Shijiazhuang Sunbo Pump Co., Ltd ☆ www.sunbopump.com ☆

ABOUT US

Brief Introdution

Sunbo Pump, headquartered in Shijiazhuang, China, develops, manufactures and globally markets progressive slurry pumps for delivering

through a piping system.

Designed for excellent performance, low energy simple maintenance. Our horizontal and ver-lurgy, power plants, sewage water treatment, dredging, as well as chemical and petroleumeral slurry transfer dealing.

Enterprise

Long-term, lasting customer relationships form the basis of the domestic and international success of Sunbo.

We consider every customer a partner. We attach great importance to securing and expanding the relationships to our worldwide customers.

We know what our customers need and can thus offer good quality, competitive price, low cost, fast and safe logistics, quick responsibly customer service. And, share the business risks together with u, all the time.

All pump bearings are using SKF, Timken and ZWZ. Being signing Using all our competence and our vast knowledge, we will find the solutions our customers need all around

SUNBO is a team of motivated and highly experienced engineers who always will find the right solution for your application...

Welcome to us.

OUR FACTORY

Your strong support of pump manufacturer

EXCELLENT. FOCUSED. QUALITY.

-

-

-

WAREHOUSE

MACHINING SHOP

FOUNDRY

SECTION ONE PAGE 05

SECTION TWO PAGE 11

SECTION THREE PAGE 12

SECTION FOUR PAGE 15

SECTION FIVE PAGE 16

SECTION SIX PAGE 20

SECTION SEVEN PAGE 23

ZGB

Horizontal

SECTION NINE

SECTION EIGHT PAGE 25

PAGE 28

SECTION ELEVEN

SECTION TEN PAGE 29

PAGE 30

PAGE 01

Slurry Pump

Slurry Pump Forth Pump Gravel Pump Dredge Pump Vertical Slurry Pump ZJ Slurry Pump TL FGD Pump DT FGD Pump

Sand Pump Blender Frac Pump

SECTION TWELVE Pump

Centrifugal

Chem. Process

Typical Applications

·Heavey Minerals

·Mill Discharge

·Chemical Process

·Power Plant

·Bottom Boiler and Fly Ash

·Cyclone Feed

·Slag Granulation

·Paper and Pulp

www.sunbopump.com

ZGB

01

o; ZGB

DESIGN FEATURES

ZGB TYPE PUMP PERFORMANCE SHEET

Pump Model Allowable Max. Power Clear Water Performance Impel. Dia. (mm) Capacity Q Head H(m) Speed r/m Effi. ( ( ( ( ( ( % NPSH(m) 65ZGB(P) 28.8-19.9 31.7-15.8 58-61 1480 62.5-47.4 4.5-3.0 390 8.37-5.8 21.0-10.5 25.4-26.7 980 62.5-47.4 2.0-1.3 80ZGB(P) 73.7-52.2 56.7-28.3 87.5-91.6 980 66.1-48.7 5.2-2.7 485 21.4-15.2 37.5-18.8 38.4-40.2 740 66.1-48.7 2.3-1.2 56.8-40.4 52.0-26.0 73.7-77.1 980 66.1-48.7 4.4-2.3 445 16.5-11.7 34.4-17.2 32.3-33.8 740 66.1-48.7 1.9-1.0 41.3-29.2 46.8-23.3 59.5-62.3 980 66.1-48.7 3.5-1.8 400 12.0-8.4 31.0-15.4 26.1-27.3 740 66.1-48.7 1.5-0.8 100ZGB(P) 124.9-91.4 116.7-58.3 85.1-91.8 1480 77.9-57.4 6.0-2.6 500 36.3-26.6 77.3-38.6 37.3-40.3 980 77.9-57.4 2.7-1.2 91.0-66.7 105-52.5 68.9-78.4 1480 77.9-57.4 4.9-2.1 450 26.4-19.4 69.5-34.8 30.2-32.6 980 77.9-57.4 2.1-1.1 64.0-46.9 93.4-46.7 54.5-58.8 1480 77.9-57.4 3.8-1.7 400 18.6-13.6 61.8-30.9 23.9-25.8 980 77.9-57.4 1.7-0.8 150ZGB(P) 215.0-165.5 200-100 85.2-90.0 980 77.7-53.3 3.8-2.7 740 92.7-71.3 151.2-75.6 48.6-51.3 740 77.7-53.3 2.2-1.5 168.0-129.3 182.4-91.2 73.0-77.1 980 77.7-53.3 3.3-2.3 685 74.2-56.8 140.0-70.2 41.6-44.0 740 77.7-53.3 1.9-1.3 131.9-101.5 169.2-84.6 61.8-65.2 980 77.7-53.3 2.8-1.1 630 57.6-44.3 129.6-64.8 35.2-37.2 740 77.7-53.3 1.6-0.6 200ZGB(P) 342.9-219.1 300.0-150.0 89.0-94.2 980 76.3-63.2 6.7-2.7 740 147.5-97.3 226.5-113.3 50.7-53.7 740 76.3-63.2 3.8-1.5 290.2-185.8 283.8-141.9 79.6-84.3 980 76.3-63.2 6.0-2.4 700 125.0-80.0 214.3-107.1 45.4-48.1 740 76.3-63.2 3.4-1.4 222.0-141.8 259.5-129.7 66.6-70.5 980 76.3-63.2 5.0-2.0 640 95.6-61.0 195.9-97.9 38.0-40.2 740 76.3-63.2 2.9-1.1 250ZGB(P) 421.2-275.6 400.0-200.0 84.0-90.1 980 78.2-63.2 7.3-3.3 740 181.4-118.7 302.0-151.0 47.9-51.4 740 78.2-63.2 4.2-1.9 356.7-233.2 378.4-189.2 75.2-80.6 980 78.2-63.2 7.1-3.0 700 153.7-100.5 285.7-142.9 42.9-46.0 740 78.2-63.2 4.0-1.7 278.8-137.9 348.6-131.6 63.8-68.5 980 78.2-63.2 5.5-2.5 645 120.1-59.4 263.2-99.4 36.4-39.1 740 78.2-63.2 3.1-1.4 300ZGB(P) 542.8-357.6 533.3-266.7 84.3-93.4 980 81.2-68.3 6.9-3.5 760 233.9-154.0 402.7-201.3 48.1-53.3 740 81.2-68.3 3.9-2.0 429.4-282.9 493.3-246.7 72.1-79.9 980 81.2-68.3 5.9-3.0 703 184.8-116.4 372.5-177.9 41.1-45.6 740 81.2-68.3 3.4-1.7 333.3-219.7 453.3-226.7 60.9-67.5 980 81.2-68.3 5.0-2.5 646 143.4-94.6 342.3-171.2 34.5-38.5 740 81.2-68.3 2.9-1.4 ZGB 03 www.sunbopump.com

