ENABLING 5G SUCCESS THROUGH SUPPLY CHAIN TRANSFORMATION T-MOBILE: T-Mobile’s SVP Max Caballero-Vieyra shares exclusive insight about the journey to become the top 5G provider in the US LOS ALAMOS NATIONAL LABORATORY LOGISTICS NETWORKS PROCUREMENT TRANSFORMATION AT HISTORIC NUCLEAR FACILITY SAP ON HOW CHAOS IS RESHAPING LOGISTICS Supply Chain Technologies ACCENTURE UNILEVER CAPGEMINI FEATURING: Mar 2023 | supplychaindigital.com

A BizClik Event Join the Virtual Event Disrupting Procurement & Supply Chain 28TH JUNE 2023 VIRTUAL CONFERENCE

Join the must-see virtual event disrupting procurement and supply chain on the 28th of June 2023.

This year, we are bringing you a solely virtual event, Procurement & SupplyChain LIVE Virtual will highlight the innovators changing the industry. Brought to you by BizClik, Procurement & SupplyChain LIVE Virtual will be held on 28th June 2023, streaming remotely to virtual audiences around the world.

The unmissable event will feature expert keynote speakers, interactive fireside and panel discussions, and more. Do not miss this 1-day deep dive into the disruption and the future of procurement, supply chain and logistics.

Sponsorship Opportunities

Do you want to position your brand in front of thousands of innovators, decision-makers and influencers?

Sponsor Procurement & SupplyChain LIVE to unlock the future of your business, access thousands of potential partners and influence businesses at the highest level.

Both global giants and innovative start-ups alike can discover the ideal platform with easy access to an engaged and active audience.

Contact a member of our team today to discuss sponsorship opportunities.

See you on 28th June 2023.

It’s time for DISRUPTION. GET YOUR PASS SPONSORSHIP

Innovators are paving the way for a more resilient, sustainable, and efficient future. The rules have changed. It’s time for disruption.

▶ Watch our showreel from PROCUREMENT & SUPPLY CHAIN LIVE London 2022

bizclikmedia.com

Ways to Work With us

We produce Digital Content for Digital People across 20+ Global Brands, reaching over 15M Executives

Digital Magazines

Websites

Newsletters

Industry Data & Demand Generation

Webinars: Creation & Promotion

White Papers & Research Reports

Lists: Top 10s & Top 100s

Events: Virtual & In-Person

Work with us

The SupplyChain Team

EDITOR-IN-CHIEF

SEAN ASHCROFT

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

PROOFREADER

JESS GIBSON

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN/

SUPPLYCHAIN LEAD DESIGNER

ANDY WOOLLACOTT

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

MARTA EUGENIO

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

JOSEPH HANA

SALLY MOUSTA

JINGXI WANG

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

CHARLIE KING

YEVHENIIA SUBBOTINA

MARKETING MANAGER

KAYLEIGH SHOOTER

PROJECT DIRECTORS

MIKE SADR

CRAIG KILLINGBACK

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

THE COMMUNITY

JOIN

+

CINDERS SHALL GO TO THE BALL

POST-PANDEMIC, PROCUREMENT IS NO LONGER A CINDERELLA FUNCTION

Procurement is often seen as a cinderella function, if it is seen at all, that is. Or at least that’s the way things were, pre-pandemic, when procurement was viewed as being the driver of cost-control, and very little else.

Now, though, the C-suite understands that it is procurement professionals who drive strategic advantage in areas such as sustainability and operational resilience. But even in pre-pandemic days procurement –alone among all facets of business – had the ability to amaze, for those who could be bothered to look.

Take the Los Alamos National Laboratory (LANL), featured in this issue. LANL is run under contract by the US Department of Energy and sits in one of the most secluded spots on Earth, in the high desert near Santa Fe in New Mexico. It houses 10,000 people, and is also the lab that was at the heart of the Manhattan Project in World War II.

“We're known as the birthplace of the atomic bomb,” says Christine Hipp, Acquisition Services Management Center of Excellence Leader at LANL. “But a lot of people don't realise we still exist.”

But exist it does, and today its work includes R&D on everything from the COVID-19 vaccine to genome sequencing, but it retains stewardship of the US nuclear weapons programme.

And it is Hipp and her team who procure everything that is needed to make these and other programmes happen. Programmes such as an Arctic exploration. For that, Hipp had to source enough equipment, food and provisions to last the crew 18 months. She had to get it right. The crew were going nowhere; they would be frozen in place in an ice floe.

So don’t let anyone tell you procurement is dull. It is the oil that keeps businesses running.

SEAN ASHCROFT

sean.ashcroft@bizclikmedia.com

SUPPLYCHAIN DIGITAL MAGAZINE IS PUBLISHED BY © 2023 | ALL RIGHTS RESERVED supplychaindigital.com 7

“We're known as the birthplace of the atomic bomb but most people don't realise we still exist”

FOREWORD

CHRISTINE HIPP, ACQUISITION SERVICES MANAGEMENT CENTER, LOS ALAMOS NATIONAL LABORATORY

CONTENTS

UP FRONT

012 BIG PICTURE Will early heatwaves hit India’s agriculture?

020 TRAILBLAZER

Reginaldo Ecclissato, Making one of the world’s biggest supply chain sustainable

024 FIVE MINS WITH Lindsey Mazza, Global Retail Lead at Capgemini

108 020 024 012

8 March 2023

5G

052 078 MARCH 2 023 FEATURES 052 SUPPLY CHAIN Los Alamos National Laboratory’s procurement transformation 078 LOGISTICS Future-proofing risk & resilience in global logistics 088 SUSTAINABILITY ESG Strategies for the future of supply chain sustainability 098 TECHNOLOGY Supply chains need to streamline procurement automation 108 TOP 1 0 Supply chain technologies supplychaindigital.com 9 088

19TH APRIL 2023 VIRTUAL CONFERENCE Watch our 2022 Showreel GET YOUR PASS SPONSORSHIP Join the Virtual Event Disrupting Sustainability A BizClik Event

062 MARCH 2 023

030 T- MOBILE Value leadership and T-Mobile’s consumer supply chain 062 G4S Embedding sustainable procurement at G4S supplychaindigital.com 11 030

COMPANY REPORTS

BIG PICTURE

Will Early Heatwaves Hit India’s Agriculture? India

Thanks to global warming, India is beginning to see severe heat waves as early as March, with the mercury rising to a record 46°C (114.8°F) in Mumbai in March 2022.

India’s scorching temperatures are adding to the world’s food security headache, as heat stroke reduces the hours people can safely work. The country is one of the largest food producers in the world, exporting US$49.6bn of crops in 2022, including rice, wheat, tea, coffee and sugar.

More furnace-like temperatures this month, and food supply chains will again be hit.

Drawing water from a well Thar Desert, Rajasthan

12 March 2023

supplychaindigital.com 13

THE BRIEF

BY THE NUMBERS

The four elements of a circular supply chain

Source: McKinsey

G4S

READ MORE

Parts, components and material are fed back into the next production cycle

Owners run repair and maintenance services to extend product life

REFURBISHMENT

Manufacturers refresh, and resell, products they collect from consumers

Owners resell products, or rent from others

EDITOR'S CHOICE

READ MORE

Top 10: Supply chain & logistics colleges in the US

READ MORE

Among the top supply chain & logistics colleges in the US are MIT, Stanford, Carnegie Mellon & Berkeley

Supply chain professional on brink of burnout, study shows

READ MORE

A study suggests over half of procurement professionals are facing burnout due to cost-cutting pressures

Gartner in plastic packaging U-turn greenwashing warning

READ MORE

READ MORE

Gartner says businesses are ditching 'unworkable' programmes to cut plastics usage in packaging, and that many will face greenwashing storm

“THE CPO ROLE IS OFTEN ABOUT TELLING THE COMPANY WHAT IT NEEDS TO HEAR, NOT WHAT IT WANTS TO HEAR”

Jon Willescroft

Chief Procurement Officer

“WE'RE KNOWN AS THE BIRTHPLACE OF THE ATOMIC BOMB YET MANY PEOPLE DON'T REALISE WE STILL EXIST”

Christine Hipp Acquisition Services Leader Los Alamos National Laboratory

RECYCLING REPAIR RESALE/RENTAL

“MANY ORGANISATIONS ARE TURNING TO SUPPLY NETWORKS RATHER THAN CHAINS TO SOURCE GOODS LOCALLY”

Richard Jowers

Director of Value Advisory, Intelligent Spend & Business Network SAP

16 March 2023

SCOPE 3 EDUCATION

Boston Consulting Group launches the Supply Chain Net Zero Academy, to tackle ignorance-fuelled inaction on cutting Scope 3 emissions.

RETAIL OMNICHANNEL

Booz Allen Hamilton urges supply chain cyberattacks

rethink

A robotics expert with consultancy firm Booz Allen Hamilton (BAH) has sounded the alarm over the dangers to global supply chains posed by social engineering.

Dr Sean Anthony Guillory, a Senior Robotics Process Automation Bot Developer says too much talk around supply chain cybersecurity is focused on hardware and technology.

“Cybersecurity discussions often focus on data, digital infrastructure, and physical systems rather than people,” he says. “But the human element is key when modelling cyber threats to supply chains.”

It is humans, he says, on whom all supply chains depend.

“It is humans who plan, gather supplies, manufacture, deliver and enable sales,” he writes. “And it is humans who are responsible for all the communications and logistics in between.”

Dr Guillory points out this is why cyber criminals target people as a way of hacking into supply chain systems.

“In some supply chain attacks, influencing humans is the end goal, and this is why cyber leadership needs to prepare for this kind of threat.”

Retail supply chain experts from SCM data solution provider SPS Commerce say omnichannel is the future and that retailers who rely on pre-pandemic business models will be left behind.

PLASTICS IN PACKAGING

A fifth of firms will have ditched initiatives on plastic usage in packaging by 2026 predicts Gartner, who warns the move will lead to accusations of greenwashing.

PROCUREMENT PROFESSIONALS

A study from autonomous sourcing solutions specialist Keelvar suggests over half of the procurement profession is facing burnout due to costcutting pressures that are the result of rampant inflation.

