Ongoing Research to Develop PLASTIC PACKAGING ALTERNATIVES

pg 10

Meet New Zealand’s FIRST MOBILE HIVE

pg 28

pg 36

Ongoing Research to Develop PLASTIC PACKAGING ALTERNATIVES

pg 10

Meet New Zealand’s FIRST MOBILE HIVE

pg 28

pg 36

Caitlan Mitchell Editor-in-Chief caitlan@reviewmags.com

Walking the halls of Anuga this year, it was clear that the global food and beverage industry is in a new phase, one grounded less in novelty for novelty’s sake and more in meaningful, scalable innovation. Sustainability and efficiency were not just buzzwords; they were embedded into every conversation and product display.

What struck me most was the shift in tone. Category buyers openly admitted that the frenzy around alternative proteins and meat replacements has eased. The appetite for experimentation has not

disappeared; it has merely matured. Innovation now feels more deliberate, focused on what consumers will actually buy rather than what simply makes headlines.

Among the thousands of products, one idea stood out for its simplicity. Air Up, a German innovation, redefines flavour by engaging the senses in a new way. Its design uses scent to create the perception of taste, flavouring plain water

through aroma pods that trick the brain into thinking it is drinking something sweet or fruity. I tried it myself and was surprised at how effective it was. Around me, others reacted the same way, smiling as if they had witnessed a small piece of magic. It is not flawless, but it represents the kind of ingenuity that moves an industry forward: minimal ingredients, clever science, and genuine surprise. This year’s Anuga was not about spectacle. The

energy was focused and purposeful. The people there were ready to talk business, to collaborate, to build. Optimism was everywhere, and it felt well-earned. If the last few years were about survival and adaptation, 2025 feels like the year of refinement. The food and beverage industry is not chasing trends. It is shaping them with intent, and that is a very good place to be.

PUBLISHER Tania Walters

GENERAL MANAGER Kieran Mitchell

BRAND MANAGER Sarah Mitchell

EDITOR-IN-CHIEF Caitlan Mitchell

EDITORIAL ASSOCIATES Jenelle Sequeira, Sam Francks

ADVERTISING SALES caroline@reviewmags.com, daniel@reviewmags.com

SENIOR DESIGNER Raymund Sarmiento

GRAPHIC DESIGNER Raymund Santos

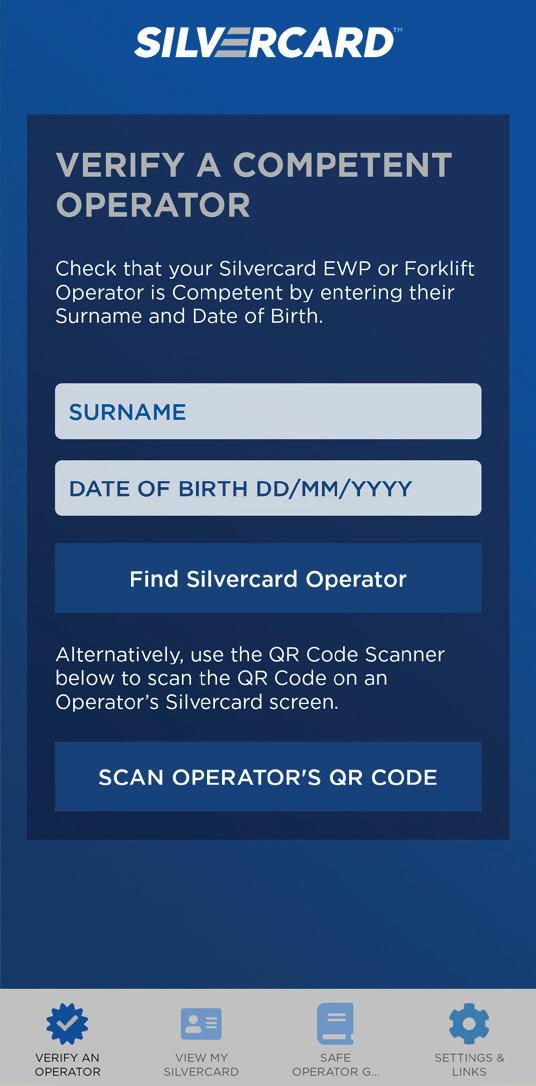

Koelnmesse has developed an app that, for the first time, enables trade fair visitors to calculate their individual climate footprint for the trip to the event.

The software, called CHEQ, compares the emissions of a consolidated trade fair visit with those that several separate trips to business partners would have caused.

“With CHEQ, we are making the ecological impact of trade fair participation measurable and transparent,” said Christian Glasmacher, Vice President Corporate Development and Sustainability at Koelnmesse.

Read more here

Australia’s leading fresh produce grower, Costa, has partnered with Coles and Opal in a large-scale trial to transition packaging for Perino tomatoes from rPET plastic to recyclable cardboard packaging across Coles’ Victorian stores.

This initiative underscored a shared commitment to reducing plastic packaging and supports Coles’ circularity targets to increase the recyclability of packaging.

“We know Perino tomatoes are a household favourite for many of our customers, and this trial is a meaningful step in reducing plastic in our stores whilst ensuring our

A major government investment in cutting-edge science will unlock new economic opportunities by transforming New Zealand’s unique natural resources into high-value pharmaceutical and bio-based exports.

The Government has invested over NZD 42 million across seven years to establish a Biodiscovery Platform, designed to accelerate the development of high-growth industries producing natural pharmaceuticals and other bio-based products. The newly formed Bioeconomy Science Institute will lead the platform.

“This is an economic growth initiative,”said Science, Innovation and Technology Minister Dr Shane Reti.

Read more here

customers who love to eat Perino tomatoes can still enjoy them at the highest quality,” said Brooke Donnelly, General Manager Sustainability, Coles.

The new cardboard Costa Perino packs, designed and manufactured by Opal and made from recycled paper, are being trialled to replace Costa’s existing 80 percent rPET punnets. This change was designed to reduce the industry’s reliance on plastic.

“This trial marks a major milestone in Costa’s packaging transformation journey,” said Manpreet Sidhu, Chief Operating Officer, Domestic Produce at Costa Group.

Read more here

Leading retail and global F&B companies, including PepsiCo and Unilever, announced the launch of Supporting Trusted Engagement and Partnership (STEP) up for Agriculture (STEP up for Ag).

Regenerative agriculture can be a powerful tool to promote healthier soil, reduce agricultural emissions, enhance biodiversity and watershed health, and help raise the standard of living for farmers and farming communities. Read more here

Emulsifier and stabiliser specialist Palsgaard has appointed Miguel Hidalgo as its new CEO in Brazil, targeting further success in the country.

Hidalgo, who started the role this October, has 30 years of experience at Palsgaard and has served as chairman of the company’s Brazilian operation since 2018.

His previous roles also include CEO of Palsgaard Mexico and Regional Director of the Americas. He has taken on the position as Palsgaard aims to become the leading supplier of emulsifiers and speciality ingredients for the food industry in Brazil. Read more here

MKGL has garnered the support of the Māori Queen to support the work of Māori kiwifruit growers domestically and overseas.

MKGL (Māori Kiwifruit Growers Forum Ltd) said it was honoured and humbled to have the support of Te Kiingitanga at the launch of a new export initiative in the United Arab Emirates.

The Māori Queen, Te Arikinui Kuini Nga wai hono i te po VIII, is leading a Kiingitanga delegation to support the work of Māori Kiwifruit Growers Ltd (MKGL), which is marking the start of its first season in the market with an elegant royal launch event. Read more here

The Magnum Ice Cream Company has announced the completion of a major AUD 35 million transformation of its Minto facility in South-West Sydney.

The upgraded Minto ice cream facility marked a significant milestone for the company and the local Campbelltown community. It will support innovation and growth, strengthening Australia’s food manufacturing sector and boosting productivity at the site, as part of the company's global supply chain transformation program. Read more here

ADM announced that Fibersol, a premier line of soluble prebiotic fibres, has received approval from the Therapeutic Goods Administration (TGA), part of the Australian Department of Health, for use as an active ingredient in biologicals, listed medicines, and prescription medicines. The approval expanded Fibersol’s role beyond conventional food and beverage applications into dietary supplements and other regulated health product categories.

Read more here

The Government has introduced changes to the Animal Welfare Act 1999, raising welfare outcomes for pigs in New Zealand while providing farmers appropriate time to

make the changes.

