THE SAFETY NET

National Safety Stand-Down to Prevent Falls in Construction is May 5-May 9, 2025 SAFE

Fatalities caused by falls from elevation continue to be a leading cause of death for construction employees, accounting for 421 of the 1,075 construction fatalities recorded in 2023 (BLS data). Those deaths were preventable. The National Safety Stand-Down raises fall hazard awareness across the country in an effort to stop fall fatalities and injuries.

Austin employees have worked 8,548,035 hours without a Lost Time Accident through 04/2025.

• Plan a Toolbox Talk or Other Safety Activity

• Take a Break to Talk About How to Prevent Falls

• Provide Training For All Workers FOR MORE INFORMATION

• osha.gov/PreventFalls

• 1-800-321-OSHA (6742)

• TYY 1-877-889-5627

RESOURCES FOR EMPOYERS AND EMPLOYEES

• Fall Prevention Training and Resources

• Ladder Safety Guidance

• Scaffolding Resources

• Educational Materials

• Stand-Down Partner Materials

• Outreach Training Materials

WHAT IS A SAFETY STAND-DOWN?

A Safety Stand-Down is a voluntary event for employers to talk directly to employees about safety. Any workplace can hold a stand-down by taking a break to focus on “Fall Hazards” and reinforcing the importance of “Fall Prevention”. Employers of companies not exposed to fall hazards, can also use this opportunity to have a conversation with employees about the other job hazards they face, protective methods, and the company’s safety policies and goals. It can also be an opportunity for employees to talk to management about fall and other job hazards they see.

WHO CAN PARTICIPATE?

Anyone who wants to prevent hazards in the workplace can participate in the Stand-Down. In past years, participants included commercial construction companies of all sizes, residential construction contractors, sub- and independent contractors, highway construction companies, general industry employers, the U.S. Military, other government participants, unions, employer’s trade associations, institutes, employee interest organizations, and safety equipment manufacturers.

PARTNERS

OSHA is partnering with key groups to assist with this effort, including the National Institute for Occupational Safety and Health (NIOSH), the National Occupational Research Agenda (NORA), OSHA approved State Plans, State consultation programs, the Center for Construction Research and Training (CPWR), the American Society of Safety Professionals (ASSP), the National Safety Council, the National Construction Safety Executives (NCSE), the U.S. Air Force, and the OSHA Training Institute (OTI) Education Centers.

HOW TO CONDUCT A SAFETY STAND-DOWN AND FAQS

Companies can conduct a Safety Stand-Down by taking a break to have a toolbox talk or another safety activity such as conducting safety equipment inspections, developing rescue plans, or discussing job specific hazards. Managers are encouraged to plan a stand-down that works best for their workplace anytime. See Suggestions to Prepare for a Successful “Stand-Down” and Highlights from the Past Stand-Downs. OSHA also hosts an Events page with events that are free and open to the public to help employers and employees find events in your area.

If you plan to host a free event that is open to the public, you may contact your Regional StandDown Coordinator.

Four Often Overlooked Types of New Workers—and the Different Dangers They Face

12.11.2024 | SafeStart

The facts are clear: new hires are at a much greater risk of injury in their first year on the job. But not all new workers face the same risks. Depending on their age, background, work history, and other issues, they may face very different dangers in the workplace. This is an outline of four classes of new workers, and some of the risks that can be particularly challenging to them. As new hires are onboarded, be sure to pay attention to these potential sources of injury in order to keep these at-risk groups of employees safe.

1. YOUNG WORKERS

Young workers are physiologically different from the rest of the workforce in ways that can put them at risk. Their organs and musculoskeletal systems are not yet fully developed, making them more susceptible to harm from certain types of trauma and hazardous substances. Additionally, as NIOSH points out, “young workers may be exposed to suspected asthmacausing agents and substances that disrupt the function or maturation of the endocrine and central nervous systems.”

Young workers also get a bad rap for being distractible. It’s trendy to blame cellphones and distraction for the high rate of incidents, but several studies suggest that injury rates among young workers are not a new trend or a result of technological distraction. A study conducted by the CDC looked at injury rates of young workers from 1998–2007, before the first iPhone was released. It found that the nonfatal injury rate “was approximately two times higher ” than older workers. This is still the case, as a recent article in ISHN notes that the current generation of 18–24-year-olds is experiencing a similar rate. Instead of blaming technological influences for distraction, we should look at other human factors that are likely to influence young workers, like overconfidence,

ambiguity, and rushing. And when you combine these human factors with a general lack of experience, it leads to the grim emergency-room data that shows that young workers are injured twice as often as their older counterparts. It’s also worth noting that many people believe that young workers are more likely to bounce back quickly from an injury and they are more likely to avoid an injury in the first place thanks to quick reflexes. But their youth can also be a disadvantage as, from a utilitarian point of view, a young worker who receives a life-long injury, such as a herniated disc or compressed nerves in the spine , will be affected for many more years than an older worker who suffers the same outcome. And this high degree of confidence in young workers’ physical resilience can skew their perspective of risk in life-altering ways.

