CAST CONNEX ® custom steel castings allow for projects previously unachievable by conventional fabrication methods.

Innovative steel castings reduce construction time and costs, and provide enhanced connection strength, ductility, and fatigue resistance.

Freeform castings allow for flexible building and bridge geometry, enabling architects and engineers to realize their design ambitions.

Custom Cast Solutions simplify complex and repetitive connections and are ideal for architecturally exposed applications.

Architect: Perkins&Will

Structural Engineer: Fast+Epp

Steel Fabricator: George Third & Son Ltd. Photography by Brett Ryan Photography

Chair John A. Dal Pino, S.E. Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Marshall Carman, P.E., S.E. Schaefer, Cincinnati, Ohio

Erin Conaway, P.E. AISC, Littleton, CO

Linda M. Kaplan, P.E. Pennoni, Pittsburgh, PA

Nicholas Lang, P.E. Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, P.E., S.E., LEED AP Gilsanz Murray Steficek, LLP, New York, NY

Jason McCool, P.E. Robbins Engineering Consultants, Little Rock, AR

Brian W. Miller

Cast Connex Corporation, Davis, CA

Evans Mountzouris, P.E. Retired, Milford, CT

Kenneth Ogorzalek, P.E., S.E. KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, P.E. International Code Council, Washington, DC

Eytan Solomon, P.E., LEED AP Silman, New York, NY

Jeannette M. Torrents, P.E., S.E., LEED AP JVA, Inc., Boulder, CO

Executive Editor Alfred Spada aspada@ncsea.com

Managing Editor Shannon Wetzel swetzel@structuremag.org

Production production@structuremag.org

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org

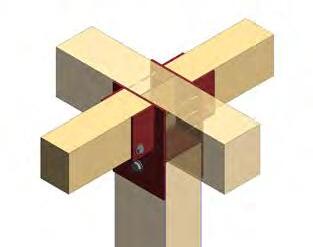

Simpson Strong-Tie provides comprehensive product solutions for commercial institutional construction. Whether you’re building an educational facility, healthcare center or public office, you can rely on a full array of products that are assembly-tested and proven for strength and versatility. From cold-formed steel and structural steel to adhesive and mechanical anchors, code-listed connectors and fastening systems, we have what you need to build safer, stronger structures. Our nationwide distribution network ensures product availability and timely jobsite delivery. Along the way, our expert field, technical and sales support teams are always ready to assist you. With Simpson Strong-Tie as your partner, you have a total solution designed to elevate performance. To learn more about our complete solutions for institutional construction, visit strongtie.com/institutional or call (800) 999-5099.

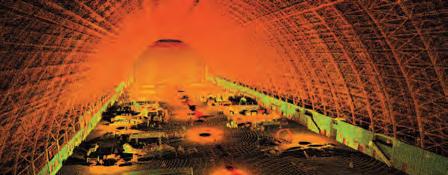

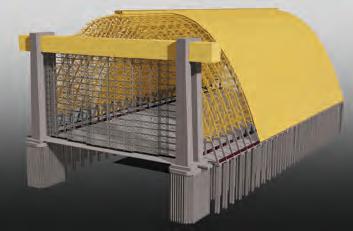

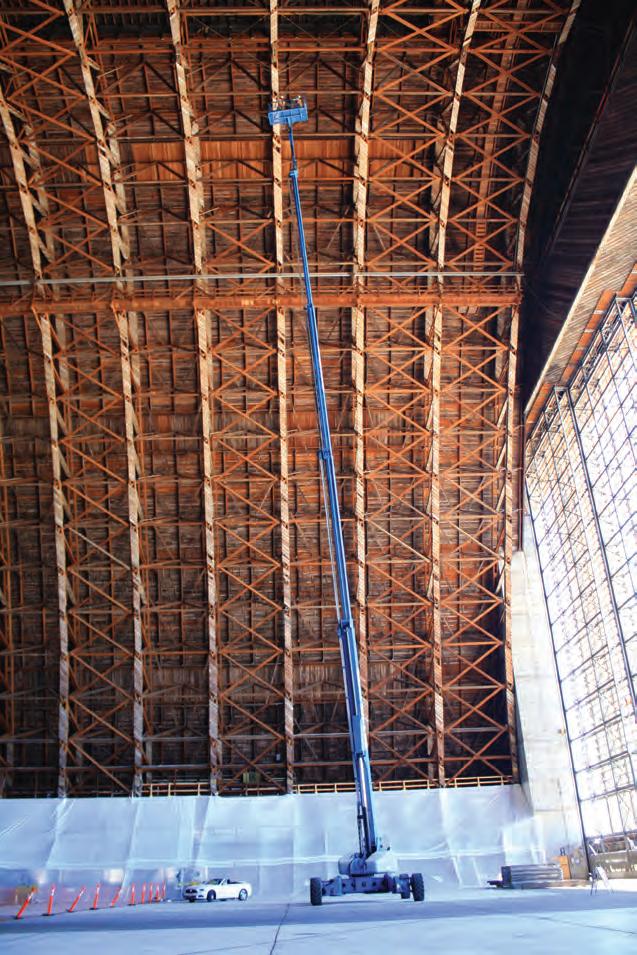

The seismic ductility and health monitoring of historic wood connections in a WWII airship hangar were enhanced using fully threaded screws.

By Peter Marxhausen, PE

By Peter Marxhausen, PE

Used efficiently, mass timber can be a cost-effective structural material to create sustainable, affordable housing.

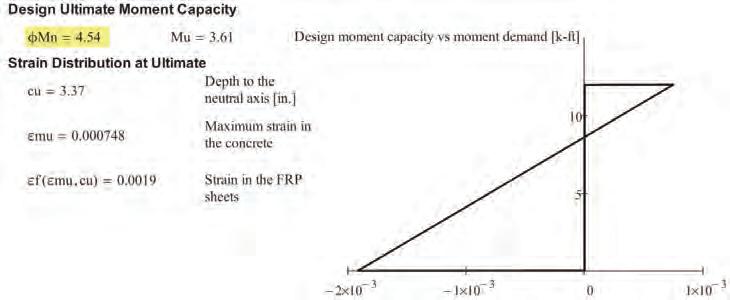

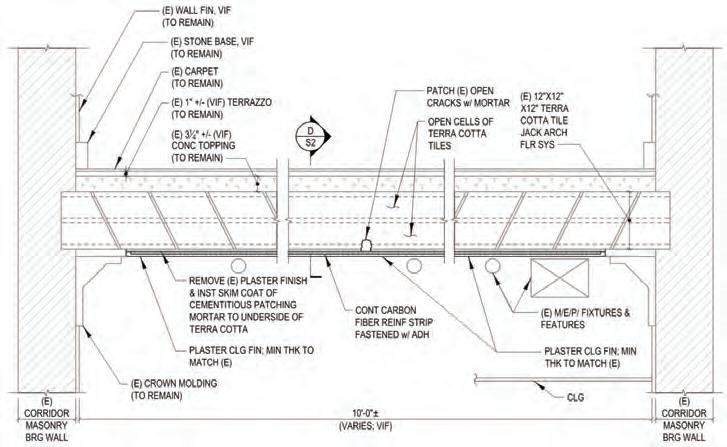

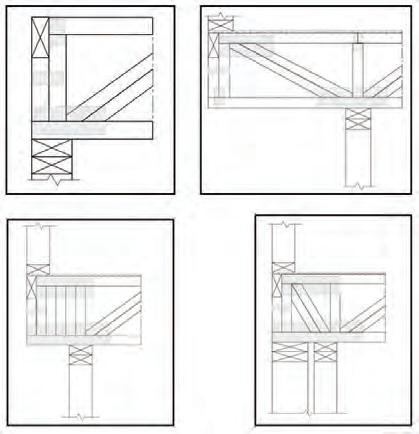

Innovative strengthening techniques saved the historic terra cotta flat-tile-arch floor structure of an iconic landmark.

Despite adequate structural design and a less-than-design snow event, a scribed log- and sawn-lumber-framed commercial lodge structure experienced a catastrophic collapse less than two years after it was built.

The real reason for the failure of a clubhouse floor was not the dancing.

nucor.com/madeforgood

Steven G. Judd, CE, SE,

John “Buddy” Showalter, PE, and Sandra Hyde, PE

Chad S. Mitchell,

Steven G. Judd, CE, SE,

John “Buddy” Showalter, PE, and Sandra Hyde, PE

Chad S. Mitchell,

Thestructural engineering profession continues to face many challenges. What is fueling the pipeline of the future workforce? How do structural engineers navigate evolving environmental hazards and even more tangible physical hazards like Panamax shipping vessels near busy ports? How will the structural engineering profession remain relevant as AI continues to rapidly advance? How will structural engineers continue to push for heightened licensure laws while some jurisdictions are attempting to weaken current ones?

NCSEA’s mission centers around support of and for the practicing structural engineer, and our greatest strength is the ability to pivot as needed to address the most pressing issues. NCSEA turns 30 this year, and the challenges to the profession are not the same as in 1994. Part of the reason that NCSEA has such an amazing and active history is because we have continued to evolve with the needs of a changing profession.

While there can be great comfort in riding the wave of good times, this year, like every year, NCSEA will continue to listen to our Member Organizations (state structural engineers’ associations, or SEAs) and look to advance initiatives that support our mission and vision through today’s lens. Change can be hard and some of the challenges facing the profession come with difficult realizations and conversations. But true growth requires us to step outside of our comfort zone to stretch as individuals and together as a profession. Complacency and the phrase “this is how we always do it” are complete demotivators to me and the amazing NCSEA staff and Board of Directors that will be serving you in the upcoming year.

In our 30th year, many longer-term initiatives are starting to bear fruit. The We See Above and Beyond advocacy campaign has gone through a full cycle of its initial push and we are taking the learning from this effort and finalizing the next phase. The NCSEA Foundation, which started almost a decade ago as a small Member Organization grant program, now has a separate Board of Directors that is steering their vision around the pillars of Innovation and Research, Awareness and Advocacy, and People. And… we launched our new website! The website,

and the back-end platform and database, is a critical baseline for NCSEA to be able to provide next generational support for our initiatives, staff, committees, linked groups, and Member Organizations.

