Billerica – Parker Elementary

Philbrook, Sydney

CONM 4200-01

3/27/25

#1.

1. JHA

a. Policy

I. Sydney Design & Build LLC is committed to maintaining the best standards for safety on all job sites. The job hazard analysis (JHA) Policy makes sure that potential workplace hazards are identified and assessed before work begins for each project. Analyzing job activities and tasks ensures that controls are put in place to protect the health and safety of workers. The controls considered and put in place include elimination, substitution, engineering, administrative, and personal protective equipment (PPE) to reduce hazards. Each task is reviewed for risks that could happen, and which safety measures are appropriate to prevent such accidents and injuries. The Superintendent, Logan Levesque, the Project Manager, and the safety manager collaboratively conduct the JHA alongside the site workers who will be performing the tasks.

b. JHA Forms

Tasks:

Site Preparation

Setting Forms

Sydney Design & Build LLC

Job Hazard Analysis (JHA) Form Foundation and Slab Pouring

Hazards:

• Uneven ground causes trips and falls

• Exposure to dust, debris, or sharp objects

• Equipment hazards, including cave-ins and trench collapses, struck-by incidents, equipment tipover incidents, and more.

• Injuries to the hand from hammering and cutting materials

• Straining of the back from lifting

Controls:

Elimination: Clear site of debris and unnecessary obstacles before work begins

Eng. Control: Proper grading and compacting of soil to create a stable work surface

Admin. Control: Clear walkways and areas around the equipment

PPE: Gloves, safety boots, and eye protection for personal safety

Eng. Control: Bracing formwork to prevent collapses

Admin. Control: Train employees on how to properly lift heavy materials

Placing Reinforcement

Mixing and Transporting Concrete

• Cuts and punctures from rebar ends

• Back strain from lifting and hunching of back from tying rebar

• Slips and trips due to lose materials

• Exposure of concrete dust causing respiratory issues

• Burns from wet cement

• Heavy lifting injuries

• Traffic hazards from trucks

PPE: Gloves and eye protection

Eng. Control: Rebar caps to cover rebar ends. Also prevents punctures

Admin. Control: Work areas kept tidy and organized. Enforce better housekeeping

PPE: Cut-resistant gloves and steeltoed boots

Elimination: Premixed concrete to reduce exposure to dry cement dust

Eng. Control: Chutes or pumps to minimize manual lifting

Admin. Control: Maintain traffic controls for concrete trucks

PPE: Dust mask, safety goggles, and gloves

Pouring Concrete

Spreading

• Burns or skin irritation from cement exposure

• Getting caught in chute or pump system

• Muscle strain from pushing and pulling tools

• Trips and falls over form edges

• Eye injuries from concrete splashing

Admin. Control: Establish clear zones and restrict access during pouring

PPE: Wear rubber gloves

Eng. Control: Use long-handled tools to reduce bending and overreaching

Admin. Control: Keep tools and materials organized away from walkways

PPE: Wear safety glasses and long sleeves

Finishing the Surface

• Slips and falls on wet concrete

• Vibration-related injuries from power tools

Eng. Control: Use powered trowels with anti-vibration handles

PPE: Use slip-resistant footwear and vibration-reducing gloves

Curing the Concrete

Site Cleanup and Inspection

• Exposure to curing compounds (chemicals)

• Exposure to dust

• Tripping over debris or leftover material

Substitution: Low-VOC or environmentally friendly compounds

Elimination: Removal of unnecessary materials and debris

Eng. Control: Proper disposal

Admin. Control: Final walkthrough to remove hazards

PPE: Gloves and steel-toed boots

#2.

Tasks:

Rigging and hoisting steel components

Sydney Design & Build LLC

Job Hazard Analysis (JHA) Form Steel Erection

Hazards:

• Failure of rigging or lifting equipment

• Struck-by hazards from falling steel beams

• Caught-in hazards when guiding steel into place

Controls:

Elimination: Inspect rigging equipment before each lift. Remove defective gear

Eng. Control: Use properly rated cranes, slings, and hooks

Admin. Controls: Train workers on safe rigging and establish exclusion zones

PPE: Gloves, hard hats, and safety glasses

Setting steel columns and beams

• Falls from height while securing beams

• Structural instability before full connection

• Caught-between hazards when aligning steel components

Elimination: Preassemble components at ground level when possible

Eng. Control: Use temporary bracing for stability

Admin. Control: Implement fall protection training and proper beam-setting

PPE: Fall protection such as harness, lanyard, and anchor points

Bolting and connecting steel members

• Falls from unsecured work platforms

• Dropped objects striking workers below

Welding and cutting steel components

• Burns and eye damage from welding exposure

• Fire hazards from sparks

• Inhalation of toxic fumes

Admin. Control: Exclusion zones below elevated work

PPE: Secure tools while working above using tether tools to prevent dropping

Substitution: Fume extractors

Eng. Control: Provide the best ventilation methods

Admin. Control: Implement hot work permits and fire watch procedures

PPE: Welding helmets, flameresistant clothing, and respirators

Working at heights (Scaffolding and ladders)

• Falling from height due to improper use of equipment

• Structure failure of scaffolding

Elimination: Ground-based assembly whenever possible

Eng. Control: Ensure ladders, scaffolds, and lifts are properly rated

Admin. Control: Enforce the wearing of fall protection and daily inspections

PPE: Full-body harness and tie-offs at designated anchor points

#3.

