SYMTECH, Inc. operates from this 32,000 square foot facility in Spartanburg, South Carolina, which serves as the distribution center for the company’s textile machinery customers.

SYMTECH, a distributor of major textile machinery and equipment, not only sells textile machinery, but also assumes the full responsibility for installation, warranty, repairs and field service, and carries a full line of spare parts.

SYMTECH, unlike most agencies that only sell the machinery while the remaining services are provided from overseas or from a subsidiary in the U.S., provides you with a partner who offers support and assistance long after the sale is made.

SYMTECH serves as the link in the U.S. and Canada between the textile manufacturer and the machinery manufacturer, and takes much pride in the partnership that forms. SYMTECH defines the true meaning of partnership is when two parties work together to promote mutual growth within the industry.

SYMTECH’sbelief is that by providing the industry with the highest quality of machinery available and offering good service, our customers derive the most benefit from their investments.

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 2

SELVEDGE THREAD LET-OFF

Designed for perfectly adjusted selvedge thread tension control. The tensioning arm measures the selvedge tension and keeps it constant from a full to an empty spool.

Individual tension control for the selvedge and the warp beam, may result in a better running efficiency, better fabric quality and a reduction in loom parts consumption, as the overall warp tension can often be reduced.

UKAST 508 WARP LET-OFF

Designed for perfectly adjusted warp tension control. It keeps the warp tension constant from a full to an empty warp beam. The tension is measured with a linear sensor on the back rest roller of the loom.

WARP THREAD FEEDING SYSTEMS FOR NARROW MACHINES

Various tension control systems for narrow weaving machines are available in form of a narrow delivery unit / driven roller or a complete let-off for narrow looms. Solutions are typically individually designed for the application.

WARP FEEDING DEVICE / DELIVERY UNIT

This device is used in combination with a package creel. The delivery unit feeds the yarn from the creel to the weaving machine by keeping a constant tension. It can be used in a wide range of applications, including in carbon weaving.

BEAM STAND AND WARP BEAM IN HIGH POSITION

Crealet offers a complete upper beam stand including electronic let-off for existing looms for most brands and types. They also offer additional beam stands sitting on the floor for weaving with multiple beams on wide and / or narrow looms.

KAST 912 LET-OFF & TAKE-UP CONTROL UNIT

Electronically controlled weaving tension between the warp in the back and the take-up in the front. No pick gears are involved as the pick density is set on the display. The peak weaving tension can be reduced resulting in less loom parts consumption and better fabric quality and efficiency.

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 3 SWITZERLAND

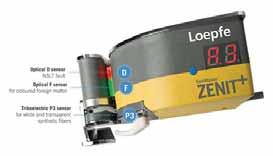

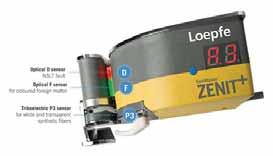

ZENIT +

Optical precision with an all-around view for detection in the winding process

•Covers any scope of application with one single sensing head

high-quality monitoring independent of changing ambient conditions

online production monitoring

LABMASTER TOP DATA MANAGEMENT

Data monitoring with value-added reports for the textile laboratory

•Provides data for laboratory and quality management

•Allows direct access to FIBERMAP and YARNMAP

•Synchronizes automatically all important information with FIBERMAP and YARNMAP

•Includes a back-up system for test results and instrument log files

•Reports with statistical analysis to support decision making

FALCON-I STOP MOTION

Optical precision with an all-around view for the winding process

•Off-color — detects smallest color and shade variations

•Hairiness — clears accurately to the surface index SFI

•Off-standard — detects 24/7 off-standard bobbins with the online laboratory

•Polypropylene — monitors reliably polypropylene faults

•Foreign matter — removes finest foreign matter (fibers) of any color in regular, melange and dyed yarns

•Fancy yarn — controls precisely unconventional fancy yarns

•Covers any scope of application with one single sensing head

•Provides high-quality monitoring independent of changing ambient conditions

•Ensures online production monitoring with the management

YARNMASTER 3N1 MULTIFUNCTIONAL YARN CLEARER

Optical precision with an all-round view for all open-end spinning mills

•Guarantees 100% online quality assurance

premium quality for open-end spinning production

an intuitive user interface for advanced yarn clearer functions

detection of:

Foreign matter

Polypropylene

Spectrogram analysis

CV% off-standard

Sliver faults

Imperfections (IPI)

Moiré effects

faults

Thick and thin places

classification

•Ensures

•Provides

•Online

—

—

—

—

—

—

—

— Clusters

—

— Defect

— HairinessSPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 4 SWITZERLAND

•Provides

•Ensures

DOS-CHEM

•Liquid chemical dispensing system with mono line distribution. Modular design to allow increases in capacity.