+0.03 00 +0.01 -0.2-0.048 +0.03 00 +0.01 -0.2-0.062 +0.03 -0.20 +0.01 -0.2-0.062 +0.03 -0.30 +0.01 -0.3-0.062 +0.03 -0.40 +0.01 -0.4-0.062 +0.03 -0.40 +0.01 -0.5-0.062 +0.03 -0.50 +0.01 -0.6-0.062 L 1 B 4 D 1 D 2 D 3 D 4 H 1 H 3 ModelAB B 1 B 2 B 3 467 445279 200ZGB(P) D H 2 432492352.5 100ZGB(P) 150ZGB(P) 220 80ZGB(P) 560636395 S 1 250ZGB(P) 300ZGB n 3d 3 L 5 n 1d 1 n 2d 2 D 5 D 6 65ZGB 735 760 50383 840675460 100255200 S 2 (S 2 ) 377 L 2 L 3 L 4 45 149 340 80 47560 150/ 360.5475415 80 290 210 780 46060 780950 950645710 649766 168.565190 60 50 210 275 320 200380 180 60 760840619684453 560636360 451 560520 22 29642982982971203 82258 45 725 216 152320270100 168.5 580 72572440 520 18 400.5230422822 394597 467402 72440 20018032 388422 1013118560615 426122282671 22 203180 109 387.5680.3 628579 820650 270655 109 32 370200380330 200180 42612261226 1222 118560 6501013 300515450250 250425 695880 445 1226 330150 1630 20331633 18032 350585514.5300520451676883 200 974650978128550628500 120 200/ 650978 109 550668 109 t 65 80 610433 4301633 32 80 120 120 120 128

ZGB www.sunbopump.com 04

ZGB Outline Dimensions

TYPICAL APPLICATIONS

Heavy Minerals

Mill Discharge

Coal washing

Cyclone Feed

Power Plant

Chemical Process

Paper and Pulp

Sugar Beet

Diamond Concen-

trate Tailings

The HS series pumps are designed for the condensity slurries with minimal maintenance requirements, the horizontal centrifugal pumps will maintain of its components. The rubber and metal lined pumps feature casings which are radially split into two halves. Minimum casing bolts reduce maintenance and

per stage is required. The range is capable of pumping at heads in excess of 90 meters per performance.

cally for successive use in slurry type applica developed head is required. The type MS and SL pump with its encapsulated design is similar de sign reduced physical size when compared to the HS pump.

05 www.sunbopump.com

HS HHS MS SL

FEATURES

Bearing assembly bearing life.

SL PUMP PERFORMANCE SHEET

Liners Casing metal

nal

350S-SL 400S-SL 450ST-SL 550TU-SL Pump Model Allowable Max. Power Clear Water Performance Capacity Q Head H(m) Speed n(r/min) Max.Eff. % NPSH (m) Impeller Dia. m3/h l/s 20A-SL 7.5 1.8-9 0.5-2.5 7-35.5 1400-3000 40 2.5-3 152 50B-SL 15 11.5-65 3.2-18 8.5-46 1400-2800 62 2.5-5.5 190 50B-SLR 15 9-61 2.5-17 3-32.4 1200-2600 48 2.75-4.5 190 75C-SL 30 21.6-136.8 6-38 7-46.4 900-2400 57 3-6 229 75C-SLR 30 28.8-154.8 8-43 9-43 1100-2300 60 3-5 229 100D-SL 60 46.8-324 13-90 7-48.30 800-1800 64 2.5-6 305 100D-SLR 60 54-288 15-80 12-38 800-1600 65 2.5-5.5 305 150E-SL 120 126-568.80 35-158 10.5-51.8 800-1500 60 2.5-6 381 150E-SLR 120 72-576 20-160 4-38 800-1300 65 2.5-5.5 381 200E-SL 120 72-1080 20-300 8-45 500-1100 74 3-6 457 200E-SLR 120 1440-1800 40-500 6-48 500-1000 73 3-10 550 300S-SL 560 568-2538 130-705 8-60 400-950 79 2-10 653 300S-SLR 560 432-1900 120-528 7-41 400-800 81 3-8 653 560 650-2800 180-780 10-59 400-840 81 3-10 736 350S-SLR 560 720-2844 200-790 10-41 400-700 86 3-7 736 560 756-3312 210-920 7-37.5 300-600 85 2-8 825 400S-SLR 560 720-3312 200-920 7-51 300-700 80 2-10 825 560 1080-4356 300-1210 9-40 300-550 87 3-10 933 450ST-SLR 560 1008-4356 280-1210 9-48 300-600 80 2-9 933 1200 1980-7920 560-2200 10-50 250-475 86 4-10 1213

www.sunbopump.com 06

and

HS HHS MS SL

HS HHS MS PUMP PERFORMANCE SHEET

HS HHS MS 07 www.sunbopump.com 25HS-B 15 12.6-28.8 3.5-8 6-68 1200-3800 40 2-4 152 25HSR-B 15 10.8-25.2 3-7 7-52 1400-3400 35 25HHS-C 30 16.2-34.2 4.5-9.5 25-92 1400-2200 20 2-5.5 330 40HS-B 15 32.4-72 9-20 6-58 1200-3200 45 3.5-8 184 40HSR-B 15 25.2-54 7-15 5.5-41 1000-2600 50 2.5-5 178 50HS-C 30 39.6-86.4 11-24 12-64 1300-2700 55 4-6 214 50HSR-C 30 36-75.6 10-21 13-39 1300-2100 2-4 213 50HHS-D 60 68.4-136.8 19-38 25-87 850-1400 47 3-7.5 457 75HS-C 30 86.4-198 24-55 9-52 1000-2200 71 4-6 245 75HS-D 60 86.4-198 24-55 9-52 1000-2200 71 4-6 245 75HSR-C 30 79.2-180 22-50 5-34.5 800-1800 59 3-5 245 75HSR-D 60 79.2-180 22-50 5-34.5 800-1800 59 3-5 245 100HS-D 60 162-360 45-100 12-56 800-1550 65 5-8 365 100HS-E 120 162-360 45-100 12-56 800-1550 65 5-8 365 100HSR-D 60 144-324 40-90 12-45 800-1350 65 3-5 365 100HSR-E 120 144-324 40-90 12-45 800-1350 65 3-5 365 100HHS-F 260 324-720 90-200 30-118 600-1000 64 3-8 720 150HS-E 120 360-828 100-230 10-61 500-1140 72 2-9 510 150HS-S 300 360-828 100-230 10-61 500-1140 72 2-9 510 150HSR-E 120 324-720 90-200 7-49 400-1000 65 5-10 510 150HSR-R 300 324-720 90-200 7-49 400-1000 65 5-10 510 150HHS-S 560 468-1008 130-280 20-94 500-1000 65 4-12 711 200HS-ST 560 612-1368 170-380 11-61 400-850 71 4-10 686 200HSR-ST 560 540-1188 200-450 7-45 300-650 80 2.5-7.5 686 200MS-E 120 540-1440 150-400 14-60 600-1000 73 4-10 549 200MS-R 300 540-1440 150-400 14-60 600-1000 73 4-10 549 250HS-ST 560 936-1980 260-550 7-68 300-800 82 6 762 250HSR-ST 560 720-1620 320-700 13-14 300-500 79 3-8 762 300HS-ST 560 1260-2772 350-770 13-63 300-600 77 3-10 965 300HSR-ST 560 1152-2520 380-850 11-63 250-550 79 4-10 965 350HS-ST 1200 1368-3060 380-850 11-63 250-550 79 4-10 1067 400HS-TU 1200 2160-5054 600-1400 8-66 200-500 80 4.5-9 1245 450HS-TU 1200 2520-5400 700-1500 13-57 200-400 85 5-10 1370 m3/h l/s Pump Model Allowable Max. Power (KW) Clear Water Performance Capacity Q Head H(m) Speed n(r/min) Impeller Dia. Max.Eff. % NPSH (m)

