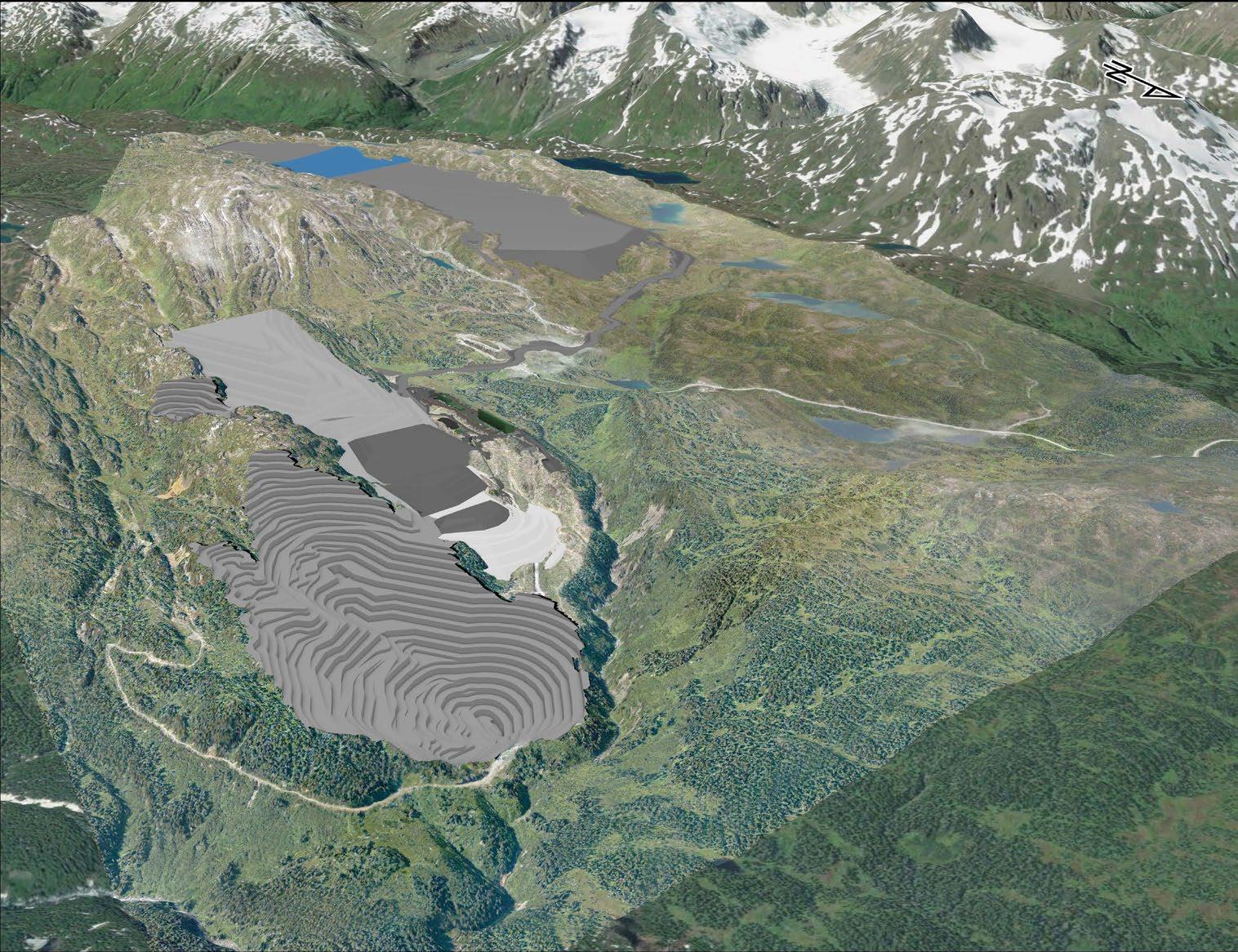

The Eskay Creek Revitalization Project (the Project) is located within the Regional District of Kitimat-Stikine in the Golden Triangle region of northwestern British Columbia, 83 kilometres northwest of Stewart, and within Tahltan Territory1

Concentrate produced by the Project will be hauled along a southern portion of Highway 37 toward Meziadin Junction then westward along Highway 37A to Stewart. This transportation route passes through the Nass Area and Nass Wildlife Areas as per the Nisga’a Final Agreement, Gitanyow Nation Territory, and lands used by Métis Nation British Columbia (MNBC). During peak years of Operations, it is expected that ten concentrate shipments will be made to Stewart daily.

New key mine infrastructure built to support the Project include:

+ Two open pits (the North Pit and South Pit)

+ Ore processing and management facilities, including the Process Plant and ore stockpiles

+ Expansion of the existing Tom MacKay Storage Facility to store tailings and potentially acid generating (PAG) waste rock under water

+ Mine Rock Storage Area to store nonpotentially acid generating (NPAG) waste rock

+ Mine Water Treatment Plant to treat contact water

1 For the purposes of this document, “territory” is defined as the established or asserted traditional territories of Indigenous Nations, except in relation to the Nisga’a Nation, which refers to Nisga’a Lands, the Nass Area, and the Nass Wildlife Area as per the Nisga’a Final Agreement.

The Project would target development of the Eskay Creek deposit, which is a high-grade, precious metals-rich epithermal volcanogenic massive sulphide (VMS) deposit.

The selected method for ore processing is flotation, which separates and concentrates ore by altering their surfaces to either repel or attract water.

Unlike heap leaching, Eskay Creek’s ore processing method does not require the use of cyanide.

The ore processing method at the site would include the construction, installation, and operation of the least amount of processing infrastructure; the smallest overall size and footprint of the Process Plant; and the lowest capital and operating costs.

20-Jun-2024

ESK-24ERM-013:1

Eskay Creek’s proposed open pits will be mined from the surface down by conventional drill, blast, load, haul, and dump methods, using a mobile mining fleet of excavators, hydraulic shovels, bulldozers, and haul trucks. PAG material will be stored under water to prevent acid rock drainage.

Compared to the open-pit method, an underground mining method at Eskay Creek would be very high-cost and require very high gold grade to be economic. It is important to note that the highest-grade material has been mined out historically.

Scoping-level work indicates the open-pit reserves of 4.6 million gold equivalent ounces would be more than double that of an underground scenario.

Scoping-level engineering economic analysis indicates project value for the open-pit scenario is 3x that of an underground case, maximizing economic benefits such as employment opportunities, taxes, and added value to local communities.

With an open pit design, the Project life is forecasted at 18 years, with 13 years of operations. Operations for an underground case would be limited to 5-7 years.