26 - 27 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

EDITOR-IN-CHIEF

SEAN ASHCROFT

CHIEF CONTENT OFFICER

SCOTT BIRCH

MANAGING EDITOR

NEIL PERRY

CHIEF DESIGN OFFICER

MATT JOHNSON

HEAD OF DESIGN/

SUPPLYCHAIN LEAD DESIGNER

ANDY WOOLLACOTT

FEATURE DESIGNERS

MIMI GUNN

SOPHIE-ANN PINNELL

HECTOR PENROSE

SAM HUBBARD

REBEKAH BIRLESON

JULIA WAINWRIGHT

ADVERT DESIGNERS

JORDAN WOOD

DANILO CARDOSO

CALLUM HOOD

VIDEO PRODUCTION MANAGER

KIERAN WAITE

SENIOR VIDEOGRAPHER

HUDSON MELDRUM

DIGITAL VIDEO PRODUCERS

ERNEST DE NEVE

THOMAS EASTERFORD

DREW HARDMAN

SALLY MOUSTAFA

PRODUCTION DIRECTORS

GEORGIA ALLEN

DANIELA KIANICKOVÁ

PRODUCTION MANAGERS

JANE ARNETA

MARIA GONZALEZ

YEVHENIIA SUBBOTINA

MARKETING MANAGER

KATHRYN WEBB

PROJECT DIRECTORS

STUART IRVING

JAMES BERRY

MEDIA SALES DIRECTOR

JAMES WHITE

MANAGING DIRECTOR

LEWIS VAUGHAN

CEO

GLEN WHITE

TECHNOLOGY MIGHT BE ADVANCING AT A DIZZYING SPEED BUT NONE OF IT MATTERS A JOT IF NOT UNDERPINNED AND INFORMED BY STRONG HUMAN RELATIONS

Strong supplier relations have always been critically important for an efficient and cost effective supply chain. In today’s uncertain world, though, it has never been more crucIal.

In the past, such a thing might have been called having an ‘in-the-round’ view of supply chain. Now, people are more likely to refer to it as having a 360-degree view of the supply chain, or of having end-to-end visibility.

It’s not just the language that has changed of course; technology has moved on – and continues to move on – at a dizzying pace. Data is the currency of supply chain visibility.

But what is the currency of data? That’s simple: relationships. Supply chain, like life itself, is built on relationships.

And like all relationships, it’s a two-way street. Suppliers want to build strong relations because this is what gives them preferred supplier status. Organisations want the same thing, because such relationships help add value outside of supplier contracts, and when scaled-up these benefits bring resilience.

In this issue we explore supplier relations in depth, and it’s a timely reminder that technology, however awe inspiring, comes in a distant second to supply chain’s most important assets. People.

SEAN ASHCROFT

sean.ashcroft@bizclikmedia.com

“Supply chain, like life itself, is built on relationships”

040 COVER FEATURE INTERVIEW: GEP ON GEN AI

026 TOP 10 Supply chain events 2023/24

040 INTERVIEW

GEP on Gen AI in procurement, with President and Co-Founder of GEP, Neha Shah

050 AMERCAREROYAL Transformation drives AmerCareRoyal to an industry leader

074 SUPPLY CHAIN Strong supplier relations keep supply chains moving

086 HYLAND AND WORKDAY

Challenges in supply chain processes need smart and partnered solutions

26 - 27 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

100 LOGISTICS

Latin America is seeing an e-commerce boom but poor service levels are eroding trust and harming progress

110 FRACHT US International freight forwarder Fracht US has digitally transformed, improving life both for the company and its customers

126 SUSTAINABILITY

Volvo Trucks is leading the way in EV production for logistics sector, as businesses like DHL Supply Chain and DFDS add e-trucks to their fleets

138 AB INBEV

Jacques Els, Procurement & Sustainability Director: BU

Southeast Africa, discusses AB InBev’s sustainable delivery of Africa’s developing supply chain

152 TECHNOLOGY

Data is the true currency of Industrial IoT tech

Global sugar prices are expected to continue to rise in the run-up to December, having already increased sharply this year – a massive 42% in June alone. The problem has been caused by extreme weather in key producing nations, including India, Brazil, Thailand and China, with drought a major cause. India is the largest producer of sugar, with around 34 million tonnes a year, and Uttar Pradesh is its biggest sugar producing region.

Nuce-Hilton is SVP, Innovation & Partnerships US with international supply chain standards body, GS1 US

» GS1 is a not-for-profit organisation whose job is to help our members implement global supply chain standards for unique identification, data capture and data sharing between trading partners. GS1 US is part of GS1 global and is the largest of the 116 member organisations.

» I lead the Innovation & Partnerships team. We look at how emerging technology can support supply chain business processes to drive positive business outcomes. Before GS1 I was working in supply chain on data management and software, and also spent time in various supply chain and consulting roles.

When I first joined GS1 US, I was leading our apparel and general

merchandise industry engagement group, working with leading brand manufacturers, retailers and other trading partners to help them assess how leveraging global standards can build consumer trust and deliver improved supply chain efficiency.

» GS1 Standards create a common foundation for business by identifying, accurately capturing and automatically sharing vital information about products, locations, assets and more, in a consistent, repeatable way that scales across industries.

If stakeholders have different processes and systems, straightforward information sharing can waste time and be highly susceptible to human error.

“To meet consumer demands, companies need complete, accurate and trusted data to back up their claims”

MELANIE NUCE-HILTON

TITLE: SENIOR VP, INNOVATION & PARTNERSHIPS

COMPANY: GS1 US

Nuce-Hilton is an experienced leader in innovation, partnership development, product management, marketing, and operations. She has a background in retail supply chain, e-commerce, software and services.

» It’s no longer enough for a company to just say its operations are sustainable, its raw materials are ethically sourced or its products are made from recycled materials – they must be able to prove it.

This is where GS1 Standards play a pivotal role. To meet consumer demands, companies need complete, accurate and trusted data to back up their claims. As this data continues to be collected, digitised and shared in a standardised way, companies have what they need for verified transparency with trading partners and customers.

» GS1 US is leading the industry toward a migration to on-pack 2D barcodes, such as QR codes. The 1D UPC barcode we’re all familiar with will coexist onpack with 2D barcodes for some time. The 2D barcode is extremely valuable

“GS1 Standards create a common foundation that is repeatable and can be scaled across industries”

because the amount of data contained delivers a wealth of consumer-engaging experiences and opportunities, while also ensuring trusted, vital brand information for consumers and enhancing many back office supply chain functions.

I see such global standards being leveraged in a better way as a means of enhanced collaboration. By leveraging globally recognised and accepted GS1 Standards, organisations can communicate with the same, consistent language.

Those same GS1 Standards also provide the unique and persistent identification to support sustainability. That unique identifier – like a Global Trade Item Number – follows items and raw materials through the product life cycle.

Looking ahead, global standards will continue to evolve to meet the more specific demands for sustainability attributions, certifications and

disclosures. Product labelling will be a huge piece of that. The increase in demand from consumers for more information is changing the future of labels, and standards are a critical enabler.

» My team inspires me to be better every day. They bring so much perspective and passion to work, trying to solve the business challenges that we can’t even see yet.

Innovation means pushing the boundaries, being an advocate for change, and also an agent for change but in a practical way. Without multiple viewpoints on the world how can we truly innovate and make an impact that the world can feel?

» Fail, and fail fast. You’ll learn from it and be stronger when you come out on the other side.

Lior Ron is an Israeli-born businessman who served in the Israel defence forces from 1997 to 2004.

In his commercial life, Ron rose to become Product Lead for Google Maps and then Product Lead for Motorola Mobility, which was acquired by Google in 2011.

In 2016 he left Google to found Otto, a company that makes selfdriving kits to retrofit big-rig trucks.

Quoted in Wired, Ron said he left Google because he “felt an obligation to bring this technology to society sooner rather than later”. In an industry where there’s a 30% chance that a truck next to you on the road is empty, it has always been Ron’s mission to change this as soon as possible.

Otto launched in May, 2016 and was acquired by Uber in late July the same

year. The Uber partnership allowed Ron and Otto the opportunity to develop a freight marketplace for truck drivers.