2. NEW TO COUNTRY, LANGUAGE OR CULTURE

A person who has just secured a job in a new country will, by definition, be a new worker. In 2021, foreign-born worker deaths in the United States were led by Hispanics, whose working population grew 16.7% and for whom workplace fatalities grew 42%. Similarly, non-Hispanic Asian workers saw a 40.2% leap in workplace fatalities and a 30.8% growth in the working population.

In both cases, as these working populations added more new workers, the number of fatalities grew even more rapidly. This is not a coincidence. We’ve already seen that new workers are at much greater risk of injury, and foreign-born workers have to contend with a tremendous amount of change all at once.

Additionally, depending on their circumstances, there could be many reasons why foreign-born workers feel unable to say no to unsafe working conditions or ask questions if the instructions for the task at hand are ambiguous.

One does not have to be an immigrant in order to encounter these challenges. A workplace may operate in a language or dialect that a domestic-born worker is unfamiliar with, rely heavily on slang or technical jargon, or be situated in an unfamiliar regional culture. A move from one city or state to the next may be enough for someone to encounter all these problems.

3. OLDER WORKERS

Older workers tend to be more experienced workers. But experience at previous jobs doesn’t necessarily translate to the new employer, and the length of time at their current job is a much stronger factor in injury risk than the number of total years they’ve spent in the workforce.

Experience can also be a double-edged sword. As safety consultant Larry Pearlman points out, older workers can often misjudge their own abilities. Pearlman says that when encountering potentially dangerous situations in the workplace, older workers can think, “When have I seen something like this before? and rely on their past experience and performance in similar situations. The trouble is that they sometimes fail to recognize that hazards, safety protocols, and technology have changed. Their ability to accurately assess and react to the situation may also have changed with age. All of which increases the risk of injury when older workers switch employers.

There’s also run-of-the-mill complacency, which can set in when someone feels like they have ample experience with a certain context or task—even if the specific job is new to them. And job-specific inexperience and general complacency can be a dangerous mix. These factors all contribute to the fact that older workers who are new to a job are at such great risk of injury.

4. NEW SITUATIONS FOR EXPERIENCED WORKERS

Change is change, period. And with enough workplace change , any worker becomes a new worker. Usually, the biggest change that can happen to a worker is when they get a new job. But sometimes an employee can show up to the same worksite as always and find that the specific environment, workflow or tasks they need to do have shifted to such a great degree that a long-tenured worker suddenly becomes “new. When a new mechanical or digital process is introduced, when new regulations need to be followed, or when high employee turnover creates a new social dynamic, workers of all experience levels are subject to the same human factors we commonly see in new hires. This also applies to temporary workers who may have general experience but lack knowledge of specific tasks and the work environment.

This advice is meant to be broadly applicable. That means it can’t always cover the nuances of every single type of new worker. Be sure to consider the specific type of new worker that is present in your workforce and adjust your takeaways accordingly.

This blog post is an adapted excerpt from the safety guide Fitting in Fast : Making a Safe Workplace for New Hires , which examines data and best practices regarding the protection of new hires in the workplace. Read the guide today for research, insights and strategies to protect new workers from injury.

What you would do if the worst happened?

Emergencies Come In Many Forms. Do Your Employees Know What To Do?

04.22.2024

| Jj Keller

Few people can think clearly and logically in a crisis, which is why it’s so important to plan for emergencies before they happen. When developing an emergency action plan, ask yourself what you would do if the worst happened. What if a fire broke out in your boiler room? What if there were a chemical spill or an act of workplace violence?

A workplace emergency is an unforeseen situation that threatens the safety and/or health of employees, customers, or the public; disrupts or shuts down operations; or causes physical or environmental damage. Emergencies can be natural or manmade and can include:

• Floods

• Hurricanes

• Tornadoes

• Fires

• Chemical spills

• Radiological accidents

• Explosions

• Workplace violence

When there’s an emergency, taking the proper action saves lives. Employees must understand their role in your facility’s emergency action plan so they’ll be able to take the appropriate actions should the unthinkable happen. For example, some employees may have training and authorization to remain behind to operate critical plant operations before they evacuate. Some may have been trained and equipped to provide rescue. Still others may have been trained to provide first aid and medical assistance.

If employees do not fall into any of these categories, they should not attempt to perform any of these functions. They’re of more help when they follow instructions and report emergencies to the people who are trained to help.