Tasks:

Handling and transportation of glass

Sydney Design & Build LLC

Job Hazard Analysis (JHA) Form

Class curtain wall and window installation

Hazards:

• Cuts from broken or sharp glass edges

• Injuries from lifting heavy panels

• Struck-by hazards if panels fall or shift

Controls:

Elimination: Mechanical lifts or suction cups rather than manual lifting

Eng. Control: Store glass panels in secure racks

Hoisting and positioning glass

Installation of curtain wall frames and anchors

• Rigging failure leading to dropped glass panels

• Struck-by hazards from swinging panels

• Wind-related instability from height

• Falls from heights

• Hand and arm injuries from dripping and fastening

• Dropped tools on workers below

Admin. Control: Train workers in proper lifting techniques and handling procedures

PPE: Cut-resistant gloves, safety glasses, and steel-toes boots

Elimination: Remove damaged gear

Eng. Control: Use vacuum lifters

Admin. Control: Establish exclusion zones beneath lifting areas

PPE: Wear hard hats, high-visibility vests, and gloves

Eng. Control: Ese properly rated scaffolding or guardrails

Admin. Control: Require fall protection training and tether tools when at heights

PPE: Wear fall protection harnesses, hard hats, and safety glasses

Sealing and weatherproofing

• Exposure to hazardous sealants, adhesives, or fumes

• Skin or eye irritation from chemicals

Substitution: Low-VOC or nontoxic sealants

Eng. Control: Provide ventilation

PPE: Chemical-resistant gloves, safety glasses, and long-sleeved clothing

Final inspection and cleaning

• Falls from ladders or lifts

• Cuts from glass edges or sharp tools

• Exposure to cleaning chemicals

Eng. Control: Extendable equipment or tools to reduce ladder use

Admin. Control: Ladder safety protocols and inspection of equipment before use

PPE: Gloves, safety glasses, and slip-resistant footwear

2. FirePreventionandProtection

a. Site Specific Hazards

I. The following combustible materials will be present on site. They will require strict safety measures.

• Wood, paper, insulation, carpet, scrap, and debris

• Plastics and roofing materials

• Flammable liquids such as paints and adhesives

• Electrical equipment, switches, and panels

II. Storage and handling: Due to Flammable liquids being present on site, they will be stored in NFPA- approved fire-rated cabinets. They will be clearly labeled “Flammable-keep fire away”. The combustible waste on site will be collected and removed at the end of each workday. Propane tanks and other flammable gases will be sure to be stored at least 10 feet away from the building, ensuring fire prevention.

b. Fire Protection Equipment

I. Fire extinguishers will be in specific locations so the employees on the job site do not need to travel more than 100 feet to access type A fire extinguishers, and 50 feet to access type B. There will be 37 total fire extinguishers in the building (figure 1). The following table shows the fire extinguisher types that will be onsite, what they will be used for as well and where they will be placed on the site:

FireExtinguisherType

TypeABC (Multi-purpose dry chemical) 2A:10BC

TypeB (CO2/dry chemical) 10B or 20B

UsedFor Locations

Ordinary combustibles, flammable liquids and gases, and electrical fires

Flammable liquids/gases (Paint, liquids, and gases)

General work areas inside the building as well as at the job site trailer

Near paint and fuel Storage

areas located between the job site trailer and storage

II. Fire extinguisher inspection will be conducted monthly by designated Safety Manager, Gabby Martin. All workers will be trained in proper fire extinguisher use which includes the PASS method (Pull, Aim, Squeeze, and Sweep).

c. Fire Extinguisher Plan

I. Placement of fire extinguishers: there will be a 2A:10BC extinguisher per 3000 ft.², next to each staircase, at every exit, and within 50 feet of fuel storage. With all of these placements there should be an extinguisher strategically places on every floor to ensure workers' accessibility.

II. Below is a floor plan with marked spots where the ABC fire extinguishers will be placed on each floor:

d. Fire Prevention Training

I. All workers will receive fire safety training, which will cover fire preventions, best practices, the proper use of fire extinguishers, emergency, fire response procedures, and housekeeping requirements. The training will occur during the site safety orientation for new employees and at least once per project

Figure 1- Fire Extinguisher placement on each floor

phase for all workers. Whenever there are significant updates to the fire prevention plan all workers will also be refreshed on fire safety.

e. Fire Watch and Hot Work Permits

I. Any and all hot work such as welding, soldering, and cutting will require a hot work permit issued by the Superintendent, Logan Levesque. A fire watch will be assigned during and after 30 minutes of any hot work to ensure no fires arise during or after the task is done. Fire blankets and extinguishers must also be readily available near all hot work areas on the job site.

f. Hot work Permit:

Hot work Permit

Sydney Design & Build LLC

Project Name: ________________

Job Location: ________________

Date of Work: ________________

Permit Expiration Time: ________________

Type of Hot Work (Check One):

Hot Work Operator: ________________

Superintendent ’s Name: ________________

Fire Watch Personnel: ________________

Pre-Work Safety Inspection (Check Yes or No)

Safety Requirement Yes No

Work area inspected for combustibles within 35 feet?

Flammable materials removed?

Fire extinguisher, ABC type, available within 25 feet?

Proper ventilation in place?

Hot work equipment inspected and in good condition?

PPE (fire-resistant clothing, gloves, eye protection) used?

Atmospheric monitoring?

Fire Watch assigned-30 minutes?

Emergency procedures reviewed?

Fire Watch and Final Inspection

Fire Watch Start Time: ________________

Fire Watch End Time (30 min after work): ________________

Final Work Area Check Completed By: _______________

Permit Approval

☐ Approved – Work may begin

☐ NOTAPPROVED

Superintendent’s Signature: ______________ Date:

Safety Manager’s Signature: ________________ Date: _______________

Emergency Contact Information

Emergency Services (Fire, EMS, Police) 911

Superintendent - Logan Levesque (617) 913-1596

Fire Watch Personnel- Carlos Botelho (617) 551-1287

Safety Manager- Gabby Martin (617) 231-4114

g. Emergency Response Plan for Fires

I. If the fire is out of control, workers must evacuate the area immediately if fire alarms or use of air horns are sounded, call 911 and notify the Superintendent, and proceed to the designated assembly area. If the fire is small, workers should attempt to extinguish it using the proper fire extinguisher on site.