Associate Minister of Agriculture (Animal Welfare) Andrew Hoggard announced these proposed changes set new requirements for the use of farrowing crates and mating stalls, and requirements for space for growing pigs.

Read more here

With over 2,500 trucks and 4,000 trailers, Tesco has one of the biggest LGV fleets in the UK. Its areas of focus for improvement included managing a vast fleet, ensuring accurate and timely deliveries, minimising empty runs and

In order to coordinate its vehicles, the supermarket giant recognised a need to track its fleet, in real-time, as well as keeping up with maintenance and safety standards.

Driver management also posed a challenge – from training and compliance to safety – which was another area of focus for Tesco.

Finally, it recognised the need to reduce empty runs to save costs and cut emissions.

Tesco’s integration of Microlise’s advanced technology aimed to transform its entire delivery operation. By implementing a comprehensive suite of software, it would enhance tracking capabilities and the overall management of its fleet.

Overall, implementation included:

Fleet Tracking: Enhancing delivery tracking and performance.

One of the core benefits that Microlise offers is real-time tracking. This functionality allows Tesco to monitor the exact location of each vehicle – at any given time – providing a live overview of the entire fleet’s status. This immediate visibility is crucial for managing delivery schedules, responding promptly to any issues and ensuring that deliveries are made on time.

Driver Performance App: Allowing drivers to monitor and improve their performance, through real-time feedback.

Microlise’s driver app equips Tesco drivers with tools to monitor and improve their driving performance. The app delivers real-time feedback on various driving parameters such as speed, braking and acceleration, helping drivers to make immediate adjustments and adopt safer and more efficient driving habits.

on-time deliveries for large stores 99 % since implementing Microlise

Fleet Safety Management: Promoting safe and fuel-efficient driving practices.

The system monitors fuel usage, helping to identify opportunities for improving fuel efficiency. By analysing fuel consumption data, Tesco can implement strategies to reduce fuel usage and lower operational costs.

•99% on-time deliveries for large stores and 96% for convenience stores

•More efficient driving, better driving styles and improved safety on the road

“•Reduced emissions, enhanced hazard perception and improved the ability to forward plan I can’t imagine what my day would look like without the Microlise system, it really does give us everything we need to run an operation this big.”

Jamie FutcherLead Transport Manager, Tesco

Since implementing Microlise's solutions, Tesco has achieved remarkable improvements in delivery performance, with 99% on-time deliveries for large stores and 96% for convenience stores.

The driver app has ignited a culture of healthy competition, leading to more efficient driving, better driving styles and improved safety on the road. Additionally, the telematics system has contributed to reduced emissions, enhanced hazard perception and improved the ability to forward plan. As a result, Tesco is expecting to see a reduction in accidents and a significant improvement in overall road safety.

“We’re always keen to work in partnership with Microlise to test any new products, and any new innovation that Microlise might have to enable us to improve the service that we deliver to our stores and customers.

“Strategically, whilst we’re looking at multiple options in terms of alternative fuel vehicles while we are operating diesel trucks, it’s really important that we continue to use the Microlise telematics system to continue to improve our drivers’ score, continue to improve the MPG that we deliver and the associated emissions reduce as a result of that.

“Microlise is really important to us here at Tesco. It’s a key enabler for us to be able to deliver fantastic service to our stores and customers.” - Chris Jones, RTM North & Head of Fuel Logistics

Microlise's comprehensive transport solutions are essential to Tesco's logistics operations, enabling it to deliver exceptional service to both stores and customers.

Microlise works with nearly all supermarket chains in New Zealand and Australia.

The collaboration highlights how technology can drive efficiency and performance in large-scale logistics. Tesco values the critical visibility and improvements facilitated by Microlise that is essential for managing their expansive transport network.

Want to know more? Microlise solutions can help you to reduce costs and environmental impact, while increasing safety, efficiency and compliance.

The Bioeconomy Science Institute is assessing food contact compliance of packaging made from agricultural by-products to meet a growing demand for plastic alternatives.

This research, led by a team of scientists with packaging research and food contact testing expertise, aims to answer questions from businesses and consumers interested in sustainable alternatives around whether they meet relevant food packaging regulatory requirements.

It builds on the Bioeconomy Science Institute’s Packaging and Decentralised Processing programme, which showed the feasibility of developing moulded fibre trays using agricultural by-products such as blueberry pomace, avocado waste, cabbage leaves, hemp and other straw.

“Our collaborators and partners, such as growers and oil producers, are enthusiastic about repurposing their by-products into fibre-based packaging that is functional and visually appealing,” said Bioeconomy Science Institute scientist Kelly Wade.

“However, much of the single-use plastic packaging they wish to replace is used for food applications, such as takeaway containers or fresh produce packaging. Before investing in the infrastructure needed to convert growers’ by-products into food packaging, collaborators must be confident that the products are fitfor-purpose.”

The Packaging and Decentralised Processing programme is a cornerstone of the Bioeconomy Science Institute’s continued work with farmers, growers and communities to provide unique product options.

The organisation has now secured Bioresource Processing Alliance (BPA) funding to employ a student who will focus solely on whether packaging made from agricultural byproducts complies with food contact standards – to help fast-track specific opportunities.

Matthew Parker, a summer student who has previously supported the Bioeconomy Science Institute’s packaging team, will take on this role.

Wade and Bioeconomy Science Institute chemist Eva Gaugler, who has expertise in food contact compliance of packaging materials, will support Matthew with scientific expertise and direction.

Fibre-based packaging is a potential sustainable alternative to single-use plastic options. Increasing concerns and awareness around microplastics mean there’s a growing demand for circular materials (fibre-based or plastic) in packaging while maintaining product quality and safety. This brings challenges for researchers.

“It’s difficult to produce an alternative sustainable solution at a relatively small scale and show that it is cost-competitive with large-scale processes that have had decades to become as efficient as possible,” said Wade.

“There are also often challenges associated with scale-up that aren’t apparent at lab or pilot scale; processes don’t behave in the same way at large scale as they do on the bench.

Bioeconomy Science Institute sustainable materials team leader Kate Parker said fibre packaging, which is biodegradable, made from renewable resources and recyclable through established paper recycling systems, is a huge growth industry. The organisation is researching different fibre waste streams to create viable alternatives to plastic packaging.

“We’re using waste streams that would otherwise go to landfill or lowvalue animal feed. This sustainable packaging replaces traditional plastics, making it better for the environment and aligning with our work to support New Zealand’s circular bioeconomy.”

Companies interested in maximising value from their agriwaste streams can contact the Bioeconomy Science Institute to discuss potential support.

The Bioresource Processing Alliance (BPA) brings expertise from across the Bioeconomy Science Institute, Callaghan Innovation and New Zealand universities to deliver maximum value from by-products and reduce environmental impact from primary production and manufacturing activities. It is funded by the Ministry of Business, Innovation and Employment and offers a range of options for support of student projects.