EMERGENCY ACTION PLANS

An emergency action plan covers designated actions employers and employees must take to ensure employee safety during a fire or other emergency. When OSHA requires an employer to develop an emergency action plan under 1910.38, the plan must include certain elements:

• Procedures for reporting a fire or other emergency

• Procedures for emergency evacuation, including the type of evacuation and exit route assignments

• Procedures to be followed by employees who remain to operate critical plant operations before they evacuate

• Procedures to account for all employees after an evacuation

• Rescue and medical duties for those employees who are expected to perform them

• The names or job titles of persons who can provide further information or explain employees’ duties under the plan

TRAINING EMPLOYEES

Educate your employees about the types of emergencies that may occur and train them in the proper course of action. The size of your workplace and workforce, processes used, materials handled, and the availability of onsite or outside resources will determine your training requirements.

Be sure employees understand reporting procedures, alarm systems, evacuation plans, and shutdown procedures. It’s important that employees participate in any emergency drills and understand:

• How to report fires, injuries, and other emergencies

• How and when to sound emergency alarms

• How to recognize different types of alarms (they may be audible or visual)

• What type of emergency the alarm identifies

• Which exit routes to use when evacuating

• Where to assemble after evacuating or whether to shelter in place

• How all employees are accounted for after an emergency evacuation

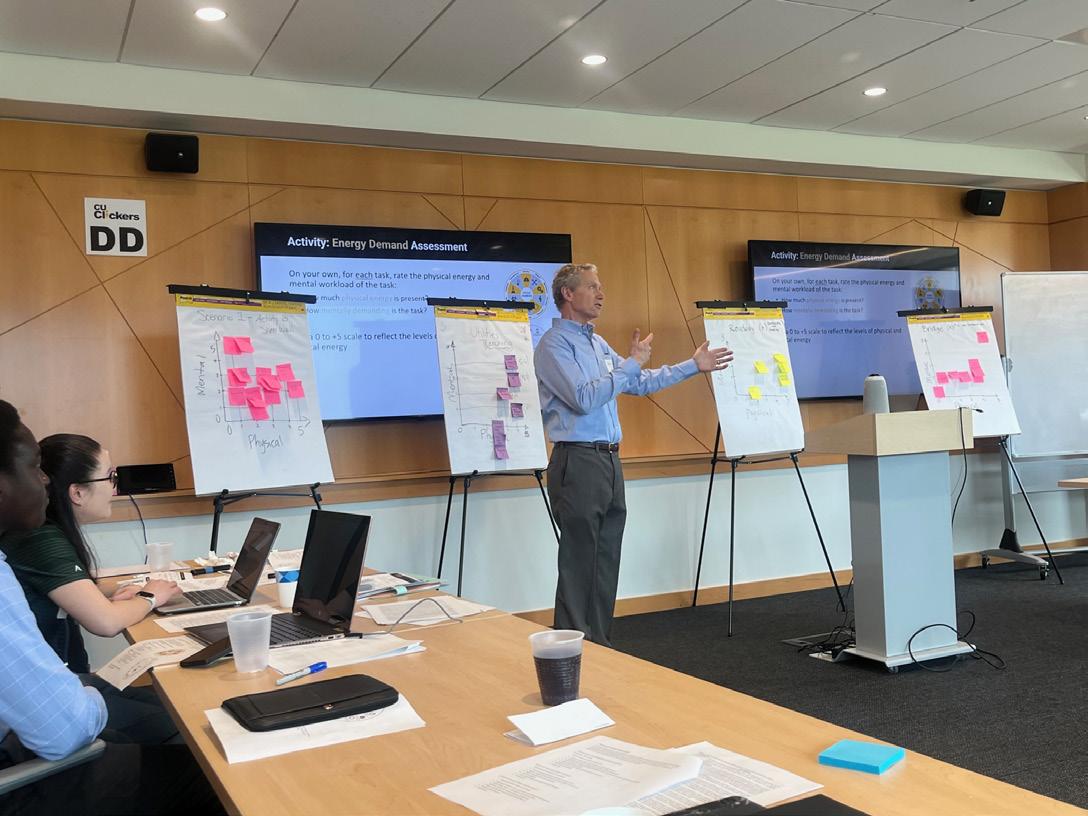

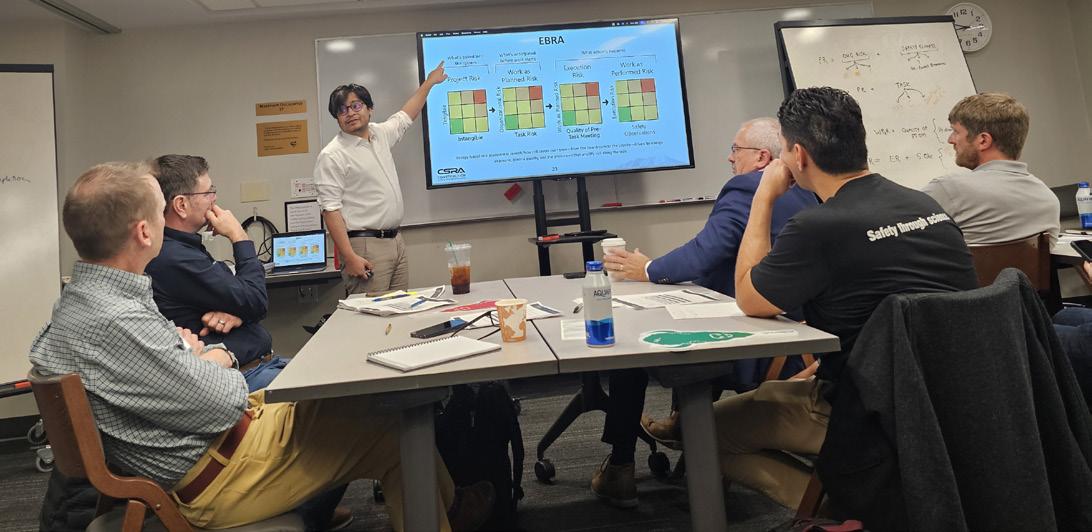

Ensuring a Safer Workplace through a Comprehensive Contractor Qualification Framework

04.11.2025 | Avetta

Ensuring a Safer Workplace through a Comprehensive Contractor Qualification Framework

Employers have a duty to protect their workers and contractors, but according to studies, there are still thousands of work-related injuries just in the U.S. alone. In fact, in 2022 the number of fatal work injuries in the U.S. stood at 5,486 with on average about 15 worker fatalities a day, or one fatality every 96 minutes.

This growing rate of work-related fatalities has led regulatory bodies like OSHA to tighten their grip on workplace safety protocol violations. Following a January 2024 revision, OSHA increased its penalty for willful or repeated violations to more than $161,000 , but the repercussions of workplace incidents go far beyond penalties.

Although there are serious repercussions for safety violations and many organizations choose safety as a focal point, businesses are ill prepared due to improper contractor management. They recognize thirdparty compliance as the most difficult risk exposure to address and properly manage. One of the best ways to address a critical aspect of ensuring an incident-free workplace is contractor compliance