A possibly lesser-known initiative is the media spokesperson program. In the after math of the Surfside collapse, many of our Member Organizations were contacted by media outlets hunting for structural engineering sound bites. NCSEA helped to serve as a central point of connection for the requests, but it was obvious that we needed to be more coordinated and prepared for future events. NCSEA contracted a media specialist firm and at the Summit last November, 10 individuals from Member Organizations across the country graduated in the first class of media spokesperson training. Early in the morning of March 26, our new system was tested with the tragic events in Baltimore. NCSEA and our media specialist mobilized the appropriate spokespeople, coordinated a set of unified talking points, and successfully delivered almost a dozen interviews across television, radio, streaming, and written platforms. While we all are deeply saddened by the events that transpire to bring forth media interview requests, we are proud to deliver a strong and cohesive message from the structural engineering profession that advocates for use and enforcement of appropriate codes, standards, and regulations, and that brings attention to the unique knowledge and expertise of structural engineers, our critical role throughout all phases of the design and construction process, and our opportunity to contribute to the safety, sustainability, and resilience of our communities.

from the profession by classes, class sizes, instructors, and subjects that are not really

In the area of evolving hazards: Can engineers actively develop, adopt, and advocate for the use of the Future Conditions chapter of ASCE/SEI 7 that is being developed? Can we continue to inform our members about the evolving standard of care with respect to climate and provide interim design recommendations while standards are being developed? Can we continue to refine hazard performance expectations and promote concepts of functional recovery and community resilience over just basic life safety? Can we work with regulators to draft a uniform vessel impact, pier protection, and operating procedure guidance for our critical ports that support megashipping fleets?

With respect to AI: Can we provide clear and truthful guidance to our members on the risks and opportunities to the profession? Can we provide education that explains the over-saturated buzzwords that appear throughout the media? Can we provide targeted education for individuals and firms of all sizes on how to effectively navigate entering or advancing your use of AI?

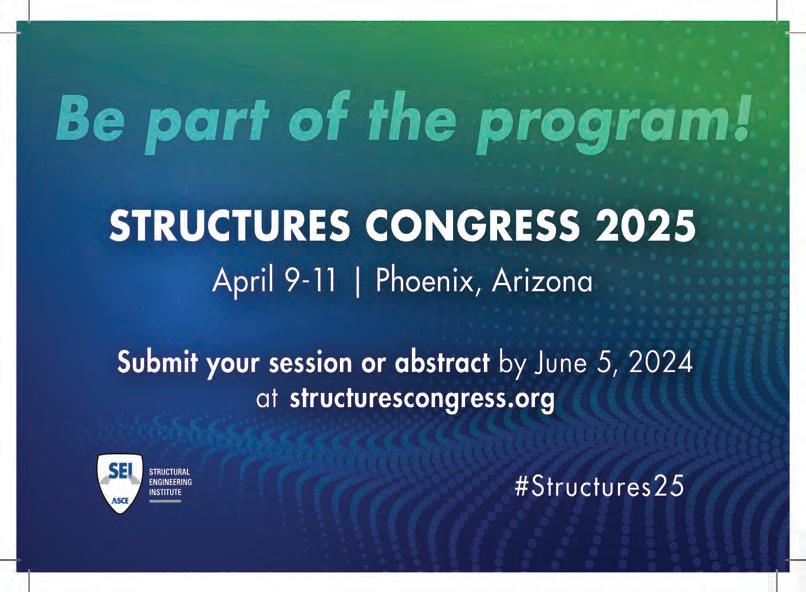

In terms of licensure: Can structural engineering media attention surrounding events fuel positive legislative change? Can the joint leadership of CASE, NCSEA, and SEI provide a strong, unified voice in state and national arenas advocating for the advancement of public safety that comes through adequate licensing and continuing education requirements?

So how will NCSEA address the current challenges in the profession?

For the question of pipeline: Can we continue to exponentially grow diversity and other scholarships for college students in need and host them at the Summit? Can we support a national “Pathways” to the SE profession program or partner with Member Organization to grow theirs? Can we challenge universities and the antiquated ABET structural engineering education model where many potential engineers are “weeded out” and driven

Structural engineers are uniquely suited to be expert leaders for owners, agencies, and developers on multi-disciplinary teams throughout the entire design, construction, and project lifecycle. We must continue to challenge our current daily practice to secure this role and to inspire and elevate the future of the profession. ■

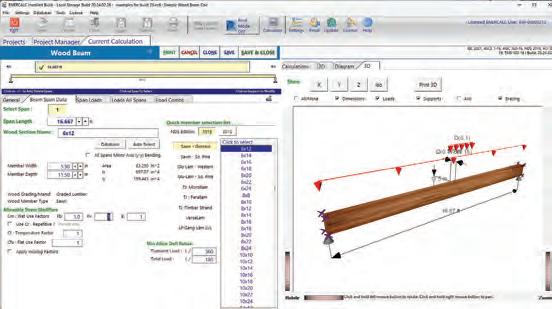

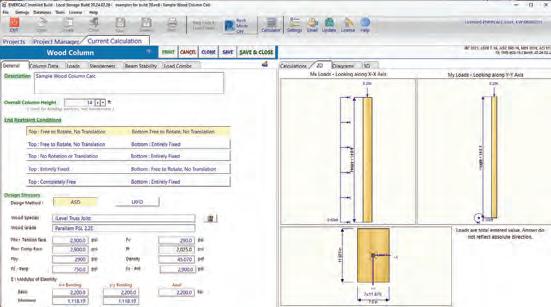

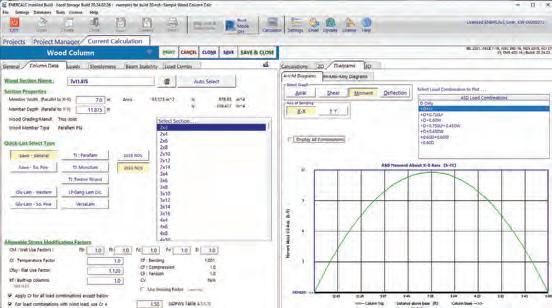

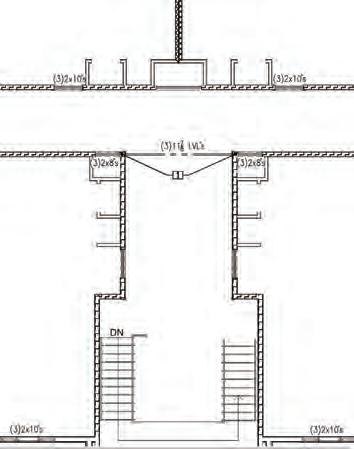

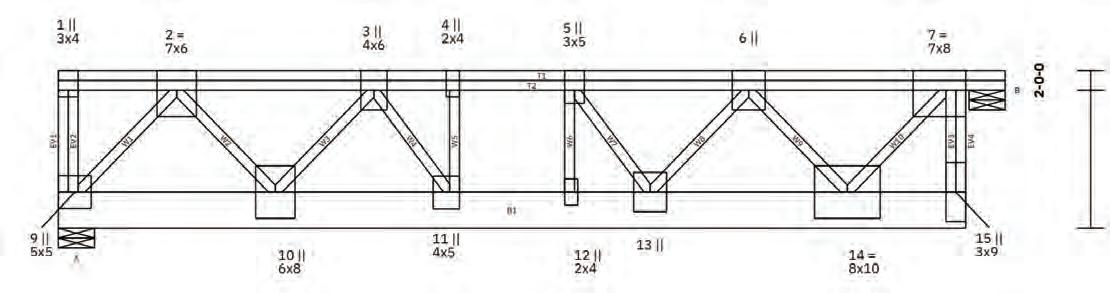

Employing effective, early communication ensures you get accurate, on-time truss designs. By Seth Duncan

Designating “Trusses by Others” on your building plans may sound trivial, but, all too often, the process for obtaining them is not. Those "others" who design and manufacture trusses from construction documents were asked what advice they would give to the building designers that create them. Everyone involved wants trusses with sufficient performance that are cost-effective, and they want a painless process for defining their requirements. Answering as many of their questions up-front as possible, along with ones they may not think to ask, is the best way to ensure you get truss designs that work without endangering your project’s timeline.

Most engineers will refer you to the architect’s drawings for the building’s dimensions, but some of them are so critical to truss performance that they are worth verifying before truss design begins: heel heights, overhangs, and bearing locations. The first two have to do with defining the roof envelope. Truss heel heights are generally determined by where the roof plane meets the bearing component (e.g. a wall or beam). These need to be clearly marked (Figure 1), and they also have to be tall enough to allow the chords of a truss to fit. Roomier heels often allow for more efficient truss designs too, which means savings on material costs. Overhangs, or any protrusion of the truss from the exterior of the structure, can experience significant uplift forces when they’re exposed to wind. These lengths, most commonly top chord overhangs, are easy for truss designers to miss, particularly when they vary within a project. Truss bearings are typically going to be a wall or beam, and these need to have their locations and heights clearly conveyed (Figure 2)—again, especially when they vary within a project. Misplaced bearings have all sorts of ramifications for truss design, from causing unnecessary chord steps to heavy reinforcement in the wrong parts of the truss, and they are sure to confound the framers in the field.

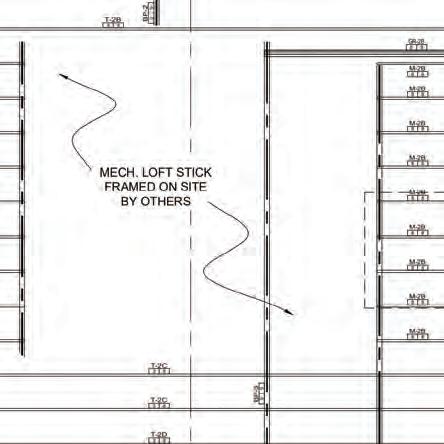

Truss repairs can be costly both in terms of time and money, and one of the most preventable causes for truss repair is clashes in the field. This can come from HVAC requirements for openings for ductwork and ventilation (Figure 3) or plumbers needing space for supply pipes and drains. You don’t want to wait until the trusses are in place to find out they need to be shifted over or cut into, or to find

out that new girders will be needed in order to accommodate other parts of your structure. This is especially important for HVAC running through a floor, as floor girders can be hard to design with large openings due to their restricted depth and webbing options (Figure 4). These are all good examples of where it can pay off to include the truss designer early in the planning stages.

An overwhelming number of parameters affect the loading and analysis of trusses. Unless they receive explicit instructions, the truss designer is unlikely to deviate from the default settings in their software except when it helps them design the truss with cheaper materials. The defaults in their truss software may be overly-conservative, leading to costly overdesigning, while changing settings for which no parameters were provided to them could lead to trusses that meet all the specifications while underperforming on-site. Supplying all of the relevant constraints is the best way to avoid these problems.