II. Evacuation and assembly: Workers must follow the posted evacuation routes. These can be found and located at the site, entry points, and main construction office. The primary assembly area is located between the restrooms and first aid station/main field office which is adjacent to the front entrance of the school building. The secondary assembly area is located outside of the

gymnasium near the main Exit. The Superintendent, Logan Levesque, will conduct a role call to ensure everyone is accounted for.

h. Evaluation and updates

I. Fire drills will be conducted twice per year as needed, the fire prevention plan will be reviewed quarterly, and any updates to fire safety measures will be communicated during site meetings.

3. EmergencyActionPlan(EAP)

a. Reporting Emergencies, Injuries, and Fires

I. Means of reporting: all emergencies (fires, gas leaks, chemical spills, active shooter, structural instability, or severe weather) must be reported to the Safety Manager, Gabby Martin. For life-threatening emergencies, call 911 immediately and then proceed to inform the Manager.

II. Documentation: Any and all incidents must be logged into the incident report log by the Safety Manager. No matter how severe the injury is, it must be documented. If a worker has an illness such as the flu or Covid-19 it will also need to be documented.

b. Alarm Systems and Emergency Notifications

I. Alarm Systems:

• Air horns and sirens: for fires

• Radios and mobile alerts: for severe weather or security threats

• Public Announcement (PA) system: for general communication

• The Superintendent and Safety Manager may sound alarms.

• Alarm signals include three short blasts for evacuation, and a continuous sound for severe emergencies.

c. Emergency Plan

I. Evacuation routes: The following information as well as a site map will be clearly posted on each floor of the building, at the main construction office, first aid station, and on the backs of doors in the outhouse restrooms.

• Primary routes include the main entrance on River Street, and the main exit on Pages Court.

• The secondary route for both entrance and exit are located on Parker Street.

II. Assembly area: the designated assembly area is located between the restrooms and first aid station/main field office. The alternate assembly point is outside the gymnasium.

III. Evacuation: In emergencies requiring immediate evacuation, workers should prioritize their personal safety and well-being over equipment. The Superintendent is responsible for identifying workers who may need assistance in an evacuation. “Buddies” will be assigned to assist such individuals during an evacuation.

d. Accounting for Employees

I. Roll Call: Logan Levesque, the Superintendent will roll call at the determined assembly area. The employees must check in with their supervisor directly. Employees that are missing after roll call will be reported to emergency responders. Workers should never enter an evacuated site unless cleared by emergency personnel.

e. Hazardous Operations during Evacuation

I. Hazardous Operations: If time allows and it is safe to do so, designated workers will:

• Secure hazardous operations before evacuating

• Secure flammable and hazardous materials

• Turn off electrical systems and gas lines

f. Medical

I. Trained personnel: first aid coordinator, Sam Albert and other trained first aid workers such as Ben Marioenzi and Jazlyn Perkins on site will provide initial medical assistance

• AEDs (automated external defibrillators) and first aid kits are in the site office, common areas, and near high-risk zones

• For severe injuries, emergency medical services (EMS) will be contacted immediately.

g. Safety Training

I. Training: Employees will receive EAP training during their first site orientation. Drills will also be done at least twice each year or job. Updates to the EAP will be conducted and communicated during safety meetings.

h. Emergency Contact Information

Contact

Phone Number

EmergencyServices 911

LocalHospital/MedicalCenter 1(987)851-7321(TewksburyHospital)

NationalOSHAEmergency 1-800-321-6742

LocalOSHAOffice (978)837-4460

PoisonControlCenter 1-800-222-1222

Superintendent(LoganLevesque)

1(617)913-1596

SafetyManager(GabbyMartin) 1(617)231-4114

FirstAidCoordinator(SamAlbert) 1(617)217-7465

Owner(DylanHebert) 1(617)231-1335

FireWatch(CarlosBotelho) 1(617)551-8785

Architect(LacyPelletier) 1(617)551-2822

SydneyDesign&BuildLLCOffice

1(617)231-4280

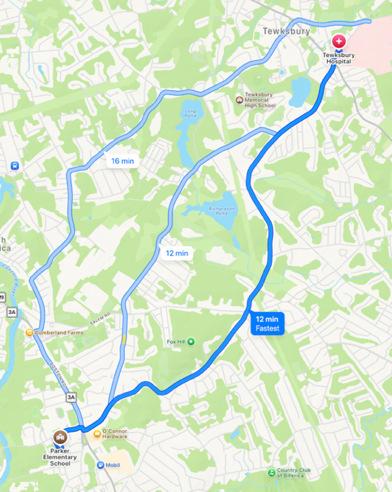

Figure 2- Route to Tewksbury Hospital

I. Route to Tewksbury Hospital (365 East St. Tewksbury, MA 01876) from Parker Elementary School (52 River St. Billerica, MA 01821):

• Head northeast on River St.

• Turn Left onto Boston Rd.

• Follow signs to East St., Tewksbury Hospital is located at 365 East St.

i. Evaluation and Updates

I. The EAP will be reviewed quarterly and after each drill or emergency event.

Tabletop exercises will also be conducted annually to test the plans' effectiveness, and feedback from drills will inform updates to the EAP.

4. HazComProgram

a. Scope

I. This program applies to all workers, contractors, and subcontractors on Sydney Design & Build LLC job sites who may be exposed to hazardous chemicals during work. It covers the following: chemical inventory and labeling, Safety Data Sheets (SDSs), employee and contractor training, non-routine tasks involving hazardous chemicals, and emergency procedures for chemical exposure.

b. Responsibilities

I. The contractor’s (Sydney Design & Build LLC) responsibilities include making sure all hazardous chemicals used on-site are properly labeled and stored, maintaining and providing access to Safety Data Sheets (SDSs) for all hazardous chemicals, conducting HazCom training for all workers before they start work, and enforcing compliance with this program among all subcontractors and workers.

