2023 Year

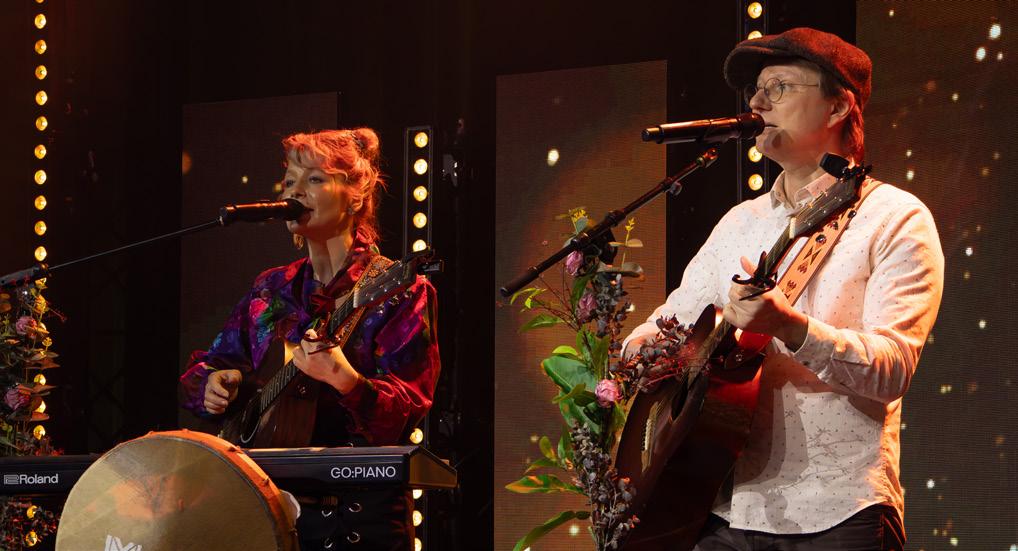

Tapojärvi operates a concentrator plant, technologically unique on a global scale in Terni, Italy.

1

SUSTAINABILITY AT TAPOJÄRVI COMPANIES

FINANCIAL REVIEW CEO’S REVIEW

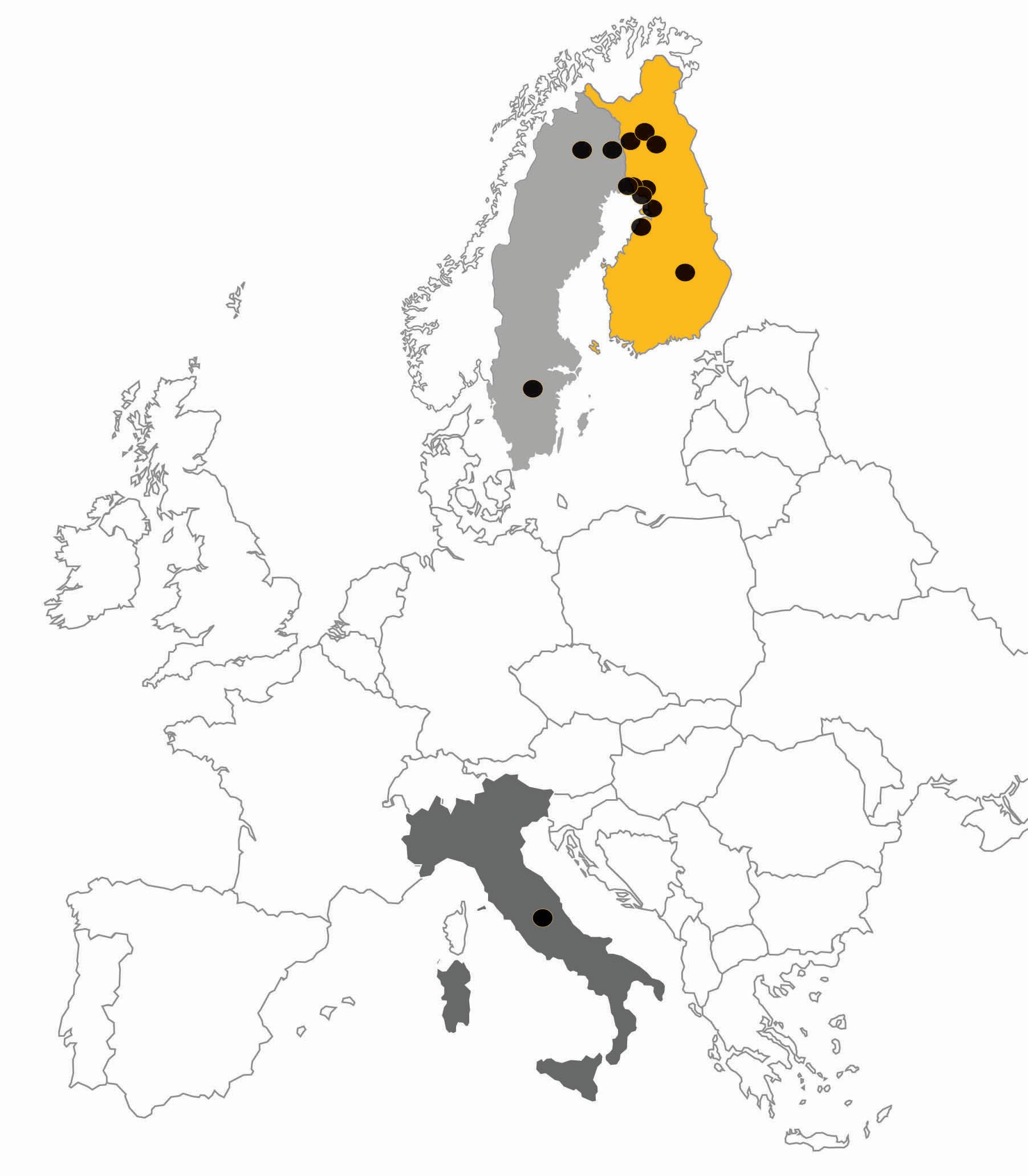

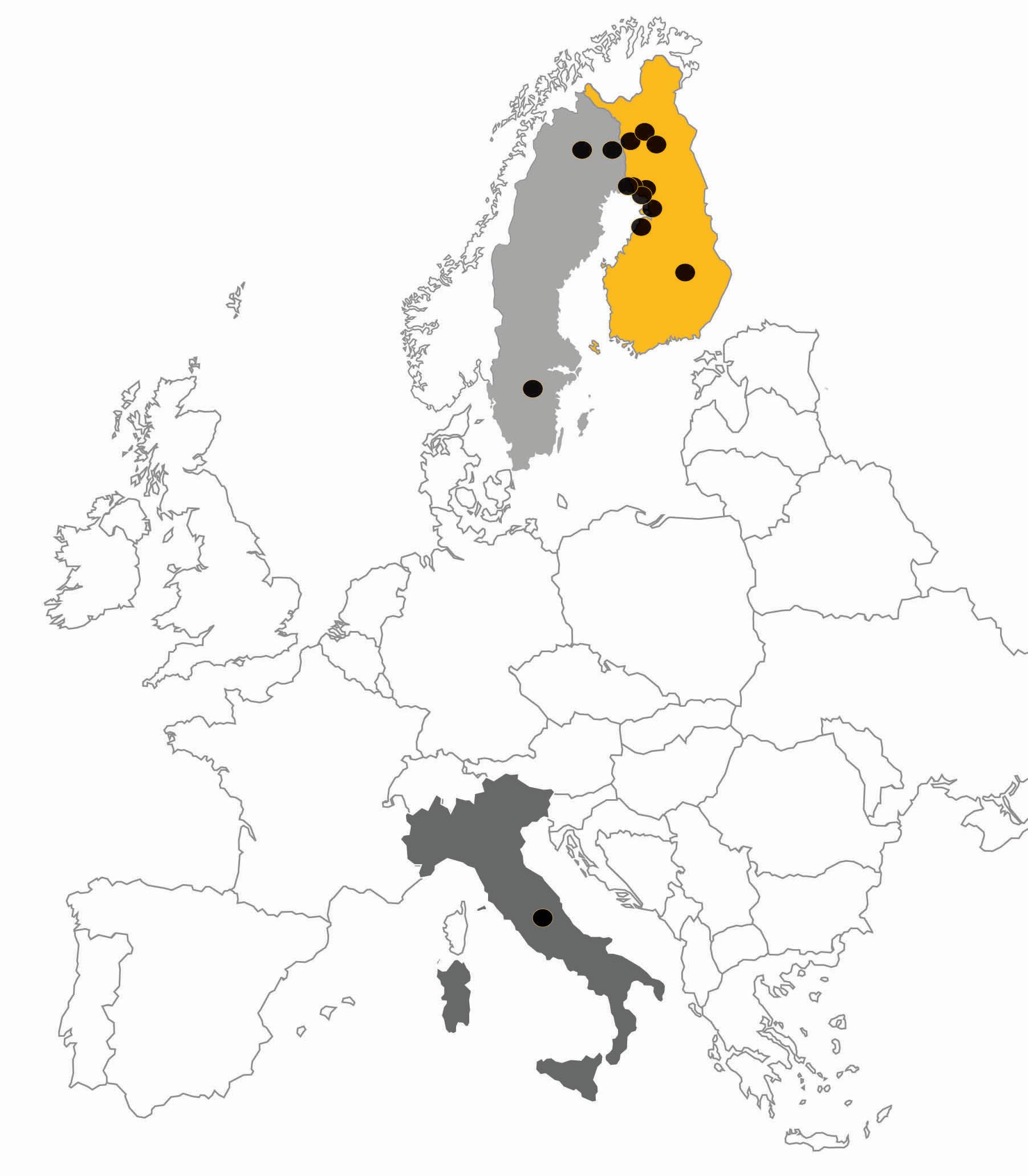

Tapojärvi is a Finnish family-owned business, which has offered environmentally sustainable products and services for nearly 70 years. The company operates in three countries and has 14 locations. At the core of the operations are mining and mill services as well as services and solutions based on sustainable development, which support clients’ needs as well as environmental and economic sustainability. The company’s internationalisation strategy focuses on expanding the business models of mining services and industrial circular economy in Europe.

INDUSTRIAL CIRCULAR ECONOMY 22% MINING SERVICES 78% 2 Contents 3 33 9 7 51 23 2023 HIGHLIGHTS BUSINESS AND SERVICES GROUP COMPANIES

2023 highlights

Agreement with Kaunis Iron took effect on 1 January 2024

TWO NEW CLIENTS IN SWEDEN

ZINKGRUVAN

Tapojärvi Sverige Ab signed a three-month agreement with Lundin Mining on cable bolting at Zinkgruvan in Sweden. The agreement is a small but significant step towards Tapojärvi’s expansion in Sweden. The agreement was extended at the beginning of 2024.

KAUNIS IRON

Kaunis Iron and Tapojärvi Sverige signed a mining service agreement in November. The agreement covers machine work within the ore production chain as well as production support work. The preparation of the agreement began towards the end of 2023.

3

LONG-TERM COOPERATION WITH OUTOKUMPU

CONTINUED

Tapojärvi and Outokumpu signed a ten-year agreement on the processing of ferrochrome slag and stainless steel slag as well as the recycling of fireproof bricks and the manufacturing of fireproof pulps.

EQUIPMENT UNITS

MACHINE AND EQUIPMENT INVESTMENTS

AMOUNTED TO EUR 25 MILLION

The financial standing of Tapojärvi Group is strong, as turnover and profit increased in 2023. The order book is also good.

First batch of asphalt produced with Tapojärvi’s circular economy products was completed in Italy in December. ANAS (the local Transport Infrastructure Agency) used products from Tapojärvi when paving an approximately 300-metre stretch of road SS209 in Valnerina in Terni. The stretch is a test field for testing, for the first time in actual use, the properties of undercoating made with artificial filler originating from stainless steel slag.