Clear communication is essential when it comes to the project’s loading as a lot of factors go into developing the loads for a structure besides the basic live and dead loading for the chords. First, those dead loads may or may not account for the weight of the lumber itself, so a careful designer will assume that weight needs to be added in unless they are told that it has already been accounted for. Another common source of suboptimal loading is storage loads in residential attics. Most trusses need to be checked for whether a 42 inches high by 24 inches wide box can fit anywhere along its bottom chord, but IRC 2009 and newer editions allow storage loading to be omitted when the bottom chord is going to be covered by insulation and the application of the project is residential. There are also exceptions

in some codes for structures without an attic access of 20 inches x 30 inches. For wind loading, you may want to specify whether to use the Envelope or Directional procedure. The envelope procedure is a newer method that can be used for “low-rise” buildings with a mean roof height less than or equal to 60 feet and is typically the more accurate of the two methods for those structures.

Snow loading can be significantly affected by the conditions in which the structure exists. The terrain and exposure categories describe to what extent wind will help prevent snow buildup on the roof, the thermal factor takes into account whether or not the structure experiences sustained freezing temperatures below its roof in winter, and estimates of snow accumulation can be dramatically affected by the “slipperiness” of the roof as well as how well-ventilated it is.

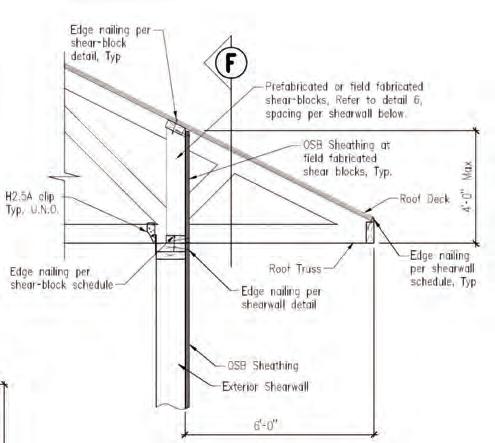

Commercial structures in particular are more likely to have things like towers or other structures that require bracing to be attached to the roof (Figure 5). Experienced truss designers will notice items like this and either request clarification or make some assumptions.

Perhaps the most important inputs the building designer can provide into the truss analysis are the deflection limits. The building code has standards for this, of course, but you may find there are cases where the code allows for long-span trusses to deflect up to 2 inches, which can lead to problems like ceiling cracks. ANSI/TPI 1-2022 Table 7.6-1 has deflection limits that account for long-term deflection. Using more stringent deflection criteria and/or compensating for bottom chord deflection by specifying sufficient camber, or upward curvature, of the bottom chords may be necessary, especially for long, unsupported spans. The stakes are even higher for floor trusses, where certain flooring materials like stone, concrete, and tile are especially prone to cracking.

There are many ways that insufficient planning up-front can lead to unnecessarily expensive trusses. One of the most common is the case of locating girders, or the trusses, that will support sets of trusses. Here are some rules of thumb: first, place a girder at a right angle to whatever it will be carrying whenever possible. That means to avoid placing girders on valley lines and at an angle relative to the wall. Angled truss-truss

connections are significantly more expensive than perpendicular ones, so use the latter as much as possible. Another is to minimize the hip girder’s setback distance from the wall, ideally about 6 feet or less in residential construction. Again, the reason is to minimize the cost of the trussto-truss connections, and, in many cases allowing for nailed connections in place of an expensive hanger.

On commercial projects, seeing if a girder is a viable option ahead of time may save money and frustration down the road. When loads are high, sometimes it is more cost effective to use a LVL or steel beam to support an area of the roof or floor as opposed to a massive girder. The last thing you want is to specify “Truss Girder by Others” only to find out when the trusses are being designed that a girder fails in that area. Having to change the architectural design of a building to accommodate an unexpected beam or column is something that can severely slow a project down.

Another way to reduce material costs is to keep the building as symmetrical and consistent as possible. The more times you can reuse a truss design, the less time designers have to spend creating truss designs and the more efficiently the trusses can be manufactured. The more you can avoid variations in wall height, roof pitches, etc., the more economical the trusses are going to be. It’s also helpful to consider allowing for trusses to have a consistent, even spacing. This convention comes from trussed roofs with plywood sheathing since plywood is sold in 8-foot sheets. Committing to a multiple of two for your truss spacing can significantly reduce framing time and material costs.

For any project, looking at the “worst case” truss design from the whole layout to find out if a design will work ahead of time is a good way to avoid costly redesigns down the road. The sooner you find what it takes to get that truss to work, the sooner you can update your cost estimates accordingly or begin the redesign process before too much work must be redone. Making the entire floor deeper or raising the heel height to improve truss performance is much easier at the beginning of the design process than at the end.

Once truss design has been completed, there are still some trussrelated items for which the structural engineer is responsible. The first

is the plan for attaching trusses to their bearings. The finalized truss designs will include the reactions at each bearing, but a plan for attaching them to the building does not come with the trusses. In some cases, the earlier you consider this the better—you don’t want to wait until the trusses have been fully designed to realize there isn’t enough heel height to tie the trusses to the walls in a high-wind area.

The other remaining work is coming up with a bracing plan. Continuous lateral bracing is needed to prevent truss buckling under construction loads. Also, some individual truss designs are going to require permanent bracing, and it is the building designer’s responsibility to determine how to attach that bracing to the trusses as well as how to tie that bracing into the rest of the building.

The more complex the project, the more critical effective communication becomes, and the earlier that communication begins, the better. As Kirk Grundahl put it in a STRUCTURE magazine article in March 2020:

“One solution that works well is Building Designers and General Contractors (GCs) who commit to work with a specific CM [component manufacturer] early in the project life cycle. Communication and collaboration at the design development stage of any project solve many of the problems that typically present themselves during a deferred submission review and revision process.”

The increasing popularity of the DesignBuild model means that building designers need finished truss designs much earlier in the submittal process, but since truss designers work for component manufacturers, getting truss designs typically means committing to use that truss manufacturer to produce the trusses up-front. The market is ripe for innovative solutions to this challenge. Whenever a truss designer does get involved, their needs are synonymous with the needs of an effective structure, and effectively anticipating those needs will lead to better outcomes for the quality and costs of all your truss projects. ■

Seth Duncan is the Director of Operations for Truss Pal, a company that provides access to wood truss design and analysis information. When he's not standing in for your buddy at the truss shop who helps answer your truss questions, Duncan likes spending time with his family outdoors. Connect with him on LinkedIn or visit trusspal.com.

Introducing the new MiTek Truss Validator. Instantly confirm floor truss viability.

24’ span

16” depth

24” spacing

Lumber species

Design considerations and common detailing strategies for Wood-Framed Type III construction are discussed.

By Jared S. Hudson, PE, and Shaun M. Kreidel, SELight frame wood construction is often a desired construction method for low-rise multifamily structures due to readily available labor and materials, speed of construction, sustainability, and relatively low construction costs. A Type V construction classification as defined by the International Building Code (IBC) is commonplace for these structures; however, this construction type is limited to four stories of stacking wood construction. A Type III construction classification allows conventional wood-framed structures to include an additional level, bringing the allowable height to five stories above grade; see Figure 1 for an example of this type of construction. This construction type may be attractive to developers looking to maximize the occupiable square footage of a defined footprint while taking advantage of the many benefits that come with light-frame wood construction. To facilitate a Type III classification, unique structural and architectural detailing is

needed to maintain the strength, stability, and serviceability of the wood-framed structure, as well as to address the applicable fire design requirements. These details are multidisciplinary in nature and require a high level of collaboration between the structural engineer, architect, and builder/developer to ensure that the project meets the owner’s expectations and the building code requirements of the Authority Having Jurisdiction (AHJ).

Depending on the requirements of a given project, practicing engineers may need to investigate certain design aspects that become critical when meeting the requirements of Type III construction. These design considerations include material requirements, fireresistance rating requirements, the importance of designing for wood shrinkage, and structural detailing strategies to accommodate fire-resistance ratings at the intersection of the floor/roof assemblies and exterior wall assemblies.

While construction Types I, II, and III all require the use of non-combustible materials at exterior walls, the IBC recognizes the use of fire-retardant-treated (FRT) sawn lumber and FRT wood structural panel (WSP) sheathing as acceptable materials to satisfy the requirement under Type III construction. Practicing engineers should account for FRT lumber and FRT sheathing strength reduction factors due to the treatment process. The strength reduction factors are manufacturer-specific, thus coordination with the architect and builder/developer is recommended if the intended product is unknown.

FRT treatment process results in sheathing strength reduction factors which can decrease both the allowable spans and the lateral strength/ stiffness of diaphragms or shear walls. FRT lumber treatment process also affects the structural properties of sawn lumber; the designer may need to augment the wall/header designs to mitigate these effects. Table 1 illustrates the strength reduction factors from two manufacturers of FRT sawn lumber. Assumed in-service temperature of the lumber is an important consideration that may cause variation in structural property values between manufacturers. High in-service temperatures of more than 100 degrees Fahrenheit will correspond to a greater reduction in strength and stiffness when coupled with fire retardant treatment. The engineer should also account for any wood incising reduction factors that might be needed to treat the lumber and consider using lumber that does not require incising to mitigate the amount of strength reduction. All minimum assumed FRT properties should be listed as design assumptions in the contract drawings to ensure that suitable lumber and WSP products are utilized. A designer may encounter situations where spans or loads require structural properties beyond what FRT lumber alone can provide. At this time, there are no fire-treated engineered wood products on the market (e.g., LVL, PSL, LSL) known to the author. One strategy available to designers is to utilize a flitch beam; a composite beam that consists of FRT wood laminations bolted to a continuous steel plate. The FRT laminations of the composite assembly will maintain the non-combustibility requirement; however, special attention to detailing to adequately conceal the heads of the bolts of the flitch beam assembly will be required. The designer should also consider

Modulus

Compression

Perpendicular to

0.950-0.960 0.977-1.000

the expansion of the longitudinal steel due to elevated service temperatures for longer-spanning flitch beams. Another strategy that the designer can employ is the use of rolled steel framing members within the exterior wall. These members may require additional fire protection along with meeting the noncombustible requirements of the code; the project architect should be consulted for additional fire protection requirements of these members.

