UNITING MATERIALS, TECHNOLOGY AND DESIGN

Commercial Spaces –Yesterday & Today

The Evolution of CNC Machines

Sustainability in the Industry

Q2 • 2024

2024 180fx® by Formica Group 9921-43 Sahara Noir www.formica.com/LivingImpressions For refreshing mornings, and timeless design. Living Impressions™ Collection

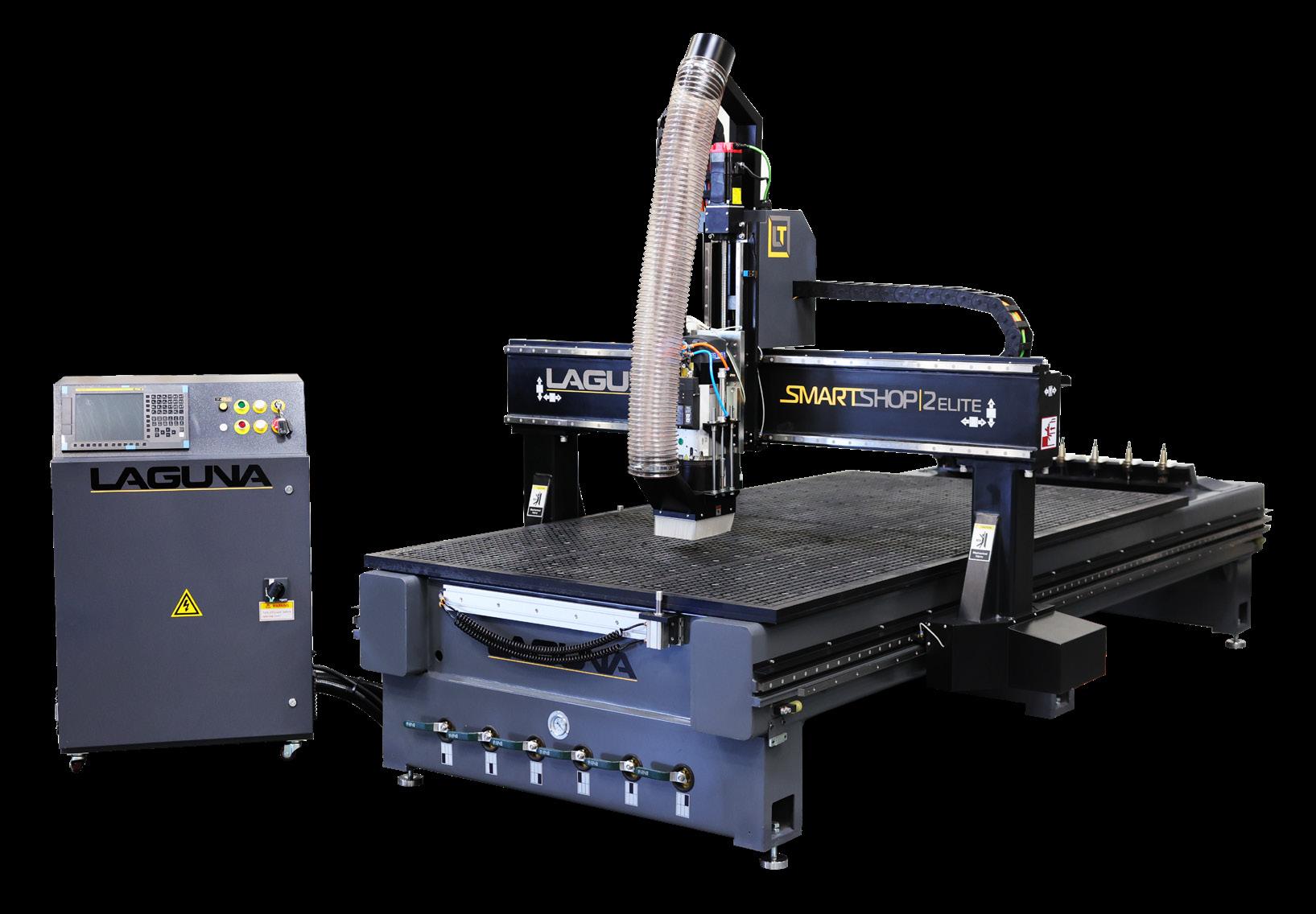

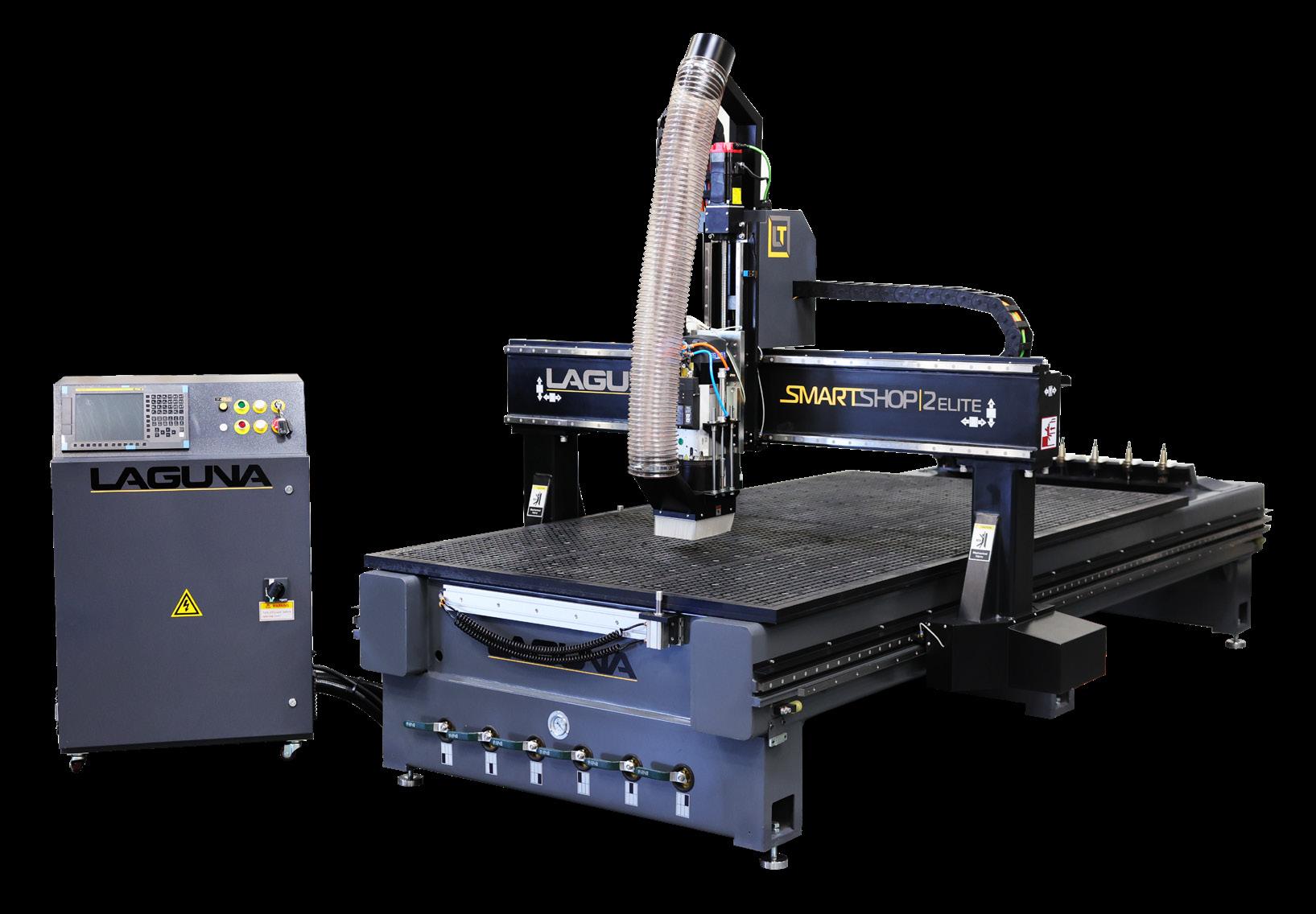

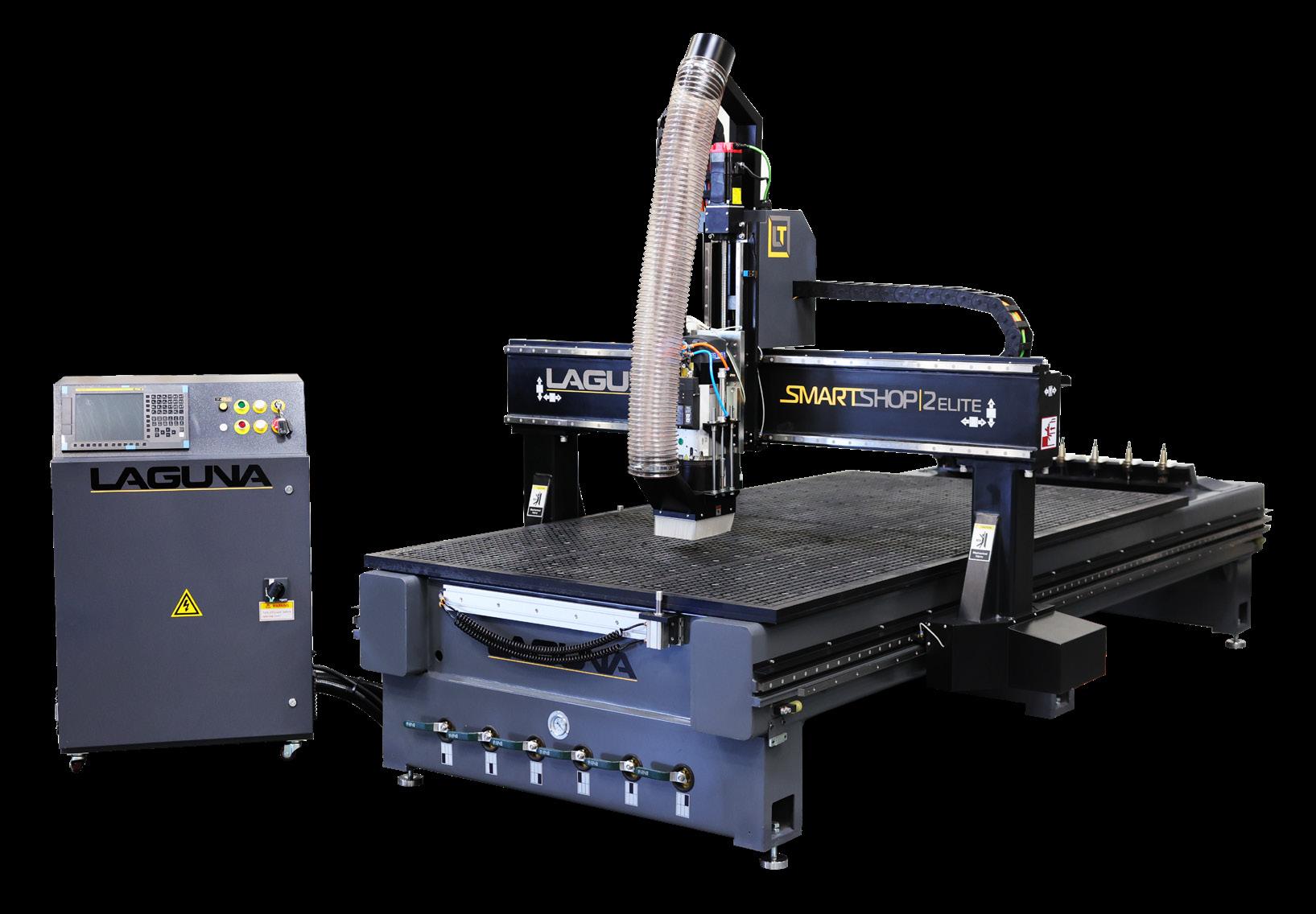

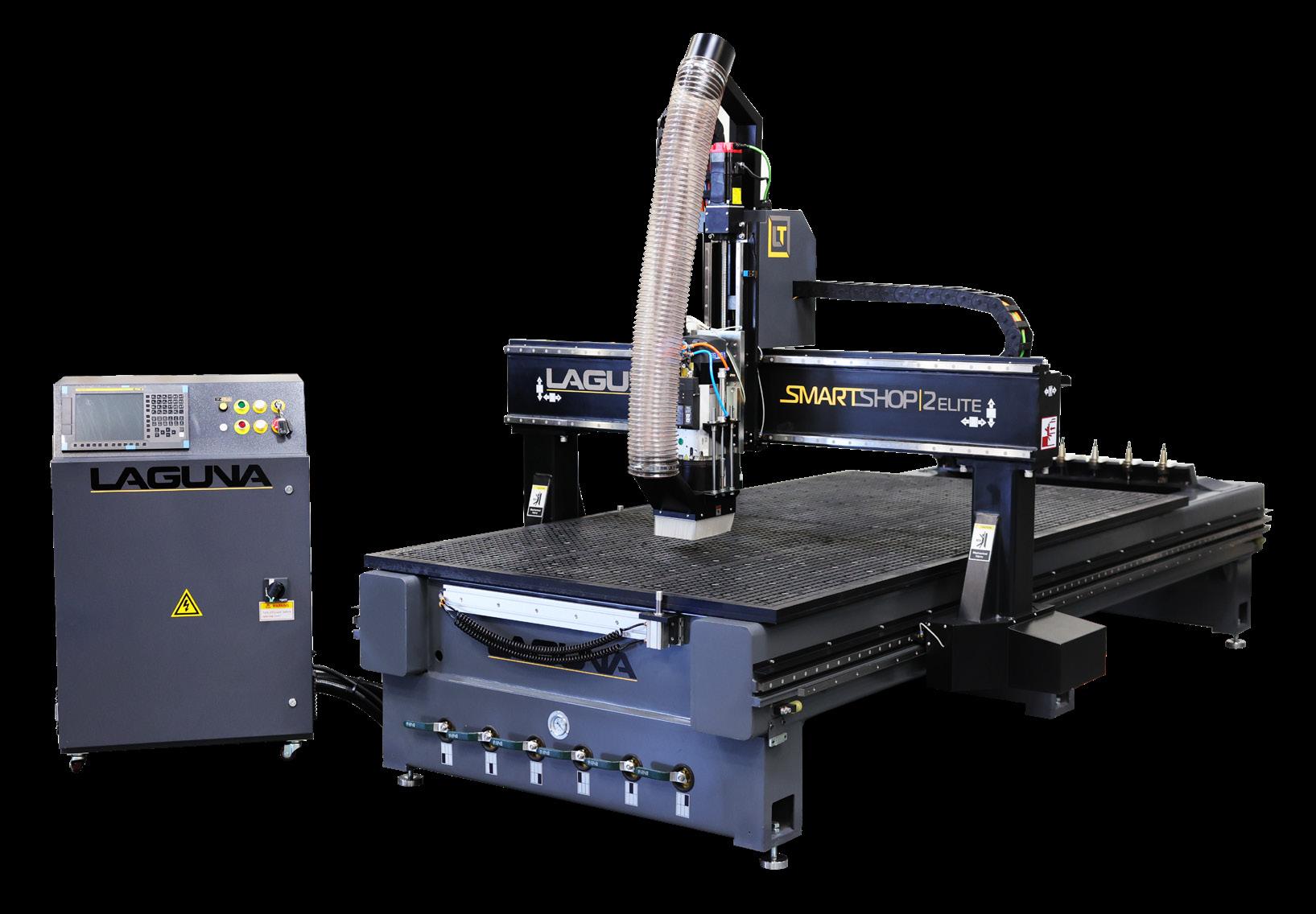

SCAN TO LEARN MORE LAGUNATOOLS.COM FOR INQUIRIES CALL, 1-(800)234-1976 Your SMART Path to Panel Processing With industry leading Fanuc controls, Fanuc servos and a heavy duty all steel frame, the SmartShop 2 Elite delivers the speed and precision to handle your highest workloads with ease.