II. Subcontractor responsibilities include providing a list of all hazardous chemicals they will use on-site before beginning work, supplying SDSs for any hazardous chemicals brought onto the site, and ensuring their workers comply with Sydney Design & Build LLC’s HazCom program.

III. Some workers’ responsibilities include reading as well as following chemical safety labels and SDSs. Workers also must use appropriate Personal Protective Equipment (PPE) when handling hazardous materials. Reporting any chemical spills, leaks, or exposure incidents to the Superintendent immediately is also another large responsibility you must undertake as a worker on a job site.

c. Hazardous Chemical Inventory and Labeling

I. Chemical inventory lists will be updated regularly. Updates will be made with the integrated QR scanning code for easy changes or updates. For every QR code changed by specified personnel dedicated to inventory list updates, a notification will be sent to everyone’s phones working on the job site. All hazardous chemicals must be labeled in accordance with OSHA’s Globally Harmonized

System (GHS). All projects will use Sydney Design & Build labeling standards. This includes the product name, hazard pictograms, signal words, and precautionary statements. If chemicals are transferred from their original container, the second container must be labeled with the chemical name and hazard information.

II. Pipes will be labeled by color coordination, which is a part of the ANSI/ASME

A13.1 Standard. Below is a reference for the pipe colors. All workers will be trained on labeling. Note that not all of these are present on every job site.

• Yellow: Flammable gases/liquids

• Red: Fire protection

• Orange: Toxic or corrosive substances

• Green: Water

• Blue: Compressed air

• Brown: Combustible liquids

• Purple: Radioactive materials

d. Safety Data Sheets (SDSs)

I. SDSs are for all hazardous chemicals and will be collected in a distinct yellow binder in the main construction field office. Weatherproof SDSs will be mounted at entry points on the job site, near hazardous material storage, and near the first aid station. Employees all have the right to review SDSs at any time. Subcontractors must provide the contractor an additional SDSs for all chemicals they bring onto the job site.

e. Employee and Contractor Training

I. All employees will receive HazCom training before starting work and when new hazardous chemicals are introduced.

f. Sharing of Information

I. The software ProCore will allow contractors to share SDSs, safety plans, training requirements, and HazCom policies. This will enable real-time access for easy updates and quick checks. This system avoids paperwork and the possibility of information loss.

g. Non-routine Tasks Involving Hazardous Chemicals

I. Workers will receive special instructions on the chemical hazards involved before performing non-routine tasks, such as cleaning spills.

h. Emergency Procedures for Chemical Exposure

I. For minor spills, you must notify the Superintendent immediately and follow the spill response procedure. For major spills, evacuate the area and call 911, as well as notify the superintendent. For chemical exposure, such as skin contact, you must rinse with water for 15 minutes. For eye contact, you must flush your eyes for 15 minutes and seek medical attention. For inhalation, move to fresh air immediately, and for ingestion, you must seek medical attention immediately.

5. SiteSpecificRules

a. PPE

I. All workers at Sydney Design & Build LLC must always wear the following minimum PPE:

• Type II, class G Hard Hats (29 CFR 1926.100) - protection against falling objects, debris, and electrical hazards.

• High-Visibility safety Vests (29 CFR 1926.201 & 1926.651(d)) - ensure visibility around heavy equipment and traffic zones.

• Work Boots – should be steel-toe, slip-resistant, and puncture-resistant.

• Safety Glasses (29 CFR 1926.102) - should be worn at all times. They should be ANSI Z87.1 rated. Workers who are cutting, grinding, or welding must use additional face shields and/or welding helmets as required.

• Gloves- Are required based on job duties and tasks being done on site.

• Hearing protection – is required when noise levels exceed 85 dB. This includes the use of power tools, cutting, or equipment operation.

• Respirator protection – necessary when working with dust, chemical vapors, or fumes.

b. Fall Protection Policy

I. At Sydney Design & Build LLC exceed OSHA standards. There is a 100% tie-off policy.

• All workers must be tied off at six feet or higher no matter the task.

• Anchor points must be rated at 5,000 pounds per worker or approved by a qualified person.

• Personal fall arrest systems (PFAS) must include a full body harness (ANSI Z359.1 compliant), a lanyard with a deceleration device or a self-retracting lifeline (SRL), and shock absorbing lanyards are required for fall distances over 18 feet.

• Guardrails and fall protection barriers must be installed on all open edges 42 inches high, with a mid-rail at 21 inches and a toe board when required.

• All control access zones (CAZ) must be clearly marked, and only trained workers may enter.

• No workers may access a leading edge without a personal fall arrest system.

• Warning lines and safety monitors are not permitted as the sole means of fall protection.

• All floor openings must be covered with a secure, labeled cover that supports twice the expected load.

• Workers also must be trained in self-rescue and assisted rescue procedures provided by the Sydney Design & Build LLC team.

c. Fall Protection Standards for Lifts, Staging, and Scaffolds

I. Aerial lifts: All workers must be tied off using a full-body harness and lanyard attached to the lift’s designated anchor point, they also must never climb or stand on railings to gain height, outriggers must be deployed, and the work surface must be inspected before operation. Only authorized and trained workers can operate lifts.

II. Scaffolding: Scaffold guardrails are mandatory at 10 feet or higher, full-body harnesses must be used when working above six feet if guardrails are not present, scaffold planks must be fully rated for the load they are to support, workers must never modify or remove scaffold components without approval, and daily inspections must be conducted by a competent person.

III. Staging: Engineered guardrails and toe boards are required on all elevated work platforms, workers must tie off when working about six feet, and platforms must be secured.

