A.M. Machado is popularising an innovative road construction method that is both quicker and more cost-effective. This environmentally friendly technique is carbon negative, using on-site materials and naturally occurring stabilisers. By eliminating the need for quarrying and transporting aggregates, the method significantly reduces fuel consumption, carbon emissions, and water usage, while also saving on vehicle wear and tear.

Urban development in Harare continues to accelerate with the erection of a new, world-class footbridge across the ED Mnangagwa Road section at Highland Park Mall. Spearheaded by Pat Dunn Zimbabwe, this pivotal project reshapes the city’s premier commercial hub, seamlessly connecting the iconic Highland Park Mall with the burgeoning Design Quarter development.

Harare’s commercial landscape is also on an impressive growth trajectory. The highly anticipated Cardinals Corner Mall, developed by Terrace Africa, has reached a key milestone with the completion of its construction. Located at the strategic intersection of Harare Drive and ED Mnangagwa Road, the mall is poised to become a vibrant hub serving the northern suburbs and providing a convenient, modern shopping destination right on their doorstep.

Local engineering prowess once again takes the spotlight as Brown Engineering completes a significant investment in Zimbabwe’s industrial capacity: a large, state-of-the-art warehouse for a client in Workington, Harare. This expansive project, a blend of new construction and retrofitting the existing warehouse, showcases modern design and robust construction, marking a pivotal moment for both companies and the broader industrial sector.

In other news, the commissioning of Midlands Park in Zvishavane by President Mnangagwa will accommodate over 300 families and 750 students. The Estate Agents Council of Zimbabwe recently hosted its annual Land Conference in Victoria Falls, tackling critical issues of ownership and sustainability.

A new pipeline from Muchekeranwa Dam is progressing, promising to solve chronic water shortages for Marondera and Chitungwiza and the youth are increasingly becoming the backbone of the construction industry, driving innovation in infrastructure projects.

It keeps getting exciting with every page. Enjoy the read.

While every effort has been made to ensure the accuracy of its content, neither editor nor publisher can be held responsible for any omissions or errors: or for any misfortune, injury, or damages which may arise there-of.

All rights reserved. Copyright 2025

No Part of this magazine may be reproduced or transmitted in any form or by any means electric or mechanical, including photocopying or recording.

PUBLISHER

Caast Media Group

MARKETING

Tinashe Mafiko

Newton Musara

+263 781 421 866 +263 781 512 568 +263 78 953 2918

DESIGN, LAYOUT & VIDEOGRAPHY

WEBSITE & SOCIAL MEDIA

Saul Chidakwa Albert Chitumba

Tinaani Francis Garikayi

Zimiso Geoffrey Nyamande

Olga Gertrude Dzingo

Princess Kuvengurwa

JOURNALISTS

Martin Chemhere

Michael Nott

DISTRIBUTION

Itai Kanyemba Gift Sepi

PHOTOGRAPHY

CAAST MEDIA GROUP

marketing1@caastmedia.org markerting@structureanddesign.co.zw

FIND US AT

31 Alexander Rd, Highlands, Harare

OUR PROJECTS

REVO SERVICE STATION

ZUVA SERVICE STATION

Mautric Electrical Pvt LTD set its foot as an electrical supply and equipment trading and services company. Over the years, the company has earned a reputation for excellence and professionalism for continuously striving to meet - and even exceed - standards which set the climate for a sustainable business relationship with its clients.

As an electrical solution specialist, we offer electrical power products ranging from transformers, switch gears, breakers, XLPE cables, panel boards, power meters, and switches. The company also offers control products such as variable frequency drive, soft starters, UPS, AVR, batteries, motors and even lighting fixtures.

Our team is composed of technically skilled and highly dedicated personnel working cohesively to promote value-added solutions with a competitive pricing structure to suit your needs.

We also engage in electrical product installations, testing and commissioning, preventive maintenance, automation, and energy saving solutions.

MANUFACTURERS OF ROLLER SHUTTER DOORS, GARAGE & SLIDING DOORS. SUPPLIERS OF SLIDING DOORS SYSTEM

Text by Michael Nott

When people talk about ‘green’ solutions or ‘green’ alternatives the term is sometimes used quite loosely.

In order to replace or upgrade existing systems, and be employed on a broader scale, ‘green’ options need to be sustainable, simple to implement, do no (or less) damage to the environment, and perhaps most importantly they need to be cost effective. If an eco-friendly choice is available that saves time and money it will quickly be adopted; often the only drawback is a lack of knowledge.

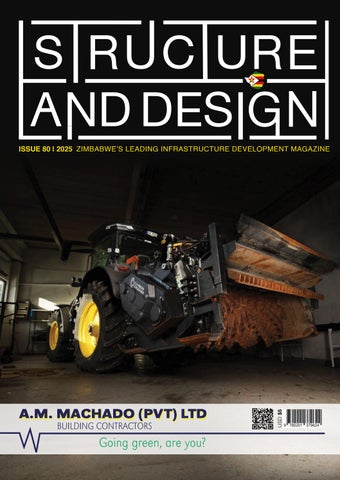

Going green, are you?

A.M. Machado has taken it upon themselves to close this information gap and be a bridge linking contractors to high quality products and systems for road building, maintenance and rehabilitation.

With the support of the Zimbabwean Ministry of Transport the new system is definitely the road forward.

