chair as a ladder. It may be tempting to step on a chair to save time, but it is not safe.

• Never place any kind of step stool or ladder on an office chair (or anything else!) to gain additional height for the ladder.

17

Building a Safer Culture in Construction

08.19.2022 | EHS Today by Jacob MacIntyre

A look at how technology and an agile mindset can make job sites safer.

Keeping employees safe and out of harm’s way while on the job site is a top priority for any business in the construction industry. Tracking the minute details of job site incidents like injuries, falls, near-misses or hazards can be an onerous task, but it’s one that must be completed with pinpoint accuracy to keep people safe.

The moment an unsafe condition exists or an incident occurs, work should come to a stop so the appropriate teams can collect data on what happened to analyze the incident. From there, safety teams can develop a root cause analysis (RCA) and subsequent corrective action plans (CAP) to prevent a similar issue from happening again. While they sound straightforward, those steps take significant time and effort to implement. The problem is compounded when incident logs and other documents are hard to access for subsequent analysis and future reference.

Safety initiatives are just like any other project—they have stakeholders, milestones, objectives and usually some type

of timeframe for completion. This is where the construction industry can benefit from additional usage of project management processes and technology , as construction projects tend to be complex in nature. Construction companies need to coordinate a multitude of contractors and subcontractors as well as keeping tabs on the status of every part of a job.

In an industry where technology adoption can be notoriously slow, there needs to be a seamless integration between the team members physically surveilling sites for incidents and the technology that can analyze that data. This is why it’s so important that the technology construction companies use must be agile: No two jobs are ever the same, and the tech being deployed to assist with it must be nimble enough to adapt from job to job.

Let’s take a look at the types of technologies available to assist safety managers and how to strike a balance between human operators and technology in order to tackle the challenges of efficiently tracking safety.

SAFETY IS COMPLEX

Finding the correct balance between what technology can help with and where human creativity and critical thinking can help is a tricky one to get right, especially in construction, where the human touch is a necessity.

The tracking and inspecting of on-site issues is a largely manual process that must be done with supervisors who are physically present; therefore, technology cannot act as a one-stop solution. Rather, there must be a balance between how much human touch is involved and what capabilities can be gleaned from agile technological solutions. Achieving this balance requires understanding what makes tracking these issues so complex.

On job sites, safety incidents are observed with the “see something, say something” credo. If an employee sees something unsafe or out of sorts, they report it to a supervisor, who can raise the red flag for a safety violation and launch a subsequent investigation.

The first set of complexities arise from the “see something” portion. These are usually the result of human dynamics, apathy and change management problems (e.g., internal politics, motivation or fear of repercussions). These factors all contribute to workers feeling unsure about reporting unsafe conditions or incidents. A worker may wonder, “Will I have to go through an uncomfortable interview process in order to not be taken out of context?” Or perhaps, “I might be implicated here. I’m going to look the other way.”

The second set of issues stem from the “say something” part. These are more tactical and technical problems for safety managers. A worker may ask: How easy is it to report an issue? Will reporting this incident require filling out a lot of paperwork? Will reporting something take a lot of time? Where is this information supposed to be stored?

TECHNOLOGY’S ROLE IN KEEPING WORKERS SAFE

While improving the “see something” portion is largely cultural and policy driven, the “say something” portion is where agile technology can assist in incident tracking. After an incident has been raised with a supervisor and an inspection is conducted, the data collected must be stored in a centralized location that is easily accessible for future analysis. For people working in trades, however, their productivity is reduced the longer they spend on administrative tasks. This isn’t to say that manual tasks like reporting aren’t essential, but these processes can be improved to allow employees to get back to work quickly—and safely.

Providing the exact inputs to a mobile app or device is complicated, especially if those inputs and requirements frequently change. Another challenge is offline capability. In many cases, new build construction sites do not yet have the infrastructure for Wi-Fi and data coverage may be intermittent or unreliable.

A lack of connectivity in some places has led to a reliance on spreadsheets in the construction space. Spreadsheets can provide some value for companies; however, they are often the only tool that people in the field have that they can control. This has led to an overuse of them being created without any uniformity in the ways they’re created or shared.