The Uber Freight app is designed for vetted and approved drivers who can browse for nearby available loads, see destination info, distance required and payment upfront and then tap to book.

Uber Freight serves shippers of all sizes, from Fortune 500 companies to small independent businesses, and it helps marshalls the estimated 1.7 million truck drivers across North America who are on it.

The platform also opens up a new revenue stream for truck companies, which now have another way to book and process loads.

In an interview as part of McKinsey’s Logistics Disruptors series, Ron says

“With the greater utilisation of trucks carriers can also increase their earning power”

that Uber Freight connects shippers to carriers with capacity by “standing on the shoulders of a giant”.

At a time when the trucking industry is battling rising fuel prices, worsening inefficiency, and difficulties recruiting drivers, Ron says his mission is to “simplify logistics to help communities thrive”

He adds that the aim of Uber Freight is to “simplify the movement of goods and streamline the process by digitising all of the supply chain infrastructure”.

It is this that minimises empty miles and makes the trucking profession friendlier for carriers.

“By releasing this additional capacity, costs should go down and shippers can also streamline their logistics and supply chains,” says Ron.

He adds that, with the greater utilisation of trucks, carriers can also increase their earning power.

“Essentially, we’re connecting supply and demand in a digital, scalable way,” he tells McKinsey.

Asked how the relationships that underpin logistics can possibly be digitised, Ron says Uber Freight helps businesses embrace relationships and augment them with technology.

“Our fundamental belief is that technology is the best way to support and build trust,” he says, adding: “When you ride with Uber, you trust that your car will be there within the displayed time. There’s tons of technology behind the scenes that makes this possible. The same is true for Uber Freight.”

Ron continues: “We have the largest digitally enabled carrier network in the market. Our technology enables companies to recover from cancellations much faster than any manual model, just like how your Uber app automatically assigns you another driver if one cancels.”

Ron points out that in trucking around 15% of daily shipments are cancelled because of weather, traffic, waiting time in facilities, or other reasons.

“We help businesses recover from these cancellations almost 90% of the time,” he explains. “A new carrier is automatically assigned and the disruption is smoothened. That’s unheard of in logistics, and it’s how we build trust.

Tellingly, he adds: “Quite simply, we’re Uber for trucks”.

UBER FREIGHT IS ONE OF THE WORLD’S LARGEST LOGISTICS AND TRANSPORTATION NETWORKS

“Quite simply, we’re Uber for trucks”

Streamline purchasing while saving on everyday supplies so you can focus on growing your business.

Enjoy great discounts, starting from just two units, on over 4 million products from the most trusted brands.

Get unlimited, FREE delivery on eligible orders for everyone on your business account, plus more benefits.

Connect your teams, create purchasing groups and share payment methods. Create a free account

Here, we take a look at the leading procurement, supply chain & logistics conferences taking place in the remainder of 2023 and into 2024. These are among the the top supply chain conferences, expos and industry events, all of which give leading figures from supply chain, procurement and logistics the opportunity to share insight, knowledge and experience. Armed with this, they are better placed to help their organisations navigate supply chain disruption, economic volatility and geopolitical uncertainty. Such events also help executives discover opportunities around procurement transformation, global logistics strategies and supply chain digitalisation.

When: March 11-14, 2024

Location: Georgia, USA Company: MHI

As the speed of manufacturing and supply chain operations continues to accelerate, the future of the industry depends on forwardthinking decisions. MODEX 2024 is a leading manufacturing and supply chain show where buyers come to engage one-to-one with solution providers and supply chain experts.

The event showcases emerging technologies and equipment, and helps businesses future-proof their supply chains. It features 150 free education sessions as well as powerful keynote addresses.

09

When: 24-25 October, 2023

Location: Brussels, Belgium

Company: Reuters Events

Reuters Events’ Supply Chain Europe 2023 brings together the end-to-end supply chain, to, it says, “share new best-practice and strategies for the future as we build the future of supply chain networks”.

Executives from across the supply chain ecosystem –including Fortune 500 retailers & manufacturers, forward-thinking logistics organisations, leading technology solution providers, government officials and industry heavyweights – will come together to share their vision of the future and, Reuters says, “make it a reality”.

Date: 19-20 March 2024

Location: Birmingham, England

Company: Akabo Media

As environmental issues become more important to consumer and business brand owners across all sectors, there is growing demand for supply chains to adopt sustainable practices, become net zero, and adopt effective ESG strategies.

The Sustainable Supply Chain Exhibition allows logistics, supply chain, and sustainability professionals to share ideas, offer solutions and help each other on their sustainable journeys.

Date: 16-17 October

Location: Manchester, England

Company: Forum Events

The Total Supply Chain Summit brings together senior supply chain and logistics executives with leading solution providers in the industry. It features keynote speakers, panel discussions, and interactive workshops on technology and automation, inventory management, transportation and distribution, sustainability, and global supply chain strategies.

Attendees can also participate in one-to-one business meetings with solution providers to learn about new technologies, services, and solutions that can help optimise their supply chain operations.

26 - 27 September 2023

Business Design Centre, London

SPONSORSHIPS GET YOUR PASS

Date: April 30-May 1, 2024

Location: Dallas, Texas, USA

Organiser: Generis

The American Supply Chain Summit is a leadership-focused event whose aim is to improve supply chain and procurement strategy across the globe.

It’s an annual platform for exchanging ideas and collaborating on new technologies for supply chain and operations leaders.

The 2024 event explores case studies on how to navigate supply chain disruption, as well as how workforce management, advanced analytics, process improvement and automation are being rolled out in the world’s best facilities.

It will feature in-depth discussions on innovation, maximising supply chain profitability, increasing visibility and mitigating risk.

Date: May 6-8, 2024

Location: Orlando, Florida, USA

Company: Gartner

Gartner Supply Chain Symposium is an annual conference organised by global research and advisory firm Gartner. It provides insights and advice to businesses in various industries. The conference is focused on supply chain management and logistics, bringing together supply chain professionals, academics, and experts to discuss the latest trends, strategies, and best practices in the field. It features keynote speakers, panel discussions, case studies, and workshops on topics such as supply chain digitalisation, inventory optimisation, logistics and transportation management, supplier relationship management, and sustainability.

Date: 22-23 May, 2024

Location: Atlanta, USA

Company: Reuters Events

At Supply Chain USA 2024, executives from across the supply chain ecosystem covering planning, sourcing, manufacturing and logistics “will gather to confront the most business-critical challenges facing our industry”, says Reuters Events.

Delegates will learn about how to build supply chains that are customercentric. resilient. ESG compliant, cost effective and data driven.

“Few supply chain events focus on the pain points of retailers and manufacturers like Supply Chain USA,” says Reuters. “This is not a vendor fest.”

Date: September 26-28

Location: Barcelona, Spain

Company: Worldwide Business Research

ProcureCon is a series of conferences and events focused on procurement and strategic sourcing. The events bring together procurement professionals from a variety of industries to share best practices, network, and to learn about the latest trends and innovations in procurement.

It features keynote speakers, panel discussions, case studies, and workshops on topics including procurement technology, category management, supplier relationship management, and contract negotiations. Attendees can also participate in roundtable discussions and networking events to connect with other procurement professionals.

Date: October 1-4

Location: Kissimmee, Florida, USA

Host: Council of Supply Chain Management Professionals

CSCMP EDGE is an annual supply chain conference hosted by the Council of Supply Chain Management Professionals (CSCMP). The conference brings together supply chain professionals from around the world to share best practices, network, and learn about the latest trends and innovations in the industry.

The conference typically features keynote speakers, panel discussions, workshops, and an exhibit hall showcasing the latest technologies and services related to supply chain management. Topics covered range from logistics and transportation to inventory management and sustainability.

Date: 26-27 September

Location: London, England Company: BizClik

Leading industry figures gather at Procurement & Supply Chain LIVE to discuss the most important and innovative ideas around the world of procurement, supply chain and logistics.

The event includes keynote speakers, fireside chats, interactive workshops and networking opportunities. With around 2,200 attendees, Procurement & SupplyChain LIVE London is the place to meet

peers and be part of supply chain solutions.