It’s common knowledge that many roads in the country are in urgent need of attention. The current traditional methods of building new roads or repairing existing ones is extremely expensive and relatively slow.

To build a new road in the traditional way consists of grading and levelling the soil, applying two or more layers of aggregate and then compacting the gravel, often using cement as a binder or stabiliser.

Cement takes weeks to cure so the process is slow. Only then can the road be surfaced with asphalt. Depending on the soil type, environmental factors and the type of road the cost can be around one million US dollars per kilometre.

The new methods that A.M. Machado is popularising and championing are much cheaper and quicker, as well as being carbon negative – much kinder to the environment.

The method makes use of materials found on site so there’s no need to quarry and transport tonnes of aggregates, saving fuel costs and reducing carbon emissions, it also saves on wear and tear on vehicles; it uses much less water and because the main components of the stabilisers are made from naturally ocurring materials, it actually sequesters carbon in the road sub structure.

Carbon Crushers uses lignin which is the organic polymer found in plants to make them ridged and woody. It’s usually sourced from the timber industry or paper recycling (another green credential).

In Zimbabwe research is underway to obtain lignin from the waste produced by the sugarcane industry.

To explain the new process very simply – a crusher digs up the surface of the existing road (including old asphalt, soil and rocks) to depth of around 35cms to create a homogenous substrate.

The stabiliser is then applied using a water bowser, the road graded and compacted and can then be open for traffic or for surfacing with asphalt.

Even without asphalt capping the road surface is smooth and predominantly dust free, reducing wear and tear on vehicle traffic, and requiring very little maintenance for many years.

The method uses existing road construction machinery so no additional special equipment is needed.

Cypher Environmental Products are an ideal system for mine roads as well as for open cast mining, tailing pipes and stock piles.

The surface is weather resistant and doesn’t become muddy in the rainy season. It’s also suitable for airport runways and for farm roads.

A.M. Machado has been liaising for a few years with two main proponents of this method of road construction – Canadian firm Cypher Environmental Products and Carbon Crusher Services and Bio Binders, based in Norway.

A.M. Machado has been a local agent for Cypher Environmental Products since 2018 and in 2020 set up a sole distribution agreement. Cypher provides two main products: ROAD// STABILIZR (formerly called EARTHZYME) and DUST/BLOKR both ideal for construction and rehabilitation of existing roads and particularly suitable for the mining industry.

ROAD//STABILIZR

• Requires 20%+ clay content in soil

• Long-lasting results: 10+ years with a single application and no additional grading

• Up to 3x harder than concrete, self-healing

• 1 litre can treat up to 33m3 of soil

• Airfreight is cost effective

• Doesn’t wash away in heavy rains

• Environmentally friendly, non-toxic & non corrosive

DUST/BLOKR

• Can be used with any soil or material type

• Results seen lasting up to 3-4 years with proper maintenance before re-grading needed

• Highly water resistant –won’t wash away in rainy season

• Environmentally friendly, non-toxic & non corrosive

Cypher Environmental Products has received confirmation of Boeing BSS7432 (D6-14787) Conformity for both ROAD// STABILIZR and DUST/BLOKR.

With these results in mind, clients in the aviation industry can be assured that their aircraft will not be exposed to any corrosion damage.

For clients in other industries, like mining and farming, that use expensive equipment and tools, they can also be assured that the products will not damage their assets.

Many projects can use a combination of both products to create resilient surfaces with minimal dust generation.

A.M. Machado has been proposing that DUST/BLOKR is so effective that it should be used on the detours along the new Bulawayo - Victoria Falls highway to reduce dust. The soil in that area is classified as Kalahari Sand which is notoriously one of the most unstable and difficult soil types to work with.

Without the use of DUST/ BLOKR, gravel that had been transported to site for the construction of the main road was being diverted to the detours, so the use of DUST/BLOKR could significantly reduce material and transport costs.

In an urban setting ROAD// STABILIZR was recently used for the rehabilitation of Willowmead Lane in Rolf Valley in Harare.

The road had not been repaired for at least 15 years and was in an almost impassable state.

The Willowmead Lane Community got together with Cypher and Bitumen World and under the guidance of the City Council (and with the approval of EMA) the road was quickly and economically completely repaired and has been maintenance free for a number of years.

One the outstanding benefits of ROAD//STABILIZR is that with heavy traffic it actually becomes stronger as it gets more compressed.

Cost reduction using the ROAD//STABILIZR method –12+% in building new roads, 17% in fuel used for transportation and construction. Using DUST/ BLOKR – 85% reduction in water and fuel savings.

The following quote is directly from Cypher Environmental Product’s website: “Your bottom line is not only important to us, it’s our promise. How? By enhancing the engineering properties of your roads, you can reduce fuel consumption, increase tyre life and reduce maintenance costs on vehicles.

Not to mention substantial cost savings in maintaining treated roads. Entire communities benefit from enhanced roads which translates to more cost-effective transport of goods, technology and people while being kind to mother nature.”

Norwegian based Carbon Crusher Services and Bio Binders uses a similar method. The company is about to receive Verra accreditation, which is the global regulator for climate action and carbon standards, so it really is a ‘green’ company.

Carbon Crusher Services and Bio Binders is committed to producing climate resilient roads with higher carrying capacity and which are carbon negative.