For example, I’ve seen many instances in which massive workbooks contained within spreadsheets would barely even load. I’ve also seen some with highly complex macros and formulas to turn them into makeshift enterprise resource planning or inventory systems. Without concrete uniformity in the way they’re built, there’s no chance to effectively manage, govern, store or analyze the documents—and the data stored inside them. For safety managers, this is a big red flag, as this data is crucial to keeping employees safe and for staying in compliance with safety regulations.

LEVERAGING AGILITY FOR SAFETY

One way to combat the use of legacy tools like spreadsheets is through the use of no-code. Nocode solutions enable anyone within an organization, regardless of technological background, to create applications and systems that create efficiencies and tackle complex problems.

The key benefit here is that those closest to the problem are the ones who can directly help solve it. This means that on-site supervisors can develop applications and data repositories on the fly to track and log the data for future analysis. No-code platforms are set up in such a way that they ensure the creation of these applications and systems are linked to back end data analytics tools, making pulling reports and analysis much easier for folks in the field looking for real-time insights on a job.

There are options that exist outside of no-code, such as point solutions or software as a solution (SaaS) tools, but they don’t offer flexibility in development. Those solutions are commonly brought in to only solve one element of the specific problem and are one-dimensional in nature. They can help to manage safety initiatives but only one element of them.

...continued on next page

19

No-code technology offers the flexibility for safety managers to instantly track, share and log vital issues that pertain to keeping workers safe on-site. Users can easily collect data from safety tasks, such as on-site walk-throughs and production reports. From there, safety managers can leverage automation to generate insights and develop RCAs and CAPs.

In addition, no-code solutions can automatically help companies keep tabs on changing safety regulations and protocols from the Occupational Safety and Health Administration as well as tracking facilities to ensure systems are up to code. This also presents an opportunity to keep all employee safety training in a centralized location and easily accessible to all when a new regulation arises or new certifications are required.

Safety is among the most important element of any job and getting safety management right is paramount. The operational agility offered through no-code solutions opens the door for anyone looking to solve a problem to become a safety expert. These solutions also help companies stay ahead of potential risks and dangerous situations in jobs moving forward.

As safety continues to evolve with the complexity of jobs, the technology used to track safety must be agile enough to adapt to these changes and give pertinent insights that will keep employees safe. Construction companies must look at the technology they have in place now and ask themselves if it can handle the complexities of today’s jobs. If not, it’s time to prioritize digital transformation and embrace a culture of safety through technology.

In a Business Group on Health survey, 13% of employers said they have seen more late-stage cancers and another 44% anticipate seeing such an increase in the future.

An unsettling statistic has come from the Business Group on Health’s 2023 Large Employers’ Health Care Strategy and Plan Design Survey , released on August 23. Cancer has overtaken musculoskeletal conditions as the top driver of large companies’ health care costs.

While the top three conditions fueling health care costs remained the same from last year – they include cardiovascular disease, in addition to cancer and musculoskeletal conditions – 13% of employers said they have seen more late-stage cancers and another 44% anticipate seeing such an increase in the future, likely due to pandemic-related delays in care.

A total of 135 large employers across varied sectors, who together cover more than 18 million people in the United States, completed the survey between May 31, 2022, and July 13, 2022.

“Employers shared that they are deeply concerned about unsustainable health care costs, the devastating effects of the pandemic on employee health, and the need to work creatively with their partners toward a more positive and sustainable health care experience, among other issues;” said Ellen Kelsay, CEO of Business Group on Health, in a statement.

COSTS

After experiencing no increase in actual health care costs from 2019 to 2020, employers experienced a significant return to rising costs, with a median 2021 cost increase of 8.2%.

Despite rising costs, employers expect to cover 82% of the cost of employee coverage in 2022, up from 80% the year before (employer support for family coverage remains at 80% of premium). As costs increase, employers have been reluctant to shift costs to employees in the short term and are looking at fundamental delivery system reforms, such as advanced primary care and centers of excellence for specific health conditions, to address unsustainable health care expenses and prescription drug costs.

