From 2001 to 2008, approximately 0.6 million tonnes (Mt) of tailings were subaqueously (underwater) deposited into the Tom MacKay Storage Facility (TMSF or “the Facility”) from the previous Eskay Creek mine.

The TMSF has safely managed tailings for more than 20 years underwater (sub-aqueous) as is being proposed for the Eskay Creek Revitalization Project.

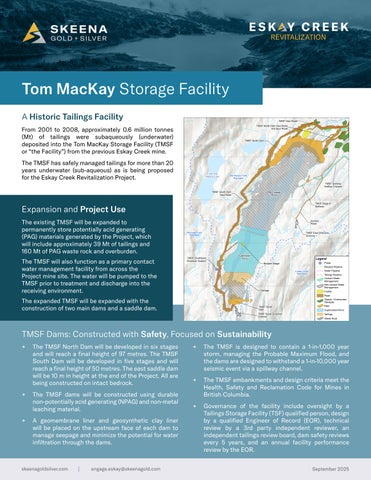

The existing TMSF will be expanded to permanently store potentially acid generating (PAG) materials generated by the Project, which will include approximately 39 Mt of tailings and 160 Mt of PAG waste rock and overburden.

The TMSF will also function as a primary contact water management facility from across the Project mine site. The water will be pumped to the TMSF prior to treatment and discharge into the receiving environment.

The expanded TMSF will be expanded with the construction of two main dams and a saddle dam.

+ The TMSF North Dam will be developed in six stages and will reach a final height of 97 metres. The TMSF South Dam will be developed in five stages and will reach a final height of 50 metres. The east saddle dam will be 10 m in height at the end of the Project. All are being constructed on intact bedrock.

+ The TMSF dams will be constructed using durable non-potentially acid generating (NPAG) and non-metal leaching material.

+ A geomembrane liner and geosynthetic clay liner will be placed on the upstream face of each dam to manage seepage and minimize the potential for water infiltration through the dams.

+ The TMSF is designed to contain a 1-in-1,000 year storm, managing the Probable Maximum Flood, and the dams are designed to withstand a 1-in-10,000 year seismic event via a spillway channel.

+ The TMSF embankments and design criteria meet the Health, Safety and Reclamation Code for Mines in British Columbia.

+ Governance of the facility include oversight by a Tailings Storage Facility (TSF) qualified person, design by a qualified Engineer of Record (EOR), technical review by a 3rd party independent reviewer, an independent tailings review board, dam safety reviews every 5 years, and an annual facility performance review by the EOR.

+ Water will be reclaimed from the TMSF supernatant pond and recycled for use as mill process water or treated in the Mine Water Treatment Plant.

+ Water management structures will divert non-contact water away from the TMSF catchment to reduce the volume of water reporting to the TMSF and help keep clean water clean.

+ Seepage control will be achieved by the use of liner systems within the TMSF dams, embankment underdrain and associated seepage collection sumps, and select use of spot or slush grouting during foundation preparation.

+ TMSF will be used to moderate contact water flows from other areas on site (Mine Rock Storage Area, Open Pits) etc. to facilitate a more consistent Mine Water Treatment Plant discharge rate.

Skeena’s priorities for TMSF at closure include safety for the entirety of facility existence, alignment with Tahltan Sustainability Requirements and long term monitoring and compliance with Tahltan Central Government guidance.

+ Monitoring locations are strategically selected to allow for early detection with the help of monitoring wells, surface seepage monitoring and surface water quality monitoring.

+ Response plans will be triggered if conditions deviate from the established normal operating conditions.

+ The TMSF at closure will have a minimum of 1 metre water cover over the tailings and Potentially Acid Generating (PAG) wasterock to maintain them underwater (i.e., in a subaqueous condition).

+ A non-potentially acid generating (NPAG) cover system will be constructed on the PAG waste rock within 200 metres of each dam.

+ Roads, ponds and channels not required for long-term monitoring and site management will be reclaimed at closure.

+ Closure monitoring activities including instrumentation and water quality / quantity monitoring.