6. SafetySitePlan

a. Site Safety Plan Elements

I. The Site safety plan shows a graphical layout of critical safety measures to protect workers on the job site during construction. The site will be secure with fencing, clear signage, and designated parking areas for workers and visitors.

b. Legend

• Site Fence: Around the project for security

• Parking area: Parking for workers

• Field Office: Main office location

• Public Walkway: Paths for pedestrian movement with safe clearances from construction

• Emergency Assembly Area: Area that is designated for emergencies

• First Aid Station: Medical assistance on job site

• Restrooms

• Traffic Flow: Vehicle and equipment routes for material arriving on site and leaving the site

• Storage Area: Place for materials and tools

• Lay down Area: Storage that is most likely temporary for large materials

• Temporary Utilities: Power and water

c. Site Safety Plan

MainFieldOffice

TrafficFlow

EntryandExits

PublicWalkway

FirstAid

EmergencyAssembly

Laydown,TempUtilities,&storage

Parking

Restrooms

Figure 3- Site Safety Plan

Project Name: ________________

Job Location: ________________

Inspection Date: ________________

Aerial Lift Inspection Form

Sydney Design & Build LLC

Manufacturer & Model: ________________

Number: ________________

Inspector’s Name: ________________

Inspect the following before operating the aerial lift: ________________

Component Pass Fail

Tires and wheels

Outriggers and stabilizers

Hydraulic hoses- no leaks or cracks

Battery and cables

Electrical system

Platform guardrails and mid rails

Entry gate and latch

Emergency stop buttons

Control labels and instructions

Test Function Pass Fail

Ground and platform controls

Horn

Steering and brakes

Lift smooth movement

Fall protection anchor points are secure

Work Area Pass Fail

Ground surface free of obstructions

No power lines, structures

Weather conditions are safe for lift use

Barricades are in place

Lift is positioned on level ground

Safety Equipment Pass Fail

Full-body harness

Lanyard or SRL connected to anchor point

Hard hat, safety glasses, gloves worn

High-visibility vest worn in traffic areas

☐ Approved for Use

☐ NOTAPPROVED – Requires Repairs

Superintendent Name: ________________ Date: ________________

Superintendent Signature: ________________ Date: ________________

8. SafetyResponsibilities

a. Scope: The following team members are responsible for implementing safety measures throughout the Billerica-Parker Elementary School Project. Each member has a specific list of responsibilities that align with OSHA requirements, safety programs, and site-specific safety plans (SSSP).

I. Project Manager: Joshua Philbrook

• Perform and document one safety inspection per month for all tasks. This will ensure tracking hazard corrections.

• Ensure finances support PPE, training, and safety resources within the budget.

• Verify and review the SSSP integrated into subcontractor contracts to be sure they are following safety requirements.

• Attend and participate in a safety meeting at least once a month to ensure that corrective actions are implemented, and leadership is defined.

• Initiate kick-off meetings with subcontractors and safety representatives to reinforce expectations.

• Review and approve all accident or incident reports and Emergency Action Plans (EAPs).

• Support the Superintendent in reinforcing job site safety rules.

II. Superintendent: Logan Levesque

• Coordinate job hazard analysis (JHAs) before high-risk tasks begin alongside Project Manager, Josh Philbrook.

• Lead pre-task safety planning for all high-risk activities. (Note that this is correlated with the job hazard analysis (JHA’s). Superintendent must correlate with Task Supervisors, Aiden Short and Lily Robbins, of any changes as they are in charge pre-task hazard assessments before all highrisk tasks.

• Oversee fall protection and compliance for all elevated work. There is a 100% tie-off policy at Sydney Design & Build, LLC !!!

• Review and approve confined space permits and lift plans before work begins.

• Lead daily job sites and hazard assessments and enforce corrective actions.

• Perform and document one job site safety inspection per week. This will help address and identify hazards.

• Be sure that all workers are wearing required PPE and following sitespecific safety policies.

• Meet with fire and EMT officials to review emergency response access points (Note the Project Manager may attend as well).

• Document and conduct all safety orientations for workers in coordination with the Safety Manager.

• Host weekly foreman safety meetings with safety as the primary agenda.

III. Safety Manager: Gabby Martin

• Lead monthly job site safety meetings while tracking trends in hazard, correction, and worker participation within the meetings and on the job site.

• Conduct weekly site safety inspections, provide, and report the findings to the Superintendent and Project Manager.

• Develop and maintain the site-specific safety plan (SSSP); this includes emergencies, evacuation routes, and hazard zones (Found in the EAP section and HazCom section).

• Ensure correct placement of fire extinguishers and emergency signage.

• Serve as the primary hazard communication (HazCom) program coordinator. This includes updating SDSs and making sure they are accessible to everyone on the project.

• Ensure workers receive proper instruction on fall protection, HazCom, and emergency response by overseeing the safety training program.

• In charge of investigating all personnel, equipment, and job site-related incidents. This includes identifying the root cause to prevent future occurrences.

• Ensure compliance with PPE rules and standards, such as those required for respiratory, hearing, eyes, and fall protection practices.

• Ensure that all administrative and elimination controls are in place properly. If updates are necessary, contact the Project Manager and Supervisor to update JHAs.

• Monitor work participation in safety programs. This includes implementing engagement strategies such as the report box by the job site trailer, where anonymous reports and feedback are dropped off and later discussed as a team.

b. Strategies for Safety Program:

I. Worker participation: At Sydney Design & Build, LLC the safety culture is encouraged in the most positive note. Employees should feel empowered to report hazards, suggest safety improvements, and participate in safety planning, whether it be anonymous or not. As mentioned, there will be a report box by the job site trailer where employees can drop anonymous reports and feedback.

II. Hazard identification and assessment: Regular job site inspections, JHAs, and near-miss investigations will happen on a regular basis to evaluate risks continuously. Workers can contact the Safety Manager, Gabby Martin, or Superintendent Logan Levesque if they would like to participate in on-site inspections.