PRESCRIPTION DRUGS

Large employers overwhelmingly (99%) said they were concerned about prescription drug trend. In 2021, prescription drugs accounted for a median of 21% of employers’ health care costs, with more than half of pharmacy spend going to specialty medications. Employers have opportunities to bring down costs through pharmacy program tactics, including biosimilar coverage, site of care and case management, among others.

While employers will continue to address the affordability of employee premiums and out-of-pocket costs, they remain

on next page

21

...continued

keenly focused on policy efforts that lower health care and prescription drug costs. Employers are particularly interested in the affordability of maintenance medications, as well as newer gene therapies. In addition, the affordability of mental health services – low- to no-cost virtual health provides affordable access – is of high importance for 24% of employers.

MENTAL HEALTH

Long-term mental health issues, both observed and anticipated, are the leading health-related impact of the pandemic, employers said, with increases in medical services due to delayed care a close second. Some 43% have already seen this trend and another 39% anticipate such increases. In response, employers plan to keep many pandemic-related health and well-being offerings in place for the foreseeable future; 85% will do so for mental health.

VIRTUAL HEALTH

Virtual health is at a crossroads, warranting further assessment and refinement. While three-quarters of employers (74%) believe that virtual health will significantly impact future health care delivery, 84% said integrating virtual health and in-person care delivery is critical for success. If integration does not occur, it could lead to the duplication of services, unnecessary care, wasteful spending and a fragmented care experience. Further, employers showed interest in virtual primary care. Some 32% will offer these services in 2022, while a total of 69% may do so in 2025.

WELL-BEING AND EQUITY

Health and well-being strategy continued to play an integral role in workforce strategy, said 65% of employers, an increase from 42% last year. This is the culmination of several factors over time, including the need to attract and retain employees and support employee overall wellbeing, and the impact of workforce well-being on business performance and culture.

Health equity continues to be top of mind for employers, with three in four sharing concern about inequities in their company’s health and well-being initiatives. Most employers plan to address such issues in 2023 and plan to tackle additional social determinants of health, including racism, and across such areas as childcare, transportation and food access/insecurity, in the years 2024 and 2025. Further, while the survey was in the field, the Supreme Court reversed Roe v. Wade abortion protections, reverting authority to the individual states to control abortion access and related issues. The ruling has exacerbated employer concerns with health equity and health care access.

First Aid: Poisoning

08.25.2022 | Weekly Safety

This safety topic provides basic first aid tips, along with information about how to contact Poison Control, in the event that a person at work is experiencing poisoning symptoms.

• First aid should be administered only by trained and authorized personnel who are able to provide a primary assessment and basic medical aid using accessible supplies.

• Before assisting someone else with first aid, always wash hands with soap and water.

Poisoning is injury or death due to swallowing, inhaling, touching, or injecting various drugs, chemicals, venoms, or gases.

• Many substances, such as drugs and carbon monoxide, are poisonous only in higher concentrations or dosages.

• Certain types of cleaners are only harmful if ingested, while others also emit toxic gases or fumes.

• Workers should consult the SDS before handling chemicals, wear proper PPE when required, and use safe work practices with hazardous substances.

Remember, after providing any type of first aid:

• Wash your hands immediately.

• Properly dispose of all hazardous waste.

• Clean and decontaminate all surfaces after exposure to blood or bodily fluids.

The information provided in this safety topic is not intended as a substitute for professional medical advice or formal first aid training.

23

...continued on next page

Poisoning symptoms can mimic other conditions, such as seizure, alcohol intoxication, stroke, or insulin reaction. Signs and symptoms of poisoning may include:

• Burns or redness around the mouth and lips

• Breath that smells like chemicals, like gasoline or paint thinner

• Vomiting

• Difficulty breathing

• Drowsiness

• Confusion or other altered mental status

If you suspect poisoning, be alert for clues such as:

• Chemicals the worker was using when they started feeling sick

• Empty drug packaging on or near the employee

• Burns, stains, and odors on the person or nearby objects

• Equipment nearby that could be generating carbon monoxide

• Required PPE for the job task that was not being used properly

• Anything else in the area that could have been ingested, inhaled, or absorbed by the worker

There are two ways to get help from Poison Control in the U.S. Both options are free, confidential, and available 24 hours a day.