Remark:

HS HHS MS SL 08

Volute

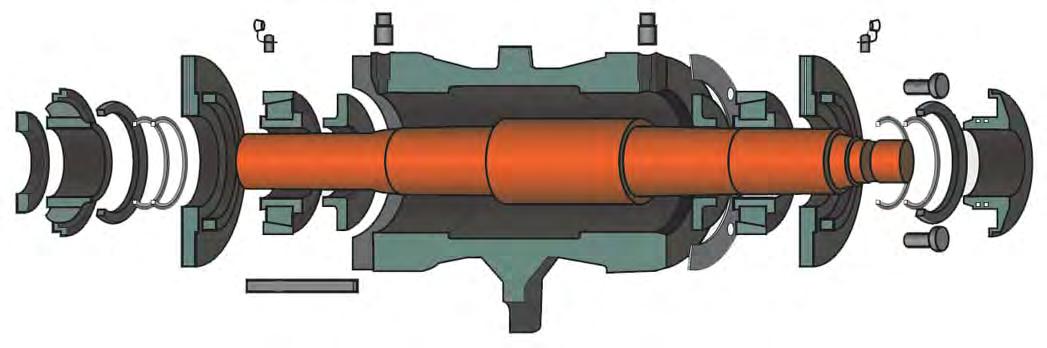

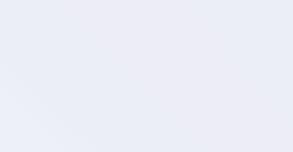

PUMP HEAD BEARING ASSEMBLY

Metal Lined Frame Plate(32) Frame Plate Liner Insert(41) Impeller(47)

Liner(110) Throatbush(83) Cover plate(13) Rubber Lined Back Liner(36) Impeller(47R) IFront Liner(18) Throatbush(83R)

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Complex Metal Impeller with Rubber Liner

1. Labyrinth Lock Nut (61)

2. Bearing-Drive end (73)

3. Shaft (73)

4. Grease Retainer (46) 5. Shim Plate (26)

6. Bearing Housing (04) 7. Plug 8. End Cover (24) 9. Grease Nipple 10. Piston Ring (108) 11. End Cover Set Screw (27) 12. Bearing Seal (89) 13. Labyrith-Pump End (62) 14. Shaft Key (70)

CONSTRUCTION

Discharge positions available in 8 positions: (facing suction side) G A B C D E F K 09 www.sunbopump.com On Site Pump

D0D1D2n-d1d0d1d2n-d2MetalRubber

25HS(R)-B58329524819728792061819817146-14325418138244-Ø141523831144-Ø16165251274-Ø169177

25HHS-B75940631125442121306270194254-1117535625248324-Ø19152381144-Ø17152251144-Ø17318- 50HS(R)-B592295248197287921720511418433-14325418438244-Ø14184511464-Ø19165381274-Ø19104118 50HS(R)-C7684063112544212128123813821071-17535623348324-Ø19216761784-Ø19184511464-Ø19191154 50HHS-D98649236433065164389384254368-5121343229864384-Ø22216761788-Ø19203511654-Ø19750-

75HS(R)-C8344063112544212135429214926224-17535627048324-Ø192791022354-Ø22229761914-Ø22263236

75HS(R)-D94349236433065164353292149262100-21343227964384-Ø222791022354-Ø22229761914-Ø22363290

75HHS-E124062244845780222492492330432--25754638176544-Ø292541022108-Ø19254762108-Ø191250- 100HS(R)-D10214923643306516442140622933811-21343231864384-Ø223371522924-Ø222791022354-Ø22626454 100HS(R)-E117862244845780222433406229338138-25754635176544-Ø293371522924-Ø222791022354-Ø22728635

100HHS-S1668920780450120280596616413546-13464076035390704-Ø353371522928-Ø223051022608-Ø222880-

150HS(R)-E130262244845780222557551318460-6225754640276544-Ø294062033568-Ø223681523248-Ø211473982

150HS(R)-R136068059035085215-511318460-17049056031270504-Ø284062033568-Ø223681523248-Ø221655- 150HHS-T227511501040650150350852835584813-160880900538125804-Ø484322033758-Ø294321523758-Ø296586- 200MS-E133762244845780222584613381470-8325754640376544-Ø295022544458-Ø294322033758-Ø2916251202 200MS-R139568059035085215-613381470-19049056031470504-Ø285022544458-Ø294322033758-Ø291836- 200HS-ST1748115078065012028069267341963527-620900439125804-Ø485022544458-Ø294322033758-Ø2937503130 250HS-ST18161150780650120280762755464674-65620900461125804-Ø4852730547012-Ø2552725447012-Ø2543183357 300HS-ST18731150780650120280812937629832-224620900486125804-Ø4858535652112-Ø2555230549512-Ø2564094672 350HS-TU2320146010509001503509531048660889-848601200597150954-Ø7970540664112-Ø3567335661012-Ø2910000- 450HS-TU247514601050900150350110014209401230-4208601200615150954-Ø7990050880012-Ø4290046080012-Ø421886415921 HJKL ModelABCDUEFG Weight (kg) TSn-d Suction Flange MNV Discharge Flange

Dimensions

HHS MS 10 www.sunbopump.com

HS(R) Outline

HS

--Important

SF 11 www.sunbopump.com

design features:

The type of SG(H) Dredge andextremely aggressive slurries, with of the casing reduces associated -