UNITING MATERIALS, TECHNOLOGY AND DESIGN

FEATURES

14 Twenty Years of Commercial Spaces

To celebrate 20 years of Surface & Panel Magazine, a look back at commercial and retail designs featured over the past two decades

18 Revolutionizing Commercial and Retail Spaces

Today’s commercial spaces adopt innovative materials and technologies to enhance aesthetics, functionality, and customer experiences

CNC Section

24 From Niche to Necessity

New technologies drive a surge in CNC popularity

28 Retrofitting with a Purpose

Many businesses are choosing to upgrade their outdated computerized parts on CNC and other machines

Sustainability Section

32 Formaldehyde in the News

A summary of the EPA's recent draft risk evaluation and its implications for users of wood panels

34 Beyond the Buzz

Sustainability efforts are no longer just the trend of the day — they have become a new standard in the industry

38 Not If, But When

Industry responds to EPA’s pending methylene chloride ruling

42 Predictions for Surfacing Innovation

Designers gear up for NeoCon

56 New Product Spotlight

Products that caught our attention at KBIS 2024

DEPARTMENTS

8 From the President

Patrick Adams talks about becoming one of “those parents”

10 From the Editor

Jennifer Williams talks about doing what you can with what you have

12 Beyond the Surface

Industry experts share what has been the most daunting challenge in creating today’s commercial spaces

22 S&P By Design

Industry innovations used in real projects around the world

44 Human Resources

Beyond resumes: 10 pro tips for recruiting

48 Sales & Marketing

The little things are big things

50 Distribution Matters

Safe is as safe does

52 Closet Convo with Eric Marshall

Closet industry veteran Eric Marshall takes us on a tour of his favorite closet innovations at KBIS

60 @TheShow

Reflections on KBIS 2024 and previewing the upcoming NeoCon

64 Ad Index

66 By the Numbers

A graphic look at sustainability in the industry

CONTENTS Q2 • 2024

62

22 VOL 23 • ISS 2 42

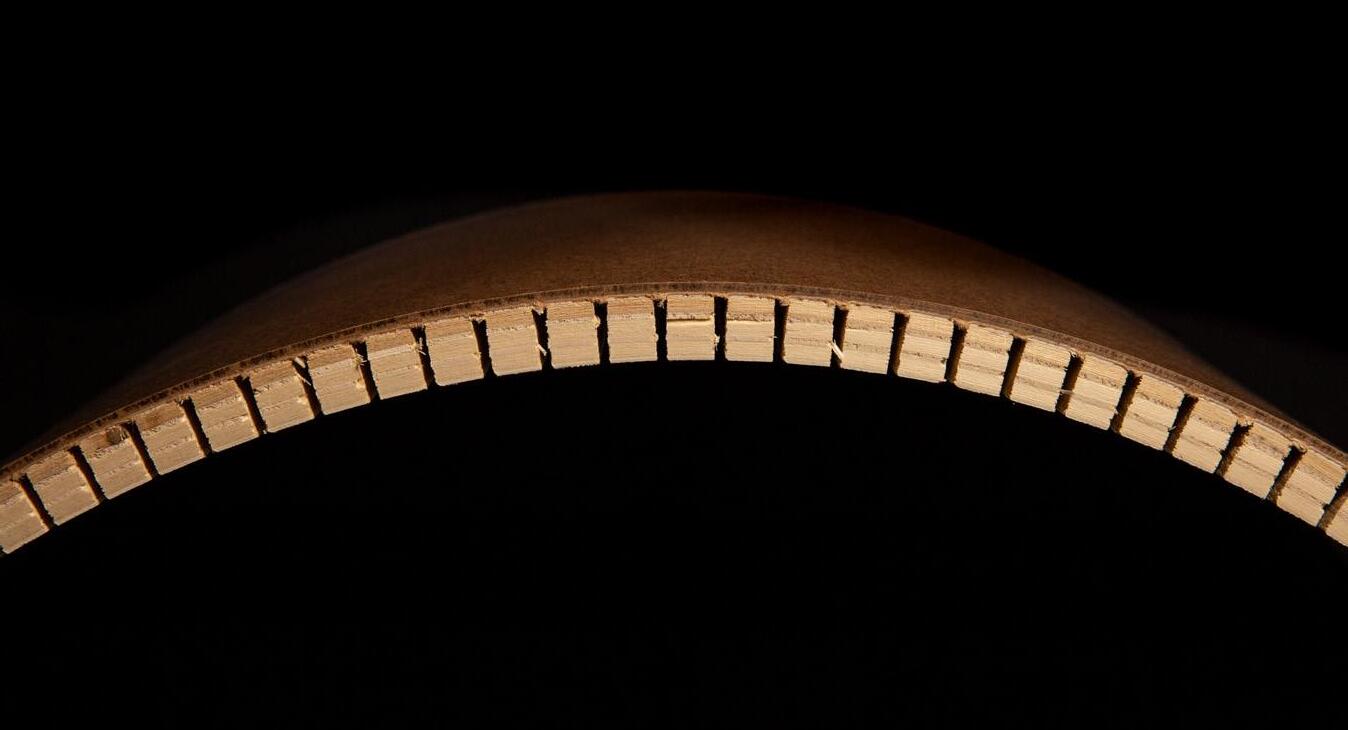

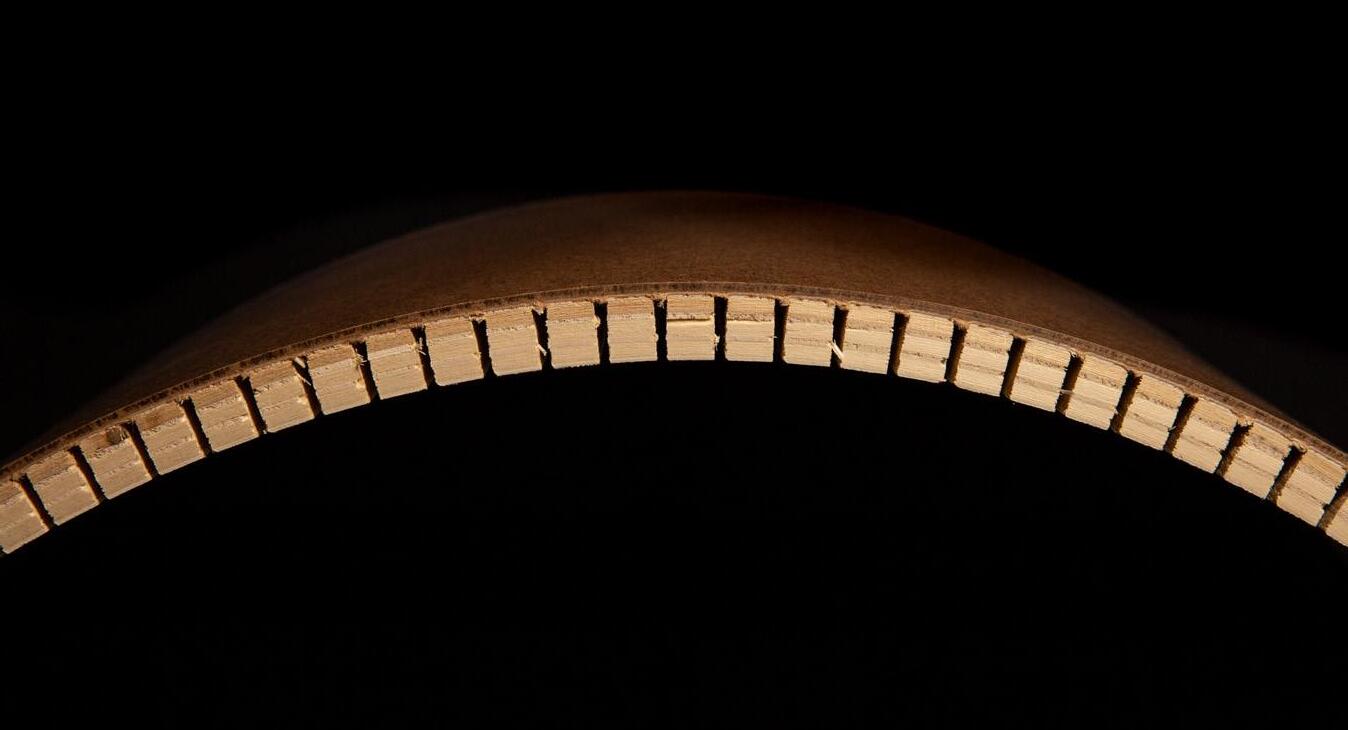

ON THE COVER: Special Flexboard panels from Kerfkore help make the new Music Education Complex at Texas A&M University-Kingsville an eye-catching showstopper. Photo by Cotton Global Disaster Solutions, courtesy of Kerfkore.

Step up to CNC Manufacturing with KCD Software, the comprehensive solution for cabinet & closet professionals. Let’s discuss the solution that’s ideal for you. KCD Software provides cabinet and closet professionals with a full suite of powerful and intuitive design tools that make it easy to create the ideal solution for virtually any space. Design Show your clients photo-realistic, 3D renderings of the finished design for their sign-off, generate real-time quotes and contracts to close the sale quickly. Sell Export accurate cut-lists for traditional manufacturing, send the nested job to your CNC machine, or outsource production through Cabinotch® integrated ordering. Manufacture DESIGNER PROFESSIONAL WORKSHOP CNC COMMANDER Call 508.760.1140 or Visit KCDSoftware.com VISIT US BOOTH #C2040

for More

Scan

PRESIDENT/PUBLISHER

Patrick Adams

PH: 714-486-2735 padams@526mediagroup.com

VICE PRESIDENT Shelly Adams

MANAGING EDITOR

Jennifer Williams

PH: 714-486-2735 jwilliams@526mediagroup.com

David Koenig, DIRECTOR OF EDITORIAL Sara Graves, SENIOR EDITOR

GUEST COLUMNISTS

Keith Christman, Meghan Howell, James Olsen, Lisa Ritchie and Denise Williams

SALES

Nick Kosan

PH: 714-486-2735 nkosan@526mediagroup.com

Chuck Casey

PH: 714-486-2735 ccasey@526mediagroup.com

John Haugh

PH: 714-486-2735 jhaugh@526mediagroup.com

GRAPHIC DESIGN

Dara Fowler

DIGITAL SUPPORT

Alekxandr Olson aolson@526mediagroup.com

Josh Sokovich jsokovich@526mediagroup.com

CIRCULATION/SUPPORT

PH: 714-486-2735 info@526mediagroup.com

526 MEDIA GROUP 151 Kalmus Drive, Ste. J3 Costa Mesa, CA 92626

PH: 714-486-2735

Never Miss a Beat.

6 SURFACEANDPANEL.COM

Surface & Panel is published quarterly by 526 Media Group, 151 Kalmus Drive, Ste. J3, Costa Mesa, CA 92626, telephone 714-486-2735. © 2024 by 526 Media Group. Patrick Adams, President. All rights reserved. No part of this publication may be reproduced or transmitted in any form, electronic or mechanical without written permission from the publisher. Subscription policy: Individual subscriptions are available, without charge, to manufacturers who engage in panel processing, qualified service providers and suppliers. Publisher reserves the right to reject non-qualified subscribers. One year subscription to non-qualified individuals: U.S. $50, Canada/ Mexico $75, all other countries $100, payable in U.S. funds. Single issues are $15, and must be prepaid. 526 Media Group does not assume and hereby disclaims any liability to any person for any loss or damage caused by errors or omissions in the material contained herein, regardless of whether such errors result from negligence, accident, or any other cause whatsoever. Printed in the U.S.A. Postmaster: Send address changes to Surface & Panel, 526 Media Group, 151 Kalmus Drive, Ste. J3, Costa Mesa, CA 92626. Please direct all subscription questions to: Surface & Panel, 526 Media Group, 151 Kalmus Drive, Ste. J3, Costa Mesa, CA 92626 or email info@526mediagroup.com.

SURFACEANDPANEL.COM/SUBSCRIBE SUBSCRIBE TO THE SURFACE & PANEL NEWSLETTER FOR NEW STORIES EVERY WEEK

At Daubert, our belief in lasting bonds begins with our commitment to your success. Whether that means developing a custom formulation that'll keep your product together, or traveling cross-country to learn about your challenges in depth, you are our only focus. We've thrived since 1935, not because we're the biggest adhesives company (we're not), but because we make your success the focus of everything we do, and the results speak for themselves.

4700 S. Central Avenue • Chicago, IL 60638 1-833-822-8141 Visit our website at daubertchemical.com. Our email is dauchem@daubert.com

Epoxy

Flat

Profile Lamination 3D Press Lamination RELENTLESSLY ADHERE

Daubond PUR is Lamination

Lamination

Lamination

“Those Parents”

As everyone knows, because of a variety of factors including my “past life” career travels, my wife and I had children later in life. I could not begin to count the many lessons, stories and realizations that this has provided us as we’ve entered the second half of our century.

One benefit is that while we were “waiting,” others were moving along with their family plans while we watched. We watched the pregnancies, the baby showers, the births, and the first few months adapting to parenthood. We went to countless baby birthday parties and celebrated first days at school. Through all of that, the thing we marveled at the most was the introduction to sports around the same time they were starting school, learning to ride a bike, and losing their first tooth.

This wasn’t the introduction to sports that I had as a kid. For me, it seemed normal to see some older kids throwing something called a football in the street in shorts in the summer, asking to play, and then getting my introduction to being blindside tackled on asphalt. After that, I understood the sport of football. Never once was there a discussion by my parents saying, “Wow, Patrick is really good at football! Even though he’s five, I think he has a shot of going pro someday! We should spend thousands of dollars and every free second to make sure he has his shot!”

And yet, all around us were people that we respected, who are friends, having this very conversation about their young children. Private lessons, coaches, trainers, camps and eventually club/travel teams were tried out for. Soon, unless we attended a game, we never saw our friends again! Six days a week, 12 months a year, they became “those parents.” They knew every venue and the perfect place to park. They had specific gear and support materials (food, coolers, first aid, back-up gear) for each event. Slowly, their personal wardrobes transformed into team parent apparel. And don’t even get me started on the antics that ensued if the ref made a bad call on their kid or the coach didn’t see their prodigy as they did!

My wife and I just sat back perplexed and in marvel at this absolute lunacy! “Do you know the odds of making it to the big leagues, even for Division 1 college players?” I asked her. We would laugh, make fun of all of the money, time and parents literally passing each other on a highway once multiple kids started their pursuit of fame and glory.

We would laugh, make fun of all of the money, time and parents literally passing each other on a highway once multiple kids started their pursuit of fame and glory.

So, as I prepare to go to Vegas next weekend, not for KIBS, not for ANME, not for SHOT Show, not for PCA, not for the World of Concrete. No, I’ve already been this year for all of those. This time, it’s for the SCVA Girls Volleyball National Qualifier. My family, along with around 5,000 of our “closest friends” will pack into the Mandalay Bay events center for three days of volleyball with my now 13-year-old daughter and her team. But, she is prepared!

This is her third year of competitive volleyball. She has escalated through some of the best club teams in Southern California. She also has a private playing coach and a private agility coach, and practices with her team three nights a week. As a supportive dad, I also practice with her during any free time we have when not at practices, training, lessons or tournaments (two weekends each month). On a recent business trip to Columbus, Oh., I took the family along and we saw the OSU women’s team play, which is now my daughter’s goal for her college experience. The season wraps up in mid-June, so my wife and I are excited for the break for a couple of months where the schedule will transition to summer camps, clinics, private instruction, and laying a strategy to try out for next year’s target club teams!

Yes, we have become “those parents.” I look in the mirror and often ask, “What have you become?” as I straighten my team hat, put on my team sweatshirt, and head out on another volleyball adventure in support of my “little” 13-year-old, 5’7” outside hitter.

Now, feel free to let me have it… I deserve it! As always, it is a great honor this great industry and each of you. I hope spring has adventure and happiness in store for you!

Patrick Adams, President | 526 Media Group, Inc.

8 SURFACEANDPANEL.COM

FROM THE PRESIDENT Send your thoughts and messages on this issue and article to Patrick at padams@526mediagroup.com

DYNAPRO

Made in Austria

Back by Popular Demand

The slide that defined a category is back. Designed and assembled in Austria, Dynapro 2D undermount slides set the standard for superior running performance, silent operation, and effortless motion. Its internal, synchronized rack and pinion system and multiple front-locking device options make it the smoothest and most versatile slide on the market.

Give your cabinetry the best with Dynapro.

www.grassusa.com

Doing What You Can With What You Have

Having recently returned from this year’s recordbreaking KBIS, I was struck by the scale and spectacle of what we can achieve when we pool our resources and ideas. Yet, amid the grand displays and cutting-edge innovations, a powerful reminder resonated with me: the most impactful changes often begin not from abundance but from making the most of what we already have

This principle of doing what you can with what you have is not just a guideline for those with limited resources; it's a universal approach that champions creativity and determination over sheer scale and capital. It teaches us that our contributions, no matter how small, are valuable and can set the stage for greater change.

Take, for example, a community garden project, which might seem worlds away from the high-tech polish of a trade show. It may have started with a single resident and a few seeds but has grown to become a community cornerstone that provides fresh produce and a green refuge in an urban neighborhood. This garden was cultivated with simple tools and a vision — a testament to starting where you are with what you have.

Similarly, in the realm of technology, innovations that now drive global industries were often born in humble settings. Think of the pioneers who worked from garages or college dorms, armed only with a great idea and a personal computer. Their initial setups were modest, but their visions were grand. These innovators didn’t wait for the perfect conditions; they created with what was at hand, demonstrating the profound impact of starting small.

My KBIS experience highlighted this beautifully. While I was not able to visit every single booth or see every new product at the show — even after walking more than 10 miles each day, I tried to prioritize and see and do as much as

It’s an approach that not only drives progress and innovation but also instills a sense of empowerment and resourcefulness in our daily lives.

possible. In other words, I did what I could. I find myself repeating this mantra when my kids’ activities overlap and I simply cannot be in two places at once or hit all the restaurant spirit nights during the school year.

Among the sprawling and flashy exhibits, I found it was the small, innovative solutions that resonated most — a reminder that you don’t need the biggest booth to have the biggest impact. It’s about leveraging what you possess: knowledge, skills, and a willingness to contribute.

In your own spheres of influence, whether personal or professional, consider how you can apply this principle. Perhaps it’s taking products seen at KBIS and the ideas behind them to creating improvements to your operational efficiency or sharing your insights with others who could not attend, turning your learnings into a resource for your whole community.

Each step we take, no matter how seemingly small, is a building block for larger change. By focusing on what we can do with the resources we currently have, we not only innovate but also foster a sustainable model of growth that benefits all.

So, as we reflect on our experiences and look to the future, let us embrace the opportunities that come from doing what we can with what we have. It’s an approach that not only drives progress and innovation but also instills a sense of empowerment and resourcefulness in our daily lives.

Here's to the big impacts of small beginnings and the endless possibilities they usher in.

Jennifer Williams, Managing Editor

10 SURFACEANDPANEL.COM JENNIFER WILLIAMS | MANAGING EDITOR | SURFACE & PANEL MAGAZINE | JWILLIAMS@526MEDIAGROUP.COM | 714-486-2735

FROM THE EDITOR

SOME SEE WOOD...

WE SEE PURPOSE

With strong industry partnerships, a commitment to sustainability, and an eye for biophilic design, we aim to enhance your business and the health of the planet. As North America's leading distributor and importer of hardwood lumber, specialty softwoods, and panel products, we are proud to partner with you to build unique solutions for the market.

THE SURFACE

Beyond the Surface is a new feature for 2024 in which prominent members of the industry are asked one question and share their best answers. Check out below on how you can be a part of this feature in our next issue.

What has been the most daunting challenge in creating today’s commercial spaces?

“Commercial interior design projects present plenty of challenges. One of the biggest challenges right now is prioritizing sustainability. Clients are increasingly focused on cutting unnecessary costs while also embracing eco-friendly design practices. Designers are responsible for creating spaces that are economically and environmentally conscious. This means finding ways to reduce electricity waste through efficient lighting, and HVAC systems. It also involves specifying sustainable, environmentally friendly materials like locally sourced products, rapidly renewable resources and carbonneutral surfacing materials. The goal is delivering designs that check all the boxes for green building standards and your client's sustainability objectives, without compromising on style or functionality. It can be difficult balancing all those priorities but getting it right benefits both the client's bottom line and environmental impact.”

— Meghan Howell, North American Design and Creative Director at Formica Corporation www.formica.com

12 SURFACEANDPANEL.COM

beyond

“One of the most daunting challenges in creating today's commercial spaces is striking the right balance between functionality, aesthetics, and sustainability. Designers and architects must consider not only the immediate needs of the occupants but also long-term environmental impacts and evolving trends in technology and work culture. Additionally, ensuring spaces are adaptable to future needs adds another layer of complexity.”