There are two conference stages and a total of eight industry workshops. Speakers include: Alisa Bornstein, Chief Procurement Officer, VISA Europe; Matthew Harris CPO, Logistics & Services, A.P. MollerMaersk; Juud Tempelman Global Chief Procurement Officer, JLL; and Nicholas Wright, Director, Procurement Innovation (Digital & Talent) bp.

The Global Supply Chain Awards 2024 will be celebrating the very best in Procurement & Supply Chain with the following categories:

Procurement Transformation Award

–Digital Supply Chain Award

–Global Logistics Award

–Supplier Diversity Award

–Supply Chain Innovation Award –

Supply Chain Sustainability Award –Procurement Technology Award –

Procurement Consultancy Award –Future Leader Award –Executive of the Year Award

–Project of the Year Award –

Lifetime Achievement Award GET INVOLVED

GET INVOLVED

As President and Co-Founder of GEP, Neha Shah describes herself as an ‘accidental entrepreneur’

WRITTEN BY: NEIL PERRY

Aboom in the 1990s, she always felt that solving problems was more important to her than simply making money. As the company now helps to lead the conversation on the use of AI in the field of procurement and supply chain software, she still warmly looks back on the early days of the company and the strong grounding it has given the leadership team.

“As an early stage company, we had to do it all. I had to do it all from the administrative tasks, all the way to selling to Fortune 500 companies and getting a foot in the door,” she says, “to hiring our first people, to figuring out a plan for our product roadmap and becoming a product manager and learning along the way.”

These phases of growth and development over nearly 25 years of GEP have resulted in one of the world’s leading procurement

• AI-First is an approach that ensures that no stone is left unturned when looking for ways in which they can help customers derive greater value from their supply chain and procurement operations.

• AI-First does not mean AI-Only – far from it. Like any set of tools, how AI is used, and used to best effect, will be determined by the people and how they interpret and act on the information at hand.

a welcome challenge.

“Our next challenge is to continue to scale a fast-growing business while not losing the culture, attracting the greatest talent in the world and still continuing to pivot as the world around us continues to change in this generative AI revolution.”

Growing a company without losing a culture GEP has grown from a small team in a co-founder’s basement, to a world-wide enterprise with 26 global offices, 6,000 employees, customers in more than 100 countries and partnerships with some of the leading companies on the planet.

With so much competition in the space for procurement transformation, with established players and innovative startups continuously entering the fray, why do their clients and customers choose to partner with GEP? Shah briefly considers the question, but is emphatic in her reasoning why companies choose them over other worthy competitors.

“For most organisations these days, they want a long-term partner who is going to solve problems and be there with them every step of the way. At GEP, given that we’re founder-led, that we’re not just a startup with a nice new toy, but have been around for 25 years with the founders fully embedded in the business and working with a much longer term vision for the company,” she explains. “They believe in us. They believe in our people, our leadership team, and our product and expertise that we bring. All we do is live and breathe procurement and supply chain.”

26 global offices

6000 employees worldwide Customers in more than

100 countries

She also speaks with genuine passion about the role a company like GEP can play in helping their partners in the age of sustainability and all forms of ESG. She believes procurement and supply chain is the most important driver in helping companies reach their targets on climate change, decarbonisation, water usage, human rights, and living wage.

“GEP is playing a role in setting the targets and strategy for these large organisations and even mid-size organisations,” says Shah. “But to make that happen, it is all about the day-to-day processes and decisions that happen every single day for a company to run.”

If that is one way she feels GEP can help make a positive difference at every partner they work with, and every deal they help facilitate, Shah is certain they also have to lead the way both in the responsible use of Gen-AI, but in digital transformation of business.

“It’s very important for GEP to, what I’ll call, take its own medicine, but also be thinking three steps ahead. Really in some respects, predicting where the future is,” she says, knowing that if they are helping to guide others through digital transformations and evolutions, they as a company need to be beyond the leading edge of that same technology.

This leads to the subject of the value, potential and change being delivered daily by generative AI, that has exploded into the consciousness of the wider-public in 2023.

The intelligent implementation of AI technology is a subject that clearly inspires Shah, as she speaks excitedly about the ever growing potential, but realistically about knowing it is up to companies like GEP to be at the forefront of responsible implementation.

“At a GEP level, it’s AI, every day 24/7. When I think about AI, of course it’s

“I think it’s really important for GEP to take that leadership role, to cut through the hype”

NEHA SHAH PRESIDENT AND CO-FOUNDER, GEP

TITLE: PRESIDENT AND CO-FOUNDER

COMPANY: GEP

INDUSTRY: SOFTWARE, CONSULTING, AND SERVICES

LOCATION: CLARK, NEW JERSEY

As a co-founder of GEP, Neha Shah is an innovative, purpose-driven entrepreneur and executive. She has been instrumental in building and growing multinational organisations through her innovative strategies and decisive leadership.

artificial intelligence. I like to think about it as augmented intelligence,” she explains. “What I’m finding is that there’s tremendous potential, and yes, there are some real concerns and I can’t predict what is going to happen, but I do believe that I see a tremendous opportunity for augmenting the people and what they’re able to do in a 10-hour or 8-hour day.”

One word she regularly returns to is ‘hype’. “I think it’s really important for GEP to take that leadership role, to cut through the hype. I will say that I think there’s a lot of individuals who, because they don’t know where to start, it all feels like hype.”

Her focus is making sure that the importance of using AI intelligently is never overlooked, given the boundless potential of the technology, and breaking it down into micro-steps and processes to ensure they serve their intended purpose. She knows

that AI without true tangible value to her customers, is not the kind of progress GEP’s partners expect.

“I think for us at GEP, it’s all about AI every single day, internally and externally, and applying that knowledge to our customers. How do we now apply these wonderful large language models that are coming out?” she says, knowing the tremendous speed of change. “How do we apply the large language models and really make a difference in some of these processes using proprietary data? That is what is at the heart of everything GEP is doing, so our platform and our advice and expertise to clients is what we can provide and really help them transform this new world.”

The future of AI and GEP

Neha Shah takes the responsibility of being at the forefront of the AI age extremely

• There is currently very limited guidance on industry standard practice and ways to minimise organisational risks during adoption.

• A procurement team needs to keep a high level of control to make sure AI tools deliver ethical, responsible and reliable solutions.

• There is a role for various business functions in the deployment of AI solutions including product teams, IT, legal and procurement.

seriously, knowing the GEP plays a crucial role in supporting their clients, but also contributing to the wider conversation of how the technology can be responsibly implemented.

“The pace is so fast, it’s hard for a normal procurement supply chain function or professional to keep up. So our job is to keep up to date and then give the right advice,”

SUBHASH MAKHIJA, CEO AND CO-FOUNDER, GEP

“In the gold rush to apply AI to improve how companies source suppliers and manage global supply chains, there is a very real risk that organisations will dehumanise decisions and unintentionally ignore waste, Co2 emissions, and inequality, with devastating consequences to business, communities and the environment”

very limited guidance on industry standard practice and ways to minimise organisational risks during adoption, and that a procurement team needs to keep a high level of control to make sure AI tools deliver ethical, responsible and reliable solutions.

Shah never loses sight of the obvious potential of the technology, and explains how by helping to lead in the field, they are already implementing it into their offering. One such example is their Total Inventory Management Solution.

“It’s really remarkable. What we’re doing is in partnership with an organisation called Eliant Inventory Solutions, which is made up of different backers, Apollo, Athene, and B N P Paribas. We are enabling clients where we, GEP, provide the technology hub to free up working capital that is tied to the inventory that’s sitting in warehouses and allow clients to improve supply chain visibility and resilience,” she explains. “We bring the digital technology hub, if there’s parts of a process

that can’t be digitised, we bring some of our talent through our managed services team.

“We have customers like one of the world’s leading largest technology companies who are utilising this hub and they’re running their supply chain for some of their, what we call high volume, high value products.”

Shah speaks warmly about her passion for solving problems, helping people solve their own, and cutting through the hype to help her customers achieve in the age of AI, but what are the touch points that convince her she has achieved her goals in any given day?

“Because of the platform of GEP, particularly as it relates to ESG, how am I making a broader impact on the things I really care about, like seeing the end of child labour and trafficking in the world,” she says. “I really care about that and how in the dayto-day work I’m doing, how is that enhancing what I want to see in a better society, a better local community, regional community and a better world? It’s so important and that’s what keeps me going.”