Carbon Crusher has been developing roads that not only store carbon but also avoid emissions from the traditional way of building roads.

This exciting advancement empowers local contractors to contribute to our country’s Nationally Determined Contributions; Zimbabwe has committed to reducing its emissions by 40%. It is an example of how private companies can drive national ambition.

Vigorous scientific and technical research, listed on their website, claims, Our carbon negative roads store 51 tonnes CO2 per mile road.

Regular methods add ~100 tonnes CO2 per mile road. In total 150 tonnes CO2 per mile road which is reduced from the atmosphere.

These are impressive statistics even for an environmentally friendly company!

An important preparatory step for their method is to ensure that there is adequate drainage for water runoff and that all drains, gutters and culverts are cleared. Excess water will damage any road.

For upgrading or refurbishing of an existing road Carbon Crusher employs a specialised in house designed crushing machine which recycles the existing road surface crushing up asphalt and soil and stones on site to a specified aggregate size and to a depth of 25 to 35 cms.

Conventional methods require the old road surface to be hauled away and either recycled or dumped so reusing the previous material on site saves the cost of taking the material away and hauling new aggregates in – also reducing emissions from the fuel used.

It also works on gravel roads without asphalt paving making it well suited to mining, forestry and rural roads. The binder is sometimes used at this stage and works well on fine or coarse graded material.

The method also only requires one lane of traffic to be closed at a time minimising inconvenience and maintaining traffic flow.

Once the road surface has been crushed to the required aggregate size a conventional grader is used to ensure all the material is incorporated and to determine the camber of the surface.

Going green, are you?

Compaction of the road is performed using a steel drum roller. Stabilisation is then carried out applying the dry environmentally friendly and non-toxic binder mixed with water and sprayed onto the surface from a bowser followed by a mixer. A second phase of grading adjusts the camber and ensures a smooth surface. Final compaction is done, usually in two or three passes.

The degree of compaction is monitored and recorded by the compactor. Normal cars can then immediately drive on the road while heavy vehicles should be limited for 3-7 days for the curing to take place.

If the client requests it a layer of asphalt can then be applied in the conventional way to cap the road. Carbon Crushers employs the first AI enabled road management dashboard called SkyRoads a software that facilitates and optimises road manintenece by continuously monitoring the condition of the finished road and indicating where problems may arise and need attention or maintenance.

The method saves time and optimises resource allocation and is convenient to ensure ongoing traffic use during construction. Carbon Crusher has also received an Environmental Product Declaration across Norway and the United States of America; third party verification that demonstrates that their roads do indeed store carbon upholding their carbon negative status.

A.M. Machado is continuously striving to engage strategic partners such as Carbon Crusher and Cypher Environmental and be the bridge between global innovation and local road construction companies.

With the ongoing support of the Ministry of Transport and EMA, the road to a greener future seems to be clear. A.M. Machado together with Carbon Crushers’ and Cypher’s engineers will take soil samples to determine the best use of their respective products and tailor-make the optimum method and resulting services.

The built environment can have a significant impact in reducing Greenhouse Gas Emmisions, conserving ecosystems and making corporate decisions that do not compromise future generations. A.M. Machado has posed a question to the industry, “We are going green, are you?”

Carbon Crusher offers a sustainable and innovative approach to road construction and repair, aiming for a carbon-negative future.

Our Sustainable Process Our process is both environmentally friendly and highly effective. We use a crusher to recycle 100% of existing road masses, including asphalt, rock, and mountain, to a depth of 35 cm (12 inches).

This creates a homogeneous mass and eliminates the need for additional aggregates. The bio-binder, sourced from the forestry and paper industries, is mixed in during the same operation. This non-toxic binder sequesters carbon within the road itself, and the finished product looks like a compact gravel road that is much harder and more stable.

Key Benefits

Carbon Reduction: Our carbonnegative roads store about 51 tonnes of CO2 per mile,

reducing the total CO2 by 150 tonnes per mile compared to regular methods.

Increased Durability: The solution results in a more durable and stable ground, increasing loadbearing capacity by 50-100% and providing better resistance to high loads and thaw damage.

Cost and Material Savings: By reusing on-site materials, we reduce the need to bring in new aggregates and lower costs over time.

Reduced Surface Temperature: Our method can also reduce the surface temperature of the road, a benefit in areas prone to heat.

Carbon Crusher's method has been proven in projects across the US, including in the scorching heat of Arizona, and has been in use since 2007.

Harare’s urban development is on a significant stride, following the successful erection of a new and world-class footbridge across the ED Mnangagwa Road section at Highland Park Mall, making this a pivotal project that has fundamentally reshaped the landscape of the city’s premier commercial hub.

The ambitious civils and engineering work, spearheaded by Zimbabwean construction specialists Pat Dunn Zimbabwe, marks a new chapter in the Highland Park Precinct masterplan, creating a seamless connection between the iconic Highland Park Mall and the burgeoning Design Quarter development.

The project culminated in a thoroughly planned operation on the weekend of September 13 and 14, which saw a temporary closure of a section of ED Mnangagwa Road.

This strategic decision was made to ensure public safety and facilitate the critical installation of the footbridge. While the closure was in effect, great care and planning by the developers ensured that Highland Park Mall remained fully accessible from Arcturus Road and its eastern entrance on ED Mnangagwa Road.