— David Carmona, Vice President of Sales, ALVIC

USA www. alvicusa.com

SHARE YOUR EXPERTISE WITH S&P!

Surface & Panel will ask industry experts one question for each issue, and will publish selected responses in each publication. The Q3 issue of Surface & Panel focuses on Commercial Spaces, so our question will be: What are you most looking forward to seeing at IWF? If you have a response, please email it to jwilliams@526mediagroup.com by June 30. Be sure to include “Beyond the Surface” in your email subject line. If selected, we will request a headshot, name and company title from you to feature in the magazine.

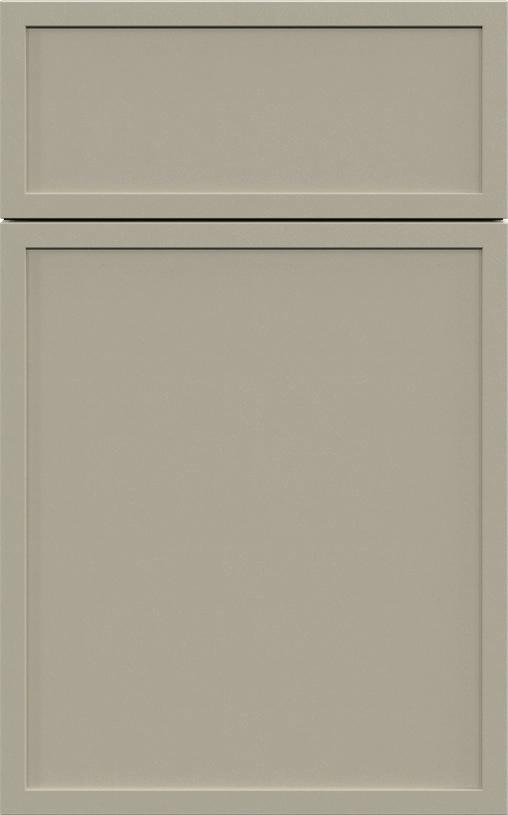

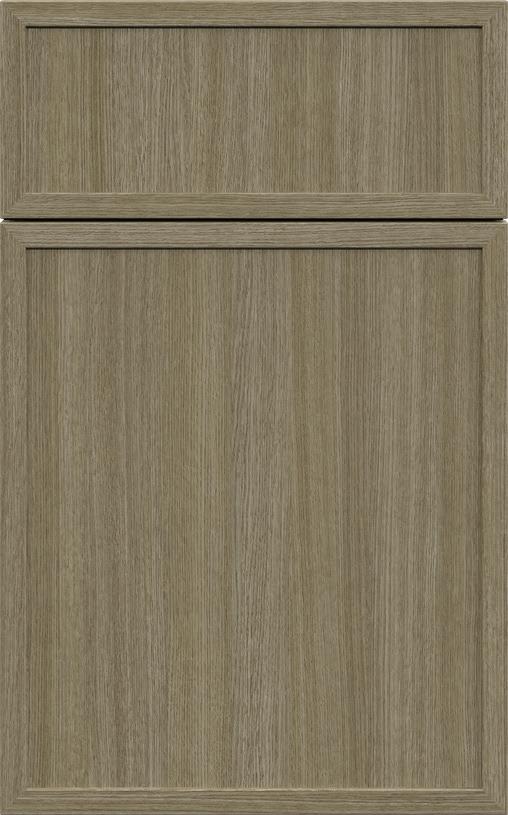

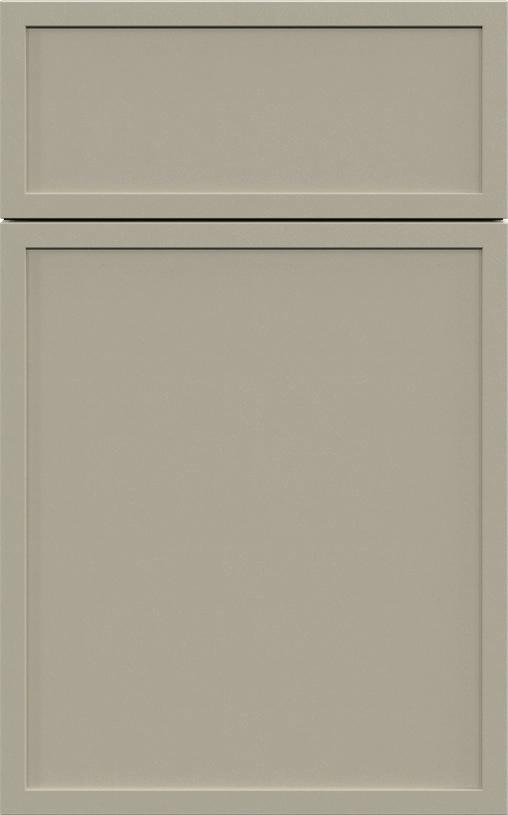

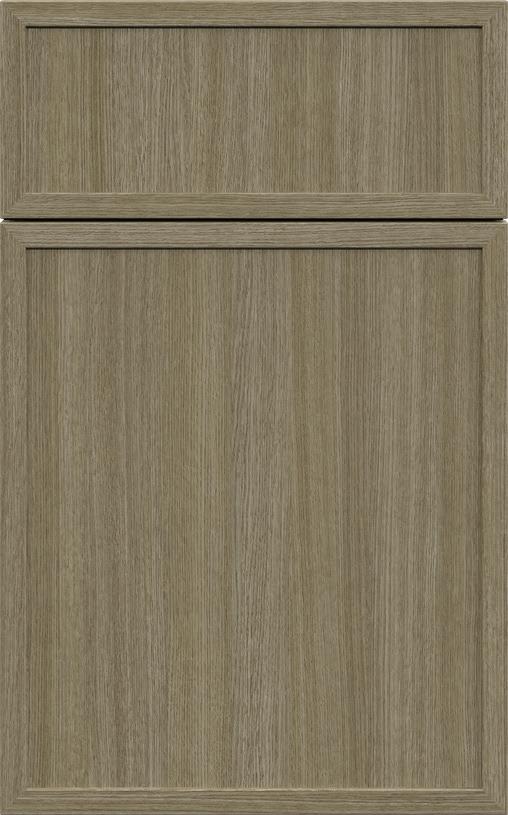

the new DS5m19 Doors — The Premier EuroCase door design library now includes a slim shaker option.

in Optimat, Roücke HD and the four newly added woodgrain finishes to a new textured melamine line: Roücke Moraine. DS5m19 doors are also available with a framed for glass option.

SURFACE & PANEL • Q2 2024 13

premiereurocase.com | sales@premiereurocase.com | 303.373.9718 | 12000 East 56th Avenue, Denver, Colorado 80239 Meet

Optimat Metallic Beige: DS5m19 Roücke Moraine Nutmeg Ri Cut Oak: DS5m19 New

Ri Cut

Ri

Beige

Visit premiereurocase.com to order samples for your next project

Roücke Moraine finishes from le to right: Natural

Oak, Nutmeg

Cut Oak,

Telluride Oak and Espresso Telluride Oak Available

20 YEARS COMMERCIAL SPACESof

Ever-Evolving Commercial & Retail Spaces

THE PAST TWO DECADES have witnessed a profound transformation in commercial design, a field that has been continuously redefined by technological advances, changing consumer preferences, and evolving cultural contexts.

From 2000 to 2019, ecommerce grew from 0.9 percent of all retail sales to 10.6 percent, with sales jumping to 14.6 percent in 2020, where they have remained steady, according to data from the U.S. Census Bureau. That seismic shift has altered the face of brick and mortar retailers and caused many to rethink their store design and functionality.

At the turn of the millennium, commercial design was largely dominated by a utilitarian approach that emphasized function over form. The aesthetic was clean and minimalistic, mirroring the technological optimism of the era. Online retail was in its infancy and brick and mortar stores reigned supreme — particularly big-box stores. Brands like Apple were pivotal in marrying functionality with sleek, sophisticated design, setting a precedent that would influence countless others. As the digital age progressed, so too did the tools, materials and methodologies designers employed. More sophisticated graphic design software and 3D modeling opened new avenues for creativity and experimentation. Materials trended

towards the Jetsons-type futuristic aesthetic, and advances in surfacing materials helped meet that need.

The mid-2000s marked a shift towards consumercentric design philosophies, with emotional branding, experiential retail, and user-focused product designs becoming paramount. Companies began to understand the importance of creating an emotional connection with their audience, leading to designs that were not only functional but also resonant on a personal level. This period also saw the rise of sustainable design practices as global awareness of environmental issues grew, prompting designers to reconsider materials, production processes, and the lifecycle of products. This attention to sustainability was not lost on manufacturers, who sought to demonstrate their ecofriendly materials to designers and architects.

In recent years, the COVID era rapidly escalated the rise in ecommerce and many consumers haven’t looked back. Retailers have had to adapt, with the trend more towards local, specialized retailers over the big-box behemoths, and individual storefronts over the shopping malls made popular in the 1980s. The integration of digital technology has further transformed today’s commercial design, with augmented

14 SURFACEANDPANEL.COM

CONTINUED ON PAGE 16 ›

TOP LEFT: STEVENS INDUSTRIES BUILT AND INSTALLED A MAJORITY OF THE CASEWORK AND MILLWORK FOR THE BORGESS MEDICAL CENTER IN KALAMAZOO, MICHIGAN, INCLUDING THIS NURSES’ STATION FROM THE Q2 2006 ISSUE OF S&P

ABOVE CENTER: THE DESIGN TEAM FOR THE NEWLY RENOVATED CRAYOLA EXPERIENCE IN EASTON, PENNSYLVANIA (THE BIRTHPLACE OF CRAYOLA CRAYONS) WAS GIVEN THREE OBJECTIVES: MAINTAIN THE BRAND, MAKE THE PRODUCT SHINE AND ENSURE THE STORE CAN STAND UP TO HEAVY TRAFFIC. FROM THE Q3 2014 ISSUE OF S&P

ABOVE RIGHT: PHOTOGRAPHER VITO PALMISANO CAPTURES THE DESIGN VERSATILITY OF MDF AND THE BEAUTY OF POWDER COATED SURFACING IN THIS ARTISTIC WORK SURFACE, MANUFACTURED BY WORKRITE ERGONOMICS. FROM THE SPRING 2003 ISSUE (FIRST ISSUE) OF S&P

LEFT: B+N'S ICONIC PANEL SERIES FEATURES LARGE-SCALE DESIGNS ROUTED INTO MDF PANELS AND THEN MEMBRANE-PRESSED WITH 3D LAMINATE FILMS, CREATING THE RIGHT ENVIRONMENT IN ECCO SALON LOCATIONS. FROM THE Q4 2017 ISSUE OF S&P

BELOW: THE LOBBY, UPSTAIRS BAR AND DOWNSTAIRS BAR AT THE LIZ AND ERIC LEFKOFSKY ARTS AND EDUCATION CENTER AT CHICAGO’S RENOWN STEPPENWOLF THEATRE, DESIGNED BY FC STUDIO INC. FROM THE Q1 2022 ISSUE OF S&P

SURFACE & PANEL • Q2 2024 15

20 YEARSof

& COMMERCIAL SPACES

reality, virtual reality, and artificial intelligence no longer futuristic concepts but practical tools that enhance interactivity and engagement in design. The ongoing digital revolution challenges designers to rethink the user experience in an increasingly virtual world. And what was once a trend to watch has now become an ingrained part of design, with sustainable materials still catching the attention of designers and consumers alike.

Many brick and mortar retailers have had to quickly adapt to the ever-changing needs and wants of consumers, who are now adept in online shopping. But the in-person experience is not lost— even online shopping pioneer and giant Amazon has retail stores now across the country. As far as materials being used today and going into the future, the amazing realism now achieved through digital printing, along with the innovations in textured and adaptable surfaces (including anti-bacterial and anti-fingerprint coatings) ensure that the surface & panel industry will continue to be in demand.

16 SURFACEANDPANEL.COM

S P UNITING MATERIALS, TECHNOLOGY AND DESIGN COVID IN THE INDUSTRY THE FUTURE OF POP-UP RETAIL TRENDS IN MATERIALS AND DESIGN HELPING CUSTOMERS KEEP THEIR PROMISES IWF PREVIEW Q2 • 2020

‹ CONTINUED FROM PAGE 14

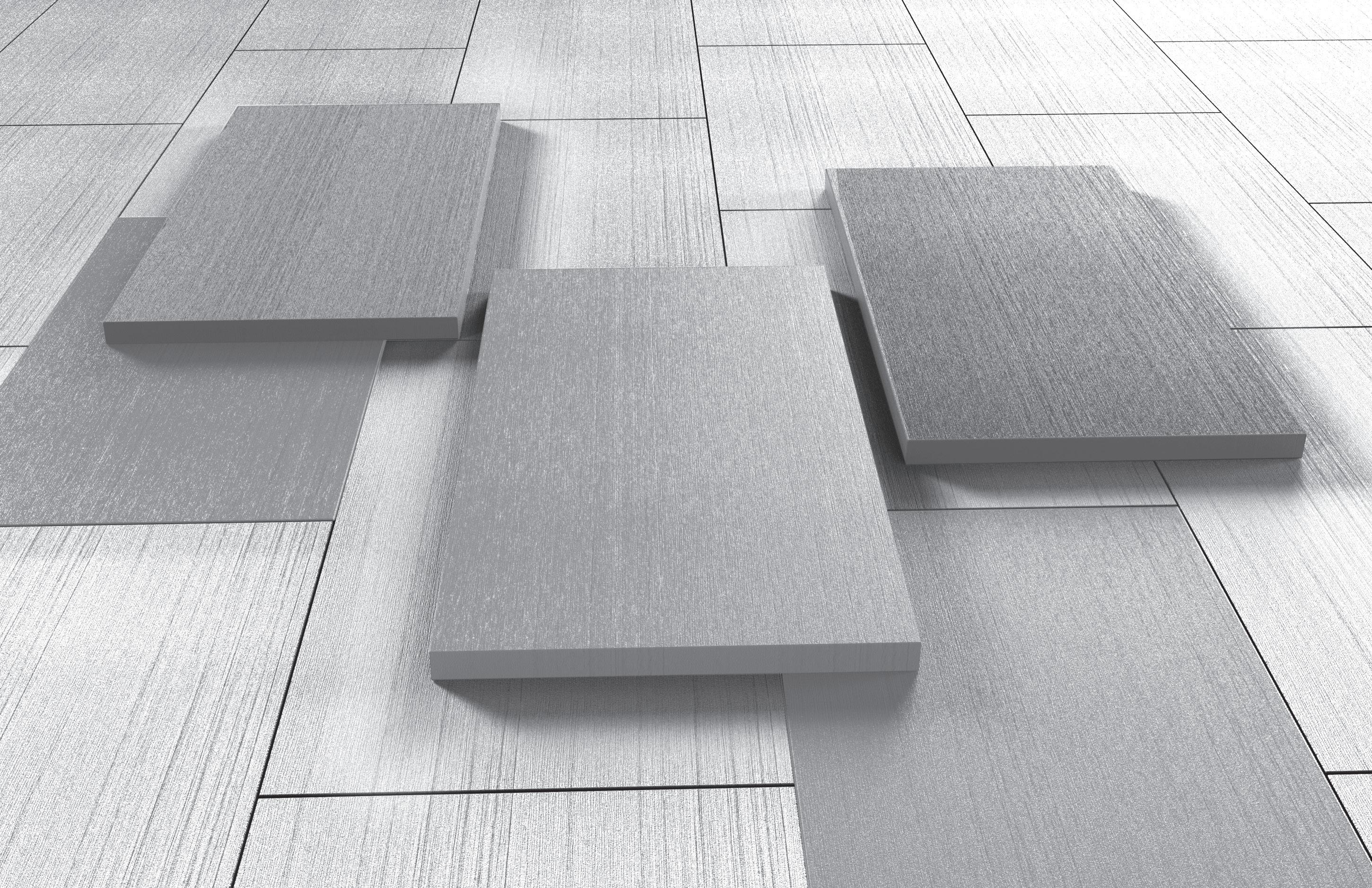

OPPOSITE PAGE TOP: SERICA 3D FOILS FROM ALFATHERM NORTH AMERICA PRESENT A WIDE RANGE OF NEW WOOD GRAIN EMBOSSING COLORS AND DESIGNS MADE POSSIBLE BY EXCLUSIVE AND INNOVATIVE EIR (EMBOSSED-IN-REGISTER) TECHNOLOGY, WHICH ENHANCES THE WOOD EFFECT. FROM THE Q4 2017 ISSUE OF S&P

OPPOSITE PAGE LEFT: THE TEMPORARY NATURE OF POP-UP STORES MEANS THE PHYSICAL SPACE NEEDS TO BE DESIGNED TO BE HIGHLY CUSTOMIZABLE AND EASY TO CHANGE QUICKLY. AND RETAIL ISN’T THE ONLY INDUSTRY GETTING IN ON THE POP-UP SCENE — DINNER WITH A VIEW OPENED DOME-STYLE FINE DINING RESTAURANTS ACROSS THE COUNTRY, INCLUDING THIS ONE IN LIBERTY STATION, SAN DIEGO. FROM THE Q2 2020 ISSUE OF S&P OPPOSITE PAGE CENTER: FUELED BY A GLOBAL PERSPECTIVE, PRODUCT LINES FROM OFFICE INTERIORS GIANT HAWORTH, INC. ARE CONTINUALLY EVOLVING TO MEET WORKPLACE TRENDS. FROM THE Q3 2014 ISSUE OF S&P

TOP LEFT: OH-WOW’S EDGY RETAIL SPACES USE STRONG, STRAIGHT, DIMENSIONALLY STABLE MDF PANELS TO CREATE FIXTURES WORTHY OF THEIR ARTISAN BOOKS. FROM THE SUMMER 2010 ISSUE OF S&P

TOP RIGHT: AT ECCO SALON’S WAUNAKEE, WISCONSIN LOCATION, A LARGE CUSTOM DESK SHOWCASES WILSONART QUARTZ COUNTERTOPS IN SANGDA FALLS. THE FACE OF THE DESK FEATURES HPL IN CAFELLE WITH A FINE VELVET FINISH. FROM THE Q4 2017 ISSUE OF S&P.

