TRUSTED HEAT TRANS FER

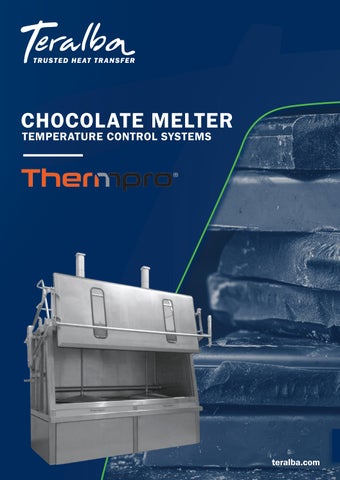

CHOCOLATE MELTER

TEMPERATURE CONTROL SYSTEMS

1 TON CHOCOLATE BLOCK MELTERS

Controlled Temperature

Easy-Load

Fast Melt Rate

Compact

Approved Design

Adjustable Thermal Capacity

DESIGN

Thermpro™ Melters combine all the unique product features of Teralba systems, including a patented stainless steel tube profile for optimising the melting surface and delivered with a range of optional control equipment such as pumps, filters, valves, temperature/level sensors, and more into a compact packaged process system.

Incorporating removable panels for protection from hot surfaces, and adjustable levelling feet to allow positioning in different locations, the Thermpro Melter is designed to be user friendly. Weightless swing door technology allows operators to access the melting deck for fast product turnaround, minimising production run times.

Suited to demanding applications such as controlled product melting rates with low hot water temperature differentials, Thermpro melters produce liquid chocolate from solid forms without changing the properties of the chocolate tempering or finish.

ADDITIONAL COMPONENTS

FEATURES

PRINCIPLE OF OPERATION

Thermpro Melters are custom engineered and manufactured units, designed with a wide variety of standard features and options to meet the most demanding requirements and to comply with your specific design parameters.

COMPACT AND FULLY INTEGRATED:

Thermpro heat transfer systems are designed for use in a wide range of applications. Systems are fully controlled and monitored via touch screen electronics. The Thernmpro units can also be configured to incorporate CIP function and steam sterilisation.

Packaged systems are mounted on compact frames, configured and can be customised to fit within your operational structure and comply with space constraints.

THE THERMPRO ADVANTAGE:

> Pre-validated / factory tested before shipping to site.

> Quick and convenient to install on-site.

> Reduces plant downtime.

> Modular design - relocatable and suitable for plant or process improvements.