Type III construction requires that exterior loadbearing walls satisfy a 2-hour fire-resistance rating (FRR). If exterior walls can be classified as non-load bearing, the FRR can be reduced to 1-hour for certain occupancies. A 2-hour FRR is usually accomplished by having two interior layers of gypsum board. Over the full perimeter of the structure, the added cost of an additional layer of gypsum board can be substantial. A common industry interpretation of a non-load bearing exterior wall is one that does not support anything but its self-weight and the self-weight of the walls above. The structural designer can strategically run the framing parallel or introduce girder members parallel with the exterior wall to avoid a load bearing situation. In doing so, a FRR of 1 hour can be utilized and thus an extra layer of interior gypsum board can be avoided. This approach and interpretation should be discussed with the project architect and the AHJ during design to ensure compliance with the local building code.

The vertical continuity requirements of the rated exterior wall assembly have been a hotly debated topic between jurisdictions and design professionals, but the requirements have finally been clarified in the 2024 IBC. According to Section 705.6 of the 2024 IBC, the exterior wall FRR shall extend continuously from the top of the foundation/ floor system below to the underside of the roof/floor sheathing above. However, if the fire separation distance (as defined in the IBC) is greater than 10 feet, the exterior wall FRR is permitted to terminate at the underside of a ceiling (floor or roof) assembly having an equal or greater FRR than the exterior wall. Detailing at the floor levels and the roof level will need to conform to these requirements. Some commonly used detailing strategies that meet these criteria are presented later in this article.

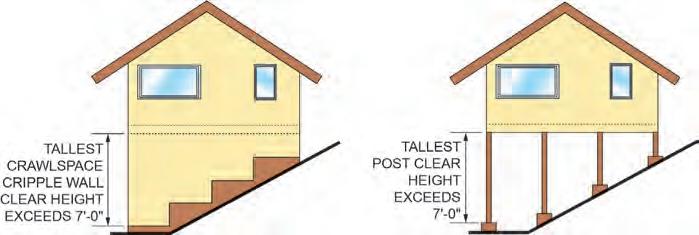

With taller wood structures, the consideration of expected wood shrinkage becomes critical. Failure to account for the natural shrinkage of the wood structure may be problematic to the performance and serviceability of both in-wall utilities such as rigid pipes, and brittle veneers such as brick. Lateral ties for brittle veneers shall be designed to accommodate the vertical movement anticipated for a given structure. Expansion of veneers such as brick, which absorb moisture and expand over time, should also be accounted for in the vertical allowance of the ties.

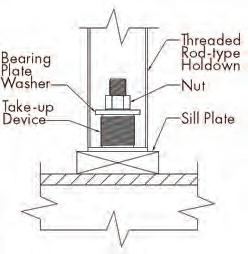

Wood shrinkage can also have a large impact on calculated shear wall deflections. Mechanical hold-down deformation is a component of the shear wall deflection equation. At shear walls where hold-downs are utilized, the amount of wood shrinkage between levels is additive to the deformation (elongation) of the hold-down device. To eliminate this effect, the building designer can utilize a take-up device as part

of the hold-down assembly to restore hold-down tautness and thus eliminate this source of added shear wall deflection.

The following subsections present a few common methods for detailing the floor assembly intersection with the exterior wall assembly for this type of construction. These methods have respective advantages and disadvantages which the designer and design team will need to weigh while considering the topics discussed above.

The common thread between all the detailing strategies is maintaining the 2-hour FRR assembly at the wall intersection with the floor system. The chosen details may affect structural member lengths (e.g., wall studs and roof/floor members), bearing conditions, hardware requirements, and blocking/fire caulking requirements. These different detailing approaches will also yield different overall expected wood shrinkage values. The shrinkage of wood parallel to grain (e.g., vertical wall studs) and pre-manufactured wood floor components is negligible when compared to the shrinkage of wood perpendicular to grain (e.g., flat plates). Limiting the total number of flat plates in the exterior wall assembly will therefore minimize the overall expected shrinkage in these structures. For structures particularly sensitive to this shrinkage, it is recommended that the designer lists the anticipated shrinkage values in the construction drawings so that the other members of the design team can coordinate their components and assemblies.

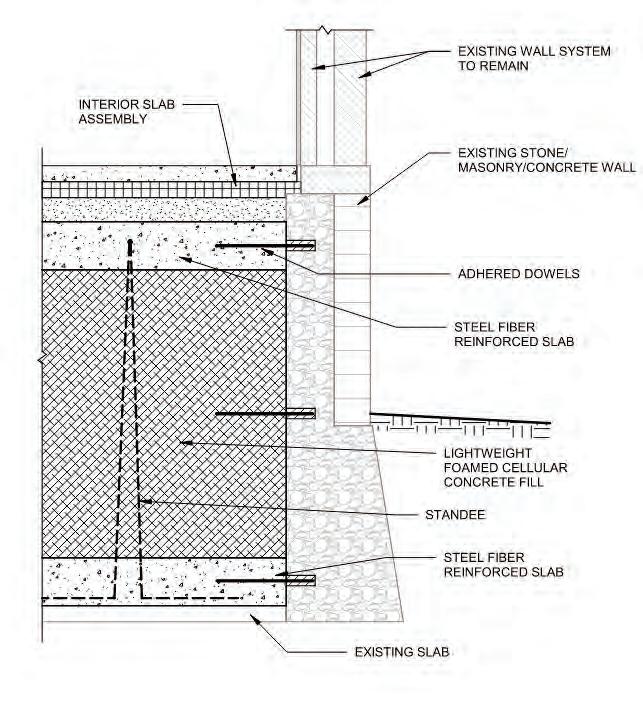

The FRT requirements of the floor system bearing components has been a topic of debate in previous code cycles. The 2024 edition of the IBC, Section 705.7.1, has clarified that the elements of the floor system bearing on the exterior walls and supporting gravity loads from the exterior wall above shall be in accordance with the requirements for interior building elements of Type III construction and are not required to be constructed of FRT lumber; however, the FRR must be extended through the floor cavity. In areas where the 2024 IBC has not been fully adopted, a discussion with the AHJ would be prudent to confirm that this added clarification will be honored by the local jurisdiction.

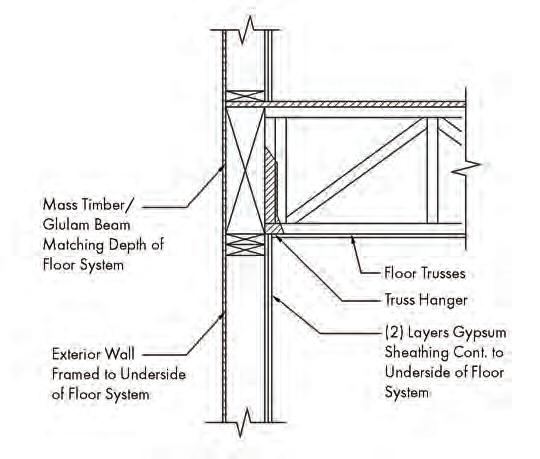

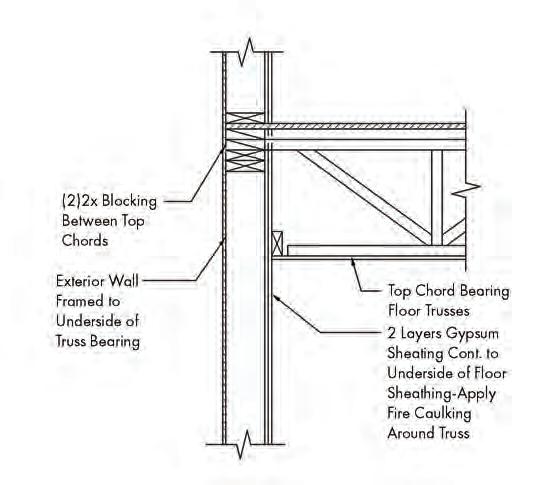

In multifamily construction, utilizing bottom-bearing floor systems is commonplace and often preferred as it allows for the use of consistent wall stud lengths and allows for the overlapping and interconnection of wall double top plates. Traditional platform frame construction with floor trusses relies on a continuous ribbon board, which distributes the loads above to the truss verticals and supports the floor sheathing edge. To meet the Type III FRR requirements, the individual floor truss end verticals and ribbon board would need to carry the same FRR as the wall above, which is impractical/uneconomical in most situations as the gypsum board(s) below would need to extend to the underside of the floor sheathing and fire caulking would need to be applied at each truss penetration. To achieve the required FRR, a solid rim board (glulam/mass timber) occupying the full width of the exterior wall assembly can be utilized per Figure 3. The FRR is achieved through the mass and char capabilities of the rim board which would need to be calculated per the provisions in Chapter 16 of the National Design Specification (NDS) for Wood Construction (or the newly released 2024 Fire Design Specification [FDS] for Wood Construction published by the American Wood Council).

The advantages of this detailing approach are consistent wall plate heights across the structure and minimized shrinkage via engineered lumber for the full depth of the floor system. Disadvantages are the added costs associated with the rim board along the full perimeter of the structure and the floor system connection hardware to the rim board, sequencing issues with the placement of the rim board prior to the floor trusses, and added difficulty in placing floor trusses due to lack of exterior bearing.

Another method to frame the intersection of the floor with an exterior wall of a wood structure is using semi-balloon framed wall construction, where the floor system utilizes top chord bearing trusses to bear on the exterior wall below. Like the platform framing method, the vertical support of the exterior wall above shall have a 2-hour FRR; however, for this method, the gypsum board from below can

more practically be extended the full height of the wall assembly due to the minimal size of the required penetrations where fire caulking would need to be utilized (Figure 4).

Advantages of this approach are reduced costs associated with truss connection hardware to the exterior wall, the ability to utilize typical rated assemblies to demonstrate the required FRR, and the use of conventional lumber to provide solid blocking to the underside of the floor sheathing above. Disadvantages are unique exterior wall plate heights relative to the interior ceiling height, limited spans of floor trusses due to the allowable capacity of top chord bearing trusses, and the addition of multiple flat plates into the exterior wall assembly which will increase overall building shrinkage.