W I N N E R S L O S E R S

MAR23

supplychaindigital.com 17

A POTTED HISTORY OF DIGITAL TRANSFORMATION

The pandemic has prompted a massive spike in businesses looking to digitally transform their operations, especially around supply chain. But digital transformation goes back way further than you’d expect…

1940s 1950s 1960s

DIGITISATION’S DEBUT

Claude Shannon, the father of modern digital communications theory, publishes a groundbreaking article, ‘A Mathematical Theory of Coxmmunication’, and, in so doing, paves the way for digitalisation.

CHIPS AND TRANSISTORS

The microchip – and today’s most widely used semiconductor transistor – are invented, meaning analogue computing can go digital for the first time.

EARLY DAWN OF THE INTERNET

The first ever message is sent over ARPANET, the first packet-switched network to use the TCP/IP protocol, and a precursor of the Internet.

TIMELINE

18 March 2023

1970s 1980s -1990s 2010 -present

HOME COMPUTING MARKS IT BOOM

Home PCs and computer games mark the widespread availability of computer technology, and, on the work front, this sees a profusion of data entry roles, as firms look to digitise their data.

WORLD WIDE WEB

British computer scientist Tim BernersLee invents the World Wide Web, a communication system first developed by US colleges. Automation in the workplace begins to take hold.

BIG-BUSINESS TRANSFORMATIONS

Pioneering digital transformation projects begin to show signs of success, while guidance from MIT and Deloitte helps businesses understand that strategy, not tech, is the key.

supplychaindigital.com 19

Making one of the world’s biggest supply chain sustainable

Reginaldo Ecclissato,

keeps the multinational giant’s goods moving, and in a sustainable way

The numbers around Unilever’s supply chain are staggering: its total supply chain spend in 2021 was €35.5bn, and it uses 53,800 suppliers to make sure that its many well-known brands can end up in our kitchens and bathrooms. These include Ben & Jerry's ice cream, Bovril, Cif cleaning fluid, Colman's mustard, and Comfort fabric softener, to name but a handful.

In charge of all this is Reginaldo Ecclissato, who took up his role as Unilever’s Chief Supply Chain Officer in April 2022. The move was part of a wider management shake-up at the consumer goods giant. Ecclissato’s appointment came at a time when Unilever announced it was cutting 1,500 jobs globally – reducing senior

Unilever total supply chain spend in 2021

35.5bn

management roles by around 15% and junior ones by 5%. The company said the move was designed to make Unilever a “simpler, more categoryfocused business”.

Market volatility continues to challenge

Upon taking up his latest role, Ecclissato said: “The impacts of the pandemic, such as record inflation and market volatility, continue to challenge us but, together with our partners, we will continue serving and delighting our consumers, generating mutual responsible growth with our suppliers, and furthering our positive action for people and planet, whatever challenges come our way.”

Since taking up his role, Ecclissato has overseen substantial progress, especially on sustainability.

Recently, the company announced that a further two of its factories – in Tianjin, China and Indaiatuba, Brazil

Chief Supply Chain Officer with Unilever,

TRAILBLAZER 20 March 2023

Reginaldo Ecclissato

TITLE: CHIEF SUPPLY CHAIN OFFICER

COMPANY: UNILEVER

– have been recognised by the World Economic Forum as ‘Advanced Fourth Industrial Revolution Lighthouses’ as part of the WEF’s international Lighthouse scheme, which aims to drive tech adoption. This means Unilever now has 6 Lighthouse sites across its business, including further sites in China, as well as in Dubai and India.

Ambitious zero waste to landfill targets

Ecclissato has a solid track record in sustainability at Unilever, ensuring the company’s supply chains are futurefit. As SVP of Americas Supply Chain, he achieved 100% zero waste to landfill at all dedicated distribution centres in North America. At the time, he said: “Reaching 100% zero waste to landfill on all waste streams at our North America distribution centres is a great example of how we are putting our sustainability strategy into action and reducing our environmental footprint to strengthen our business, as well as our commitment to partnership and collaboration.

“This achievement builds on the journey we began a few years ago when all of our Unilever-owned factories in North America became zero waste to landfill, but it is far from the end. We will continue to challenge ourselves and our partners in our mission for sustainable growth.”

Before his current role, Ecclissato was Executive VP Mexico, Central America & Greater Caribbean. He

Number of suppliers:

53,800

took over from Marc Engel, who moved on after 30 years with the company. In that role, he oversaw 11 countries, 12 product categories and high levels of growth, despite the pandemic.

Prior to that, he was in charge of Unilever’s supply chain in North America and Latin America, generating double-digit growth in the profitability of one of its largest regions. Ecclissato graduated from Universidade de Sao Paulo as an electrical engineer and

22 March 2023

TRAILBLAZER

started his journey at Unilever Brazil as a trainee in 1991. Two years later, he was responsible for building a new factory and the production of a new category: powder detergents.

Waste elimination a key target

In 1998, he took up a position as Supply Chain Development Manager in the UK, following this up in 2001 by becoming Home Care Logistics and Planning Director for Latin America. In 2003, he moved back to his native

Brazil, becoming Home Care Supply Chain Leader, and two years later, moved to Central America as Supply Chain Director.

Solutions to avoid sending finished goods to landfill include: focused inventory management; composting; creating animal feed; package recycling; and generating biodiesel fuel. Eliminating waste in distribution centres resulted in cost savings of more than $1.9mn in 2013, the company has reported.

“We will continue to challenge ourselves and our partners in our mission for sustainable growth”

Unilever has €1 billion euro brands

supplychaindigital.com 23

REGINALDO ECCLISSATO, CHIEF SUPPLY CHAIN OFFICER, UNILEVER

24 March 2023

“ALWAYS, ALWAYS, ALWAYS TAKE THE MORE CHALLENGING ROLE, BECAUSE THAT’S HOW YOU LEARN”

FIVE MINUTES WITH...

LINDSEY MAZZA

Q. TELL US A LITTLE OF YOUR PROFESSIONAL BACKGROUND

» I started my career in systems engineering and, over the years, have expanded my solutioning to include everything from supplier to consumer. I currently work with leading retailers to reimagine how they fulfil consumer promises. An exciting part of my role is leveraging AI, analytics, and emerging technology to reinvent operations and meet consumer expectations.

Q. HOW DO YOU MEET THE CHALLENGES OF YOUR CAPGEMINI ROLE?

» I help retailers navigate today’s many challenges and transform their businesses. I rely on my systems engineering background to research and learn where opportunities exist,

then collaborate with our immensely talented teams to deliver solutions that drive business outcomes. That might be creating intelligent, adaptive supply chain ecosystems, fulfilment options, unlocking channel growth, underpinned with technology and analytics that deliver personalised and engaging consumer experiences.

Q. HOW CAN RETAILERS COUNTER RISING OPERATIONAL COSTS?

» Automation, AI, and other leading technologies can make all the difference, and I am seeing the benefits with our clients. Data and analytics, AI, and automation in product and supply chain planning processes – not to mention that last-mile consumer fulfilment can support optimised costs – maximise use of labour, and

GLOBAL RETAIL LEAD AT CAPGEMINI, LINDSEY MAZZA, ON HOW A SYSTEMS ENGINEERING BACKGROUND IS HELPING HER SERVICE THE SUPPLY CHAIN NEEDS OF CUSTOMERS

supplychaindigital.com 25 25

further sustainability objectives. For example, analytics can be used to reduce inventory, identify underperforming areas, and recommend solutions to increase efficiency. Using real-time data and intelligent integrated planning, consumer products companies and retailers can customise the right assortment mix, and have the right inventory for each store or channel. And autonomous vehicle delivery – although early in development – could transform the lastmile delivery cost model.

Q. HOW CAN FIRMS BEST DEVELOP SUSTAINABLE PRODUCTS?

» Sustainability can be embedded throughout the entire product

lifecycle, starting from the design process and selection of materials to end-of-life management. To address Scope 3 emissions, businesses need to consider the system as a whole. It’s also important to conduct a life-cycle assessment to evaluate the environmental impact of a product – from raw material extraction to disposal – to identify areas where the environmental impact can be reduced.

Q. CAN RETAIL BE BOTH SUSTAINABLE AND AFFORDABLE IN TODAY'S WORLD?

» Definitely, and it must be. Retailers need not sacrifice affordability or profitability to meet their sustainability goals. Our own research shows 41% of consumers globally are willing to pay more for a product they believe to be sustainable. So, while consumers are keen to buy sustainable products, they are not willing to pay more.

Brands and retailers must respond to consumer concerns by keeping prices fair – providing affordable sustainability will therefore be key. Consumers are

FIVE MINUTES WITH...

“RETAILERS DON’T NEED TO SACRIFICE AFFORDABILITY OR PROFITABILITY TO MEET THEIR SUSTAINABILITY GOALS”

WATCH NOW 26 March 2023

The Next Factor with Lindsey Mazza

also conscious about reducing waste and mindful about consumption practices. Retailers embracing circular economy will create a brand ethos that matches the ethics of the consumer.

Q. WHAT ADVICE WOULD YOU GIVE TO YOUR YOUNGER SELF?

» I’ve had tremendous leaders and mentors throughout my career. There are two lessons I’m so grateful to have learned from them: Always, always, always take the more challenging role, because you’ll learn more. I’ve built a view across the supply ecosystem by taking unexpected roles where I was able to learn. Create your next job. We can all see areas where our companies can improve. Design that role, develop a benefits case for why that role will create value, advocate for it to be in next year’s budget, and get that role.

Q. WHO INSPIRES YOU?

» I’ve always been inspired by the artwork of MC Escher.

His work changes one creature or shape into another and forces you to look from a different perspective – it encapsulates transformation through maths. What more could a supply chain strategist want, other than mathematicallyderived ecosystem transformations?!