•Can be connected to ‘Supercolor’ and ‘Dyematic’ for total chemical and dye automation system.

ITALY

SUPERCOLOR

•Automatic powder dye weighing system in modular structure for 10 to 120 dyes in standard silo size of 150 liters.

•Can be connected with the automatic dissolving and distribution system ‘Dyematic’ for a complete and highly flexible weighing/dissolving/distribution approach.

CANADA

ELECTRIC VEHICLES

Achieve your lean manufacturing and safety goals with our low-maintenance, operator-approved electric industrial vehicles. Industries rely on our low-noise, no-fume tow tuggers, tractors and utility trucks to tackle everything from assembly line feeding to fire-fighting — quickly, efficiently and safely.

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 5

•Burden Carriers •Personal Carriers •Tow Vehicles •Textiles •Utility Vehicles •Sliver Cans

Customized yarn processing

SCHARER SCHWEITER METTLER AG

SCHARER SCHWEITER METTLER AG

In the combined 300-year-old tradition of the Schärer, Schweiter and Mettler companies, which in 1989 merged as SSM, there was always commitment in textile machinery and facilities for yarn processing.

People, markets, technologies and fashion are subject to continuous change - however what remains at the center of our activities is our endeavor to make available to the textile industry top products for yarn processing and winding.

Outstanding competence in processes and winding

Our competence is in the yarn handling and processing during the winding operation as well as in the production of a top quality package for the downstream process. Following processes benefit directly with quality and efficiency improvements. SSM is committed in many applications of the textile process chain.

The following chart illustrates our most important activities:

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 6

SWITZERLAND-USA

MACHINERY

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 7

ASSEMBLY WINDING: DURO-TD Precision assembly winder for technical yarns CONVENTIONAL COVERING: FM1 Manual high-speed parallel winder YARN SINGEING: GSX3-E Yarn singeing and precision winding machine SWITZERLAND-USA SEWING THREAD: TK2-20 KTE Automatic high-performance Kingspool winder DYE PACKAGES/REWINDING: XENO-YW Precision package winder FALSE TWIST TEXTURING: TG2-FT False-twist texturing machine

SINGLE AND DOUBLE COVERED YARNS

Conventional single and double covering machines

Ratti and OMM machines can be configured for single or double covering and thanks to the new mechanic or electronic gear box, allow the production of bobbins that can be used directly on hosiery machines without prior rewinding. The section of machine can be easily accessible for simple and rapid maintenance to minimize the stop time.

YARNS

YARNS

COVER

COVERING

YARNS

TWISTING

Two–for-One’ twisting for filament yarns

Ratti ‘two-for-one’ twisters for natural silk, continuous artificial and synthetic filament yarns, with different lines of textile machines for sewing and embroidery threads, covered yarns, technical yarns, fancy yarns. A wide range of machines that includes almost all the twisting process application fields, providing a great advantage: a marked flexibility to meet customers’ specific needs.

YARNS

YARNS

SET YARN

YARNS

THREAD

YARNS

ITALY SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 8

•SPOOLERS •SPOOLS •SINGLE

•DOUBLE COVER •NYLON •POLYESTER •STRETCH

•MEDICAL

•RUBBER

•ELASTIC

•ELASTANE •HOSIERY

•TUBES •FILAMENT

•SILK •POLYESTER •NYLON •SEWING THREAD •ELASTANE •FANCY

•HEAT

•TECHNICAL

•CABLED

•EMBRODERY

TECHNOLOGY FOR SHORT WARP PROCESSING

Short warp is our profession. No matter how far digitizing technology has advanced, it can only visualize the color-matching of the envisioned fabric, and the touch of the fabric cannot be composed artificially. There is no better way but to present a piece of actual sample cloth in order to appeal to the buyer’s emotion — the sample is the solution. Suzuki offers machinery to cope with quick response expected in today’s demanding specifications market. No matter whether fashion or industrial fabric, Suzuki offers appropriate warping technology for sample fabrics to showcase to buyers, and at the same time, a weavability that is verified in advance.