The intersection of Arcturus and ED Mnangagwa Road was also partially open, allowing for a smooth flow of traffic and minimizing disruption to the public.

The installation of the footbridge was the cornerstone of this weekend’s work, signifying the efficient execution and high-level collaboration between all parties involved.

Pat Dunn Zimbabwe has a rich history dating back to 1969. Known for their specialisation in steel, civils, and engineering, the company has built a sterling reputation for delivering quality projects on time and within budget, particularly in the industrial, mining, and agricultural sectors.

The Highland Park footbridge project now stands as a powerful addition to their portfolio, showcasing their versatility and expertise in modern urban infrastructure.

The team, composed of highly trained professional mechanical and structural engineers, tirelessly and professionally handled every aspect of the project, from the initial design to the final, high-stakes installation.

The crane used for lifting the massive elevated walkway sections even bore the company’s name, “Pat Dunn & Mark Rutter,” a proud signature on a landmark achievement.

True to the Pat Dunn Zimbabwe work ethic and principle, the detailed, behind-the-scenes work involved in the project was a showcase of precision and global-standard engineering.

A casual walk during construction highlighted the robust foundational work. White, flared metal columns were securely bolted to square concrete footings using thick anchor bolts, ensuring the long-term stability and integrity of the structure. Workers in blue uniforms and hard hats were seen perched on the towering steel beams, using wrenches to tighten each crucial connection.

This hands-on approach and attention to detail underscored the commitment to quality controls that Pat Dunn Zimbabwe

is renowned for. The elevated white walkway, a large beam, was expertly hoisted into place by a crane, a sight that spoke volumes about the scale and complexity of the operation. With workers on the raised structure wearing harnesses, the project demonstrated a paramount focus on safety protocols.

The footbridge is a vital link in the grand vision of the Highland Park Precinct. Developed by Terrace Africa, a property development company with a strong focus on convenience and lifestyle retail across Sub-Saharan Africa, the precinct is a master-planned community. It is designed to be an"international standard" hub that will redefine urban living and commerce in Harare.

The pedestrian-friendly design is a core element of the precinct, and this footbridge seamlessly connects the two main components: the existing Highland Park Mall, which is a prime shopping location with over 40 household brands, and the new Design Quarter. The Design Quarter, the second phase of the precinct, will provide an additional 200,000 square metres of mixed-use commercial and residential space, including showrooms, offices, and lifestyle amenities.

This new walkway will allow shoppers and residents to move effortlessly between the two sites, transforming the precinct into a cohesive and unified destination.

The final result of the work is a new and refreshing scenic experience for those who travel along ED Mnangagwa Road.

The once-separate entities of Highland Park Mall and the emerging Design Quarter are now physically and symbolically linked by an elegant, functional bridge.

The project’s success, from the strategic road closure to the precise installation, reinforces the capability of local companies like

Pat Dunn Zimbabwe to handle large-scale, complex civil engineering projects. It stands as a powerful symbol of confidence in Harare’s industrial and commercial future.

This new footbridge, an essential piece of urban infrastructure, will not only facilitate easier access for thousands of shoppers and visitors but will also serve as a landmark, highlighting the city’s continuous growth and the commitment of developers like Terrace Africa to creating modern, sustainable, and integrated spaces.

Interior & Exterior Painting

Decorative & Protective Coatings

Road & Line Markings

Sports Field & Court Markings

Epoxy & Resin Flooring

Waterproofing Solutions

Wallpaper Installation

Driveway Sealers & Surface Protection

Colour Consultation & Scheduled Maintenance

• WeatherTough Protection

• 2x Thicker Paint Coating

• Prevents Damp on Walls

FROM CARDINALS CORNER MALL TO ZIMBABWE’S LEADING INSTITUTIONS, STAR PAINTERS DELIVERS FINISHES THAT DEFINE SKYLINES.

Great buildings deserve more than walls—they deserve finishes that endure. That’s why Star Painters partnered with Plascon on the Cardinals Corner project, to deliver results that combine beauty, precision, and lasting protection. Star Painters is the go-to partner for commercial painting projects across Zimbabwe. With the expertise and capacity to handle large scale developments, we guarantee quality finishes, professional service and lasting impressions. From large-scale malls to universities to corporate spaces and residential spaces, our work transforms buildings into Landmarks that inspire and endures, transforming houses to homes.

Star Painters (Pvt) Ltd, a division of Yamalek Investments, is Zimbabwe’s leader in professional painting and surface finishing solutions. Since 2015, we have earned the trust of developers, corporates, and institutions through quality, consistency, and innovation, which lead to the birthing of Star Contracting. Star Contracting was established to cater to the growing demands of our loyal clients who required services beyond painting such as concrete floors, tiling, ceilings and renovations to mention a few.

Interior & Exterior Painting

Decorative & Protective Coatings

Road & Line Markings

Sports Field & Court Markings

Epoxy & Resin Flooring

Waterproofing Solutions

Wallpaper Installation

Driveway Sealers & Surface Protection

Colour Consultation & Scheduled Maintenance

Track record with major clients: Swift, Total Energies, Mashonaland Tobacco Company, United States of America Embassy, Namibia Embassy, University of Zimbabwe, Old Mutual, First Capital Bank, CBZ, Pick n Pay, Simbisa, African Horizon, West Properties, UNDP, Zimplats, and Anglo American.