LINDSEY MAZZA

TITLE: GLOBAL RETAIL LEAD

COMPANY: CAPGEMINI GROUP

INDUSTRY: PROFESSIONAL SERVICES

LOCATION: US

A results-focused, relationship-oriented Management Consulting

Professional who stimulates retailers and CPG companies to achieve seamless integration of process and technology in supply chain, sales, and marketing transformations. Serving clients across segments including fashion apparel, grocery, specialty goods, intimate apparel, footwear, personal care and hightech with emphasis in the areas of AI-enabled integrated planning and execution, collaborating with clients to surprise and delight consumers from demand to receipt.

supplychaindigital.com 27

more

more

more

Learn

Learn more Learn

Learn

VALUE LEADERSHIP

AND T - MOBILE’S CONSUMER SUPPLY CHAIN 30 March 2023

LEADERSHIP

supplychaindigital.com 31

PRODUCED BY: GLEN WHITE

T - MOBILE

WRITTEN BY: JOSEPHINE WALBANK

32 March 2023 T - MOBILE

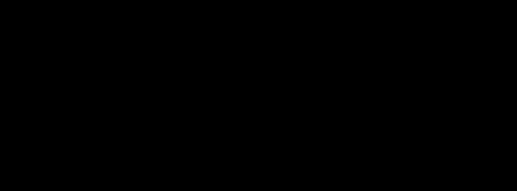

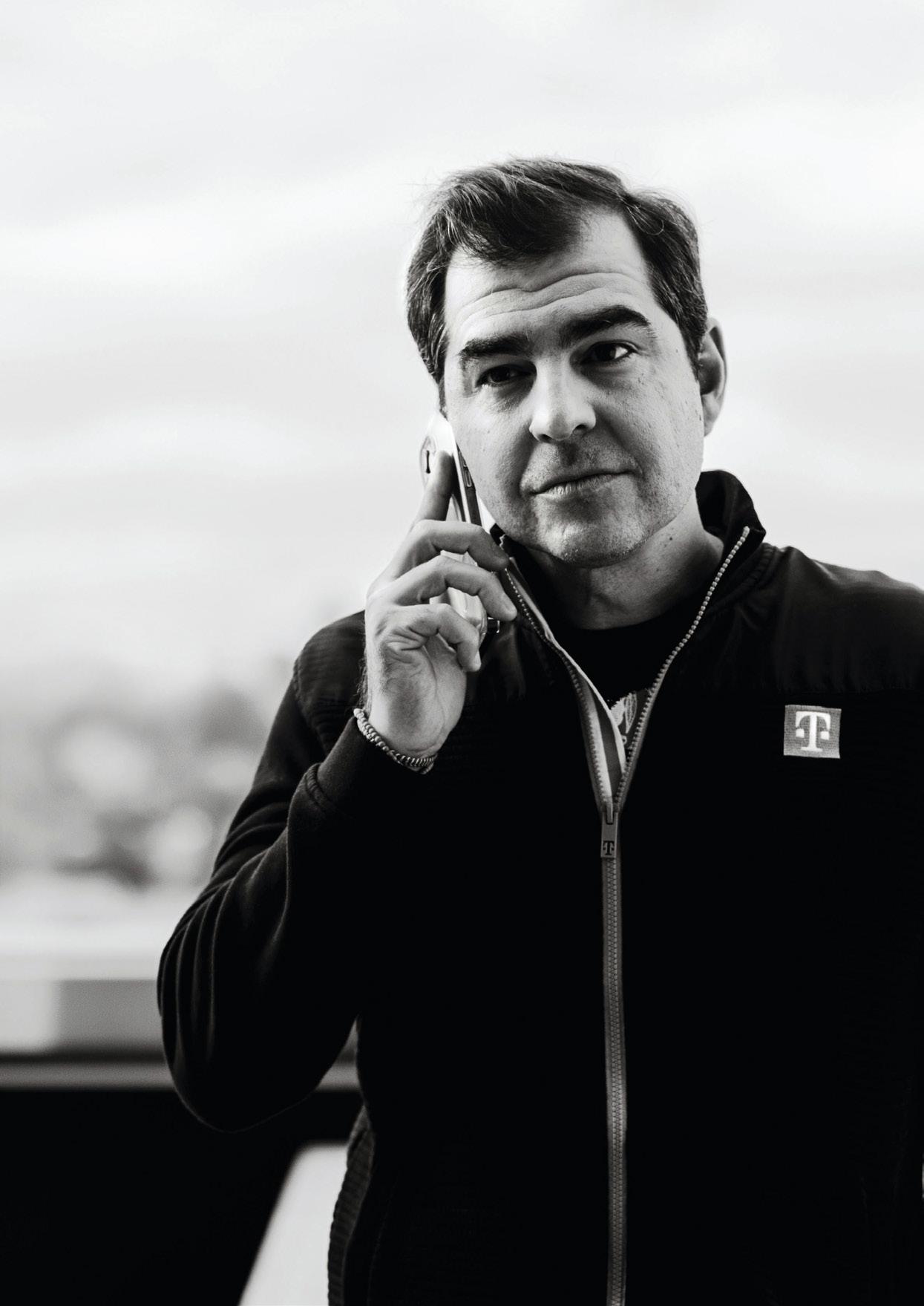

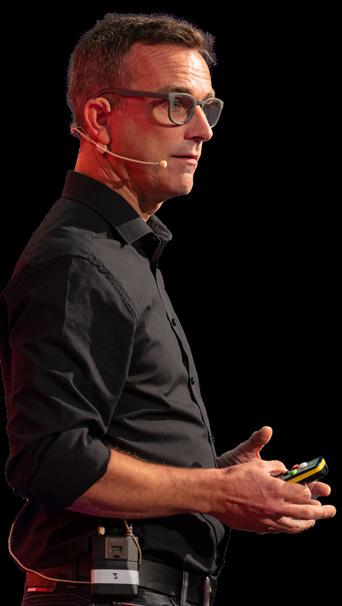

Caballero-Vieyra, SVP

Supply

T-Mobile has achieved nothing short of becoming America’s 5G Leader, with the country’s largest, fastest and most reliable 5G network.

And, even after nearly three years of highscale merger implementation/execution and a global pandemic, the mobile giant has managed to not only retain but expand on the leading 5G service in the country.

In an exclusive interview with Max Caballero-Vieyra, Senior Vice President of Devices & Supply Chain, we learn how T-Mobile has built resilience into its consumer supply chain, tackles the unique challenges of the American market, and plans to further digital transformation in the future.

Max

of Devices &

Chain, provides exclusive insights into how supply chain transformation is asserting T-Mobile as value leader

YOUR SUPPLY CHAIN DOESN’T HAVE TO BE SO COMPLEX

The Apkudo Circular Industry Platform simplifies in the connected device supply chain so you can have real-time answers to device inventory, quality, and pricing questions – not only within your own organization, but across your global partner network.

Learn more

APKUDO FINDS HIDDEN PROFIT AND ENABLES CIRCULAR ECONOMY

Josh Matthews and Chad Gottesman from Apkudo, share how companies can tackle supply chain complexities and benefit from the circular economy

Connected device supply chains are becoming increasingly complex as the number of products and industry participants grow. As a result, many organizations struggle with fragmented legacy systems and high labor costs yet still don’t have the transparency, security, and connectivity across the supply chain they need to maximize profits.

Apkudo helps customers tackle this complexity head on with its Circular Industry Platform, a single operating system that optimizes the lifecycle of connected devices, from launch to end of life. “No matter where a company operates within the supply chain, they’re dealing with all of this intense complexity,” says President Chad Gottesman. “Apkudo enables our customers to tackle this complexity and create new opportunities in the process.”

Apkudo’s Circular Industry Platform replaces inefficient labor and disjointed legacy systems with a purpose-built integrated solution including hardware, software, and market connections. “The Apkudo Platform ensures that items such as mobile phones, tablets, laptops, and wearables move quickly and smoothly to the highest value outcome,” continued Gottesman

T-Mobile, an early adopter of the Apkudo Platform, uses it throughout the device lifecycle. “Our platform assists T-Mobile with onboarding devices into their ecosystem, liaising with the device manufacturer, assessing each device, predicting its future issues in the field, predicting customer satisfaction, and determining the best possible value and positioning of that device after initial use,” says Josh Matthews, Co-Founder and CEO of Apkudo.

T-Mobile also benefits from the Apkudo Platform because it provides a simple and secure way to connect to their business partners that participate in the device lifecycle. “We provide the fabric that connects all of those stakeholders together and allows them to automate their business processes, gaining the best possible outcomes for the devices that move through the supply chain,” Matthews observes. “The Apkudo Platform is there for T-Mobile at every step of the way, tracking devices and ensuring they have the data to make the optimal decision every time.”

Learn more

EXECUTIVE BIO

Max Caballero-Vieyra

TITLE: SENIOR VICE PRESIDENT OF DEVICES & SUPPLY CHAIN

COMPANY: T-MOBILE

INDUSTRY: TELECOMS

LOCATION: US

Max Caballero is responsible for the end-to-end life cycle of T-Mobile’s consumer-facing hardware and accessories portfolio, accountable for selecting and procuring the devices that T-Mobile carries, and the best way to get them into customers’ hands. Within his span of control are hardware and accessories supplier partnerships, to device and accessories roadmaps, procurement and pricing negotiations, over $22bn annual hardware and accessories purchases, supply chain operations and inventory management, reverse operations, as well as used device monetization.

Prior to joining T-Mobile, Max spent 4 years at Sprint, where he most recently served as the VP of Product & Supply Chain, leading all aspects of Sprint’s P&SC organisation including portfolio, procurement of device and accessories, OEM management, Forward and Reverse logistics and operations, and second life device sales. Among his most notable achievements at Sprint, Max led all commercial negotiations with products suppliers, as it relates to Sprint’s 5G strategic initiative, and successfully secured a range of 5G products to launch on Sprint’s 5G network in 2019. In addition, Max has expertly negotiated and launched multiple lucrative iconic programmes

with suppliers at Sprint, including exclusive upgrade programmes that delight customers by allowing them to access the latest and greatest devices on an annual basis.

Before joining the Sprint executive team, Max acted as Managing Director of Brightstar – Southern Europe, based in Madrid. While there, he managed the device procurement and end-to-end supply chain (including 400 Brightstarowned points of sale) of mobile operator Mas Movil (formerly Yoigo).

Prior to moving to Madrid, Max spent 8 years in London, where he held multiple roles at Brightstar, including:

> VP Mobile Distribution managing all device procurement and OEM relationships across Europe,

> VP of Strategy leading multiple acquisitions in the Distribution and Buy Back and Trade-in business as well as opening Brightstar’s first Auction House in Hong Kong that served as a key sales channel in the rapidly growing business of returned devices.

Max holds a degree in Business Economics from Universidad Di Tella (Argentina), a Master’s degree in Distribution and Supply Chain from Texas A&M, and multiple executive coaching programmes at Ashridge Business School (Hult) in London.