“When I think about AI, of course it’s artificial intelligence. I like to think about it as augmented intelligence”

NEHA SHAH PRESIDENT AND CO-FOUNDER, GEP

WRITTEN BY: MARCUS LAW

WRITTEN BY: MARCUS LAW

Formed by a number of acquisitions, we highlight the path, challenges, and success of disposables and supply chain leader ACR’s digital transformation

Since it was formed with the initial platform in 2014, AmerCareRoyal (ACR) has been on an incredible journey building scale and breadth to become an industryleading platform.

Its products are consumed in every part of the North American foodservice industry,

including large international restaurant chains, emerging regional organisations, local neighbourhood eateries, cafeterias, and institutional feeders, and the broadline and supply distributors that serve them all. Major brands like Five Guys, Tim Horton’s and Yum Brands, and hundreds of other brands that operate and distribute to restaurants trust

ACR as a single-stream resource for over 6,000 disposable products used to keep their businesses humming.

“We’ve transformed from a regional player to a leading national supplier of disposable products across 20 categories in the food service industry,” comments Brett Barnello, ACR’s Chief Operating Officer. “We have

unmatched infrastructure and product breadth. We have over 6,000 product SKUs. We’re roughly a billion in revenue today, and we have an aspirational growth plan to triple that to be at US$3bn in five years or so.”

As Jeff DeSandre, ACR’s Chief Information Officer, describes, what is particularly notable about the organisation is that it is greater than the sum of its parts.

“If you add up the nine acquisitions that we’ve made to form ACR, they equate to less than our current revenue,” he explains. “The work that’s being done here allows for synergising. There is a large portion of organic growth that’s part of this acquisitive growth and I think that’s pretty interesting that the sum of the component parts is less than what we are today.”

The COVID-19 pandemic caused welldocumented disruption on a global scale, with ACR’s supply chains no exception. ACR leverages domestic manufacturing and international sourcing, which amounts to a truly global supply chain, so it was greatly impacted by the pandemic.

However, as Barnello points out, the company’s supply chain issues were not solely pandemic-induced. In fact, ACR was already grappling with growing pains in the pre-pandemic period. As Barnello states, these challenges involved stitching a number of small business units together and linking those and creating synergies.

“The pandemic was another in a series of this unprecedented global supply chain disruption and how we fare and manage through that,” he explains. “Then, the challenge was to not only survive the day-

TITLE: CHIEF OPERATING OFFICER

COMPANY: AMERCAREROYAL

INDUSTRY: FOODSERVICE

LOCATION: US

Barnello has over 25 years of Supply Chain experience in consumer businesses. He is a proven leader with a consistent record of organisational success through sustained results-oriented focus and innovative processes, products, and services. He develops, motivates, and builds organisations and partners with colleagues with a relentless focus on business imperatives.

Development backlogs are unique combinations of company goals, requirements, and constraints. As a company's needs change, our flexible engagement models adapt, and we back our work with an industry-unique Happiness Guarantee.

Kip Kugler, SVP of Sales, explains how Programmers.io’s unique skill set leaves the company well-placed to deliver firstclass customer service to clients

For Programmers.io, an on-demand provider of software development professionals, commitment to great customer service starts at the very top.

“Anshul Choudhry, our Founder, is extremely passionate about doing the right thing,” says Kip Kugler, SVP Sales. “If customers aren’t happy, they don’t have to pay. We may have eight or nine months of great work together but, if something doesn’t feel right in month 10, we won’t invoice and we’ll make a plan to fix it.”

“To this point, I haven’t had any customers leave because they’re unhappy.”

Programmers.io boasts unique skills

Programmers.io specialises in assisting the tens of thousands of US companies using IBM iSeries (AS/400), while also working on at least 50 other programming languages.

The lack of college students learning legacy languages means there exists a distinct shortage of workers – which is where Programmers.io comes in. A key priority for modern-day CIOs in terms

of future-proofing, Kugler explains, is deciding whether or not to migrate away from iSeries. He continues: “iSeries is so reliable and consistent that we say to people ‘we’ve got the workforce and we’ve got the ability to help you stay there longer – you don’t have to take that risk yet.”

AmerCareRoyal benefits from Programmers.io expertise

In recent years, Programmers.io has worked closely with AmerCareRoyal, a producer of disposable supplies that uses a unique legacy ERP system built on iSeries.

Kugler explains: “The issue for AmerCareRoyal is finding the relevant workforce. It’s not just about knowing the legacy programming language, but also the specific ERP – and we have that skill set.” The pair have worked together on countless projects relating to warehouse and pricing metrics, purchase order functionality, and vendor and order management.

“It’s a collaboration, but we see ourselves as an extension of their team,” adds Kugler. “We guarantee a budget-friendly environment with unique skills that are hard to find.”

to-day of the pandemic, but actually also on a separate track start to think beyond the pandemic and how we come out stronger and more stabilised.

“We knew everyone would come out of the pandemic at the same time, but some would be worse off than others. For us, our goal was to be stronger and have corrected systems and processes and different people capability.”

As DeSandre describes, ACR’s transformation began with the transformation of its leadership team,

with an end goal of creating a solid bedrock upon which to build.

“I had to make sure that the foundation was right. That meant no noise, and making sure the table stakes worked,” DeSandre explains. “It’s like the gutters on a house. No one notices them if you put new gutters on, but they do notice if they don’t work.”

As a result, ACR worked with OpenSystems on a fully-managed, SASE (secure access service edge) SD-WAN solution. “That was a foundation, and was one less piece of noise that I had to worry about,” DeSandre explains. “This technical foundation afforded us time to focus on

other key digitisation drivers including master data.”

As DeSandre explains, security is a continuous consideration. “We live and breathe considering security. We have to focus on that on a regular basis,” he comments. With this in mind, ACR worked with OpenSystems’ Ontinue service, its managed detection and response (MDR) division, to help find problems in real-time. Its AI-Powered MXDR expertly blends the best of MDR, as well as assessment and prevention.

From there, DeSandre worked on developing ACR’s API layer, working with

VAI – its ERP supplier – and its S2K platform. “Even though our ERP system may not be from one of the big suppliers, the architecture of the system, and the amazing partnership of VAI, has really enabled us to take deficiencies that might be in any ERP system and react really quickly.”

“The flexibility that comes with the S2K platform is really a differentiator for us, because it allows us to continuously optimise, especially in the warehouse, which is really important.”

The final piece was a trusted managed services partnership which afforded ACR strong technical resources which can be

With the cloud-native Digital Commerce Platform and Commerce Execution Platform, Emporix, Avatria and Celonis are working with AmerCareRoyal to drive increased efficiency and deliver better business outcomes — decrease costs, increase customer satisfaction and set the stage for innovation.

Learn more

Avatria

Celonis

Emporix

Avatria

Celonis

Emporix

With the cloud-native Digital Commerce Platform and Commerce Execution Platform, Emporix, Avatria & Celonis are helping AmerCareRoyal drive better outcomes.

With its leading cloud-native Digital Commerce Platform and Commerce Execution Platform (CXP), Emporix enables wholesalers, distributors, manufacturers, retailers and brands to utilise insights and ultimately deliver better outcomes.

“So many commerce systems were built more than two decades ago: before the millennium and even before the cloud itself,” explains Eberhardt Weber, Emporix’s Founder and CEO. “We decided to build a new cloud-native and API-first commerce platform from the ground up, with a focus on enterprise businesses in B2B and also sophisticated B2C business models.”

Emporix worked with its preferred integration partner in North America, Avatria, on implementing the Digital Commerce Platform for AmerCareRoyal, a leading supplier for disposables used in the catering, janitorial, sanitation, industrial, hospitality and medical industries.

“AmerCareRoyal had been a customer of Celonis and they were working heavily with their business process mining capabilities to identify bottlenecks and streamline their

processes,” Weber explains. “Now, together with Celonis, Emporix has developed a new product called Commerce Execution Platform (CXP)” CXP helps organisations optimise outcomes by leveraging up- and downstream process insights to guide and drive the orchestration of multi-step scenarios.

Celonis, the global leader in Process Mining technology, was central to AmerCareRoyal’s ongoing process transformation initiatives. Now, Celonis’ process intelligence facilitates the end-to-end orchestration that has made the Commerce Execution Platform indispensable for AmerCareRoyal.