Strategic supply partnerships with Plascon, Halsteds, Union Hardware, and ICC. Proven commitment to quality, safety, and sustainable practices. Industry recognition: Megafest Business Awards 2023 & 2024.

To deliver world-class painting and finishing solutions that protect assets, elevate environments, and exceed expectations—anchored by the expertise of Star Painters Craftsmanship.

Star Painters (Pvt) Ltd 177 Monavale Complex, Harare, Zimbabwe

+263 242 257 317 or +263 784 022 907

www.starpainters.co.zw admin@starpainters.co.zw

The retail and commercial landscape in Harare is on an impressive growth trajectory as the highly anticipated Cardinals Corner Mall, developed by real estate investment giant Terrace Africa, has reached a key milestone with the completion of its construction phase. The new shopping centre, located at the strategic intersection of Harare Drive and ED Mnangagwa Road in Chisipite, has already proved its investment worth as a vibrant hub for several of Harare’s key northern suburbs.

The project, which has been a prominent fixture on the Chisipite skyline for months, represents a landmark development for the area. Situated at a crucial crossroads, Cardinals Corner Mall is perfectly positioned to serve the high-demand residential and commercial zones of Highlands, The Grange, Glen Lorne, Umwinsidale, and Shawasha Hills. Its strategic placement will provide residents with a convenient, modern, and comprehensive shopping destination right on their doorstep, eliminating the need to travel long distances for essential goods and services.

Supply & Installation of: Hardwood Floors, Carpeting, Blinds & Curtaining for Domestic and Commercial use.

Laminate - a cost effective option to a quick fix and turnaround time.

Decking - both wood and compsite. You can be assured of peace of mind on the outdoor area.

Carpeting - serving both commercial and domestic market and hospitals, hotels, apartments and private homes

Hardwood flooring- from the reliable and trusted teak to the high end oak or walnut. You are spoiled of choice. Available as solid blocks or engineered

Vinyl- the click and stickdown. The click for A quick seamless installation and the hospital grade stick down medical labs and hospitals . The stickdown sheeting is a RELIABLE solution where wet cleaning is inevitable

Terrace Africa’s commitment to architectural excellence is evident in the mall’s design. The building showcases a multi-level structure with a sophisticated, modern aesthetic. The exterior features a striking combination of white plaster walls and a light-colored wooden facade, which contrasts elegantly with a dark-coloured canopy and supporting columns that define the main entrance.

The mall’s roof is a distinctive feature, a two-part corrugated metal roof in varying shades of grey, indicating a thoughtful and functional approach to design.Throughout the construction process, a dedicated team of workers, easily identifiable in their blue overalls and yellow hard hats, worked tirelessly to bring the architectural vision to life. In one of Harare’s biggest retail and commercial projects, aerial photographs captured the meticulous progress, from the initial installation of parallel metal beams and the structural framework to the final placement of the “CARDINALS CORNER” signage in large, white, dimensional letters.

The use of scaffolding was a constant reminder of the intense work being done to perfect every detail, from the exterior slatted cladding to the roofline.The internal layout of the mall is designed for a seamless shopping experience. While the construction phase revealed the raw beauty of the unfinished interior, with its exposed brick and concrete walls, the final design has transformed these spaces into a welcoming environment. The ceiling, with its metal framework and corrugated metal sheeting, has been integrated with modern elements like exposed wooden slats arranged in a triangular pattern, creating a unique and contemporary look in the covered walkways.

The successful completion of the Cardinals Corner Mall was a collaborative effort involving several key suppliers and partners. BD Stodart was responsible for the crucial earthworks, laying the groundwork for the entire project. The beautiful paved areas were made possible by Cement City, who supplied the necessary pavers.

The elegant garden décor, decking, and front facets were expertly handled by Fusion Flooring, while Agri-Structures provided the roofing, contributing to the mall’s distinctive exterior.

Cardinals Corner Mall is set to host a diverse array of local and international tenants that will significantly elevate its appeal. The anchor tenants, Electrosales, Spar Supermarket, a CFAO Toyota Showroom, and RK Fuels Service Station, provide a strong foundation for the centre’s offerings.

The presence of a major local grocery chain like Spar ensures that residents will have access to a wide variety of fresh produce and household essentials. Meanwhile, international brands like Spur Corporation’s new Doppio Zero restaurant, mark the first introduction of the brand to Zimbabwe.

The CFAO Toyota Showroom adds a premium automotive retail component, making the mall a multi-purpose destination for both everyday needs and major purchases. The site also includes several other retail stores, promising a comprehensive mix of fashion, food, and specialty services.

• Steel Shades and Structures

• Architectural Steelworks

• CNC Services

• Crane Hire

• Prefab Homes/Offices

• Steel Fabrication

• Steel Profiling

• Solar Carport

• Balustrades & Staircases

• Billboards

• Clearview Fencing

• Security Grills

• Entrance Canopies

• We are the premier option for all your steel fabrication needs. Please reach out to our team at.

• Address 6a Rivonia Dr, Mt Pleasant, Harare

• Email admin@cityfabricators.co.zw

• Phone +263772 786 189, +26378 52 822 52

• Instagram cityfabricators

• Twitter @cityfabricators

• Facebook Cityfabricators

The thoughtful inclusion of a drive-thru lane further underscores the focus on customer convenience, catering to the fast-paced modern lifestyle. Beyond its retail function, Cardinals Corner Mall exemplifies the growth and development of Harare’s urban infrastructure – rapid, upmarket and intentional. The project has not only created numerous jobs during its construction but will also provide long-term employment opportunities for the local community through its retail outlets and services.