ABOVE: ENGINEERED MATERIALS, LIKE THESE INNOVATIVE PANELS FROM ATI DECORATIVE LAMINATES AT A HARLEY-DAVIDSON DEALERSHIP, CAN MEET ENGINEERED NEARLY ANY DESIGN OBJECTIVE. FROM THE Q3 2014 ISSUE OF S&P

SURFACE & PANEL Q2 2024 17

paintinG the future! NEWwww.giardinagroup.com USA via V. Necchi, 63 I-22060 Figino Serenza (CO) phone +39 031 7830801 info@giardinagroup.com www.giardinagroup.com Giardina Group Usa 4850 Crittenden Drive Suite 4B Louisville, KY 40209 phone: 1-502-361-1003 1-877-631-1003 www.giardinausa.com summer 2010 & u NITING m AT er IAL s T e CHNOLOGY AND D es IGN Q3 2014 UNITING MATERIALS, TECHNOLOGY AND DESIGN mHOUSE RISING AN INTEGRATED PALETTE fOR EvOLvING DESIGN RETAIL wITH ICONIC ALLURE OPENING THE DOORS Of OPPORTUNITY: NEw MARkETS fOR NEw MATERIALS fINDING THE SwEET SPOT: UPDATE ON LIGHTwEIGHT PANEL IN NORTH AMERICA COLOR ME DURAbLE SPECIAL SECTION Finishing matters AT THE SHOw! &

Revolutionizing Commercial and Retail Spaces

BY JENNIFER WILLIAMS

The commercial and retail environments have always been at the forefront of adopting innovative materials and technologies to enhance aesthetics, functionality, and customer experiences.

In recent years, the retail industry has witnessed a significant transformation due to the rise of e-commerce that initially posed a challenge to brick-and-mortar stores, leading to a so-called "retail apocalypse." However, far from succumbing to this fate, physical retail spaces are experiencing a renaissance by integrating digital technologies that help meet their customers’ needs.

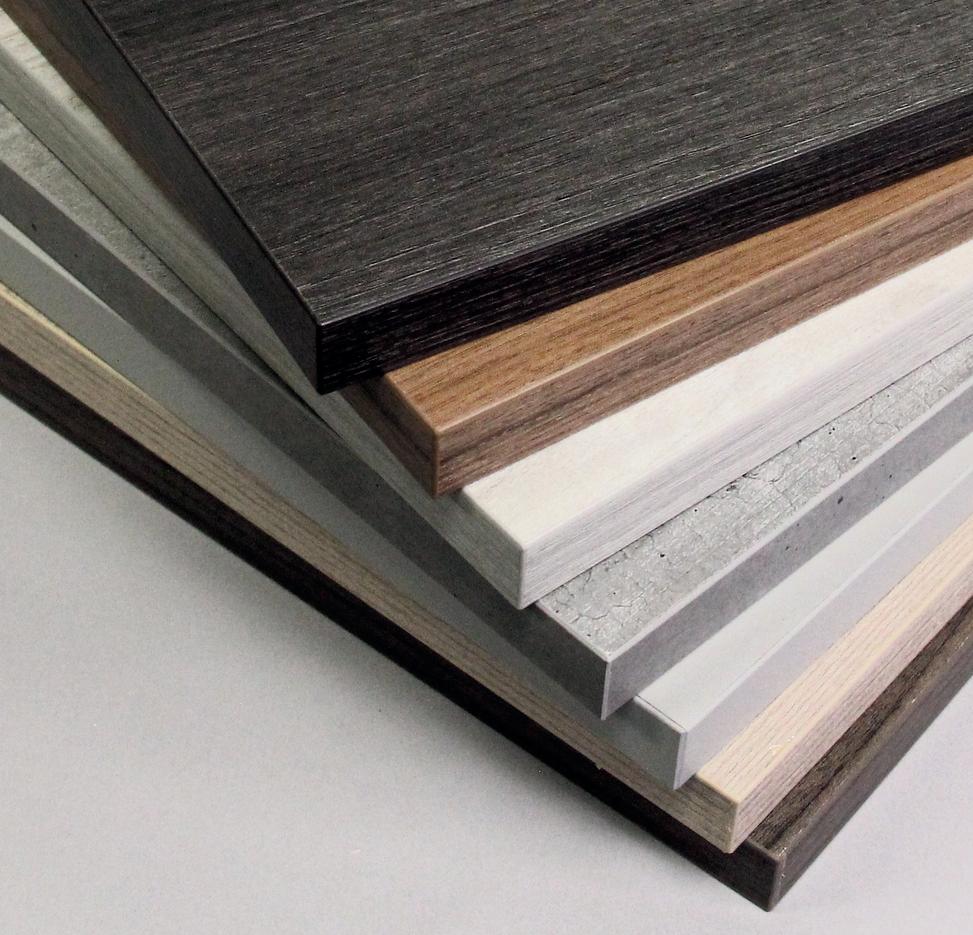

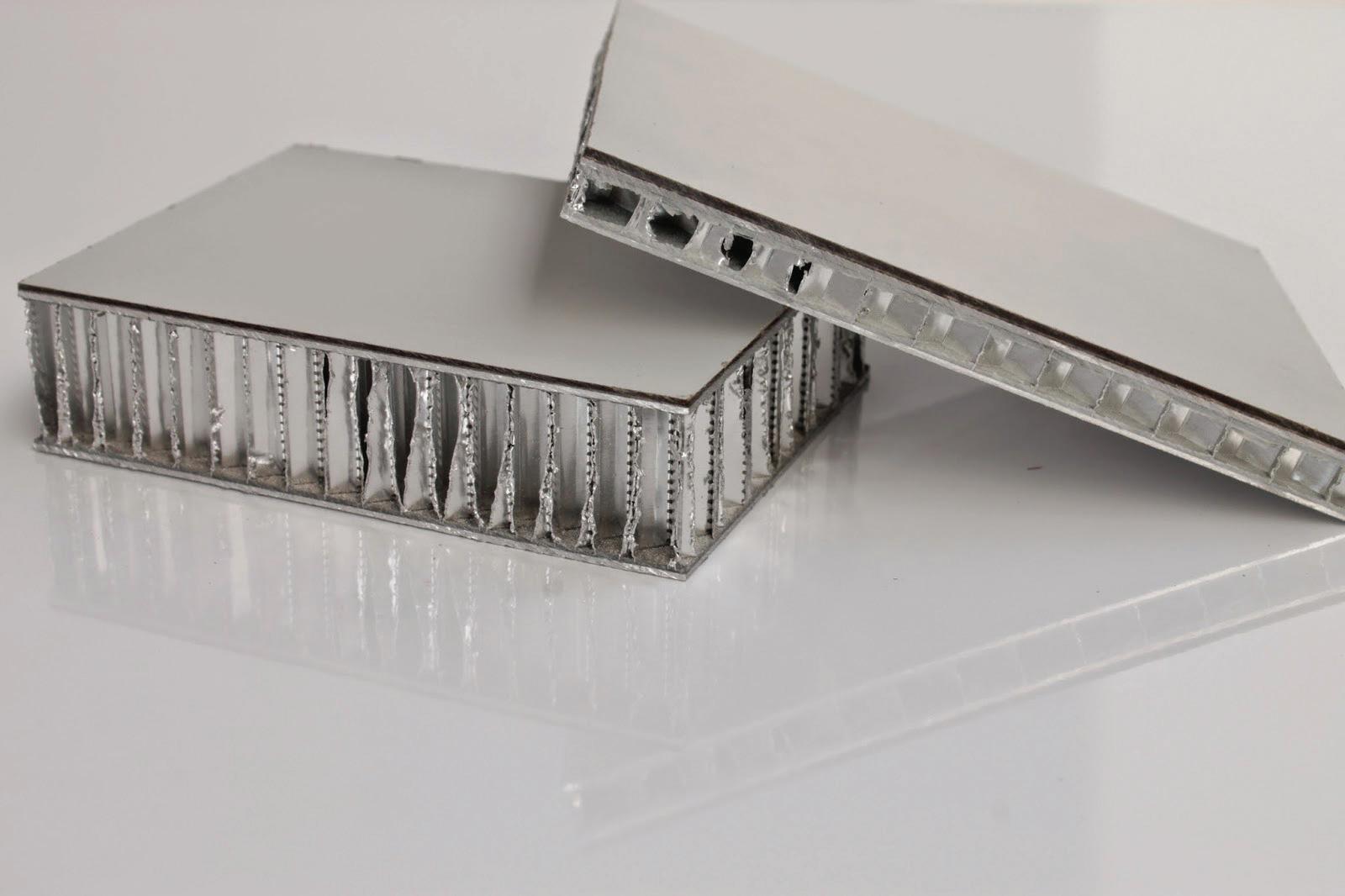

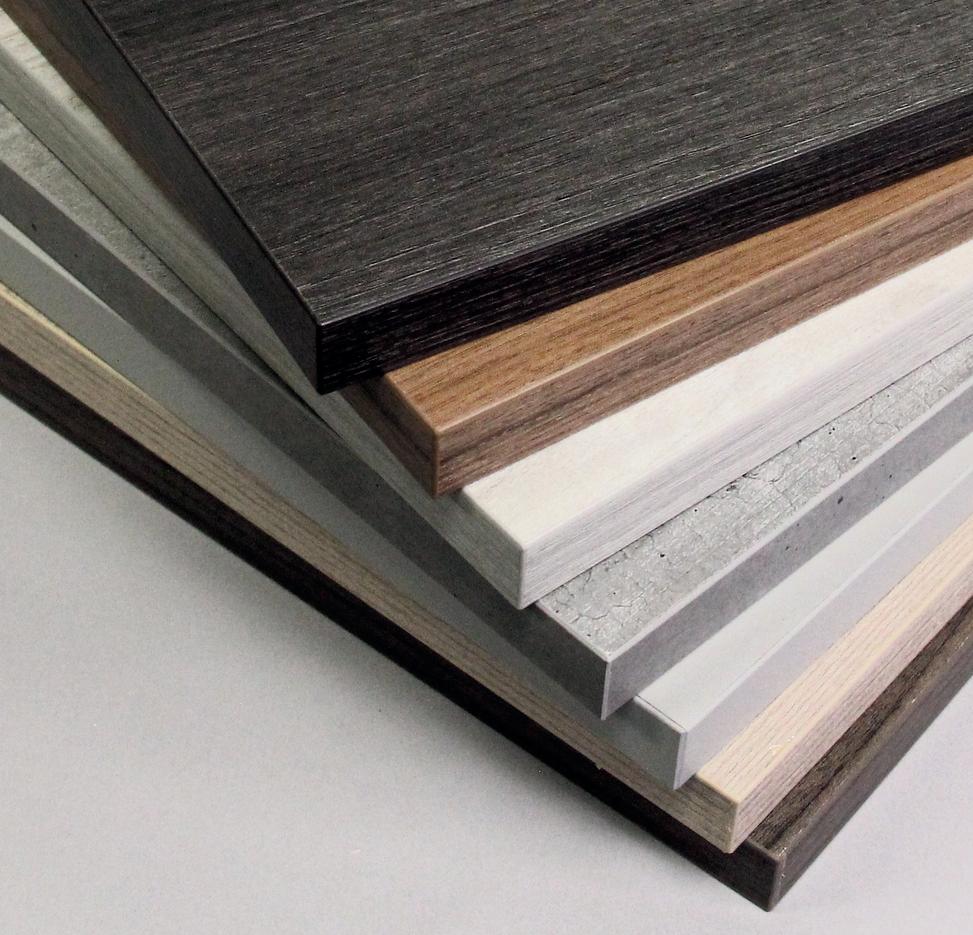

The use of new materials emerged as a game-changer, offering unparalleled flexibility, durability, and design possibilities. As innovations continue, these materials are transforming commercial and retail spaces with a focus on specialization. Engineered panels, including high-pressure laminates, composite materials, and architectural panels, have become staples in the design and construction of commercial spaces. Their appeal lies in their ability to closely mimic natural materials

like wood and stone, while offering superior durability and ease of maintenance. These specialized laminates allow a commercial space to exactly reflect a desired aesthetic.

Adaptive retail spaces continue to be popular, in which the layout and displays can be easily modified to suit different themes or product launches. A lot of this flexibility comes from specialty hardware, including hidden sliding door systems to customizable shelving, which plays a crucial role in maximizing the functionality and visual appeal of commercial spaces. Modular shelving systems and flexible display units enable retailers to quickly reconfigure spaces, offering a fresh experience to customers with each visit.

The continued integration of technology is setting the stage for the future of commercial design, with smart panels that can change appearance or display interactive content promising to create dynamic and engaging environments that can adapt to the evolving needs of businesses and customers alike. And it's clear that the boundary between physical and digital retail spaces will continue to blur.

18 SURFACEANDPANEL.COM

CONTINUED ON PAGE 20 ›

OPPOSITE PAGE: LIGHT STAINLESS ALUMINUM FROM CHEMETAL IS USED ON THIS SET FOR THE NBA ON TNT, STUDIO J IN ATLANTA. PHOTO BY JACK MORTON

TOP LEFT: BRUSHED PEWTER ALUMINUM FROM CHEMETAL IS USED ON THE ESPN SPORTSCENTER SET. THESE SPECIALIZED MATERIALS FROM CHEMETAL ARE IDEAL FOR INLAYS, CUT-TO-SIZE, STRIPS, PANELS, AND ANY OTHER APPLICATION IN WHICH THE MODERN, LUXURIOUS, AND ENERGETIC LOOK OF REAL METAL IS DESIRED. “FOR A SET DESIGNER, THEY MIGHT OPT FOR A DARKER, LESS REFLECTIVE BRUSHED ALUMINUM SINCE THEY ARE MANAGING LIGHTING HOT SPOTS,” SAYS CHEMETAL CREATIVE DIRECTOR AND PRESIDENT GEOFF SCHAEFER. VISIT WWW.CHEMETAL.COM FOR MORE INFORMATION. PHOTO BY RAEFORD DWYER, COURTESY OF CHEMETAL

CENTER LEFT: ITALIAN LUXURY ACCESSORIES BRAND VALEXTRA CHOSE A STRIKING WALL TO DISPLAY ITS PRODUCTS WHEN IT OPENED ITS MIAMI LOCATION IN 2019. DESIGNED BY ARANDA\ LASCH, THE GOAL WAS TO CREATE AN ORIGINAL RETAIL SETTING INSPIRED BY THE COMPANY’S MILANESE ROOTS. THE EYE-CATCHING BACK WALL, CLAD IN TREEFROG’S DECORATIVE ALPI WOOD VENEER IN SOTTSASS GREY, DESIGNED BY THE LATE ETTORE SOTTSASS, A CELEBRATED ARCHITECT AND DESIGNER WHO PIONEERED THE MEMPHIS DESIGN MOVEMENT IN THE 1980S (THINK BOLD AND CLASHING COLORS). THIS DESIGN WAS REINTRODUCED IN MORE MUTED WOOD TONES BY TREEFROG’S ITALIAN SUPPLIER. AND AS PART OF ITS 20TH ANNIVERSARY, TREEFROG RECENTLY MADE ALL OF ITS PREFINISHED VENEERS EVEN BETTER, SWITCHING TO A MORE FLEXIBLE AND GREENER COLOR-MATCHED WOOD BACKER THAT ELIMINATES THE BROWN LAMINATE BACKER AND CREATES CLEANER EDGES. VISIT WWW. TREEFROGVENEER.COM FOR MORE INFORMATION. PHOTO BY ROBIN HILL, COURTESY OF CHEMETAL BOTTOM LEFT: THIS TASTING ROOM FOR THE SPIRITS MAKER SCHWARZE UND SCHLICHTE IN OELDE, GERMANY, IS EQUIPPED WITH SEVEN-METER HIGH SHELVES TO NOT ONLY MAKE OPTIMUM USE OF THE ROOM HEIGHT, BUT TO BE CONVINCING IN TERMS OF DESIGN. DESIGNED BY THE TEAM OF RSA ARCHITEKTEN LIPPSTADT, THIS SPACE USES ST10 HAMILTON OAK FROM EGGER, IDEAL FOR LARGE SURFACES WITH ITS XL REPEAT, AND EGGER’S PERFECTSENSE PREMIUM LAMINATES MATT (FORMERLY TOPMATT LAMINATES) WITH ITS SUPER-MATTE, VELVETY-SMOOTH LACQUERED SURFACE FEATURING FINGERPRINT RESISTANCE. THESE ABRASION-, IMPACT- AND SCRATCHRESISTANT LAMINATES ARE IDEAL FOR USE ON HIGH-TRAFFIC VERTICAL SURFACES. THE BAR FRONT IS ONE OF CHEMETAL’S SUPER FUNCTIONAL, EASY-TO-USE BRUSHED METAL DESIGNS THAT ECHO THE POPULAR STAINLESS APPLIANCE LOOK. THE MATERIAL COMES IN SOLID ANODIZED ALUMINUM THAT BENDS EASILY AND CREATES CLEAN EDGES OR HPL ALUMINUM THAT’S MORE DENT-RESISTANT AND FORGIVING FOR PEOPLE USED TO FABRICATING WITH LAMINATE. VISIT WWW.EGGER.COM AND WWW.CHEMETAL.COM FOR MORE INFORMATION. PHOTO COURTESY OF CHEMETAL

SURFACE & PANEL • Q2 2024 19

‹ CONTINUED FROM PAGE 18

Innovations in processing and finishing have created specialized finished surfaces — many offering unparalleled durability and unique features including anti-fingerprint, impact resistance, or antimicrobial properties. These features can enhance the functionality of the space by making it more user-friendly and hygienic. And advances in digital scanning and printing allow for customization in colors, patterns and even textures on these surfaces.