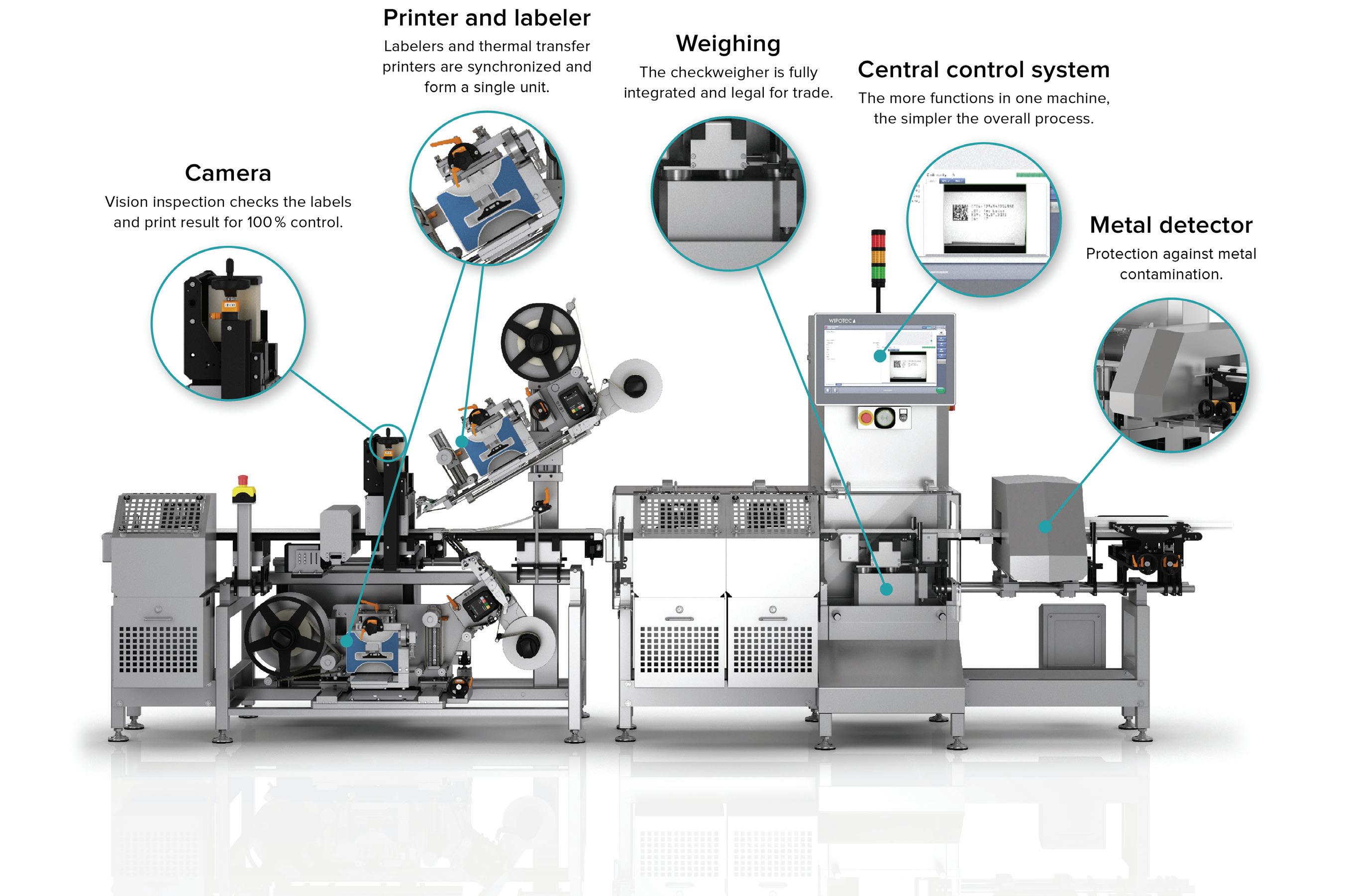

INLINE-PRINTED QR CODES ENABLE TRUE DIGITAL TRACKING WITH VARIABLE DATA

In an era of globalised supply chains, ensuring the safety and quality of consumer goods – especially in the food and beverage sector – has become not only a regulatory imperative but a public health priority.

COLIN SEDDON GM, Wipotec Australia

According to the World Health Organisation (WHO), more than 600 million people fall ill each year due to contaminated food, with an estimated 420,000 deaths. These sobering statistics highlight the urgent need for stringent quality control systems at every stage of production and distribution.

Quality and safety – defined respectively as product consistency and the ability to prevent harm – are increasingly seen as fundamental to long-term brand success. Technological advancements in inspection and traceability are playing a critical role in supporting manufacturers to meet these expectations while enhancing operational efficiency.

The ability to quickly and accurately detect contaminants is key to maintaining high safety standards.