Warper

Rotational Creel

positions

m/min max. speed

and Rotational in one process

Featuring

both from stationary & rotational creel in one process

creel can change color at the Maximum warping speed of 1500 m/mim

yarn drawing back system

yarn aligning system

shift control system for differnet yarn count

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 9 JAPAN

Sample

— NAS140 Working Width •to 2250-2500 mm Warping Length •420 m to 600 m Warping Speed •300 - 1500 m/min Creel Stand •10 package creel w/tensioning •Slack yarn compensators •Adjustable tensioners

•8

•1500

•Standard

•Feeding

•Stationary

•Slack

•Wound

•Belt

TUMBLING AND SOFTENING

BRIO® 24

Continuous, open-width drying and active relaxation machine for knitted fabric.

Designed for relax-drying and stabilizing any kind of knitted fabric, in any composition and weight, both in tubular and open form, ensuring the highest degree of shrinkage and permanent stability, with a soft hand and increased volume, in a completely safe and tensionless continuous process.

Technical specifications

Working width up to 220 cm open, or tubular any size

Production speed 5-50 m/min

Processing speed up to 500 shakings per minute

Fabric inlet free / pin chain / in line from other devices

Fabric delivery plaiter / in line to other devices

Maximum air temperature 150°C (pre-drying), 120°C (treatment)

Production capacity up to 16 ton/day

Installed electrical power starting from 87 kW

Installed thermal power starting from 450 kW

Average utilisation of gas | steam starting from 13 Nm/h (gas) | 190 kg/h (steam)

AIRO® 24

Continuous open-width tumbling and softening machine for fabrics up to 3200mm wide. Excellent hand and bulk for a wide variety of fabrics. Production speed up to 50m/min.

From natural fibers to artificial and synthetic ones in all types of construction such as woven, knitted, flock and non-woven, Airo 24 finishes fabrics for different applications: apparel, upholstery, home, and technical textiles.

Cotton, linen, silk, wool, polyamide, Tencel, Lyocell, Modal, nylon… all types of products such as natural fibers, artificial fibers and synthetic fibers can be treated without limits in terms of weight and width. Results are obtained in complete safety and without defects for a high-quality finish.

•Drying, tumbling, chemical-free softening

•Three-dimensionality on jacquards

•Swelling, perfect straightening

•Hand breaking coupled and laminated fabrics

•Uniformity, no directionality on pile fabrics

•Grain-enhancement on synthetic leather

•Peachy hand on emerized/brushed surfaces

•Single pass wrinkled effect and casual look

•Defibrillation after surface finishing

•Softness and uniformity on printed cloths

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 10 ITALY

AUTOMATED PACKAGE HANDLING SYSTEMS FOR MAN-MADE FIBERS

•Automatic doffing of yarn packages from Extrusion take-up winders.

•Overhead doffing solution so not to block operator access to the extrusion frame.

•Suited well for BCF and Nylon yarns

TEXTRA – ROVING BOBBIN TRANSPORT

•Utilizes a “train concept” providing overhead storage to balance production flows.

•Automatic yarn bobbin loading and unloading at the roving frame.

•Automatic Bobbin Stripper to clean off all yarn from the bobbin between processes.

AUTOMATIC GUIDED VEHICLES (AGV)

•AGV transport for transport of sliver cans between Draw Frames and Spinning frames.

•Suitable for movement of both Round and Rectangular sliver cans.

•Utilizing Laser and Natural Navigation.

AUTOMATED BOXING OF YARN

•Automatic Boxing Cells for packing yarn into boxes.

•Each package is individually placed in a plastic bag prior to boxing.

•Suitable for multiple box sizes and package weights.

•Complete line to box, weigh, and label each box.

CENTRAL PALLETIZING

•Providing a centralized solution for palletizing high volumes of yarn packages produced in a typical manufacturing facility.

•Suitable for multiple pallet types, sizes, and layer patterns.

•Including pallet conveyor lines to strap, stretch wrap, weigh and label complete pallets

CANTRAC – CAN TRANSPORT SYSTEM

•Ideal for can transport within a roving frame can creel.

•Floor based providing a closed system for movement of full and empty cans between Draw Frame and Roving Creel.

•Cost effective solution for can handling under a Roving Creel.

SPARTANBURG, SC TEL 864-578-7101 • TELEFAX 864-578-7107 11 GERMANY

INCORPORATED Post Office Box 2627 • I-85 Business Exit 7 & Bryant Road • Spartanburg, SC 29304 USA Phone (864) 578-7101 • Fax (864) 578-7107 E-mail symtech@symtech-usa.com Website www.symtech-usa.com ROTARY SHEAR GRINDING FACILITY WAREHOUSE FACILITY

SCHARER SCHWEITER METTLER AG

SCHARER SCHWEITER METTLER AG