WHAT IS CONTRACTOR QUALIFICATION?

Contractor qualification or prequalification is the act of gathering and assessing information that determines a contractor’s capability, capacity, resources, management processes and performance.

One of the most effective ways to deal with third-party non-compliance is to develop a strong and effective contractor qualification framework . Prequalifying, training, and requalifying contractors form the cornerstone of safe work.

If a company fails to establish an effective contractor qualification program, it could face significant risks such as civil penalties from government regulatory agencies, tort liability arising from personal injury and fatality, and even criminal prosecution of company supervisors and upper management.

SUPPLY CHAIN QUALIFICATION AND MANAGEMENT SOLUTIONS CAN:

• Improve safety

• Reduce risk and costs

• Provide additional value to contractors

• Strengthen existing relationships

• Simplify the compliance process

WHAT CHALLENGES CAN ARISE WHEN ESTABLISHING A ROBUST CONTRACTOR QUALIFICATION PROGRAM?

• Staggering Levels of Documentation – Many programs require mountains of paperwork and documentation to sift through or provide.

• Differences in Expectations – Where organizations fail to establish an effective supply chain qualification and management process is when they take a one-size-fits-all approach. Qualifications should be adjusted based on company size, risk exposure or business discipline.

• Communication – For an effective qualification process, companies must properly communicate safety compliance requirements to contractors to reduce frustrations and prevent any noncompliance issues.

• Difficult Software – Even when contractors understand qualification requirements, non-transparent and difficult software can be an impediment. Having intuitive tools and processes that support the demands of reporting can be greatly beneficial.

• ROI – Even with thousands of safety incidents a year, business and contractors still find third-party qualification as an unnecessary expense. Using an efficient program with a large supplier network and compliance support will save both time and money.

Avetta is a leader in contractor management, and with over 15 years of industry experience, we help you establish a robust contractor pre-qualification program that aligns with your expectations and your business goals.

Harnessing AI and Machine Learning for Enhanced Safety

The Industrial Internet of Things (IIoT) serves as the eyes and ears for AI, providing crucial data for identifying dangerous trends and prompting corrective actions.

In the ever-evolving manufacturing landscape, a remarkable transformation has occurred over the past few decades, with a substantial decrease in injuries and illnesses. According to the Indiana Safety and Health Achievement Recognition Program, their sites have had more than a 70% reduction in the injury rate on production lines since adopting a more digital focus.