Design and Uninque Features

SG PUMP PERFORMANCE SHEET

12

-

SG Pump Model Allowable Max.Power (KW) Clear Water Performance Capacity Q Head H(m) Speed n(r/min) Max.Eff. NPSH (m) Impeller Dia. m3/h l/s 100D-SG 60 36-250 10-70 5-52 600-1400 58 2.5-3.5 378 150E-SG 120 126-576 35-160 6-45 800-1400 60 3-4.5 378 200F-SG 560 216-936 60-260 8-52 500-1000 65 3-7.5 533 200S-SGH 560 180-1440 50-400 24-80 500-950 72 2.5-5 711 250G-SG 600 360-1440 100-400 10-60 400-850 65 1.5-4.5 667 250T-SGH 1200 288-2808 80-780 16-80 350-700 73 2-10 950 300TU-SG 1200 576-3024 160-840 8-70 300-700 68 2-8 864 300G-SG 600 720-3600 200-1000 18-44 300-500 70 3-9 1016 350TU-SGH 1200 324-3600 90-1000 26-70 300-500 72 3-6 1270 350TU-SG 1200 720-4320 200-1200 12-48 250-500 72 3-6 1016 400G-SG 600 864-3816 240-1060 9-48 250-500 72 3-6 1067 400T-SG 1200 864-3816 240-1060 9-48 250-500 72 3-6 1067

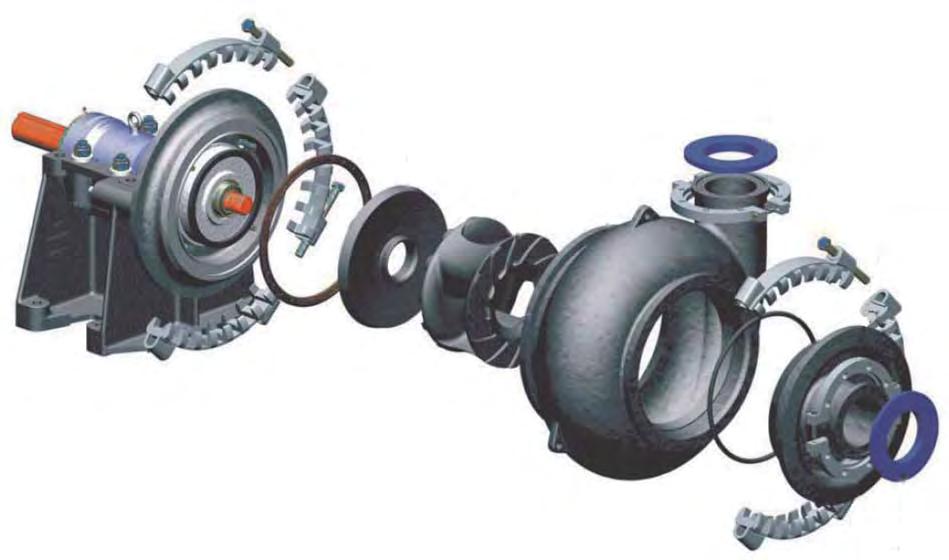

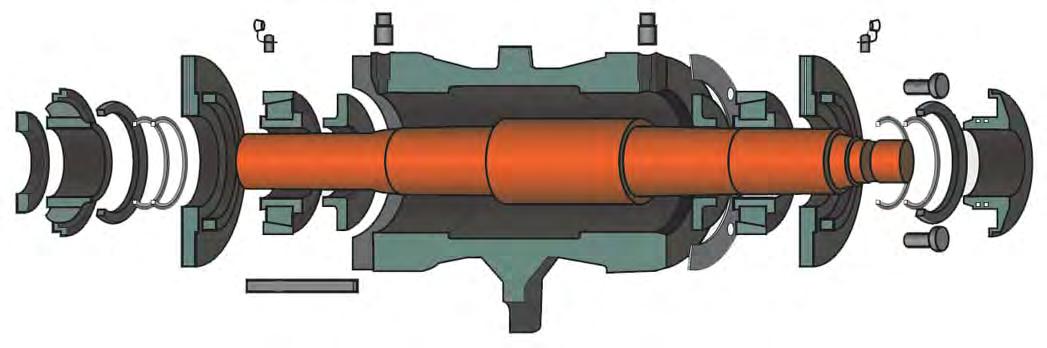

STRUCTURE CHART

PUMP HEAD

BEARING ASSEMBLY

13

www.sunbopump.com

Frame Plate Liner Insert (41)

Impeller (37)

Frame Plate (31)

Discharge Joint Ring

Cover Plate (13)

Intake Joint Ring

Packing Box (78)

1 2 3 4 5 6 7 8 9 10 11

Gland Assembly (44) Packing (111)

1. Gland Assembly (44) 2. Packing (11)

3. Latern Ring (63) 4. Shaft (73)

5. Neck Ring (67) 6. Shaft Sleeve (75) 7. Expeller Ring (29) 8. Shaft O-Ring( 109) 9. Expeller (28) 10.Impeller O-Ring (64) 11.Gland Bolt (45)

Centrifugal Expeller Seal

SG

Gland Packing Seal

SG Outline Dimensions SG 14 www.sunbopump.com d2 d1 d3 d4 d1d2n-d1d3d4n-d2 ModelABCDEFGHLMNPTn-d Suction FlangeDischarge Flange Weight (kg) 100D-SG1006492432213383302895420334326033016422260305819210254419460 150E-SG12866225462575439236575295405352457544293243688192603058191120 200F-SG 15918577623494548754098330533416610604354064578223243688192250 17028837625844541170598368667522610-343547052712224064578223320 200S-SG 17209207606407037878090330533416450-1024354064578223243688192285 250G-SG201012078517496447387615236866552285123844147052712224064578224450 300G-SG209612078517496450287615242478761085112144149555282247052712225400 400G-SG 2111120785174964508876152432914692851-73441641705162558464012256950 400H-G260713971194921/538104022270914692851/441641705162558464012258850 200S-SGH177492076064070455780330620473450-206-2064354064578223243688253188 250G-SGH 2062121985174964/876152496800851/4414765338294324838254638 250F-SG

WN

WN type Dredging Pump is horizontal, single-stage

requirement of the contractor demanding and comprehen-

WN TYPE PUMP PERFORMANCE SHEET

15

15 Model Capacity (m3/h) Head (m) Speed (r/min) Efficiency (%) NPSHr (m) Inlet Diameter (mm) Outlet Diameter (mm) Max. Flow Particle Size (mm) Weight (kg) 200WND600-80020-40700-90060-65<4.52502001782500 200WN750-100040-65700-85070-72<42502001803000 250WND950-110020-40500-70065-70<43002502203000 250WN1100-130040-65500-65070-74<43502501443513 300WND1500-180020-40400-60065-68<43503002416000 300WN1800-220040-65400-55074-78<44503002417000 350WN2600-300040-65400-55074-78<4.54503502457300 400WN2800-320020-40400-55074-78<4.54504002507500 450WN3200-385040-67350-50076-80<4.56004503547850 500WND3600-420020-40220-32072-75<4.86005003308000 500WN4500-550040-65350-45078-80<4.865050025011300 600WN70006247080<670060022030000 600WNQ70003038083<670060022016000 700WN100008538085<676070028045000 700WNQ100002828085<676070028021000 800WN125005934981<680075030040000 800WNQ 125003225881<680075030023000 700WND125003225881<680075030023000 850WN144007033085<690085032065000 900WN160003017585<6100090034080000 1000WN16000-2500023-76181-29085-87<612001000350121000