The transformation of a raw construction site—once dominated by scattered pipes, materials, and large cylindrical tanks—into a world class commercial centre highlights the positive impact of strategic investment in the city. It also highlights Terrace Africa’s leadership in the provision of convenient retail shopping. The paved parking lot and newly landscaped areas around the building mark a complete transition from a construction zone to a finished, functional, and visually appealing space.

As the final touches were being applied, including the installation of interior HVAC units and the completion of the landscaping, Cardinals Corner Mall commanded a strong presence as a new landmark for Chisipite. More than just a shopping centre; it is a thoughtfully planned and executed project that promises to become a cornerstone of the community.

With its modern design, strategic location, and carefully curated mix of tenants, it is ready to fully open its doors and redefine the retail experience for the residents of Harare’s northern suburbs.

ANOTHER TERRACE AFRICA DEVELOPMENT

MAIN CONTRACTOR - African Horizon

Fusion Flooring

Cement City

Agristructures

City Fabricators

Star painters

Plascon Paints

BDS Stodart

KingKold

Security Shop

Kingson Engineering

Inso aluminium

Nical Transformers

RK Fuels

Electrosales

Spar

CFAO

Simbisa Brands

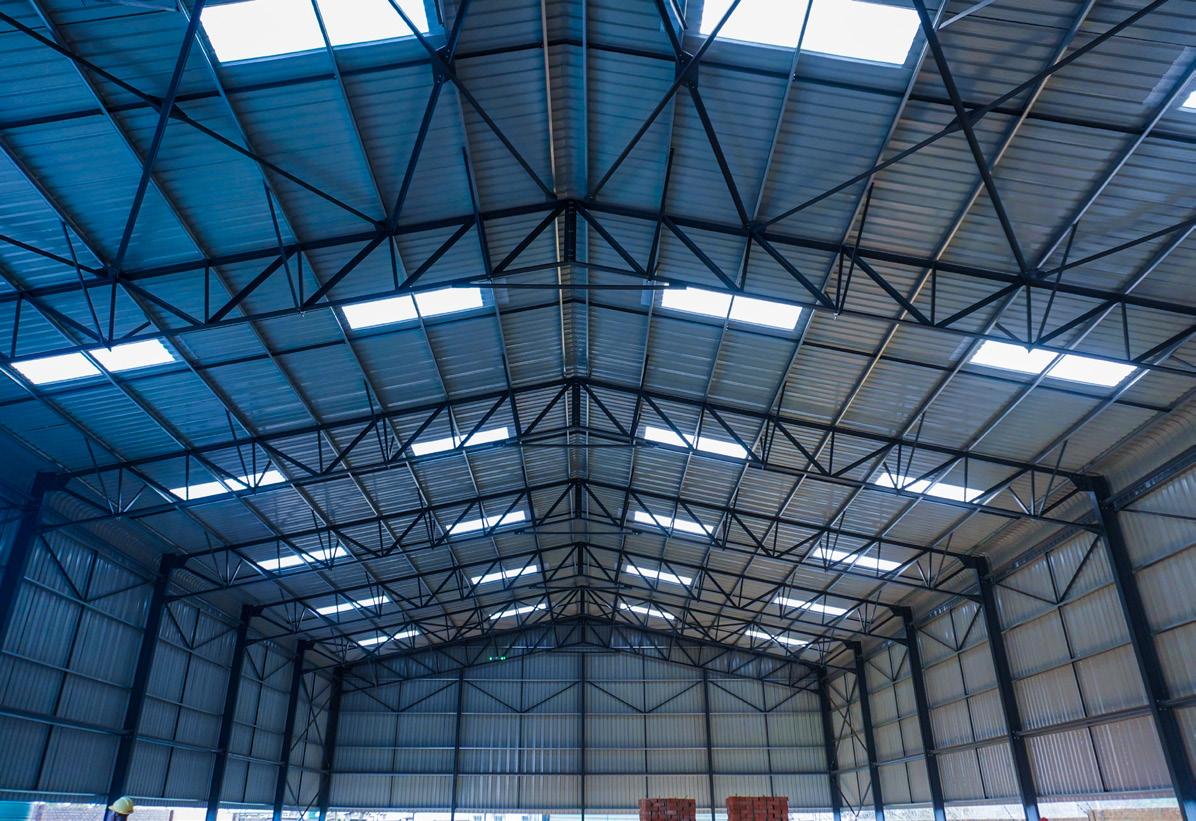

Local engineering prowess shone once again recently as a significant investment in Zimbabwe’s industrial capacity was completed by Brown Engineering in the form of a large, state-of-the-art warehouse for a client in Workington, Harare. This expansive project, a mixture of new build and retrofit to the existing warehouse, showcasing modern design and robust construction, marks a pivotal moment for both companies and for the broader industrial sector in Harare.

The project, which has been a hive of activity over recent months, has transformed a previously raw industrial space into a highly functional and durable facility. From the outset, the site was characterized by the rugged nature of preparatory work. The ground was a mix of dirt, gravel, and rubble, with large piles of sand and stacks of red bricks awaiting deployment. The presence of workers in high-visibility vests and hard hats, actively engaged in tasks like bricklaying and groundwork, underscored the scale and dynamism of the project from its very beginnings.