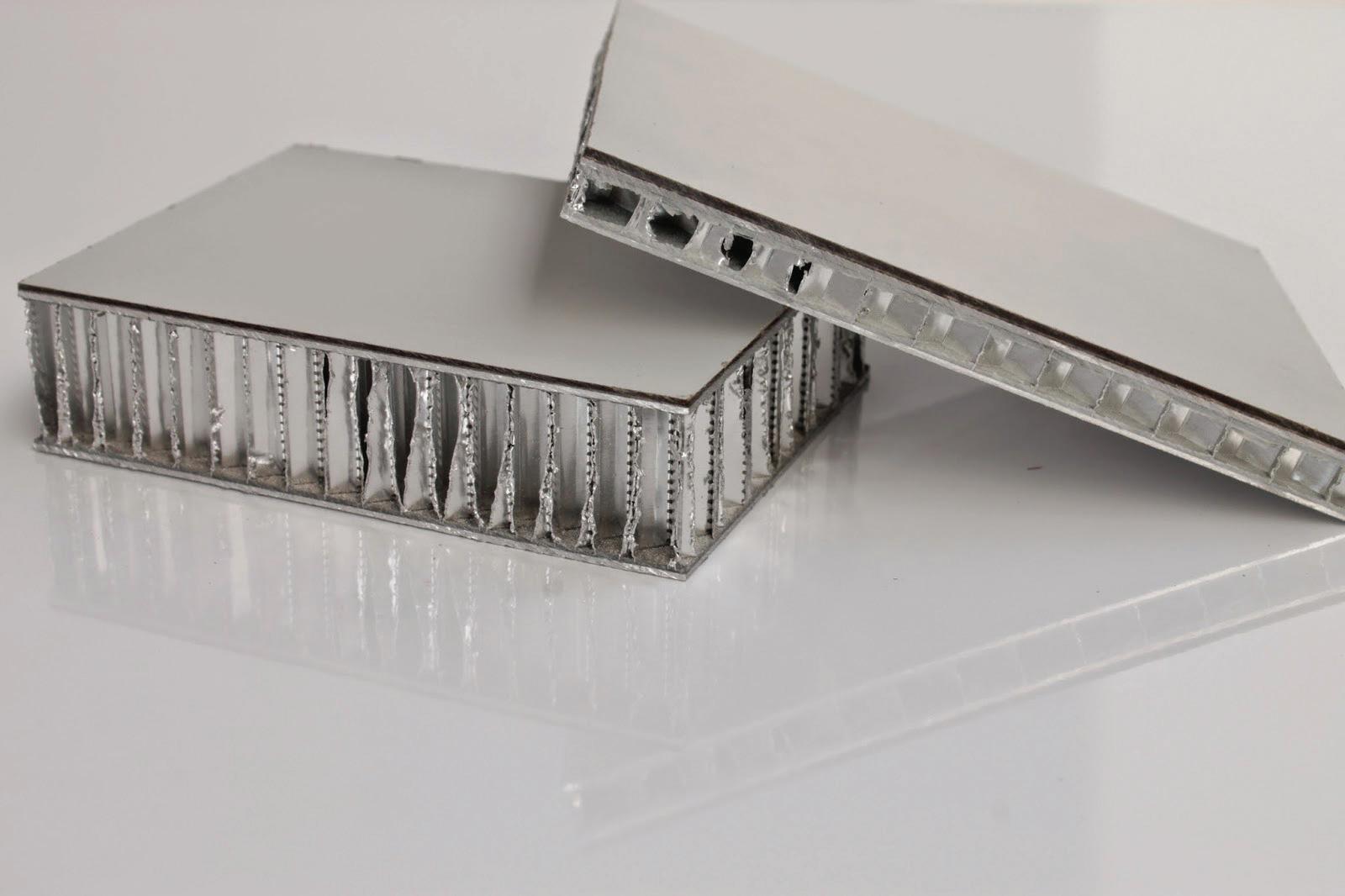

The advancement of composite panels has enabled architects to push the boundaries of commercial design. Lightweight yet sturdy, these panels offer enhanced insulation properties and have been pivotal in the construction of energy-efficient buildings. And digital printing now allows for such large-format products, entire building facades can now be customized with a pattern — while maintaining durability.

“Imagine building facades that are not merely appealing but also weather-resistant, public spaces that maintain their beauty for years or interior walls with striking colors and finishes,” says Andrea Brotini, CROMATICA sales director with the Marcegaglia Group of Italy. “All this is reality, now.”

The COVID-19 Pandemic also affected the way we work, and workspaces have had to keep pace — many adopting the latest in surface innovations for the same reasons retail spaces are embracing them. From surfaces that offer antimicrobial finishes to touchless technologies and adaptable furniture designs, these trends are becoming more the norm.

ABOVE: THIS HOTEL LOBBY DESIGN FEATURES CALCUTTA MARBLE GREY FROM 3A COMPOSITES NEW MONARC COLLECTION, A RANGE OF NEW COMPOSITE WALL PANELS FOR INTERIOR SPACES ENGINEERED TO REDEFINE THE BOUNDARIES OF CREATIVITY AND FUNCTIONALITY IN THE COMMERCIAL MARKET. VISIT HTTPS://3ACOMPOSITESUSA. COM/MONARC FOR MORE INFORMATION. PHOTO COURTESY OF 3A COMPOSITES

20 SURFACEANDPANEL.COM

BELOW: TECHNOLOGY COMES TO TODAY'S COMMERCIAL SURFACES, WITH THE OPTION TO INCORPORATE WIRELESS CHARGING STATIONS INTO ANY NON-METAL SURFACE. FREEPOWER SAYS THEY'VE RECEIVED A LOT OF ATTENTION FROM HOTELS, RESTAURANTS AND BARS FOR THEIR LATEST PRODUCT, A FAVORITE AT KBIS THIS YEAR. PHOTO COURTESY OF FREEPOWER

Today’s offices are moving away from the traditional cubicle-centric layouts to more open-plan designs devised to foster collaboration and creativity. Coworking spaces also emerged from this trend, catering to freelancers, startups, and mobile workers, emphasizing flexibility and community.

The use of surfaced panels and specialty hardware in commercial and retail spaces is more than a trend; it's a strategic approach to creating environments that are adaptable, sustainable, and forward-thinking. As we look to the future, the continued evolution of these materials and technologies promises to further enhance the functionality and aesthetic appeal of retail and commercial spaces, making them more responsive to the changing needs of businesses and consumers. S P

SURFACE & PANEL • Q2 2024 21

BY DESIGN S P

We at Surface & Panel are constantly amazed by the new products and their applications in our industry. S&P By Design is an opportunity to share some of those innovations used in real projects around the world.

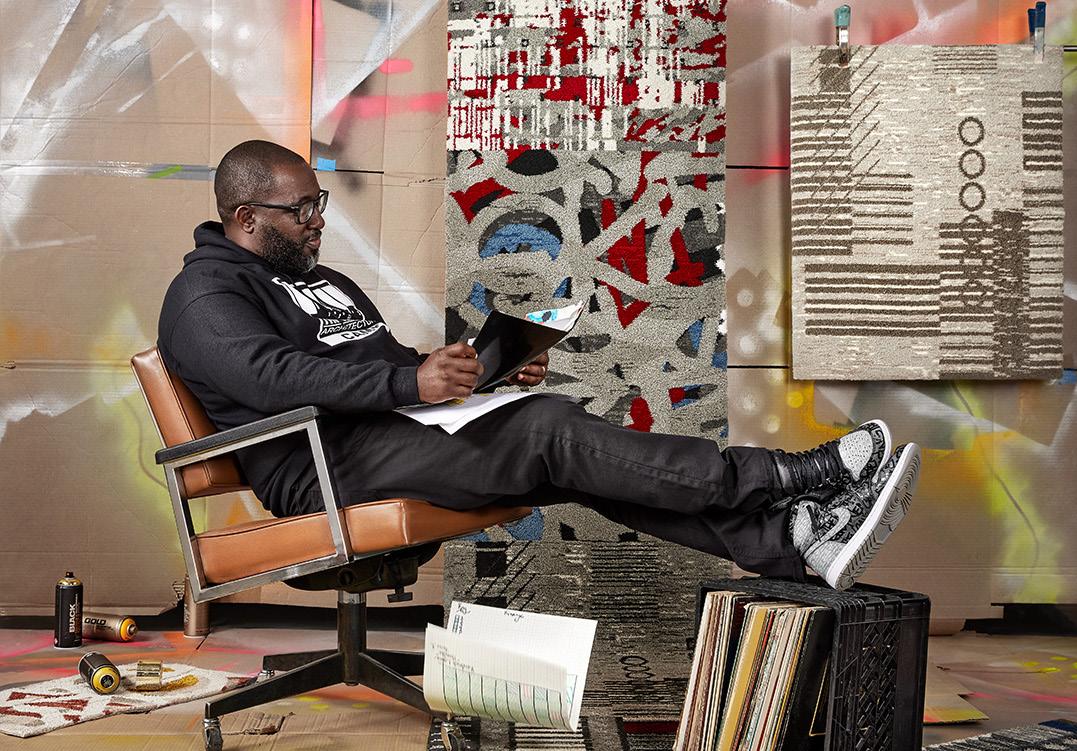

MUSIC EDUCATION COMPLEX AT TEXAS A&M UNIVERSITY-KINGSVILLE

Texas A&M University-Kingsville approached Houston-based custom millwork designer Brochsteins to help bring the vision for their new Music Education Complex to life — replacing an aging facility that no longer could serve the growing program. This project nearly tripled the music program’s space from 32,000 square feet to 90,000 square feet, and included a stunning, 500-person performance hall to visually enhance and provide a tangible demonstration of the department’s

contribution to the larger campus. The fabricators at Brochsteins worked with Kerfkore products in previous projects and determined their Flexboard panels offered the optimum solution to provide both the flexibility and density required for the wraparound balcony with varying heights.

When comparing the Flexboard panels to other alternatives, like bending plywood, to achieve this panel system design,

22 SURFACEANDPANEL.COM

▲

Flexboard was found to be the most efficient solution, and delivered a cost savings for the overall project budget of 73 percent. For the design team, leveraging Kerfkore panels to complete the balcony wrapper portion of this project offered tremendous benefits. For one, these flexible panels eliminated both the costly materials and extra labor installation required, helping to keep the project under budget and within the preferred timeline. Additionally, Flexboard panels were able to easily meet the specified density requirements for the project by simply double layering the panels throughout. In the end, Kerfkore’s flexible panels were essential to ensuring a fluid aesthetic for the wrapping, despite the varying heights and wave-like flow. Unlike other, resource-intensive products that would require templating and vacuum-pressed lamination efforts, Flexboard panels were able to alleviate any unnecessary stress and pressure in order to complete the project.

Photos by Cotton Global Disaster Solutions, courtesy of Kerfkore

BE A PART OF S&P IN 2024!

Help celebrate 20 years of Surface & Panel by sharing your interesting and innovative projects to be featured in S&P By Design! Submit 1-3 images and a brief explanation of the project, including materials used, along with your company name and URL to jwilliams@526mediagroup.com. You will be contacted if your project is selected for publication in an upcoming issue.

Our Q3 issue will be looking ahead to this year’s IWF in Atlanta, but projects of all kinds are welcome! The deadline for submissions for the Q3 issue is June 30.

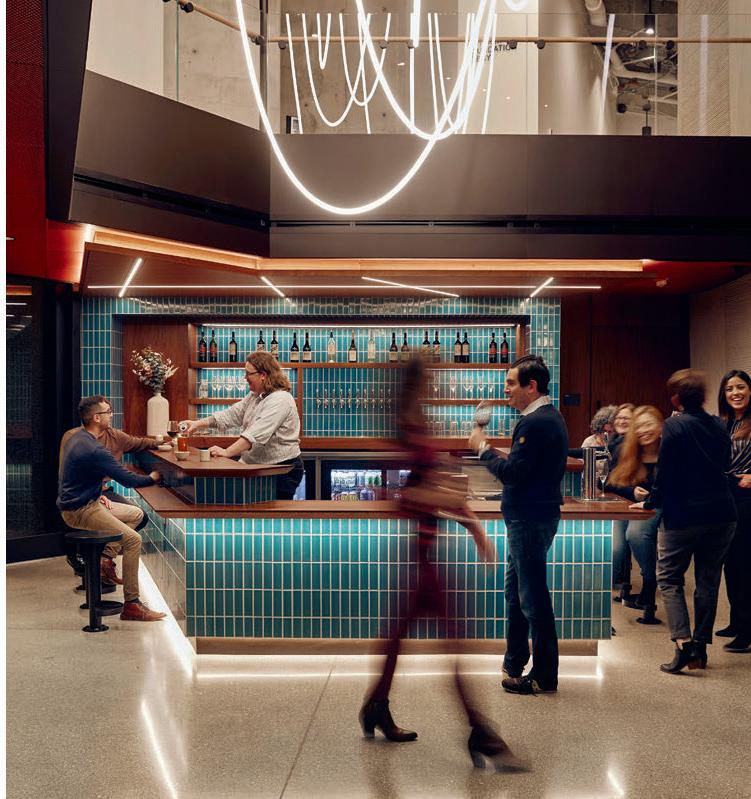

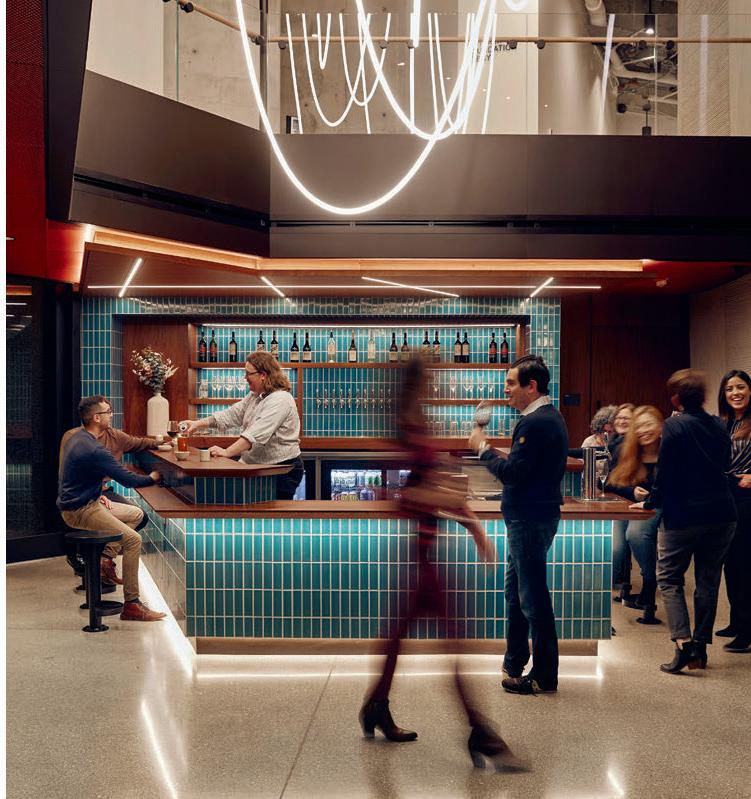

36 BELOW COCKTAIL BAR, PHOENIX, ARIZONA

An underground lounge where the combination of design, enticing refreshments, and matchless hospitality was a perfect place for installing the city’s tech phenomenon FreePower wireless charging system, which allows for a seamless, free-positioned charging area right in the bar top, thanks to a patented system that is installed underneath the surface. And while fabricators have found that materials like quartz offer the best clarity for seeing the charging halo light (which also features a remote control and color and fade options), it can work with any non-metal surface and you wouldn’t even know it’s there, says Jake Slatnick, FreePower CEO. “You can almost toss your phone and even if it slides to a stop, it'll still charge so it's large enough [at about 5 by 8 inches] to not have to worry—you have that convenience factor and that piece of mind that wherever your phone lands, it's gonna charge.”

The system can charge up to three phones at the same time, so there’s plenty of power to go around at the bar, says Slatnik, whose company recently took home not only the Best of KBIS award this year but also the People’s Pick in the DesignBites Award. “We're seeing a really a positive response from all kinds of industries—home builders want this in their homes, hotels want it in their common areas and nice rentals want it for their nightstands or their bathroom vanities, restaurants and bars are interested, and the list goes on.”

“This is surface power and it belongs in surfaces everywhere,” he adds. “It's exciting to see where it’s being used…some people are coming up to us with places that we had never even thought of.” Slatnik says he has plans to expand the charging area, perhaps making it to where an entire tabletop or countertop can act as a wireless charger. “That’s a little overkill, to be honest,” he says, “and it would take a bit more engineering and technology to do, but yeah, why not? That’s definitely a long-term dream.” Visit www.freepower.io for more information.

Photos courtesy of FreePower

SURFACE & PANEL • Q2 2024 23

▲

C From Niche to Necessity

NEW TECHNOLOGIES DRIVE A SURGE IN CNC POPULARITY

BY JENNIFER WILLIAMS

omputer Numerical Control (CNC) machines are revolutionizing the machining industry by offering unprecedented precision, efficiency, and automation.

As a result, the CNC machines market, valued at $66.74 billion in 2023, is expected to surge up to $154 billion by 2032, driven in large part by the increasing demand for automation and efficiency across various sectors. CNC machines are expected to offer continued advancements in machine precision, workflow streamlining, and project completion speeds.

The implementation of new CNC technologies is driven by several trends and innovations, including the integration of additive manufacturing (AM) or 3D printing technology combined with traditional CNC machining. This allows for the creation of parts with complex geometries that were previously unattainable, offering new design possibilities, reducing material waste, and increasing production efficiency.

“Emerging machining advancements typically set the course for novel tooling concepts and designs,” says Karin Deutschler,

CEO of GDP Tooling. “As machining speeds escalate, the demand for tools capable of meeting heightened requirements intensifies. These tools must facilitate efficient chip evacuation, uphold surface finish standards, and whenever feasible, prolong tool life to manage costs effectively.”

Industry 4.0

Industry 4.0 is the integration of intelligent digital technologies into manufacturing processes. Experts say these technologies are key in advancing the CNC industry by offering increased flexibility and enabling CNC machines to adjust in real-time to varying production demands and thereby enhancing operational efficiency and cost-effectiveness.

