STOPPIL, specialized in the

they will support

and

of

and

are

over the

to your

term thanks to their

Upgradeable and

machines, provides packaging solutions for

Our

We have been

Our

for

and

have

We

Volumetric, electromagnetic or mass flowmeters depending on your product.

Dosing of liquid, viscous or pasty products via a peristaltic or piston pump.

The product is weighed using a scale certified in legal metrology.

We can pack all your liquid, viscous and foamy products. Whatever the format of your bottles, we have a filling, capping and labelling solution for you.

We discuss with you by phone or videoconference about your installations, your products, your processes and we study your project in detail. We or one of our agents can also visit you if it is best regarding your project.

After the analysis of your needs, an offer including one or several solutions is sent to you. For packaging line projects, our design office draws up a first layout plan. These elements serve as a basis for discussion until the final project.

Our design office draws each machine according to the characteristics you have chosen. The machines are then manufactured and assembled in our workshop. They are each tested before departure or before the FAT in our premises.

We take care of the installation and training of your staff on your new production tool. Our after-sales service is available by phone to inform you or to help you during the whole life of your machine.

Easy to use, the Stoppil automatic dosing system is very accurate. It is suitable for all your liquid raw materials.

Equipped with a volumetric, electromagnetic or mass flow meter painted steel cabinet Control by electronic card

Dosing flap valve or membrane valve Speed depending on your application Options: ATEX or corrosive version, Stainless steel cabinet

Intended for all types of products, this device allows the precise dosage of liquids without volume limit.

Equipped with a volumetric, electromagnetic or mass flow meter Automatic control

7" Color touch screen

Dosing flap valve or membrane valve Speed depending on your application Options: ATEX or corrosive version, stainless steel structure, printer

The Stoppil kegging station is equipped with 2 to 4 wheels for easy movement close to your work area. This machine is particularly adapted to the filling of barrels and drums.

Filling directly on pallet

Filling by flowmeter system

Options: ATEX or corrosive version

Flow rate according to your needs, the pump and the diameter of the piping defined

For containers from 5 to 1000 liters

Designed for repeated filling of large volumes, this machine ensures operator comfort through effortless handling.

Filling directly on pallet

Filling by flowmeter or weight system

Working radius of 4 meters

Options: ATEX or corrosive version, diving head

Flow rate according to your needs and the defined pump

For containers of 20 to 1000 liters and more

The Ecopil table is designed for small productions. Ergonomic and easy to use, it provides a very precise dosing of your products, saving time and making your work more comfortable. It has a very good quality-price ratio.

Filling by flowmeter system

Control by electronic card

Centrifugal pump for very liquid products (max 150 cps)

Speed: around 350 bottles / hour (format 1 liter)

For containers from 100 ml to 10 liters

The standard table is totally adjustable to your product and your containers. It is equipped with an optional manual pneumatic or electric screwer to manage the filling and capping process quickly and efficiently.

Filling by flowmeter, weight or peristaltic system

Control by electronic card or PLC Machine equipped with one or two filling heads

Options: diving head(s), ATEX or corrosive version, distance filling nozzle, pneumatic or electric manual screwer

Speed: around 350 bottles / hour (format 1 liter)

For containers from 5 ml to 10 liters and more

The diving table is a version of the standard table adapted to foaming products. It is totally customizable according to your product and your needs.

Filling by flowmeter or weight system

Control by electronic card or PLC Machine equipped with one or two diving heads

Options: ATEX or corrosive version, distance filling nozzle, pneumatic or electric manual screwer

Speed: around 350 bottles / hour (format 1 liter)

For containers from 50 ml to 60 liters

For more comfort, our tables are available in different heights. The roller table is suitable for large volumes that are difficult to handle.

Filling by flowmeter or weight system

Control by electronic card or PLC Machine equipped with one or two filling heads

Options: diving head(s), ATEX or corrosive version, pneumatic or electric manual screwer

Speed: around 180 bottles / hour (format 5 liters)

For containers from 1 to 60 liters and more

The non scalable automatic Ecopil linear filling machine is adapted to the low speed packaging of your liquid products.