TEST RUN OF GREEN LIQUOR

DREG SUCCESSFUL, PLANNING OF A CEMENT PLANT BEGAN

RESEARCH

AND DEVELOPMENT INVESTMENTS GROUP’S TAX FOOTPRINT

4.9

Tapojärvi invests 2–4% of its turnover in circular economy projects every year

The planning of the TapoEko cement plant was launched, as the test run process of UPM’s by-products carried out in May was completed.

In the test run, Tapojärvi made low-carbon TapoEko cement products from the by-products of several plants on an industrial scale.

UPM and Tapojärvi aim to start production in 2026.

4

500

MEUR

MEUR 39.2

2023 highlights

5

6

CEO’s review

Tapojärvi reached several significant milestones in 2023. We faced many challenges, but also identified opportunities, which we took by expanding our operations and further deepening our partnerships.

We invested EUR 4.9 million in research and development projects. A significant share of our projects focus on utilising by-products from different industries and on product development, resource efficiency, reduction of environmental impacts, and economic growth.

The Group’s total investments focused primarily on machinery and equipment, since modern technology supports Tapojärvi’s reliable and efficient service operations.

In our 2023 sustainability work, we defined our sustainability agenda and targets to guide our future development work. These targets emphasise obtaining a more accurate picture of our carbon footprint and carbon handprint.

We work continuously to improve occupational safety and employee well-being, and therefore we monitor the safety figures closely.

The number of personnel increased in 2023. It reflects the company’s growth and commitment to the well-being of our personnel.

The financial standing of Tapojärvi Group is strong, as turnover and profit increased in 2023. The order book is also good.

The internationalisation of the mining services continued in alignment with our strategy in Sweden, where we added two responsible mining companies to our client base.

Tapojärvi is a global pioneer in the industrial circular economy. We have carried out slag treatment at the Outokumpu mill in Tornio for more than ten years. Towards the end of the year, we signed a ten-year extension to our agreement with Outokumpu. This was a major indication of

trust for us, and we will respond to it by developing our production.

A construction and development period of two years has begun at the Tornio mill, and it will be followed by a ten-year period of production with renewed processes.

In Terni, Italy, circular economy services and the metal recovery process, as well as products made from stainless steel slag are at the heart of our operations.

“OUR STRATEGY IS PRODUCING EXCELLENT RESULTS. I WOULD LIKE TO EXTEND MY THANKS TO OUR PERSONNEL, CLIENTS AND ALL PARTNERS FOR THEIR CONTINUED TRUST IN THE TAPOJÄRVI COMPANIES.”

MARI PILVENTÖ ACTING CEO

7

TAPOJARVI ITALIA S.R.L. RECEIVED THE ISO 9001:2015 CERTIFICATE

The certificate is a significant step for the internationalisation of Tapojärvi’s circular economy services.

METRES OF TUNNEL MINED PER YEAR

PROCESSED MATERIAL IN A YEAR

12,159

45.8 mln tonnes

8

Comprehensive solutions

Tapojärvi has competence and an extensive range of services, which is always tailored to the client’s needs. The client sets the goal, and we achieve it.

OPTIMISED PERFORMANCE

Mining of ore and waste rock

Loading and hauling

Crushing

Concentration

Other productive activities

Recycling of industrial by-products

Material processing

Industrial services and transport services

SAFETY AS A PRIORITY

Occupational safety

Induction

Risk identification and anticipation

Systematic review of issues

Safety management and reporting

ADVANCED TECHNOLOGY

Equipment designed to the client’s needs

Competent and trained technology organisation

Own maintenance on all work sites

Central repair shop in Keminmaa

Reliable and safe operation

Digital reporting and analytics

Central laboratory in Oulu

Production laboratories in Tornio and Terni

Primary partner in the client’s value chain

9

We produce circular economy, mining and industrial services for the needs of the environment and society

Tapojärvi’s business model is based on solid special expertise in mining and mill services, as well as on the development of the circular economy. The company provides new solutions for a sustainable life, emphasising cost-effectiveness, operational excellence and the implementation of new technologies.

Tapojärvi’s aim to be the preferred provider of services for its clients is manifested in our commitment to provide environmentally sustainable products and services – in a safe and sustainable manner. The company’s strategy and management include continuous improvement, development of the service provision, financial foresight, and risk management.

Safety is emphasised in all operations, and the company works to actively prevent accidents and promote a safe working culture.

Tapojärvi’s sustainability agenda and objectives reflect the company’s commitment to sustainability. This encompasses the promotion of the business models of the mining services and industrial circular economy, the development of employee well-being, safety, product quality and ethical operating methods, as well as the reduction of climate emissions.

Tapojärvi works to minimise its climate impacts and promote raw material recovery and use industrial side streams as circular economy products.

Our business model supports sustainable development.

FOCUS AREAS OF STRATEGY IMPLEMENTATION

INNOVATIVENESS

Tapojärvi is recognised for its ability to innovate and develop new technologies and processes which promote the utilisation of industrial side streams and reduce environmental impacts.

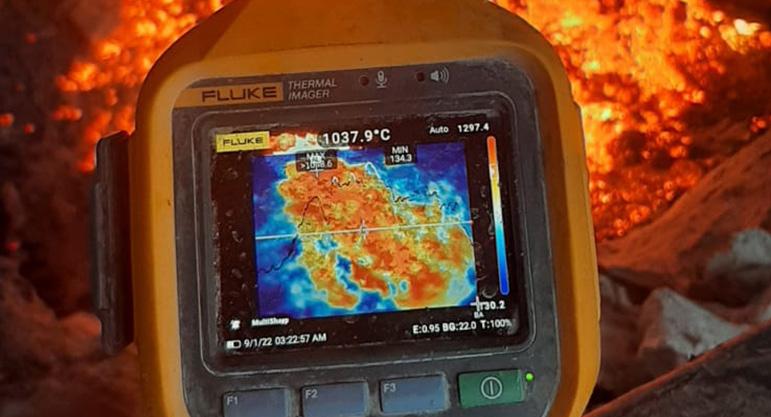

TECHNOLOGY AND EQUIPMENT

Tapojärvi uses modern and cost-effective technology. Modern equipment and technology ensure the high quality and effectiveness of the services. Preventive maintenance and the implementation of new technologies manifest directly as the well-being of the environment, client, personnel and the economy.

SUSTAINABLE DEVELOPMENT

Responsibility is at the core of the company’s operations. Tapojärvi focuses on sustainable development, resource efficiency and minimising environmental impacts in all of its operations.

LONG-TERM PARTNERSHIPS

Tapojärvi has built strong and long-term relationships with its clients and partners, and this approach supports the company’s growth strategy and market position.

10

Industrial-scale environmental actions

01

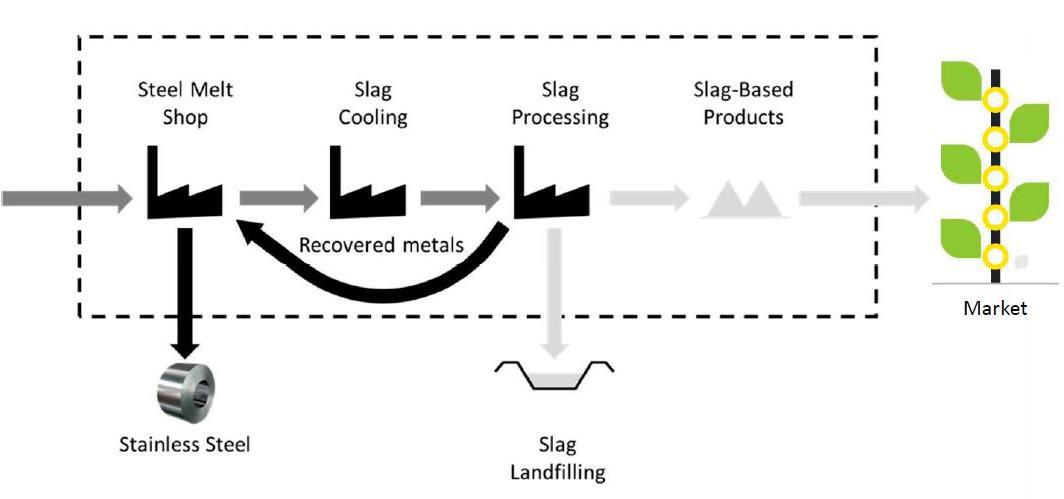

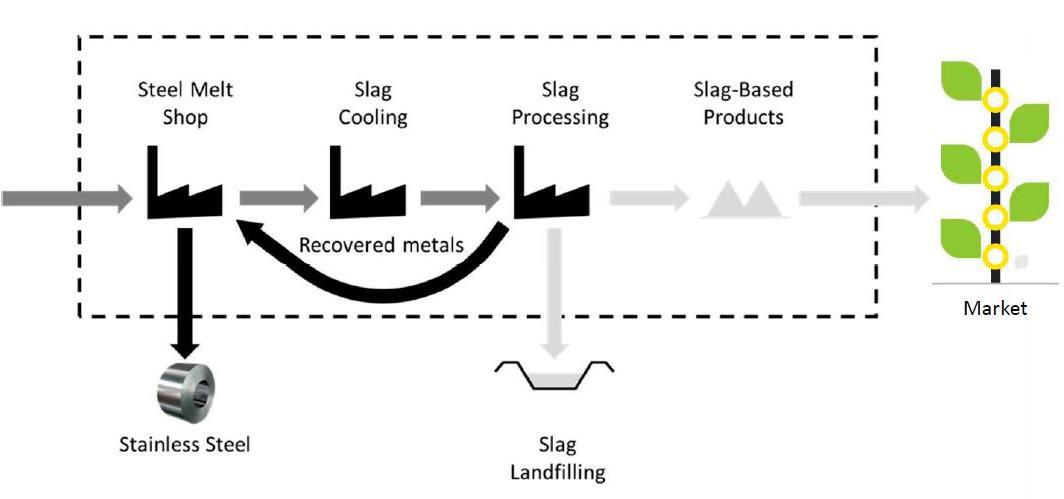

Steel industry

· Transportation and dumping of liquid slag

· Cooling of slag

· Slag concentration

· Material processing services

• Recovery of metals

• Utilisation of side streams

Mining industry

· Ore and waste rock Mining

Loading and hauling · Crushing ·

Other productive activities in mines ·

02

• Geopolymer cover structure

• Water treatment solutions

• Reuse of closed mines

03

Forest industry

· Productisation of green liquor dregs

• Utilisation of side streams

• Reduction of waste

Electronics industry

WEEE recovery plant · WEEE recovery as a service ·

04

Circular economy products and services

Production of aggregate

Production of fillers

Production of raw materials replacing concrete

Manufacture of mine closing structures

Mine filling

Construction industry

· Mining industry

· Chemical industry

• Reuse of precious metals and critical earth metals

Production of chemical products

Industrial-scale environmental actions

11

Vision

We produce products and services that are sustainable for our living environment and create new solutions for a sustainable life.

Customer promise

Mega trends

We keep our promises and go beyond.

Main

goals

· Electrification Sustainable development Scarcity of natural resources Artificial intelligence and digitalisation · · · · Culture of continuous improvement Responsible production Client’s success Financial profitability · · · Global forerunner of the circular economy « « « « Innovations Profitability E ffi c i e cn y irtsudnIla ic r c u la r economy Mining services Tech n o ygol « S a f e ty » « Competence » 12

Mining services

“THE CULTURE OF CONTINUOUS IMPROVEMENT REQUIRES THAT WE UPDATE OUR COMPETENCE AND MAKE NEW INVESTMENTS IN MACHINERY AND EQUIPMENT, FOR EXAMPLE.”

Tapojärvi is one of the largest mining services providers in its sector in Finland.

In Sweden, Tapojärvi has operated since 2017 and is growing its market position.