COLIN SEDDON

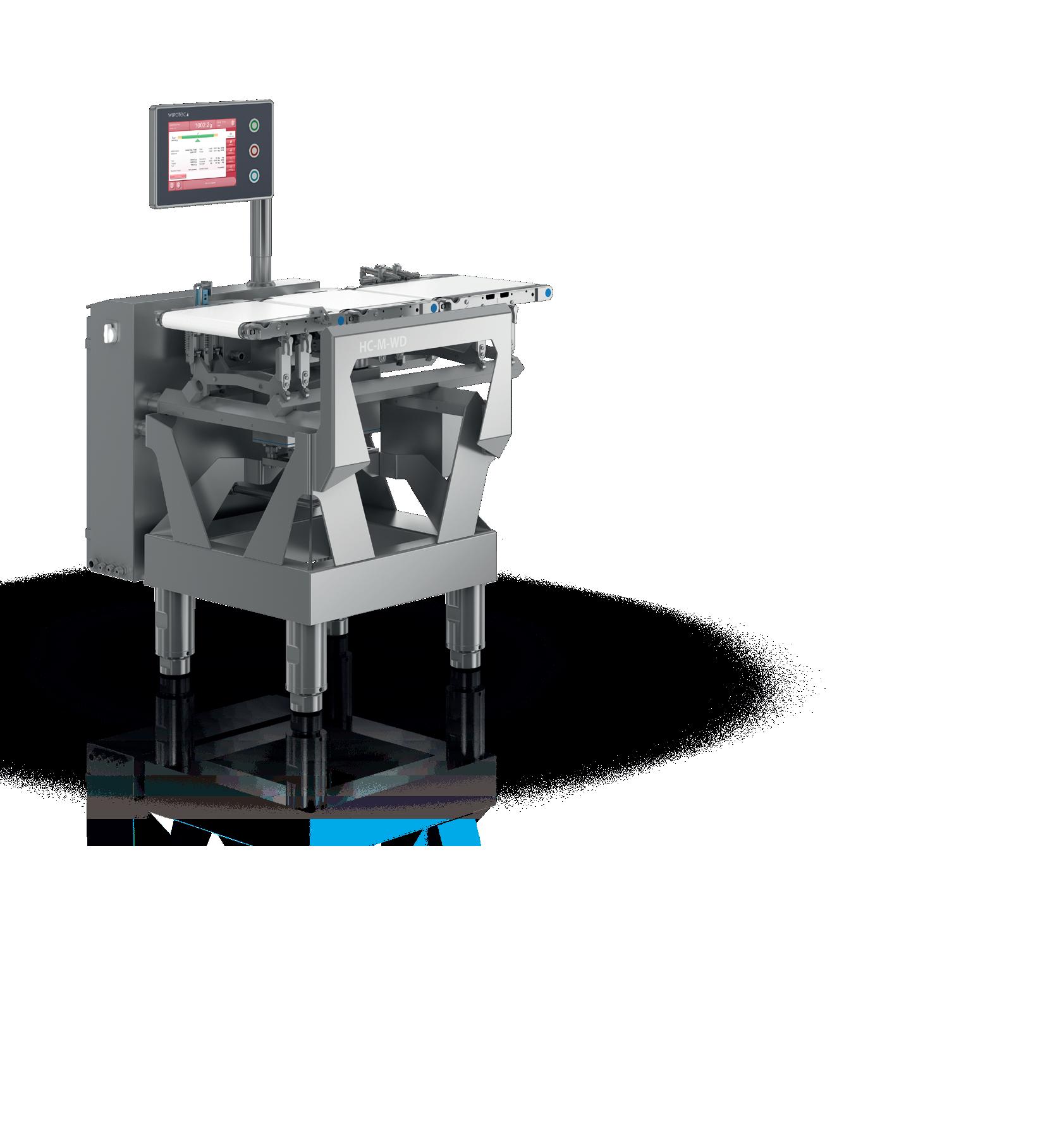

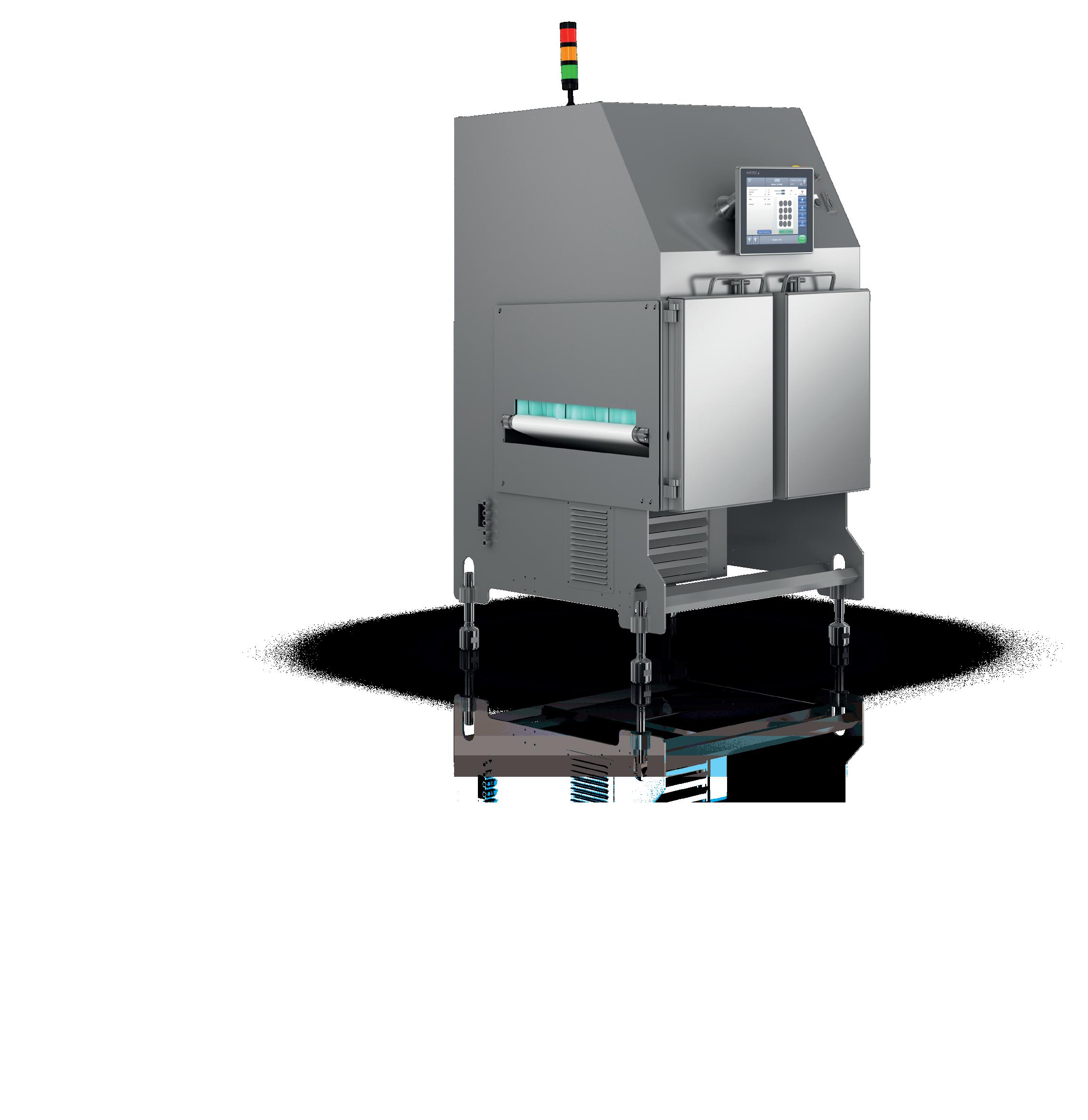

Among the key technologies gaining ground in this space are X-ray inspection systems for physical contamination, automated weight control for regulatory compliance, and real-time traceability tools that track a product’s journey from origin to shelf. These systems are designed to identify faults early, improve accountability, and safeguard both brand reputation and consumer health.

Colin Seddon, Managing Director of the Australian arm of German inspection technology firm Wipotec, said the deployment of advanced control systems is becoming standard practice across the food industry.

“It’s essential for companies to implement technologies that help meet international safety standards

while also improving production efficiency,” he notes.

Founded in 1988 in Kaiserslautern, Germany, Wipotec has grown into a global supplier of weighing and inspection systems, including X-ray, metal detection, marking, and traceability solutions. Since 2022, the company has had a direct presence in Australia, covering the New Zealand, Papua New Guinea, and Fiji markets. It also conducts “Testing Days” at its facilities in Australia – sessions where customers can evaluate product performance on inspection lines and train personnel on system operation.

As markets expand and crossborder trade accelerates, risks such as product counterfeiting and quality fraud have become more prevalent. The World Intellectual Property

Organisation (WIPO) estimates that as much as 10 percent of globally traded goods are affected by some form of fraudulent activity. This has direct consequences for consumer safety, brand integrity, and economic loss.

To combat this, manufacturers are investing in traceability systems capable of tracking products through every phase of the supply chain. Realtime data provides early warning for quality deviations and enables swift action before products reach retailers or consumers.

Alberto Gómez, Wipotec’s regional marketing manager for South America, Spain, and the Asia–Pacific, said traceability solutions are helping companies demonstrate their

Continued on page 14.

COMBINING X-RAY, WEIGHING AND VISION INSPECTION MAXIMISES SAFETY

Systems now can detect even the smallest foreign materials that could compromise consumer safety.

Continued from page 13.

commitment to transparency and consumer protection.

“It’s not just about risk prevention, but about building trust through verifiable quality assurance,” he said.

With growing consumer demand for transparency, authenticity, and sustainability, the role of packaging and product inspection is evolving rapidly. Technologies that can reliably detect contaminants, verify product weight, and ensure labelling accuracy are increasingly essential to regulatory compliance and to meeting expectations around fair trade and ethical production.

“The ability to quickly and accurately detect contaminants is key to maintaining high safety standards,” said Seddon.

“Systems now can detect even the smallest foreign materials that could compromise consumer safety.”

In this climate, companies adopting

a proactive approach to quality and safety – backed by robust technologies – are better positioned to navigate shifting regulations, meet consumer expectations, and stay competitive.

As Gómez pointed out, “Today’s consumers are more engaged and informed than ever before. They want to know where products come from, how they’re made, and that they meet high standards.”

The convergence of advanced inspection technology, real-time data analytics, and global quality standards is reshaping how consumer goods are produced, monitored, and delivered. For packaging and processing stakeholders, this underscores the need for continued investment in control systems that are not only accurate and efficient but also adaptable to the demands of a fast-changing industry.

Modular design for tailor-made applications and fast integration. Comprehensive application software packages. Easy, user-friendly operation.

Wipotec Australia Pty Ltd

1/46 Aylesbury Drive

Altona 3018 Victoria

Australia phone +61 3 7031 6100

info.au@wipotec.com wipotec.com

tnateam@tnasolutions.com tnasolutions.com

New Zealand’s food safety landscape has undergone a quiet revolution. From precision pathogen tracking to eco-friendly antimicrobial solutions, the convergence of science and technology is ensuring New Zealand remains a global leader in trusted, high-value food exports.

Food safety and quality research has evolved rapidly through the integration of digital, genomic, and sustainable technologies.

Whole-genome sequencing (WGS) is now routinely used by MPI and Public Health and Forensic Science (PHF) for outbreak detection, traceback, and source attribution, improving responsiveness across the

dairy, meat, and horticultural sectors.

Artificial intelligence (AI), machine learning, and digital twins are increasingly applied to predict contamination risks, optimise processing parameters, and strengthen traceability from farm to export markets.

Research groups at Bioeconomy Science Institute (formed by the merger of New Zealand Crown Research Institutes: AgResearch, Manaaki Whenua – Landcare Research, Plant & Food Research, and Scion) and universities are also pioneering non-thermal antimicrobial technologies, including cold plasma, ultraviolet LED, plasma-activated water, electrolysed water, as environmentally friendly alternatives to chemicals for extending shelf life and reducing waste.

Rapid, on-site biosensing and

hyperspectral imaging are emerging as valuable tools for near real-time monitoring in processing plants, supporting New Zealand’s reputation for high-integrity food exports. There is also growing emphasis on One Health approaches, with work addressing antimicrobial resistance, the impacts of climate change on foodborne pathogens, and the need for sustainable biosecurity solutions. Standards for novel and emerging foods, such as precision-fermented ingredients, cell-based meat, and plant-based alternatives, are under active development to ensure consumer safety, market access, and public trust.

Collectively, these developments reinforce New Zealand’s position as a global leader in science-based, export-driven food safety and quality innovation.

The integration of AI, sensors, and data analytics is transforming how food contamination and quality issues are detected and prevented across the supply chain.

BSI is applying machine learning and Bayesian modelling to detect microbial growth and product shelf life. At the same time, hyperspectral imaging and AI are being developed to enable real-time quality monitoring and process optimisation in in vitro cultures.