What sets T-Mobile’s supply chain apart?

The supply chain sphere is competitive, particularly within the telecom industry. In addition, a variety of obstacles over the past few years have added new complexities and introduced new risks. Competition, risk management, optimising efficiencies while maintaining an unwavering focus on innovation are the main pillars on which the Supply Chain of the future will stand.

This presents a unique challenge for leaders. Strong leadership is key, but leaders also need to understand customers’ needs in-depth and have a clear vision for the future while creating the right strategic partnerships to enable success today.

Caballero-Vieyra is responsible for managing T-Mobile’s complete portfolio of devices – including smartphones, tablets, watches, and routers – as well as the portfolio design, strategic supplier relationships, terms and pricing negotiation with partners, and the selection process across multiple channels.

“It involves everything that has to do with the operations, whether it's for sourcing, logistics, reverse logistics, or inventory management,” Caballero-Vieyra explains. “We manage thousands of retail doors, big web and telesales avenues, so we fulfil every single channel T-Mobile operates.”

The complexities of T-Mobile's consumer supply chain come from managing a large network of partners as well as thousands of retail locations. Alongside this, T-Mobile is working to ensure that it can supply the full spectrum of devices customers want at the right time and at the right place, while offering our best possible value.

“Our planning and execution are frequently impacted by changes in promotions, particularly around devices.

T - MOBILE

supplychaindigital.com 37

T-Mobile partnership helps catapult Motorola to #3 in the US Market

Motorola and T-Mobile have been doing business for a long time. However in 2020, that partnership was taken to the next level as they both started to trust each other and plan for the long term. That trust has paid massive dividends for both companies

Learn more

Motorola rekindled a selling relationship with T-Mobile in 2017, and in 2020 that partnership took the next leap. During the pandemic and times of supply uncertainty, T-Mobile trusted Motorola to deliver on their device needs and extended their forecasts to give Motorola the visibility to procure the right parts – despite extended lead times and delivery dates more than six months in the future.

T-Mobile provided Motorola with enough certainty that they would take product orders and clearly communicated their needs for a longer period, so that the duo could collaboratively plan to create combined success.

The trust that was developed and ongoing relationship that has blossomed since the supply shortages of 2020 have led to other partnerships between the companies.

As a trusted innovation partner, Motorola was the first supplier to launch a device that delivers power class 1.5 on T-Mobile’s network with its motorola edge2022. PC 1.5 brings faster, more powerful 5G to more people, helping T-Mobile live up to its claim of more bars in more places!

The partnership doesn’t stop there - T-Mobile and Motorola are working diligently to bring even more products and innovations to North American consumers, including innovative form factors, differentiated color options and enhanced communication ecosystems. Learn more

Your Partner for Smart Connectivity and Entertainment

Sercomm connects people to what they love! Network operators across the world rely on Sercomm to deliver reliable, differentiated services to enhance customers’ lives. Check out Sercomm for a full portfolio of smart home, business connectivity, and entertainment solutions.

www.sercomm.com Learn more 5G FWA IP Streamer WiFi 7 Mesh IP Cameras

And the complexity comes in managing all that demand of products – different price points, different customer needs –and ensuring that we can always have the products that our customers need, where they need them,” Caballero-Vieyra explains.

Anticipating changes in supply and demand that result from promotional fluctuations is a unique skill not often seen in supply chain leaders, yet CaballeroVieyra and his team not only do this, but go further.

“We deliver world-class quality of service by understanding our customers and offering optionality – whether it's in products or price points – while making sure that we can always fulfil their product needs consistently and as fast as possible – whatever interaction they have with T-Mobile, whether that’s in a retail store, on the web, on the phone, or in an app.”

A permanent shift in risk management

In such a dynamic and global role, it’s highly telling that Caballero-Vieyra’s proudest achievement comes from the way that T-Mobile navigated the COVID-19 crisis.

“The US market is very, very big. Between 2020 and 2021, I was managing the merger of T-Mobile and Sprint – integrating processes and consolidating infrastructure – while the world was going through a pandemic,” Caballero-Vieyra explains.

“Being able to succeed and keep the business stable in an unprecedented environment, while navigating the volatility in the system for at least a year, was extremely challenging. That was, without a doubt, the most demanding job I've ever had.”

“We deliver world-class quality service by ensuring that we are tuned into our customers’ needs, and offering them optionality”

supplychaindigital.com 41 T - MOBILE

MAX CABALLERO-VIEYRA, SVP OF DEVICES & SUPPLY CHAIN, T-MOBILE

So, from a supply chain management perspective, how are the lessons learned being implemented now, in a consistently volatile, almost-post-pandemic world?

“At the end of the day, supply chain is a game of certainty, and you need that certainty to operate. When you are getting hit by an event like the pandemic, the certainty that’s essential to operate isn’t there,” Caballero-Vieyra outlines.

“Then you start thinking: if we're not going to be receiving the products when we expect them, what do we need to do in terms of safety stock to be able to mitigate those risks? So we started leveraging our network of supplier relationships to find alternative supply sources and protect our value proposition. That gives you options to begin making decisions, or start adjusting what you were thinking originally, based on the new information coming in day-to-day.”

Caballero-Vieyra explains how one of the critical lessons learned from this situation was the need to constantly rethink diversifying to avoid risk.

“Supplier diversity becomes crucial in minimising those unexpected events. So we implemented that across every step of the process – from the moment we are designing a portfolio of products, we start thinking, ‘What would happen if we go through a repeat of 2020 and 2021?’.

“When you go through a shock to the system like the pandemic, it brings supplier partnerships and risk management to the forefront of your thinking.”

Challenges of the American mobile market

According to Caballero-Vieyra, the main way T-Mobile differentiates from its competitors is by offering America’s leading 5G network.

“We have always been a value leader: we have fantastic prices, and the best value for those prices. And now, we also have an incredible network to match our incredible value.

“We offer amazing content to our customers and, with respect to devices or accessories, we give them tons of options. We also ensure that we design a portfolio

supplychaindigital.com 43 T - MOBILE

At the end of 2022, T-Mobile serviced a network of over 113.6mn CUSTOMERS

Driving 5G today, Preparing for 6G future

As the world’s largest supplier of smartphone chipsets, we’ve empowered US customers with connected devices. We’re excited to continue working with T-Mobile to create the best 5G products today, and on into the 6G era.

Dr. JC Hsu Corporate Vice President and General Manager of Wireless Communications Business Unit at MediaTek

Learn more

of products that covers the wide range of our customers' needs – all the colour variants, all the memory variants, and all the price points.”

Interestingly, one of the most significant complexities of T-Mobile's consumer supply chain comes from the promotion-led approach of the American mobile market, which significantly differs from other mobile markets across the globe.

“Here in the US, we operate in a very promotional market. Those promotions change and, as they do, demand for certain devices and accessories moves up and down. The complexity lies in managing the network of suppliers we have around these promotions, feeding our distribution centre with the right amount of inventory so we can meet consumers' needs while keeping an optimal inventory level across thousands of points of sale,” Caballero-Vieyra explains.

“We're talking about hundreds of products, thousands of points of sale, and a very large number of partners. And managing all that complexity in an efficient way is extremely challenging.” It certainly sounds like it.

Consumer demand, telco innovation, and supply chain evolution

In the mobile industry, building a supply chain that’s flexible enough to successfully support these complex technologies and their rapid evolution is no mean feat.

So, how does T-Mobile manage the evolving demands of the customer landscape with an ever-expanding range of mobile devices?

MAX CABALLERO-VIEYRA, SVP OF DEVICES & SUPPLY CHAIN, T-MOBILE

“We are a value leader –we have amazing prices and incredible ßvalue for those prices”

supplychaindigital.com 45 T - MOBILE

Connected Future With

World Leading Home Network Solution Provider

5G Indoor/Outdoor Solution

Wi-Fi Home Mesh Solution

Next-Gen Broadband Gateway

Learn More

“We need to give customers what they want. So, we design a portfolio of products, ecosystems, and experiences that fit every price point, every consumer lifestyle, and every segment of the market,” says Caballero-Vieyra.

“Sometimes, businesses require different products than consumers. So we need to think broadly and try to make it so that we always have a path to every customer, that we always have the product that best fits their needs and their desires.”

For T-Mobile, telco innovation and supply chain development are focused on retaining its position as the industry value and network leader.

“If you look at what we've been doing for the past couple of years, we've been consistently a leader in the market, in terms of giving consumers the best value

for money. We've been the value leader,” Caballero-Vieyra asserts with pride.

“And now, it’s probably the first time in the history of telecoms that any wireless company is striving to be the value leader and the product leader at the same time. Our 5G network has been ranked number one by many network experts, and they always rank our 5G performance very highly, whether it's in coverage, speed, reliability or all three.”

T-Mobile is also working closely with its strategic partners to anticipate industry trends ahead of the competition – a core element of remaining ahead of the pack.

“There's a lot of innovation coming, whether it's on the hardware design or the OS. The OS has been playing an increasingly important role in the experience customers have with their devices and related

WATCH NOW supplychaindigital.com 47 T - MOBILE

Value leadership and T-Mobile’s consumer supply chain

THE WORLD’S LEADING COMPANY IN TELECOMMUNICATIONS INTEGRATION, SEMICONDUCTORS, AND OPTICAL MODULES

On July 28, 2022, T‑Mobile released their new flagship 5G mobile phones: REVVL 6 and REVVL 6 Pro which were developed and manufactured by Wingtech Technology. In addition to launching in the U.S. and collaborating with DT, the T Phone and T Phone Pro was also launched in 10 European countries. This joint collaboration between T Mobile and Wingtech Technology offers T Mobile and DT customers outstanding smartphones at a more affordable price point.

Contact us

products, because it's not just about the device anymore – it's about the entire experience. So, we're thinking about all those experiences and understanding how we can better present those to consumers on our website or in our retail locations.”

One of the key aims that T-Mobile is prioritising is continually improving the online experience for its customers.

“A lot of customers are used to buying online, particularly post-pandemic. When they make a purchase, online customers want transparency on when a product is going to be delivered,” Caballero-Vieyra says. “This is about modernising the system so that we can ensure customers have full transparency and certainty around when they’ll receive their order.”

To this end, T-Mobile’s partners are proving instrumental in enabling digital

transformation and improving overall customer experience.