When Weber introduced the platform to Jeff DeSandre, AmerCareRoyal’s CIO, he says he immediately realised that he is a visionary.

“That’s why we decided to start together with AmerCareRoyal for this new product,” Weber explains. “And then they realised that they were looking also for a B2B platform for their customers, so more like a self-service portal. This is where Avatria came in, because they customised and integrated this solution based on our digital commerce platform.”

After Avatria completed the initial implementation, they began to transition to ACR resources, shifting to an advisory role.

COMPANY: AMERCAREROYAL INDUSTRY: FOODSERVICE

LOCATION: US

Jeff DeSandre is an accomplished technology executive with more than 15 years of experience in leading complex IT organisations. He currently serves as the Chief Information Officer (CIO) at AmerCareRoyal, a food service company, where he is responsible for the strategic direction and delivery of technology solutions that support the company’s business objectives.

In his role as CIO, DeSandre has a proven track record of transforming IT organisations and driving innovation through the use of emerging technologies. He has successfully led large-scale digital transformation initiatives, resulting in significant improvements in operational efficiency and customer experience.

Prior to his current role, DeSandre held several senior leadership positions in technology at companies within the consumer goods space. DeSandre holds a Bachelor’s degree from the College of New Jersey. He sits on the advisory board for UCX.

scaled up quickly. For this ACR partnered with ProgrammersIO (PIO), which provides high quality global development resources. “PIO provided us very technically sound resources to support the S2K platform. The level of commitment and quality of their work is outstanding. They are a key part of our IT team,” says DeSandre.

With this foundation established, ACR could set its sights on future projects. Since the transformation got underway, ACR has worked on three major projects: Unity – its ongoing integration project; Spotlight –which focuses on commercial optimisation; and Rubik – its Supply Chain continuous improvement initiative.

As Barnello explains, Project Rubik is part of ACR’s transformative initiative around its supply chain and back-end operations.

“Rubik started with network design and optimisation as well as inventory management, and how we could become more efficient coming out of the pandemic,” he describes. “We had higher inventory levels, low service rates, and we had high back orders as well as splits, in terms of a customer receiving something from a different location on the same order and not at the same time – which was causing customer pain and complexity.”

As part of the strategy, ACR worked with its partners to develop a sustainable roadmap. “We put together a large crossfunctional team that involved IT, Sales, Finance, and Operations and then executed that plan.”

As Barnello describes, ACR has worked with partners across its supply chain, including

Understanding your environment to provide superior protection.

Ontinue Chief Product Officer Tom Corn discusses how the company leverages AI in managed detection and response to deliver a distinctive solution

Driven to define the next evolution of Managed Detection and Response (MDR) for its partners all around the world, Ontinue ION AI-Powered MXDR expertly blends the best of managed extended detection and response — as well as assessment and prevention — into a service specifically designed for Microsoft security customers.

“We specialise in customers who are leveraging a lot of Microsoft security technology,” comments Tom Corn, Ontinue’s Chief Product Officer. “We have a unique process that isn’t just about reactive detection and response, but about constantly improving companies’ security posture, in what we call a proactive reactive service.”

When outsourcing security to MDR players, understanding the client’s control stack poses challenges. While MDR providers may offer expert security support around the clock, the crucial factor is their comprehension of the client’s unique environment. To go beyond basic alerts, effective investigation and response necessitate a deep

understanding of the company’s assets, architecture, and operational constraints.

As Corn explains, Ontinue was started by a group of data scientists with the idea of applying AI to MDR in a unique way. “We are doing something quite different here, where we’re applying AI to understanding the customer and the environment we’re defending, their operational constraints, and how the defenders have to work in their environment. This allows us to solve that problem of how to understand the environment quickly, deeply, and then localise the solution for a customer.”

Ontinue has also innovated with its interaction model. “We started with the premise that the world doesn’t need another management console,” say Corn. “Instead, Ontinue built its interface into Microsoft Teams, so customers and Ontinue defenders collaborate in a shared channel, taking advantage of Teams capabilities they’re already using during the workday. By doing this, we look, feel and act like a true extension of our customers’ teams.

“We’ve specialised more deeply in customers who are using the Microsoft security stack. This has allowed us to do very deep things that you just don’t see from other places because we’ve really specialised.”

GAINSystems is ACR’s planning partner that it utilises for supply and demand planning efforts, he explains, in a partnership over a number of years.

“Not only are they being used for our planning software and all of the inventory and operating policies that go along with that, but they’re also moving into network design as well,” Barnello comments.

“We are seeing tremendous value in a single partner that has both the planning capability and the operating policies as well as the ability to help us design and run simulations and optimisation.”

3GTMS, meanwhile, has provided ACR with visibility across its transportation network. “What they’ve really done is given us the visibility and the data to be able to effectively manage our outbound freight and understand where we’re winning and losing and then really to chase that down,” Barnello adds.

When it came to looking at ACR’s data strategy, DeSandre emphasises the importance of a clean stream of master data which can be easily accessed in near-real time. This is where ACR’s partnership with global process mining technology leader Celonis came into play.

“Our work with Celonis really is at the heart of our data strategy, to the point now that we’re really moving towards having all of our data in one place within Celonis. Today, we’re just starting to tap that potential and I think the executive team is just starting to really understand the power of having that data model.”

Drive faster, smarter decision making everywhere inventory matters. GAINS helps businesses move forward faster with greater agility, resilience, and confidence, even in disruptive times. The GAINS AI-driven cloud platform guides supply chain decision makers to the outcomes that optimally balance the tradeoffs between freeing working capital, lowering operating costs, and meeting service goals for global manufacturing, distribution, retail and aftermarket/maintenance companies.

As a leader in supply chain design and planning, GAINS focuses on putting its customers first and moving them forward faster. Jeff Metersky, the VP of Solution Strategy at GAINS, guides and directs the overall strategy of the GAINS supply chain solution.

With decades of experience providing supply chain solutions and services, Metersky knows that traditional supply chain design and planning strategies no longer fit volatile business environments. They lack the flexibility to plan for disruptions and continuously optimise inventory.

“Supply chains are no longer predictable and stable. They have become fragile and exposed due to increased variability and the rise in global disruptions,” Metersky says. “Businesses can no longer rely on the same techniques because our environment has changed – the focus cannot be on cost alone. Today’s decisions need to balance the trade-off between cost and service to mitigate risk and drive performance.”

“Using GAINS’ solutions, companies will be able to navigate uncertainty in their supply

chains, enabling much greater adoption of designs instead of making them academic exercises. Designs will become more pragmatic so that companies can fully understand their impact and increase the likelihood of adoption.”

Partnering with AmerCareRoyal to enhance supply chain decision making

GAINS has been on a journey with AmerCareRoyal (ACR) to automate and transform its operations. Consequently, ACR has grown rapidly – doubling in size – as they continue to acquire new businesses.

“Due to their partnership with GAINS, ACR has achieved rapid results, optimised inventory across their network, managed volatility, and become more resilient by being open to continuous improvement and looking for new ways to improve performance,” Metersky states. “This strategy achieves their desired outcomes and provides a scalable foundation on which they can embrace volatility and serve their customers well”.

Jeff Metersky, GAINS’ VP of Solution Strategy, explores how better supply chain decisions are moving AmerCareRoyal forward

From procurement optimization to sales automation and warehouse management, VAI’s ERP applications help wholesale distributors, like AmerCareRoyal, improve customer service and boost productivity.

VAI provides you with an ERP without limits by integrating business processes across your organization.

An example of this success comes through ACR’s work with Emporix and Avatria on implementing a new Digital Commerce Platform, which enables its customers to utilise insights and ultimately deliver better outcomes. The product is known as the 1ACR portal.

“We just went live with our new portal, and I’m happy to say that we don’t have a point-to-point interface. Any information that we already know is clean, and is in Celonis, is being syndicated to our portal, which makes us very unique. We really are starting to get to a point where

our transactional data is able to be syndicated and used in these different systems.”

As DeSandre explains, the ultimate goal is to achieve a single version of the truth with a low amount of manipulation.