BSI is advancing sensor technologies, including volatile organic compound detectors and wireless sensor networks, to monitor fruit quality and detect biosecurity risks. The University of Auckland’s Future Food Research Centre is leveraging AI, blockchain, and big data tools to strengthen traceability and improve packaging sustainability. These innovations are creating a more intelligent, more predictive foodsafety system that supports New Zealand’s global reputation for safe, trusted, and high-value food exports.

Translating food-safety and quality innovations from laboratory research to commercial application remains challenging. Key barriers include limited access to sustained funding, complex regulatory approval

processes, and the difficulty of validating technologies at pilot or industrial scale.

Bridging the gap between proof-ofconcept and market-ready solutions requires specialised infrastructure and strong industry partnerships. Facilities such as BSI’s Te Rou Rou Food Pilot Plant and Massey University’s FoodPilot, both part of the New Zealand Food Innovation Network (NZFIN), provide critical platforms for scaling and validation under real-world conditions.

Commercialisation networks such as KiwiNet and Sprout Agritech play a vital role in mentoring researchers, supporting IP development, and connecting innovators with investors and industry end-users. Initiatives like FoodHQ and regional innovation hubs further strengthen collaboration across the research–industry interface.

However, aligning academic research timelines with commercial priorities and market needs remains a persistent challenge. Addressing these barriers is key to accelerating New Zealand’s progress from scientific discovery to globally competitive, high-value food technologies.

Effective collaboration between industry and research requires mutual understanding of differing objectives,

Continued on page 18.

Continued from page 17. timeframes, and regulatory constraints, alongside structured frameworks for communication and co-creation.

Initiatives such as the New Zealand Food Safety Science & Research Centre (NZFSSRC) play a defining role in bridging this gap, connecting researchers with industry partners to address priority food-safety challenges through coordinated research programmes.

Networks such as KiwiNet, Sprout Agritech, and the New Zealand Food Innovation Network (NZFIN) further enable collaboration by providing access to pilot-scale facilities, commercialisation support, mentoring, and funding opportunities.

Collaboration is strengthened by sharing best practices, developing supportive policies, securing flexible funding mechanisms, and establishing clear intellectual property frameworks.

Industry and research partnerships are further enhanced by appointing dedicated relationship leaders who

can navigate regulatory, commercial, and technical landscapes, ensuring that innovative solutions are efficiently translated into safe, highquality food products that meet both domestic and global market needs.

For New Zealand, emerging risks over the next decade span environmental, societal, technological, and geopolitical domains. Climate change remains a defining challenge, with increasing extreme weather events, shifting pathogen profiles, and impacts on water quality, agriculture, and food security.

Societal risks such as inequality, workforce shortages, and the need for sustainable rural development will influence resilience in the food system. Technological risks include cyber threats to critical food supply infrastructure and the potential misuse of AI in areas such as food fraud, biosecurity, and misinformation. Geopolitical fragmentation, supply chain volatility,

and changes in trade relationships pose additional risks to New Zealand’s export-driven economy.

Proactively addressing these challenges will require integrated risk assessment, investment in resilient infrastructure, ongoing innovation in food-safety science, and collaboration between government, industry, and research organisations to safeguard New Zealand’s reputation for highquality, safe, and sustainable food production.

By Gale Brightwell,

Principal Scientist, Science Team Leader for Food System Integrity Team based at the Hopkirk Institute, and Associate Director of the New Zealand Food Safety Centre.

The NZFSSRC was established in 2016 as a virtual partnership between the food industry, government, Māori and research providers. It is the focal point for food safety science and research in New Zealand, helping to safeguard consumers of NZ food products. More information is available here Home | NZFSSRC.

According to food technologist Justin Maher, founder of Foodie Tech, the core principles of quality assurance have not really changed over time.

Things like allergen control, preventing foreign bodies, and managing food safety hurdles such as pH and pasteurisation have remained critical today as they’ve always been, maybe even more so.

“These days, if you want to innovate and move quickly, QA can’t just sit at the end of the line with one team. It needs to be woven right through the whole process. From the first feasibility check and ingredient sourcing, through to manufacturing. That shift has made an enormous difference,” said Maher.

“When QA is part of every stage, information flows better, decisions get made faster, and there are far fewer nasty surprises later, like discovering an undeclared allergen.”

For start-ups, one of the biggest early-stage oversights has been simply not having the correct information or certification for ingredients. Maher added that a few simple requests go a long way: an ingredient specification or PIF (industry standard), a manufacturer’s food safety certification, and any certification supporting key claims, e.g. halal, kosher, or gluten-free.

“Get this information upfront, and you’ve dramatically reduced the risk of compliance and food safety issues down the line.”

He suggested starting by familiarising with where the current FSANZ and Plain English Allergen Labelling (PEAL) requirements are located. Create a product-specific checklist, and if you’re unsure, have a food technologist draft one and review it against FSANZ at least once a year.

Complete a checklist for every new or updated product. Check all ingredient specs for allergens and cross-contact risks. If you’re making allergen-free claims, ensure your controls are robust and verified through lab testing.

A factory mixer or homogeniser will produce much finer oil droplets than a benchtop blender, increasing the surface area of fat in contact with water.

If there aren’t enough emulsifiers, like protein or lecithin, to cover that larger surface area, producers may end up with separation or unexpected texture changes. Sometimes that’s positive, like a thicker, creamier mouthfeel, but it can also cause flow issues, such as the product not dispensing properly through a packaging nozzle.

“At the end of the day, the biggest challenge in scaling up is simply that: you don’t know what you don’t know.”

As the global population continues to grow, so does the demand for food. Consumers have been increasingly looking for protein-rich, natural, minimally processed products and sustainable packaging. The industry challenge has been meeting these expectations while maintaining shelf life and consistent quality.

One technology that Maher highlighted as a real game-changer was CAS (Cells Alive System). During traditional freezing, water molecules expand, forming ice crystals that damage the food’s structure. Once defrosted, products can become mushy and lose flavour.

“Even obvious details can be overlooked, and allergen mistakes are a serious risk to consumers. When in doubt, get a food technologist to check; it’s worth it.”

Scaling from benchtop to factory can also impact ingredient functionality, dispersion, texture, and flavour. Experienced manufacturers, who have navigated scale-up many times, know how to adapt their benchtop methods to better predict factory outcomes, but for startups, it’s often a case of not knowing what they don’t know.

Maher said that’s where an experienced food technologist becomes invaluable. Someone who can identify key risk areas early, based on how sensitive certain ingredients can be to factory conditions like heat and mixing.

He provided an example of mayonnaise, an oil-in-water emulsion, which is somewhat sensitive to shear.

However, CAS exerts even pressure on cell walls during freezing, creating much smaller ice crystals that preserve texture and flavour. Frozen products are often perceived as lower quality than their chilled counterparts, despite having similar nutritional value and minimal processing.

CAS could help close that gap, giving frozen products a true-fresh texture, while also reducing food waste through drastically improved shelf life, increasing sustainability, and expanding export pathways by shifting from air to sea freight.

“Over the next five years, it will be critical to validate CAS’s effectiveness and return on investment for New Zealand products. The potential for improving food safety, quality, and market growth is significant.”

As of 2025, over 60 percent of AI adoption in food manufacturing has been focused on real-time quality inspection and contamination detection. This has reflected a shift from traditional batch testing to continuous, automated safety systems.

According to the latest study from BCC Research, the “AI in Food Safety and Quality Control Market” is projected to reach USD 13.7 billion by 2030.

The report highlighted how artificial intelligence has revolutionised food safety and quality control across the global food value chain. The AIdriven food safety and quality control market has undergone a significant transformation.

Rising regulatory pressures, frequent global food safety incidents, and the complexity of modern supply chains have driven the urgent need for real-

Increasing number of outbreaks caused by pathogens such as Salmonella and E. coli has made food safety a top priority. AI can help detect contamination early by analysing sensor data, lab results, and environmental conditions, enabling faster response and prevention.

time, automated monitoring.

Advances in AI technologies like ML, computer vision, and IoT have also enabled predictive safety systems, while labour shortages, sustainability goals, and consumer demand for transparency have accelerated adoption.

Consumers today want to know where their food comes from and how it’s made. AI systems verify product origins, detect mislabeling, and ensure ethical sourcing, building trust and meeting regulatory standards.

At the same time, AI has enabled the delivery of tailored food recommendations based on consumers’ health data, allergies, and preferences. This supports safer consumption and helps manufacturers develop customised, health-conscious products.