The technologies that make up Industry 4.0 include:

• Industrial IoT networks

• AI

• Big Data

• Robotics

24 SURFACEANDPANEL.COM

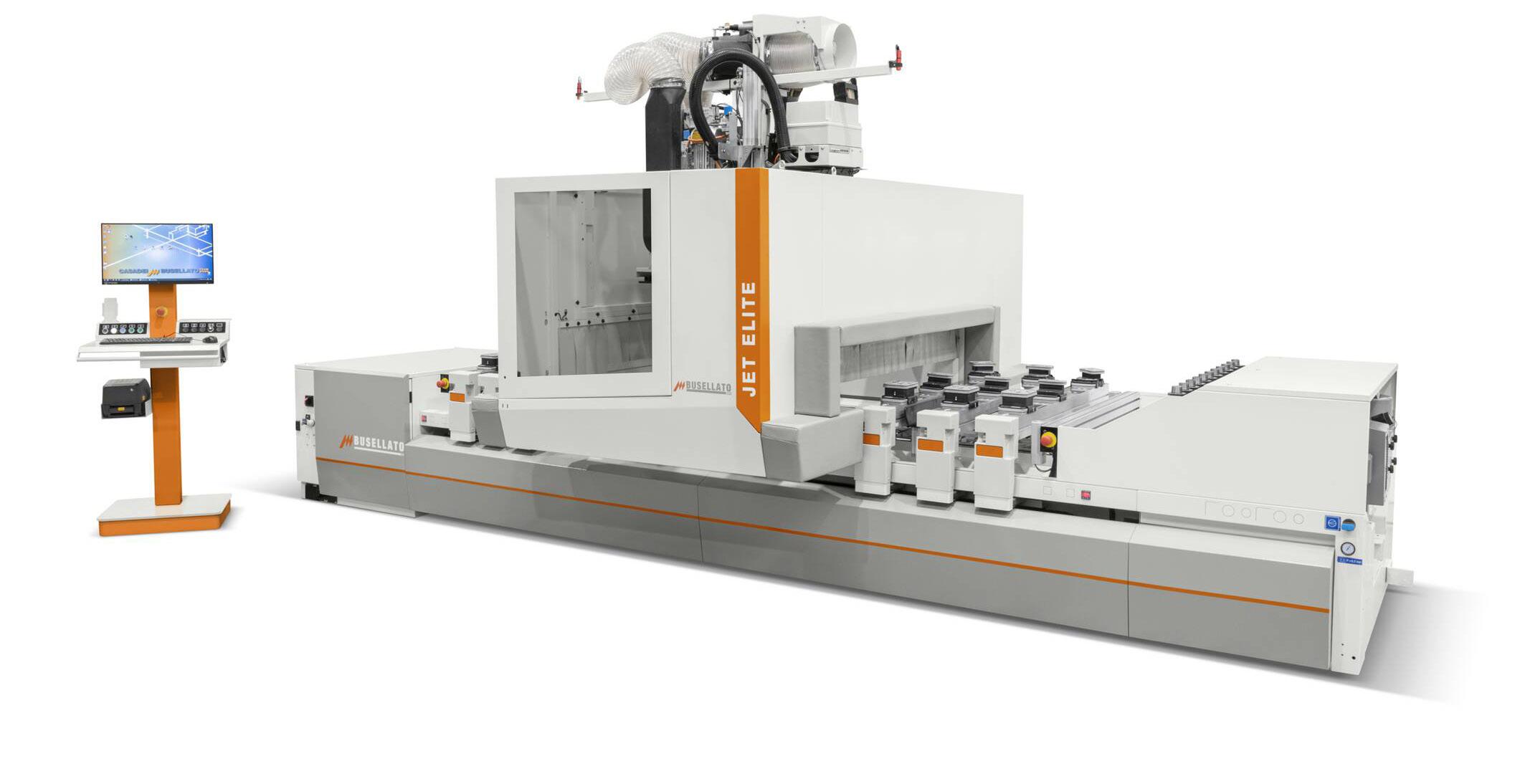

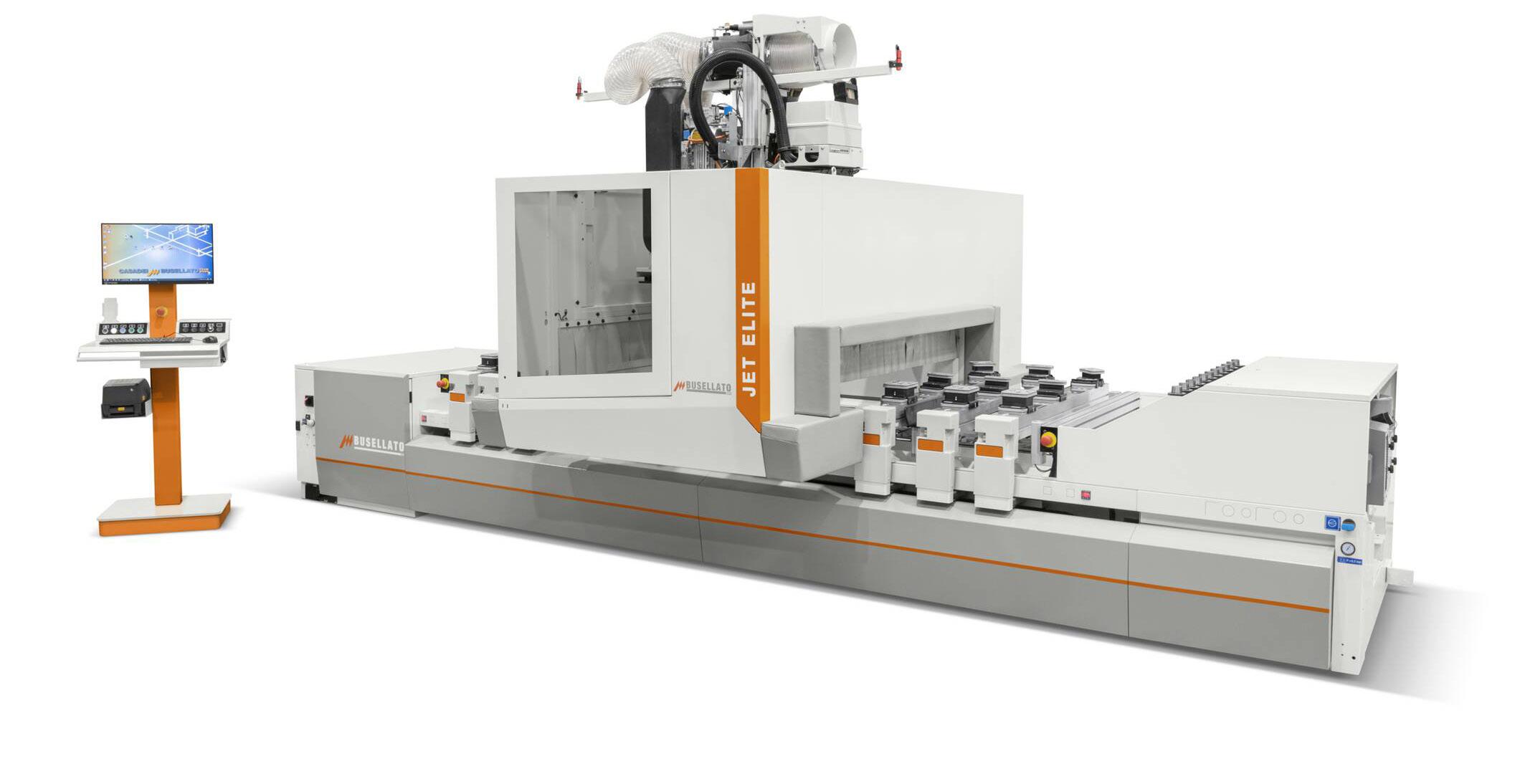

LEFT: THE JET ELITE CNC WORKING CENTER FROM BUSELLATO OFFERS THE MAXIMUM OF TECHNOLOGY IN A MINIMUM OF SPACE, AND QUALITY WITHOUT COMPROMISES. WWW.CASADEIBUSELLATO.COM

REDESIGNED FROM THE GROUND UP, UTILIZING AN INDUSTRY LEADING FANUC CONTROL & STATE-OF-THE-ART HSD SPINDLE. THE SMARTSHOP 2 ELITE GIVES YOU THE CONFIDENCE TO HANDLE THE HIGHEST PRODUCTION LOADS WITH EASE, WHILE GUARANTEEING ACCURACY & CUT QUALITY.

• Automation

• Analytics

• Additive manufacturing

LEFT: THE JET ELITE CNC WORKING CENTER FROM BUSELLATO OFFERS THE MAXIMUM OF TECHNOLOGY IN A MINIMUM OF SPACE, AND QUALITY WITHOUT COMPROMISES. WWW.CASADEIBUSELLATO.COM

BELOW: AUTOMATE AND ELEVATE YOUR PRODUCTION PROCESS, CONFIDENTLY HANDLING EVEN THE MOST DEMANDING WORKLOADS WITH PRECISION AND SUPERIOR CUT QUALITY WITH THE SMARTSHOP 2 ELITE FROM LAGUNA TOOLS — METICULOUSLY CRAFTED FOR THE MODERN ARTISAN. ENGINEERED WITH A CUTTING-EDGE FANUC CONTROL SYSTEM AND A STATE-OF-THE-ART HSD SPINDLE, THIS MACHINE IS A GAME-CHANGER. WWW.LAGUNATOOLS.COM

BELOW: SHOPSABRE RECENTLY ANNOUNCED THE LAUNCH OF THEIR IS-A SERIES CNC ROUTER, A TESTAMENT TO AMERICAN ENGINEERING EXCELLENCE AND THE LATEST INNOVATION IN CNC TECHNOLOGY. DESIGNED FOR UNPARALLELED PRECISION AND POWER, THE IS-A SERIES SETS A NEW INDUSTRY STANDARD, FEATURING ADVANCED SERVO MOTORS, AN HSD ITALIAN-BUILT SPINDLE, AND A DEDICATED M8 SERIES CONTROLLER FROM MITSUBISHI. ALL THIS OFFERS UNMATCHED ACCURACY AND EFFICIENCY WHILE THE ROUTER’S ROBUST CONSTRUCTION ENSURES LONGEVITY, MAKING IT A VALUABLE INVESTMENT FOR PROFESSIONALS SEEKING TO ELEVATE THEIR MANUFACTURING CAPABILITIES.

“Welcome to the era of Industry 4.0 — where the buzz is all about making our manufacturing processes smarter and more connected,” says Jeff Farr, National Sales Manager for JKL Machinery. “In woodworking, precision is everything, and diving into Industry 4.0 isn't just a trend — it's a must-have for staying on top of our game.”

“To ride the Industry 4.0 wave,” he adds, “our CNC machines need to tick some boxes:

• Interoperability — Our machines gotta talk to each other and to the digital systems, all in sync. Think of it like a smooth jam session where everyone's in tune. This is where protocols like OPC UA come in handy, ensuring seamless communication between different machines and systems.

• Real-time Data Analysis — We need to keep our eyes on the machines' pulses with real-time monitoring. It's like having a radar for spotting any hiccups before they turn into headaches. IoT sensors onboard our machines gather data in real-time, giving us insights into performance and productivity.

• Predictive Maintenance — Let's get proactive with maintenance! By using fancy algorithms and machine learning,

WWW.SHOPSABRE.COM

SURFACE & PANEL • Q2 2024 25

CONTINUED ON PAGE 26 › SCAN TO LEARN MORE

‹

we can predict when our machines might throw a tantrum and fix 'em up before they do.

• Remote Accessibility — Whether we're on the shop floor or chilling at home, we need to keep tabs on our machines. Remote control, anyone? It's like having a superpower to tweak things from wherever we are. Thanks to IoT connectivity, we can monitor and control machines remotely.

• Comprehensive Data Reporting — Let's crunch those numbers and get some juicy insights! Detailed reports help us understand how our machines are performing and where we can make improvements. It's like having a GPS to navigate our way to efficiency.”

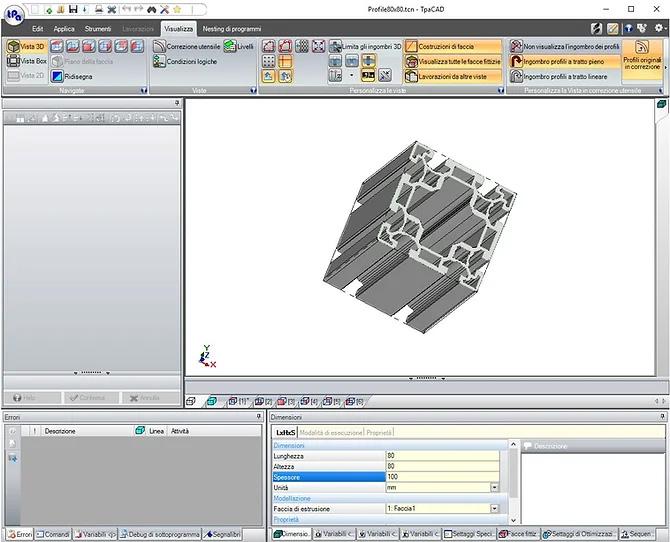

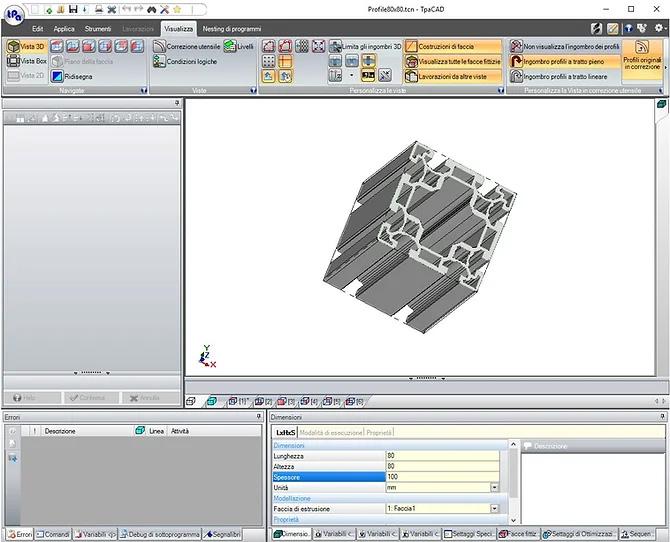

Companies including Busellato and Vitap are leading the charge into Industry 4.0 with the help of Tpa's control software. TpaCAD is Tpa’s CAD/CAM programming system for Microsoft Windows environments. It can interface with 3- or 5-axis CNC machining centers. TpaCAD can

BELOW: DEPTH OF CUSTOMIZATION MEETS LEAN MANUFACTURING FOR THE ULTIMATE IN POWERFUL CUSTOM DESIGN TO MANUFACTURING SOFTWARE.

KCD SOFTWARE CNC COMMANDER EXCELS WITH A USER-FRIENDLY DESIGN INTERFACE AND ROBUST MANUFACTURING ENGINE. GET YOUR CNC MACHINE UP AND RUNNING QUICKLY WITH KCD SOFTWARE’S FREE ONE-ON-ONE TECHNICAL SUPPORT INCLUDED. WWW. KCDSOFTWARE.COM

RIGHT: USHERING IN A NEW ERA IN CNC AUTOMATION IS THE VITAP K2 2.0 WITH FLOW SYSTEM. NOW, EVEN THE SMALLEST SHOP CAN AFFORD TO AUTOMATE. THE SYSTEM IS FULLY AUTOMATED WHICH ALLOWS FOR USER-FREE OPERATION. SIMPLY PROVIDE THE MACHINE WITH THE REQUIRED PARTS AND PROGRAM AND THE MACHINE WILL LOAD, PROCESS, AND UNLOAD AUTOMATICALLY. COMPACT, AFFORDABLE AND RELIABLE. WWW.JKLMACHINERY.COM

Challenges to Growth

The CNC industry faces several challenges, including cybersecurity issues, a shortage of qualified operators, and an increased demand for the technology across different manufacturing sectors.

And as CNC operations become increasingly reliant on more advanced technologies, protecting these systems from cyber threats becomes most important. The additional dependence on more technical, digital platforms for operation means that workers, too, much become more tech-savvy, highlighting the need for more comprehensive training programs in the industry. And while the certification programs to train future operators are many, the right training needed for more advanced technologies may be more difficult to find.

“With the advent of automation, the quest for qualified operators has become even more daunting,” says GDP Tooling CEO Karin Deutschler. “Operating CNC equipment demands a heightened level of expertise, necessitating proficiency in basic computer skills, comprehension of programming concepts, proficiency in working with DXF files, and a grasp of tolerances and fundamental tooling concepts such as chiploads and feed speeds, among others.

26 SURFACEANDPANEL.COM

CONTINUED FROM PAGE 25

TOP LEFT: TPACAD IS TPA’S CAD/CAM PROGRAMMING SYSTEM FOR MICROSOFT WINDOWS ENVIRONMENTS. IT CAN INTERFACE WITH 3- OR 5-AXIS CNC MACHINING CENTERS. TPACAD CAN BE USED TO WORK WITH SEVERAL TYPES OF MATERIALS, SUCH AS WOOD, MARBLE, METAL, GLASS, AND PLASTICS. THE STRONG SUIT OF TPACAD IS OFFERING IN A SINGLE ENVIRONMENT THE HIGH PERFORMANCE OF A GRAPHIC EDITOR AND THE EXCELLENT DEDICATED FUNCTIONS TYPICAL OF A CAD SOFTWARE. WWW.TPASPA.COM

BOTTOM LEFT: C ABINET PRO CNC ALLOWS FOR AUTOMATIC TOOL SELECTION FOR A DESIGNATED MACHINING OPERATION. THIS FEATURE WILL REPLACE THE TOOL WHEN NECESSARY, IN ORDER TO ADJUST TO MATERIAL THICKNESS CHANGES, WHICH MAKES YOUR MACHINING MORE ACCURATE AND EFFICIENT. THE AUTOMATIC TOOL SELECTION OPTIONS ARE VAST. FOR INSTANCE, IN THE CNC TOOL LIBRARY THE COMPANY CAN DESIGNATE THE TOOLS WHICH THEY WOULD WANT CABINET PRO TO AUTOMATICALLY INSERT INTO ANY GIVEN ROUTING OPERATIONS SUCH AS A DADO CUT OR A RABBET CUT. WWW.CABINETPRO.COM

be used to work with several types of materials, such as wood, marble, metal, glass, and plastics. The strong suit of TpaCAD is offering in a single environment the high performance of a graphic editor and the excellent dedicated functions typical of a CAD software.

Dr. Vito Dimichele, CEO of Vitap, says he embraces the implementation of new technologies. "We're not just embracing Industry 4.0; we're shaping Transition 5.0,” he says. “We're all about pushing the boundaries to create smarter manufacturing environments.

By embracing all things Industry 4.0 — from interoperability to predictive maintenance — companies will not just keep up with the times, but can set the pace, says Farr.