“There are still some shortcomings with not all required data being tracked in our master data as part of our ERP,” he adds. “To correct for this and enable change as ACR continues its evolution we have amended our ERP to support non-native master data allowing our ERP to serve as a system of record where necessary.”

For ACR, which continues to grow through acquisitions, the message for the future is one of continued partnership. And through its projects – Unity, Rubik and Spotlight –the transformation will continue to evolve.

“I don’t think it stops,” Barnello comments. “This is really a jumping off point for us. We’ll continue to refresh the network as we continue to acquire new businesses, new geographies and new customers. We’re turning to using data and the digital transformation on our spend cube and in our procurement space as well.”

As DeSandre concludes, the future will see ACR continue to drive innovation across its ongoing transformation projects.

“I really do feel like we’re at a point of almost best of breed in our supply chain capability. But on our commercial processes, our pricing strategy, how we process rebates, bill backs, how we deal with the commercial aspects of our customers, I do think that we’re probably still about a year or two away from being a best of breed there. So I think that’s going to be a lot of our focus.

“We have really strong leadership now, and so the future for me is really about continuing the great work that we’ve been doing for the last three years,” he concludes. “It’s going to be about pulling it all together and continuing driving our supply chain optimisation projects in Rubik as well as our commercial optimisation projects in Spotlight.”

It is hyper-connectivity with suppliers that brings resilience to supply chains, rather than super-lean, super-fast operations

WRITTEN BY: SEAN ASHCROFT

“When a business is looking to improve its performance, suppliers are often overlooked compared to other key stakeholders”

RICHARD HOGG, CEO, VIZIBL

Strong supplier relations are forged by the management of frontline operations, contracts performance and risk. Put like this, It sounds simple, but in reality requires businesses to know their supply chain inside out.

In old money such knowledge might be called having an ‘in-the-round’ view of supply chain. Today, it’s more likely to be dubbed ‘hyper-visibility’, a 360-degree view or end-to-end visibility.

The naming conventions might have changed, but the prerequisites for healthy supplier relations have not. The clue is in the title: it’s all about relationships.

And like all relationships, it’s a two-way street. Suppliers want to build strong relations because this is what gives them preferred supplier status. Organisations want the same thing, because such relationships help add value outside of supplier contracts, and when scaled-up these benefits bring resilience.

Richard Hogg is CEO of Vizibl, a collaboration and innovation platform, that helps both buyers and suppliers manage their relationship. Hogg says strong supplier engagement is a way to improve supply chain resilience and sustainability.

“When a business is looking to improve its performance, suppliers are often overlooked compared to other key stakeholders like shareholders and customers,” he says. “This view is not only misjudged, but it’s also a wasted opportunity.”

He says supplier engagement can cover a broad set of actions, activities and tactics to deepen relations, but feels the best results come from “higher-intensity tactics”, which include supplier collaboration and innovation.

Knowing where to start can often be the most difficult thing, says Hogg.

One logical place he says is for businesses to not only have clear strategic aims as a

TITLE: CEO

COMPANY: VIZIBL

INDUSTRY: SUPPLY CHAIN

Former JAGGAER executive Hogg joined as Vizible’s new CEO six months ago. He says of himself: “I specialise in B2B SaaS GTM planning, marketing, customer acquisition, sales cycle processes, expansion, successful implementation, adoption and retention focus with full sales bookings and P&L responsibility.”

Streamline purchasing while saving on everyday supplies so you can focus on growing your business.

Create

business but to share these with suppliers.

“These should include the metrics you need to meet in order to be a success, and how your procurement strategy and tactics fit into that broader goal,” he says.

He adds: “Strategy sharing should address short-, medium-, and long- term plans, and include a sense of the pains your business is responding to.”

This he says gives suppliers an idea of how they can strengthen their relationship with an organisation based on its priorities, meaning they are better able to meet and understand its needs.

“This should also be reciprocal,” Hogg advises. “Suppliers should be invited to share strategic plans for their own businesses, as this facilitates joint opportunities for mutual growth and development early on in the relationship.”

Data collection is another crucial aspect of strong supplier relations, Hogg says.

“This allows you to identify areas for improvement or opportunities for growth, in addition to laying the groundwork to prove the value of other engagement tactics.”

He says this data should include indicators of performance, risk, and opportunity, across areas such as spending, quality, sustainability, resilience and innovation.

“How you collect these will vary,” he says. “When it comes to spending, quality, and operational performance it’s likely to be a case of enriching the data you already have on a given supplier.”

By contrast, he says for sustainability, the data-gathering process is likely to be more involved.

“Turning to disclosure platforms is a great way to ease this friction,” says Hogg.

By way of example, Hogg says businesses can ask suppliers to disclose to CDP, the not-for-profit body that runs the global disclosure system for investors, companies, cities, states and regions to manage their environmental performance.

But what if there is a mismatch between an organisation’s strategies and those of a supplier?

“It’s important to remember that some targets can undermine your relationship with suppliers if they do not yet have the capacity or knowledge within their business to understand or meet them,” warns Hogg. “Begin with manageable, leading indicator

targets. Regardless of your use case, it’s important for suppliers to feel reassured they’ll receive support to achieve them.”

In short, Hogg says it’s best to “aim high but start small”, with a view to scaling successes.

Another expert in the field of supplier relationships is Andreas Baader, who is SVP Supply Chain Serviceline, Germany, with US professional services firm, Genpact.

Baader feels that some organisations can become too focused on supply chain performance levels, and that such a ‘need for speed’ approach can be to the detriment of supplier relations.

TITLE: SVP SUPPLY CHAIN SERVICELINE, GERMANY

COMPANY: GENPACT

INDUSTRY: PROFESSIONAL SERVICES

Genpact for four years, and is based in Munich. Prior to this he was Managing Partner with Barkawi Management Consultants, a Genpact company.

“Hyper-connectivity with suppliers, rather than lightning-fast speed, should be the ultimate measure of a successful supply chain”

ANDREAS BAADER, SVP SUPPLY CHAIN SERVICELINE, GERMANY, GENPACT

Best practice supply chain strategies –including those to boost supplier relations – is overseen by the Institute for Supply Management.

The ISM is the oldest not-for-profit supply management organisation worldwide.

Founded in 1915 it is committed to advancing supply management to drive value and competitive advantage for its 50,000 members. It publishes professional guides, including the ISM Report On Business, and also runs highly-regarded certification and training programs, corporate services and events.

It also offers advocacy and thought leadership around supply management, and lobbies on issues that affect its members at national and international levels.

“We work to promote the value of supply chain management and contribute to policy discussions on issues affecting the profession,” it says.

According to PwC research, almost a quarter (23%) of businesses do not have an SRM programme

“Lightning-fast speeds should not be the ultimate measure of a successful supply chain,” he says. “Rather, the target should be hyper-connectivity with suppliers, and the inherent resilience that comes with this.”

Baader adds: “While the global supply chain continues to struggle with new demand patterns, looming recession, and geopolitical tensions, there still lies a sense of urgency to bolster production and return to the status quo, which in some minds, equals speed.

To counter this, Baader says businesses must begin to accept that “the supply chain does not need to be lightning fast to succeed”.

He adds; “Companies should instead focus on creating a hyper-connected supply chain that through successful supplier

relationships, planning, and data, tech and AI reduces their supply chain footprint and builds onto existing capabilities – essentially concentrating on reliability and resilience.”

Supply chains should allow sales to match customer demand and constraint supply, Badder points out, adding: “To do this organisations can embed agility into all aspects of the supply chain using digital enablers such as IoT, data analytics, and advanced control towers.”

These tools, he says, “will improve insights and help streamline processes, from sourcing to demand”. He adds: “Speed will come for free through reliability, and the use of technology, data, and AI will create sustainable, nimble, and hyper-connected supply chains that are prepared to serve the next generation of consumers.”

6 - 7 December 2023

1,000+ Virtual Attendees

2 Day Learning and Networking Event

30+ Acclaimed Speakers

6 Interactive Panel Discussions

The Manufacturing stage is here, and it’s putting on an exclusive 2-day virtual event for the industry.

Join Manufacturing Digital LIVE on 6 and 7 December for a two-day virtual event, where the brightest minds in Manufacturing will grace the stage.

Experience a unique opportunity for knowledge sharing, learning, and networking with industry professionals from all corners of the globe.