Machine equipped with one or two filling heads

Filling by flowmeter or peristaltic system

7" color touch screen

Options: ATEX or corrosive version, diving heads

Speed: up to 1200 bottles / hour

For containers from 5 ml to 30 liters

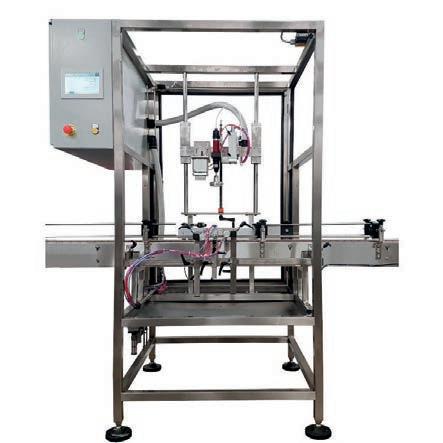

The automatic standard filling machine meets most filling needs, regardless of the product. This scalable machine can be upgraded as your production needs increase.

Machine equipped with 2 to 10 filling heads

Filling by flowmeter or peristaltic system

7" color touch screen

Remote maintenance

Options: ATEX or corrosive version

Speed: up to 4000 bottles / hour

For containers from 5 ml to 30 liters

The automatic Premium filling machine has additional features compared to the standard filling machine: premium frame, statistics management, Cleaning In Place...

Equipped with 2 to 12 filling heads

Filling by flowmeter or peristaltic system

10" color touch screen

Remote maintenance

Options: ATEX or corrosive version

Speed: up to 5000 bottles / hour

For containers from 5 ml to 30 liters

The automatic diving filling machine combines working comfort, modularity and simplicity of use. It is particularly suitable for foaming products.

Equipped with 2 to 12 filling heads

Filling by flowmeter or peristaltic system

15" color touch screen

Remote maintenance Diving fillers managed by Servo motors

Options: ATEX or corrosive version

Speed: up to 5000 bottles / hour

For containers from 5 ml to 30 liters

The automatic EB 2000 capping machine offers the possibility of capping all types of containers at a low speed.

Equipped with 1 screwing head Manual removal of plugs by the operator

7" color touch screen

Options: capping station for clip-on caps, Servo motor screwing

Speed: up to 1200 caps / hour

For all types of containers from 50 ml to 5 liters

For all types of caps (according to option)

The automatic EB 3000 capping machine allows the capping of all types of cantainers with caps, pumps, triggers.

Equipped with 1 screwing head Automatic feeding of caps by conveyor 10 or 15" color touch screen

Torque management by Servo motor

Options: Vibrating feeding bowl, ATEX version

Speed: up to 1200 caps / hour

For all types of containers from 50 ml to 5 liters

For all types of caps, pumps, triggers

The EB 6000 automatic linear capping machine is designed as a stand-alone module to be placed above a conveyor.

Adapted to all conveyors

Manual removal of plugs by the operator

3.5" color touch screen

Tangential screwing by 3 sets of wheels for progressive screwing Options: pneumatic driver for clip-on plugs

Speed: up to 5000 caps / hour

For all types of containers from 50 ml to 5 liters

For all types of caps, pumps, triggers

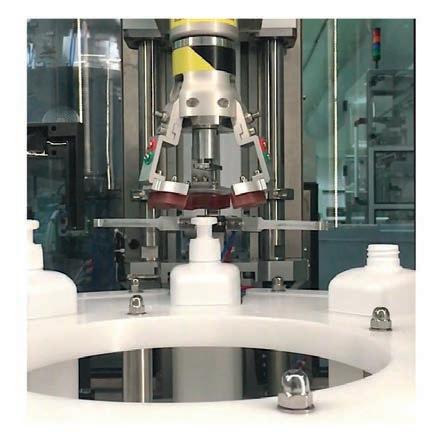

The automatic screwer EB 7000 allows the capping of all your containers whatever the type of closures.

Equipped with a double application head

Screwing heads managed by Servo motor

Automatic feeding of caps by conveyor

15" color touch screen

Remote maintenance Options: orientation of pumps, automatic ejection system for nonconforming products, control of the content before screwing...

Speed: up to 40 caps / minute

For all types of containers from 50 ml to 5 liters

For all types of caps, pumps, triggers

Automatic

A compact solution for low speed, with manual removal of the caps by the operator before screwing.

Equipped with 1 to 2 filling heads

Filling by flowmeter or peristaltic system

7" color touch screen

Manual removal of the caps by the operator

Options: ATEX or corrosive version, diving filling heads, screwing by Servo motor

Speed: up to 1200 bottles / hour

For containers from 10 ml to 10 liters

This rotating monoblock is particularly suitable for small doses.