“With their commitment to innovation and technology,” he says, “the woodworking industry is in for one heck of a ride!” S P

SURFACE & PANEL • Q2 2024 27 CABINETS DIVIDERS ORDER BY 6 PM FOR SAME DAY SHIPPING METRO OFFICE COLLECTION π COMPLETE CATALOG 1-800-295-5510 uline.com

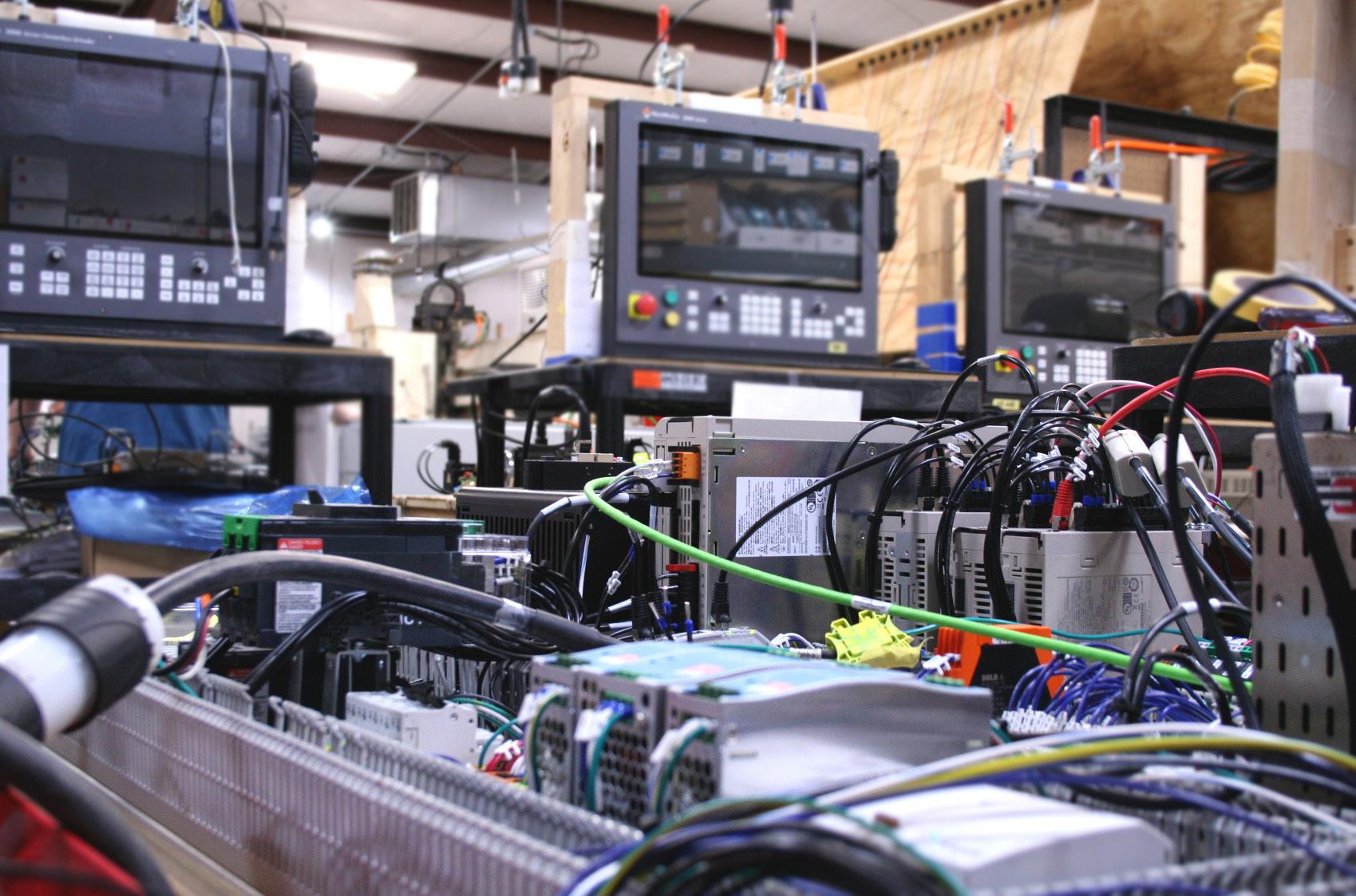

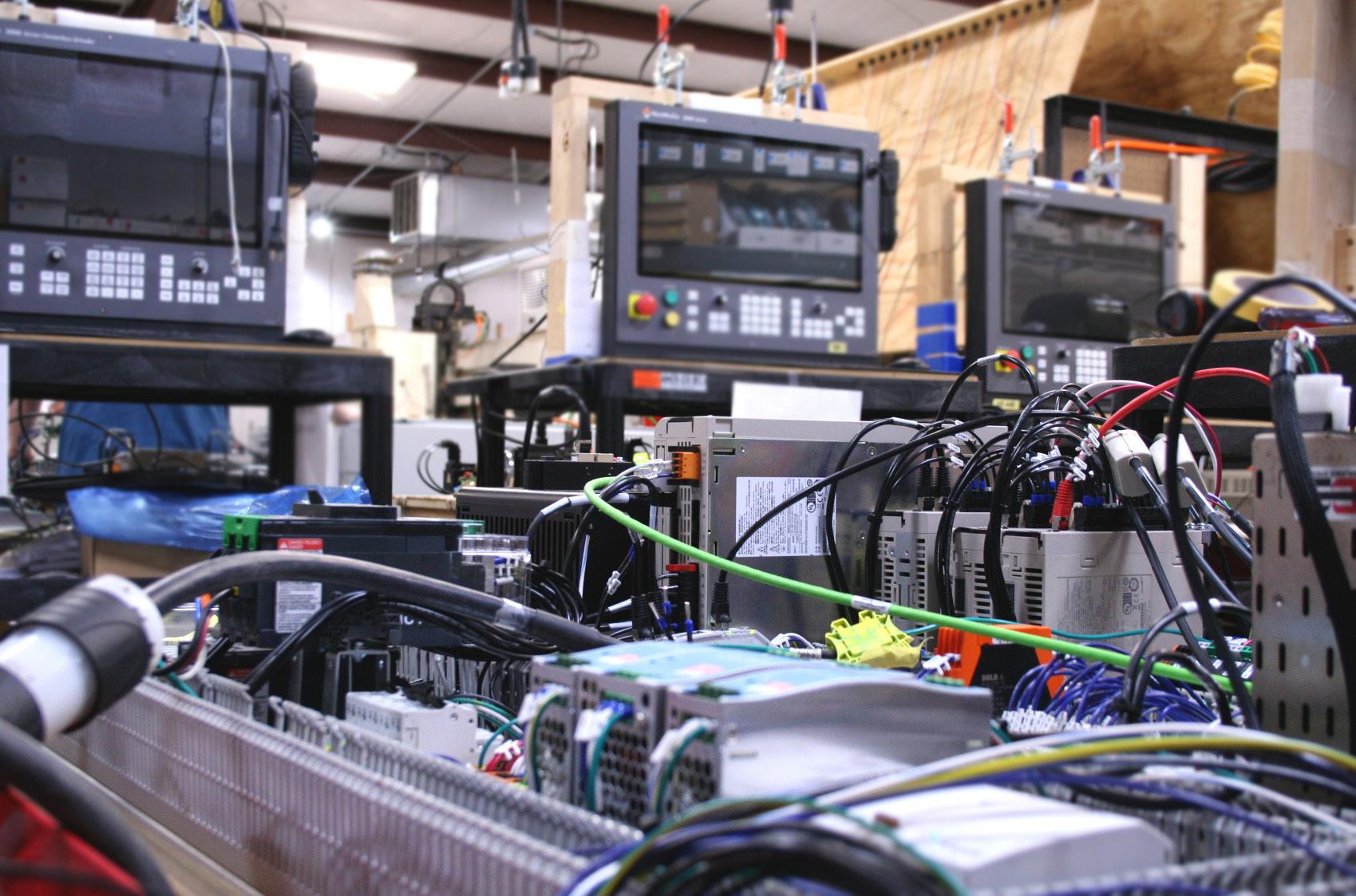

Retrofitting with a Purpose

MANY BUSINESSES ARE CHOOSING TO UPGRADE

THEIR OUTDATED COMPUTERIZED PARTS ON CNC AND OTHER MACHINES

BY JENNIFER WILLIAMS | PHOTOS COURTESY OF MACHMOTION

The computer system on one of Eddie San Juan’s CNC routers started glitching in the early days following the worst of the pandemic, so the high-end door fabricator knew he had to find a solution. He started by working with the machine manufacturer — even sending in the computerized control panel for repair. But the lead time was long and San Juan was worried about the prolonged downtime for a third of his business.

So he did some research online and found MachMotion, a company that offers solutions for aging computerized parts and panels for a variety of equipment, including CNC machines and routers.

“What we had were machines that are extremely well taken care of, but their electrical systems were just aging,” says San Juan, who owns E.F. San Juan, Inc. in Youngstown, Florida. “One in particular was really acting up … it got to the point that the computer

systems were failing very quickly, and we had to come up with a solution or potentially be stuck with an inoperable router. So, I found MachMotion and started the process to replace just the computerized control system.”

He says it was a great experience and he will replace the same system on a second machine this summer. “[MachMotion] came in and worked with us to figure out what exactly we needed, then they went back and built it to our specifications. They came back and did the switchover — we were only down about a week.”

And that can really make a difference for smaller manufacturers and companies, says Chad Hodge, director of marketing at MachMotion. “Typically they'll come in with a problem they’ve likely tried to correct themselves — maybe with what we call ‘band aids and bubble gum,’” he says. “They're buying parts off eBay and have somebody come in to patch it up — maybe it's their maintenance

28 SURFACEANDPANEL.COM

"... they'll come in with a problem they’ve likely tried to correct themselves — maybe with what we call ‘band aids and bubble gum,’” he says. “They're buying parts off eBay and have somebody come in to patch it up ..."

— CHAD HODGE, DIRECTOR OF MARKETING AT MACHMOTION

team and they're soldering a wire together or whatnot and they're really tired of it … they have a job to get done and need to meet a client deadline and their machine is down for four hours. Now that may be fine one time, but when it happens 10 times … not so good.”

That’s about how it happened for San Juan, who says he found MachMotion after searching for another solution online. “Our total cost was about 25 percent of what we would’ve spent on a new machine,” he says. “Not to mention the extended downtime from having to swap out the entire machine and the waste and all that.” You basically get a brand new machine with the upgrade/retrofit, he adds, and that includes outstanding customer service.

“When you go with MachMotion, you gain a partner with expertise to help you get a new machine experience without actually having to buy a new machine,”

With a ShopBot CNC, you can increase production throughput while minimizing material handling. For example, you can drill shelf pin holes, cut rabbets and dados, and profile-cut the completed panel. The operator only needs to handle the full sheet once to load the machine, and then remove the perfectly cut parts that are ready for assembly.

Thanks to the affordability of ShopBot’s professional grade CNC machines, the technology of manufacturing cabinet boxes, doors, drawer fronts, shelves, and even countertops, is now well within the reach of smaller shops, not just large cabinet manufacturing facilities.

See our full line of CNCs at ShopBotTools.com

Then give us a call at 888-680-4466

We’ll find the CNC machine that works best for your needs.

Panel

SURFACE & PANEL • Q2 2024 29

SHOPBOT CNC MACHINES ARE ENGINEERED, MANUFACTURED, AND SUPPORTED IN THE USA

Pro Without the

Process Like a

Pro Price Tag

CONTINUED ON PAGE 30 ›

‹ CONTINUED FROM PAGE 29

says Hodge. “And what I mean by that one is you're supported. We offer lifetime customer support for every customer — it’s not a warranty but it's helping them work through the issues and things like that and we can do that because we're using modern technologies. We can remote into the machine with U.S.-based remote support, we can see if you had something fail at 5:56 p.m. and we can go in and look at it and help you solve it right away.”

“Once we come out and access just what you need, we get to work building it for you,” he continues. “It then takes roughly 6-8 weeks to build everything, depending on the parts needed, etc., and then we come out and make the transition and make sure the customer can fully operate the machine before we leave. And we try to do this with the least possible disruption to their business.”

“These machines are iron — they're meant to last a lifetime,” says Hodge. “But they do have wearable parts. If you're keeping your machine updated, you know there are things that are going to need to be updated or replaced: the wiring inside the machine, the relays, everything inside the cabinet or panel and the control itself — those aren't meant to last 20 years, right? The best comparison I can give you to that is you would not carry the same phone for 20 years in your pocket or keep the same laptop for 20 years … it would be a waste of technology as it relates to security and things like

"There’s always little quirks here and there that come up when you're using the CNC that you gotta tweak. This way, we can kind of stress test it to make sure that everything is in good shape and ready to go."

— EDDIE SAN JUAN

that. So the iron on these machines are meant to last a lifetime, but what we do is come in and basically replace all the electrical components, the wiring, everything in the cabinet or replace the cabinet. And we can do the switchover and get you back in operation within a week most of the time.”

MachMotion has worked on many different machines and brands, including machines you may never have heard of, says Hodge. “We do the majority of our business with CNCs and routers,” he says. “But in every job we do, we take a few pictures of the machine, including of the serial plate, then we custombuild the solution for every customer. We are not just sending out a replacement part based on your model number… there might be different size motors or a number of variations, so we actually

customize it, ship it to you and come out — usually the following week — to make the switch.”

San Juan says he opted for MachMotion to come out for an extra week when they upgrade their second machine in June, just to run through various programs and settings. “There’s always little quirks here and there that come up when you're using the CNC that you gotta tweak. This way, we can kind of stress test it to make sure that everything is in good shape and ready to go.” And he says he has been more than impressed with their customer service. “We are in Florida and get started about 5:30 in the morning,” he explains. “I texted our guy when we had an issue and he got back with us by 5:45 — and it was even earlier for him. I was pretty impressed.” S P

SURFACE & PANEL • Q2 2024 31

FORMALDEHYDE IS IN THE NEWS: Wood Panels Appear to Be Ahead

A SUMMARY OF THE EPA'S RECENT DRAFT RISK EVALUATION AND ITS IMPLICATIONS FOR USERS OF WOOD PANELS

BY KEITH CHRISTMAN

What is Formaldehyde?

Formaldehyde is a colorless, flammable gas that is used as a precursor for many industrial chemicals and products, such as adhesive, resins, plastics, paints, and textiles. Formaldehyde can also be released from natural sources. Living things — plants, animals, and people — produce and release formaldehyde just through natural life (biogenic) processes. In addition, forest fires, or human activities, such as smoking, cooking, or burning fuels also release formaldehyde.

Why is Formaldehyde in the News?

In March 2024, the EPA issued a draft risk evaluation for formaldehyde under the Toxic Substances Control Act (TSCA), which regulates the manufacture, use, and disposal of chemicals

in the U.S. The draft risk evaluation “preliminarily finds that formaldehyde presents an unreasonable risk of injury to human health.” EPA found that workers who are in workplaces where formaldehyde is used are at the most risk from formaldehyde exposure. EPA made these conclusions assuming that workers don’t use protective equipment, though EPA acknowledged that many employers do take measures to protect the safety of their workers. According to the American Chemistry Council, “EPA’s suggested workplace limits are unworkable and ignore practices that are already in place to protect workers … The suggested risk thresholds are 30 times below the recently updated European Union occupational limits of 300 parts per billion, lower than levels that can be detected, and below levels measured in ambient urban air and U.S. residences.”

EPA also found that people who frequently use certain consumer

32 SURFACEANDPANEL.COM

products that contain formaldehyde are at risk. These products included car waxes, some crafting supplies, and fabrics or leather goods treated with formaldehyde. However, a person’s risk from these products depends on how long and how frequently the products are used, and in many cases, exposures from these products are at the same or lower levels than exposures from other sources of formaldehyde in the home such as candles or cooking.

TSCA Title VI “Laminated Product Producer Exemption” Expires

Formaldehyde is also in the news because the composite wood products regulatory landscape changed in March as well. The EPA’s TSCA Title VI regulation has regulated formaldehyde emissions from composite wood products in the U.S. since 2018. Over that time, entities that applied a wood or woody grass veneer to a regulated platform like veneer core, particleboard, or medium density fiberboard (MDF) panels specifically in support of producing finished goods (e.g. furniture, cabinetry, engineered wood flooring) were considered “laminated product producers” and were exempt from the certification and testing requirements that apply to hardwood plywood panel manufacturers. As of March 22nd, 2024, this is no longer the case: laminated product producers which use an adhesive other than a “no added formaldehyde” (NAF) or phenol formaldehyde (PF) adhesive to adhere those veneers must now be third-party certified like a hardwood plywood producer. This could impact thousands of finished goods manufacturers in the U.S. and abroad, many of which may be unaware of this important implementation date. For guidance on determining whether or not you are now considered a laminated product producer or hardwood plywood producer, contact DHA technical director Josh Hosen at jhosen@decorativehardwoods.org to discuss your production process.

How is the Wood Panel Industry Ahead?

Composite wood products, including hardwood plywood, medium density fiberboard, particleboard and engineered wood flooring, are potential sources of formaldehyde exposure in residential and commercial buildings. These products are made from wood fibers or veneers that are bonded together with resin, which may contain formaldehyde as an ingredient. As mentioned earlier, the EPA already regulates the formaldehyde emissions from composite wood products under TSCA Title VI, which sets emission standards and test requirements for these products.

The TSCA Title VI regulation also requires that composite wood products sold in the U.S. are certified by third-party certifiers and labeled as compliant

with the emission standards. Wood panel producers have taken many steps to reduce formaldehyde concerns since 2018 including, in many cases, switching to “no added formaldehyde” and “ultra-low emitting formaldehyde” adhesives.

According to the EPA's draft risk evaluation, the composite wood products sector may be ahead in reducing formaldehyde exposure and risk for consumers. The agency stated that "in this preliminary determination, EPA is finding the conditions of use related to exposure in residences from wood articles does not contribute to the unreasonable risk of formaldehyde." At this point it’s unclear what if any workplace changes might be required to address worker exposure in wood panel manufacturing.

What are the Next Steps?