Dive into the innovative networking platform, Brella, to build meaningful connections, schedule meetings, and prepare yourself for the immersive LIVE stream about to unfold.

There are more than 30 internationally acclaimed leaders that you can’t afford to miss!

Covering five key themes, the event will showcase engaging presentations, interactive sessions, panel discussions and fireside chats, facilitating deep learning and exploration: Factory of the Future, Sustainability, Digital Manufacturing, Tech & AI and Women in Manufacturing.

Mark your calendars, set your reminders, and get your complimentary pass to Manufacturing Digital LIVE!

It’s time to connect with like-minded professionals who share your passion for innovation and growth.

WRITTEN BY: NEIL PERRY

PRODUCED BY: JAMES WHITE

WRITTEN BY: NEIL PERRY

PRODUCED BY: JAMES WHITE

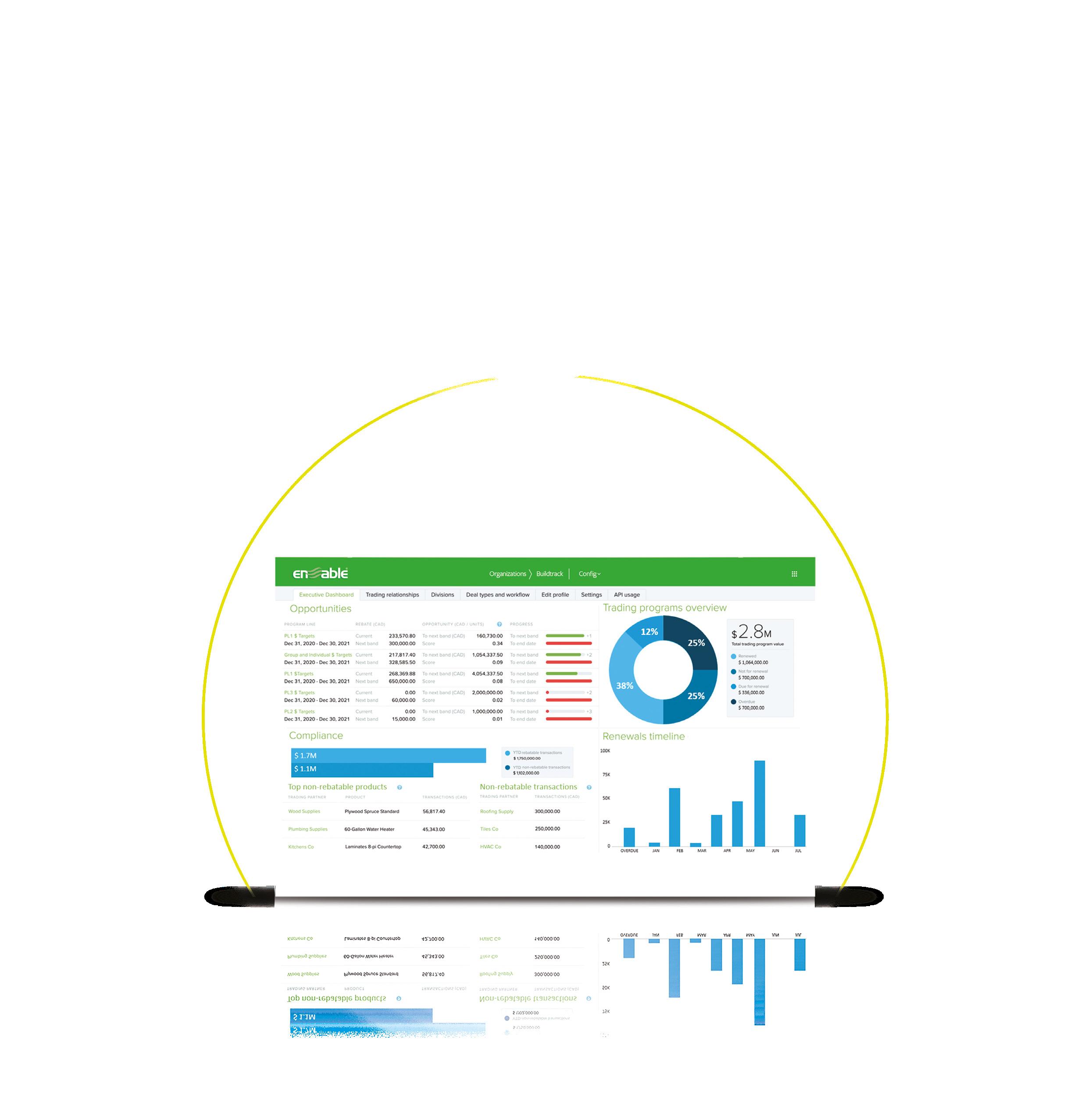

With some businesses operating with multiple ERP, procurement, merchandising or warehouse systems that may not communicate intelligently with each other, it can create a complex set of problems that lead to wasted time, money and effort.

When financial management experts Workday and software solutions specialists Hyland first began working together in 2015, with different perspectives on such problems, it created an opportunity for a solution that can join disparate systems together and solve a wide range of issues. They set in motion a partnership that would result in the development of the Hyland Direct Spend Matching for Workday solution that provides any organisation that pays direct spend invoices with more efficiency, accuracy and visibility.

With different experts coming together, it was a collaboration primed to offer this product that would maximise the strengths of each other.

“The solution that Hyland offers is called Hyland Direct Spend Matching for Workday,” says Danielle Simer, Product Manager at Hyland, whose background began in the marketing space, before transitioning into product management. “Hyland is acting as an intermediary or a bridge between your Workday ERP and your front-end procurement system.

TITLE: PRODUCT MANAGEMENT LEADER

COMPANY: HYLAND

As a member of Hyland’s product management team, Don Dittmar is setting the vision and direction for products and solutions specific to all of Hyland’s Vertical Solutions. His domain expertise in business process automation helps Hyland discover, build, and deliver solutions that enable customer automation and innovation throughout their business processes. Prior to joining Hyland in 2019, Dittmar has held leadership roles in Finance, HR, and Shared Services in a number of industries, and is a 3-time customer of various Hyland Solutions.

TITLE: SENIOR DIRECTOR, INDUSTRY STRATEGY

COMPANY: WORKDAY

Sharon Schell is the senior director of industry strategy at Workday, responsible for the product direction and strategy for the retail, consumer goods and hospitality industries. Sharon has been at Workday for five years and has more than 30+ years of retail industry management and software product strategy experience. As an advocate for change and improvement within retail. consumer goods and hospitality industries, Schell collaborates with our customers and partners to continuously innovate and evolve our solution portfolio to meet their current and future business needs.

TITLE: PRODUCT MANAGER

COMPANY: HYLAND

Danielle Simer is a product manager focused on managing the life cycles of Hyland’s financial process automation solutions, including major ERP integrations. She joined Hyland in 2015 and spent her first six years as a portfolio and product marketing manager covering Hyland’s Cross-Industry vertical and Capture products. Prior to Hyland, Simer was a marketing manager at the business research and advisory firm CEB (now Gartner). She received her bachelor’s degree from The Ohio State University and her MBA from Georgetown University’s McDonough School of Business.

So, we’ve developed this with companies in mind who are generating purchase orders in a procurement system or some sort of thirdparty system that is not Workday, but they want to pay their vendors through Workday.”

Sharon Schell is the Senior Director of Industry Strategy at Workday for Retail, Consumer Goods and Hospitality. She brings with her three decades of management and strategy experience from the retail and software industries, collaborating with Workday’s customers and their partner ecosystem to solve for key business challenges in the industries.

“Companies with inefficient AP processes often lose opportunities to take advantage of early payment discounts,” explains Schell, as she digs into her first-hand experience in retail. “So not leaving discounts on the table, controlling costs and finding cost efficiencies

wherever we can are critical nowadays. Companies with these inefficient processes often lose opportunities to take advantage of these, adversely impacting, again, their cashflow and then obviously contributions to bottom line and overall margin.”

It is the broad range of business experience in the two teams that helps the product deliver to the differing needs of clients and has helped to inject real-world reality into the product.

Don Dittmar is the Director of Industry and Product Strategy for Hyland Software, and his role takes in the strategic direction and roadmapping for all their industry solutions.