III. Program evaluation and improvement: Leading indicators, such as participation rates and training completion, will be tracked, along with lagging indicators, like incident and injury reports. This will improve safety over time.

9. IncidentInspections

a. Purpose of Incident Investigations:

I. Identifies causes of incidents, injuries, and near misses on the project to prevent future occurrences.

II. Documents facts and does not assign blame. This will ensure investigations are conducted professionally.

III. Implementing corrective actions based on reports.

b. Incidents that require investigation:

I. Fatalities

II. Serious injuries that require hospitalization, amputation, or loss of vision.

III. Minor injuries that require first aid or medical attention.

IV. Near misses that could have resulted in an injury or damage.

V. Fires, hazardous material spills, or environmental releases.

VI. Property damage, incidents affecting equipment, materials, or structures.

VII. Security threats or unauthorized site access.

c. Timeline for an incident investigation

I. Start immediately after emergency procedures are complete. Before the accident scene is changed, preserve evidence as best as possible. This can be done with tape, just as you would during a police investigation. Gather accurate witness statements before the memories fade. This includes pulling the witnesses aside to ask questions and, if possible, separating the witnesses so there are no biased answers. Complete within 24 to 72 hours, depending on severity. Must report to OSHA eight hours or less for a fatality or 24 hours or less for hospitalization, amputation, or loss of an eye.

d. Investigation, team, and responsibilities

I. Lead investigator: Safety Manager (Gabby Martin)

II. Supporting investigator: Superintendent (Logan Levesque) shall document the scene and assist with corrective actions as quickly as possible.

III. Supporting investigator: The Project Manager (Joshua Philbrook) implements corrective actions and follows up on solutions.

IV. Witnesses and affected workers: Provide statements on the circumstances and what observations they saw, smelled, or heard.

V. Subcontractor representatives: Can participate if their workers or equipment are involved in the scene.

e. Information collected during investigations

I. Investigators will document and collect the following:

• Who, what, when, where, why, and how

• More specifically, collecting the names of all individuals involved, a detailed account of the incident, the date and time of the occurrence, the exact location on the job site, and any possible contributing factors, including training, gaps or equipment, failures, and the sequence of events leading up to the incident should all be reported during the investigation.

• If applicable or possible, include the exact location, date, and time, what the injured worker was doing at the time, the nature of the injury, what the environmental and weather conditions at the time were like, PPE availability, and whether it was in use, conditions contributing to the incident as well as actions that may have led to the event occurring.

f. Conducting the investigation

I. Isolating the accident scene to preserve and record all evidence using photos, videos, and diagrams. Identify witnesses immediately and follow up with an immediate interview process with witnesses. Be sure to ask open-ended questions (this will help to encourage detailed responses). When questioning, take thorough notes or audio record statements for accuracy and future use, have witnesses

reenact the accident if safe to do so, Encourage witnesses to suggest ways to prevent similar incidents from happening.

g. Using investigation findings

I. Use the information to implement corrective preventative measures, determine if injuries are OSHA recordable then decide if disciplinary action is necessary for noncompliance with safety rules and regulations if required. If so, update job hazard analysis (JHAs) to reflect new measures of prevention and share at the next safety meeting, train workers on lessons learned and reiterate safety rules and regulations, as well as continue to monitor compliance with corrective actions carefully and thoughtfully.

h. Blank incident investigation report form

Incident Investigation Report

Sydney Design & Build, LLC

Project Name: ___________________

Job Location: ___________________

Date of Incident: / / Time of Incident: AM/PM

Reported By: ___________________

Contact Number: __________________

Incident Details

Type of Incident: Injury NearMiss PropertyDamage Environment

Location of Incident: ____________________________________________________________________

Describe the Incident (What happened?): ____________________________________________________

Individuals Involved

Injured Party Name (if applicable): _______________

Job Title: ____________________________

Company/Employer: _________________________________

Injury Type (if applicable): Minor

Was First Aid Admin.? Yes No

Was EMS Called? Yes No

Witness Statements

Witness Name: ___________________________________ Statement: ________________________________________

Environmental Conditions & Equipment Involved

Weather Conditions: Clear Rain Snow Windy ExtremeTemp.

Equipment Involved: Yes No Was PPE being Worm? Yes No

Root Cause Analysis

Check all that apply: What Factors contributed to the incident?

WhatPPE:_______________

Unsafe Work Conditions Lack of Training Equipment Failure Human Error PPE NonCompliance Weather Conditions Other: ____________

Corrective Actions Taken

Immediate Actions Taken to Prevent Recurrence:

Further Corrective Actions Required? Yes No

Person Responsible for Corrective Actions: __________________________________________________

Completion Deadline: / /

Investigation Closure

Investigator: _____________________________________

Title: ____________________________________________________

Date Investigation Closed: / /

Project Manager Approval: Yes No

Signature: __________________ Date: / /

10.ReportingRequirements

a. OSHA Reporting Requirements

I. Fatalities: Report within 8 hours of learning about the fatality. Work-related fatalities occurring on-site. If an off-site fatality occurs, it must be workrelated, such as transporting materials during the workday. OSHA still must be notified if a worker dies from a work-related injury within 30 days of the incident.

II. Injuries and Illnesses: If a worker is hospitalized as an in-patient, not an emergency room treatment report must happen within 24 hours. This includes amputation of any body part and loss of an eye. If a worker has a work-related illness, the report must also be made within 24 hours of hospitalization.

b. Reporting Exceptions

I. Some incidents do not require OSHA reports such as the following:

• Non-work-related medical conditions, illnesses, or injuries that result in hospitalization.

• X-rays, ointments, band-aid fixes, and rigid finger guards for strained or sprained finger treatments.

c. Methods of Reporting to OSHA

I. The designated Safety Manager, Gabby Martin is responsible for informing OSHA when a reportable incident occurs. Martin will also be sure that all required information is provided during the safety report.