According to the U.S. Bureau of Labor Statistics, the injury rate in manufacturing was reported at 3.3 per 100 workers in 2021, a fraction of the 12.2 reported in 1994. However, it is definitely still a concern.The U.S. Bureau of Labor Statistics also reported 5,190 fatal work injuries in 2021, emphasizing the urgency of addressing industrial safety.

AI-driven digital transformation presents a compelling solution to mitigate risks and enhance safety across various

industries. Among other factors, AI has emerged as a key player in mitigating workplace hazards. The Industrial Internet of Things (IIoT) serves as the eyes and ears for AI, providing crucial data for identifying dangerous trends and prompting corrective actions.

Pursuing further progress in workplace safety has led to integration of artificial intelligence (AI) and machine learning (ML) innovations. This amalgamation, despite potential risks as well, promises not only to drive the injury rate even lower but also to enhance overall efficiency in manufacturing processes.

AI-enabled safety technologies encompass many tools and techniques, including drones, robotics, wearables, sensors, AR/VR, computer vision, mobile apps, and analytics software. These technologies collect and analyze data, offering insights into safety hazards and enabling proactive measures. Let’s dive into the details.

COMPUTER VISION: KEEPING AN EYE OUT

The primary technology to enable safety initiatives is computer vision, a technology that employs sophisticated algorithms to analyze live video feeds. Cameras equipped with AI capabilities can detect potential hazards that may elude the human eye. For instance, AI-enabled cameras can monitor safety gear compliance, identify incorrect lifting techniques, and ensure adherence to safety zones around heavy machinery. Drones, equipped with cameras, extend this capability to identify structural issues in hardto-reach and hazardous areas, ensuring a comprehensive approach to safety.

Additionally, monitoring for fatigue symptoms, fall detection in construction, site inspections using drones, conversational AI for safety, incident reporting using voice, AR for equipment repair, and safety training in VR showcase the versatility of AI applications in industrial safety.

Advancements in computer vision technology are also continuously expanding its applications. For instance, companies are leveraging AI algorithms to interpret visual data, creating smart cameras that record and interpret visual information. This innovation takes workplace safety to new heights, as these smart cameras can identify risks that might go unnoticed through traditional monitoring methods.

BRIDGING THE GAP: NATURAL LANGUAGE PROCESSING

Natural Language Processing (NLP) serves as a bridge between humans and computers, addressing language barriers within the workplace. This technology enables the

translation of safety instructions and machine manuals into multiple languages, fostering a more inclusive safety culture.

NLP can also analyze written reports to identify patterns in incident logs or safety audits, offering valuable insights into potential safety issues. AI-powered virtual assistants equipped with NLP capabilities provide real-time guidance to workers, enhancing safety procedures and fostering a more informed workforce.

PREDICTIVE POWER: PUTTING IOT DATA TO WORK

Predictive analytics, fueled by IoT data, emerges as a powerful tool for anticipating and preventing safety issues. Machine sensors collect a wealth of data, from temperature and vibration to pressure and duty cycles. Through continuous analysis, AI can unveil patterns indicative of wear and tear, facilitating proactive, predictive, preventative maintenance and avoiding equipment malfunctions that could lead to dangerous situations.

Predictive analytics is not limited to equipment maintenance; it extends to analyzing overall safety trends and highlighting areas for improvement. For instance, if a specific production line reports more incidents than others, predictive analytics can help determine the cause and suggest corrective actions.

A HOLISTIC APPROACH TO AI IN MANUFACTURING SAFETY

The integration of AI technologies extends beyond the three pillars discussed above. Reports from the National Safety Council highlight the role of robots in making

...continued on next page

workplaces safer by undertaking tasks that pose risks to human workers. Proximity monitoring technology prevents collisions between humans and machinery, while wearable devices monitor fatigue. AR and VR technologies offer training solutions for hazardous tasks.

By investing in and implementing these technologies, companies can establish proactive, responsive, and efficient safety protocols. This not only safeguards their bottom lines but also contributes to building a more productive future for the entire manufacturing sector.

AN ENTERPRISE ROADMAP FOR INDUSTRIAL SAFETY

AI and smart technologies are integral to a manufacturer’s journey toward improved safety. However, successfully implementing these technologies requires a supportive organizational culture and robust risk management processes. Workplace accidents incur both tangible and intangible costs, making the case for adopting AI in business safety scenarios

stronger. AI-driven data practices can shift organizations from reactive reporting to proactive improvements, creating a sustainable and safer working environment.

FINAL THOUGHTS

Integrating AI and ML innovations in manufacturing safety marks a transformative era for the industry. By leveraging these technologies, companies can not only reduce injuries but also enhance overall efficiency and productivity.

The future of workplace safety is here, and the intelligent application of AI and machine learning in every aspect of the manufacturing process drives itself

As technology continues to evolve, the potential for further advancements in enhancing factory efficiency and safety remains limitless. As we move forward, embracing these innovations will not only redefine the manufacturing landscape but also set new standards for workplace safety in the digital age.