“We're working with multiple partners. Starting with our logistics and transportation partners, we are working to implement robust systems to ensure we can fulfil products as quickly and transparently as possible.

“We're also working on developments that will enhance everything about the postpurchase notification process, making sure we can inform customers when to expect the product.”

Caballero-Vieyra explains how, within the next couple of years, T-Mobile is anticipating a shift towards an omnichannel purchasing

MAX CABALLERO-VIEYRA, SVP OF DEVICES & SUPPLY CHAIN, T-MOBILE

supplychaindigital.com 49 T - MOBILE

“All things considered, supply chain is a game of certainty and you need that certainty to operate”

MAX CABALLERO-VIEYRA, SVP OF DEVICES & SUPPLY CHAIN, T-MOBILE

MAX CABALLERO-VIEYRA, SVP OF DEVICES & SUPPLY CHAIN, T-MOBILE

“We're talking about hundreds of products, thousands of points of sale, and a very large number of partners. And managing all that complexity in an efficient way is extremely hard”

approach. “Of course, while everybody started buying online during the pandemic, our customers want to see, feel, and touch these devices or accessories, and talk to a person about their best plan options.

“But I think digital channels will continue to grow, and customers will increasingly interact with us online and through our app,” Caballero-Vieyra predicts.

Caballero-Vieyra states that, “from a supply chain perspective”, T-Mobile then needs to “ensure that our online and app experiences are second to none.”

“For example, when a customer places an order, we fulfil that order reliably, the product gets delivered reliably and on time. And, through the entire process of buying to receiving, customers know where that product is, ensuring transparency end-to-end.”

Continued innovation is, for CaballeroVieyra, a core part of retaining T-Mobile’s industry leadership: “The companies that find and spend the resources to invest in new ways of creating value for consumers are typically the companies that end up winning. Prioritising innovation today is the key to unlocking tomorrow’s growth, so we can’t lose sight of that.”

“It’s not about being just another player in the industry. Typically, the ones that you're going to see flourishing are those partners who are bringing a new perspective, a new experience, something new consumers need (even though they sometimes didn't expect it).”

As firm proponents of industry disruption, we couldn’t agree with that sentiment more.

supplychaindigital.com 51 T - MOBILE

Los Alamos National Laboratory’s SUPPLY CHAIN

PROCUREMENT TRANSFORMATION 52 March 2023

PROCUREMENT TRANSFORMATION Laboratory’s

Christine Hipp, Procurement Leader at LANL, discusses modernising their ‘Source-to Pay’ Solution’ (S2P) by implementing SAP Ariba & SAP Fieldglass

WRITTEN BY: SEAN ASHCROFT

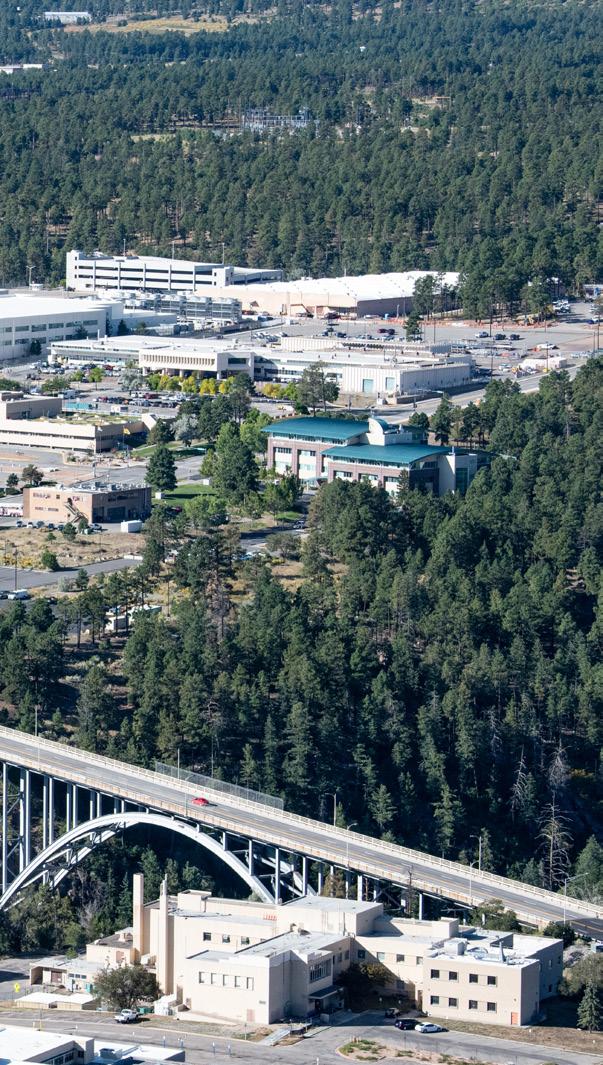

LOS ALAMOS NATIONAL LABORATORY, Los Alamos, New Mexico, USA

WEBSITE: www.lanl.gov

INDUSTRY: Defence and Security

PRODUCTS AND SERVICES: Nuclear Energy Technology and Energy Security Solutions

EMPLOYEES: 13,806

REVENUE: US$4BN

supplychaindigital.com 53

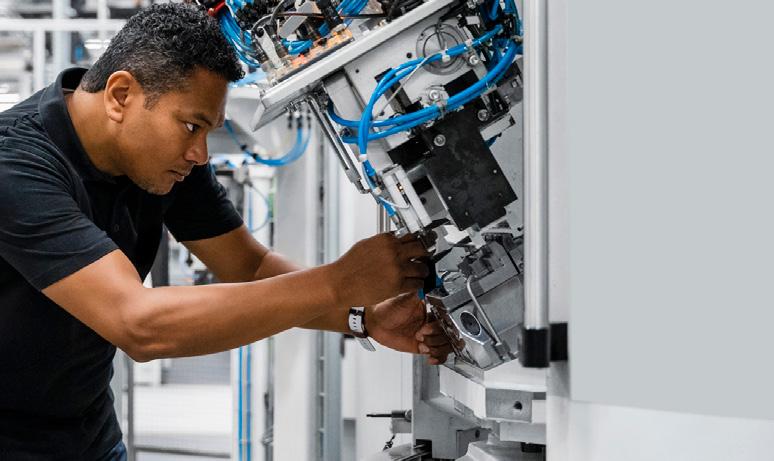

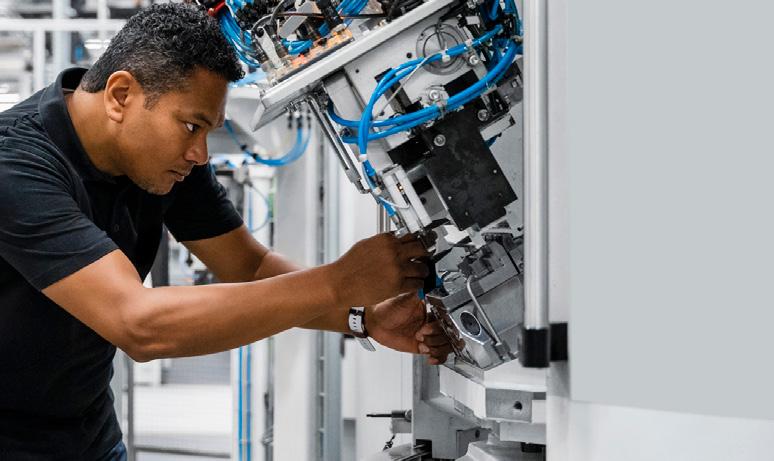

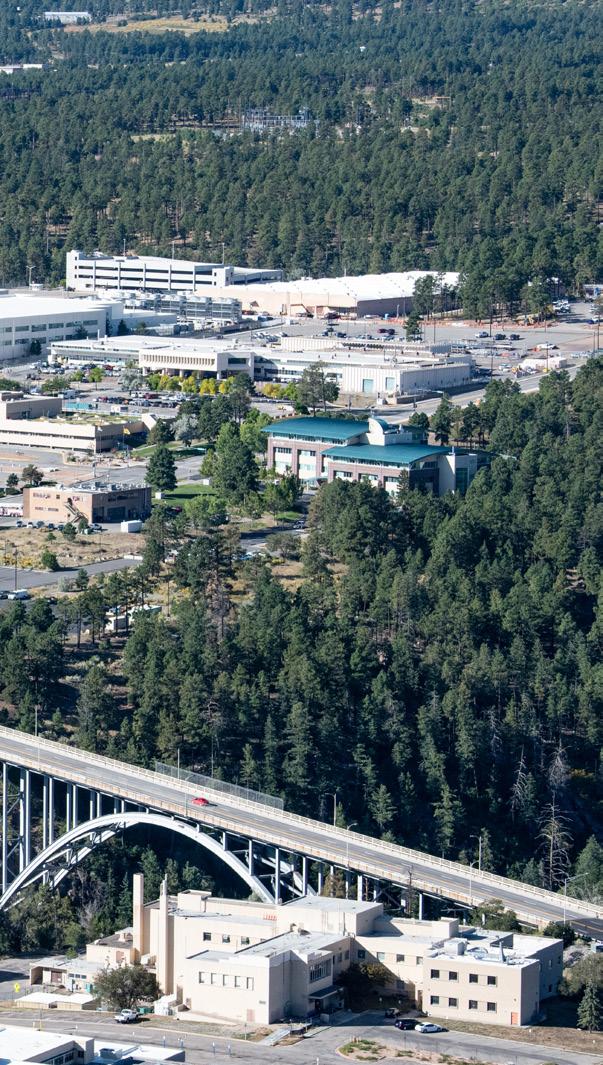

In one of the most secluded places on Earth, in the high desert near Santa Fe in New Mexico, 10,000 people work in one of the most cutting-edge facilities in the world – one that, as part of the Manhattan Project in World War II, was instrumental in developing the first ever atomic bomb. The Los Alamos National Laboratory (LANL) is one of 16 R&D laboratories run under contract by the US Department of Energy.

“We're known as the birthplace of the atomic bomb,” says Christine Hipp, Acquisition Services Management Center of Excellence Leader at LANL. “A lot of people don't realise we still exist.”

Today, LANL undertakes R&D on everything from the COVID-19 vaccine to genome sequencing, but retains a strong nuclear function, too, having stewardship of the US nuclear weapons programme.