II. How to notify OSHA:

• Call the nearest OSHA Office in Andover, MA (978)837-4460

• Call the OSHA 24-hour hotline at 1-800-321-6742

• Report online at www.osha.cov

III. The following information is required for reporting:

• The company name (Sydney Design & Build, LLC)

• Names of employees affected

• Date and time of the incident

• Location of the incident

• Brief description of the event

• Contact person and phone number

IV. The following forms shall be used for recordkeeping of incidents

• OSHA form 301: Injury and Illness incident report

• OSHA form 300: Log of work-related injuries and illnesses

• OSHA form 300A: Summary of work-related injuries and illnesses

d. Access to Records

I. OSHA form 300A must be signed by either the Superintendent or Project Manager and posted in a visible area where all employees can access it.

11.SafetyWalkthroughs

a. Responsibilities

I. Safety Manager Gabby Martin will be the primary inspector, and Logan Levesque, the Superintendent, will be the secondary inspector. They shall conduct all safety walkthroughs and on-site inspections and report the findings to Joshua Philbrook, the Project Manager.

b. Safety Walkthrough Schedule

TypeofInspection

ConductedBy Frequency

Daily Safety Walkthrough Superintendent (Logan Levesque) Daily (Start of shift)

Weekly Safety Inspection

Pre-Task Hazard Assessments

Task Manager (Jack Delgiudice) Weekly (End of week)

Task Supervisors (Aiden Short & Lily Robbins) Before High-risk work

Monthly Site Audit Safety Manager (Gabby Martin) Monthly (Second Wednesday of every month)

Incident-Specific Inspection Safety Manager (Gabby Martin)

c. Safety Walkthrough Checklist

General Site Conditions

Walkways and work areas are clear and free of obstructions

Adequate lighting and signage in all work areas

Emergency exits are accessible and marked correctly

Housekeeping is maintained

Fire Extinguishers are accessible

Personal Protective Equipment (PPE)

Hard Hats, gloves, and safety goggles/glasses are being worn

Respiratory protection is available and worn where it needs

PPE is not damaged and stored correctly

Fall Protection

Guardrails and toe boards are in place in elevated areas

Ladders and scaffolding are adequately secured

Harnesses and lanyards are used where required

After any incident, near miss, or safety complaint

Floor openings are barricaded, labeled, and/or covered properly

Electrical and Equipment

Extension cords are not damaged

Electrical panels are covered

Lockout/Tagout are followed correctly

Heavy machinery is maintained and being operated safety

Tools are stored correctly

Fire Prevention and Hazardous Materials

Fire Extinguishers are in designated locations

Flammable materials are stored properly

Hazardous chemicals are labeled and stored correctly

SDSs are available

Excavation

Trenches over 5 feet are protected with shoring or sloping

Piles are kept at least 2 feet from trench edges

Ladders or proper exits are 25 feet from workers in trenches

Emergency Preparation

First Aid kits are accessible and stalked

Emergency contact numbers are posted in the correct site locations

Evacuation routes are posted and visible

12.ReportingHazards

a. Process

I. The hazard reporting process is established to ensure that all workers can report hazards without fear and promptly using various methods such as:

• Report drop box with paper forms attached in a weatherproof folder. This is located next to the job site trailer.

• On the weatherproof folder, a QR code and a website link will be visible for scanning. Scanning will bring your digital device to an online version of the paper form to report hazards.

• Verbal reporting is also welcome to the Superintendent and/or Safety Manager.

a. Hazard Reporting Form Template

Hazard Report Form

Sydney Design & Build, LLC

Date of Report: ___________________________________

Report by (optional): ____________________________

Role/Trade (optional): __________________________________

Location of Hazard: _______________________________

Description of Hazard/Concern: ____________________

Potential Risk Level (Low/Medium/High): ____________________________________

Immediate Actions Taken: _________________________________________________

Suggested Solution: _______________________________

b. Hazard Investigation and Resolution Form

I. The results will be shared at safety meetings after the Safety Manager, Gabby Martin, has investigated with the help of the Superintendent. The investigation and follow-up verified form must be completed no longer than one week after submitting the Hazard report form. Safety Manager Gabby Martin must collect physical forms and review digital ones at the end of each day to ensure the deadline is met. Attach this form to the hazard report form:

Person Assigned to Investigate/Correct: ___________________________________________

Investigation Findings: ___________________________

Corrective Action Implemented: ____________________

Date Completed: _________________________

Verified By (Safety Manager): _____________________________

13.ElectricalSafety

I. Workers on-site will be protected against electrical shock and burns through regulations based on OSHA standards. Temporary wiring systems will be managed to prevent electrocution, arc flashes, and fire hazards.

a. Protection

I. Electrical Hazards

• Ground-fault circuit Interrupters (GFCI) protection will be on all temporary wiring to ensure quick power disconnection in case of ground fault. GFCI will be required in all 120-volt and 15- and 20amp receptacle outlets used for temporary power. Must be tested before each shift and at least once per month.

• Lockout/tagout (LOTO) procedures are strictly enforced on all job sites. Only authorized personnel are allowed to de-energize circuits during maintenance or repairs.

• Assured equipment grounding conductor program (AEGCP) is also used on Sydney Design & Build, LLC project sites. Regular inspections and tests of grounding conductors will be done to make sure there are safe electrical connections.

• Temporary panel boards, all panels, and distribution boxes will be clearly labeled, locked, and secured to prevent access unless authorized.

• Clear signage and barricades will be set in place where there is temporary wiring or electrical hazards that are found during inspections to prevent contact.

• Weatherproofing of temporary electrical installations should always be rated for outdoor use to protect against moisture, physical damage, and environmental conditions.