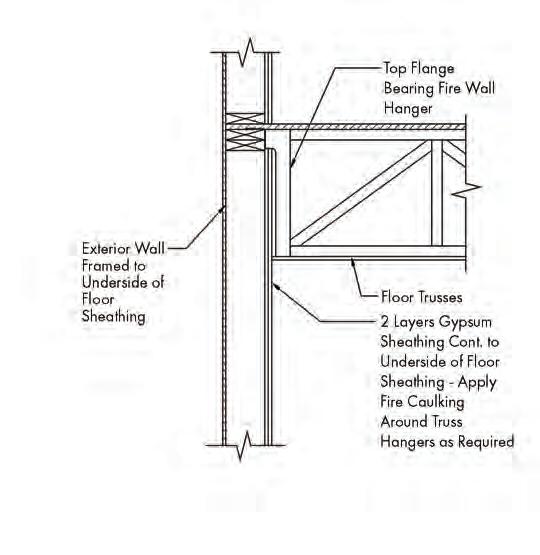

The final method presented in this article is balloon-framed wall construction, where the top plate of the exterior wall below extends to the underside of the floor sheathing above per Figure 5. For this construction type, the floor trusses are supported by specialty fire wall hangers that utilize a top flange that bears on the exterior wall. Due to the popularity of this approach, these specialty hangers have evolved to allow for the interior gypsum board sheathing to be placed around the installed trusses to achieve the required exterior wall FRR.

Advantages of this approach are flexibility in the sequencing of gypsum installation, lack of additional flat plates within the exterior wall assembly thus limiting overall shrinkage, and a simplified bracing load path of the exterior walls via direct attachment to the floor sheathing. Disadvantages are the coordination of the exterior wall plate heights relative to the interior ceiling height, the potential for additional studs within the exterior wall to facilitate required hanger loads, added costs due to specialty truss connection hardware, and added difficulty in the placement of trusses due to the lack of exterior bearing.

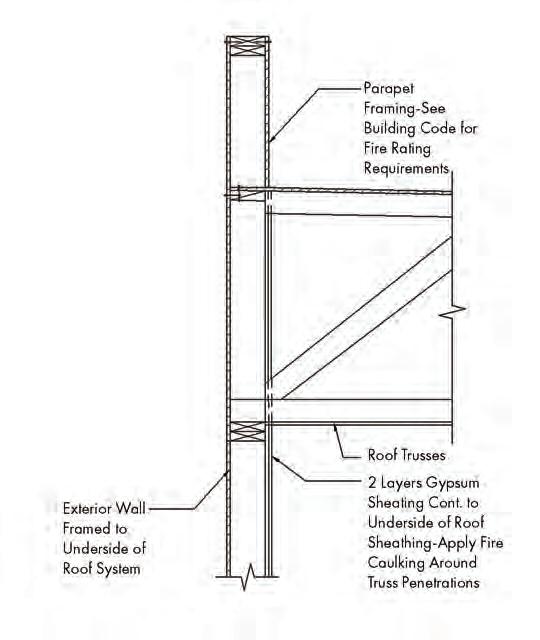

Similar to the detailing at the floor levels, the detailing strategy at the roof/exterior wall intersection can vary widely by locale and preference of the design team (Figure 6). As stated for the floor framing options, the exterior wall FRR must continue to the underside of the sheathing above. Due to a lack of practical alternatives at the roof, the author's experience has been that commonly, the roof detailing for these structures consists of direct bearing of the bottom chord of the roof trusses on the exterior wall below. The gypsum board below shall extend to the underside of the roof sheathing; all penetrations in the gypsum board to allow for truss webs, chords and verticals shall be fire caulked to maintain the required FRR. In cases where the exterior wall FRR is 1 hour, the rated assembly is permitted to be terminated at the underside of the 1-hour rated roof assembly.

The structural designer must consider many factors when pressing the limits of conventional wood framing to new heights to ensure appropriate fire-resistance ratings, structural performance, and constructability. Despite the added complexity that comes with Type III construction, it can yield a structure that is cost-competitive with other structural framing materials that have been more traditionally used in midrise construction. Collaboration between members of the design team is essential on multiple fronts to ensure the delivery of a high-quality, codecompliant design while minimizing construction issues and delays. ■

Jared S. Hudson, PE, is a practicing project engineer based in the Atlanta office of Mulhern & Kulp Structural Engineering. (jhudson@mulhernkulp.com)

Shaun M. Kreidel, SE, is an Associate Owner and the Atlanta Office Director for Mulhern & Kulp Structural Engineering. (skreidel@mulhernkulp.com)

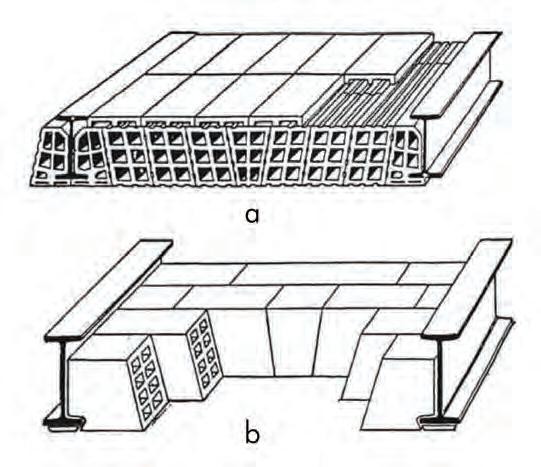

Reinforced hollow clay masonry is a viable material for high load demand structures.

By Steven G. Judd, CE, SE, CBSAlthough reinforced hollow clay masonry (RHCM) represents a small portion of structural masonry design in the United States and Canada, RHCM has high strength which makes it very suitable and desirable for high demand facilities, such as tornado shelters. There are over 100 times more structural concrete masonry unit producers as there are structural clay masonry producers in the U.S. and Canada, which is one reason why most facilities constructed with structural masonry tend to be constructed with concrete masonry units (CMU). The other drawback to the use of hollow clay masonry (HCM) is an engineer’s lack of knowledge and familiarity with the HCM material. This article helps bridge that lack of knowledge.

Please note this article references The Masonry Society’s TMS 402/60216, Building Code Requirements and Specification for Masonry Structures. Where different, TMS 402/602-22 items will be noted in brackets, thus: [ ]. The American Society of Civil Engineers’ ASCE 7 -16, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, is also the standard used.

A brief comparison: Concrete block can easily and regularly be produced with compressive unit strengths of 3,250 pounds per square inch (psi), which equates to a wall assembly compressive design strength (f’m) of 2,500 psi. Most manufacturers of HCM produce material with average gross net area compressive strength of 9,000 psi up to, and exceeding 18,000 psi, which far exceeds the compressive strength of concrete masonry units, and generally produce units that can be designed for f’m of 3,500 psi or 4,000 psi—without the need for prism testing. Design strengths (f’m) higher than 4,000 psi can be achieved if needed, but prism testing would be required.

In general, the higher f’m provided by RHCM can produce thinner walls for a given height and applied loads, or taller walls with a given unit depth or wall thickness. RHCM is uniquely suited for tornado shelters made with structural masonry to provide the thinnest—sans pilasters— walls possible in structural masonry. (Note: the use of strategically placed pilasters can reduce the wall thickness.)

Wall assembly compressive design strengths (f’m) based on the average unit net area compressive strength, combined with mortar of different types, can be found in TMS 602 § 1.4-B-2-a, Table 1 (for HCM). Type S mortar is most often recommended for structural masonry and is one of the variables in the table.

Also, as a preamble to an actual design example provided later in this article, it is worth noting that the 2021 International Building Code (IBC) and later codes have specific tornado wind (WT) design requirements and design load cases that

are different than the typical wind design pressures and load cases from previous code editions. These tornado wind load cases, which must be checked, apply to all facilities east of the Rocky Mountains. These tornado wind design requirements in ASCE 7 are considered to be “pass by” or “near miss” scenarios and are not appropriate or even applicable for tornado (or hurricane) shelters. For that special class of facilities, one must use the International Code Council’s ICC 500, Standard for the Design and Construction of Storm Shelters.

Wind design pressures used for tornado shelter wall designs may be 15 to 20 times higher than wind design pressures for typical or standard single-story buildings. In some cases, tornado wind design pressures can exceed 200 pounds for square foot (psf). For the demand generated from those extreme wind design pressures, HCM having roughly double the f’m, as compared to CMU, will prove to be an appropriate choice.

The case study illustrating the capability of RHCM focuses on a community tornado shelter with outside dimensions of 100 feet by 70 feet and day-to-day use as a gymnasium for a school. The walls are 28-feet-8-inches tall from the interior floor to roof. There is no parapet. The flat (shallow sloped) roof system is comprised of open web steel joints spanning the 70-foot width, spaced at 4-feet on center supporting a 6-inch thick concrete-on-metal-deck roof. The joist layout starts two feet from the 70-foot end walls. Total roof dead load is 103 psf.

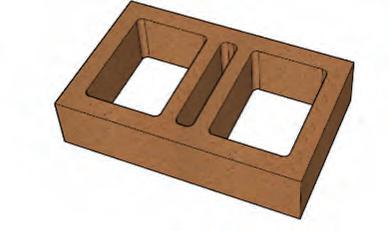

Ten-inch deep HCM units were chosen for the single-wythe wall. The unit size used for this case study was 10 inches deep by 4 inches tall by 16 inches long, (nominal dimensions), called a 10416 unit, with two large rectangular cells adjacent to the end webs, and a single narrow cell in the center (Fig. 1) The design assumes (requires) a fully grouted wall. Wall weight was calculated at 103 psf. The terms “fully grouted” or “solid grouted” (currently used interchangeably in TMS 402/602) allows for voids in the head joints between the mortared face shells (standard mortar bedding) of square ended units (for CMU and HCM) and should allow for the unfilled center cells of HCM and the large head joint voids for CMU units made with “ears” due to recessed end webs. These voids are generally assumed to remain unfilled when using standard coarse grout and standard grouting procedures. The tornado shelter walls were fully grouted to provide the durability needed for tornado shelter projectile impact resistance, per ICC 500, which has been proven via testing by at least one HCM

manufacturer. Reinforcing also requires fully grouted walls.

This case study was based on Strength Design (SD) concepts (TMS 402 chapter 9) with f’m = 4,000 psi. The minimum grout strength (f’g) was chosen to equal f’m, so, f’g = 4000 psi, in accordance with TMS 602.

Per ICC 500, the tornado design wind speed (VT) from Figure 304.2(1) was 250 mph; roof live load was 100 psf, to account for wind borne debris landing on the roof; Exposure Category C is prescriptive; Topographic effects Kzt = 1.0; wind directionality factor, Kd = 1.0; gusteffect and internal pressure coefficient, GCpi = +/-0.55 (partially enclosed). This assumed GCpi coefficient may be conservative if the openings are properly designed and constructed for tornado wind and impact resistance, wherein +/- 0.18 is allowed.

the two noted appeared to be the most critical.

The assumed ground elevation for this example is 750 feet above sea level (Ke = 0.97).