In 2023, Tapojärvi continued to focus on achieving operational excellence in its mining services, which is manifested in the implementation of new technologies and the streamlining of processes. This is part of a more extensive goal of improving cost-effectiveness and strengthening competitiveness.

During 2023, Tapojärvi worked in the Outokumpu Chrome Oy’s Kemi mine, Agnico-Eagle Finland Oy’s Kittilä mine, Yara’s Siilinjärvi mine and Bolide’s Kevitsa mine in Finland.

In Sweden, Tapojärvi worked in the LKAB Malmberget mine and in the Lundin Mines Zinkgruvan mine.

In 2023, preparatory work was also launched for starting aboveground work in the Kaunis Iron mine. The service agreement took effect on 1 January 2024. The services were provided using extensive production equipment.

Tapojärvi has its own maintenance organisation, which operates near the production unit at every mine.

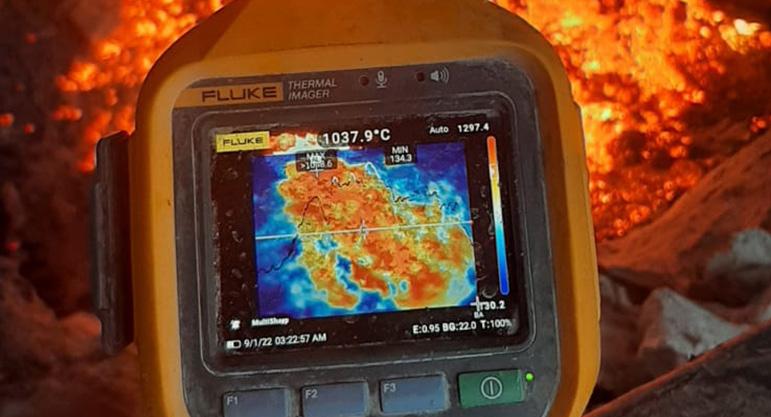

Tapojärvi aims to improve safety and boost production by implementing digital and automated solutions. We use sensor technology and machine intelligence to support maintenance and

ANSSI RYTKÖNEN

DIRECTOR OF MINING SERVICES

equipment life cycle planning, for example.

Technology development includes analysing machines and equipment. Production data provided by the company is utilised in the development of mining services.

Customers and suppliers are also provided with production data to support their own development work.

Modern technology allows us to build a vast data bank for the purposes of continuous development of the operations. The technological development of the mining sector offers opportunities to improve effectiveness and reduce environmental impacts. At the same time, the rapid development of technology and the integration of new solutions introduce additional challenges to the operational activities.

OUR INNOVATIONS

• Cover structures for waste-rock areas

• Treatment and stabilisation of mine water

• Dust control solutions

• Mine filling

• Urban mining

• Mine safety

13

TYPES OF WORK

PRODUCTION AND DRIFTING

Longhole drilling

Development drilling

Charging and blasting

Loading and hauling

Backfilling

Scaling

Crushing and screening

PRODUCTION

Drilling

Charging and blasting

Loading and hauling

Scaling

Crushing and screening

ROCK SUPPORT SERVICES PRODUCTION SUPPORT

Bolting and meshing

Shotcrete

Cablebolting

Equipment installation and construction:

- ventilation, water, electricity, construction and dismantling

Breaking

Road maintenance

Spraying

Industrial circular economy

TAPOJÄRVI’S

BUSINESS OPERATIONS ARE INDUSTRIAL-SCALE

CIRCULAR ECONOMY,

IN WHICH MILL SERVICES ARE PRODUCED AND INDUSTRIAL SIDE STREAMS ARE PROCESSED USING A CONTINUOUS PROCESS.

The operating model of industrial circular economy is based on innovative approaches in the processing and utilisation of materials. The company works to create solutions that support sustainable development and promote the circular economy in various ways.

MILL SERVICES

Tapojärvi offers a wide variety of mill services, including the processing of industrial side streams, maintenance of industrial facilities, and logistics services. Our service provision optimises production processes, reduces waste and improves production effectiveness.

INDUSTRIAL CIRCULAR ECONOMY

Tapojärvi specialises in developing and providing solutions that promote the recycling and reuse of materials. The company works actively to find ways to convert industrial side streams into valuable resources, which can be returned to the production chain or refined into new materials. This covers, for example, the processing of metallurgic waste and the utilisation of industrial side streams from the steel and forest industries.

CIRCULAR ECONOMY PRODUCTS FROM STAINLESS STEEL SLAG.

15

During 2023, Tapojärvi worked at three mills: the Outokumpu Tornio mill, the SSAB Raahe mill and the Arvedi Assiai Speciali Terni mill in Italy.

In addition, Tapojärvi’s RDI team worked in several development projects with partners in the forest and electronics industries.

In May–June, Tapojärvi completed a test run of green liquor dregs using UPM’s lime kiln in Valkeakoski.

Tapojärvi processed 45.8 million tonnes of material in mines and mills in 2023.

Some of the processed material is industrial side streams, which Tapojärvi refines into recycled products.

During 2023, there were 179 employees in the industrial circular economy operations. The operations were further strengthened by the personnel of Tapojärvi companies’ business support and technology.

Tapojarvi Italia S.r.l has a longterm agreement on slag treatment in Terni, Italy. The second

phase of the concentrator plant in Terni was completed in the spring of 2023, after which the company has had increasing opportunities to manufacture slag-based products.

The operations focus on continuous production and the development and optimisation thereof.

In June 2023, Tapojarvi Italia S.r.l received the ISO 9001:2015 quality certificate for the steel mill slag treatment, recycled steel cutting and metals recovery. The certification supports the sales of circular economy products manufactured from stainless steel slag.

Outokumpu Oy and Tapojärvi signed a ten-year agreement on the treatment of ferrochrome slag and stainless steel slag as well as on the recycling of fireproof bricks and the manufacturing of fireproof pulps. The construction and development period of two years is followed by a ten-year period of production with renewed processes.

CONCENTRATION AND MILL SERVICES, MAINTENANCE

• Processing and productisation of industrial side streams

• Production of fireproof recycled pulp

• Processing of materials as part of industrial processes

• Loading

• Transportation

• Crushing

• Screening

• Flame cutting

• Transportation of liquid slag

• Cooling of slag

• Management and maintenance of slag dams

16

Innovations

MEUR 4.9

FOR RDI ACTIVITIES (2.9% of turnover)

Tapojärvi participates in many Finnish and international research, development and innovation (RDI) projects together with industry and research organisations and companies.

MEUR 1 PATENT

OF PUBLIC FINANCIAL SUPPORT (0.6 MEUR as a grant, 0.4 MEUR as loans)

The RDI activities aim to make possible the reduction of virgin materials by utilising circular economy products obtained from industrial side streams. The benefits of circular economy are directly evident in the environmental impacts of companies, well-being at work, safety and finance.

Tapojärvi applied for a patent for compounds and concrete produced from themas well as for related methods and their use in cover structures of the mine’s waste rock piles. The patent was issued on 19 April 2023

The company actively studies and inquisitively seeks new product and business opportunities in the industrial circular economy for the steel, forest, construction, chemical, electronics and mining industries by utilising side streams from these industries.

Tapojärvi has taken significant steps in the field of slag treatment and recycling by developing

processes that make possible the use of industrial side streams as raw material for reuse. These innovations not only reduce the amount of dumping waste but also offer new, environmentally friendly materials for the construction industry and other areas of industry, for example.

Tapojärvi has recognised the importance of cooperation in the development of innovations.

During the year, the company participated in several projects based on cooperation. These projects focused on improving material efficiency, developing new circular economy concepts and researching sustainable mine technologies.

17

SLAG TREATMENT AND PRODUCTISATION

PRODUCTION OF FIREPROOF RECYCLED PULP

TAPOEKO IS A PRODUCT FAMILY OF CIRCULAR ECONOMY SOLUTIONS PRODUCED BY TAPOJÄRVI. TAPOEKO’S FEATURES INCLUDE QUALITY, DURABILITY AND ENVIRONMENTAL CONSCIOUSNESS.

TapoEko products are generated in industrial-scale conditions.

The products are safely produced and do not cause harmful impacts to the environment or human health.

The TapoEko product family also includes production services for the industrial circular economy.

18

CE-merkintä EEJ-status Concrete Cement Chem Road Aid Mining Solutions EOW status CE label

RESEARCH AND DEVELOPMENT PROJECTS WORKED ON IN 2023

Briquetting

Development and production of low-carbon binders and pulps

The Fossil Free Steel project

TYPKI – resource-wise nutrient recovery from industrial wastewater

EU Horizon project: DigIT

EU Horizon project: MasterMine

Hydrometallurgical treatment plant for waste electronic and electrical equipment

Modular treatment of slag

Cement mill for forest industry side streams

Geopolymeric base and cover structures

Geopolymer asphalt patching material

Bio-based dust suppressant and stabiliser for gravel roads

Reuse of fireproof products

Eco Innovation Research Center

Chemical products from industrial side streams

PUBLICLY FUNDED PARTNERSHIPS

1. New eco-innovative materials for mining infra – Mineco

2. High value slag-based hydrometallurgical modular pilot plant – HVP

3. Digital circular production – DCP

4. Stabilisation of mine water – TYPKI

5. A human-centred internet of things platform for the sustainable digital mine of the future – Dig_IT

6. Production plant for low-carbon binders and pulps

7. Productisation of green liquor dregs

8. Digital cover structure

9. European mining in the green and digital era – MASTERMINE

FINANCIAL INSTRUMENTS

19

Tapojärvi Innovation Challenge invited students to develop new business opportunities promoting circular economy

Innovation Challenge is a competition for Master’s level university students, founded by Tapojärvi with the aim to recruit new talent and obtain new ideas for the productisation of industrial side streams.

In 2023, the competition was organised for the third time. The competition received applications from a total of 29 teams from 22 universities. The teams, totalling 71 students, represented 43 different nationalities. After the prequalification stage, five teams advanced to the final round and had the opportunity to present their circular economy business innovations to the distinguished jury on Tapojärvi’s anniversary, 27 October.

Tapojärvi awarded the winning team with a monetary award of EUR 10,000. The first and second runners-up received EUR 3,000 and EUR 2,000, respectively. In addition, the finalist teams

An audience of 50 invited guests attended the final on site. During 2023, the livestream recording was viewed 1,869 times.

were offered an opportunity to develop their ideas further together with Tapojärvi.

“By acting as an example, Tapojärvi has demonstrated that ‘circular economy’ is not just a trendy marketing word but an impactful practical concept. It has been a delight to follow how the company engages systematically in sustainable business

activities in line with its values,”

Juliette Bourden, French member of the winning team, said in the final.

Bourden appreciated the opportunity provided to the finalists to learn about the operations of Tapojärvi’s concentration plants at the Outokumpu site in Tornio.

“We saw in practice how industrial by-products can be utilised.”

Towards the end of 2023, Tapojärvi and Team React, who won the competition, began to jointly examine the opportunities of the innovation to become a new service product in the sustainable circular economy. This work will continue during 2024.

The winning team and Tapojärvi’s CEO Mari Pilventö participated in the ExpertForum held in Prague.

20

Tapojärvi’s technology department has two subdivisions: procurement and maintenance. The central repair shop is located in Keminmaa, Finland.

Technology

DIGITALISATION AND AUTOMATION

In addition to equipment purchases, technology investments focused on the advancement of digitalisation and automation.

Investments helped develop data analytics and implement new generation

AI and machine learning technology for process optimisation.

Investments also targeted drone technology, which can be used in mine services provision and in the monitoring of quarries.

DURING 2023, THE COMPANY FOCUSED SPECIFICALLY ON OPTIMISING EQUIPMENT AND PURCHASES AS WELL AS ON UTILISING TECHNOLOGY IN THE PROVISION OF SERVICES.

During the year, significant investments were made in updating and expanding the fleet. The machine and equipment investments amounted to EUR 25 million.