Brown Engineering, leveraging its reputation as a leading steel structure specialist, has constructed a building that is a modern combination of form and function, and which will meet the needs of the company. The building’s walls present a striking visual contrast: a solid lower section of exposed red brickwork provides traditional strength and character, while the upper sections are clad in sleek green corrugated metal panels. This design choice is not only aesthetically pleasing but also speaks to the use of modern, efficient materials for the primary structure. At the core of the building’s design is its steel framework.

A series of black-painted steel columns, anchored to robust concrete footings, provides the skeletal support for the entire structure. Close-up images captured during construction highlight the precision of these foundational connections, secured with large bolts and nuts, and reinforced with diagonal support beams. This attention to detail in the structural framework ensures the building’s long-term stability and integrity.

The roof is a defining feature of the new warehouse. It is composed of a symmetrical metal truss system that supports corrugated metal roofing. A major design element is the integration of numerous rectangular skylights, which are evenly spaced across the roof. These panels allow natural light to flood the vast interior, creating a bright and energy-efficient workspace. This deliberate use of natural light is a testament to the modern, sustainable approachtaken in the building’s design.

Building Divisions: The warehouse is designed as a vast, single-span structure with no internal obstructions, maximizing its utility.

Main Warehouse Floor: A large, open space with a smooth, durable concrete slab floor, ideal for heavy industrial use, storage, and logistics operations.

Office and Service Area: A small, enclosed structure with a staircase is planned in the background, likely to house administrative offices, restrooms, and other support services.

Infrastructure: The interior is equipped with essential infrastructure, including a thick red pipe running horizontally along a large white concrete beam supported by a tall white pillar, indicating the thorough planning of utilities and services. A large roll-up door is also visible, facilitating easy entry and exit for trucks and machinery.

The completion of this warehouse is a significant win for the company. As a company that has been a continuous presence in Zimbabwe since 1995, specializing in cleaning chemicals, disinfectants, and hygiene solutions, this new facility will be instrumental in consolidating and expanding their operations.

The spacious new building will enable them to streamline their supply chain, enhance storage capacity, and improve overall operational efficiency.For Brown Engineering, this project serves as a key addition to their portfolio of successful industrial constructions. Their ability to manage a project of this scale—from the foundational groundwork, including clearing debris and laying a concrete slab, to the final cladding and structural details—demonstrates their comprehensive expertise. The company’s delivery is evident in the quality of the finished product, which meets the specific needs of a modern, forward-thinking client.

The new warehouse is a symbol of confidence in Zimbabwe’s industrial future. It represents a tangible investment that will facilitate growth, create efficiencies, and contribute to the economic vitality of the Workington industrial hub. This collaboration between the client and Brown Engineering stands as a shining example of how local companies can partner to build the infrastructure necessary for a thriving and prosperous nation.

The commissioning of Midlands Park in Zvishavane by President Emmerson Dambudzo Mnangagwa, marks yet another milestone in Zimbabwe’s ongoing efforts to provide modern human settlements.

Midlands Park comprises a mixed-use housing development and purpose-built student accommodation, delivered through a combined investment of US$37.7 million spearheaded by the Public Service Pension Fund.

The development will accommodate over 300 families and provide accommodation for 750 students.

President Mnangagwa emphasised that the residential and student apartments represent more than just infrastructure — they are an investment in the dignity of Zimbabwean citizens, providing highquality, secure living environments.

The President also explained that by deliberately addressing the housing needs and responding to the demand for modern student accommodation, we are also nurturing and developing young people from across our country’s ten provinces to be versatile and have high self-esteem as they pursue their education and innovation.

Families on the other hand are being enabled to live in secure, peaceful and stable environments.

The project has had a significant impact on the local economy, creating over 3,000 jobs and improving livelihoods, particularly for youth and women.

Additionally, the surrounding community has benefitted from improved water and sanitation systems, along with upgraded road infrastructure, he explained.

Speaking at the event, the Minister of National Housing and Social Amenities, Honourable Zhemu Soda, hailed Midlands Park as a prime example of how Government policy, private sector partnerships, and community aspirations can converge to deliver sustainable housing with integrated amenities.

“The Midlands Park stands as a shining example of how the Zimbabwe National Human Settlements Policy — launched by His Excellency in 2021 — is being effectively implemented,” said Minister Soda.

“This development embraces key elements of the policy, including densification, on-site infrastructure, and the provision of social amenities.

With a shopping mall and student accommodation included, it truly represents a well-planned, self-sufficient community.”

The Minister also stated that the great leap in surpassing the initial set target of 220 000 housing units by 2025 which was then followed by a review to 1 million, has been made possible through collaborative efforts between government and private institutions. He also underscored that Public Private Partnerships (PPPs) are proving essential in addressing the country’s housing deficit explain that Midlands Park alongside many others across the country, stand as a beacon to show what can be achieved when we work together towards a common national goal.

The Estate Agents Council of Zimbabwe (EACZ) recently hosted its annual Land Conference from 23 to 26 October, at the Elephant Hills Resort in Victoria Falls. This premier event brought together key stakeholders from various sectors to tackle critical issues surrounding land ownership, investment, and sustainability in Zimbabwe.