Also, the increasing number of outbreaks caused by pathogens such as Salmonella and E. coli has made food safety a top priority. AI can help detect contamination early by analysing sensor data, lab results, and environmental conditions, enabling faster response and prevention.

Food products often pass through

multiple countries and suppliers, increasing the risk of contamination and fraud. AI has enhanced traceability, monitoring each stage of the supply chain to help identify weak points and ensure product integrity.

AI utilises historical and real-time data to predict potential risks, such as spoilage or equipment failure. It also automates quality checks, ensuring consistent standards and reducing waste or recalls.

Despite rapid innovation, less than 30 percent of global food manufacturers have fully integrated AI-based traceability systems, highlighting a significant opportunity for expansion in supply chain transparency and recall management.

Looking ahead, several AI startups in food safety have begun partnering with regulatory bodies to co-develop compliance-ready platforms, blurring the line between enforcement and innovation.

A report by New Zealand Food Safety earlier this year identified the recall of imported sesame seeds with the potential to cause Salmonella poisoning as last year’s most significant food safety event.

The 2024 report showed that New Zealand Food Safety supported food businesses in conducting 88 consumer-level food recalls. At the same time, it was essential to note that the number of recalls was not a reliable indicator of the level of risk to consumers.

Many factors, including regulatory changes, business and public awareness of food-related issues, and the reporting of those problems, can influence numbers.

Of the 88 recalls, 56 were initiated for domestically produced foods and 32 were for imported foods. Allergens in food were the leading cause for recalls in 2024, accounting for 46 percent of all recalls.

“Recalls are an important part of our work to protect consumers. New Zealand’s food safety system has a strong track record of keeping people safe, and given the volumes of food being produced, manufactured, and imported, incidences of related illness remain rare,” said New Zealand Food Safety deputy director-general Vincent Arbuckle.

“However, there are occasions when food safety issues occur, and that’s when we work quickly with food businesses to recall the affected product, removing it from the food supply chain and promoting public awareness. Good regulations also play a key role.”

A new consumer survey commissioned by GS1 US revealed that while 85 percent of Americans

Recalls are an important part of our work to protect consumers. New Zealand’s food safety system has a strong track record of keeping people safe, and given the volumes of food being produced, manufactured, and imported, incidences of related illness remain rare.

believed food recalls were effective in protecting public health and safety, 93 percent were concerned about how frequently they occur.

Sixty percent of consumers said they have avoided an entire food category, such as lettuce, following a recall, while 57 percent admitted to discarding recalled food even if their state or region was not impacted, with millennials most likely to take this precaution.

More than half also reported hesitancy to purchase the same product or brand again after a food recall, especially millennials and Gen Z, compared to baby boomers.

“Food recalls are issued for a variety of reasons, including contamination with bacteria like Salmonella or E. coli, undeclared allergens, the presence of

foreign objects, or even mislabeling,” said Bob Carpenter, president and CEO of GS1 US.

“Though the frequency of food recalls may seem concerning to some, it shows that the food safety system is more proactive and effective due to advances in science, technology and modern regulations. Improved tracking tools, barcoding standards and traceability requirements are evolving to help identify and remove affected products and better respond to recalls.”

Regulation taking shape to strengthen recall effectiveness includes FSMA Rule 204, which is part of the U.S. Food and Drug Administration’s (FDA’s) Food Safety Modernisation Act (FSMA), signed into law in 2011 to improve food

safety processes.

The FDA recently proposed to extend the implementation deadline until the 20th of July, 2028, for the rule, which will add stricter recordkeeping requirements for foods that are most often implicated in food recalls, such as leafy greens, shell eggs and nut butters, among others, on the FDA’s Food Traceability List (FTL).

It also requires that complete traceability data needed to support a recall be made available to the FDA within 24 hours, which allows for quicker action to protect consumers.

GS1 US has been helping the food industry meet these requirements by applying GS1 Standards to enhance supply chain visibility, improve data sharing and enable rapid identification of affected products.

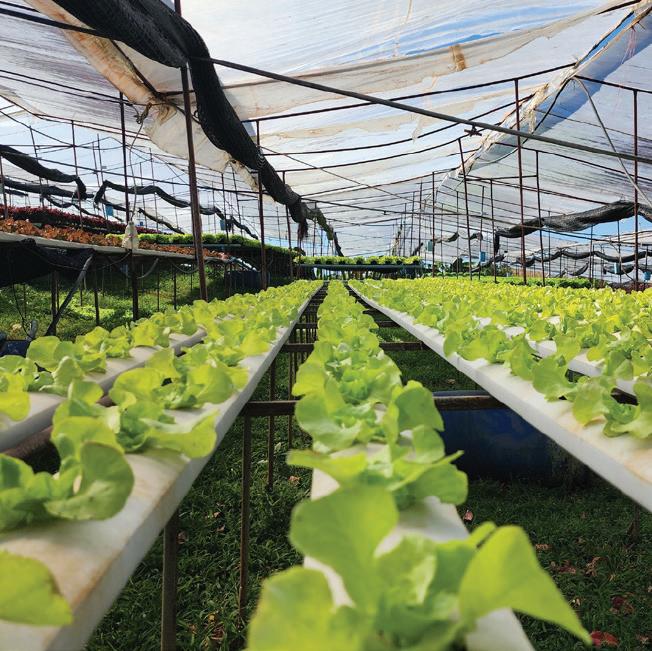

Modern indoor farming has gained attention as a promising approach to food production.

In a highly urbanised world, its attractiveness has relied on the possibility of growing crops in a reduced space and in an energyand resource-efficient manner, bringing benefits such as economic efficiency, sustainable food production, and enhanced food security.

Released last month as a corollary to a previous FAO report, the factsheet “Indoor farming, safer food or new risks?” unpacked what indoor farming entailed, the benefits and the risks that need to be managed.

It also presented evidence-based content aligned with the Codex Alimentarius General Principles of Food Hygiene and Guidelines for the Safe Use and Reuse of Water in Food Production and Processing.

It may serve as a primer for policymakers, trainers, and investors who wish to take the first steps towards understanding the food safety risks and solutions that matter in urban farming for agrifood systems transformation.

The factsheet mentioned that

by 2050, the world’s population is expected to reach 10 billion people, putting pressure on how food is produced and supplied.

Traditional outdoor farming has already been facing serious challenges, including climate change, water shortages, degradation, and pollution, which make it harder to grow enough safe food.

Despite the perception that food grown indoors is automatically safer than conventionally farmed produce, indoor farming is not immune to food safety risks. In reality, it presents similar food safety hazards to those found in conventional outdoor farming.

In fact, even in a controlled environment, various sources of microbial contamination exist, and they should not be understated.

Keeping indoor-farmed crops safe depends on applying the proper practices from the very start. A hygienic growing environment, seed disinfection, and regular water disinfection treatment are crucial in preventing hazards from spreading.

Because indoor farming shares similarities with sprout production, similar safety protocols can be applied. At the same time, regulators and inspectors must learn to adapt existing food safety systems to these new production methods.

Indoor farming is still evolving, and more research is needed to understand its unique risks. Looking ahead, artificial intelligence and predictive

tools could detect problems early, but only if reliable data are generated and shared across the sector.

Finally, success depends not just on technology but also on people.

Building a strong “food safety culture” within indoor farms, where everyone, from workers to owners, views safety as their responsibility, will be key to making the promise of indoor farming a reality.

LuminUltra has entered into a partnership with Kikkoman Biochemifa to expand access to its industry-leading food safety and hygiene monitoring tools across North America.

Through this agreement, LuminUltra has become an official distributor of Kikkoman’s Food Safety Testing Solutions, uniting two leaders in microbial monitoring innovation.

Kikkoman has a reputation as a globally respected food producer and trusted supplier of food safety technologies, while LuminUltra has 30+ years of proven expertise in developing tools and workflows that help industries manage their microbial challenges with confidence.

“Food producers and distributors across Asia have trusted these solutions and Europe for decades, but they are underutilised here in North America,” said Pat Whalen, President and CEO of LuminUltra.

“This is about accelerating access to more accurate and sensitive testing for the North American food and beverage market. Producers want

better and more proactive insights, but haven’t had access to or awareness of the right solutions. We’ve built our business on educating industries on why a better test matters, and we’re bringing that expertise to rolling out these game-changing tools for the food and beverage industry.”