Equipped with 1 to 4 filling heads

1 to 2 screwing heads (Servo motor)

Filling by flowmeter, peristaltic system or piston

15" color touch screen

Options: corrosive version, diving filling heads

Speed: up to 6000 bottles / hour

For containers from 1 ml to 1 liter

This monoblock is suitable for low-speed packaging of all types of products

Equipped with 1 to 4 filling heads

Filling by flowmeter or peristaltic system

1 screwing head by Servo motor for all types of caps, pumps, triggers

15" color touch screen

Options: ATEX or corrosive version, diving heads

Speed: up to 1200 bottles / hour

For containers from 50 ml to 20 liters

The DWR ROUND labelling machine is suitable for short-run labelling and takes up little space. It can be installed on a table for easy handling. It is an ideal machine for a first approach of the automation of your self-adhesive labels in small speed.

For the application of adhesive labels on cylindrical containers

For containers from 20 to 130 mm in diameter

Maximum label width 200 mm

Maximum roll diameter 300 mm

Quick and easy format changeover

We have been a partner of Altech company for many years. This Italian labelling specialist designs top of the line machines that meet Stoppil standards.

Automatic application of all types of adhesive labels

Multi-sided labelling: from 1 to 4 dispensing heads

Labeling of all types of containers: tubes, vials, syringes, canisters with or without handles, rectangular products...

Simple and intuitive format changeover

Many options available

Are you looking for a tailor-made

product.

you to clarify your project and to define the most suitable

Design Office can create the layout plan

are a few examples among many possibilities. There are as many configurations as customers!

Our packaging lines are composed of

Stoppil

they are more adapted to

premises and then for after-sales service.

contact

other machines

be made by us or by our

the design of the line to its installation in

Our semi-automatic lines allow the packaging of all your liquid products. They require the intervention of one or more operators, depending on their configuration.

Standard packaging table equipped with a manual screwer

1 head Automatic ALline labelling machine

Turntable at the end of the line

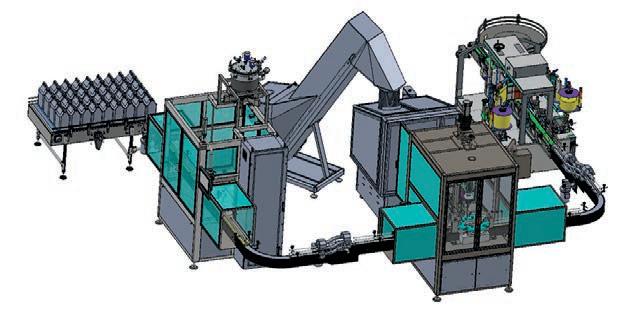

For higher speeds and limited operator intervention, our automatic packaging lines can handle several container formats. They are tailor-made according to your specifications.

Automatic linear diving filling machine

1 head automatic capping machine

2 heads automatic ALline labelling machine

Turntable at the end of the line

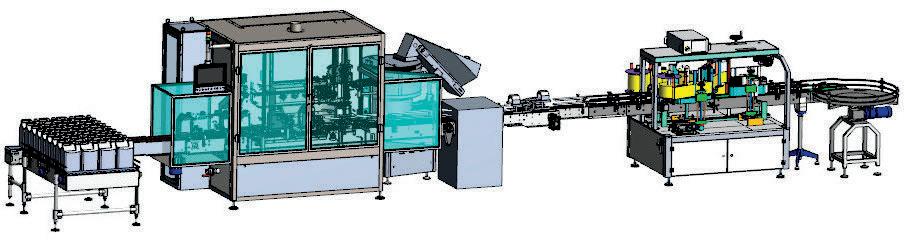

Our production lines can be adapted to the evolution of your needs: addition of machines or modification.

Feeding table

Automatic linear Standard filling machine

Automatic screwing machine EB 6000

1 head automatic ALline labelling machine

Turntable at the end of the line

Numerous layouts are possible. We design your production line together with you, depending on the space available.

Feeding table

Automatic filling-capping linear monoblock

Vibrating feeding bowl

2 heads automatic ALline labelling machine

Turntable at the end of the line

Our lines are scalable. Additional machines can be added later for boxing, palletization...

Feeding table

Automatic linear diving filling machine

Automatic EB 7000 capping machine

2 heads automatic ALline labelling machine

Turntable at the end of the line

sas - ZAC du Chêne Saint Fiacre -

rue

Découverte -

Chanteloup-en-Brie - France