OSHA Releases 2024 Injury, Illness Data

Data from more than 732,000 OSHA Forms 300 Log of WorkRelated Injuries and Illnesses and Form 301 Injury and Illness Incident Report record is available.

On April 27, the U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) released the 2024 workplace injury and illness data collected from its Injury Tracking Application . Under federal recordkeeping rules, employers are required to electronically submit injury and illness data to OSHA.

The data comes from 370,000 reports submitted on OSHA Form 300A Summary of Work-Related Injuries and Illnesses. In addition, OSHA has posted partial data from more than 732,000 OSHA Forms 300 Log of Work-Related Injuries and Illnesses and Form 301 Injury and Illness Incident Report records.

The agency said that by providing access to injury and illness data, it will assist employers in identifying unsafe conditions and workplace hazards that may cause occupational injuries and illnesses. Recognizing these hazards will help detect ways to control or prevent them and reduce future injuries.

The agency notes that it is “taking additional steps to protect worker privacy by reviewing the remaining data for certain personally identifiable information.” The agency will make additional data publicly available following the review.

Learn more about OSHA’s injury and illness recordkeeping and reporting requirements.

Recognizing these hazards will help detect ways to control or prevent them and reduce future injuries.

Is OSHA a Self-Funded Agency?

04.16.2025 | OSHA Training Services Inc.

I was chatting with a fellow safety professional the other day, someone I consider a very seasoned pro, to discuss some OSHA citations a client of his received. During the course of our conversation, he made what I thought was an off-hand remark about OSHA issuing citations and penalties so they could make more money to operate on. I chuckled and said, “Thank goodness they don’t actually do that.“

Suddenly, I could tell by the look in his eye and his body language that he was taken aback; he really thought federal OSHA was a fully self-funded agency. After clarifying my position, he asked me to send him some info to back up my statement so he could review it. So, I composed an email and sent it to him the next day. Then I realized that he probably wasn’t the only person who might think this is true, so I decided to add some more meat to the info in the email and turn it into a blog post.

WHERE DOES OSHA GET ITS FUNDING?

OSHA is a federally funded agency, meaning it receives its budget through congressional appropriations. Each year, the U.S. Congress determines OSHA’s funding as part of the overall federal budget. This money is allocated to cover OSHA’s enforcement efforts, workplace safety programs, training grants, and administrative costs.

For Fiscal Year (FY) 2023, OSHA’s total budget was approximately $632 million, allocated as follows:

• Federal enforcement programs: ~$250 million

• State Plan programs (which help fund OSHA-approved state-run safety agencies): ~$120 million

• Compliance assistance, training, and outreach: ~$90 million

• Whistleblower protection and legal support: ~$25 million

(Source: U.S. Department of Labor Budget Reports)

While OSHA receives all funding from the federal government, it’s important to note that not all government agencies operate the same way. Some federal agencies are self-funded, meaning they generate revenue through the services they provide, rather than relying on taxpayer dollars. These agencies include:

• The Securities and Exchange Commission (SEC) – Collects fees and fines from financial market participants to help fund its enforcement and regulatory activities.

• The Federal Communications Commission (FCC) – Charges licensing fees to broadcasters and telecommunications companies, which contribute to its budget.

• The Consumer Financial Protection Bureau (CFPB) –Receives funding from the Federal Reserve, which itself generates revenue through various bankingrelated activities.

• The Federal Deposit Insurance Corporation (FDIC) –Financed through insurance premiums paid by member banks, not taxpayer dollars.

In contrast, OSHA has no direct revenue stream and depends entirely on congressional appropriations to meet its budgetary needs.

OSHA’S BUDGET VS. PENALTIES COLLECTED

In contrast to its $632 million budget, OSHA collected a total of $204 million in penalties from violations during FY 2023. While this may sound like a significant amount, it is important to note that penalties collected are not used to fund OSHA’s operations. All fines go directly to the U.S. Treasury’s general fund and do not benefit OSHA directly.

This discrepancy highlights the point that OSHA is not self-funded and has no financial incentive to issue penalties. Instead, its funding comes primarily from federal appropriations to fulfill its mission of ensuring workplace safety. In fact, even if OSHA wanted to fund itself through penalties, it clearly could not—the total penalties collected in FY 2023 amounted to less than one-third of its actual budget. This further disproves the myth that OSHA operates as a self-sustaining agency.

THE REAL PURPOSE OF OSHA PENALTIES

OSHA’s primary goal is not to generate revenue but to ensure safe working conditions. Penalties serve as a deterrent to encourage employers to comply with safety regulations, reducing workplace injuries and fatalities.