LANL procurement ‘quite unlike other organisations’

The super-sensitive nature of its work means procurement processes at LANL are, to say the least, quite unlike those of most businesses. I interviewed Hipp in Dallas at SAP Spend Connect Live – a conference and expo where SAP unveiled updated versions of its spend management solutions to highly-regulated US industries such as

54 March 2023 SUPPLY CHAIN

Los Alamos National Laboratory main campus

defence, medicine, government and space exploration. At present, this functionality is available to these sectors only in the US, but SAP has plans to also serve regulated industries outside of the United States.

LANL’s procurement transformation kickstarted in 2019, when it began its move from Oracle e-Business Suite to SAP Ariba.

“We were seeing significant growth in our procurement demand and needed to modernise our tool set,” explains Hipp. “We chose Ariba as our source-to-pay solution and implemented it between January 2020 and June 2021.”

A key reason for the switch was because Ariba, in Hipp’s words, “allowed us to

Christine Hipp

TITLE: ACQUISITION SERVICES MANAGEMENT, CENTER OF EXCELLENCE LEADER

COMPANY: LOS ALAMOS NATIONAL LABORATORY

INDUSTRY: SCIENCE & TECHNOLOGY

LOCATION: US

At LANL Christine Hipp leads the ACE (Agility, Capability, Excellence) programme for procurement. This includes implementing new technology, and, she says, “adopting robust spend analytics and focusing on strategic sourcing and category management for procurement”.

Hipps adds: “Los Alamos is a government contract-run laboratory for the Department of Energy. We are run by a company called Triad, which is made up of a combination of Battelle Memorial Institute and the University of California.

“It's always been run by educational institutions. Historically, LANL was created as part of the Manhattan Project during World War II. We're known as the birthplace of the atomic bomb. Today, we do all kinds of work, from R&D and science to genome sequencing for the Covid-19 vaccine.

“We maintain a heavy presence in US national security, being stewards of the nation's nuclear weapons programme. So it's an interesting place to work".

supplychaindigital.com 55

GET YOUR PASS SPONSORSHIP Watch our 2022 Showreel A BizClik Event Join the Virtual Event Disrupting Procurement & Supply Chain 28TH JUNE 2023 VIRTUAL CONFERENCE

address our compliance requirements. We have very heavily regulated procurement procedures; had we not switched many of the requirements we have to follow, they might have prevented us from streamlining and automating procurement processes.”

SAP Ariba configurability ‘was key’

Ariba’s configurability, she says, “gave us the opportunity to do exactly this, thanks to its best-in-class solutions around automation”.

Hipp says LANL its procurement transformation has delivered “new tools and capabilities”, and that these have helped it manage the $1bn uptick in

procurement spend over the past two years. The doubling of its spend in this time “is an interesting problem to have as a government contractor”.

She adds: “The Federal government needs us to expand, and so we're acquiring things to facilitate that. Our revenue has grown from $2bn to more than $4bn, and half of that goes into more procurement. We’re also modernising our facilities in Atlanta, so that has also led to a lot of large procurement spend.”

The huge increase in spend has seen LANL’s more agile procurement transformation come into its own.

supplychaindigital.com 57 SUPPLY CHAIN

Pentagon Memorial in front of National Security Sciences Building

Expansion has meant more staff are required, and with a burgeoning payroll comes an increase in indirect procurement, such as office supplies –another reason LANL needed a more agile procurement solution.

And, as with so many organisations, the pandemic also sent Hipp and her procurement team into overdrive.

“With working from home, everybody needed a new laptop, so there was a lot of investment in IT infrastructure, and many of those people have remained working from home.”

‘Breadth of our procurement brings challenges’

Hipp also says that the breadth and variety of work LANL does brings its own procurement challenges: “We procure across space exploration, geophysics, medicine and sustainable energy, and each of these present their own challenges.

“We probably have one of the most unusual procurement functions anywhere. One of the nice things about SAP Ariba is it gives us visibility into each of these areas, which allows us to optimise our processes and address needs quickly."

58 March 2023

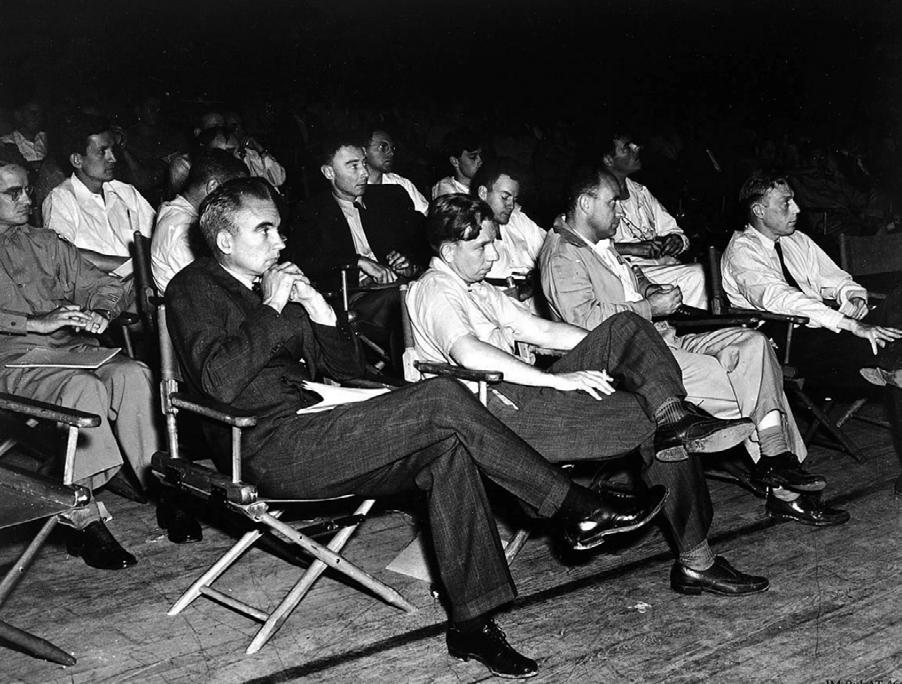

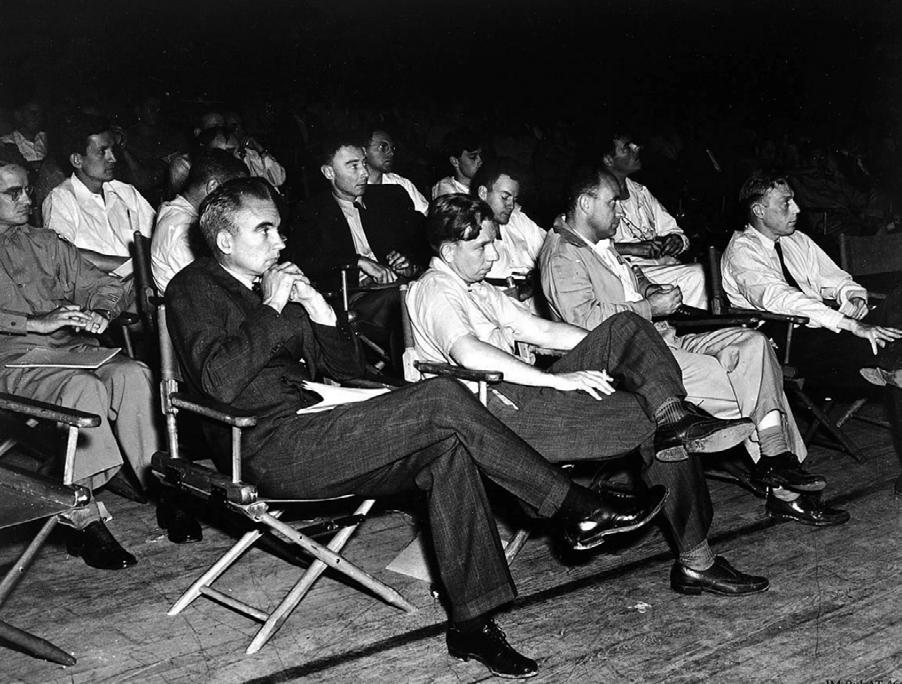

(ABOVE) Physicists at a war-time Manhattan Project meeting at the Los Alamos Laboratory. Robert Oppenheimer, a key figure in the evolution of nuclear weapons, is in the middle of the second row, wearing a dark coat

Needs like that of a ship-based research team in the Arctic Circle, who were frozen in an ice floe for 13 months as they measured climate change.

“Somebody in our organisation had to figure out how to buy the supplies they needed for those 13 months,” says Hipp. “They had to work out what they needed, where to source it and how to get it to them.”

But on a more conventional note, LANL’s procurement team is – like everyone else –battling to help their organisations recover from the supply chain disruptions of the past few years.

“SAP Ariba helped us learn how to pivot from being an organisation that was very reactive in its sourcing, to being proactive. It wasn’t enough any more to source something only after somebody had asked for it. Now, we are far more focused on supplier management".

"We have established far more relationships with key strategic suppliers than we did before.

“We used the SAP Ariba Network to source more suppliers. Now, we see suppliers more as business partners, who we need to have procurement planning conversations with."

Radiological Control Technicians simulate work processes in a glove box training facility

supplychaindigital.com 59 SUPPLY CHAIN

Value-Driven Results of the SAP Ariba and SAP Fieldglass Implementation

» Better-informed decision-making based on advanced spend analytics

» Accelerated workflows, with transactions processed more than 18 times faster than before

» Transparent processes and reporting in line with requirements for public sector agencies

» Smooth transition, due to a realignment of roles and extensive consultation with users prior to go-live

» Improved supplier relationships, thanks to more efficient processes and faster payment

» Increased agility, with the ability to quickly adjust software configuration according to changing needs

» Continuous improvement opportunities based on SAP's road map

“SAP Ariba and SAP Fieldglass solutions have enabled us to drastically change the way we do business and turn our suppliers into business partners”

CHRISTINE HIPP, HEAD OF PROCUREMENT CENTRE OF EXCELLENCE, LOS ALAMOS NATIONAL LABORATORY

PROJECT STATISTICS

<8 HOURS: to process commercial transactions under US$250,000: down from 30 days

250%: Projected increase in contingent labour over a two-year period

Key to LANL’s procurement transformation, says Hipp, was Chief Procurement Officer Drew Fuller, who joined the organisation at the outset of the project.