1. Visit the poison control website online at www.poison.org

2. Call the poison control help line at 800-222-1222

It’s always a good idea to have a sign, magnet, or sticker posted in a visible location at work that has the poison control phone number and website.

• Poison control centers are excellent resources for poisoning information and, in many situations, may advise that observation is all that’s needed.

In the case of poisoning, or suspected poisoning, DO NOT give syrup of ipecac or do anything to induce vomiting.

• Expert groups, including the American Association of Poison Control Centers and the American Academy of Pediatrics, no longer endorse using ipecac for anyone who has ingested a potentially poisonous substance.

• No good evidence proves its effectiveness, and it often can do more harm than good.

• If you still have old bottles of syrup of ipecac in the first aid kit at work, throw them away.

Reach out to Poison Control 800-222-1222 or www.poison.org in the following suspected poisoning events:

• The person is stable and has no symptoms

• The person is going to be transported to the local emergency department

You may be asked to describe the person’s symptoms, age, weight, other medications they are taking, and any information you have about the poison. The person who is ill should be able to help you answer these questions. Try to determine the amount of poison that was ingested and how long since they were exposed to it.

Call 911 (or emergency medical services) immediately if the person feeling ill is:

• Drowsy or unconscious

• Having difficulty breathing or has stopped breathing

• Uncontrollably restless or agitated

• Having seizures

• Known to have taken medications, or any other substance, intentionally or has accidentally overdosed

• Begin CPR if the person shows no signs of life, such as moving, breathing, or coughing.

• Assign someone to gather evidence and information about the poison to send along with the ambulance team. This may include empty packaging, photos of labeling, or any other details that could be relevant to diagnosis and treatment.

Take the following actions for specific poisoning incidents while someone is reaching out to Poison Control 800-222-1222 or poison.org) or you are waiting on emergency medical services to arrive.

Swallowed poison. Remove anything remaining in the person’s mouth. If the suspected poison is a cleaner or other chemical, read the container’s label and follow instructions for accidental poisoning.

• Have them drink a small amount of water or milk immediately if the product swallowed is burning, irritating, or caustic, and the person is conscious, not having convulsions, and is able to swallow.

• If the person vomits, turn his or her head to the side to prevent choking.

Poison on the skin. Remove any contaminated clothing using gloves. Rinse the skin for 15 to 20 minutes in a safety shower or with a hose.

• If there is blistering, large or deep burns, pain, redness, or swelling that persists, gets worse, or is severe, seek emergency medical care immediately after rinsing.

Poison in the eye. Gently flush the eye with room temperature water for 15-20 minutes or until help arrives.

Use the workplace eye wash, safety shower station, or a sterile eyewash bottle from the first aid station or kit.

Inhaled poison. Get into fresh air as soon as possible and thoroughly ventilate the area.

• After moving into fresh air contact Poison Control 800-222-1222 or www.poison.org to get specific recommendations.

COPYRIGHT AND DISCLAIMER This material is the copyrighted property of Weeklysafety. com, LLC. Purchase of this material from Weeklysafety.com, LLC grants the owner the right to use this material for workplace safety and education purposes only. Use of this material for any other purpose, particularly commercial use, is prohibited. This material, including the photos, may not be resold. Weeklysafety.com, LLC does not warrant or assume any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed in these materials. Photos shown in this presentation may depict situations that are not in compliance with applicable Occupational Safety and Health Administration (OSHA) safety requirements. These materials are meant for informational purposes only and it is not the intent of Weeklysafety.com, LLC to provide compliance-based training. The intent is more to address hazard awareness in the construction and related industries, and to recognize the potential hazards present in many workplaces. These materials are intended to discuss Federal Regulations only, as individual State requirements may be more stringent. Many states operate their own state OSHA and may have standards that are different from information presented in this training. It is the responsibility of the employer and its employees to comply with all pertinent OSHA safety rules and regulations in the jurisdiction in which they work.

PHOTO ACKNOWLEDGMENTS

Unless specified below, all photos are the copyrighted property of Weeklysafety.com, LLC and may not be used in any other training materials or resold for any purpose.

25