In FY 2023, OSHA issued several significant penalties to companies that violated workplace safety standards, highlighting the consequences of non-compliance:

• A food processing company faced a $2.8 million penalty after a worker was killed while cleaning a conveyor system that had not been properly locked out.

• A manufacturing firm was fined nearly $1.9 million after an employee lost a limb due to inadequate

machine guarding and failure to implement lockout/ tagout procedures.

• A construction company received over $685,000 in penalties for repeated fall protection violations, despite previous citations and fatal incidents on their worksites.

• A city government was fined over $600,000 for improper handling of asbestos during a renovation project, putting workers at risk of serious health hazards. These penalties underscore the importance of compliance with OSHA regulations. The fines are not about revenue—they are about holding employers accountable and preventing future tragedies.

WHAT HAPPENS IF OSHA PENALTIES GO UNPAID?

While OSHA issues significant penalties each year, not all of them are collected. Between FY 2018 and FY 2020, OSHA classified nearly $100 million in penalties as uncollectible, with about 20% of cited employers failing to pay.

OSHA’S DEBT COLLECTION PROCESS

When a company refuses to pay, OSHA follows a multistep process to recover the debt:

1. Payment Notices & Calls – Employers receive multiple reminders at 7, 30, and 60 days past the due date, plus follow-up phone calls.

2. Debt Collection via the U.S. Treasury – If payment is still not made, the debt is referred to the Treasury Department, which can take collection actions like wage garnishment or federal payment withholding.

3. Legal Action – In extreme cases, OSHA may involve the Department of Justice to recover unpaid fines.

...continued on next page

WHAT IF A COMPANY THAT OWES MONEY TO OSHA DECLARES BANKRUPTCY?

Some companies attempt to avoid paying OSHA fines by declaring bankruptcy. OSHA must file as a creditor in the bankruptcy case, but if assets are insufficient or OSHA misses filing deadlines, the fines may go uncollected. This happened in a case involving a metal manufacturer, where OSHA never recovered penalties tied to a worker’s fatal accident due to a bankruptcy filing.

WHAT HAPPENS IF OSHA DOESN’T SPEND ITS BUDGET?

If OSHA does not spend all of its allotted funds during a particular fiscal year, the unspent money generally does not carry over for future use by the agency. Instead, the funds are returned to the U.S. Treasury. This “use-it-or-loseit” system means that unspent funds by the end of the fiscal year are effectively lost.

Some funds may be “obligated” (committed to specific contracts, grants, or planned expenditures) before the fiscal year ends, allowing those obligations to carry over. However, if OSHA consistently under-spends its budget over multiple years, Congress may reduce its future funding, based on the assumption that OSHA does not need as much money.

In contrast, if OSHA were to overspend or fail to manage its budget appropriately, it could face scrutiny and reductions in future appropriations.

HOW ARE STATE OSHA PROGRAMS FUNDED?

Many states operate their own OSHA-approved workplace safety programs, known as State Plans. These state-run programs cover about half of all U.S. workers and are funded through a combination of state and federal dollars.

While no state OSHA program is fully selffunded through penalties, their funding structures vary. In general:

• Federal OSHA provides 50% of a state OSHA program’s funding through grants.

• The remaining funds come from state budgets, typically through legislative appropriations.

• Penalty revenue does NOT go directly back to the state OSHA program but instead follows state-specific budgeting rules.

Some states, like California’s Cal/OSHA, assess significant penalties, but those funds do not go directly back into Cal/OSHA’s operating budget. Instead, like federal penalties, they go into the state’s general fund or other designated accounts.

This means no OSHA program—federal or state—operates on fines alone.

THE BOTTOM LINE: OSHA IS NOT SELF-FUNDED

The idea that OSHA funds itself through penalties is a myth. The agency operates on a federally approved budget, and all fines collected go into the U.S. Treasury’s general fund—not back into OSHA’s budget. While penalties are a crucial tool for enforcement, their true purpose is to encourage workplace safety, not to serve as a financial engine for OSHA.

If OSHA were self-funded, its penalty revenue would have to match or exceed its $632 million budget—which it doesn’t. In short, OSHA could never sustain itself solely on fines, even if it wanted to.

Foreign Object in the Eye

A foreign object in the eye can become dangerous and it’s important not to make the situation worse before the item can be removed.

• Do not rub the eye or attempt to remove an object that’s embedded in the eye.

• Before bringing your hands to your face, or assisting someone else with first aid, always wash hands with soap and water.

• If it feels like there is something in the eye, gently flushing the eye may be the best course of action.

• If you’re wearing contact lenses, it’s best to remove the lens before or while you’re irrigating the surface of the eye with water in case the object is stuck to the undersurface of the lens.

You can try to flush the object out of your eye with a gentle stream of clean water.

A gentle wash can be achieved by:

• Safely utilizing an eyewash station.