The investments were used to procure new, low-emission vehicles and machines, which are both

MEUR 25

The machine and equipment investments amounted to EUR 25 million.

more efficient and safer to operate.

During the first months of the year, the procurement team toured work sites to determine the needs for competitive bidding. The centralised procurement facilitated the daily operations on work sites and provided cost savings.

The fourth quarter of 2023 was particularly busy in terms of machine purchases, when investments were made in new machines under the Kaunis Iron mine services agreement in Sweden on a tight schedule. Orders were also placed on Europe’s first hybrid loading machines during the year, and the machines

21

were delivered to the work site of Outokumpu’s Kemi mill in February 2024.

MAINTENANCE IMPROVEMENTS

The origins of production disturbances were placed under closer scrutiny during 2023. Changes were made to maintenance record entries, and entry methods were specified in more detail.

The maintenance indicators were built around the entries, and they provide information on the work site’s operations. Preventive maintenance programmes and maintenance programme standardisation were developed to cover the life cycle of the machines, which reduces production disturbances caused by technical malfunctions. Information gathering from the machines was expanded, which makes it possible to automate manual operations and enables personnel to focus on other tasks.

Operational analyses can be used to target measures effectively and to reduce production disturbances caused by own actions. This will ensure Tapojärvi’s competitiveness in the future as well.

135

TECHNOLOGY DEPARTMENT

EMPLOYEES IN TOTAL

MAINTENANCE:

• Own maintenance personnel

• Own central repair shop:

• Reducing the burden on maintenance at the mine by centralising the operations to the central repair shop.

• When needed, the Keminmaa repair shop provides support to maintenance at the mines with a short response time.

• Midlife repairs

• Aiming for disturbance-free production between maintenance sessions (preventive maintenance)

• Extensive spare part inventory

• Close cooperation with machinery and equipment manufacturers

• Technological development projects

22

Tapojärvi Oy

Tapojärvi Oy was involved in production at four mines and two steel mills and develops circular economy products jointly with several industrial companies.

MINING SERVICES

Tapojärvi Oy’s mine services provision at Outokumpu Chrome’s Kemi mine focused on improving safety and streamlining processes. Outokumpu Chrome Oy and Tapojärvi have agreed to extend the Kemi mill agreements until 2026. The extension of the agreements is a considerable sign of the client’s trust in the services. At the same time, it challenges Tapojärvi to improve the safety culture and cost-effectiveness of its mine services provision at the Kemi mine.

The alliance agreement of Tapojärvi and Yara Siilinjärvi in 2020 introduced a new operating model to the mine services provision. The alliance model makes it possible to combine the planning and implementation processes, accelerate the flow of information and share the responsibilities concerning production targets and risk management. In practice, the alliance creates a foundation for mining operations which are safer, more profitable and of higher quality.

In 2023, the Yara Siilinjärvi mine experienced considerable production growth, resulting in

the recruitment of new employees. Due to the production increase, new types of work were implemented at the work site, such as measurements and production charging, and extensive road improvements were carried out. New equipment also arrived in the summer. In November, an independent project was launched to remove surface soil and carry out overburden excavation at the Jaakonlammi mine.

In Agnico Eagle Finland Oy’s mine, Tapojärvi focused on support work as well as innovative projects, such as percussion drilling of the quarry. The project was praised for effectiveness and professionalism, in particular. During 2023, Tapojärvi also trained the client’s own personnel on cement bolting in Kittilä. Tapojärvi commenced the CW mine covering contract in Bolide’s Kevitsa mine in July. At the same time, the current agreements were extended for the next three years.

INDUSTRIAL CIRCULAR ECONOMY

Tapojärvi Oy met the safety, quality and production targets at Outokumpu’s Tornio mill. Noise and dust measurements by the Finnish Institute of Occupational Health were carried out during the year, and corrective measures were taken based on them. The corrective measures were completed by the end of the year.

The regulations of the new environmental permit were taken into account in production. A project aiming to improve disturbance logging was also launched in Tornio.

The most significant event of the year was the signing of a ten-year extension agreement with Outokumpu Oyj.

With the new agreement, investments will be made at the Tornio mill which will support metals recovery, the productisation of slags and the reduction of environmental impacts. The development projects in the implementation of the 5S method and the improvement of work efficiency at the Tornio location progressed well.

Tapojärvi Oy’s operations at SSAB’s Raahe steel mill were positive during the production year.

The safety and production targets were met, and there were no changes with regard to agreements.

No accidents or incidents to be investigated were reported at the Raahe location in any quarter, which indicates a high level of safety. The implementation of the MHMS production control system and the improvement of the road network in the lime kiln area were key development projects in the production process in Raahe.

23

Tapojärvi participated in SSAB’s Fossil Free Steel (FFS) project, which examined the manufacturing of steel with hydrogen instead of carbon.

FINANCE

Tapojärvi’s financial performance was strong in 2023. The company’s turnover was EUR 131.2 million, which is slightly less than in the previous year (2022: EUR 132.8 million). Nevertheless, the slight reduction in turn-over

did not have a significant impact on the company’s profitability, since operating profit grew to EUR 15.1 million, corresponding to 11.6% of turnover (2022: 10.5%). This shows that the company has been able to streamline its operations and improve profitability despite the slight reduction in turnover.

The return on equity was 21.20% (2022: 21.8%), and the equity ratio was 32.7% (2022: 35.1%).

The business outlook is stable. The company’s financial and material resources are

A solid and long-term order book offers the company a stable framework for future operations, and the model of working based on agreements provides predictability in the planning of the business operations. The improved profitability, strong return on equity and the maintained equity ratio show that the company has succeeded in the execution of effective strategies to maintain and improve its financial performance.

24

strong.

Tapojärvi Sverige Ab

Established in 2014, Tapojärvi Sverige Ab is a company offering its extensive expertise to mines in Sweden. Operations are always tailored to the client’s needs. The advantages of Tapojärvi’s operations in the Nordic countries are its local presence, operations near the mines and good contacts with partners. In addition, as a provider of mining services, Tapojärvi is a strong and trusted brand. This is an advantage when bidding for contracts and other opportunities in the provision of mining services.

The company’s long history, experience and reliability guarantee operating reliability in all projects and circumstances. Competent personnel and modern equipment are the company’s most important assets.

MINING SERVICES

During 2023, Tapojärvi Sverige faced challenges but also broke production records in its operations in Sweden.

At the LKAB Malmberget mine, significant production volumes were achieved, several production records were broken and work was carried out safely without accidents for more than 12 months.

During the second quarter of the year, the client reduced the metric volumes, and as a result, the company had to adjust its

Founded in: 2014

Managing Director: Mari Pilventö

Industry: Mining services

Employees: <100

Turnover: MEUR 21.2

operations and the number of personnel to the reduced metric targets.

The operations in Sweden expanded to southern Sweden in October, when the company signed a three-month agreement on cablebolting at Zinkgruvan. It was a significant step towards Tapojärvi’s expansion in Sweden, although the contract itself was small. At the turn of the year, the wire rope installation

project at Zinkgruvan mine was continued. Tapojärvi Sverige’s last quarter continued on a positive note, as Tapojärvi signed a major contract with Kaunis Iron in November to follow the Zinkgruvan contract.

The service contract with the Kaunisvaara open pit mine covers machine work in ore production as well as production support work, which includes all opencast production activities other than rock transportation, drilling and charging.

Following the signing of the contract, a rapid ramp-up of production began. Approximately 60 new employees were recruited. The launch was supported by employees from other Tapojärvi sites. Equipment purchases were also sizeable.

FINANCE

During 2023, Tapojärvi Sverige Ab demonstrated its ability to adjust to changing situations, reach its targets and maintain a high level of safety in its operations. The new agreements strengthened the result. Turnover increased to EUR 21.1 million (2022: EUR 19.4 million).

The company is poised to face the future challenges and to seize future opportunities in the mining sector in Sweden. The business outlook is good.

25

“WE HAVE THE PASSION AND THE DRIVE TO MEET THE CLIENT’S NEEDS AND TO KEEP DOING SO BETTER, MORE EFFICIENTLY AND MORE COST-EFFECTIVELY.”

MIIKA MIETTINEN PRODUCTION MANAGER, TAPOJÄRVI SVERIGE AB

Tapojarvi Italia S.r.l

Tapojärvi Italia S.r.l was established in 2018 and specialises in the treatment of materials used in the steel industry. The company productises industrial side stream s and develops new business around materials in its modern slag treatment unit. The utilisation technology of the Terni

plant is globally unique. The company’s operations include the development and manufacture of CE-certified products made from stainless steel slag to the market as an alternative to natural materials in asphalt construction or the production of concrete and other materials.

INDUSTRIAL CIRCULAR ECONOMY

Tapojarvi Italia S.r.l has a long-term agreement on slag treatment in Terni, Italy. The second phase of the concentrator plant in Terni was completed in the spring of 2023, after which the company has had increasing opportunities to manufacture slag-based products.

In 2023, the company’s operations focused on continuous production and the development and optimisation thereof. The company carried out several research and development projects, which focused on the potential of filler produced from stainless steel slag in various applications, such as asphalt and concrete.

In June 2023, Tapojarvi Italia S.r.l received the ISO 9001:2015 quality

certificate for the steel mill slag treatment, recycled steel cutting and metals recovery. The certification supports the sales of circular economy products manufactured from stainless steel slag.

The CE-marked filler product was delivered to ANAS for the construction of the first stretch of test road in December 2023. The stretch is a test field for testing, for the first time in actual use, the properties of undercoating made with artificial filler originating from stainless steel slag.

In the second quarter of 2024, further tests will be carried out in the test field, and if the filler meets the requirements of ANAS’s specifications, the product can be put into service.

27

TAPOJARVI ITALIA S.R.L PAID SPECIAL ATTENTION TO THE DEVELOPMENT OF SAFETY MEASURES IN 2023.

Tapojarvi Italia S.r.l LTIF

7.21

(Tapojarvi Group 2.2) THE FIGURES MEASURING ACCIDENT FREQUENCY DEVELOPED WELL

(Tapojarvi Italia S.r.l 2022: 20.34).

The company has taken continuous measures to improve the safety culture and succeeded in remaining accident free for ten months.

The accidents and near miss situations that occurred during the year were investigated thoroughly, and several corrective measures were taken based on the investigations to improve safety at work. Special attention was also paid to safety tours during which the safety of the workplace was reviewed and necessary action was taken immediately.

In Italy, eight new employees were added to the personnel (a total of 110) (2022:102).

PERSONNEL FINANCE

Personnel training and development were active during the year. Specialisation and safety courses were organised for personnel with introductions to new tools and working methods. During the year, there were also temporary layoff periods during production shutdowns, which was necessary for production effectiveness. At the end of 2023, the company started negotiations with trade unions to review the employees’ performance bonus. It demonstrates the commitment of Tapojarvi Italia S.r.l to the well-being and appreciation of its personnel.

The company is lagging behind in the financial targets of its operations in Terni. The lag is due to a prolonged construction and commissioning stage as well as unfinished matters in production processes. The company’s turnover increased to EUR 18.7 million (2022: EUR 11.4 million).

28

29

Hannukainen Mining Oy

STATUS OF PROJECTS

Hannukainen Mining, owned by Tapojärvi, is in the process of opening an old mine in Kolari, Finland. Previously, mining activities in the area were carried out by Rautaruukki and Outokumpu.

The goal of reopening the old mine is to contribute to reducing Europe’s dependence of third countries, which currently supply a large share of the strategic metals needed by the EU.

Hannukainen Mining Oy’s iron, copper and gold mine project is currently in the permit stage. The central permit matters, the environmental permit, mining permit and the zoning of the mine area have moved forward, although not in the schedule the company anticipated.