LuminUltra will now add the ability to support food safety and hygiene programs through two of Kikkoman’s flagship tools: The A3 Hygiene Monitoring System detects ATP, ADP, and AMP, providing a more complete picture of surface cleanliness than traditional ATP-only tests.

With a more thorough picture in the same amount of time as traditional ATP, food safety teams receive more data to ensure they have thoroughly sanitised their production space, and the insights to take more action if they haven’t. This is especially relevant to sectors such as ready-to-eat, dairy, and meat products, where the impact of improper sanitisation is highest.

Easy Plate, a ready-to-use, selfcontained culture-based solution for detecting pathogens and indicator organisms, reduces preparation time by half by eliminating the need for a spreader step.

Users get testing that is simpler, faster, and more accessible, with no special equipment required, unlike traditional plating solutions. When combined with the Colony Counting System for Easy Plate, labs can further boost performance by eliminating the variability and time burden of manual counting.

“LuminUltra brings the kind of deep technical focus and customerfirst mindset we value in a partner,” said Yoshiaki Asami, President of the Kikkoman Biochemifa Company.

“As a food manufacturer ourselves, we understand the real-world needs and challenges that QA/QC teams face every day. We have seen firsthand how valuable and important these tools are to other geographic markets across Asia and Europe. With this announcement, we’re proud to be expanding the reach of these solutions into North America and to be supporting a stronger, safer food system globally.”

LuminUltra and Kikkoman’s partnership marked a significant evolution of their relationship, formalising a commitment to bring full-service, proven food safety technologies to more producers across North America.

In a New Zealand first, 120,000 bees have hit the road across the North Island, travelling in a van that’s been transformed into a mobile hive.

Local beekeeper James Green from Hidden Honey, who has spent the past eight years caring for honeybees alongside his two brothers, has been leading the Volkswagen Pollination Tour.

Along the way, he has shared why pollinators are so important and how simple it is for Kiwis to make a difference, from planting bee-friendly blooms to supporting local beekeepers and creating safe spaces for pollinators.

Much of New Zealand’s food production relies on pollination; however, as flowering habitats decline and land use changes occur, pollination rates are falling in parts of the country, putting pressure on both ecosystems and food production.

“Bees aren’t just pollinators;

they’re tiny gardeners of New Zealand. Every garden, every patch of flowers, helps our native landscapes and our food grow strong. We want Kiwis to feel that connection and see how easy it is to make a difference, one backyard at a time,” said Green.

The bees will travel in a fully electric Volkswagen ID. Buzz, a modern evolution of the iconic VW Type 2 Kombi, which in the 1960s symbolised natural harmony and helped transport a cultural revolution known as the Flower Power movement.

Now affectionately known as Polly the Pollinator, the van has been transformed into a fully functioning “bee hive,” carrying not only two active colonies across the North Island but also the spirit of the original Kombi and those same ideals into a new era.

Along the way, beekeeper Green

Continued on page 30.

Continued from page 29.

will visit farmers’ markets, hand out wildflower seeds, and give communities the chance to see the hives up close and learn about the vital role pollinators play in keeping New Zealand blooming.

“Bees are incredible little beings, quietly shaping our world.

Following them on this journey is a way to celebrate that magic, and hopefully inspire Kiwis to plant flowers, nurture their gardens, and give a little love back to the land.”

Bee welfare is at the heart of the project. The van has been transformed into a hive-like environment, now housing active colonies with entry and exit tubes that allow the bees to come and go as they please to pollinate.

The interior is climate-controlled

to replicate natural conditions and maintain a comfortable temperature for the bees, just as they would in a standard hive. Green will oversee the colonies throughout the tour, ensuring they are safely supported during their journey.

“We’re taking our buzzing friends on the road to meet communities, kids, and gardens across the North Island. It’s not just about bees, it’s about showing how every small action, every flower, can help our environment thrive.”

With tens of thousands of bees buzzing along the North Island, this first-of-its-kind project combines education, community engagement, and sustainability –all in a mobile hive on wheels.

Bees are incredible little beings, quietly shaping our world. Following them on this journey is a way to celebrate that magic, and hopefully inspire Kiwis to plant flowers, nurture their gardens, and give a little love back to the land.

Textile Products is a family-owned and operated business, with recycling at its core since its founding in the 1970s.

From the very beginning, Textile Products has focused on transforming waste into something useful, rather than simply disposing of it. That philosophy has always been at the forefront of its operations and remains the foundation of its approach today.

“We’re not just a recycling facility, we’re converters of waste into new, high-value products. Our integrated model enables us to collect end-of-life textiles, wool, insulation, and other challenging waste streams, then

process and remanufacture them into usable solutions for construction, furniture, bedding, and packaging,” said Georgia Willis, Community & Marketing Coordinator, Textile Products.

“Importantly, we also take back all the products we manufacture at the end of their life and recycle them into the same or similar products, ensuring proper product stewardship. That approach guarantees we don’t become a dumping ground.”

One of the company’s latest innovations has been Retex. What

started as a recycled textile solution has now proven itself across a wide range of applications, from temporary signage and floor protection to building protection systems. Customers value that it’s not only sustainable, but also durable and reusable.

Retex was initially developed from end-of-life hi-vis gear and overalls. Textile Products saw a growing issue with workwear ending up in landfill, and wanted to prove there was a better way.

At the same time, the team identified gaps in the building sector, particularly the widespread use of single-use corflute and plastic for protection on scaffolds, floors, and construction sites. That’s where Retex building, scaffold, and flooring protection products were designed to step in.

To close the loop, the company created the Retex Recycling Bin system. By supplying bins directly through building merchants such as Mitre

10, Carter’s, ITM, and Placemakers, recycling becomes visible and straightforward.

When customers purchase their Retex products in-store, they can also drop off their worn-out workwear items into the bins. This model ensures that workwear isn’t just discarded; it’s converted into new protective products that replace single-use plastics and corrugated plastic (also known as corflute).

Beyond Retex, the team has also been working with local charitable trusts and op shops that face a growing challenge of an influx of donated goods, many of which are unsellable due to damage.

Currently, most of this ends up in landfill, and Textile Products saw a massive gap in the market and designed a temporary mattress made from recycled foam and textiles. These mattresses provide every New Zealander with the chance for a deserved night’s rest, while also

tackling a waste stream that has been difficult for charities to manage.

Alongside these projects, the company has continued to manufacture a wide range of recycled textile products, including insulation (made from wool and polyester), felts, carpet underlays, furniture removal blankets, and waddings. Each of these demonstrates how waste can be converted into durable, practical alternatives to virgin and single-use materials.

Willis highlighted that Textile Products currently processes around five tonnes of waste per day. That impact is tracked both quantitatively and qualitatively, for example, by monitoring the ratio of returns versus outputs, which provides visibility into which industries are closing the loop.

Textile Products also works with trusted partners, such as Workwear Recycled, which specialises in PPE and Continued on page 34.

Continued from page 33. workwear. They carefully decommission clothing, removing zips, buttons, and logos, before it enters its streams, ensuring security and traceability.

Willis added that market trends have moved away from “feel-good” recycling toward verified conversion, measurable impact, and circularity, and that’s where Textile Products is positioned: delivering solutions that stand up to both customer scrutiny and environmental science.

“When businesses choose Textile Products, they’re not just reducing emissions, they’re replacing singleuse imports with locally converted alternatives. By sourcing locally, businesses also reduce freight kilometres and the associated emissions of imported materials.

The regional economy benefits too, as every tonne we process supports local jobs, manufacturing skills, and community investment,” said Willis.

“As we manufacture with recycled rather than virgin materials, our products have a significantly lower environmental footprint. However, the real value lies in the fact that this impact isn’t just theoretical; it provides businesses with a credible and measurable story to share with their own customers, staff, and stakeholders.”

In practice, choosing recycled felts, underlays, insulation, and protection products means organisations can demonstrate they’re moving beyond a ‘tick-the-box’ approach to sustainability, toward authentic change that strengthens both the

climate and the local community.

Looking forward, Willis said the company would continue to develop engineered felts and panels designed to substitute plastics and composites, helping more industries make the shift to sustainable, circular options.

One of the clearest opportunities she mentioned was in packaging, which has long relied on single-use polystyrene and foam.