“I’ve been an IT manager and have implemented a lot of systems, but I’ve never had a partnership with someone like Drew before, who himself was embedded into the project and determined we were going to stick with it. His commitment got me more

excited about the project and this built my commitment to it, which was very inspiring.

“The entire project was delivered over Zoom calls, which I never thought would be possible. With things like the work we had to do to implement SAP Ariba, it’s important to keep an open mind, and to not have preconceived notions. This definitely allowed me to achieve more than I otherwise would.”

supplychaindigital.com 61 SUPPLY CHAIN

EMBEDDING SUSTAINABLE PROCUREMENT AT G4S

WRITTEN BY: SEAN ASHCROFT

PRODUCED BY:

CRAIG KILLINGBACK

62 March 2023

supplychaindigital.com 63 G4S

Willescroft

Search the term ‘G4S personnel’ in Google images and the result is startling: screen upon screen of vigilant security staff clad in armoured clothing, many of whom are armed. They are protecting everything from gas and oil plants in troubled regions to cash-in-transit vans transporting banknotes and coins.

These are the frontline employees of G4S, the multinational company that specialises in manned security services.

Asked who inspires him, Jon Willescroft –Chief Procurement Officer at G4S – doesn’t even pause.

“We've got half a million people, globally, on the front line, and every day those men and women pull on their uniform, they’re putting themselves at risk,” he says. “They define our business, putting themselves in harm’s way to deliver services. It's impossible not to be inspired by these people who have the toughest jobs.”

G4S is part of Allied Universal, a leading security and facility services company that provides proactive security services and cutting-edge smart technology to deliver tailored, integrated security solutions that allow clients to focus on their core business.

It provides trained and screened security officers, as well as security systems such as access control, CCTV, intruder alarms, fire detection, video analytics, and security and building systems integration technology.

Jon

is Chief Procurement Officer for G4S – part of the world’s largest security company – and it’s his job to drive meaningful, sustainable change

64 March 2023 G4S

supplychaindigital.com 65

As a result, G4S spends over a billion dollars a year with suppliers and subcontractors, giving business to thousands of SMEs across the globe. “Suppliers and subcontractors are a critical part of how we deliver for our customers and those in our care,” says Willescroft. “This is why it’s essential we partner with the best companies and organisations across the globe.”

Managing global & fragmented team ‘a huge challenge’

Easier said than done, when you have 150 procurement people scattered across the globe. Willescroft concedes that managing a large global, fragmented team is a massive undertaking.

“Managing a global team is all about communicating and then adapting that communication to the local audience”

66 March 2023

JON WILLESCROFT CHIEF PROCUREMENT OFFICER, G4S

“It’s really challenging,” he says. “From a procurement perspective, I've got people spread across the world, and within that you've also got big cultural differences as well as a wide range of capabilities, skills and knowledge.”

This, he says, is why G4S has crystal clear minimum standards and requirements.

“Whether I’m talking to a procurement administrator in Columbia or a head of procurement in Belgium, I talk in a language that figuratively they understand,” he says. “And I also have to take the time to embed the message.”

“You can't be passive about it. You can't just send out one set of standards and expect people to understand and comply with them.”

JON WILLESCROFT

TITLE: CHIEF PROCUREMENT OFFICER

INDUSTRY: SECURITY

LOCATION: LONDON UK

Jon Willescroft is an ambitious, energetic and commercial CPO, specialising in reshaping procurement in large and complex organisations. Jon currently leads procurement at G4S, part of the world’s largest security company, encompassing 150 people across 90 countries, and over $1Bn spend. His focus at G4S is driving sustainable, commercial transformation across this complex global business and its supply chains. Prior to G4S, Jon held a number of procurement leadership positions in financial services and pharmaceuticals, as well as procurement advisory roles.

G4S

Willescroft also uses what he dubs “positive tension” as a management strategy.

“By positive tension, I mean regions and categories challenging one another to drive value. It’s important that this exists between my global category leads – who deal with the international business – and the regional local procurement leads.

“This is the matrix model I've employed and I think it works pretty well.”

Data is another weapon in his arsenal.

“The insight you drive from data is absolutely key. It's the glue that holds the procurement function together. Data allows us to talk about risk, performance, cost savings and sustainability in the same language, which makes it much more powerful to the wider business.”

Keeping his global team engaged, informed and motivated is another major challenge, says Willescroft: “Given the complexity and the geographic spread of the team, my objective is to make everyone feel part of a single team – one global

“If you don’t embed sustainability into your everyday processes and routines, then you’re just sticking stuff on that will eventually fall apart”

68 March 2023 G4S

JON WILLESCROFT CHIEF PROCUREMENT OFFICER, G4S

professional procurement function – and to feel proud to work in that team.”

Consistency of message is key with global teams

There are no “dark arts” involved in this. “It’s all about communicating,” Willescroft says, “and adapting that communication to the local countries.

“Within this, you also need consistency of message. You need to clearly lay out the roadmap of where we're going across our core pillars of procurement – whether that’s sourcing, supplier management, or sustainability.”

Technology helps, too. G4S is in the process of launching a global procurement capability development tool, which Willescroft says will provide people with “a map of where they are today from a development perspective against the skills and competence we'd expect them to have”.

If managing people is one onerous challenge, then protecting the bottom line is another. So, how does Willescroft drive value in such a fragmented global market?

“Wherever we can leverage globally with suppliers, we do so,” he says. “But a lot of our supply chains are by their nature localised, which is why we always make sure our category leaders are very collaborative. They need to be smart but also have a high emotional quotient. They have to be able to drive change, which is a big part of the job.”

In Willescroft’s view, this is vital. “If our people lack the right skill set or aren’t motivated in the right way, then we'll fail. You need the right people, and you need to know how they’re executing in their country.”

Because G4S is a low-margin business, Willescroft says the role makes specific demands of him.

“You're more likely to primarily think short term in a low-margin business,” he says. “If

supplychaindigital.com 69 G4S

Connect with us here T 033 3939 0022 E sales@radiocoms.co.uk www.radiocoms.co.uk Let’s work together. Bringing your team closer together. Communication devices and software to keep your team connected, safe and efficient regardless of their location. Learn more

you're a higher-margin business, you have the flexibility to think a little longer term.”

He adds: “But whatever business you work for, as a CPO, you have to be a commercially-focused leader and deliver what the business needs to be successful. And what ‘successful’ looks like changes from business to business.

“I think there's more of a pull for procurement in a low-margin business like G4S, and probably the biggest challenge here is you have to work really hard to educate and drive the agenda of the business. You have to give the business what it needs, not what it wants.”

Helping Willescroft and his team give G4S what it needs is a raft of technology-driven changes. Yet, underpinning this multilayered transformation process is something that has nothing whatsoever to do with tech: rock-solid values.

Improvement only works if there are solid foundations

“Before you try and improve things, you've got to strengthen the foundations,” he says. “By that, I mean strengthening the procurement community network by evolving the controls we have in place and making sure we're delivering sustainable, measurable savings across the business. These are the building blocks.”

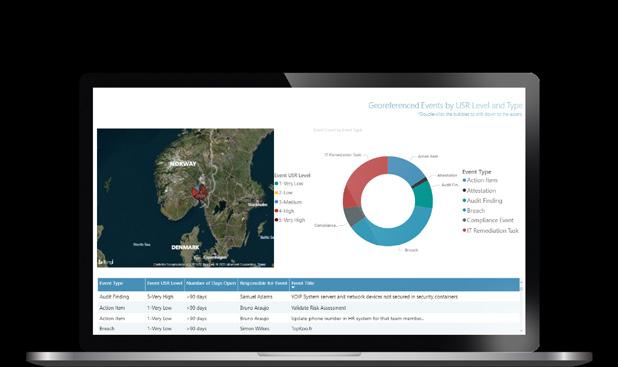

On top of this G4S is driving change through data insights and KPI dashboards to give it visibility, both of its internal controls and its supply chain.

supplychaindigital.com 71 G4S

With any change project, taking people along with you is critically important – and Willescroft’s approach to this sees him again drawing from the communication well.

“You communicate clearly around purpose and direction, as well as why we're doing what we're doing. You make clear the benefits of working in a leaner organisation with leaner teams, such as there being more development opportunities for people within the team.”

He adds: “I'm also keen that everyone is stretched beyond their core role in procurement, because this puts people at

“Understanding the sustainability standards of suppliers worldwide involves knowing where the risk sits and how we can best manage that risk”

JON WILLESCROFT CHIEF PROCUREMENT OFFICER, G4S

WATCH NOW 72 March 2023 G4S

Embedding sustainable procurement at G4S

the heart of driving the change. In this way, you win their hearts and minds, rather than rendering change as something that is done to them.

G4S has, according to Willescroft, worked closely with Page Consulting on this. “They've helped us ramp up and execute really quickly in the UK on procurement capability development.”

One key area of the change process at G4S is supply chain sustainability –something that’s growing exponentially in importance across all organisations. Another is transformation around supplier

management and assurance, which is designed to give the company better visibility of suppliers, not just from a risk perspective but also in terms of performance.

The goal is to drive value and innovation, Willescroft says.

Embedding sustainability and ESG is the goal

With sustainability and ESG initiatives –digitally-driven or otherwise – Willescroft believes the danger is that “you stick stuff on to existing processes and then it just falls apart”. Embedding, he stresses, is key.

supplychaindigital.com 73 G4S

YOUR PARTNER FOR PEOPLE, PROJECTS AND PROGRAMMES, EVERY STEP OF THE WAY.

Page Consulting focusses on supporting customers with talent management, consulting & advisory services across transformation, technology, supply chain, operations and HR.

We support our clients in solving tomorrow’s challenges, today – delivering efficient, affordable, highly specialised and customised solutions.

LEARN MORE

“How do we do that? By making sure that, at a functional level, ESG and sustainability are a core part of how we are measured and how our objectives are measured. This way, everything flows all the way down to individual objectives.”

“Over the coming year, everyone has targeted individual measures that are not only around commercial delivery, but are also really clear on ESG and sustainability objectives. This means these topics are standing agenda items every time we engage with the business. Every time we sit down and review performance with the business units, or talk about sourcing, deals, or supply management performance, then sustainability is a core part of that.”

Only by constantly talking about sustainability and ESG does Willescroft believe you can fully embed them into a business. He also points to the importance of having clarity on priorities.