Several specifying plans were prepared for the environmental permit application in 2023. An extension until the end of November 2023 was filed for the submission of a supplement to the environmental permit. Another extension was filed for the supplement in October, since the review of the groundwater classification by the Lapland ELY Centre (Centre for Economic Development, Transport and the Environment) was still pending. In December, the Regional State

ORE PROSPECTING FEES IN 2023

26,000

Ore prospecting is carried out around the mine envisaged for Kolari and in Kelontekemä, Kittilä.

The methods used include modelling and analysing old documentation as well as carrying out geophysical measurements and diamond boring.

Administrative Agency for Northern Finland declined to grant an extension and would not take the application under review.

The company appealed the Regional State Administrative Agency’s decision in Vaasa Administrative Court.

The mining permit application was filed in 2022.

The test structure of the TYPKI project continued during 2023. Hannukainen Mining and Tapojärvi constructed extension structures at the planned mine area in Kolari to test belite cement as a covering material for the wall rock. The production of belite cement uses

green liquor dregs and fly ash generated in the forest industry.

The aim of the testing project is to test technical working methods and the functioning of the structure for covering the waste rock area in practice.

Alternative materials aim to replace membrane structures commonly used in covering structures.

The goal is to develop new, sustainable solutions for the management of environmental impacts of mines.

The company has faced challenges, such as the prolonged court proceedings and complex permit processes, in particular. However, Tapojärvi is committed to continuing the project investment to advance the mine project and is actively looking for new solutions to the challenges.

SUSTAINABILITY

Hannukainen Mining is committed to sustainable mining operations and to minimise the impacts of the mine.

The company has paid special attention to the development of water management and the minimisation of environmental impacts. The completed environmental surveys, water treatment plans and noise and dust surveys are part of the company’s pursuit of

EUR

minimising the impacts of the mining operations as much as possible.

The company has worked actively to build a positive relationship with the local community and to gain broad acceptance for its project in society.

The project is expected to bring significant economic benefits to the local community and the whole of Finland through tax income, jobs and industrial activity.

Resident surveys and an ongoing dialogue with the community are part of Hannukainen’s commitment to sustainable mining operations.

The company supports local and neighbouring municipalities’ club activities with emphasis on improving the well-being of children and young people, in particular, as well as promotes environmental and cultural activities.

STAKEHOLDER COMMUNICATION

• Vänkätupa open 41 times, with 19 visitors each time

• 5 public events

• 8 targeted stakeholder events

• 4 press events

• 17 web articles

• 6 electronic newsletters

• 25 feedback channel conversations

30

STAKEHOLDER ENGAGEMENT

Hannukainen Mining’s stakeholder engagement covers local communities, the authorities, environmental organisations, reindeer owners association and landowners, as well as other key stakeholders.

The company pursues an open and transparent dialogue in order to understand and address the concerns and expectations of different stakeholders. This is particularly important in mining operations, which may have considerable environmental, economic and social impacts.

The company shares information on its website and through newsletters, videos and public notices to ensure that the information is reached simultaneously by as wide an audience as possible. In addition, the company keeps Vänkätupa open on Mondays, offering stakeholders the opportunity to come and discuss the project.

In 2023, Vänkätupa was open 41 times and was

Team Hannukainen Mining just slightly missed the gold in the JM-SM Liiga 2023 folk racing final, coming in second. The team represented the Kolari motor club.

visited a total of 780 times. The communication and interaction channels also included phone, email, discussions and meetings. During 2023, personnel participated in 13 public events in which information was provided on the project.

Stakeholders can give feedback via several channels. A system has been set up for handling feedback, and all pertinent feedback is responded to. The aim is to develop the operations based on the feedback received.

At the end of 2023, a stakeholder survey concerning the mine project targeted the residents of the municipality of Kolari. The survey mapped the attitudes of Kolari residents towards the mining project and their expectations and concerns regarding the project. Kolari residents feel mostly positive (60%) about the mining project. 13% of the respondents said they have no clear opinion on the project. Just over a quarter (27%) expressed a negative opinion.

31

Lapland’s representatives in the parliament visited Hannukainen Mining to familiarise themselves with the mining plans and Tapojärvi’s circular economy solutions which can be applied in the planned mine.

32

33 Sustainability

In our 2023 sustainability work, we defined our sustainability agenda and targets to guide our future development work. These goals emphasise the importance of having a more accurate picture of our carbon footprint and how to reduce it, our carbon handprint and the opportunities to highlight it, as well as the continuous development of our personnel and occupational safety and sustainability. We have compiled a code of conduct for our suppliers and, for the first time, also included in our carbon footprint calculation indirect Scope 3 emissions categories, such as raw materials and other production materials, oils and chemicals, waste and travel. In the case of Tapojärvi, the most essential sources of emissions, however, are various fuels (Scope 1) and electricity (Scope 2), which emphasises the role of technology and fuel choices in the minimisation of our emissions. The performance, condition and

TAPOJÄRVI’S THREE KEY OBJECTIVES IN PROMOTING SUSTAINABILITY ARE:

age of the equipment play a significant role in both the business operations and their environmental impacts.

We renew our equipment on a continuous basis, since new technology generates less emissions and is more reliable and efficient.

Preventive maintenance prevents equipment malfunctions and subsequently reduces the burden on the environment: our goal is for machines and equipment to operate between

maintenance sessions without needing repairs.

In future, some of the energy used in our central repair shop will be provided by solar panels. We also want to make the positive environmental impacts of our operations, or our carbon handprint, more visible in future. Industry produces various side streams that are categorised as by-products or waste. Unutilised side streams often result in environmental damage and significant costs.

Hannukainen Mining, a Group company, pays special attention to environmental impacts, such as dust and noise control, water treatment and chemicals treatment, when examining and developing process alternatives in the mine’s preparation and development stage.

For example, measures have been taken in the project planning stage to take any side streams into consideration and to utilise them to minimise the generation of waste.

Unutilised industrial side streams often result in environmental damage and significant costs.

Tapojärvi seeks solutions that would provide side streams a new life as circular economy products.

34

CIRCULAR ECONOMY AND ENVIRONMENTAL MEASURES

IN 2023

• Procurement of Europe’s first hybrid loading machines.

• Tapojärvi treated a total of 872,130 tonnes of slag from steel mills. The treatment and recycling of slag returns metals to production and reduces the amount of waste disposed of at landfills.

• The company processed side streams from the forest industry at UPM’s Tervasaari mill in Valkeakoski, where the pulp mill’s decommissioned lime kiln was used for the purpose. Low-carbon concrete fillers were produced in the process.

• The company carried out several projects to improve energy efficiency and increase the use of renewable energy.

• Hannukainen Mining Oy has paid special attention to the development of water management and the minimisation of environmental impacts.

• We organised the Tapojärvi Innovation Challenge, which seeks new innovations for a sustainable future.

Circular economy and the environment

Responsible operations are at the core of Tapojärvi’s strategy. The services, solutions, innovations and products provided by the company help clients and partners to promote the circular economy and the meticulous use of the scarce natural resources, as well as to protect biodiversity.

Sustainable business operations are based on cooperation with clients and partners, as well as continuous innovativeness. The results of the activities are not only reflected in Tapojärvi’s operations but also in our clients’ production: together we will carry out industrial-scale environmental actions. Tapojärvi is committed to developing solutions based on the circular economy, which reduce the amount of industrial side streams and works to replace new materials with recycled materials. The operations of Tapojarvi Italia is a fitting example of Tapojärvi’s pursuit of promoting sustainable development and the circular economy. The company minimises the amount of dumping waste and uses such waste in the production of new, sustainable

products, which can replace virgin raw materials.

The technological development of the mining sector offers opportunities to improve effectiveness and reduce environmental impacts. Europe’s first hybrid loading machines ordered by Tapojärvi in 2023 are an example of this. The lower emissions generated by the equipment support Tapojärvi’s pursuits in the promotion of sustainable development and in responsible business operations.

In 2023, Tapojärvi focused its operations on the development of innovative projects. These development projects reflect Tapojärvi’s commitment to the protection of the environment, improvement of operational effectiveness and utilisation of technological development.

Tapojärvi aims to be the world’s leading industrial circular economy company. This objective guides the company’s research, development and innovation activities, investments and daily operations towards a more sustainable and resource-efficient future.

OBJECTIVES AND INDICATORS

Tapojärvi’s operations are guided by four basic values: safety, competence, efficiency and profitability. Based on these values, the company works to produce services and products that meet client needs, offer a safe work environment and minimise the environmental impacts of its operations.

Responsible business operations and the pursuit of zero adverse impacts are key sustainability targets. Safety, quality, profitability and employee satisfaction are key performance indicators at Tapojärvi.

Tapojärvi acts with integrity in its business operations. The company is committed to complying with laws and regulations and making sustainable, ethical decisions. The services are provided for various industries and plants. Our production is always planned according to the client’s environmental permits and requirements.

The themes of the sustainability agenda are linked to the UN’s Sustainable Development Goals, of which Tapojärvi has recognised and focuses on the five most essential ones:

Safety and responsibility are not just words, but deeply rooted values and the foundation of Tapojärvi’s operations. Tapojärvi uses the latest technology and innovative methods to ensure that mining production is not only efficient but also sustainable from the environmental perspective.

Behind the concrete measures of the sustainability agenda, the operations are guided by Tapojärvi’s Code of Conduct. They define the general responsibilities and obligations. Tapojärvi’s Code of Conduct is binding for all Tapojärvi employees, partners and our supply

1 Development of sustainability in a way that supports production NEAR-FUTURE DEVELOPMENT NEEDS

2 Keeping up with digital development and ensuring modern competence needs

3 Utilisation of databased information and metering

4 Commercialisation of RDI projects

chains. The principles of the Code of Conduct are deployed in practice through the management system and detailed operating guidelines.

36

37 Personnel and safety

AT THE END OF THE FINANCIAL PERIOD, THE TAPOJÄRVI GROUP HAD 781 EMPLOYEES. THE NUMBER OF PERSONNEL INCREASED BY 22 EMPLOYEES FROM THE PREVIOUS YEAR.

At Tapojärvi, social responsibility means responsibility for our own personnel, safety, expertise and equality, for example. We respect human dignity and treat everyone with respect.

As a contract partner, Tapojärvi is honest and loyal, listens to its stakeholders and conducts ongoing dialogue with them.

Tapojärvi respects all internationally recognised human rights and pays attention to human rights matters and work conditions in supply chains in countries with the highest human rights violation risks.

We have intentionally removed unnecessary intermediate levels and any structures compromising equality.

In our family business, everyone is treated equally and every employee can take responsibility for and influence their work.

The company encourages personnel to obtain training, innovate and develop both themselves and the work community as well as the way the company does business.

YEAR 2023 RECRUITMENT

In 2023, 155 employment contracts were signed (2022: 205)

Personnel turnover percentage is 18 (2022: 25%)

A total of 1,070 applicants, of whom 10% were women, applied for jobs at Tapojärvi

The number of applications received was 1,160 (2022: 772)

of personnel is men. Of the women, 40% work in administration.

91% 38

Permanent employment 63% work in mining services 33% The largest age group is 35–44-yearolds. 94% Alle 1 vuotta 15 % 1 - 5 vuotta 50 % 5 - 10 vuotta 21 % yli 10 vuotta 14 % Työsuhteen kesto 2023 Alle 1 vuotta 1 - 5 vuotta 5 - 10 vuotta yli 10 vuotta Duration of employment Management 16 Clerical employees 94 Supervisors 75 Maintenance 100 Machine operators 315 Mining machine operators 87 Mine equippers 33 Process operators 44 Support 17 Total 781 Occupation 2023

More than 10 years 14% Less than 1 year 15% 1–5 years 50% 5–10 years 21%

EQUALITY AND NON-DISCRIMINATION

Of Tapojärvi Group’s employees, 94% (736) are men and 6% (45) are women. The majority of Tapojärvi’s employees being men is explained by the nature of the sector and the duties, due to which significantly more men than women seek employment in the sector. During the financial period, 10 per cent of the job applicants were women.