• Using a small, clean cup positioned with its rim resting on the bone at the base of the eye socket.

• Aiming a gentle stream of water in the shower on your forehead over the affected eye while holding your eyelid open.

SEEK IMMEDIATE MEDICAL ASSISTANCE IF:

• The object cannot be removed with simple irrigation or embedded in the eye.

• There is abnormal vision at any time or pain, redness or the sensation of an object in the eye persists more than 24 hours after the object is removed.

DISCUSSION

If you needed to, how would you safely flush your eyes at work?

If it feels like there might be something in your eyes, why is important not to rub them?

Tough Conversations, A Blood Test for Alzheimer’s and Bodega Cats: What I’m Reading This Week

04.11.2025 | EHS Today

A look at some news of note for safety professionals.

This is the last weekend before taxes are to be filed. This is the last Friday before Passover and the Easter Tridiuum. Even if you are not observing these religious traditions, you may be busy preparing for brunches, egg hunts and the like.

So, I’ve decided to look for some more uplifting news this week. I hope you find something that encourages you, inspires you or simply makes you smile. (The last story definitely will.) Until next time, be safe, be kind and be well!

The first mistake is thinking that the first conversation will be the last conversation.

TOUGH CONVERSATIONS

I recently learned of Jefferson Fisher, a fifth generation Texas lawyer who has become famous for his communication advice. Fisher, who goes by the handle @JustaskJefferson on TikTok, first went viral for his “How to Argue Like a Lawyer” series. In 2024, he launched a podcast . Listening to him speak is like drinking an iced glass of sweet tea on a hot summer’s day. He’s got a calm, measured cadence and a slight southern drawl that is instantly soothing to the nervous system.

In March, he published a book, The Next Conversation: Argue Less, Talk More. He’s been promoting the book and doing a lot of interviews. While reading his interviews in The Wall Street Journal and The New York Times, I found it interesting how he approaches conversations, in part because of experiences in the courtroom with being a husband and father.

For example, when asked about having a productive conversation on which you and your partner don’t see eye to eye on, he says: “The first mistake is thinking that the first conversation will be the last conversation. You need to treat the first conversation almost as if you’re priming for the second conversation and the third one and the fourth one. The bigger the issue, the more conversations that are needed.”

I suspect part of his appeal is how simple and elegant everything he says is. I find myself listening, nodding along, then pausing and saying, “Wait, what did he say?” then stopping and rereading or replaying.

I’ve added myself to the waitlist for his book at my local library. I encourage you all to check out his platform and see why we need to have more tough conversations and conflict if we really want to listen and learn more from each other.

A BLOOD TEST FOR ALZHEIMER’S

In a previous job, I used to do a lot of reporting on dementia and Alzheimer’s disease, the only top 10 cause of death in the U.S. with no known cure.

So, when I see articles about reducing risks and new testing, I get excited. This study article from CNN detailed how researchers are using biological markers, also known as biomarkers , to detect Alzheimer’s.

“No one is really looking at the changes in these biomarkers as outcome measures, as a way of tracking

progress in a person’s journey to improve their brain,” said lead study author Dr. Kellyann Niotis, a preventive neurologist who studies Alzheimer’s and Parkinson’s diseases at the Institute for Neurodegenerative Diseases in Boca Raton, Florida. “We believe these biomarkers may show how the disease progression is being modified biologically by a person’s actions.”

Niotis and her colleagues examined a host of biomarkers, such as blood pressure, sleep hygiene, diet and exercise. They found through simple blood tests, not invasive or costly spinal taps, that improvement in the biomarkers also resulted in a measurable decrease in levels of amalyoid plaques and tau protein tangles, two hallmarks of the disease. In other words, researchers could see improvement in study participants’ physical and mental health.

Researchers caution that more investigation is needed, but it is yet another study that supports the mantra: What’s good for your body is good for your mind.

I hope you read this study article and let it guide you to make healthy choices.

BODEGA CATS

On my past visits to New York City, I haven’t managed to meet a bodega cat. I am, however, delighted I am to see the cats at my local hardware store, garden center and bookstore. So, it’s easy to see how they have become a beloved fixture in the city.

I appreciate why food safety laws and regulations prohibit animals from stores that sell food. But I also understand why New Yorkers could so fiercely love their feline friends.

Some fans argue these aren’t any ordinary felines; these are cats with jobs, protecting the stores’ contents and customers from pests and rodents. The rest of them probably just like seeing, or perhaps petting, the bodega cats, who offer a fleeting connection in such a fast-paced and sometimes lonely city.

Honestly, just reading this story, which features photographs of many adorable cats, brought me joy, especially the yawning Marshmellow. If you’ll excuse me, I need to go find a cat or dog to pet.

I highly recommend you read this story and start following @BodegaCatsofNewYork on Instagram.