DESIGN FEATURES

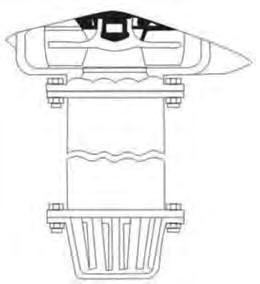

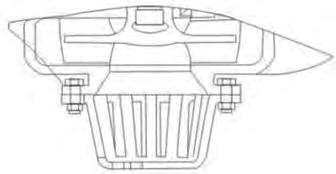

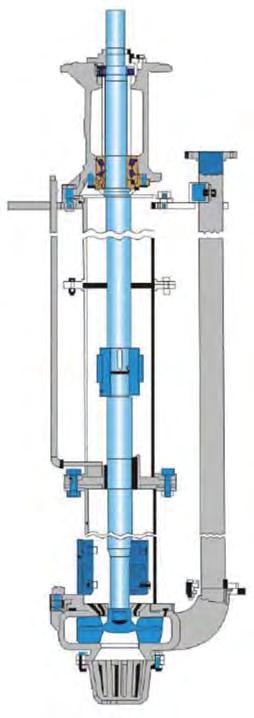

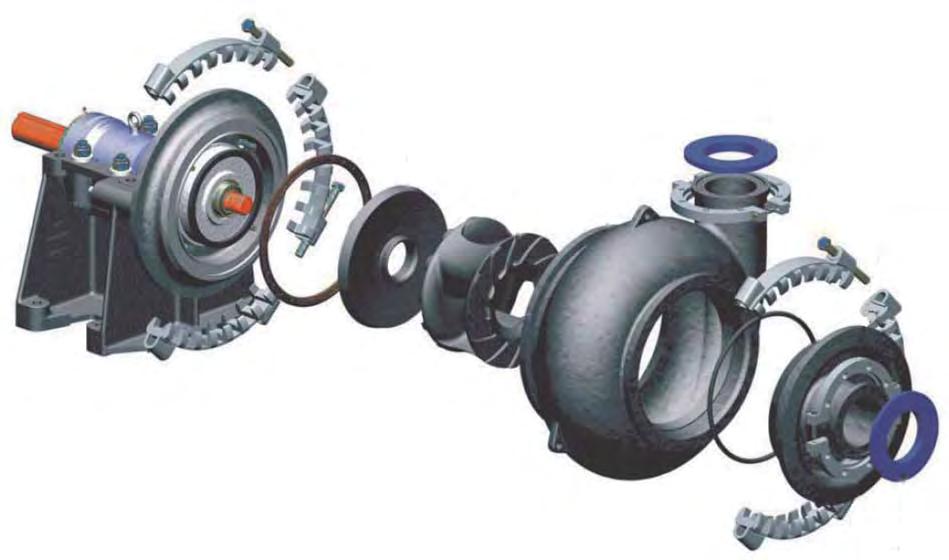

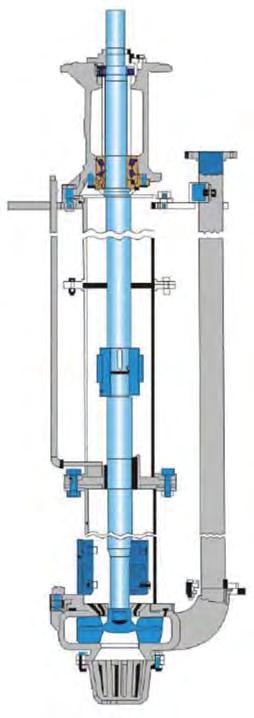

SHAFT LARGE PARTICLE IMPELLERS BEARING ASSEMBLY 15 www.sunbopump.com CASING COLUMN and DISCHARGE PIPE UPPER STRAINERS LOWER STRAINER SV 16 www.sunbopump.com