II. Extension Cord Safety

• Only heavy-duty grounded extension cords are to be used to prevent tripping hazards, equipment failures, and electrical fires. They must also be inspected daily for damage, such as fraying, missing prongs, and exposed wires. If damage is found, the cords should be removed immediately. To help prevent damage, such as pinching or crushing, the cords must have a cover or cable protector. If the cord is not long enough, never plug one extension cord into another (daisy chain), and always keep cords away from water, oil, or flammable materials. These simple mistakes can cause fire hazards and electrical shocks. Along with ensuring the safe usage of extension cords, workers must also always store the cords properly. This means avoiding tangling and damage while they are being stored and not used.

b. Training and Compliance

I. All workers will receive electrical safety training during the safety orientation. Weekly safety meetings will be reinforced by consistent repetition for best electrical safety and hazard recognition practices. All electrical hazards must be reported to the Superintendent, Logan Levesque, and Safety Manager, Gabby Martin.

14.Training

I. Sydney Design & Build, LLC is committed to making sure that all workers, subcontractors, and site visitors receive proper safety training before entering the site. All training aims to educate people about hazards, emergency procedures, and safety policies to minimize risks, all while complying with OSHA rules, regulations, and standards. The Safety Manager, Gabby Martin, will oversee and facilitate training programs. She will ensure all personnel are trained properly before starting work.

a. New Worker Orientation

I. Workers must complete a safety orientation before beginning work on-site. The topics covered during the orientation include emergency procedures, PPE requirements, fall protection, fire prevention, HazCom, and site-specific hazards. Workers who have not completed initial training will not be permitted on-site until they receive full training.

b. Ongoing Training

I. Safety training sessions will be conducted at least once per project phase to reinforce safety. Training will also be provided when new hazards, equipment, or procedures arise. Workers will complete refresher training when the safety program is updated.

c. Fire Prevention Training

I. Workers must receive training on fire safety, fire extinguisher use (PASS Method), emergency fire response, and housekeeping standards and requirements. This training will be during the initial orientation and at least once per project phase.

d. Emergency Action Plan (EAP) Training

I. Workers will receive training on emergency evacuation procedures, hazard identification, and emergency contacts. Drills will be done twice yearly or per job to ensure everyone on site is familiar with procedures.

e. HazCom Training

I. Those who handle hazardous materials must undergo HazCom training. This includes chemical labeling standards, Safety Data Sheets (SDSs), and PPE requirements. Training will be provided before handling chemicals, when new chemicals are brought on the site, and when updates or changes to chemicals or labels are made.

f. Fall Protection Training

I. All workers must complete the fall protection training on the job site. This includes harness use, anchor points, and fall arrest systems. The training will be refreshed for everyone annually and before high-risk tasks.

g. Electrical Safety Training

I. Workers will be trained to recognize electrical hazards, handle and store extension cords correctly, and work safely around temporary wiring. The training will cover the use of Ground-fault circuit interrupters (GFCI), the assured equipment grounding conductor program (AEGCP), Lockout/tagout (LOTO) procedures, and how to inspect equipment for damage. This training will happen during orientation and reminded of during safety meetings for reinforcement.

h. Site Visitor Training

I. Short-term visitors such as inspectors and clients must attend a brief orientation before entering the site. Once they have completed it once they do not need to again during the next visit. They will, in fact, always be escorted

by a trained personnel member, and they must wear minimum PPE such as a hard hat, high-visibility vest, and appropriate footwear.

II. Long-term visitors such as subcontractors must complete the entire site safety orientation before working or moving around the job site freely without an escort.

i. Workers without initial training

I. Workers who have not received the initial training shall not be permitted onsite until it is completed. If there is an exception, they must always be supervised.

j. Evaluation and Updates

I. All training programs will be reviewed quarterly and updated when necessary. Feedback from workers will be collected at the end of training or an incident to improve their effectiveness. Safety meetings will have safety topics, including training, as the main priorities to reinforce safety importance.

15.ElectricalSafetyInspectorGuideforTraining(Additionalinformation)

I. This checklist guide is what the inspector (Safety Manager) should complete to ensure electrical safety compliance on the job site. The ultimate goal is to prevent electrical hazards such as shocks, burns, and fires by enforcing proper training and safe, undamaged equipment that complies with OSHA.

II. Inspection requirements:

• Verify compliance with OSHA electrical standards for construction and Sydney Design & Build, LLC policies. Inspections should occur at the start of each shift, after updates or changes, and following any electrical incidents.

Temporary Wiring and Power Distribution

Are all temporary power installations inspected before use and at regular intervals?

Are all temporary panels, boxes, and wiring adequately labeled?

Are cords protected from damage (For example, not run through doorways)?

Are Electrical enclosures weatherproof and secured from unauthorized access?

Ground-Fault Circuit Interrupters (GFCI)

Are GFCIs installed on all 120-volt, 15- and 20-amp receptacles?

Are GFCIs tested before each shift and documented at least once per month?

Have any damaged GFCIs been removed from service immediately?

Extension Cord Safety

Are only heavy-duty, grounded extension cords being used?

Are extension cords inspected daily for cuts, fraying, missing prongs, or exposed wires?

Are cords kept away from water, oil, and flammable materials?

Is daisy-chaining being used?

Are cords adequately stored when not in use to prevent damage?

Lockout/tagout (LOTO) Compliance

Are LOTO procedures followed before electrical repairs?

Are only authorized personnel de-energizing the circuits?

Are LOTO locks and tags being properly used?

Electrical Equipment and Tools

Are all power tools double-insulated and/or properly grounded?

Are damaged tools being removed immediately?

Are tools and cords kept away from water and hazardous conditions?

Are the portable generators grounded and bonded correctly?

Worker Training and Compliance

Are workers aware of how to recognize electrical hazards and how/where to report them?

Are safety meetings reinforcing electrical safety?

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No