The applicants’ gender plays no role in recruitment and hiring. All work duties suit both women and men.

The most competent person with the best fit is always hired to each position, regardless of their gender.

The pay for the same work or work of equal value is always the same, regardless of the employee’s gender.

The employee’s gender is not a factor when their pay is determined, but the pay is based on the applicable collective agreement, the position’s difficulty level and the person’s qualifications (such as work experience, education, competence).

Pay comparison between the genders cannot be performed without compromising privacy, due to the low number of women employees.

The working conditions in work sites are arranged so that both genders find working as practical and comfortable as possible.

Sexual harassment or other improper behaviour is not allowed, and if such behaviour is observed, it is addressed immediately.

The primary means to normalise the situation is discussions between the employee (their representative) and the employee (their representative) and, if needed, the occupational health and safety service.

All people are equal and no one is discriminated on the basis of age, origin, nationality, language, religion, belief, opinion, political activity, trade union activity, family relationships, health, disability, sexual orientation or other personal characteristic.

Management and supervisory work take into consideration personnel diversity, and recruitment provides qualified applicants with equal opportunities to be chosen.

Our induction training is sensitive to different cultural and linguistic needs.

We intervene in discrimination and bullying effectively and have zero tolerance for any form of inappropriate treatment.

We have a notification channel in place in compliance with the whistleblowing directive, which can be used to report improper treatment or otherwise reproachable actions anonymously.

OCCUPATIONAL SAFETY

Tapojärvi is committed to continuously improving its safety culture and preventing accidents and promoting occupational health systematically.

Safety is based on induction, systematic prevention of risks and compliance with instructions. Employees have been instructed to pause and think before acting and to anticipate potential risks in their daily work. Preventive safety actions include the use of the work card model on a daily basis, work community meetings, safety walks, and safety observations.

Employees make observations of incidents that could have resulted in an accident, hazardous situation, deterioration of health or negative environmental impact. Employees are also encouraged to report positive observations.

Monitoring occupational safety and intervening in issues are part of our daily operations

and carried out in close cooperation with our clients.

All accidents and hazardous situations are investigated and their root causes are analysed. The number and impact of HSEQ observations are monitored daily.

At Tapojärvi, every employee has the right and responsibility to ensure their own and other people’s safety.

WELL-BEING AT WORK

Well-being at work comprises of work and finding it meaningful, health, safety and well-being. In addition to physical safety, attention is paid to psychological safety, and the work community is developed so that every employee feels valued and accepted.

In practice, the goal is to create working conditions that offer appropriate challenges and a balanced work load and where everyone has the opportunity to develop themselves and find meaning in their work.

Well-being and coping at work are monitored, for example, in various weekly

meetings, performance appraisals, one-to-one meetings between the supervisor and employee, and in early support discussions.

Tapojärvi monitors employee satisfaction regularly by conducting a pulse survey twice a year. The pulse survey measures the personnel’s overall satisfaction and determines the Net Promoter Score.

Employees can also give the employer open feedback in the survey. The results of the survey are communicated to personnel.

In 2023, pulse surveys were conducted in April and September. Tapojärvi Oy’s overall satisfaction score was 74 and Net Promoter Score 13 in the pulse survey carried out in the autumn. That of Tapojärvi Sverige AB’s was 79 (04/2023: 74). The Net Promoter Score also improved considerably and is now 34 (04/2023: 7).

The overall satisfaction at Tapojarvi Italia S.r.l. declined by three points to 71. The Net Promoter Score was 7, which is four points higher than in spring 2023.

2.2 96% 74 40 Safety observations LTIF SAF rate Overall satisfaction

9,485

WORK ABILITY

Tapojärvi Italia’s employees visited Finland to learn about the parent company’s way of operating.

Our goal is a well-being, healthy, and capable work community. We take social responsibility by taking care of our employees’ occupational well-being and work ability. Our focus in work ability management is on preventive actions, which include activities aimed at maintaining and improving work condition and strengthening the leadership skills of supervisors. Employee well-being is important to us. We continually strive to find ways to develop work and the work environment to support work ability, so that our staff can remain in the workforce for as long as possible. We train our supervisors in early support models, allowing us to identify potential challenges and issues with work ability early on and focus on their prevention. We support the return to work after long absences due to illness and utilize various support measures in this process. Our staff has access to preventive and statutory occupational health services.

EXERCISE AND RECREATION

Tapojärvi takes care of the work ability of employees through the Tapojärvi Sport Club activities. The purpose of the club is to encourage and motivate personnel to adopt a healthy lifestyle and to exercise as well as to promote coping at work.

The Sport Club activities are organised locally at each Tapojärvi unit under the guidance of the production manager.

Tapojärvi Cooper is one of the most awaited events every year. Each year, participants are rewarded with a sports bonus of EUR 100–400 based on the Cooper test fitness level assessment table.

In 2023, the voluntary fitness test was taken by 259 runners. There were 91 new runners, and the average test result was 2,171.41 metres, which is close to the previous year’s average.

EUR 65,400 Sports bonuses paid in 2023

41

Competence development

Personnel competence and development are central factors in the meeting of the company’s objectives. At Tapojärvi, the overall competence level of personnel is good. Nevertheless, strengthening and developing competence is always on the agenda. Compiling induction and training materials for the eLearning platform began during the 2023 financial period. The goal is for the platform to include, in addition to the general induction and safety materials and other shared materials, specific induction materials / a manual for supervisors and managers by the end of 2024. Training needs are mapped by conducting monthly/quarterly interviews at work sites. The employee’s competence and their training need are assessed at the recruitment stage, during induction and occupational guidance at the beginning of employment, and during employment.

Competence and training needs are reviewed, in particular, when the employee’s post or duties change or work methods change. Supervisors are responsible for ensuring our personnel have adequate competence as well as for planning and implementing personnel development processes. Personnel are provided with internal training or directed to participate in courses organised by other parties. The personnel’s development

Our orientation and training processes are standardised and described in writing. Every site has trained workplace instructors who participate in separate training days.

and training needs are also assessed during performance appraisals.

During the financial period, safety training, qualification training, client-organised training and other statutory training courses were organised on a regular basis for employees whose duties / working environment required such training and who had not yet taken the training or whose training had expired. Tapojärvi’s own vocational qualification programme in vehicle services (the repair shop services competence area), which began

in April 2021, ended in May 2023. From that group, a total of ten students graduated in 2023 and one person at the beginning of 2024. As a result of the positive feedback received about the training, a similar programme was also launched in Siilinjärvi, customised to the local operations. A new group also began the studies in the Kemi–Tornio area in the autumn of 2023.

In addition, members of the personnel participated in training supporting professional skills, organised by other parties.

42

REMOTE WORK AND A HYBRID WORK MODEL

Tapojärvi has a positive attitude towards remote work and the flexibility it offers. Applying the hybrid model to work is made possible in duties in which such model is suitable and the employee has signed a written agreement concerning such work with their manager. The hybrid model is adapted on a case-bycase basis, taking into account the requirements of the position in question. The employee does not have a subjective right to work remotely, but whether and what prerequisites exist for remote work are agreed separately in each workplace. When working in the hybrid model, more attention is paid to the employees’ coping at work, since the strain caused by work may increase without the employee noticing it.

The employer is responsible for the employee’s safety in remote work as well. This is why potential harmful impacts of remote work on the health and safety of the employee are monitored regularly and systematically. This includes both physical and psychological occupational safety and work-related stress factors. The employee also bears responsibility for their own well-being, and this responsibility is emphasised in remote work.

The ground rules of hybrid work will be reviewed and aligned with the current need and practices in 2024.

PERSONNEL AND SAFETY: MEASURES IN 2023

• Tapojärvi prioritised workplace safety with the goal of zero accidents and the improvement of the safety culture, including training.

• The company organised training opportunities for its employees and supported their career paths and development of professional skills.

• The recruitment process of clerical employees was supported by deploying the digital and automated Refapp reference checking tool in 2023.

The tool improves the checking of references in alignment with the GDPR requirements.

• Noise and dust measurements were carried out at the Tornio steel mill. The corrective measures were taken immediately.

• The company allocated EUR 125,000 in sponsorship and association support to club activities in the neighbouring municipalities.

• Resident surveys and ongoing dialogue with the community are part of Hannukainen Mining’s commitment to sustainable mining operations. A stakeholder survey targeting the residents of Kolari was carried out in 2023. The survey mapped the attitudes of the local residents towards the planned mining operations.

• The Tapojärven Kiinteistöt housing company was the developer of terraced house flats for Tapojärvi employees in Siilinjärvi. The new flats will increase employee well-being and comfort.

43

TAPOJÄRVI’S MAINTENANCE

MANAGER MARKUS PARTANEN RECEIVED THE ALUMNI OF THE YEAR AWARD.

The Lapland University of Applied Sciences grants the title of the Alumni of the Year to a person who has been specifically active in promoting the UAS or their own sector or in collaborating with the UAS, or received recognition and been tenacious in their own life. The alumni are graduates of Lapland University of Applied Sciences or its predecessors.

44

Customer satisfaction and reliability

A financially sound company meets the stakeholders’ needs, fulfils the social and environmental obligations, and supports non-profit activities in society. Tapojärvi contributes to well-being in all its service sectors.

Tapojärvi’s economic responsibility manifests through new business opportunities and jobs as well as responsible investments in sustainable

development projects.

The company pays the salaries and taxes on time and continuously improves its own result, effectiveness and profitability as well as those of its clients.

TAX FOOTPRINT

Tapojärvi pays, collects, accounts and reports its direct and indirect taxes in the proper amount at the right time and to the right place,

TO BEAR OUR ECONOMIC RESPONSIBILITY, WE MUST ENSURE OUR PROFITABILITY AND COMPETITIVENESS.

OUR profitable and competitive operations enable us to be:

• an important employer

• a reliable partner

• a good corporate citizen

• a profitable investment

in other words where the economic activity, value added and work generating income actually take place.

Tapojärvi’s operations are guided by economic principles and grounds independent of taxation.

Tapojärvi is a proud taxpayer. We pay our taxes in the proper amount in the country of operation in question.

GROUP’S TAX FOOTPRINT

45

MEUR 39.2

How we create added value

TECHNOLOGY COMPETENCE

New solutions for a sustainable life

CLIENTS

- We provide responsible services

- We solve problems together

- We also support the client’s responsibility

PERSONNEL

- We offer meaningful work

- We take care of our personnel

- We create development opportunities

OWNERS

- We grow rapidly through continuously developing business operations

- We invest in the markets of the future

SOCIETY

- We create new solutions for the circular economy

- We promote economic growth and increase jobs

- We reduce operational risks when our dependence on limited natural resources and fluctuations in the raw material markets decreases.

- We promote the preservation of biodiversity

46

PARTNER NETWORK

LOCAL

MOST VALUABLE ASSETS:

capital

competence

GLOBALLY

OUR

Financial

People and

Natural resources

Supply chains and services

Stakeholder engagement

Tapojärvi’s key stakeholders are personnel, clients, owners, the authorities, as well as suppliers of equipment, machine and material, financiers, development partners, and audit firms.

The focus areas of Tapojärvi’s sustainability work are realised through the main impacts of the company’s services and stakeholder expectations.

We actively collect feedback from our clients concerning projects, products, services and operations, and adjust our operations based on the feedback. Tapojärvi’s operations have significant impacts, especially on its employees, the growth and development of its clients, and the environment.

The company pursues an open and transparent dialogue in order to understand and address the concerns and expectations of different stakeholders. We have developed feedback systems to be used by our stakeholders.

We encourage our employees to report their concerns. Employee satisfaction is measured on a regular basis.

We partner with educational institutions and educational sectors that are directly or indirectly related to our industry.

For Tapojärvi, it is important to contribute to the well-being of its

locations and neighbouring municipalities.