Shaft Bearing

Bearing Housing

Bearing Spacer Bearing

Shim

Column Strainer

Frame Plate Liner Insert Impeller

Pump Casing

Lower Strainer

Standard Type

Coupling Part

Middle Supporting Part

Extention Type

THREE-TYPE CONSTRUCTURE OF PUMP INLET

Discharge Pipe

CONSTRUCTION

SV 17 www.sunbopump.com

Standard Type with Strainer Suction Pipe With Strainer Agitator Type

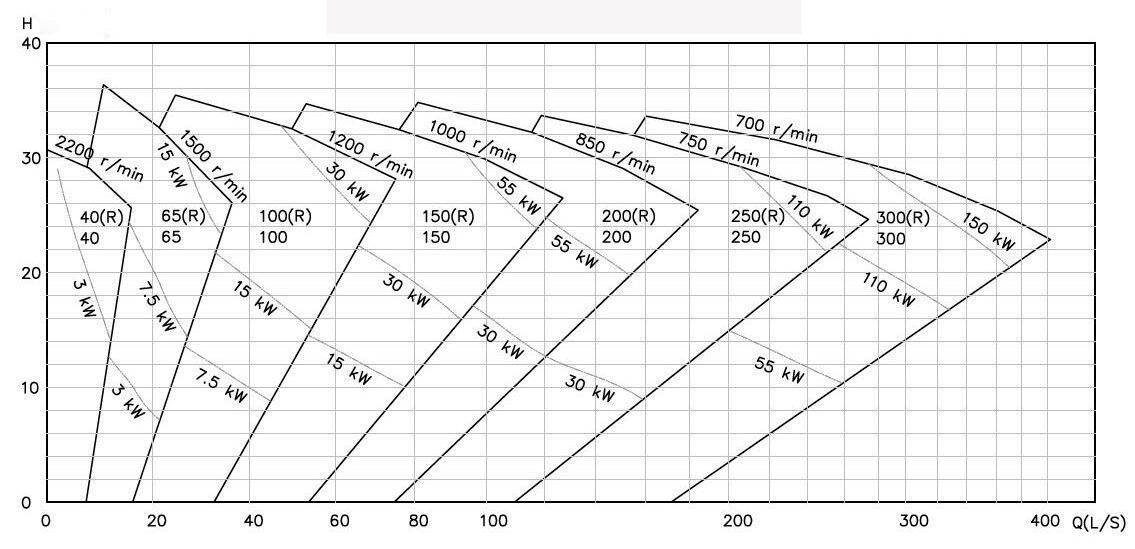

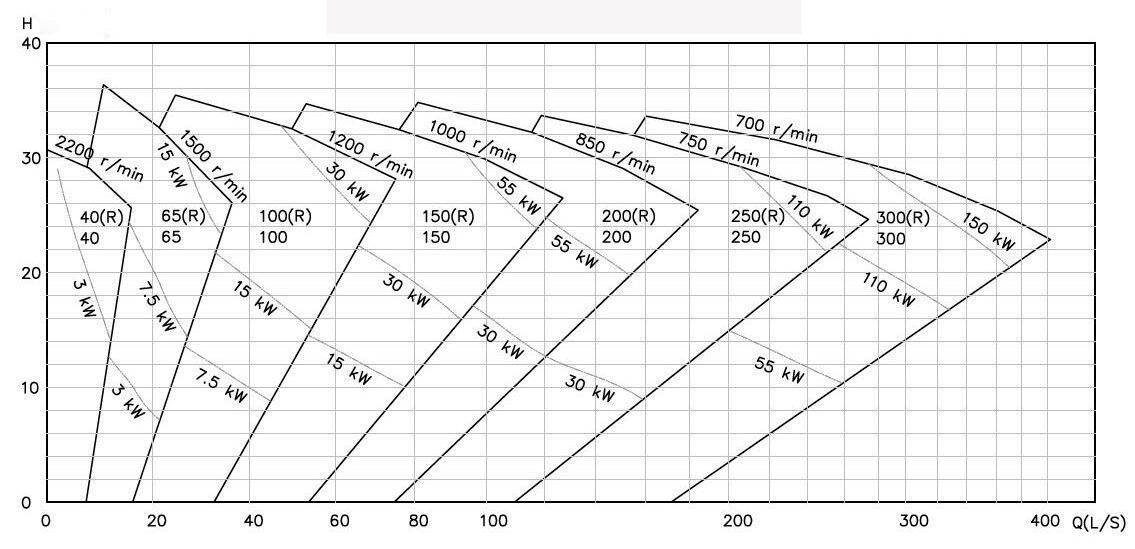

SV PUMP PERFORENCE SHEET

SV 18 www.sunbopump.com Pump Model llowable Max. Power Clear Water Per ormance Capacity Q Head H m Speed n r/min Max.E . % Impeller Dia. m3/ l/ 40PV-SV R 15 17-43.2 4.7-12 4-28.5 1000-2200 40 188 65QV-SV R 30 18-114 5-32 5-31.5 750-1500 60 280 100RV-SV R 75 54-289 15-80 5-36 500-1200 62 370 150SV-SV R 110 108-479 30-133 8.5-40 500-1000 52 450 200SV-SV R 110 189-891 52.5-247.5 6.5-37 400-850 64 520 250TV-SV R 200 360-1152 100-320 7-33 400-750 60 575 300TV-SV R 200 540-1548 150-430 5.5-26 350-700 60 580 mm KW

SV PUMP PERFORENCE CURVE Remark:

MNPQ Outlet Dia. (mm) FrameType Standard Type King-size Type D1D2D0X-d EF D 2500 137 140 Note: change with motor size, the dimension is max. value. Discharge Flange Size ABC Weight (kg) S nK G 40PV SV SVR Pump HJ 285 265 153 175 900 1200 1800 2000 960876350 350 1113 500500450450 332 1200 1500 1800 229 675248629285 416 280127 20518174 1113 680680 SVR230380260 399231 2200 2800 3200 3200 2400 2700 60QV SV227 266535 400 28518265 1390 1396 393 800 794290 620620 930 1803 1809 1020 22 1200 1500 1800 2000 2400 870 3000 1000 2700 3000 2500 4-Ø16 178651404-Ø19 4098 681432 100RV SV SVR 900 1200 1500 265538317 1001918-Ø19 150SV SV SVR 390 395 670 1100 1100 670 365 400 1500 1800 2100 2800 3200 3400 3600 350280 1030103050028475 2186 1737 1502418-Ø22 2194 12004761011 450 450 805 805 200SV SV SVR 11001200600 440 440 1500 1800 2100 550 1300476 2191 2191 2800 3200 3600 13001200 200298 1650700685 10112800350343 28 8-Ø22 250TV SV500930470 18002800 17501350 250 2572 17505611246 400406 48 559 36212-Ø25 21003200 2572 24003600 3700 1450 1450 SVR500930470 300TV SV5001170 300430 70048700 2476 175056112463700483 630 2832 24003600 13501650 18002800 1750 12-Ø25 21003200 SVR4001090 400 SV(R) Outline Dimensions SV 19 www.sunbopump.com

-

ZJ SPECIFICATION

H:

Impeller Diameter 200ZJ I A60 20 www.sunbopump.com

trial sites. PUMP MODEL EXPLANATION

O.D: 40-300mm

2-135 m

ZJ Series Slurry Pump Performance Chart

ZJ

Capacity Head Speed Effi.NPSH Q(m3/h)H(m)n(rpm) (%)(m)(mm)(kg) 300ZJ A100450464-182615.3-65.2300-59081.13885265 300ZJ A95400441-173513.8-58.8300-59078.13885220 300ZJ A90560505-184421.2-79.9400-73082.83.9855005 300ZJ A85450477-174218.9-71.3400-73079.83.8854965 300ZJ A70630635-233316.0-76.8490-98080.43.9923560 300ZJ A65500589-216613.8-66.2490-98077.43.7923531 300ZJ A56250395-15689.7-46.0490-98080.93.5963030 250ZJ A103560402-157329.7-110.5400-73074.52.8695085 250ZJ A96560403-146625.4-93.7400-73077.83.5695035 250ZJ A90450378-137422.3-82.4400-73073.83.4694980 250ZJ A85800376-150430.1-128.7490-98076.53.5764530 250ZJ A83800367-146928.7-122.7490-98075.53.5764514 250ZJ A80710354-141626.7-114.0490-98073.53.4764490 250ZJ A78630415-179621.1-102.5490-98071.53.2764474 250ZJ A75560300-148020.8-97.5490-98077.53723480 250ZJ A73500292-144119.7-92.4490-98076.53723466 250ZJ A70450280-138118.1-84.9490-98074.52.9723446 250ZJ A68450272-134217.1-80.1490-98073.52.7723432 250ZJ A65315299-124915.4-71.0490-98076.93723020 250ZJ A63315290-121114.4-66.7490-98075.93723008 250ZJ A60280276-115313.1-60.5490-98073.92.8722991 200ZJ A85560221-90732.0-133.7490-98070.52.8544110 200ZJ A75355225-90022.8-102.9490-98074.13563070 200ZJ A73355219-876 21.6-97.5490-98073.13563056 200ZJ A70315205-97619.4-86.4490-98075.62.8562465 200ZJ A68315199-94818.3-81.5490-98074.62.8562453 200ZJ A65250235-95016.4-72.0490-98079.62.5622323 200ZJ A63250228-92115.4-67.6490-98078.62.5622311 200ZJ A60185218-87013.9-62.0490-98083.52.5622223 200ZJ A58185211-84113.0-57.9490-98082.52.5622214 150ZJ A70185 93-40120.0-91.2490-98062.32372245 150ZJ A65 200150-60017.4-75.7490-98070.82.5482223 150ZJ A63185146-58216.3-71.1490-98069.82.5482211 150ZJ A60160135-55014.7-63.5490-98075.92.5482203 150ZJ A58132131-53213.7-59.3490-98074.92.5482033 150ZJ A55110124-50412.3-53.4490-98072.92.3482019 Pump Weight Pump Model Allowable Max.Power (Kw) Performance in Clear Water Max. Diameter of Particle 21 www.sunbopump.com

