2 minute read

It’s Possible to Create Materials with Dramatically

As a professor at the Fashion Institute of Technology in New York, Theanne Schiros has made sneakers from algae and wool from human DNA. Surprisingly, it didn’t take a team of scientists to create these biofabrics. Apart from a lab, there was also a tepee involved. Interview: Petrina Engelke. Photo: Jon B

Theanne, how do you turn algae into fabric?

All the fibres we work with are biopolymers, long chains of building blocks. Cellulose is the most common of them, but there are many others. You can extract the biopolymers from kelp and turn them into a yarn that you can knit or 3D print to shape. We made a zero waste tank top from kelp. You can put it on the compost, but it is not going to biodegrade on your body. We call that just-in-time degradability.

Are there other materials?

Of course! It is exciting to see microbes, fungi, and bacteria as the fabric factories of the future. For a project called Werewool, we even worked with proteins that my students extracted from their own cheek cells. Proteins are the factories of the cells, and in these proteins, function follows form. We demonstrated that protein sequences can be turned into fibres and you can programme functions at DNA level. That is meaningful for the future of fibres. Because there are more sequence combinations than there are stars in the galaxy.

That sounds so much like science fiction!

It does! And you have to keep in mind that this was not achieved by huge team of scientists. A few undergraduate textile development students learned the basic synthetic biology in my class, we teamed up with Sebastian Cocioba of Bionimica Labs, and in only eight weeks we went from cellular protein from a coral to naturally fluorescent fibres.

Which obstacles did you have to overcome?

We hit a wall when we started growing a kind of bio-leather from bacteria that you can use to make kombucha tea. The bacteria spin a mat of pure cellulose that will grow exactly to shape, but if you use this material in textiles, it gets brittle, it takes on water, for example from sweat, and it swells. So, to get to the necessary properties, we wound up using Native American techniques on the microbial cellulose, tanning it

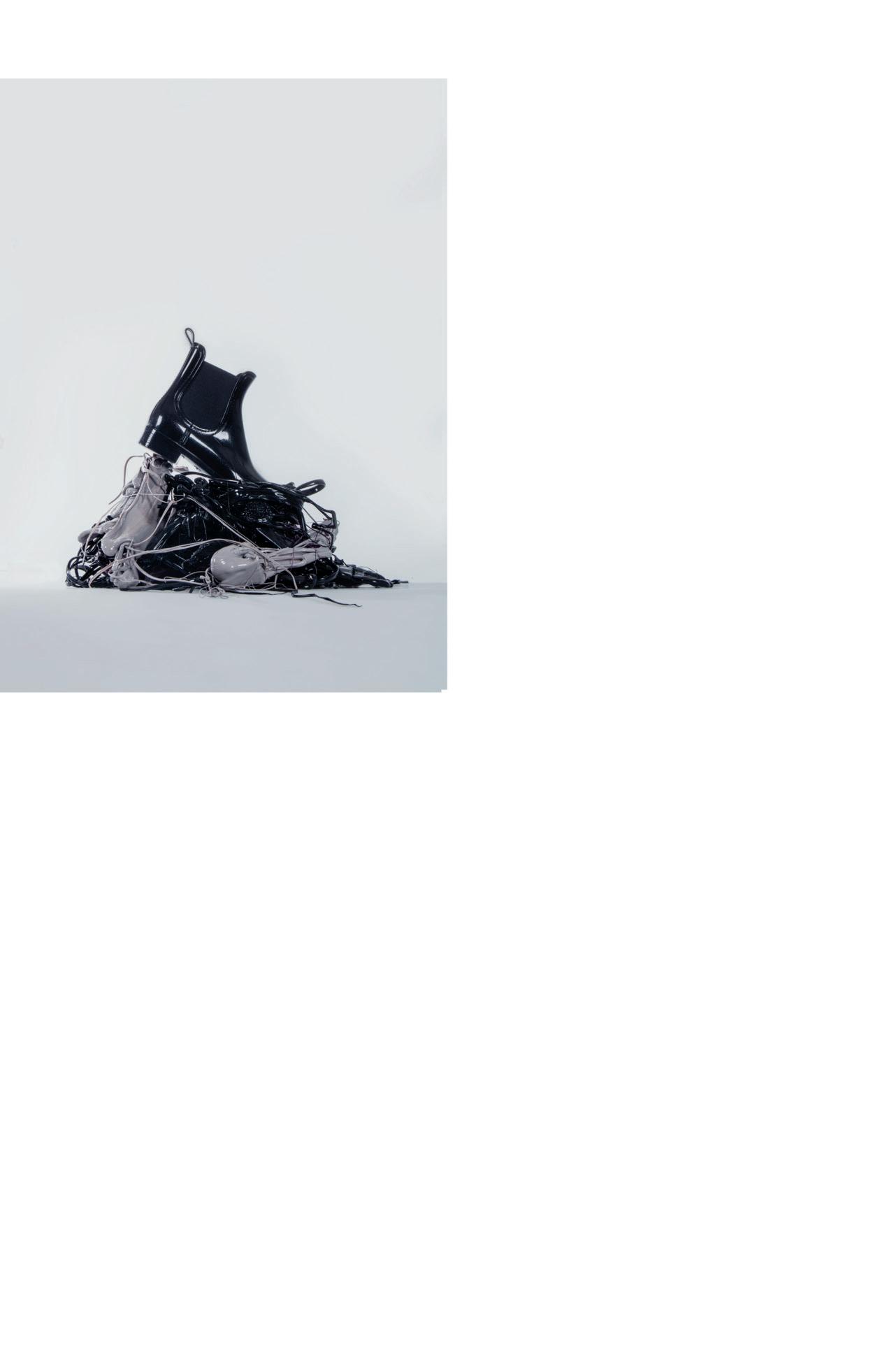

Chemical physicist Theanne Schiros works on a future of textiles that are independent of agriculture, fossil fuels, and livestock. She is wearing a zero waste kelp-based tank top and bacterial cellulose sneakers with a kelp and coconut husk fibre insole.

with plant and animal enzymes and smoking it in a makeshift tepee over a fire in my back yard. Much to our surprise, the material became water resistant, its strength and flexibility nearly tripled, and under a 2,800 degree flame, hot enough to melt metal, this material didn’t catch fire.

How did you come up with combining synthetic biology with indigenous cultures?

Our research is imitating the way nature makes materials. And the next closest thing to nature is the handbook of indigenous cultures who have a symbiotic relationship with their environment.

What will it take for bio-fabrication to head towards mass production?

Modern Meadow is already collaborating with Stella McCartney. Scalability will always be an issue you talk about, but most of all people will have to see that it is possible to create a material with a dramatically lower environmental impact.