“A recent pilot with a major manufacturer in the building industry showed exactly what’s possible. They switched from foam packers to our Retex packing boards; the result was outstanding: equal protection, lower waste, and no difficult-to-dispose-of foam. Some of their customers have even found additional uses for the recycled packers,” she added.

“This proves the bigger point: recycled textiles can disrupt entrenched supply chains by replacing single-use materials with durable, sustainable solutions. Packaging is just the start; we see similar potential in construction, furniture, and beyond.”

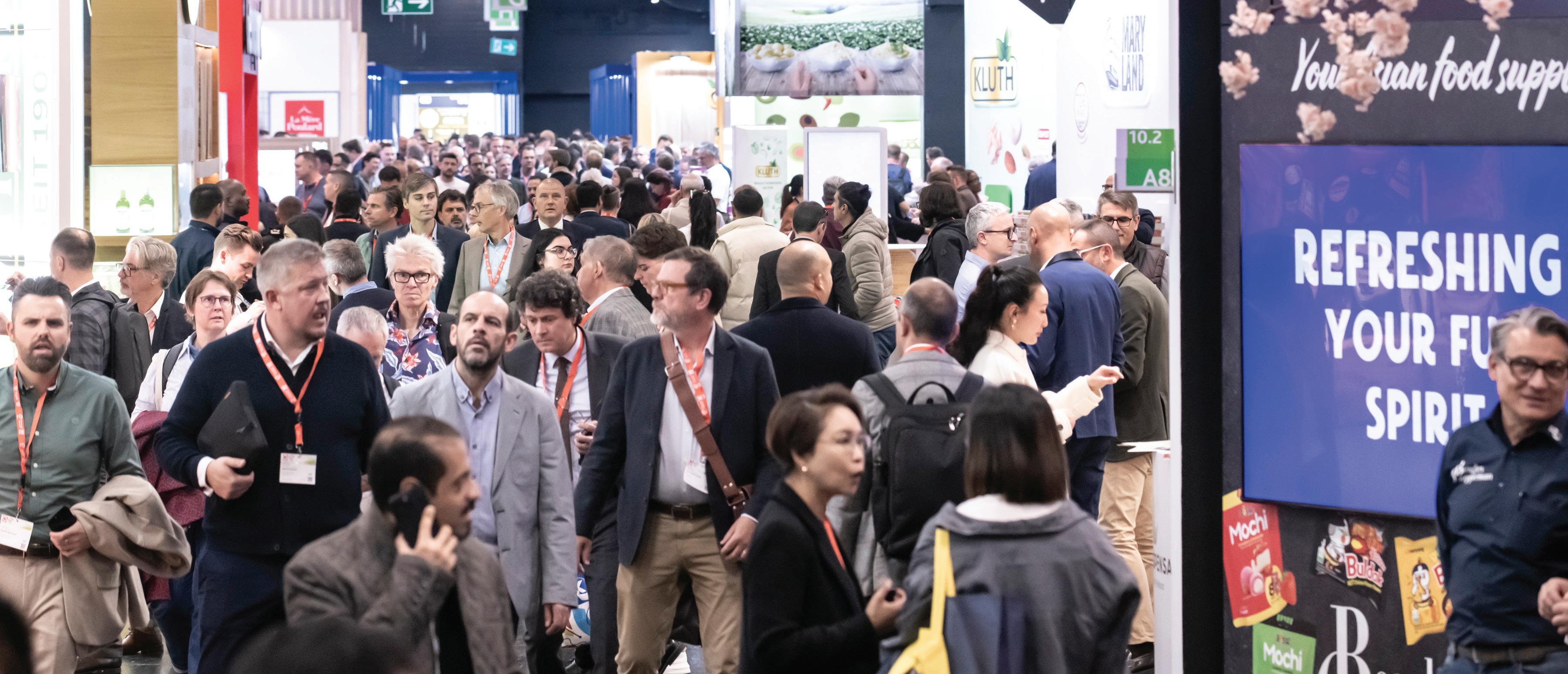

Anuga broke all previous records with its 2025 edition, as over 8,000 exhibitors from 110 countries showcased their products in Cologne this October.

More than 145,000 trade visitors from over 190 nations took advantage of the opportunity to discover innovations, experience trends, and establish international business contacts.

The trade audience was especially strongly represented from Great Britain, Italy, the Netherlands and Spain. Outside Europe, Brazil, China, Japan, Canada and the USA were among the top nations.

With a 94 percent share of foreign exhibitors and 80 percent share of visitors from abroad, and with its ten trade shows, Anuga impressively reinforced its position as the undisputed global platform for the F&B industry.

The visits of Alois Rainer, the German Minister of Agriculture, Food, and Regional Identity, and Miryung Song, Minister of Agriculture, Food, and Rural Affairs from the Republic of Korea, as well as numerous international delegations, also underscored the high level of political interest in the trade fair.

“Anuga impressively demonstrates the central role it plays for the international food industry: It is a showcase for the success of an entire sector and a key driver of billions in sales,” said Gerald Böse, President and Chief Executive Officer of Koelnmesse GmbH.

“The global food industry is one of the most important growth drivers worldwide. This strength becomes tangible at Anuga; it underscores the innovative power and international significance of the sector.”

The appearance of the partner country, Korea was a special highlight of this year’s trade fair. Around 100 exhibitors presented the culinary diversity and innovative strength of the country, from fermented classics like kimchi and gochujang, through to modern food tech solutions. Guided Tours, tastings, and cultural events brought Korea’s cuisine to life for the trade audience.

“This year’s Anuga brought K-food and global food trends together. The result was numerous successful meetings between important buyers and the establishment of new business partnerships. This demonstrates once again why Anuga is the central platform for the global food trade,” said Bong Jun Yoo, Director of the Korea Food Industry Association (KFIA).

Continued on page 38.

Continued from page 37.

Trends, talks and tastings: An event programme with added value

Anuga successfully brought politics, business, research and the industry together, which was particularly visible on the new Anuga HORIZON Stage. International experts, such as

Edwin Bark (Redefine Meat), Hector Freitas (LIVEKINDLY Collective), and Dr Giuseppe Scionti (Novameat), provided insights into alternative proteins, sustainability, food tech, and vertical farming.

Supported by partners such as BALPro, ProVeg, Vegconomist, DLG, Lidl and REWE, the dialogue between

politics and business was promoted in a targeted manner. The new trade show, Anuga Alternatives, celebrated a successful premiere in the immediate vicinity.

“Anuga has once again presented itself as the leading global trade fair for food and beverages. Particularly in today’s era of protectionism and

global tension, the trade fair has set a strong signal for international dialogue and trade,” said Björn Fromm, President of the German Association of the Retail Grocery Trade (BVLH).

The Anuga Trend Zone was a further highlight. Together with the knowledge partners, Innova Market Insights and Euromonitor International, the Stage

provided in-depth analyses on global food and drink trends, sustainability, plant-based food, as well as health and wellness.

The Anuga Organic on Stage focused on organic, plant-based food and sustainability. Among others, the highlights included the Organic Trade Academy’s market discussion with the

Minister for Agriculture, Alois Rainer, who talked about the EU Goals “30 percent organic space by 2030”, as well as discussions on new regulations for genetic engineering and non-GMO products.

Further topics encompassed the future of plant-based food, sustain-

Continued on page 40.

Continued from page 39. ability strategies and innovative product developments.

The exhibitors particularly praised the high quality of the trade visitors, including many decision-makers.

Almost all of the top 20 companies from the German food retail sector were present, including Aldi Nord and Süd, the Edeka Group, Lidl, Metro AG, and the Rewe Group. Over the course

of the trade fair, Anuga achieved double-digit growth in the number of trade visitors from Germany.

Representatives from Aeon Co., Ahold Delhaize, Amazon, Auchan, Carrefour, Costco Wholesale Corporation, Intermarché, JD.com, Lotte Shopping, Tesco, Walmart and the Woolworths Group came from abroad.

Anuga’s strength not only lies in

Cologne, but also in its global network. With satellite events in Milan, Brazil, China, India, Japan, and Thailand, as well as the latest newcomer, Anuga Select Ibérica in Madrid, the brand is continually growing. Today, the Anuga portfolio comprises ten international formats.

The next Anuga will take place from the 9th to the 13th of October 2027.