ZJ Series Slurry Pump Performance Chart

ZJ

Capacity Head Speed Effi.NPSH Q(m3/h)H(m)n(rpm) (%)(m) (mm) (kg) Pump Weight Pump Model Allowable Max.Power (Kw) Performance in Clear Water Max. Diameter of Particle 150ZJ C58160134-59612.8-61.0490-98069.12752063 150ZJ A5711095-42713.2-56.3490-98067.81.8322023 150ZJ A5075115-4609.5-43.1490-98076.82.5481735(1648) 150ZJ A4875111-4428.7-39.7490-98075.82.5481728(1641) 150ZJ C42132142-55012.1-62.8700-148077.12.2691605(1518) 100ZJ A5016085-36020.5-100.2700-148069.62.5341475(1388) 100ZJ A4613279-33117.3-84.8700-148067.62.3341461(1374) 100ZJ A429066-27514.7-70.8700-1480712.5 351075(1021) 100ZJ A397561-25512.6-61.0700-1480692.4351064(1010) 100ZJ B427583-36512.7-66.8700-148063.22.5181085(1031) 100ZJ A365561-2459.7-49.5700-148071.62321010(956) 100ZJ A334556-2258.2-41.6700-148069.61.8321003(949) 80ZJ A52160 51-24222.1-109.8700-148056.32.1211465(1378) 80ZJ A4275 61-20414.4-70.4700-148066.72.5241053(963) 80ZJ A3955 57-18912.4-60.7700-148064.72.4241042(952) 80ZJ A3645 46-1909.6-51.4700-148067.72.524980(926) 80ZJ A3337 43-1748.0-43.2700-148065.72.324973(919) 65ZJ A3015 23-797.4-34.8700-146063.5219504(512) 65ZJ A2711 20-716.0-28.2700-146061.51.819500(508) 50ZJ A5090 27-11122.3-110.7700-148045.13131378 50ZJ A4655 23-9417.9-85.8700-148044.71.4141082(992) 50ZJ A3318.5 12-547.7-42.5700-148042.12.913537(545) 40ZJ A177.5 4-239.0-44.61400-290052.42.511121(127) 150ZJL A35 37 99-3643.0-17.9490-98069 15800 100ZJL A34 45 74-2935.5-36.8700-148065.8 14630 80ZJL A3645 50-2017.3-45.5700-148058.2 12650 65ZJL A3018.5 18-985.9-34.7700-147053.7 8650 50ZJL A204 8-381.4-10.7700-144038.6 10240 22 www.sunbopump.com

TL 23 www.sunbopump.com

The pump design adopts back pull-out structe, which is easy to disassemble and without need to remove the inlet and outlet pipeline.

The containerized mechanical seal specially used for the desul adopted

TL Series Slurry Pump Performance Chart

TL

(m3/h) (l/s) 350TL(R)1600444259604.5350/400 3200 400TL(R)2500694257255.0400/450 3500 500TL(R)37501040257255.0500/500 4500 600TL(R)6300175023.56205.5600/700 6000 700TL(R)68401900264856.0700/800 8000 800TL(R)93602600314857.0800/900 8800 900TL(R)150004167304858.5900/1000 11400 1000TL(R)104402900154857.01000/1200 / Clear Water Performance Capacity Q Pump Model Head (m) Speed n(r/min) NPSH (m) Weight (kg) Dia. Out/Inlet (mm/mm) Application Medium: PH: 1.3-2.5 24 www.sunbopump.com

DT 25 www.sunbopump.com

DT Capacity (m3/h) Head (m) n Speed (r/min) Max.eff. (%) (NPSH)r (m) 900DT-F11016004907-140768.5-32.7300-49088.36.59611800 800DT-A909004104-106907.8-27.8400-59586.44.3887101 700DT-A909003551-898810.0-33.8400-59586.75.6686030 700DT-A836302677-64918.7-30.2400-59585.96.0706002 700DT-B785603378-720010.0-21.8400-59584.74.3655136 600DT-A825001664-56005.2-27.8300-59588.32.21524900 500DT-A764001555-38819.9-27.9450-59576.84.5583512 500DT-A705001908-43999.3-32.5490-74276.06.0553100 400DT-A654001134-33308.8-31.1490-74280.15.2603200 350DT-A78500720-286511.6-51.1400-74078.03.51043700 300DT-A60400574-23848.7-52.0490-98981.14.3962790 250DT-A75560300-148020.8-97.5490-98077.53.0723191 250DT-A4590221-8045.0-27.0490-98068.26.5561321 200DT-B4590136-6395.5-30.1490-98080.82.0511750 150DT-A60450156-70428.9-150.0700-148070.72.1391657 150DT-B55130139-63011.3-53.7490-99078.12.3561540 150DT-A509062-2799.3-44.6490-98065.72.1301470 150DT-A40132122-50311.2-61.2700-149073.12.640830 100DT-A6022071-30529.1-147.0700-148057.92.418890 100DT-A5016085-36020.5-100.2700-148069.62.534975 100DT-A459047-22814.8-83.5700-148058.72.222810 100DT-A407561-26812.0-61.0700-148070.41.729620 100DT-A357577-3238.8-45.9700-148073.21.942550 80DT-A363741-1678.9-47.1700-1480 62.41.516480 65DT-A405534-15911.5-60.1700-148062.12.116490 65DT-A302221-997.0-35.6700-147054.62.219260 50DT-A509027-11122.3-110.7700-148045.13.013856 50DT-A455521.6-93.615.2-81.0700-148048.43.69.5849 Pump weight (kg) Performance and Main Technical Datas of DT & TL Desulphurization Pumps(1) Allowable max.power of ass.Motor (KW) Type Clear water performance Particle max.size handled occasionally (mm) 26 DT SERIES SLURRY PUMP PERFORMANCE CHART

DT SERIES SLURRY PUMP PERFORMANCE CHART

Note: 1.(NPSH)r refers to the value at the specified point at the second in the sample book.