Local growth is supported by concentrating service and material purchases to local businesses. In addition, Tapojärvi invests in the areas surrounding its industrial areas.

In 2023, Tapojärven Kiinteistöt completed a terraced house in

Siilinjärvi, near the Yara Siilinjärvi mine. Our employees can use the new flats when travelling for work.

Tapojärvi participates in several working groups and networks. Tapojärvi contributes to its networks free of charge.

MEMBERSHIPS

Tapojärvi participates in the activities of the Kemi Circular Economy Centre and uses its expertise and services to boost the industrial circular economy cluster in Lapland.

Tapojärvi also networks with organisations in the extractive industry. For example, CEO Mari Pilventö is a member of the Board of the Finnish Mining Association.

Tuomas Tapojärvi, the Business Controller of the Tapojärvi companies, is a member of Elo Mutual Pension Insurance Company’s Employers Advisory Board. The Employers Advisory Board promotes cooperation between

CLIENTS Authorities Suppliers Competitors Society Financiers Personnel Owners 47

Elo’s policyholders, provides Elo with information about business operations insofar as the information has general impact on tending to insurance matters, and gives recommendations on and takes initiatives in matters concerning policyholders’ pension insurance.

The Ministry of Economic Affairs and Employment set up a coordination group for circular economy in the extractive industry for the period of 15 May 2022–31 December 2023. The

group consisted of representatives from companies, research institutions, organisations, financiers and ministries.

Tapojärvi’s Development Manager Juha Koskinen was a member of the coordination group. Hannukainen Mining Oy is a member of the Kaivosteollisuus ry mining industry association and participates in the activities of the association’s working groups. Hannukainen Mining is also a member of the Network for Sustainable Mining in Finland.

An EU Horizon DigIT project meeting.

48

The Pesti Career Day at the University of Oulu.

The Skyltsöndag event in Pajala.

MANAGEMENT SYSTEM

Tapojärvi Oy’s quality management system complies with the quality management requirements of the ISO 9001:2015 standard.

In the 2023 audit, the Siilinjärvi location and its operations were assessed for the first time and were included in the scope of the certificate. In June 2023, Tapojärvi Italia S.r.l received the ISO 9001:2015 quality certificate for steel mill slag treatment, recycled steel cutting and metals recovery.

All Tapojärvi Oy locations will undergo a re-audit during 2024.

PROCEDURE FOR REPORTING MISCONDUCT

Every Tapojärvi employee is expected to report, without delay, any violations of law or commitments included in Tapojärvi’s Code of Conduct.

Usually these notifications are submitted to one’s manager. The notifications can also be sent anonymously through Tapojärvi’s whistleblowing channel to detect any misconduct.

The whistleblowing channel has been opened on Tapojärvi’s website where it is accessible to all stakeholders. The channel can be used to report all

detected violations of laws, practices or human rights.

All cases reported via the whistleblowing channel will be investigated and, when necessary, processed and solved in accordance with the agreed procedures.

In 2023, there were no misconduct notifications reported via the channel.

COMMITMENTS:

• In its mining services provision and the Kolari mining project, Tapojärvi is committed to complying with sustainability principles concerning nature, people and the economy, in accordance with the sustainability standard for mining.

• Hannukainen Mining Oy participates in the Making Finland a leader in the sustainable extractive industry programme.

• The Tapojärvi companies are committed to complying with the UN Declaration of Human Rights and the UN Guiding Principles on Business and Human Rights.

• The company complies with ILO Declaration on Fundamental Principles and Rights at Work.

• We are committed to the UN’s Sustainable Development Goals.

CUSTOMER SATISFACTION AND RELIABILITY: MEASURES IN 2023

• During 2023, Tapojärvi prepared the Code of Conduct promoting responsibility.

• In the 2023 audit, the Siilinjärvi location and its operations were assessed for the first time and were included in the scope of the certificate.

• In June 2023, Tapojärvi Italia S.r.l received the ISO 9001:2015 quality certificate for steel mill slag treatment, recycled steel cutting and metals recovery.

• Ongoing internal quality inspection

• Internal and external audits

50

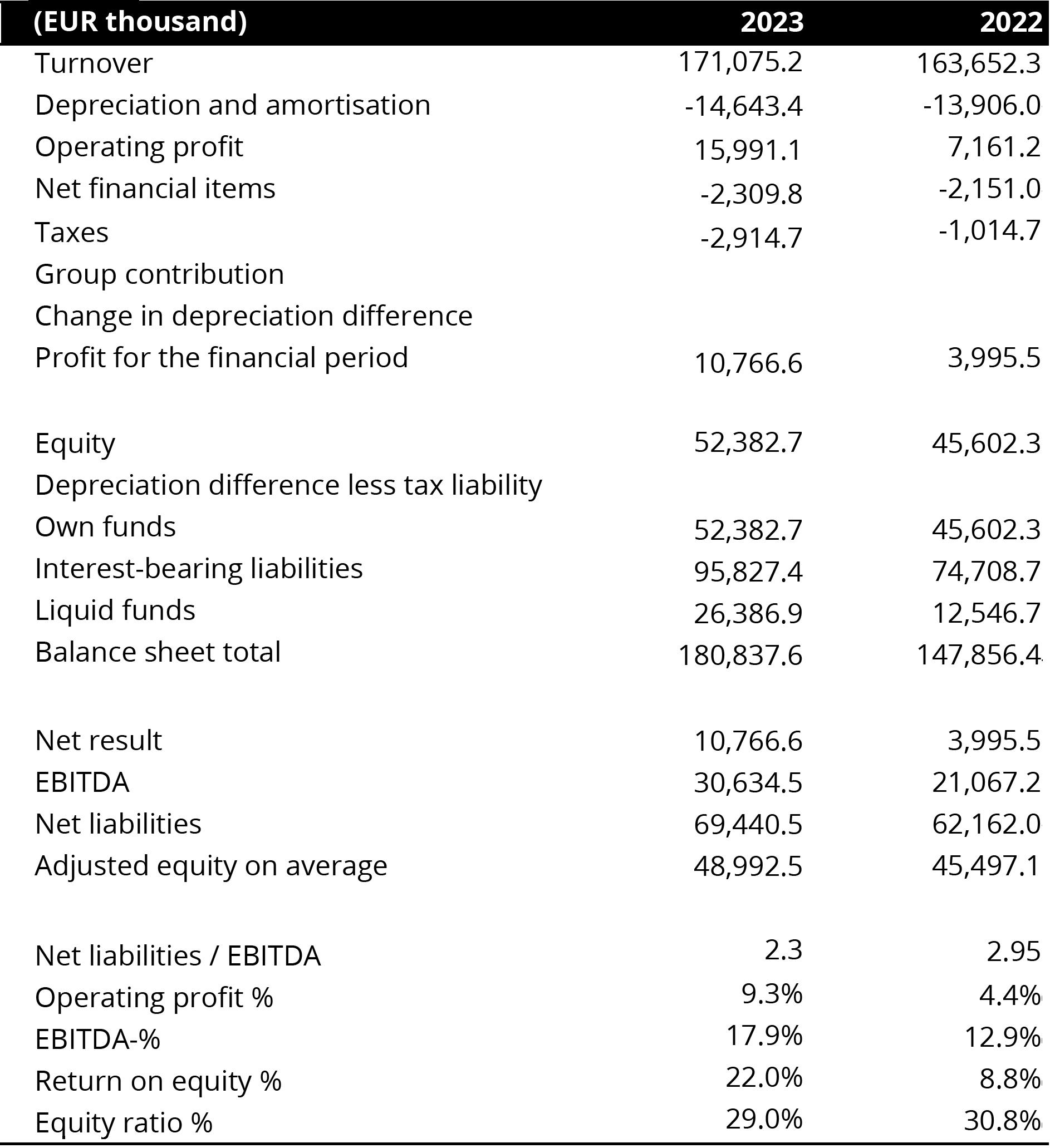

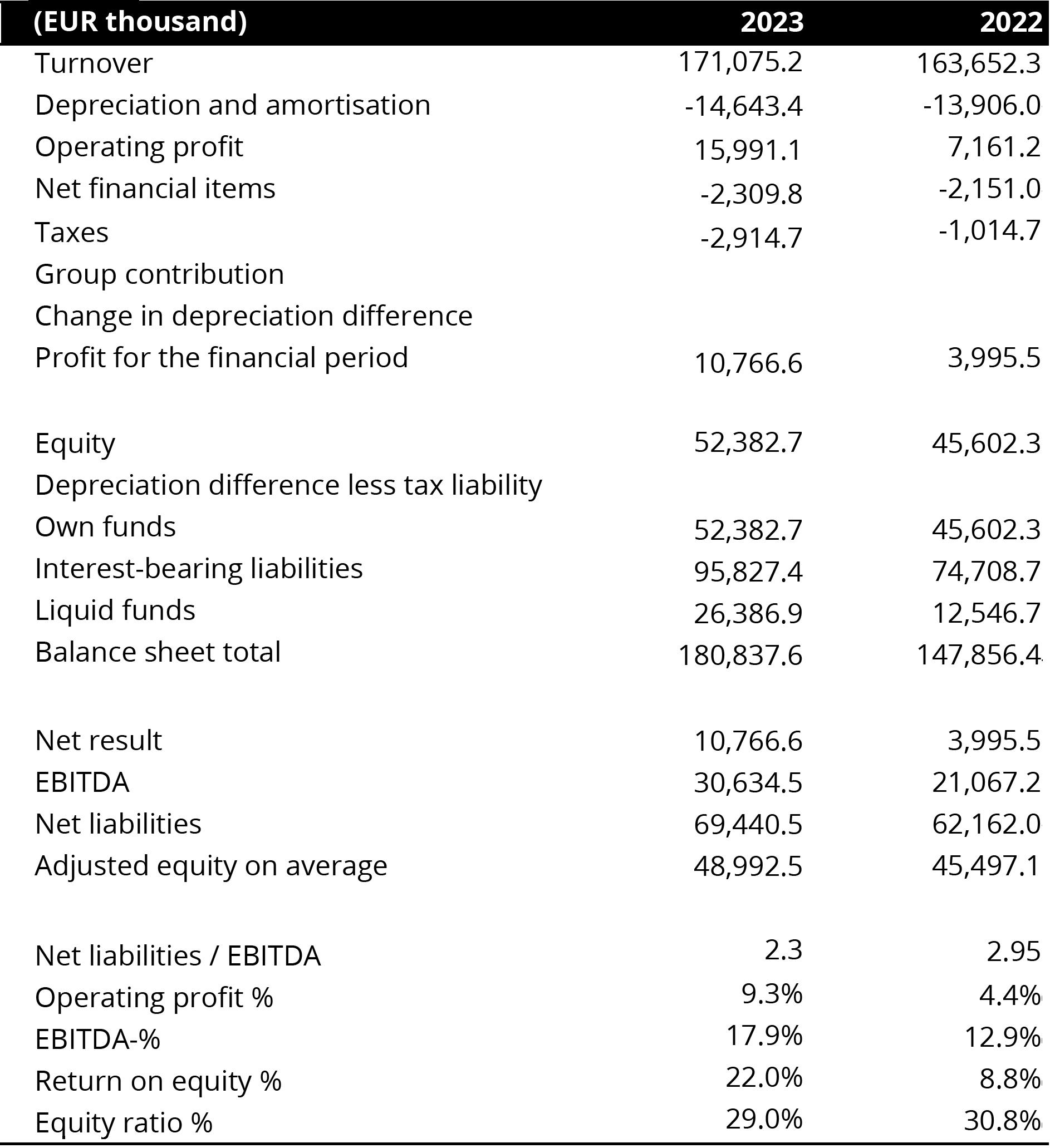

Financial review

Our production continued to face challenges, such as increased costs, delayed deliveries and unpredictable fluctuations in production, resulting from the global political situation.

During 2023, we signed new agreements, but in the last quarter of the year, we had to launch co-determination negotiations targeting employees of underground mines and the ferrochrome concentrator plant and machinery work in Tornio.