The EPA's draft risk evaluation for formaldehyde is open for public comment until May 14. The agency will review comments and other input and then finalize the risk evaluation reportedly by the end of 2024. After it’s finalized, EPA will propose risk management rules that may include restrictions or bans on the manufacture, use, or disposal of formaldehyde and formaldehydecontaining products, as well as requirements for exposure monitoring, labeling, or reporting. S P

KEITH CHRISTMAN

is President of the Decorative Hardwoods Association, formerly known as Hardwood Plywood and Veneer Association. He is a new contributor for Surface & Panel and welcomes your thoughts and questions at kchristman@ decorativehardwoods. org. Visit the DHA at www.

SURFACE & PANEL • Q2 2024 33

PRODUCT EMISSION STANDARD Hardwood Plywood - Veneer Core 0.05 ppm of formaldehyde Hardwood Plywood - Composite Core 0.05 ppm of formaldehyde Medium-Density Fiberboard 0.11 ppm of formaldehyde Thin Medium-Density Fiberboard 0.13 ppm of formaldehyde Particleboard 0.09 ppm of formaldehyde

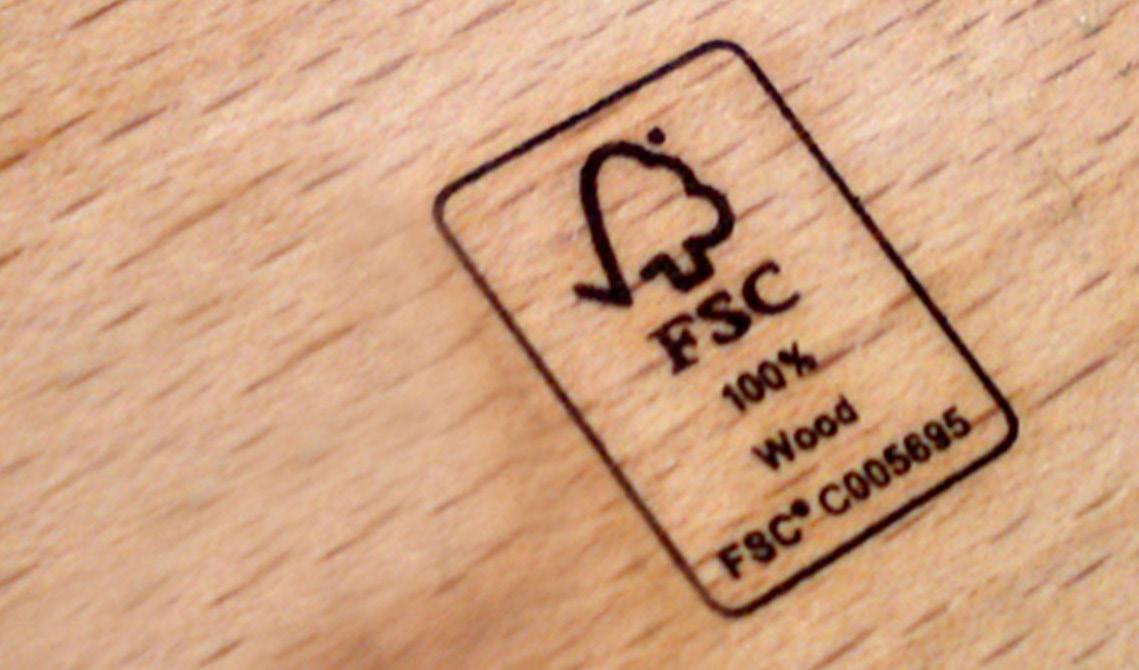

Beyond the Buzz

SUSTAINABILITY

EFFORTS ARE NO LONGER JUST THE TREND OF THE DAY — THEY HAVE BECOME A NEW STANDARD IN THE SURFACE & PANEL INDUSTRY

As environmental awareness expanded over the past 20 years, companies across the globe have increasingly pivoted towards more eco-friendly practices, integrating more green materials and energy-efficient processes into their core operations.

And while some materials, including wood and fiberboard, have always been a consistently sustainable resource, experts say the industry needs to do a better job of telling its story. “The idea that there is no more sustainable material on the planet or in the galaxy than wood as a construction material is completely lost, because we have done a terrible, terrible job of communicating that,” says Kenn Busch, founder of MaterialIntelligence.com and ClimatePositiveNOW.org. He also creates Certified Education Unit content for architects and designers and speaks about materials and sustainability to design students and at industry and design events in North America, Europe, Asia and South America.

“Recently, I was working out some messaging with the kitchen cabinet industry and we came up with this idea of what if we said, ‘Look, you can build your next kitchen out of 600 pounds of naturally captured carbon how cool will that be?’ But the thing is, you're already doing that,” says Busch. The average North American kitchen is storing about 600 pounds of carbon in its wood cabinets. And wood naturally captures carbon in the air and stores it within—to the point that 50 percent of

BY JENNIFER WILLIAMS

dried wood is captured carbon that’s been pulled out of the atmosphere with little or no involvement by humans…it’s just a natural air scrubbing machine.”

“That’s just what nature designed wood to do,” he continues. “It’s a crazy great story that is so powerful but when you just lay it out in cocktail conversation with an architect or designer even some consumers, they're like ‘that just sounds like greenwashing’ or ‘that sounds too good to be true.’ But it is true, and most of us learned that in science class years ago: wood captures CO2 from the atmosphere and releases oxygen.

Evolution of Eco Expectations

Kelsey Spitz-Dietrich, chief commercial officer for the UCS Forest Group of Companies, which includes Sierra Forest Products and Upper Canada Forest Products, says they have a good communication strategy to help their customers understand the language and to navigate the opportunities to be more sustainable.

“It starts with a mindset,” she says. “The domestic lumber industry is inherently aware of sustainability and their impact on the environment. Basically, you do well by doing good. If you don’t take care of your forest, you cannot take care of your business, your people, or your community … it’s a pretty clear feedback loop.”

And while UCS has been involved in sustainable practices from the beginning, they continue to evolve. “The founder of the

34 SURFACEANDPANEL.COM

Common Materials Framework Unites Leading Sustainability Organizations

For the first time, leading organizations committed to sustainable building practices have agreed to align their efforts to advance materials sustainability, transparency, and optimization in the construction and design industries.

The Common Materials Framework establishes a common language for holistic material sustainability in the building industry. Organizations including the American Institute of Architects (AIA), the International Living Future Institute (ILFI), the International WELL Building Institute (IWBI), the U.S. Green Building Council (USGBC) and mindful Materials (mM) agreed to the collaboration at the 2023 Greenbuild International Conference and Expo last year.

Leaders from the five organizations presented “Building Alignment: The Role of Project Certifications to Drive Impact” to emphasize the importance of their joined efforts to utilize a common language in this area.

company started with a sustainability mindset, so that mindset was inherent to the company’s mission,” says Spitz-Dietrich. “It has evolved over the years — from the start, we paid attention to vendor selection and with whom we partner. And then we were one of the first distributors to become FSC Chain of Custody Certified.”

Supply chains have become increasingly more complicated with more complex certification processes, she adds, “but we try to ensure that there’s a clear chain of transparency from product to consumer. We align with and learn from leading environmental organizations so that we can continue to do better. We do know some companies in our supply chain who won’t get certified, because they’re actually doing better than the certification standard and, in their minds, they can’t afford to go through the process ‘just for’ the sticker. But it’s important to avoid greenwashing and there are some certifications that verify compliance with audits that are very much worth the effort to prove authenticity.”

In the early days, UCS partnered with companies and organizations to bring green energy into our operations, and now the company is targeting to be carbon neutral in 2026, says SpitzDietrich. “And that’s something we’ve been working towards and are very excited to see come about. But it’s only one piece of the puzzle. We are trying to pay more attention to other resources, including our impact on water, air and ecosystems. There’s so much more we can do.”

Durability is also important to sustainable practices, she says,

“Materials have remained one of the toughest sustainability puzzles to solve. Partly, that’s because their impacts are so diverse and global — and because so many entities impact material choices from design to installation,” says Alex Muller, VP of Strategy at mindful MATERIALS. “But it’s also been a confusing world to wrap your arms around. Every organization defines product sustainability differently and asks for different pathways or labels to meet the same objectives — safe, sustainable, and socially just materials. So it’s not surprising we’ve made less progress than we’d want. That’s all about to change thanks to the Common Materials Framework — and the commitment from these organizations to find meaningful alignment on holistically sustainable materials.”

The Common Materials Framework, introduced in 2021, translates complicated language, data and standards across the industry into consistent impact categories: Human Health, Climate Health, Ecosystem Health, Social Health + Equity, and Circularity. Once digitized, the CMF will act as a smart filter, allowing practitioners to search for sustainable products at any depth. mindful MATERIALS’ intention is that the CMF will work seamlessly across all leading building and material databases and technology platforms, ensuring a consistent foundation of information wherever material decisions are made.

“It’s not overstating anything to say these are some of the most influential groups in the built environment where sustainability is concerned,” says Annie Bevan, mindful MATERIALS CEO. “The announcement at Greenbuild represents years of collaboration and months of direct conversation. To have everyone up on the stage together, speaking in the same language and with the same urgency about aligning like ‘no more talk, this is it’ — I mean, wow, that was powerful and something I have been hoping to see my entire career.”

Visit www.mindfulmaterials.com/the-common-framework for more information.

SURFACE & PANEL • Q2 2024 35

CONTINUED ON PAGE 36 ›

"Basically, you do well by doing good. If you don’t take care of your forests, you cannot take care of your people and your community … it’s a pretty clear feedback loop."

— EKELSEY SPITZ-DIETRICH, CHIEF COMMERCIAL OFFICER, UCS FOREST GROUP OF COMPANIES

by not having to replace a product every few years. “I’ve been waiting for durability to become relevant,” she laughs. “Now there is a new design trend of ‘quiet luxury’ in 2024, that actually translates to durability. And we have products with a 50-year warranty. Spend a little more now, but you will have something that lasts, reducing waste and costs over time.”

In fact, keeping an eye on the future is a key corporate value for UCS. “We are focused on the opportunity of intergenerational value building and long-term ecosystemic sustainability — what our world is going to be like for the next generation and their kids and their great grandchildren. That’s important to us.”

The Business Side of Sustainability

And while this shift towards more sustainable products and processes is a positive thing overall, companies have also discovered it can be good for their bottom line.

Wilsonart has a robust sustainability program, says John Bank, the company’s director of commercial marketing. “It’s become more and more important over time and it just makes sense from a business standpoint,” he says. “Particularly when using recycled materials to make certain products — we are reusing or repurposing materials that were once considered a waste product, but now, we are using it to make new, marketable materials. That just seems like a win-win, because the excess materials that used to be trash and we had to figure out how to get rid of it, now we are actually using that ‘throwaway’ material to make different products.”

Bank says that companies also try to keep up with the rules, regulations and certifications for sustainable products and practices. “Becoming more and more important these days is your EPD, or your Environmental Product Declaration, because it addresses a lot of the greenhouse gases, carbon and more, so it really gives great insight to specifiers in terms of content of that product so they can make informed decisions based upon that.”

Formaldehyde has been a big issue for the panel industry [see page 32], but Bank says it’s important to know the facts. “Maybe one of these days, our R&D and our tech guys in all their brilliance will come up with a way to eliminate the trace amounts of formaldehyde that are found in HPLs. And we have read articles that say to stay away from high pressure laminate because it contains formaldehyde — but so does an apple, and it's kind of on that level. So while it gets a bad rap, it’s really more of an education situation. Some people are open to that discussion and others just hear the word and they shut down, so that’s been part of our challenge … to make sure that you know we provide accurate and clear information.” S P

CONTINUED FROM PAGE 35

‹

Sustainability Certifications

According to Kenn Busch with Climate Positive Now, there are currently more than 600 possible certifications for sustainability in the building and industry.

“It has almost gotten to the point that it’s just white noise, there are so many,” he says. “But several of them are more important to the industry — the trick is figuring out which are which.”

Below is a list of some prominent sustainability certifications along with explanations of what these certifications signify:

FSC (Forest Stewardship Council): This certification ensures that products come from responsibly managed forests that provide environmental, social, and economic benefits. The certification tracks the wood from forests through the supply chain.

Sustainable Forestry Initiative (SFI): Covers key values such as protection of biodiversity, species at risk and wildlife habitat; sustainable harvest levels; protection of water quality; and prompt regeneration.

LEED (Leadership in Energy and Environmental Design):

This globally recognized certification assesses the environmental performance of a building and encourages market transformation towards sustainable design. It covers aspects like energy efficiency, water usage, air quality, and the choice of building materials.

ISO 14001: An international standard that specifies requirements for an effective environmental management system (EMS). It provides a framework that an organization can follow, rather than environmental performance requirements.

Declare Labels from ILFI: Manufacturers voluntarily disclose product information on easy-to-read Declare labels, which report all product ingredients and use a simple color code system to flag chemicals of concern. Further information is provided on the product’s final assembly locations, life expectancy, end-oflife options, and overall compliance with relevant environmental requirements. All active Declare labels are accessible on a free and searchable database, used by designers, builders, and homeowners to specify products they know they can trust and that meet the requirements of leading green building standards.

Environmental Product Declarations (EPDs): These documents provide professionals with important information on environmental and health aspects, and are also available to interested end users.

Green Seal: A certification that uses science-based programs to empower consumers, purchasers, and companies to create a more sustainable world. It signifies that a product meets rigorous, science-based environmental leadership standards.

Blue Angel: German certification for products and services that have a reduced environmental impact. It mainly applies to products like coatings and finishes that are less harmful to the environment.

Cradle to Cradle Certified: This certification assesses product safety for human and environmental health, design for future life cycles, and sustainable manufacturing processes. Products are rated at five different levels (Basic, Bronze, Silver, Gold, Platinum).

Zero Energy Certification from ILFI A standard: Developed by the International Living Future Institute that recognizes the highest levels of energy performance that built projects can achieve. To receive this certification, 100 percent of a building’s energy needs on a net annual basis must be supplied by on-site renewable energy. No combustion is allowed.

Rainforest Alliance Certified: This certification focuses on biodiversity conservation and sustainable livelihoods. It assures consumers that the products are sourced from farms or forests that meet rigorous environmental and social standards.

CARB Compliance (California Air Resources Board): This certification ensures that composite wood products sold or used in California meet strict formaldehyde emission standards. It is crucial for manufacturers of products like MDF and plywood.

GREENGUARD Certification: The products that achieve GREENGUARD Certification meet rigorous low chemical emissions standards, contributing to the creation of healthier interiors by reducing indoor air pollution and the risk of chemical exposure.

Eco-Certified Composite (ECC) Standard: This certification is awarded to manufacturers who meet criteria for air quality, resource management, and environmental stewardship. It is specifically relevant to panel products like particleboard and MDF.

PEFC (Programme for the Endorsement of Forest Certification): This certification ensures that products are produced with respect to the highest ecological, social, and ethical standards. It is important for companies sourcing wood-based products like MDF.

Green Star: Launched by the Green Building Council of Australia (GBCA), the Internationally recognized Green Star seal assesses the sustainable attributes of a project through several impact categories: management; quality of the indoor environment; energy; site; water; materials; use of energy; and emissions.

SURFACE & PANEL • Q2 2024 37

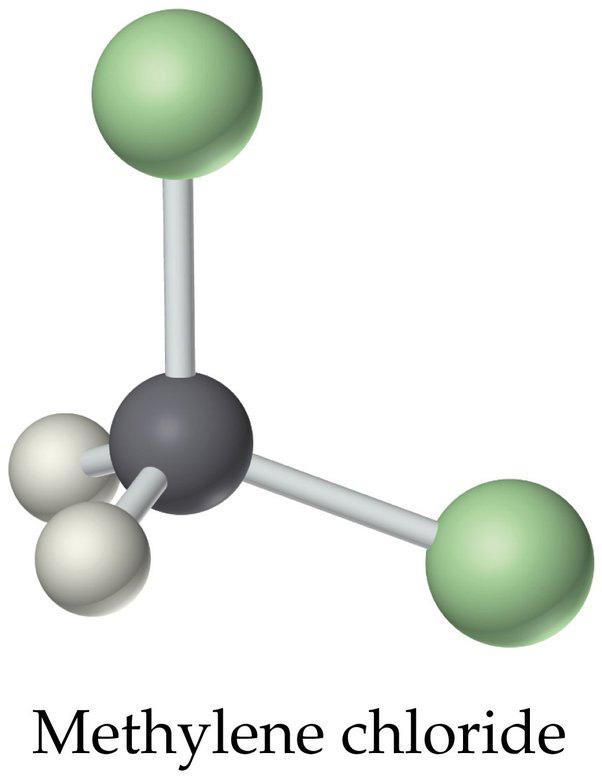

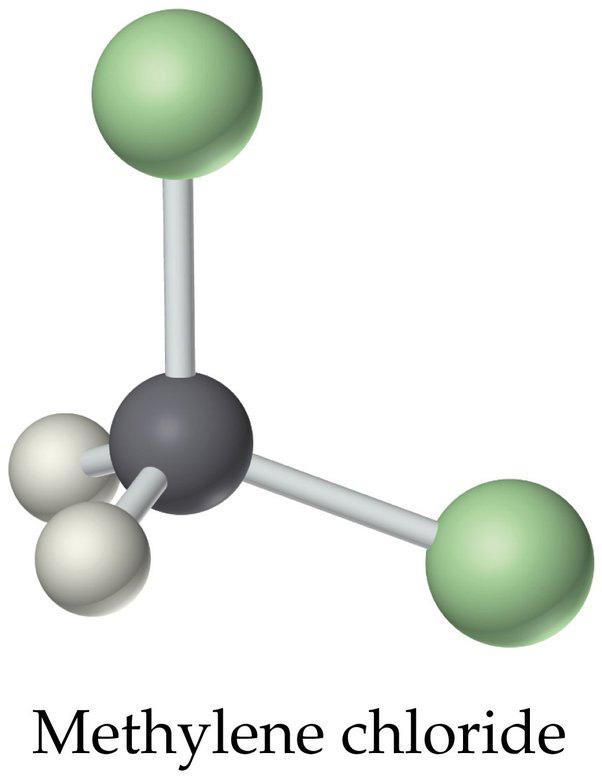

Not If, But When:

INDUSTRY RESPONDS TO EPA’S PENDING METHYLENE CHLORIDE RULING

BY SARA GRAVES

BY SARA GRAVES