2.The normal size of particle handled is 56% of the max. size that can be handled occasionally.

DT Capacity (m3/h) H Head (m) n Speed (r/min)) Max.eff. (%) (NPSH)r (m) 50DT-B403724.5-99.512.0-60.7700-147055.03.114490 50DT-A3018.516-785.8-35.1700-146048.50.816210 40DT-A254516.8-74.713.7-88.61400-295042.52.69185 40DT-B20157.9-37.110.7-57.51400-293053.00.97160 40DT-A19157.8-34.912.3-57.11400-293058.81.211173 40DT-A177.54.6-23.49.2-44.61400-290052.42.511127 25DT-A2544.7-19.93.3-21.6700-144038.03.35107 25DT-A155.54.4-19.36.2-34.41390-290041.81.3889 150TL-A353099-3643.0-17.9490-98069.015712 100TL-A344574-2935.5-36.8700-148065.814502 80TL-A4511059-28612.5-81.6700-149058.415785 80TL-A364550-2017.3-45.5700-148058.212645 65TL-A404530.2-142.810.2-62.6700-148050.012658 65TL-A3018.518-985.9-34.7700-147053.78436 50TL-A455521.9-117.310.4-78.4700-148039.99.5778 50TL-B403015-658.6-58.3700-147034.19502 50TL-A352219-876.8-45.3700-147048.115498 40TL-A3518.59.4-47.67.2-43.9700-147038.77524 40TL-B255.54.9-22.93.9-21.5700-144037.68225 40TL-A2144.6-25.93.3-17.0700-144044.610210 25TL-A155.54.3-19.33.9-30.81390-290029.88195 Performance and Main Technical Datas of DT & TL Desulphurization Pumps(2) Type Allowable max.power of ass.Motor (KW) Clear water performance Particle max.size handled occasionally (mm) Pump weight (kg)

27

www.sunbopump.com

SM series centrifugal sand pump mainly supplies to and be used to provide drilling liquid with a centain discharge and

The SM10x8x14 centrifugal sand pump applies to with big viscosity

centrifugal sand pump applies to more than 3000-me also can be can be used to supply mud to triplex mud mounted drilling rigs or

SSA series centrifugal sand pump includes series pumps are more compact in design it can be

SM SSA 28 www.sunbopump.com

The SXP type blender pump is

Sand Slurry

Dredge Tailing

Slag Blending

Dimensions(mm)

Pump model

centrifugal slurry sand pump, which is -

D1n1-d1D2 n2-d2

Sewage

SXP 29

www.sunbopump.com

Sunbo accept OEM business of centrifugal chemical processing pumps, Goulds 3196 and Durco mark III equivalent. These two type pumps are widely used in chemical, petrochemical, puple & paper, primary metals, good & beverage, and more other general industries.

3x2-106x4-16

3x3-10A8x6-16

4x3-108x6-16A 4x3-10H

1x1.5-64x6-10 1x1.5-84x6-10H 1.5x3-61.5x3-13 1.5x3-82x3-13 2x3-63x4-13 3x4-74x6-13

3x4-88x10-13 3x4-8G8x10-15 1x2-108x10-15G 1.5x3-106x8-15 2x3-104x6-17

G series avaliable list 1.5x1-626x4-10 1.5x1-826x4-10H 3x1.5-623x1.5-13 3x1.5-823x2-13 3x2-624x3-13

2x3-86x8-13

3x4-106x8-17 3x4-10H8x10-17

3x2-824x3-13HH 4x3-826x4-13A 2x1.5-10A8x6-14A 3x1.5-1010x8-16 3x1.5-10A10x8-16H

D series avaliable list

PUMP

CHEM.

Metal Material

Rubber Material

material of SR33,SR08,SR42,SS10, SS01,SS02,SS21,SS31...

and corrosive resistance in low PH condi on. Its wear resistance

nearly equal

SA03

for low pH corrosion du es, where erosive wear is also a problem. The alloy is par cularly suitable for Flue Gas Desulphurizaon(FGD) and other corrosive applica ons, where the pH is less than 4. It can also be used in other mildly acidic environments.SA49 has

w/ b(MPa) a k(J/cm2)HRC SA05KmTBCr26 6--10 The erode resistance is a li le bit lower than SA07 with certain corrosive resistance Used for higher wear condi on with PH between 5 and 12 SA07KmTBCr15Mo3 4--8 Best erode resistance but lower wear resistance than SA04 and SA05 Used for higher wear condi on SA01KmTBCr8 550 550 700 56 59 55 6--6 The erode resistance is about 90% of SA05. Used for Mud Pump SA11KmTBMnMo 400 3--638-42 Light erode resistance but lower wear hardness. It can be performated and tapped. Used for light wear condi on with ne grain. SA49KmsTBCr28Ni2Mo2Cu2 600 * 43-49 It has

SA33 * * * 35 It has certain ercode resistance condi on. Its corrosion resistance is nearly equal to SA03 Suitable for PH1 oxidability solid and mixture. SA22 * 1200 * 45 Fine an -erode & an -corrosive and high hardness Used for dredge pump casing. SA23 * 700 * HB 500-600 Higher hardness and an -erode. Used for an -wear & an -corrosive and high erode condi on such as parts of dredge pump, clear pump, sewage pump and slurry pump. SA25 * * * HB 300-350 Lower hardness,be er an -wear & an -corrosive and weldable. Used for light erode and wear condi on such as transport water media contain ne solid. An -wear Cast Steel An -wear White Iron An -wear & An -corrosive Iron Special Performance Applica on Type Material Code Material Descrip on Mechanism Performance 190 400 2200 500 25 40 2000 500 30 40 Type SR26SR55 41±4 52±3 Natural Rubber Item Descrip on Hardness(Shore A) 300% Stretching Strenght N/cm2 Breaking Strength N/cm2 Elongat Break % Pull-apart Permanet Deforma on % Pull Strength g/ cm2 31 www.sunbopump.com MATERIAL

certain ercode resistance

is

to

Suitable

an erosion resistance similar to Ni-Hard 1.

32 www.sunbopump.com

33 www.sunbopump.com

34 www.sunbopump.com * O ’

OUR SERVICE

Tel.: 0086-311-80895089 Fax: 0086-311-67565598 E-mail: sales@sunbopump.com Web: www.sunbopump.com Add: #25 Huifeng Road,Shijiazhuang, Hebei China 050000 CONTACT US