He began his career in finance, before moving into finance technology and then into the realm of product management.

Dittmar is excited to see the evolution in

content automation – from being an application to more of a service – over the last 20 years.

“The really exciting part about what we have with our partnership with Workday is that there’s no more bounce rate for our customers,” he said. “They aren’t working in one application, going to another, and coming back. We’re starting to share screen space to share a user experience where the content services that Hyland provides is less and less visible.”

It’s these kinds of seamless solutions that excite the whole partnership, as it allows the realisation of benefits like performing threeway matches, to check if the order matches what was invoiced for and if it matches what was received. There are also other cashflow management solutions, such as an approval reporting feature that identifies received items that have not yet been invoiced.

“All of these benefits, from general AP automation and then this combined solution, really go a long way in terms of paying vendors on time, managing cashflow, keeping your CFO happy and getting rid of a lot of just extra paper that is floating around your office,” Simer said.

Alongside the opportunities to optimise processes, Simer highlights the evolution of the last decade, with increased use of the cloud and the value of the data that’s produced. It’s these enhanced reporting capabilities that she finds interesting, as accounts payable data can be utilised to support the goals of the finance operation.

The well-established links between the two companies has allowed rapid development of new solutions, thanks to the trust built up

from years of collaboration. After signing as official partners in 2015, Hyland and Workday launched their first joint venture in 2017.

“Hyland has been in business since 1991, and we’ve helped thousands of customers automate their accounts payable processes. To be successful in this area, ERP integrations are key. We launched the initial version of AP automation for Workday in early 2017, and it’s been one of our highest-growth products, which is a true testament to our partnership,” Hyland’s Dittmar said.

Workday saw Hyland as a key solution that complimented Workday’s financial management capabilities by capturing and managing critical invoice details alongside customer AP records. The collaboration would then speed up processing and approval processes and increase visibility throughout the transaction.

“We really saw this as a win-win for our customers – two best in class solutions delivering differentiated value for our co-customers,” said Schell from Workday.

DON DITTMAR PRODUCT MANAGEMENT LEADER, HYLAND

“What Hyland and Workday have really established is not only that go-tomarket motion partnership, but a product-to-product alliance as well”

10,000 Organisations use Workday worldwide

14,000 Active customers at Hyland

The partners were able to jointly develop the solution and build out and solve the integration challenge, which was helped through the seven years of experience jointly developing integration points with both platforms. By working together at every stage, the quality of the data moving between the systems has been maintained.

“There are a lot of partnerships in the software industry ecosystem that are what I’ll call sales or alliance partnerships,” Dittmar said. “Those are great, and they form a good foundation, but what Hyland and Workday have really established is not only that go-to-market motion partnership, but a product-to-product alliance as well.”

DANIELLE SIMER PRODUCT MANAGER, HYLAND

“If our solution can make someone’s day-to-day job easier and it’s easy to follow, it’s easy to answer questions and just makes their life easier, that’s what it’s about for me”

The depth of the collaboration is obvious, as both companies know that there is a level of trust to help each succeed long after initially going to market.

“We have a trust level where I know that if Schell’s organisation (Workday) is working with a particular customer, they are representing us, and vice versa, that we’re representing Workday as a complete offer to that customer,” Dittmar said. “So having that product-to-product connection is really critical for us and for the customer.”

The challenge facing growing businesses Growing businesses creating an increasingly large system footprint and disparate systems

not communicating properly with each other creates what Schell from Workday describes simply as a “big data challenge.” It’s the type of problem that the two parties were looking to ultimately solve for their customers, whether it’s instances of multiple ERPs, procurement, merchandising or warehouse systems.

“We conduct system architecture workshops where we’re looking at a retailer’s system footprint,” Schell said. “Each company typically find ourselves solving for this interoperability and the issues resulting from that interplay between the systems, and this solution makes it more seamless for the end user.”

When businesses grow and expand, invoice volume increases, as do all the associated challenges of managing that volume. There are expensive options like adding staff and complicated logistical problems like adding systems, which can increase the layers of complexity.

“When you get down to the processlevel challenges that we see, our customers really do struggle in AP with manual data entry,” Simer said. “You would think it was something so simple and easy to solve, but it really is a problem. If you have an invoice with multiple lines, multiple line items that need codes and to be matched against the purchase orders and entered into the ERP, that’s a significant amount of work just for one sheet of paper. That’s assuming that the invoice is one sheet. It’s a small thing, but it really, really adds up.”

Manually entering this kind of information can lead to errors finding their way into the ERP, and when those errors are identified, it adds extra layers of steps and corrections to get invoices paid. Simer adds that if you process tens to hundreds of thousands of invoices a month, these types of manual issues can add up, which emphasises the importance of having accounts payable automation systems to improve efficiency and accuracy.

With so many disparate systems in use, especially in retail and hospitality sectors, it’s essential that any solution like the options presented by Hyland and Workday is flexible and adaptable.

Dittmar believes that’s an area where Hyland’s product platform really excels.

“It’s extremely complex but can be managed through a set of logical rules,” he said. “That allows enough flexibility from customer to customer or even retail system to retail system. Workday at one end is very fixed, but at the other end, there are multiple retail systems and, in some cases, even the same customer may have more than one retail system that they’re using to generate different types of purchases.”

He said it’s essentially taking the way that the retail buyer wants to work, and the way the finance operation needs to record the transaction, and building a translation layer in between the different systems.

“Connecting those systems and reducing that friction from a data standpoint, from a technology standpoint, from a business process standpoint, from a stakeholder’s visibility and insight to action on all of these pieces as well,” Schell added.

The two companies expect their collaboration to produce continuous improvement and innovation.

“We are continuously evolving the product. Everyone is on the same version of Workday,” Schell said. “With this partnership with Hyland, we’re in sync all along due to this single version. We can innovate together, so as we deliver additional functionality in our financial solution that complements their portfolio, and we can collaborate directly with them accordingly.”

It’s the complementary relationship between the partners that’s one of the greatest strengths of the end product, Dittmar said. He recalled a customer who praised the single user experience that helped them make a decision on both parties, which ultimately increases the pipelines of both companies.

“I think the really big differentiator is where we make it seamless to that end user that we are interoperating with and providing them a differentiated experience between two best-in-class solution providers and really helping them solve for a very complicated issue in a very streamlined, interactive, seamless way between the two solutions,” Schell added.

With the varied experiences brought to the development table by the companies, there’s genuine pride in knowing the results of the platform for the end users.

“Having lived on the customer side, it’s exciting and it’s rewarding for me in that I’ve lived that problem. I’ve lived the workarounds, I’ve lived the late nights when you’re reconciling an inventory or something at the end of a quarter,” Dittmar said. “Knowing not only the value we’ve created, but also what we’ve prevented, the headaches and the long nights, that it is rewarding to me.”

Schell from Workday shares that feeling, having the experience from the perspective of the end user.

“As we do at Workday, we’re going to leverage the most modern technology, whether it’s AI and machine learning, and how we are bringing that intelligent automation to the process,” she said. “We’re bringing that visibility and making sure that we are making this process more efficient, and then freeing up time to have more value-add to be able to actually analyse the business and really make some of those critical decisions and adapt to the business and respond accordingly.”

The power of the partnership between Hyland and Workday ultimately comes down to the experience of the end user and solving the problems they may have had before implementing the solution.

“If our solution can make someone’s day-to-day job easier and it’s easy to follow, it’s easy to answer questions and just makes their life easier, that’s what it’s about for me,” Hyland’s Simer said. “That is what I am most proud of is relieving someone’s headache who is going to be in the system every day.”

SHARON SCHELL SENIOR DIRECTOR, INDUSTRY STRATEGY WORKDAY

“We can innovate together, so as we deliver additional functionality in our financial solution that complements their portfolio, we can collaborate directly with them accordingly”

HYLAND

Latin America is seeing an e-commerce boom but poor service levels are eroding trust and harming progress.

Fulfilment specialist Melonn is beginning to change all this

WRITTEN BY: SEAN ASHCROFT

ith so many moving parts that are vulnerable to disruption of all kinds –road traffic accidents, extreme weather and industrial action, for example – last-mile logistics has always been the most expensive and problematic part of supply chain.