“Sustainability is a broad subject, and you're in danger of spinning your wheels if you don't prioritise. I have top-down support from the executive committee, who align the procurement sustainability objectives with the corporate ones.”

In this way, the areas he agrees upon with the executive committee “become our absolute focus”.

Willescroft adds: “So, we have our core standards and policies – which are like hygiene factors – and then beyond this, the focus is on supply chain transparency.”

“The CPO role is often about telling the company what it needs to hear, rather than what it wants to hear”

supplychaindigital.com 75 G4S

JON WILLESCROFT CHIEF PROCUREMENT OFFICER, G4S

Understanding the sustainability standards of its suppliers around the world is a big part of this.

‘Do we understand where the risk sits?’ and ‘Can we manage it?’ are the two key questions that Willescroft highlights here. “The areas where we're investing most time, effort and resources are net zero, supplier diversity, and human rights.”

To this end, G4S recently launched an initiative in the UK to promote a broader representation of diverse-owned suppliers in its supply chain, with the aim of furthering

diversity and inclusion throughout. Broadly speaking, a supplier is considered diverse when half or more of the venture is owned and operated by a variety of ethnicities, those with disabilities, women, from a range of social backgrounds, or those from the LGBTQIA+ community.

As part of the scheme, G4S is working with Kaleida International – a UK and EMEA B2B marketplace for tenders connecting buyers to diverse suppliers.

Willescroft says: “We’re committed to supporting diverse suppliers. Our suppliers

G4S 76 March 2023

play a critical role in helping us run a successful business, delivering excellent service to our customers.

“Greater diversity of suppliers brings a richness of thoughts, ideas and innovation. It’s also critical that our business reflects and supports the societies in which we operate, including often more marginalised, diverse communities.”

G4S is also taking big strides in its global 2050 net-zero commitment, with procurement at the heart of this programme.

Willescroft says: “We’ve made great progress this year with our fleet decarbonisation. Working closely with our UK partner, Leaseplan, over three quarters of our new vehicle orders have been low-emission vehicles.

“We’re also now getting to grips with our supply chain emissions which account for 70% of the total, and will be working collaboratively with our major suppliers to drive this down.”

supplychaindigital.com 77

FUTURE RISK IN GLOBAL

78 March 2023

FUTURE-PROOFING RISK & RESILIENCE GLOBAL LOGISTICS

Supply Chains are vulnerable to risks that can disrupt the flow of global goods and services; logistics operators must mitigate risk and enhance resilience

WRITTEN BY: SEAN ASHCROFT

In recent years, organisations have been rocked by unforeseen supply chain vulnerabilities and disruptions, in industries ranging from pharmaceuticals and consumer goods to electronics and automotive.

Risk mitigation and operational resilience has never been more important, especially in the realm of logistics, a profession that’s always been in the front line of risk.

Risk & Resilience was the theme of April 2022’s Procurement & Supply Chain LIVE event. As part of that event, a three-man panel of experts discussed risk and resilience in supply chains – alongside how this should and shouldn’t look. One panel member was Richard Jowers, Director of Value Advisory, Intelligent Spend & Business Network at SAP.

LOGISTICS supplychaindigital.com 79

Richard Jowers

TITLE: DIRECTOR OF VALUE ADVISORY, INTELLIGENT SPEND & BUSINESS NETWORK

COMPANY: SAP

INDUSTRY: BUSINESS SERVICES

LOCATION: GERMANY (HQ)

Jowers says of himself: “I work collaboratively with clients to drive their digital transformation agenda through the introduction of SAP technologies.” To do so he draws upon 25 years’ experience working with global organisations across a range of industry sectors.

Specialties include: Digital procurement solutions, procurement transformation, strategic sourcing, supplier relationship management, and logistics engineering.

Jowers said the very shape of logistics is being changed by the disruptive forces at work in today’s world, and that businesses are learning to adapt as they go. “Take the decision of some companies to hold high levels of inventory to protect themselves against supply risks – many have discovered that such an approach itself comes with its own risks. Materials and products can go out of date or become obsolete.”

As a result of this, continues Jowers, organisations are now turning to supply networks over chains to source goods locally. “It might not even be for purely logistical reasons, but for ESG purposes. They might want to support a particular part of their domestic economy, for example, or a particular region or group of people.

80 March 2023 LOGISTICS

Disruptive companies reassessing customer & supplier network models

“At SAP, we get asked quite often to provide analysis of what suppliers exist in this or that region, so that organisations can prioritise minority-owned suppliers. People are becoming far more mindful around sourcing.”

A fellow panellist and colleague was Andrea Ricciarelli, Sustainable Supply Chain Management Domain Advisor at SAP, who holds in-depth logistics expertise and experience, with a focus on transportation and warehouse management.Ricciarelli believes that agility around logistics is vital for businesses who not only want to mitigate risk, but also want to compete in today’s volatile markets. He cited Amazon as a game-changer here, particularly around last-mile logistics.

“Amazon has been very disruptive these past five years. Now, when we place an order, we want to know exactly when we’ll receive it. This is why so many retailers now organise logistics networks to ship products to final customers and are also organising returns. This has given rise to a different customer model in the logistics industry.”

Ricciarelli also referenced Procter & Gamble, who he says has moved from a wholesale model to a direct-to-consumer model by delivering products to endconsumers.

“In that sense, retailers are moving into the logistics service-provider space,” he says, adding that logistics service providers are also rolling with the punches of uncertainty and disruption by evolving their services.

supplychaindigital.com 81

Inform your supply chain resilience planning with our time-measured report series

Ensuring the agility and resilience of your business and supply chain starts with identifying the risks.

Download our report to start your resilience planning today.

Download ASCRI Report

Because

Hindsight

Insight Beats

“Many logistics companies now use additive manufacturing (3D printing), which allows on-demand parts printing. They’re moving away from transporting the physical inventory of customers to producing on-demand digital inventory. This is a radical change.”

“For example,” Ricciarelli added, “Airbus is now producing 10% of its parts through additive manufacturing. In the US, UPS is building an additive manufacturing plant to produce customer parts on-demand, so it has shifted from selling products to selling services.”

Asked how important visibility is to mitigating logistical risk, Ricciarelli said such questions always lead him back to the same event: the Ever Given container ship that blocked the Suez Canal, which brought global sea shipping to its knees for weeks in early 2021.

“Every company was left wondering if it had a container on one of the hundreds of ships that were going nowhere,” said Ricciarelli. “If they did have goods on those ships, the next thing was to find out what

orders were delayed and who the customers for those goods were.”

Benefits of visibility & preparation

He said having no visibility in such a situation “is the worst thing that can happen”, before adding: “Yet the Suez Canal has been blocked five or six times in its history, so businesses really should have been prepared for it.

“Today, technology means more businesses are prepared, because they can use geolocation and telematics to know exactly where a container is en route. They can also map the relationship between orders, deliveries, items and containers, and analyse exactly what orders are in specific containers.”

“MANY ORGANISATIONS ARE TURNING TO SUPPLY NETWORKS RATHER THAN CHAINS TO SOURCE GOODS LOCALLY”

RICHARD JOWERS, DIRECTOR OF VALUE ADVISORY, INTELLIGENT SPEND & BUSINESS NETWORK, SAP

supplychaindigital.com 83 LOGISTICS

Andrea Ricciarelli

TITLE: SUSTAINABLE SUPPLY CHAIN MANAGEMENT DOMAIN ADVISOR

COMPANY: SAP

INDUSTRY: BUSINESS SERVICES

LOCATION: Germany (HQ)

Based in Milan, Italy, Ricciarelli says he has “strong sales and technical skills and keen business vision”. He has more than 20 years’ experience in logistics and supply chain management, as well as 10 years in business development at international level across the ICT and technology enabled sectors. He is a skilled speaker “with a broad perspective on the market and latest trends”, and says he has “a track record of achievements in the development & execution of growth strategies, largescale business development and joint partnerships”.

The third panellist was Tom Woodham, a Partner at PwC who works with clients to embed supply chain technology into operations. Woodham warned that, although tech-led risk mitigation is important, it is not the “be-all and end-all”, because “ultimately, it’s about your people, your processes and your data. Technology can really help, but the most important thing is to identify risk before you know it exists,” he continued.

Woodham gave the example of a PwC client company that works in aerospace: “It puts sensors on all of its parts, so not only does it know if a part is delayed, but it also knows what condition that part is in and what temperature it is.

84 March 2023

“Companies wouldn't have known such things years ago – so technology can definitely help – but really it's about identifying the key risks before they happen, so you can build that into your processes. Then it's about having your people trained, so they can respond to these problems.”

But in such a tough economic climate, what if a business can afford to invest in only one area of risk mitigation? Where should it start?

“Data,” said Woodham. “That’s the place to start, but it’s also how you invest in data. Too often, businesses invest in technology based on their most recent crisis, rather than around predicting what the next crisis will be.”

Ebb & flow of supply chain management and mitigating risks

Woodham referenced the semiconductor shortage to illustrate his point: “Lots of companies invested in risk mitigation around the chip shortage, but the truth is that the shortage will sort itself out, because supply and demand usually does. The question those companies need to ask is: Why was I unable to predict the semiconductor crisis? The answer to that comes down to how they use data.”

Another strategy to which organisations are turning to mitigate logistical risk is shortening their supply chain via nearshoring or reshoring manufacturing. Woodham told

ANDREA RICCIARELLI, SUSTAINABLE SUPPLY CHAIN MANAGEMENT DOMAIN ADVISOR, SAP

supplychaindigital.com 85 LOGISTICS

“SOME LOGISTICS COMPANIES ARE MOVING AWAY FROM TRANSPORTING PHYSICAL INVENTORY TO PRODUCING ON-DEMAND INVENTORY USING 3D PRINTING”

Tom Woodham

TITLE: PARTNER

COMPANY: PWC

INDUSTRY: PROFESSIONAL SERVICES

LOCATION: UK

Woodham says “my craft is the transformation of supply chain and procurement for PwC’s clients”. He adds: “The new challenges of the digital age give me the opportunity to work with amazing teams to reinvent companies to win in the future.

“As an engineer, I have a natural bias for problem solving and how to use new technology and ideas to drive improvement. This is an exciting time for supply chain and procurement, and an amazing opportunity to make digitally enabled transformational change based on new technologies like AI, automation and blockchain.”