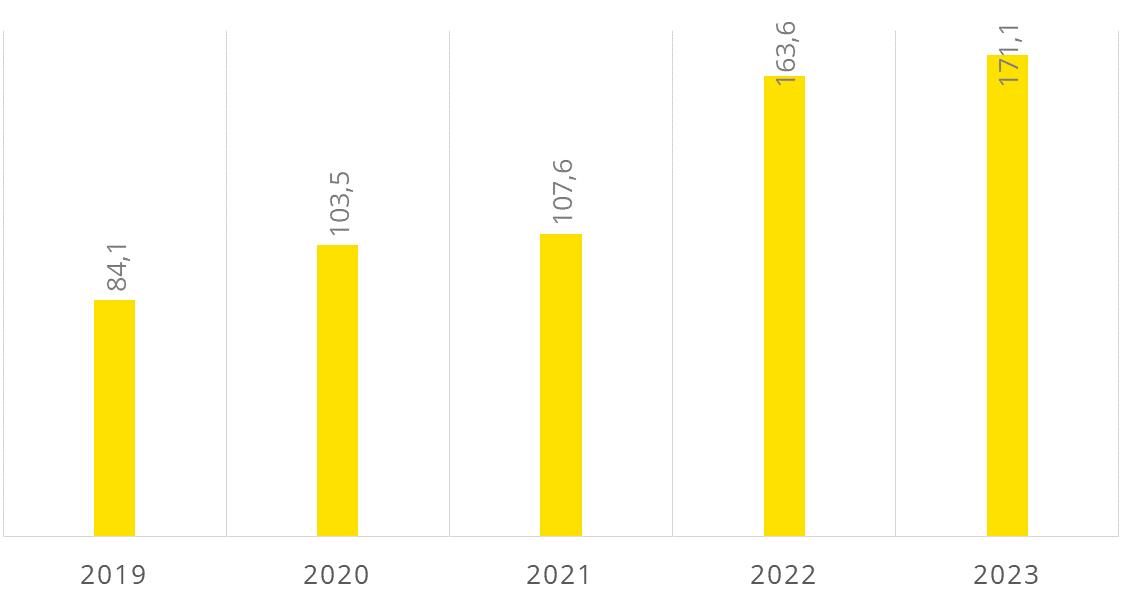

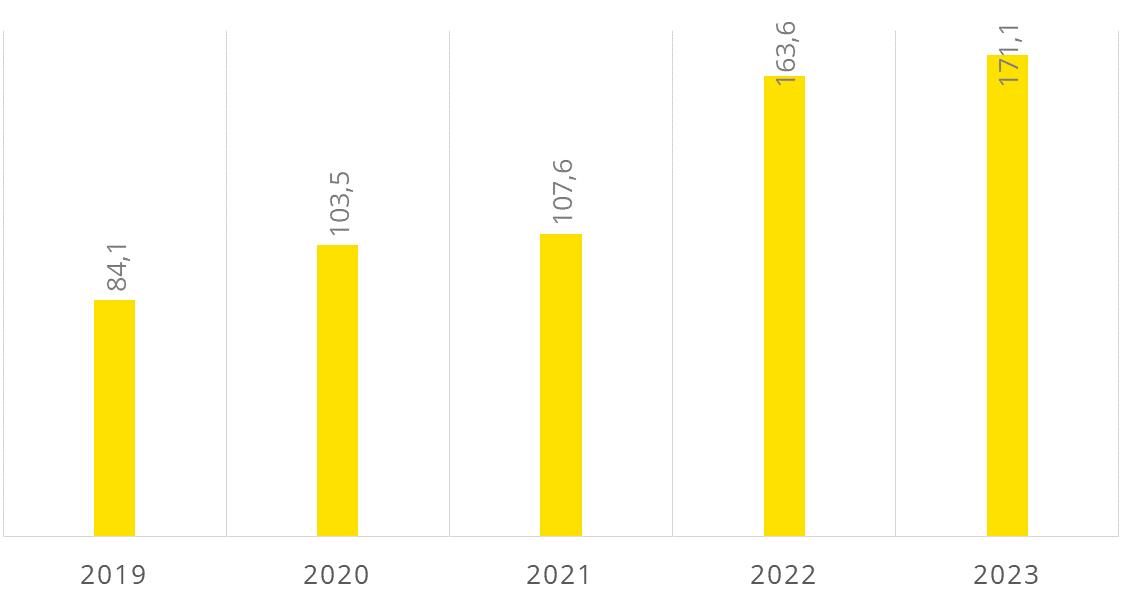

The Group’s turnover was EUR 171.1 million, operating profit EUR 16.0 million and equity ratio 29%.

The Group’s overall investments in the financial period amounted to EUR 25 million. The majority of this amount was invested in mining equipment. Equipment is a central part of Tapojärvi’s reliable and efficient operations, and the performance of the equipment is ensured by the company’s own maintenance organisation.

During the financial period, EUR 4.1 million (2.4% of the Group’s turnover) was invested in research, development and innovation activities. RDI activities received public financial

support in the form of a grant (EUR 0.6 million) and loans (EUR 0.4 million).

In Terni, we are lagging behind in terms of our economic goals due to the prolonged construction and commissioning stage and unfinished matters relating to the production process.

Outokumpu’s production restrictions concerning the Kemi mine and the Tornio steel mill will have a reducing impact on business volumes in the first half of 2024.

The LKAB Malmberget mine contract expired on 31 March 2024, ending work in Gällivare. The termination of contracts and the start of new contracts are part of the day-today routine of mining contracts.

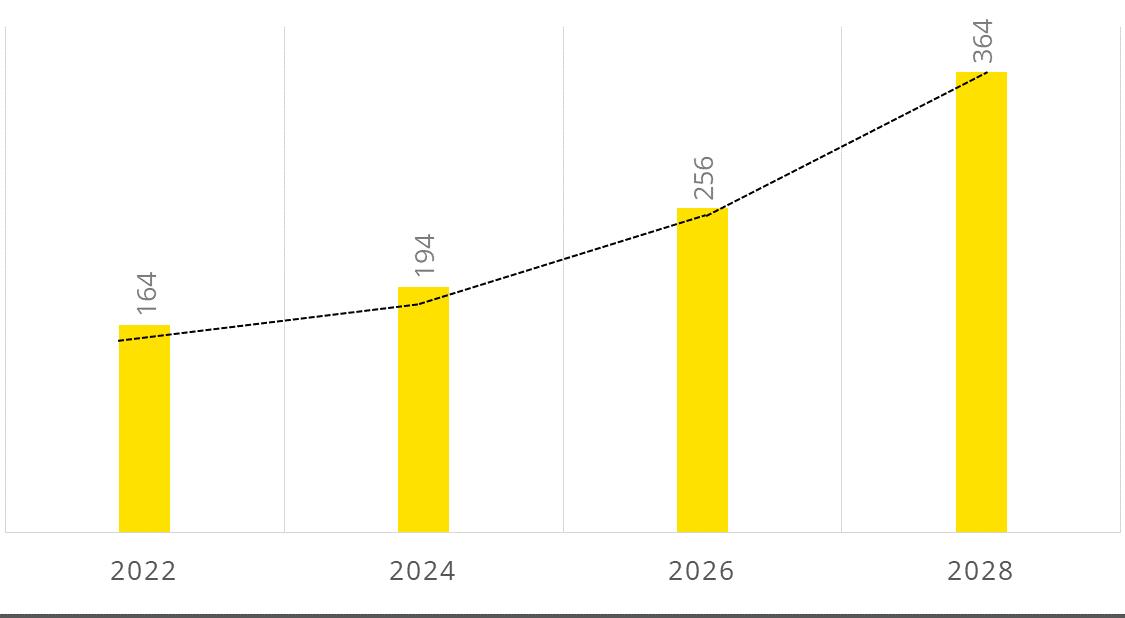

The company’s business outlook is stable. The market in our areas of business is positive, and thus we see potential for our company to grow.

The work is based on agreements, and our agreement base is solid and long-term. As a company, we must take care of our competitiveness and agility and be able to offer cost-effective quality work to our clients.

2023 in brief:

Turnover showed an increase of 4.4% and was EUR 171.1 million (2022: 163.7).

Operating profit was EUR 16 million, which was 9.3% of the Group’s turnover (2022: 4.4%).

The return on equity showed an increase of 22% (2022: 8.8%).

The company’s equity ratio declined by 29% (2022: 30.8%).

Tapojärvi paid salaries and bonuses in the amount of EUR 39.4 million (2022: 40.8).

The Group’s income adjusted with non-recurring items grew to EUR 9.4 million (2022: 2.3).

51

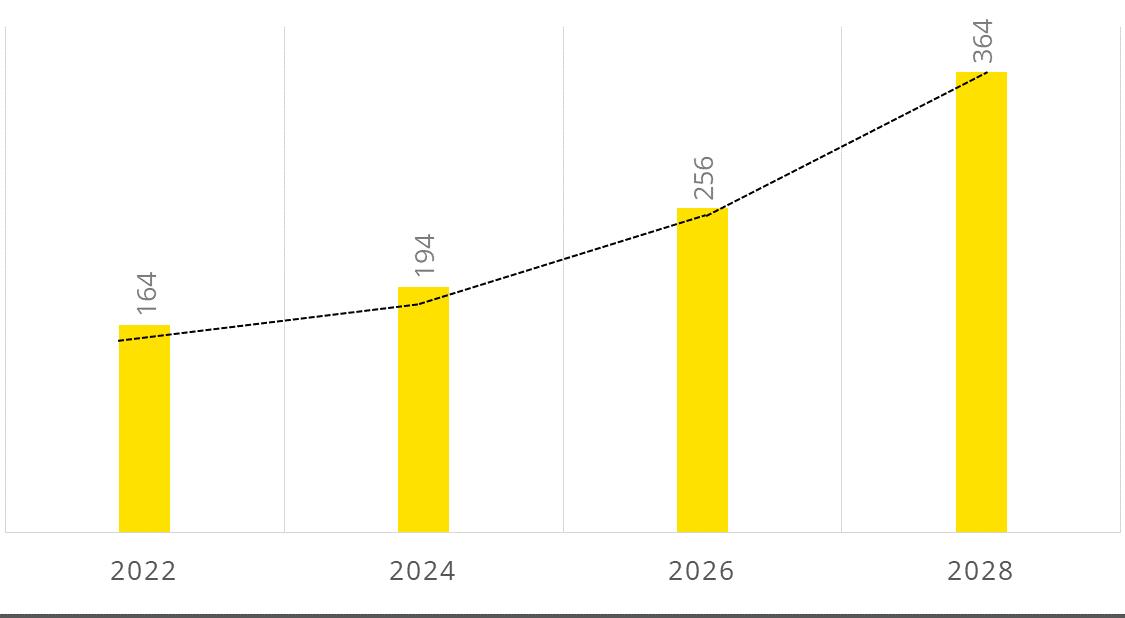

TURNOVER

FORECAST

52

Equity ratio 30.8% 29% Operating profit Taxes paid, MEUR Investments 6 Personnel expenses, MEUR Group’s income adjusted with non-recurring items MEUR 25 EQUIPMENT MEUR 4.9 RDI: 4.4% 9.3% 3.0 11.7 FINLAND OTHER COUNTRIES 51.5 49.3

9.4

2022

2.3

2023

53

CORPORATE GOVERNANCE STATEMENT

Tapojärvi’s financial reports, including the consolidated financial statements, are prepared in compliance with the International Financial Reporting Standards (IFRS) adopted by the EU and the related reporting interpretations (IFRIC), as well as the regulations issued by the Finnish Financial Supervisory Authority.

The following acts and the Group’s internal rules and procedures have been taken into consideration in the preparation of the financial statements:

A B

Limited Liability Companies Act

Accounting Act