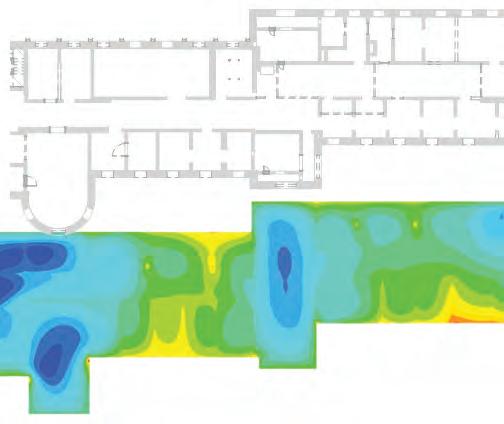

For monolithic structural masonry walls, there is some debate as to the most appropriate derivation of the “Effective Wind Area” (EWA) used for Components and Cladding (C&C) design. EWA is part of several nomographs in ASCE 7 used to determine various pressure coefficients. With the amount of reinforcing anticipated in these walls the EWA was chosen to be 2L2/3, or double the minimum suggested (but not required) by the code. [An EWA of 2L2/3 was chosen because a monolithic wall most likely performs more like a plate or membrane for out of plane load distribution than discrete framing members like stud wall framing or roof joist/purlin framing]. For the roof C&C wind pressures EWA of L2/3 was used relative to the discrete roof framing members. EWA for monolith planar masonry walls is not universally interpreted as L2/3, with such variations as L x 6t; L x joint spacing; and/or L2 used by various engineering practitioners. Main wind force resisting system (MWFRS) wind pressures were used for walls acting as shear walls for wind blowing parallel to the wall, and C&C design wind pressures were used for wind perpendicular to the walls (which were not acting as shear walls for that load case). Maximum negative (suction) out-of-plane (OOP) design wind pressure for C&C design was -219.0 psf; maximum negative OOP design wind pressures for MWFRS design was -174.1 psf. Maximum C&C wind uplift pressure for the roof was -297.0 psf while the maximum wind uplift roof pressure for MWFRS was -160.0 psf.

The 100-foot-long walls were divided into thirds, horizontally, with movement joints; the 70-foot walls were divided in half with movement joints. The maximum design in-plane (IP) shear in the short 70-foot-long end walls derived from MWFRS wind pressures on the 100-foot-long walls was 57.45 kips per wall segment. For the 100-footlong wall, the IP design wall shear was 24.9 kips per wall segment.

Two particularly critical load cases for the tornado shelter emerge: 1) the 100-foot-long wall oriented perpendicular to the wind generating the highest C&C OOP suction (leeward side) and roof up-lift with no IP shear, and, 2) the 100-foot-long wall oriented parallel to the wind direction with MWFRS IP shear, while resisting the MWFRS OOP suction pressures and uplift forces on the tributary roof area. In this case, uplift exceeded the gravity loads on the wall, putting the wall into net tension throughout its height. Of course, all code prescribed load cases and load combinations must be checked and satisfied, but

Some consideration should be given to the assumed fixity at the base of the wall based on the detailing and construction at the base of the wall. A pinned base would have Mu-p-base = 0.0, and Vu-p-base = wLb/2; a fixed base would have Mu-f-base = wL2b/8, and Vu-f-base = 5wLb/8, where ‘b’ is the effective unit width, or length along the wall being considered, and ‘L’ is the span length. For this case study, a pinned base was assumed. Also, keeping the maximum moment away from the base simplifies the foundation design and will prove to be important when checking dowels.

EleMasonry software was used to facilitate the actual design and code checks. The main wall reinforcing that satisfies the various load combinations is shown in Figure 2.

This is a lot of reinforcing, but the walls are nearly 30-feet tall with extreme winds. Horizontal steel selected was (1) #4 @ 48” o.c. vertically to meet code minimum bar size. The maximum vertical spacing allowed by code is 120 inches. Interestingly, deflection control is a main consideration and impacted the reinforcing selection.

The roof joists attached to the wall and the top courses of masonry must have sufficient tension capacity to resist the extremely large net uplift loads. Special detailing may be necessary to develop the reinforcing in tension at the very top of the wall to resist the roof joist uplift loads at their supports. (This could be steel bearing plates with fusion welded deformed bar anchors extending a sufficient length downward into the wall to lap with the vertical wall reinforcing. Another special detail could include also creating a 24-inch deep “beam-in-the-wall” at the top of the wall to facilitate developing hold-down reinforcing and spreading the joist reactions laterally would be a wise choice).

Using #3 180-degree hairpin dowels at the top of the wall to match the vertical reinforcing, placed to engage the top horizontal steel, is a good design choice.

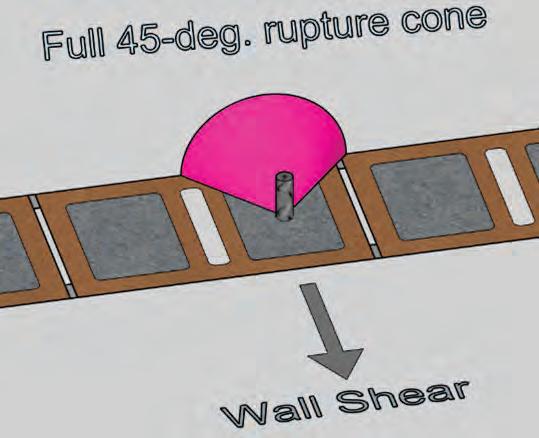

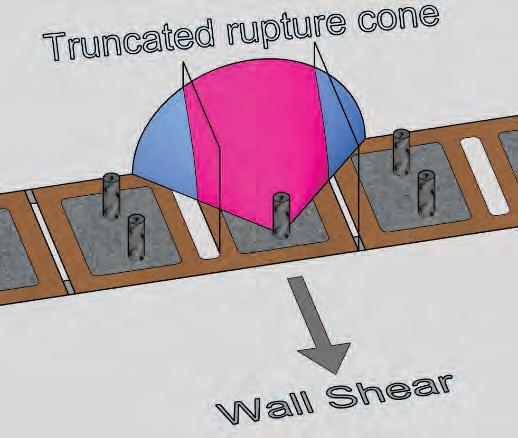

For most design cases, the OOP wind design pressures creating OOP shear at the base of the wall is generally not much of a design consideration, but it is something that requires some specific attention for tornado shelters—especially for tall walls due to the high OOP C&C wind design pressure. Procedures developed for “headed and bent-bar anchor bolt” design were used to check the wall base connection for OOP shear, substituting the foundation rebar dowels for anchor bolts. This is made somewhat more complicated because the center cell of the HCM units will likely be, and should be assumed to be, unfilled, as previously noted. This center cell void and head joint void can create a truncated shear cone, depending on dowel placement, for masonry breakout design checks, which is one of the two primary masonry strength items to check at the base of the wall

for OOP forces. This truncated cone “devalues” the masonry shear breakout strength at the base connection of the wall. The other critical masonry strength design check is crushing of the masonry material (crushing the grout, actually) as the foundation dowels bear against the grout in the filled cells. For these checks, one generally assumes that the foundation dowels will match the vertical reinforcing and will be well developed into the foundation, most likely via hooks into the footings or pile caps, and well developed by sufficient development or lap lengths into the wall above the foundation. For this case study, prying failure and pull-out failure were not an issue. Lastly the rebar shear strength must be checked.

If all the vertical reinforcing is doweled into the foundation, it would be difficult to consider the base of the wall as a pinned connection. Consequently, a single #7 dowel was assumed, centered in the cell, at 16” o.c. as the sole reinforcing connection between the wall and foundation to represent a pinned base most closely.

For the rebar dowel centered in the cell at the base of the wall shown in Figure 3, the rupture cone for the 10-inch deep units would be a full 45-degree half cone with a surface area of 44.08 in2. (For dowels placed at the maximum distance from the rupture face of the unit shown in Figure 4, the rupture cone would be truncated (devalued) as it passes through the plane of the head joint void and the plane of the center cell void – but still greater than the 44.08 in2.) The capacity reduction factor (Φ) for shear is 0.50 for masonry modes of anchor failure (breakout and crushing), and 0.9 [0.65] for steel modes of failure (9.1.4.1). Using the single #7 rebar dowel centered in the cell (left image above) the masonry breakout capacity (Eqn. 9-6 [9-4]) was ΦVnbOOP = 5.6 kips. The masonry crushing capacity (Eqn. 9-7 [9-5]) was ΦVnc OOP = 6.1 kips and the rebar shear capacity (Eqn 9-9 [9-7]) was ΦVnsOOP = 19.4 [14.0] kips, assuming full capacity of the steel.

The C&C Zone 5 wind pressure at the pinned base of the wall generated an OOP shear force of Vu = 4.2 kips at 16” o.c. The OOP shear capacities previously noted for the #7 dowels at 16” o.c. indicated that there was sufficient capacity at the base of the wall to resist the C&C OOP shear demand for the “non-MWFRS” walls – walls perpendicular to the wind direction. Utilization ratio = 0.22.

Checking combined wind effects: Some masonry design programs will only check IP and OOP loadings as separate load conditions, individually. For the MWFRS walls, IP and OOP forces act simultaneously so the design must account for those superimposed effects—basically a biaxial bending issue, plus shear, both IP and OOP shear. Combinations and utilization ratios vary with height, so several checks should be made to confirm that adequate strength is provided at various wall heights. So, after said checks were performed, the design was deemed adequate.

Also, consider checking shear friction at critical heights of the wall to ensure that uplift is not impacting the shear strength detrimentally. The default coefficient of friction, μ, value is 0.7.

The intent of this case study was to show that RHCM can be designed for tall walls under extreme wind loadings from tornados due to the inherent strength advantage of RHCM. Additionally, this case study

provided an opportunity to clarify the terms “fully grouted” and “solid grouted,” which may not be what most designers assume. Further, the question of determining the EWA for monolithic walls and wall elements is worth an additional discussion since there seems to be varying interpretations and little consensus of what is the “correct” EWA formula for monolithic walls.

By way of comparison, if this particular facility was to be constructed with CMU, using units with a net area compressive strength of 3,250 psi, the wall thickness would need to be a minimum of 12-inches deep; plus, for the finished brick appearance, which is one of the design imperatives, brick veneer or thin brick would need to be added to the CMU. A single wythe RHCM wall will always be less expensive than brick over CMU due to the reduction of materials and, most importantly, the reduction of labor to install one wythe versus two. Secondary benefits are more interior space and thinner/smaller foundations. [In general, walls designed for CMU can be swapped to HCM without any redesign, but the full efficiencies of the higher strength HCM material will be somewhat limited.]