Under the theme, “Land Ownership, Investment, and Sustainability:

Navigating Challenges and Opportunities in Zimbabwe,” the conference provided a crucial platform for dialogue and collaboration.

The land sector in Zimbabwe is a complex environment, shaped by historical legacies, economic realities, and evolving policies.

This event demystified these complexities and charted a clear path forward for sustainable development.

Participants engaged in a wide range of sessions, including expert-led panels, interactive workshops, and keynote addresses from leading figures in government and the private sector.

Topics for discussion were expected to include property rights, legal frameworks for land ownership, financing models for real estate development, and the role of land in driving economic growth.

The choice of the Elephant Hills Resort as the venue added to the conference’s significance.

Located in the worldrenowned tourist destination of Victoria Falls, the setting provides a conducive environment for high-level discussions while showcasing Zimbabwe’s potential as a prime investment destination.

The conference was a call to action for all who have a stake in the nation’s future.

It was an opportunity to share knowledge, forge new partnerships, and make a tangible impact on the country’s land landscape.

For those who were ready to dive deep into these issues, this was an unmissable opportunity.

Prior to the event, the EACZ encouraged professionals, investors, policymakers, and all interested parties to attend and contribute to the vital conversations that would shape the nation’s future.

Anew dawn for water security is on the horizon for the residents of Marondera and Chitungwiza, as the construction of a critical pipeline from Muchekeranwa Dam progresses.

The project, a cornerstone of the Second Republic’s development agenda, is set to provide a long-term solution to the chronic water shortages that have plagued the two urban centres for years.

Muchekeranwa Dam, a 75-million-cubic-meter reservoir, was officially commissioned by President Mnangagwa in May 2021. Since then, plans have been underway to harness its abundant water resources.

The pipeline, which is now under construction, is a vital link that will not only supply potable water but also unlock immense agricultural potential along its route.

According to the Zimbabwe National Water Authority (ZINWA), the pipeline is designed to move 30 million litres of water per day upon completion.

For Marondera, this new source will augment the existing supply from Wenimbe Dam, which has been severely affected by low water levels.

The project is a “gamechanger” for the region, according to local officials, with the pipeline also set to boost several irrigation schemes.

Farmers and communities along the 26-kilometer route, particularly in Marondera East, are expected to be the biggest beneficiaries, transforming their agricultural activities from rain-fed to yearround production.

Beyond Marondera, the pipeline will also provide a much-needed lifeline to Chitungwiza, a city that has long relied on Harare for its water supply and has been grappling with a severe and persistent water crisis.

The new infrastructure is a crucial step towards ensuring a reliable and sustainable water source for its rapidly growing population.

The project is a testament to the government’s commitment to providing basic services and improving the quality of life for all Zimbabweans.

A new generation of skilled and ambitious young Zimbabweans is making its mark on the nation's construction industry, driving innovation and playing a critical role in the country's ambitious infrastructure development agenda. Far from being relegated to the sidelines, youth are increasingly becoming the backbone of a sector poised for significant growth, spurred by both private and public investments.

The presence of young people in construction is a testament to the success of various government and private sector initiatives aimed at youth empowerment and vocational training.

While formal employment opportunities have traditionally been limited, programs focusing on skills development in areas like bricklaying, carpentry, plumbing, and electrical work are providing a vital pathway for young people to enter the industry. For many, these training opportunities lead directly to employment on major projects or to the establishment of their own micro and small construction enterprises.

However, the journey is not without its challenges. Young contractors often face hurdles in accessing formal contracts and securing adequate funding. Despite these difficulties, many are showing remarkable resilience and entrepreneurial spirit.

Stories of young people starting their own construction companies after gaining valuable experience on large projects are becoming more common. This trend not only creates jobs but also builds a sustainable base of local contractors capable of handling complex national projects. Established construction firms are increasingly being urged to mentor these emerging contractors, a move that would strengthen the entire industry.

The Zimbabwe Building Contractors Association (ZBCA) has actively promoted this mentorship, recognizing that nurturing new talent is essential for sustained growth and ensuring quality standards are met across the board.

The "a nation is built by its own people" mantra, which has become a hallmark of the government's infrastructure drive, is coming to life as young, homegrown talent takes center stage.

The youth are not just building roads and houses; they are also bringing fresh perspectives to the industry, particularly in the adoption of new technologies and sustainable practices. As the country moves towards a more modern and eco-friendly approach to construction, young professionals, with their keen interest in innovation and efficiency, are wellpositioned to lead this transformation.

With continued support for training, access to capital, and mentorship, the youth of Zimbabwe are proving to be a powerful force in building the nation's future, one project at a time.

At Bitumen World, we deliver top-tier civil engineering solutions that stand the test of time. From roads and bridges to large-scale infrastructure projects, our expertise ensures quality, durability, and innovation in every build. Partner with us for a future engineered for success.

We are expanding beyond Zimbabwe, delivering high-impact projects in Mozambique and Zambia. We are driving growth, innovation, and operational excellence across borders.

HARARE OFFICE:

30 George Avenue, Msasa, Harare

Tel: +263 24 2447 231-3

Email: enquiries@bitumenworld.net

Website: www.bitumenworld.net

Bitumen World (Pvt) Ltd

Civil Engineering Contractors