HCM is a material that has the three building qualities espoused by Vitruvius - Firmitas, Utilitas, and Venustas, which means strength, utility/usefulness, and beauty. Consequently, RHCM can be used effectively to construct buildings with those same three qualities, especially for buildings with extremely high wind design pressures—like tornado shelters. Where tornado safety is a concern, building with RHCM is a viable solution. For the safety conscious, RHCM also has proven performance via testing for tornado driven projectiles, ballistic impact, and fire-resistive ratings up to four hours—for 8-inch deep units in a filled assembly. RHCM is an excellent choice where safety or protection of valuable assets is a design imperative. ■

Steven G. Judd, CE, SE, CBS is the Technical Director of Interstate Brick, a Western U.S. brick manufacturer. He is current Chair of several committees and task groups in Western States Clay Products Association, The Masonry Society, and Brick Industries Association, and is active in various other committees in those organizations as well as in ASTM committees and task groups related to masonry.

The author would like to recognize and give special thanks to John Hochwalt of KPFF Engineering, Seattle, Washington, for insight and assistance regarding shear in masonry walls under net tension.

• Complement to Mass Timber wood framing systems

• Sustainable Forestry Initiative (SFI®) Certified

• Manufactured with superior strength southern yellow pine MSR Lumber

• Available in range of appearance grades for structural and architectural applications

• Superior alternative for Tall Wall applications

• Load path solution for Engineered Beam and Header Products

• Framing members such as Power Beam® can easily be attached to Power Column® with simple connection detailing

Used efficiently, mass timber can be a cost-effective structural material to create sustainable, affordable housing.By Michael Scancarello, PE, and Andrew Ruff

Mass timber structures are becoming more frequently studied as a leading choice for high-end residential and commercial structures for their sustainability and aesthetic benefits. Perhaps often overlooked, mass timber also belongs in the conversation when it comes to multi-family residential projects, including those classified as “affordable housing.” Providing 69 units of affordable housing along with ground floor retail while funded through typical methods for affordable housing projects, the 340+ Dixwell project is one project that demonstrates this possibility. While this article does not spend time addressing the funding or specifics of affordable housing, it will present challenges and solutions to successfully delivering a cost-effective mass timber structure in this typology.

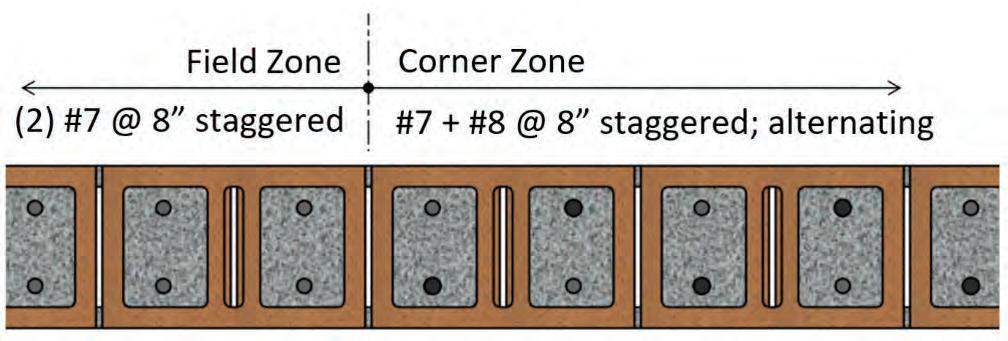

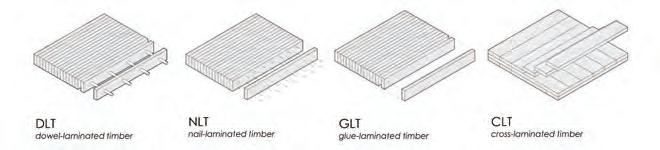

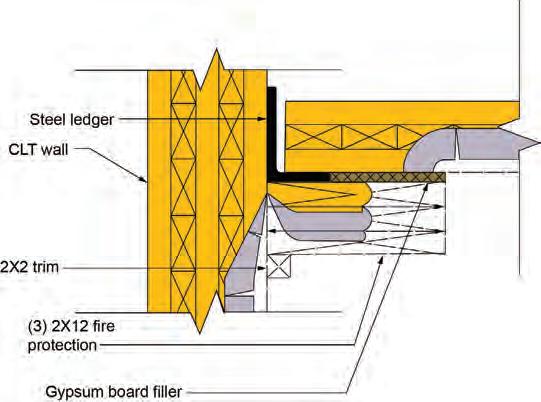

The 340 and 316 Dixwell buildings are each four-story structures comprised primarily of 5-ply cross-laminated timber (CLT) floor panels and 3-ply CLT roof panels that are supported on CLT bearing walls at unit demising and partition walls in addition to coldformed metal framed (CFMF) bearing walls at most corridor walls. The exterior walls, while typically non-load bearing, are also CLT. At the ground floor retail spaces, glulam timber columns and beams support the bearing walls above while steel framing and a composite slab on deck are used above exterior covered parking areas to minimize structural depth. On this project, the following key design considerations helped achieve the project’s ambitious goal of demonstrating the feasibility of mass timber affordable housing.

Typically, the building’s construction type classification as defined by the building code is not something that structural engineers will be particularly familiar with, and it is usually selected without substantial input from the structural engineer. However, when the architectural goals include exposing the structure without the use of applied fireresistant materials, knowing the options and limitations with mass timber systems is important. One of the first conversations between the structural engineer and architect (and likely code consultant) should be centered around selecting a construction type that can meet the project’s goals as efficiently as possible. In many cases, the construction type will drive the decision-making for structural layouts. This project was designed and permitted before the 2021 IBC provisions for mass timber in construction types went into effect, and was permitted as Type VA, with a 1-hour fire rating. However, it is likely that even had the new construction types within Type IV been available, the same code path would have been followed. The excerpt from the International Building Code (IBC) Table 601 summarizes some of the key structural considerations based on construction type. As can be seen in this table, both Type IIIA and Type VA require a 1-hour fire rating for most components of the structural system while

each of the new construction types—including Type IV-C, which generally allows for exposed timber surfaces—require a minimum 2-hour rating for the primary structural systems. When fire rating is provided by the code prescribed methods that account for charring of the timber frame, it is the author’s experience that 3-ply panels will typically be insufficient for meeting a 1-hour rating for most span conditions. However, at shorter spans, thin 5-ply panels will often be sufficient and even at more moderate spans this 1-hour fire rating will only moderately decrease the maximum permissible spans of 5-ply panels. When the fire rating requirement increases to 2 hours for exposed panels, the result is frequently a significant amount of wood fiber increase or a requirement for panel specific test data acceptable to the Authority Having Jurisdiction (AHJ). Reliance on fire testing at early stages of design and permitting often requires early selection of suppliers, which can be a challenge for projects that rely on public funding sources. Much like floor panels, when using CLT bearing walls exposed on one or both sides, the difference between a 1-hour and 2-hour rated structure can result in significant wood fiber increases. With glulam framing members, it has been shown that a 1-hour fire rating can be achieved for glulam beams exposed on three sides that meet the traditional “heavy-timber” minimum sizing without significant impact on member sizing. However, like CLT, when a 2-hour fire rating is required, it is likely to control the design for most efficient beam sizes. (Glulam members with a non-uniform layup have additional requirements that may increase cost over an unrated structure even when timber volumes do not change.) Finally, while a structural system with any rating requirement also requires rated connections, 1-hour fire ratings are more easily achieved without significant impact on member sizing or aesthetics. The footnotes of IBC Table 601 are important to understand. Footnote c, which has been clarified in the 2021 IBC, allows for the use of heavy timber for roof construction in many situations. Heavy timber requirements are generally less restrictive than those of a prescribed one-hour rating and were used at this project to reduce the panel thickness—and cost—of the roof structure.

A key factor in successful mass timber projects is the early selection of a mass timber supplier. However, waiting as long as possible to commit to a particular manufacturer also has advantages. In some cases, like affordable housing, the timing of bidding and selection may also be dictated by funding streams. In the case of this project, a substantially complete design was needed prior to onboarding a supplier. This requirement allowed for a competitive bid process which, while a requirement here, is an approach more familiar and comfortable for many owners and developers accustomed to utilizing conventional structural systems.

This process can provide competitive pricing, but in the U.S., CLT is not sold as a commodity product in the same way as steel or concrete. Most manufacturers produce a variety of panels as slightly different products with different constraints tied to materials, manufacturing processes, and transportation limitations. This presents a different challenge for the design team than many may be used to.

When a supplier is onboarded early, the design team’s goal is to optimize their solution for the selected supplier. Conversely, in a competitive bid, the design team must ensure the design is compatible with as many suppliers as possible. In this scenario there is more responsibility on the design team to be familiar with the capabilities and strengths of multiple suppliers. In the case of 340+ Dixwell, the design team was able to rely on previous experience working with several of these suppliers as Architect and/or Engineer of Record (EoR), Delegated Design Engineer, or both. However, when that experience is not available, it is recommended to communicate with as many suppliers as possible at multiple steps of the design process. Even with ample experience, frequent feedback from suppliers can help the team ensure that their design does not preclude suppliers from bidding or put unnecessary constraints on them that would limit their ability to provide competitive pricing.

As a simple spanning element, CLT is often not as efficient as other panelized timber elements like Nail-Laminated Timber (NLT) or Glued-Laminated Timber (GLT) decking which orient dimensional lumber stacked on edge, placing all fibers in the primary strength direction of the panels. However, by placing the panel fibers in alternating directions, CLT provides several distinct advantages that can make it an efficient choice (Figure 2).

In addition to providing dimensional stability in both axes perpendicular to the face of the panel, CLT panels also have significant in-plane shear strength, making them suitable to be used as diaphragm elements when properly joined together. The ability to use the CLT as a diaphragm and eliminating the need for the topping slab to be structural allowed the design team to study non-cementitious topping systems. Although ultimately not selected for this project due to budgetary constraints, a dry lay assembly could reduce the embodied carbon and reduce the number of “wet” products applied over the timber, potentially providing a schedule savings. With new products and data continuing to become available, this could become a beneficial alternative in the future for projects where a cementitious topping is not required by code. CLT panels also provide flexural capacity in two directions. While creating true fixity across panel joints is very difficult, if supported frequently enough, it is possible to achieve two-way spans with individual panels. Some notable mass timber projects have leveraged this and utilize fully point-supported panels with closely spaced columns. At 340+ Dixwell, this attribute of CLT was used to provide beam-free

c. In all occupancies, heavy timber shall be allowed where a 1-hour or less fire-resistance rating is required.

corridors as well as beam-free zones within primary bearing lines, allowing MEPFP distribution to be kept tight to the ceiling. Early coordination between the structural and building systems were critical to ensure that a 10 foot-6 inch floor to floor height could be achieved while maintaining an 8-foot ceiling height within the portions of units with dropped ceilings. As part of the early design process, multiple framing options were presented for review and coordination, and the choosing by advantages method (a decision-making process, often used by the authors, taken from lean construction practices) was used to select the preferred choice. While the authors have frequently found that spanning CLT panels across the width of double loaded corridor residential buildings results in efficient layouts for non-bearing wall structures, because of the architectural desire for exposed CLT partition and demising walls it was determined that eliminating additional framing members and spanning the CLT panels directly between these walls provided the most advantages to the project. This decision then drove revisions to architectural layouts to improve the efficiency in panel selection.

The two-way spanning capability of CLT was leveraged at two primary conditions that repeated throughout the building. First, corridors were designed to be beam-free by utilizing corridor walls as bearing walls, a strategy commonly used in traditional light-frame construction. To accommodate the different capabilities of potential suppliers, these spans were confirmed to work in two different ways. For manufacturers who could provide the exterior laminations (and therefore primary strength direction of the panel) in the short direction of the panel, panels would be able to span directly across the corridor and either 3-ply or 5-ply panels would be sufficient. However, for suppliers who primarily supply panels with the outer laminations parallel to the length of the panel, spans were confirmed to be acceptable for the panel to span in the weak direction of the panel, including the impacts of fire rating. This flexibility prevented the need to have multiple short span corridor panels that would increase the number of pieces to erect.

Near the corridor, door openings between bearing walls were sized to allow for panels to span these openings while being supported on wall panels only, without any headers above the door. This arrangement was stacked on each floor to ensure no concentrated loads would occur above unsupported sections of the CLT. Additionally, these openings were aligned from unit to unit so that consistent panel layouts could be used throughout the building, maximizing repetition and reducing restrictions on panel layout (Figure 3).

The requirement to provide beam-free corridors and door openings without using headers placed two constraints on the decisions driving the layout of floor panels, slightly minimizing opportunities for efficiency. However, by grouping these constraints together in the center of the building, the area of impacted panels was reduced. Additionally, choosing corridor and door widths and locations that didn’t push the limits of individual panel widths, multiple solutions were available to allow suppliers flexibility in the final approach.

In part due to the uniqueness of each supplier, it was determined that a delegated design would make the most sense for the final mass timber package. This would allow the selected supplier as much flexibility as possible to reduce costs by tailoring their solution within the constraints outlined by the design team. However, to sufficiently finalize the design without running the risk of changes that could not be mitigated during construction administration, it was important for the engineer of record to be very involved in developing the design of

the mass timber systems by providing:

• A range of expected wall thicknesses for each supplier so that appropriate tolerances could be built into the floor plan, allowing for slight changes in dimensions without impacting code required dimensions. The architect then set all unit dimensions based upon centerlines of the mass timber and ensured there was room for these walls to grow or shrink as dictated by the supplier’s available products while maintaining critical required interior dimensions and clearances.

• A range of expected floor thicknesses to ensure adequate clearance for required MEP routing while working with the exterior wall detailing. The thickness of the floor assembly was used to set floor to floor heights. This project also aimed to aid the speed of erection by minimizing piece counts by using single panels where the width of the panel was the floor-to-ceiling height in the platform type construction, allowing for an entire wall segment to be comprised of one piece of CLT. Therefore, heights were also limited by the maximum panel widths a manufacturer could produce (Figure 4).

• Guidance on the limitations of suppliers, particularly as it pertained to maximum panel dimensions that would impact the ability to use single panels as bearing walls and where the location of openings might dictate panel layouts. Corridor layouts were confirmed and door locations within units were set to provide maximum flexibility to systems distribution and panel layouts as described in detail previously.

• Anticipated timber connection details at any locations where they would impact the architecture and at the interface between different trades, including connections to supporting concrete

and steel elements. The authors attempted to allow the greatest flexibility to each supplier’s preferences, however the design team also had to be proactive to provide details that helped to dictate conditions that may increase the scope of one trade to simplify constructability and coordination between trades and/or improve the product that is ultimately delivered.

• Providing guidance on floor plan inefficiencies that will impact costs. Early unit layouts typically had a framed drywall surface applied to one side of all CLT walls to provide acoustic separation and vertical routing of building systems. However, after selection of a code path and structural system, this drywall was standardized to be continuous on the same side of each wall for the full length of the wall and height of the building instead of alternating where architecturally preferred so that it could also be used to provide the fire resistance rating for exposure on one side of the wall. By using materials that would already be present, the total wood fiber requirements for the walls were substantially reduced. Typical bearing wall to bearing wall dimensions varied throughout the building in initial unit layouts. After the selection of the framing approach, unique layouts were moved to areas of the building where site constraints would require unique solutions, maximizing repetition in the primary structural layout and allowing for uniformity in most governing spans, therefore allowing for more panel thickness reductions.

By leveraging the strengths of each unique material and following through on good design decision making, the new affordable housing units on Dixwell Avenue are proving it is possible to build high-quality affordable housing on a tight budget. It is possible to use mass timber as a cost-effective and biophilic element in a sustainable fashion on a project that will be certified to PHIUS passive house energy efficiency standards. It is also possible to introduce new materials to the market and build up a skilled local workforce to construct these buildings. Every project presents opportunities to learn from as we continue to improve what we build, how we build, and who we build it for. This project was informed by many before it and the authors hope its demonstrated successes, as well as its recognized challenges, will contribute to continued improvement in our industry. ■

The case study of a lodge collapse provides considerations for structures under construction. By Peter

Despite adequate structural design and a less-than-design snow event, a scribed log- and sawn-lumber-framed commercial lodge structure experienced a catastrophic collapse less than two years after it was built. The subsequent investigation involved a piece-by-piece selective dismantling of the debris pile to determine the cause of the devastating failure.

The recreational ranch facility where the subject building was located is a vacation-type resort situated on leased federal land in a high alpine environment of the Rocky Mountains. The summer activities of the ranch cater to horseback riding, hiking, bike riding, and exploring the nearby national park. During the months of October to April, the area where the ranch is located can receive upwards of 20 feet or more of snow, making wintertime access by tourists impractical for some and infeasible for others.

Under the terms of the ranch owner’s long-term land lease with the United States National Forest Service, the ranch was permitted to construct permanent structures on the property. As part of a broader facility expansion, the ranch owner began procuring plans for an approximate 3,100-square-foot, one-story fourplex log building that included a wrap-around exterior wooden deck. The plans for the log building were developed by a professional engineer who was licensed in the state where the structure was to be built. The snow loads specified in the construction plans were appropriate for the proposed location of the log building.

The ranch owners/managers were acting as the general contractors for the project. The onsite log erection/assembly, roof covering installation,

and rough framing of some of the interior walls took place in early summer. The interior finishes, including interior drywall, insulation, floor coverings, electrical wiring, plumbing, and HVAC equipment, were not installed before the onset of the first winter. Due to project financing issues, all construction progress stopped, and the project remained incomplete for the first winter, the following spring, summer, and fall. The status of the project remained nearly unchanged for the second winter season.

On May 1, the building collapsed catastrophically (Figure 1). The damage was significant and global. It was believed that only the concrete foundation could be reused if the structure was to be rebuilt. Information provided by witnesses who discovered the collapse indicated that 10 or more feet of snow and a thick layer of solid ice had accumulated on the roof at the time of the collapse.

Unified Building Sciences and Engineering, Inc. (UBSE) was hired by an insurance company to determine the cause of the building collapse. As part of the investigation, USBE conducted a site visit once the roads became navigable, approximately one month after the collapse. Based on a detailed review of the weather records, the maximum roof load during the first winter after the initial construction was determined to be 20 to 30 pounds per square foot. The maximum roof snow load on May 1st at the end of the second winter was determined to be 60 to 70 pounds per square foot.

USBE visually and tactiley inspected the logs, framing, connectors, and foundation as part of the investigation. The structural members were still in a near-new state. No corrosion, decay, rot, or deterioration

was observed that could have caused or contributed to the building collapse. Aside from the stresses imparted by the collapse, the logs were in good condition and well-suited for their intended function. Similarly, conditions were not observed that would suggest the logs or dimensional framing were improperly fabricated, shipped, or assembled onsite.

The configuration of the building debris after the structural collapse indicated that the failure originated near the center of the building. USBE analyzed the design that was set forth in the construction documents and determined, before the inspection, that the beams, headers, and roof trusses were appropriately designed for the anticipated loads and would have been expected to endure the snow loads that were presented in the weather records.

The approved construction plans specified that the roof structure was to be vertically supported by two triangular-shaped log frames that would be vertically supported along the bottom chord by two 12 foot tall first-floor 2x6 stud-framed interior load-bearing walls. The roof ridge was also to be supported in the transverse direction with two back-to-back 2x4 continuous walls that were to serve as the fire assembly party walls.

The examination of the physical evidence located within the building collapse revealed the following:

• The two 2x6 first-floor interior load-bearing walls were installed; however, they were not sheathed with a gypsum wallboard panel product as specified in the approved construction plans.

• The lack of wall sheathing violated the National Design Specification for Wood Construction (NDS) slenderness ratio for solid columns and rendered the studs vulnerable to weak axis buckling.

• Without sheathing, the code-permissible (allowable) load-bearing capacity of the 2x6 wall was effectively 0 (zero) pounds per square foot; however, the calculations indicate the ultimate (failure load) capacity would have been reached with approximately 55 to 65 pounds per square foot of snow on the roof.

• Blocking had not been installed between the studs that comprised the central 2x6 load-bearing wall.

• The two back-to-back 2x4 continuous first-floor party walls specified on the plans were not installed. The failure to install the specified walls resulted in the roof ridge being vertically unsupported; however, at a laterally unsupported height of 18 feet, these 2x4 walls would have had an ultimate capacity (failure load) of less than 5 percent of the applied load.

• The 2x6 studs that comprised the center load-bearing walls buckled

and collapsed under heavy snow loads in early May. The compression buckling of the load-bearing walls caused the log roof frames to fail and the roof structure to come crashing down through the first-floor framing into the crawl space.